Intelligent Automation in Knitting Manufacturing: Advanced Software Integration and Structural Optimisation for Complex Textile Design

Abstract

1. Introduction

2. Materials and Methods

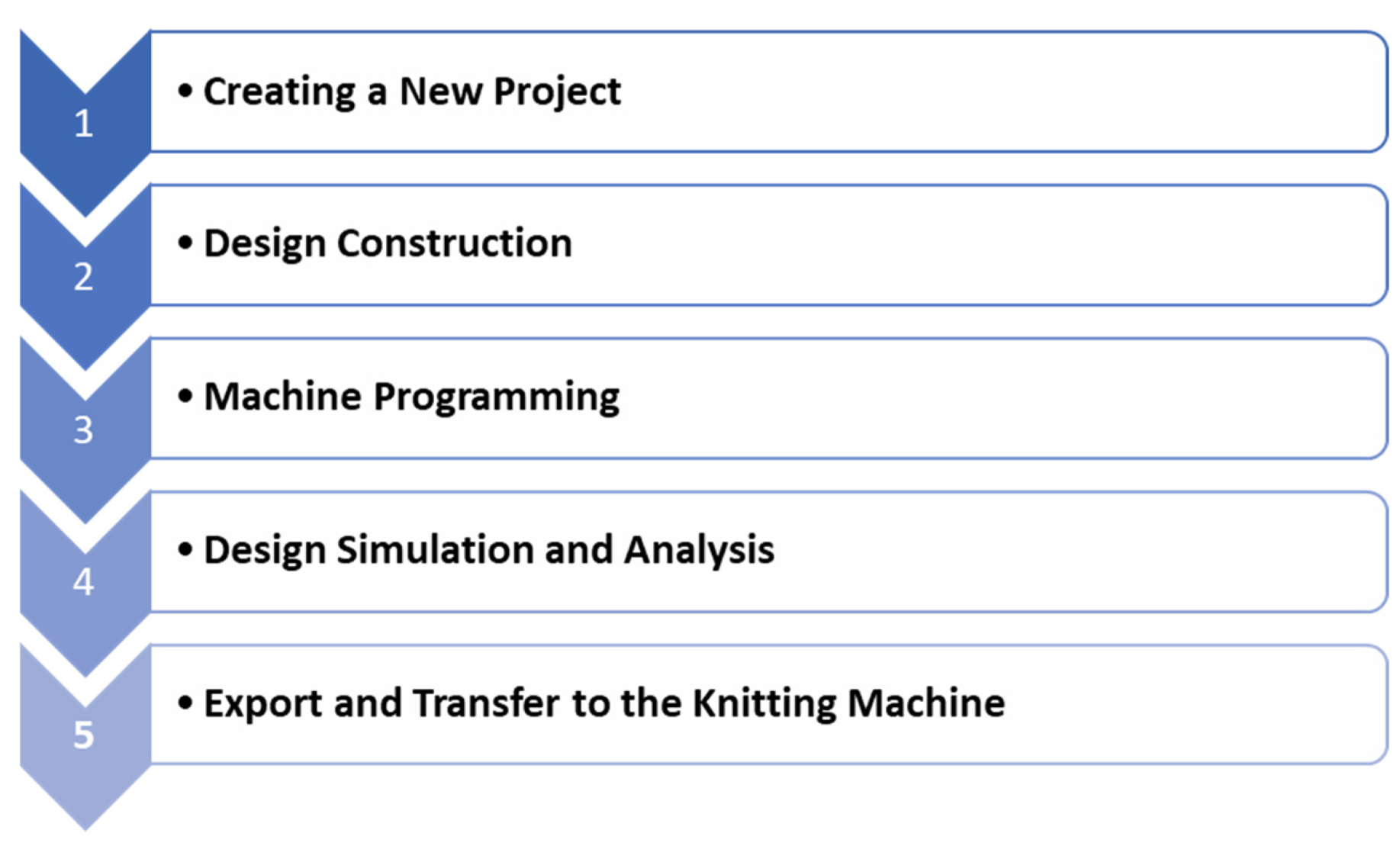

2.1. Design Methodology Using M1plus V7.5

2.1.1. Creating a New Project

- Knit pattern—selection of single jersey, double jersey, jacquard, textured, and other knitting structures, depending on the design requirements.

- Machine gauge—setting the number of needles according to the specifications of the selected industrial knitting machine.

- Knitting density—a crucial parameter that determines the degree of yarn interlocking, directly affecting the structure and dimensional behaviour of the final product.

