Refined Consolidation Settlement Calculation Based on the Oedometer Tests for Normally and Overconsolidated Clays

Abstract

1. Introduction

2. Derivation of Equations for Laboratory Test Results

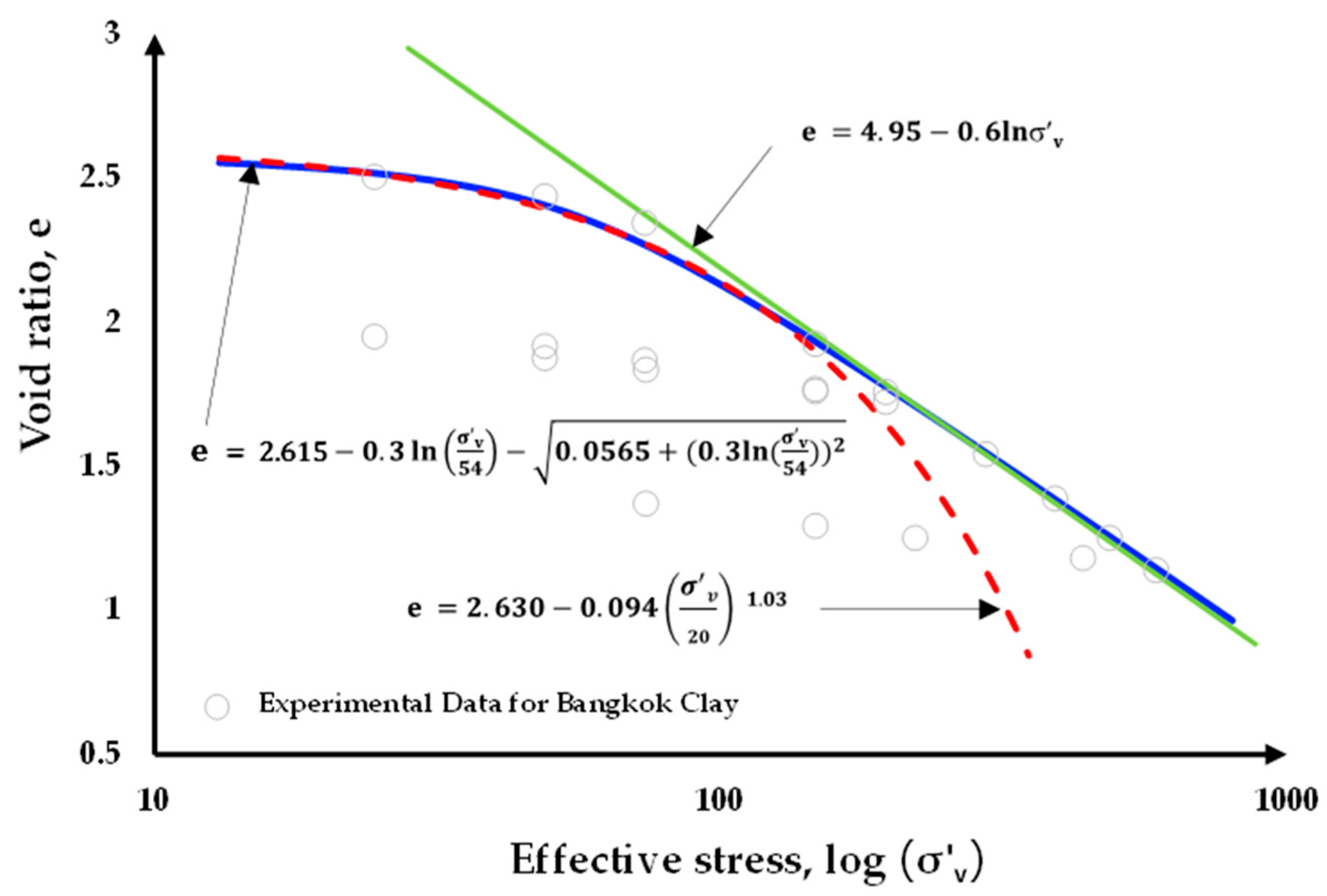

2.1. Equation for the Virgin Compression Line (VCL)

- (1)

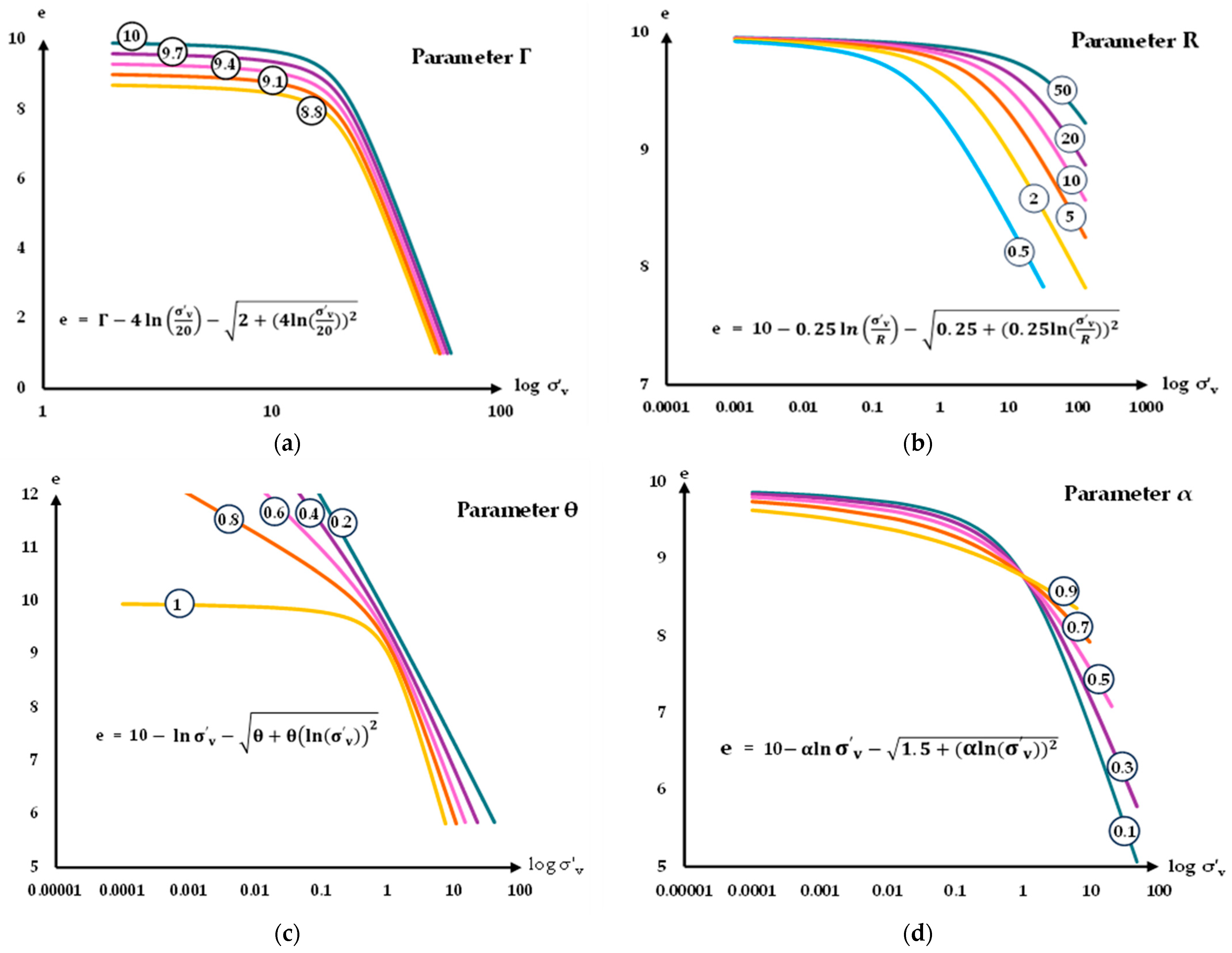

- Parameter Γ primarily controls the asymptotic upper bound of the void ratio. As such, it has a strong influence on the vertical position of the curve at low stress levels. A small change in a affects the curve globally, particularly in the initial loading phase.

- (2)

- Parameter R governs the horizontal shift of the curve along the logarithmic stress axis. While its effect is not as dominant as that of α, it moderately influences the stress range at which transition between recompression and virgin compression occurs. Improper selection of R may cause a misalignment with the test data, especially in the mid-stress range.

- (3)

- Parameter controls the slope of the curve in the virgin compression region. It exhibits high sensitivity in the high-stress domain, and an over- or underestimation of can result in significant errors in predicted settlements, particularly for deeper soil layers or higher loads.

- (4)

- Parameter adjusts the degree of curvature of the curved portion of the virgin compression line. It is most sensitive in controlling the smoothness of the transition zone. A small change in can significantly alter the curvature behavior. When = 0, the model reduces to a piecewise function with a sharp corner; as increases, the transition becomes smoother, better capturing gradual changes in stiffness.

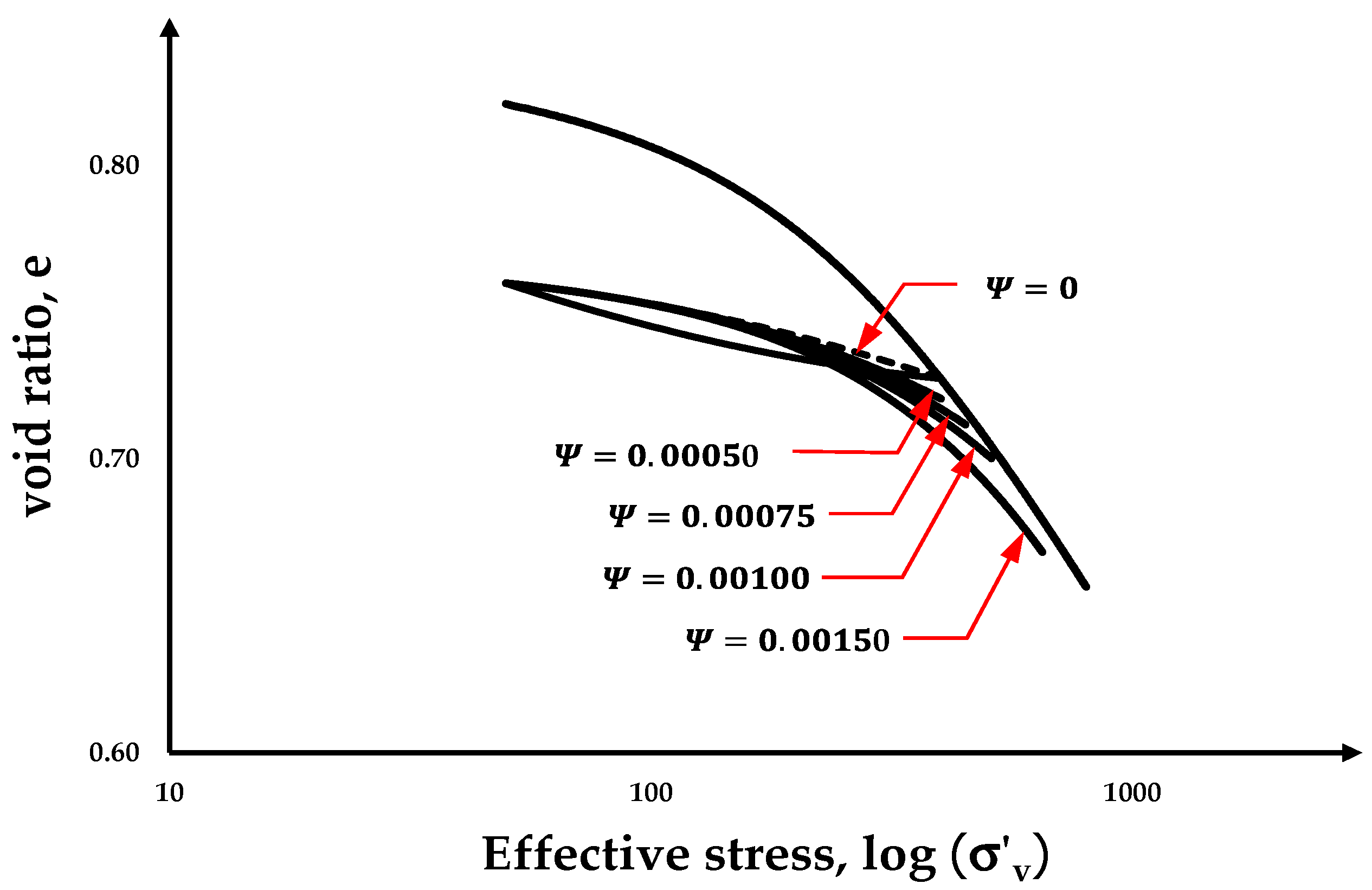

2.2. Equations for the Hysteresis

2.2.1. Equations for the Symmetric Hysteresis

2.2.2. Equations for the Asymmetric Hysteresis

3. The Process of Calculating One-Dimensional Consolidation Settlement

- (1)

- Fit the experimental consolidation data to the VCL using the AJOP equation (Equation (6)) to obtain four parameters and .

- (2)

- Fit the experimental consolidation data using Equation (8) to obtain three parameters for the upward-facing parabola (unloading portion) , , and .