- Yarn types—selection of the yarn(s) to be used; the software supports a wide range of options including cotton, wool, synthetic fibres, and various blends of natural and synthetic materials.

2.1.2. Design Construction

- Plain stitch—a uniform macrostructure with evenly distributed loops;

- Jacquard stitch—combining multiple colours and yarns to form intricate pattern motifs;

- Textured structures—involving loop transfers and needle skips to generate three-dimensional surfaces.

2.1.3. Machine Programming

2.1.4. Design Simulation and Analysis

2.1.5. Export and Transfer to the Knitting Machine

2.2. Materials

2.3. Methods

3. Results and Discussion

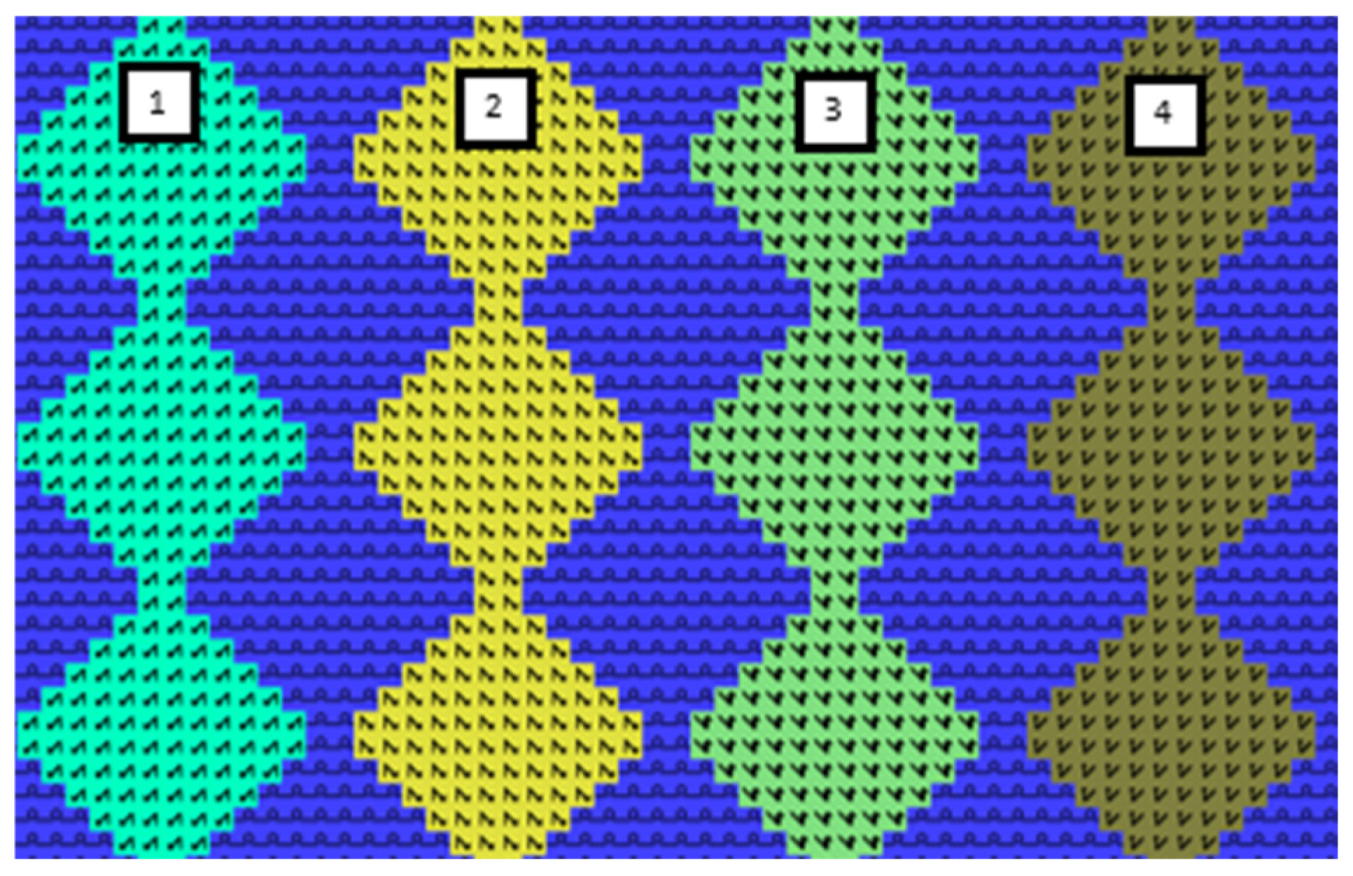

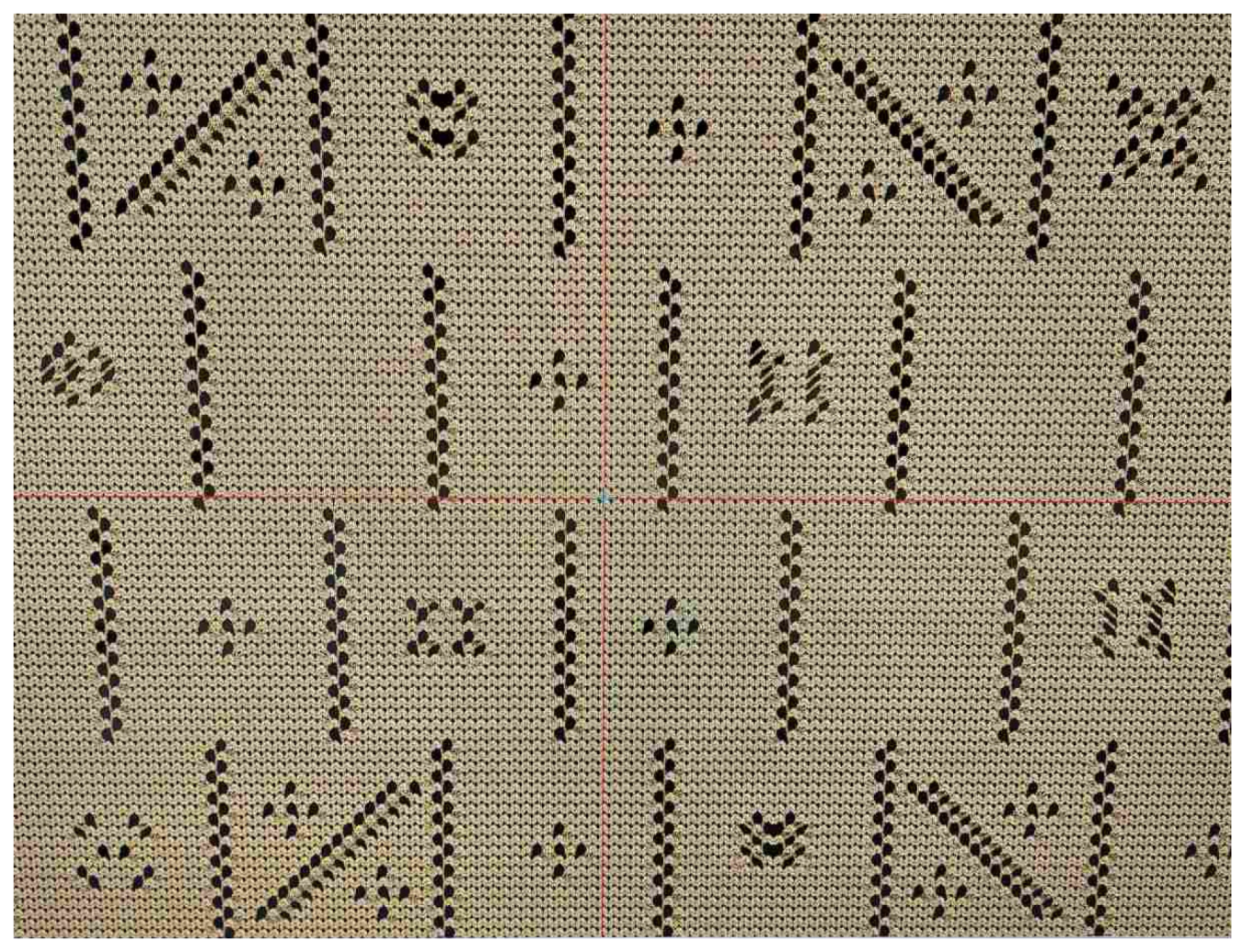

3.1. Design of the Knit Macrostructures

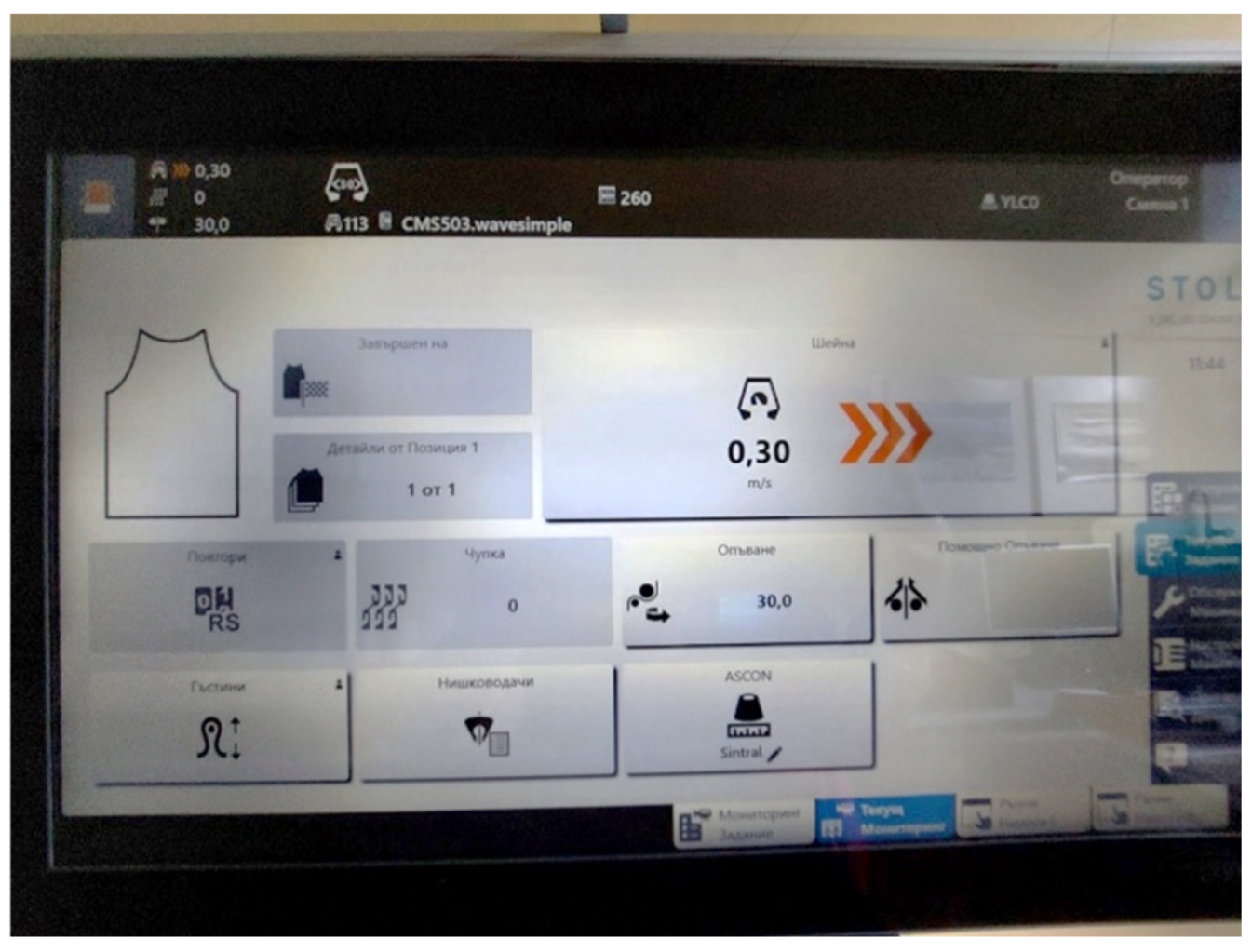

3.2. Manufacturing of the Knit Macrostructures

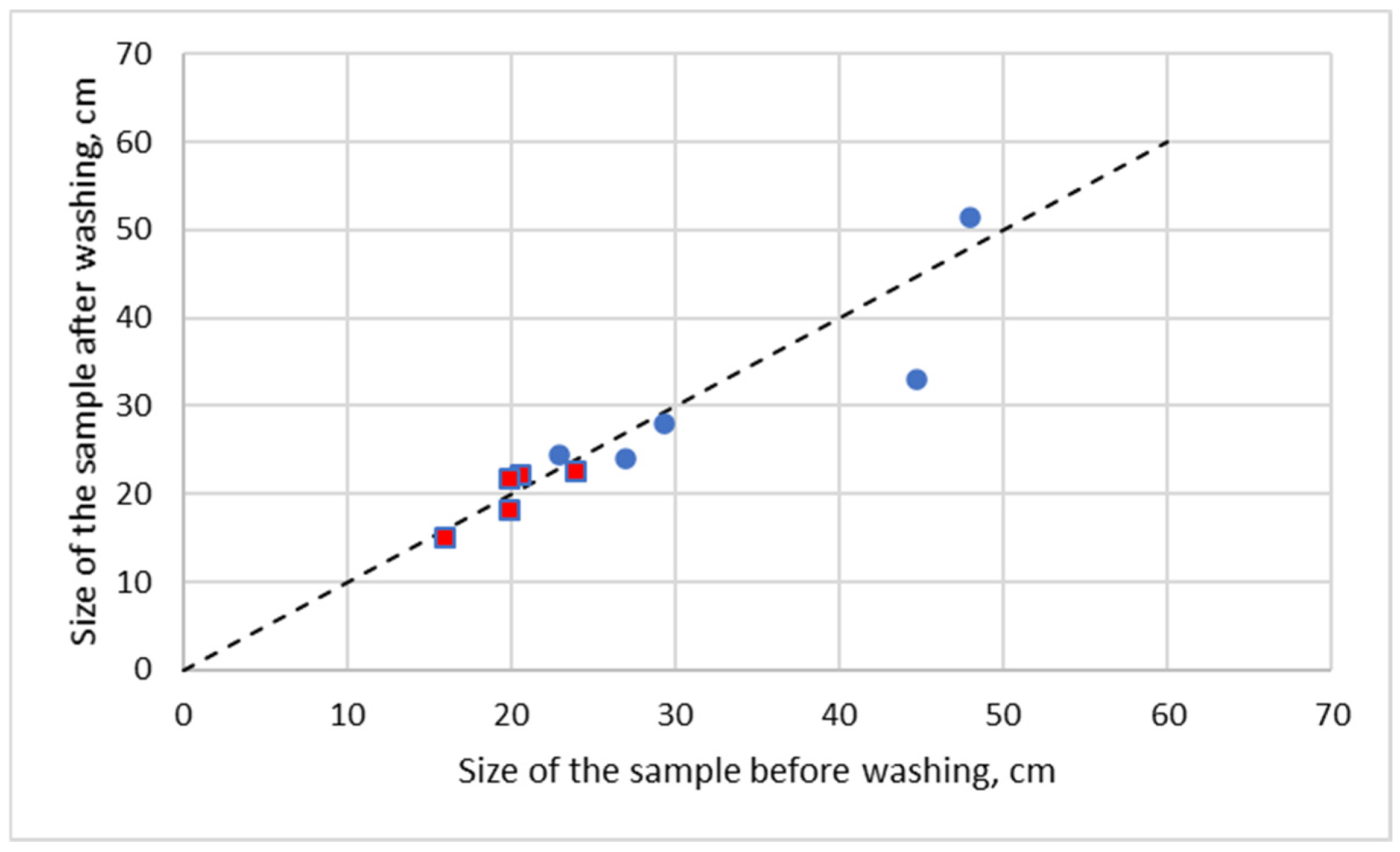

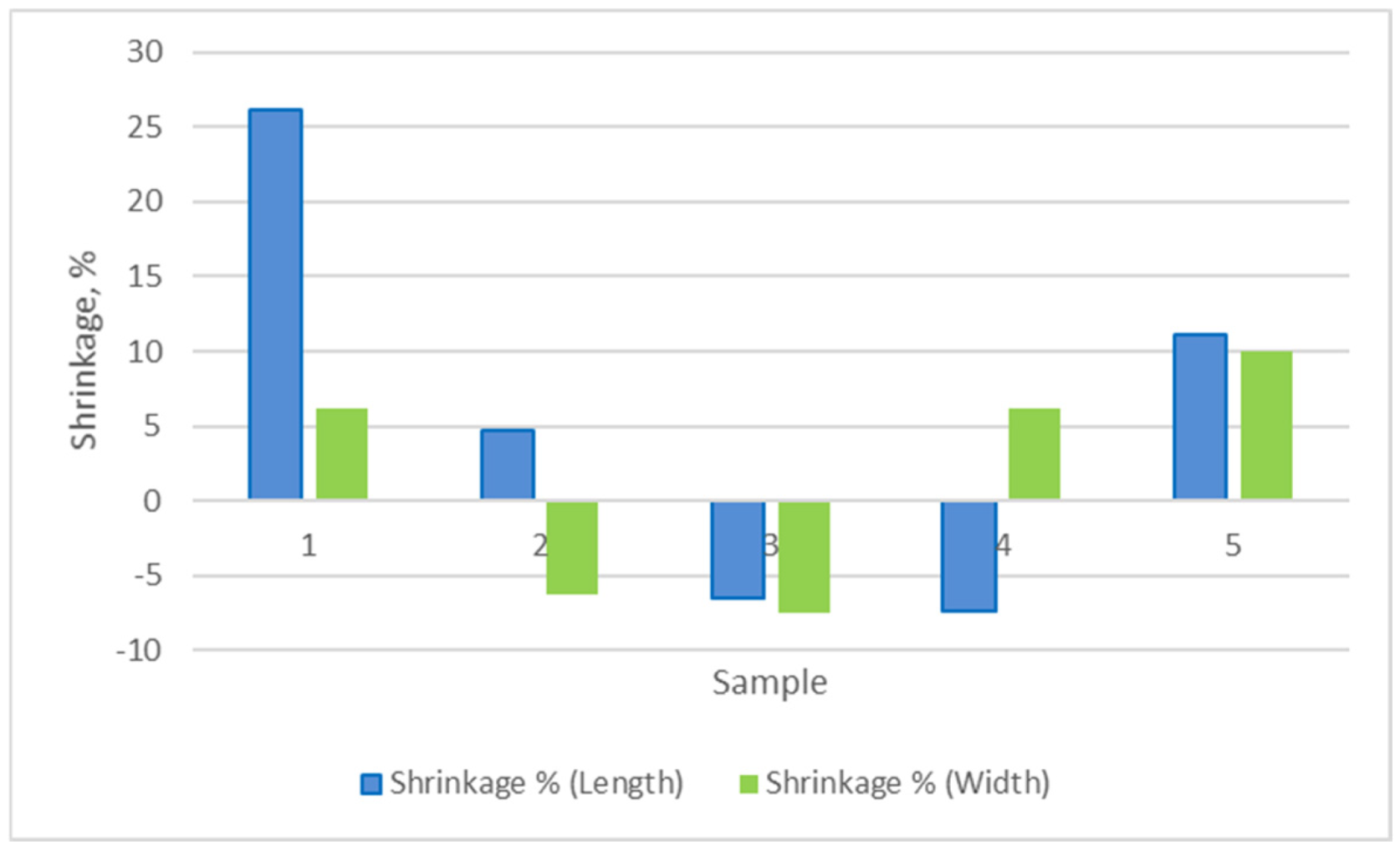

3.3. Shrinkage Results and Analysis

3.4. Discussion

- Dense structures (Sample 1) are prone to vertical shrinkage;

- Balanced, repetitive structures (Sample 2) perform best in terms of dimensional stability;