- (3)

- Fit the experimental consolidation data using Equation (18) to obtain a parameter for the downward-facing parabola (reloading portion). ( for symmetric hysteresis).

- (4)

- Divide the soil to be analyzed for settlement into the sublayers.

- (5)

- Determine the initial and the final stresses resulting from construction at the middle point of each layer. The elastic solution can be used for simplification.

- (6)

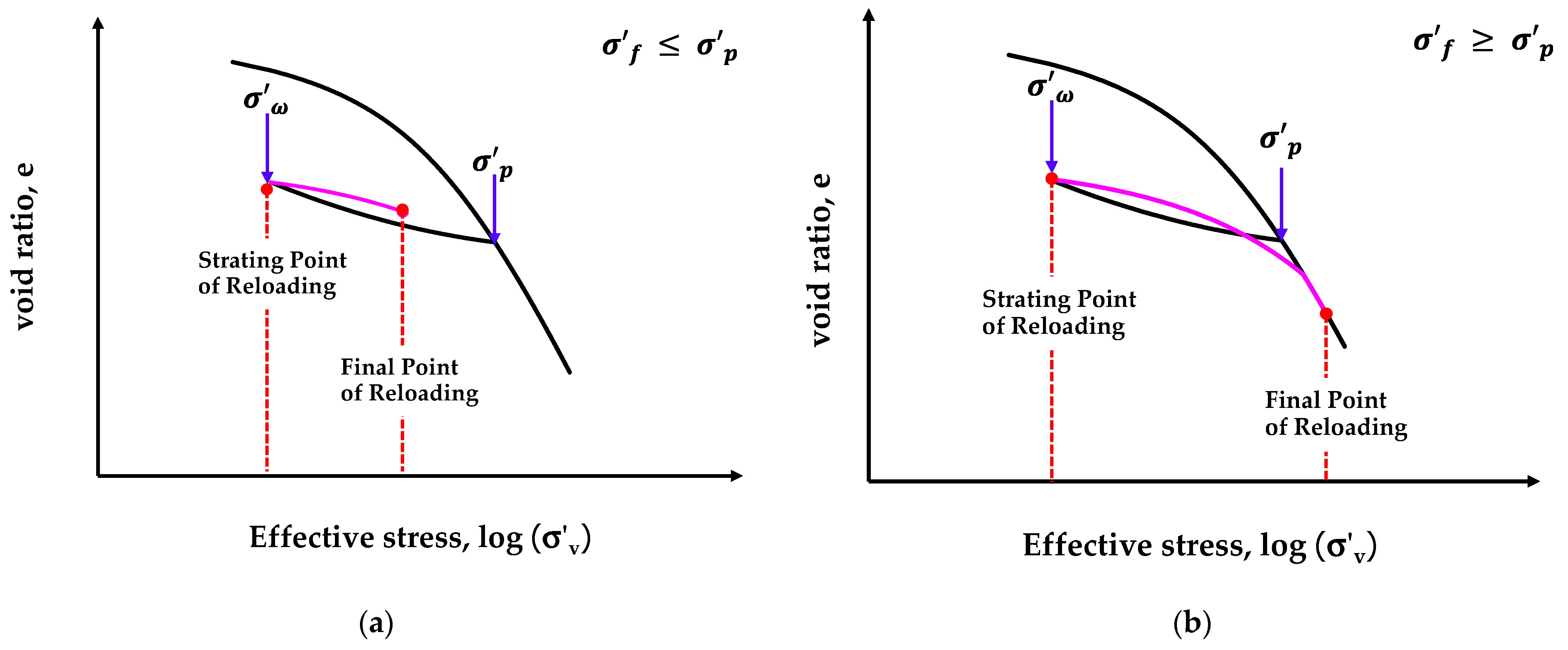

- For the overconsolidated clay, it is necessary to calculate more steps as follows:

- (6a)

- Calculate the maximum past stress which will be used as the unloading point on the VCL of each layer.

- (6b)

- Calculate the void ratio of the unloading point at in the step (6.1) using AJOP equation.

- (6c)

- Determine the parameters (, , and ) (, , and ) of the unloading of each midpoint.

- (6d)

- Calculate the void ratio of the initial stress , which will be the same value of the void ratio of the starting point of reloading process .

- (6e)

- Determine the parameters (, , and ) (, and ) of the reloading of each mid-point.

- (7)

- Calculate between the initial and final stresses mentioned above in step (5) as follows:

- (7a)

- For NC (normally consolidated) clay, use Equation (7).

- (7b)

- For OC (overconsolidated) clay, use Equation (19) or (21).

- (8)

- Calculate the consolidation settlement of the layer using

- (9)

- The total consolidation settlement can be calculated as the sum of the settlements for each individual layer; i.e., when n is the number of soil layers.

4. Examples for the Prediction of One-Dimensional Consolidation Settlement

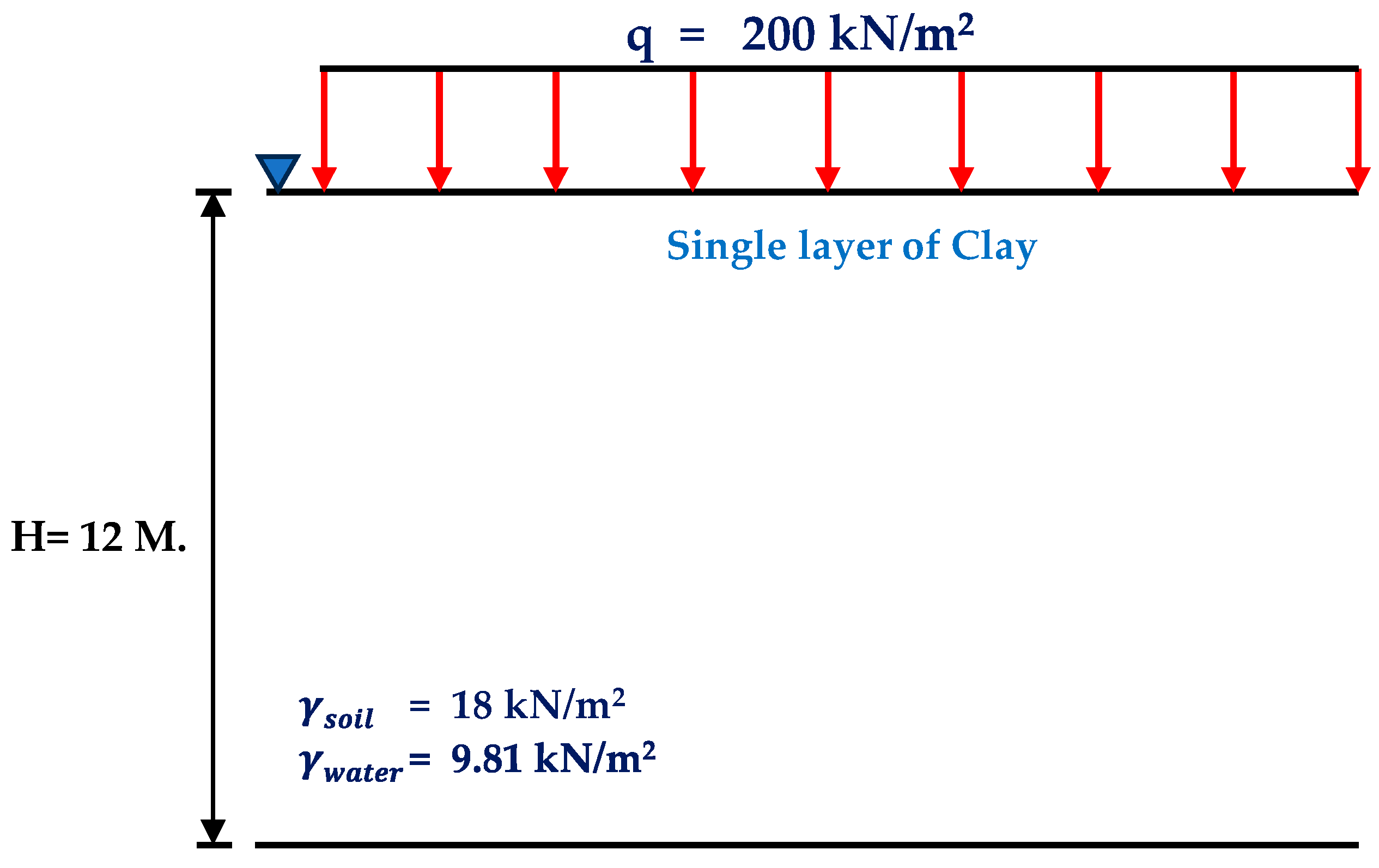

- (a)

- A single-layer clay model;

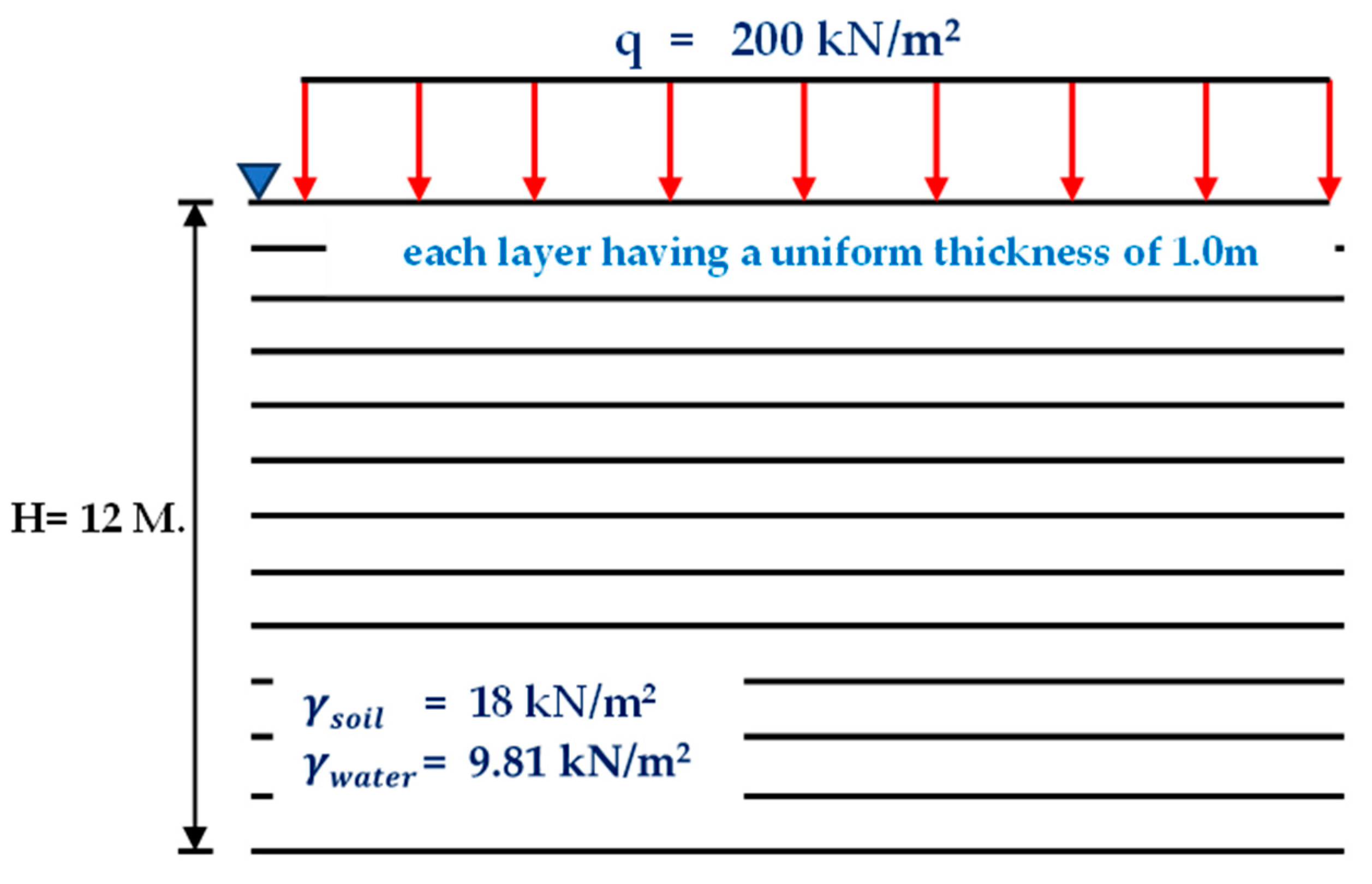

- (b)