- Openwork and decorative designs (Samples 3 and 4) may expand or distort due to loop relaxation;

- Geometric pointelle structures (Sample 5) can offer stable shrinkage ratios if well distributed.

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Nayak, R.; Padhye, R. Introduction to Automation in Garment Manufacturing. In Automation in Garment Manufacturing; Woodhead Publishing: Cambridge, UK, 2018; pp. 1–27. [Google Scholar]

- Djiev, S.N.; Pavlov, L.I. Automated Systems Techniques for On-Line Quality and Production Control in the Manufacture of Textiles. In Computer-Aided Design, Engineering, and Manufacturing; CRC Press: Boca Raton, FL, USA, 2019; pp. 8-1–8-24. [Google Scholar]

- Haq, U.N.; Khan, M.M.R.; Khan, A.M.; Hasanuzzaman, M.; Hossain, M.R. Global Initiatives for Industry 4.0 Implementation and Progress within the Textile and Apparel Manufacturing Sector: A Comprehensive Review. Int. J. Comput. Integr. Manuf. 2025, in press. [Google Scholar] [CrossRef]

- Čuden, A.P. Recent Developments in Knitting Technology. In Advanced Knitting Technology; Čuden, A.P., Ed.; Academic Publisher: Ljubljana, Slovenia, 2022; pp. 13–66. [Google Scholar]

- Jana, P.; Tiwari, M. Industrial Engineering in Apparel Manufacturing; Apparel Resources Pvt. Ltd.: New Delhi, India, 2020. [Google Scholar]

- Elmogahzy, Y. Engineering Textiles: Integrating the Design and Manufacture of Textile Products; Woodhead Publishing: Cambridge, UK, 2019. [Google Scholar]

- Stoll. Train_en Technical Manual. Available online: https://nfc.stoll.com/faq/253492_06_train_en.pdf (accessed on 25 March 2025).

- Shima Seiki. Product Design Software. Available online: https://www.shimaseiki.com/product/design/software/ (accessed on 25 March 2025).