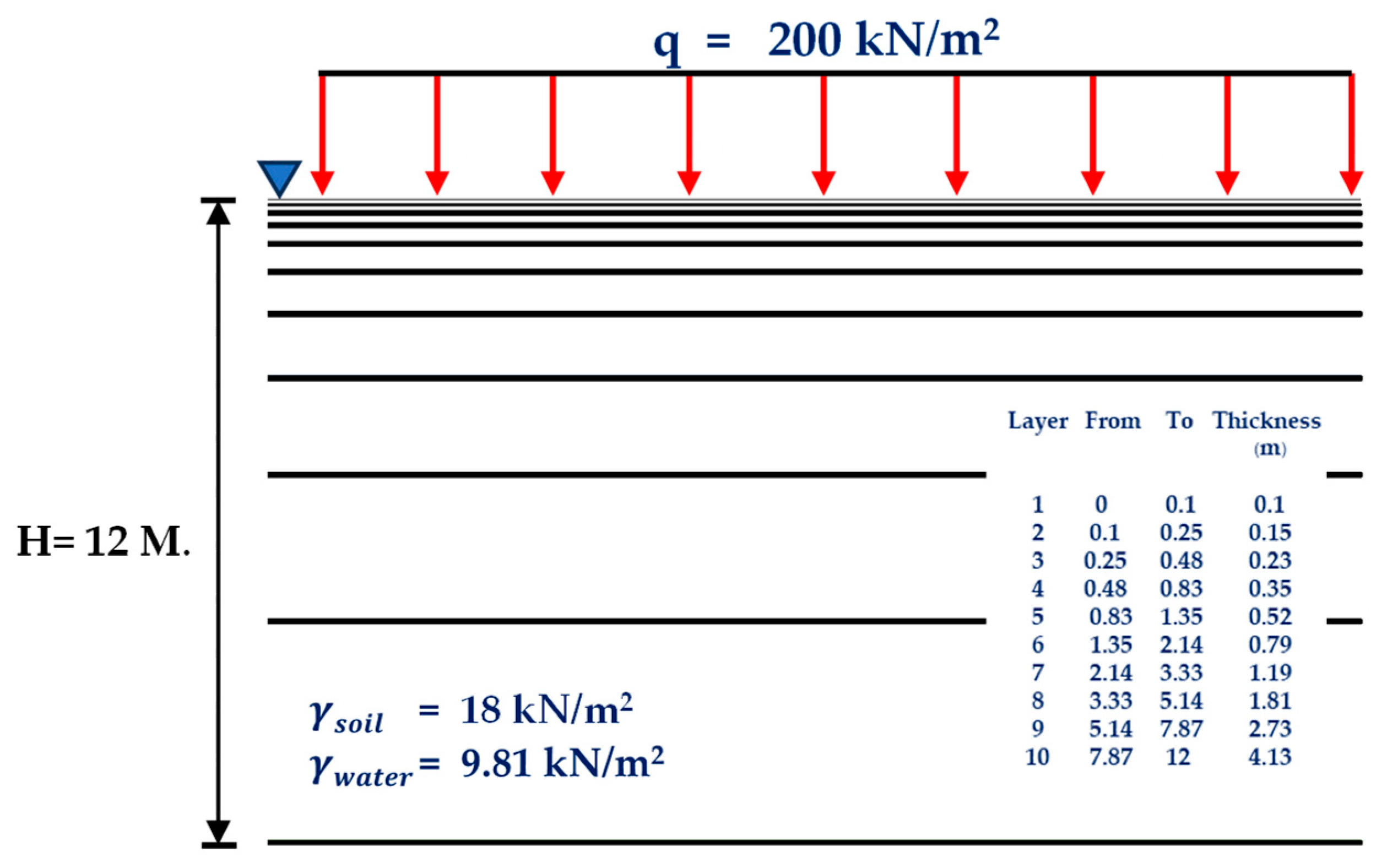

- A multi-layer model with uniform layer thickness of 1 m;

- (c)

- A variable-thickness layered model, in which thinner layers are used near the surface and layer thickness increases with depth.

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Davis, E.H.; Raymond, G.P. A Non-linear Theory of Consolidation. Geotechnique 1965, 15, 161–173. [Google Scholar] [CrossRef]

- Barden, L.; Berry, P.L. Consolidation of Normally Consolidated Clay. Soil Mech. Found. Div. 1965, 91, 5–35. [Google Scholar] [CrossRef]

- Gibson, R.E.; England, G.L.; Hussey, M.J.L. The Theory of One-Dimensional Consolidation of Saturated Clays. Geotechnique 1967, 17, 261–273. [Google Scholar] [CrossRef]

- Gray, H. Simultaneous consolidation of contiguous layers of unlike compressive soils. ASCE Trans. 1945, 110, 1327–1356. [Google Scholar]

- Poskitt, T.J. The Consolidation of Saturated Clay with Variable Permeability and Compressibility. Geotechnique 1969, 19, 234–252. [Google Scholar] [CrossRef]

- Schiffman, R.L.; Stein, J.R. One-Dimensional Consolidation of Layered Systems. Soil Mech. Found. 1970, 96, 1499–1504. [Google Scholar] [CrossRef]

- Mesri, G.; Rokhasar, A. Theory of Consolidation for Clays. Geotech. Eng. Div. 1974, 100, 889–904. [Google Scholar] [CrossRef]

- Lee, P.K.K.; Xie, K.H.; Cheung, Y.K. A Study on One-Dimensional Consolidation of Layered Systems. Int. J. Numer. Analyt. Methods Geomech. 1992, 16, 815–831. [Google Scholar] [CrossRef]

- Xie, K.; Pan, Q.Y. One-dimensional consolidation of soil stratum of arbitrary layers under time-dependent loading. China J. Geotech. Eng. 1995, 17, 82–87. [Google Scholar]

- Lekha, K.R.; Krishnaswamy, N.R.; Basak, P. Consolidation of Clays for Variable Permeability and Compressibility. J. Geotech. Geoenviron. Eng. 2003, 129, 1001–1009. [Google Scholar] [CrossRef]

- Zhuang, Y.C.; Xie, X.B.; Li, J. Nonlinear analysis of consolidation with variable compressibility and permeability. J. Zhejiang Univ. 2005, 6, 181–187. [Google Scholar] [CrossRef]

- Abbasi, N.; Rahimi, H.; Javadi, A.A.; Fakher, A. Finite Difference Approach for Consolidation with Variable Compressibility and permeability. Comput. Geotech. 2007, 34, 41–52. [Google Scholar] [CrossRef]

- Conte, E.; Troncone, A. Nonlinear Consolidation of thin layers Subjected to Time-Dependent Loading. Can. Geotech. 2007, 44, 717–725. [Google Scholar] [CrossRef]

- Carrera, E.; Brischetto, S. Analysis of Thickness locking in Classical, Refined and Mixed Multilayered Plate Theories. Compos. Struct. 2008, 82, 549–562. [Google Scholar] [CrossRef]

- Zheng, G.Y.; Li, P.; Zhao, C.Y. Analysis of Non-liner Consolidation of Soft Clay by Differential Quadrature Method. Appl. Clay Sci. 2013, 79, 2–7. [Google Scholar] [CrossRef]

- Li, C.; Huang, J.; Wu, L.; Lu, J.; Xia, C. Approximate Analytical Solutions for One-Dimensional Consolidation of a Clay Layer with Variable Compressibility and Permeability under a Ramp Loading. Int. J. Geomech. 2018, 18, 06018032. [Google Scholar] [CrossRef]

- Xie, K.H.; Xie, X.Y.; Jiang, W.A. Study on One-Dimensional Nonlinear Consolidation of Double-Layered Soil. Comput. Geotech. 2002, 29, 151–168. [Google Scholar] [CrossRef]

- Chen, R.P.; Zhou, W.H.; Wang, H.Z.; Chen, Y.M. One-Dimensional Nonlinear Consolidation of Multi-Layered Soil by Dif-ferential Quadrature Method. Comput. Geotech. 2005, 32, 358–369. [Google Scholar] [CrossRef]

- Hu, J.; Bian, X.; Chen, Y. Nonlinear Consolidation of Multilayer Soil under Cyclic loadings. Eur. J. Environ. Civ. Eng. 2021, 25, 1042–1064. [Google Scholar] [CrossRef]

- Kim, P.; Ri, K.S.; Kim, Y.G.; Sin, K.N.; Myong, H.B.; Paek, C.H. Nonlinear Consolidation Analysis of a Saturated Clay Layer with Variable Compressibility and Permeability under Various Cyclic Loadings. Int. J. Geomech. 2020, 20, 04020111. [Google Scholar] [CrossRef]

- Kim, P. Analytical Solution for One-Dimensional Nonlinear Consolidation of Saturated Multi-Layered Soil under Time-DePendent loading. J. Ocean Eng. Sci. 2021, 6, 21–29. [Google Scholar] [CrossRef]

- Trani, L.; Bergado, D.; Abuel-Naga, H. Thermo-Mechanical Behavior of Normally Consolidated Soft Bangkok Clay. Int. J. Geotech. Eng. 2010, 4, 31–44. [Google Scholar] [CrossRef]

- Whittle, A.J.; Degroot, D.J.; Seah, T.H.; Ladd, C.C. Model Prediction of The Anisotropic Behavior of Boston Blue Clay. J. Geotech. Eng. 1994, 120, 199–224. [Google Scholar] [CrossRef]

- Santos, L.M.; Oliveira, P.J.; Sousa, J.N.V.; Lemos, L.J.L. Effect of Initial Stiffness on The Induced Horizontal Displacements of Geotechnical Structures Built on/in Overconsolidated Clays. In Proceedings of the International Society for Soil Mechanics and Geotechnical Engineering, Imperial College, London, London, UK, 26–28 June 2023. [Google Scholar]

- Aysen, A. Soil Mechanics: Basic Concepts and Engineering Applications, 1st ed.; Swets & Zeitlinger, B.V.: Lisse, The Netherlands, 2002; pp. 221–222. [Google Scholar]

- Matsuoka, H.; Yao, Y.P.; Sun, D.A. The Cam-Clay Models Revised by the SMP Criterion. Soils Found. 1999, 39, 81–95. [Google Scholar] [CrossRef]

- Yao, Y.P.; Sun, D.A.; Luo, T.A. Critical State Model for Sands Dependent on Stress and Density. Int. J. Numer. Anal. Methods Geomech. 2004, 28, 323–337. [Google Scholar] [CrossRef]

- Yao, Y.P.; Sun, D.A.; Matsuoka, H. A Unified Constitutive Model for Both Clay and Sand with hardening Parameter Inde-pendent on Stress Path. Comput. Geotech. 2008, 15, 161–173. [Google Scholar]

- Cao, L.F.; Teh, C.I.; Chang, M.F. Undrained Cavity Expansion in Modified Cam Clay I: Theoretical Analysis. Geotechnique 2001, 51, 323–334. [Google Scholar] [CrossRef]

- Grimstad, G.; Degago, S.A.; Nordal, S. Modeling Creep and Rate Effects in Structured Anisotropic Soft Clays. Acta Geotech. 2010, 5, 69–81. [Google Scholar] [CrossRef]

- Yin, Z.Y.; Xu, Q.; Hicher, P.Y. A Simple Critical-State-Based Double-Yield-Surface Model for Clay Behavior under Complex loading. Acta Geotech. 2013, 8, 509–523. [Google Scholar] [CrossRef]

- Ou, C.Y.; Liu, C.C.; Chin, C.K. Anisotropic Viscoplastic Modeling of Rate-Dependent Behavior of Clay. Int. J. Numer. Anal. Methods Geomech. 2011, 35, 1189–1206. [Google Scholar] [CrossRef]

- Li, X.S.; Wang, Y. Linear Representation of Steady State Line for Sand. J. Geotech. Geoenviron. Eng. 1998, 124, 1215–1217. [Google Scholar] [CrossRef]

- Yang, Z.X.; Li, X.S.; Yang, J. Quantifying and Modelling Fabric Anisotropy of Granular soils. Geotechnique 2008, 58, 237–248. [Google Scholar] [CrossRef]

- Yang, J.; Wei, L.M.; Dai, B.B. State Variables for Silty Sands: Global Void Ratio or Skeleton Void Ratio? Soils Found. 2015, 55, 99–111. [Google Scholar] [CrossRef]

- Murthy, T.G.; Loukidis, D.; Carraro, J.A.H.; Prezzi, M.; Salgado, R. Undrained Monotonic Response of Clean and Silty Sands. Geotechnique 2007, 57, 273–288. [Google Scholar] [CrossRef]

- Rahman, M.M.; Lo, S.R.; Baki, M.A.L. Equivalent Granular State Parameter and Undrained Behaviour of Sand–Fines Mixtures. Acta Geotech. 2011, 6, 183–194. [Google Scholar] [CrossRef]

- Rahman, M.M.; Lo, S.R.; Dafalias, Y.F. Modelling the Static Liquefaction of Sand with Low-Plasticity Fines. Geotechnique 2014, 64, 881–894. [Google Scholar] [CrossRef]

- Duriez, J.; Vincens, É. Constitutive Modelling of Cohesionless Soils and Interfaces with Various Internal States: An Elas-to-Plastic Approach. Comput. Geotech. 2015, 63, 33–45. [Google Scholar] [CrossRef]

- Kaewhanam, N.; Chaimoon, K. A Simplified Silty Sand Model. Appl. Sci. 2023, 13, 8241. [Google Scholar] [CrossRef]

- Yin, J.H.; Graham, J. General Elastic Viscous Plastic Constitutive Relationships for 1-D Straining in Clays. Int. Symp. Numer. Models Geomech. 1989, 3, 108–117. [Google Scholar]

- Yin, J.H.; Graham, J. Equivalent Times and One-Dimensional elastic Viscoplastic Modelling of Time-Dependent Stress–Strain Behaviour of Clays. Can. Geotech. J. 1994, 31, 42–52. [Google Scholar] [CrossRef]