- Saggiomo, M.; Wischnowski, M.; Simonis, K.; Gries, T. Automation in Production of Yarns, Woven, and Knitted Fabrics. In Automation in Garment Manufacturing; Woodhead Publishing: Cambridge, UK, 2018; pp. 49–74. [Google Scholar]

- Farhana, K.; Kadirgama, K.; Mahamude, A.S.F.; Mica, M.T. Energy Consumption, Environmental Impact, and Implementation of Renewable Energy Resources in Global Textile Industries: An Overview towards Circularity and Sustainability. Mater. Circ. Econ. 2022, 4, 15. [Google Scholar] [CrossRef]

- Roy Choudhury, A.K. Green Chemistry and the Textile Industry. Text. Prog. 2013, 45, 3–143. [Google Scholar] [CrossRef]

- Khattab, T.A.; Abdelrahman, M.S.; Rehan, M. Textile Dyeing Industry: Environmental Impacts and Remediation. Environ. Sci. Pollut. Res. 2020, 27, 3803–3818. [Google Scholar] [CrossRef]

- Stone, C.; Windsor, F.M.; Munday, M.; Durance, I. Natural or Synthetic–How Global Trends in Textile Usage Threaten Freshwater Environments. Sci. Total Environ. 2020, 718, 134689. [Google Scholar] [CrossRef]

- Sharma, K.; Nagabhooshanam, N.; Dasi, S.; Srinivas, B.; Kaur, K.; Rajaram, A. Design and Implementation of Closed-Loop Water Reuse Systems in Urban and Industrial Settings for Maximizing Resource Recovery and Minimizing Waste. Desalination Water Treat. 2024, 320, 100850. [Google Scholar] [CrossRef]

- Wojnowska-Baryła, I.; Bernat, K.; Zaborowska, M. Strategies of Recovery and Organic Recycling Used in Textile Waste Management. Int. J. Environ. Res. Public Health 2022, 19, 5859. [Google Scholar] [CrossRef]

- Khude, P. A Review on Energy Management in Textile Industry. Innov. Energy Res. 2017, 6, 169. Available online: https://www.omicsonline.org/open-access/a-review-on-energy-management-in-textile-industry-2576-1463-1000169.pdf (accessed on 24 March 2025). [CrossRef]

- Kumar, D.; Bhardwaj, R.; Jassal, S.; Goyal, T.; Khullar, A.; Gupta, N. Application of Enzymes for an Eco-Friendly Approach to Textile Processing. Environ. Sci. Pollut. Res. 2021, 28, 71838–71848. [Google Scholar] [CrossRef]

- Luján-Ornelas, C.; Güereca, L.P.; Franco-García, M.L.; Heldeweg, M. A Life Cycle Thinking Approach to Analyse Sustainability in the Textile Industry: A Literature Review. Sustainability 2020, 12, 10193. [Google Scholar] [CrossRef]

- Wójcik-Karpacz, A.; Karpacz, J.; Brzeziński, P.; Pietruszka-Ortyl, A.; Ziębicki, B. Barriers and Drivers for Changes in Circular Business Models in a Textile Recycling Sector: Results of Qualitative Empirical Research. Energies 2023, 16, 490. [Google Scholar] [CrossRef]

- Ortega-Gras, J.J.; Bueno-Delgado, M.V.; Cañavate-Cruzado, G.; Garrido-Lova, J. Twin Transition through the Implementation of Industry 4.0 Technologies: Desk-Research Analysis and Practical Use Cases in Europe. Sustainability 2021, 13, 13601. [Google Scholar] [CrossRef]

- Dal Forno, A.J.; Bataglini, W.V.; Steffens, F.; Ulson de Souza, A.A. Industry 4.0 in Textile and Apparel Sector: A Systematic Literature Review. Res. J. Text. Apparel 2023, 27, 95–117. [Google Scholar] [CrossRef]

- Blaga, M. Use of CAD in Knitted Apparels. In Advanced Knitting Technology; Woodhead Publishing: Sawston, UK, 2022; pp. 181–202. [Google Scholar]

- Elkateba, S.; Métwallib, A.; Shendyc, A. Real-Time Monitoring of Knitting Machine Performance Using IoT and Machine Learning: Innovations and Applications. J. Fiber Bioeng. Inform. 2023, 16, 297–309. [Google Scholar]

- Ozek, A.; Seckin, M.; Demircioglu, P.; Bogrekci, I. Artificial Intelligence Driving Innovation in Textile Defect Detection. Textiles 2025, 5, 12. [Google Scholar] [CrossRef]