- Yin, J.H.; Graham, J. Elastic Visco-Plastic Modelling of One-Dimensional Consolidation. Geotechnique 1996, 46, 515–527. [Google Scholar] [CrossRef]

- Yin, J.H. Non-Linear Creep of Soils in Oedometer Tests. Geotechnique 1999, 49, 699–707. [Google Scholar] [CrossRef]

- Zhu, Q.-Y.; Yin, Z.-Y.; Hicher, P.-Y.; Shen, S.-L. Nonlinearity of One-Dimensional Creep Characteristics of Soft Clays. Acta Geotech. 2016, 11, 887–900. [Google Scholar] [CrossRef]

- Nishimura, T. Shear Strength of an Unsaturated Silty Soil Subjected to Creep Deformation. Geotech. Sustain. Infrastruct. Dev. 2020, 62, 977–984. [Google Scholar]

- Degago, S.A.; Nordal, S.; Grimstad, G.; Jostad, H.P. Analyses of Väsby Test Fill according to Creep Hypothesis A and B. In Proceedings of the International Conference of the International Association for Computer Methods and Advances in Geomechanics, Melbourne, Australia, 9–13 May 2011. [Google Scholar]

- Leroueil, S.; Kabbaj, M.; Tavenas, F.; Bouchard, R. Stress–Strain–Strain Rate Relation for the Compressibility of Sensitive Natural Clays. Géotechnique 1985, 35, 159–180. [Google Scholar] [CrossRef]

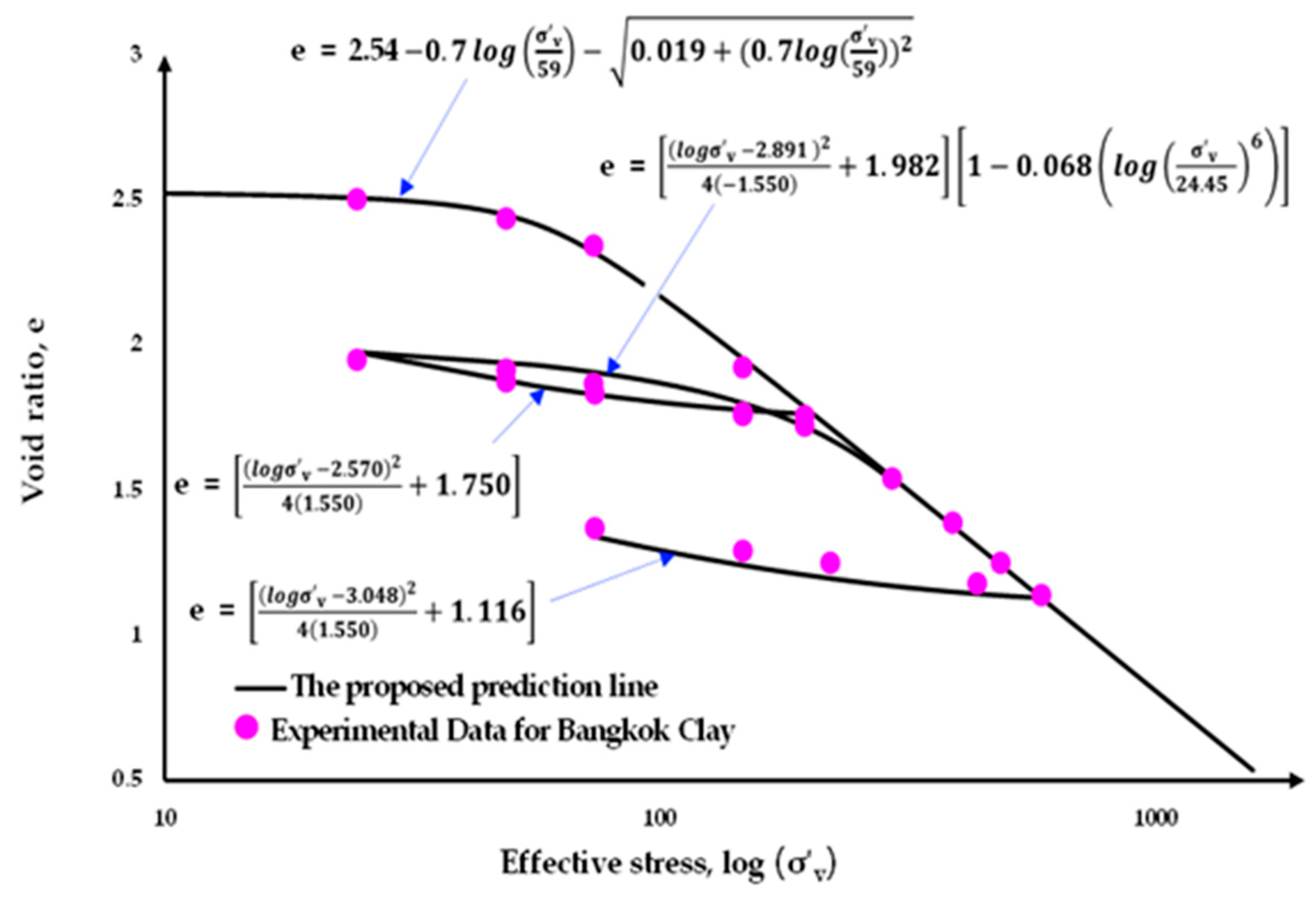

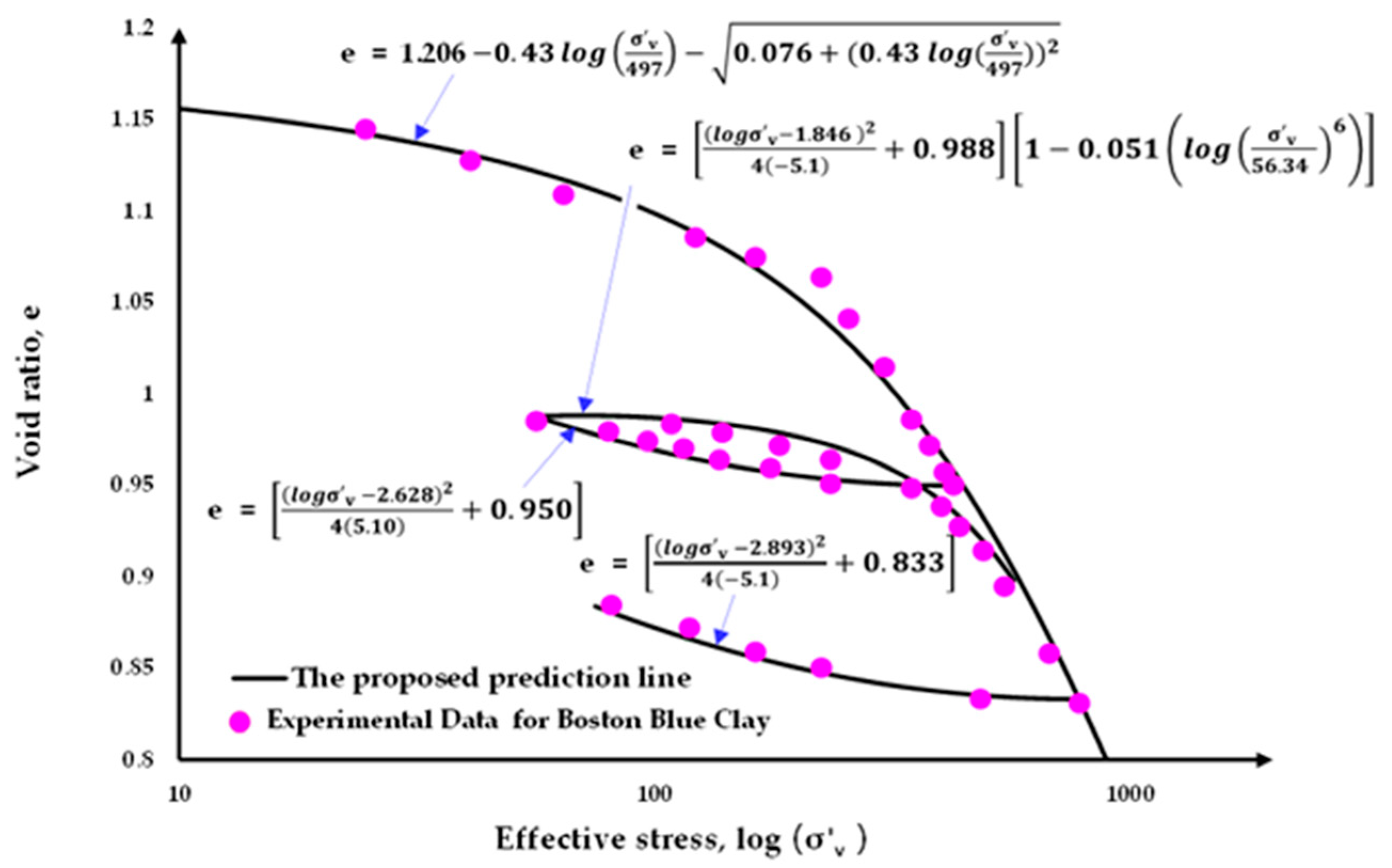

| Type of Soil | Virgin Compassion Line | Unloading–Reloading Line | ||||||

|---|---|---|---|---|---|---|---|---|

| Boston blue clay | 1.206 | 0.430 | 497 | 0.076 | 5.10 | 2.628 | 0.950 | 0.051 |

| London clay | 0.850 | 0.135 | 530 | 0.0058 | 5.70 | 3.800 | 0.64 | 0.004 |

| Bangkok clay | 2.540 | 0.700 | 59 | 0.019 | 1.55 | 2.570 | 1.75 | 0.068 |

| Type of Soil | Case | LF (Equation (3)) | CF (Equation (4)) | AJOP (Equation (6)) |

|---|---|---|---|---|

| Boston blue clay | (a) Single layer | 1.566 | 0.302 | 0.284 |

| (b) Equal layer thickness | 1.967 | 0.323 | 0.310 | |

| (c) Varied layer thickness | 1.988 | 0.323 | 0.309 | |

| London clay | (a) Single layer | 0.806 | 0.102 | 0.089 |

| (b) Equal layer thickness | 1.012 | 0.109 | 0.097 | |

| (c) Varied layer thickness | 1.023 | 0.108 | 0.097 | |

| Bangkok clay | (a) Single layer | 2.334 | 3.453 | 1.832 |

| (b) Equal layer thickness | 2.933 | 3.667 | 1.781 | |

| (c) Varied layer thickness | 2.964 | 3.663 | 1.780 |

| Type of Soil | Case | AJOP Method (Equation (6)) |

|---|---|---|

| Boston blue clay | (a) Single layer | 0.178 |

| (b) Equal layer thickness | 0.207 | |

| (c) Varied layer thickness | 0.205 | |

| London clay | (a) Single layer | 0.072 |

| (b) Equal layer thickness | 0.080 | |

| (c) Varied layer thickness | 0.080 | |

| Bangkok clay | (a) Single layer | 1.015 |

| (b) Equal layer thickness | 1.119 | |

| (c) Varied layer thickness | 1.101 |

| Type of Soil | Case | AJOP (Equation (6)) |

|---|---|---|

| Boston blue clay | (a) Single layer | 1.084 |

| (b) Equal layer thickness | 1.139 | |

| (c) Varied layer thickness | 1.138 | |

| London clay | (a) Single layer | 0.397 |

| (b) Equal layer thickness | 0.417 | |

| (c) Varied layer thickness | 0.417 | |

| Bangkok clay | (a) Single layer | 3.578 |

| (b) Equal layer thickness | 3.659 | |

| (c) Varied layer thickness | 3.651 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Phonchamni, N.; Chatwong, T.; Udomchai, A.; Sultornsanee, S.; Angkawisittpan, N.; Sangiamsak, N.; Kaewhanam, N. Refined Consolidation Settlement Calculation Based on the Oedometer Tests for Normally and Overconsolidated Clays. Appl. Sci. 2025, 15, 5777. https://doi.org/10.3390/app15105777

Phonchamni N, Chatwong T, Udomchai A, Sultornsanee S, Angkawisittpan N, Sangiamsak N, Kaewhanam N. Refined Consolidation Settlement Calculation Based on the Oedometer Tests for Normally and Overconsolidated Clays. Applied Sciences. 2025; 15(10):5777. https://doi.org/10.3390/app15105777

Chicago/Turabian StylePhonchamni, Nopakun, Thammanun Chatwong, Artit Udomchai, Sivarit Sultornsanee, Niwat Angkawisittpan, Noppadol Sangiamsak, and Nopanom Kaewhanam. 2025. "Refined Consolidation Settlement Calculation Based on the Oedometer Tests for Normally and Overconsolidated Clays" Applied Sciences 15, no. 10: 5777. https://doi.org/10.3390/app15105777

APA StylePhonchamni, N., Chatwong, T., Udomchai, A., Sultornsanee, S., Angkawisittpan, N., Sangiamsak, N., & Kaewhanam, N. (2025). Refined Consolidation Settlement Calculation Based on the Oedometer Tests for Normally and Overconsolidated Clays. Applied Sciences, 15(10), 5777. https://doi.org/10.3390/app15105777