- Donmezer, S.; Demircioglu, P.; Bogrekci, I.; Bas, G.; Durakbasa, M.N. Revolutionizing the Garment Industry 5.0: Embracing Closed-Loop Design, E-Libraries, and Digital Twins. Sustainability 2023, 15, 15839. [Google Scholar] [CrossRef]

- Zulfiqar, A.; Manzoor, T.; Ijaz, M.B.; Nawaz, H.H.; Ahmed, F.; Akhtar, S.; Umar, M. Artificial-Neural-Network-Based Predicted Model for Seam Strength of Five-Pocket Denim Jeans: A Review. Textiles 2024, 4, 183–217. [Google Scholar] [CrossRef]

- Wu, X.; Li, L. An Application of Generative AI for Knitted Textile Design in Fashion. Des. J. 2024, 27, 270–290. [Google Scholar] [CrossRef]

- Gong, Z.; Cao, Z.; Liu, H. Research on Intelligent Textile Shrinkage Prediction Based on Digital Twin Technology. J. Intell. Plant Dev. 2023, 8, 7455. [Google Scholar] [CrossRef]

- Zhang, H.; Chen, X.; Wang, Y. A Smart Quality Monitoring System Based on Machine Vision and AI for the Textile Industry. J. Intell. Plant Dev. 2023, 8, 6639. [Google Scholar] [CrossRef]

- Mohiuddin Babu, M.; Akter, S.; Rahman, M.; Billah, M.M.; Hack-Polay, D. The Role of Artificial Intelligence in Shaping the Future of Agile Fashion Industry. Prod. Plan. Control 2024, 35, 2084–2098. [Google Scholar] [CrossRef]

- Elshafie, M.Z.; Salem, R.S.; Mostafa, H.; Amer, A.M. Deep Learning-Based Intelligent Fabric Shrinkage Detection and Prediction Using Thermal Images. Alexandria Eng. J. 2024, 15, 103116. [Google Scholar] [CrossRef]

- Ingle, N.; Jasper, W.J. A Review of the Evolution and Concepts of Deep Learning and AI in the Textile Industry. Text. Res. J. 2025, in press. [Google Scholar] [CrossRef]

- Banerjee, P.K. Principles of Fabric Formation, 3rd ed.; CRC Press: Boca Raton, FL, USA, 2014; pp. 1–300. [Google Scholar]

- Gokarneshan, N.; Varadarajan, B.; Sentil Kumar, C.B.; Balamurugan, K.; Rachel, A. Engineering Knits for Versatile Technical Applications: Some Insights on Recent Researches. J. Ind. Text. 2012, 42, 52–75. [Google Scholar] [CrossRef]

- Twigg-Smith, H.; Peek, N. Dynamic Toolchains: Software Infrastructure for Digital Fabrication Workflows. In Proceedings of the 36th Annual ACM Symposium on User Interface Software and Technology, San Francisco, CA, USA, 29 October–1 November 2023; pp. 1–20. [Google Scholar]

- Santos, T.F.; Santos, C.M.; Zilio, L.; Dias, M.; Jagadeesh, P.; Sanjay, M.R.; Medeiros, I. Impact of Yarn Compositions, Loop Length, and Float Stitches on the Mechanical Behavior of Knitted Fabrics via Full Factorial Design and RSM. Heliyon 2023, 9, 8. [Google Scholar] [CrossRef]

- Ray, S.C.; Blaga, M. Yarns for Knitting and Their Selection. In Advanced Knitting Technology; Woodhead Publishing: Cambridge, UK, 2022; pp. 141–159. [Google Scholar]

- Au, K.F. (Ed.) Advances in Knitting Technology; Elsevier: Oxford, UK, 2011. [Google Scholar]

- Duprat, C. Moisture in Textiles. Annu. Rev. Fluid Mech. 2022, 54, 443–467. [Google Scholar] [CrossRef]

- Dyagilev, A.; Bykouski, D.; Charkovskij, A.; Holovenko, T.; Shovkomud, O. Estimation of Hygroscopicity of Knitted Fabrics. AIP Conf. Proc. 2022, 2430, 050003. [Google Scholar]

- Spencer, D.J. Knitting Technology: A Comprehensive Handbook and Practical Guide, 3rd ed.; CRC Press: Boca Raton, FL, USA, 2001; Volume 16. [Google Scholar]

- Underwood, J. The Design of 3D Shape Knitted Preforms. Ph.D. Thesis, RMIT University, Melbourne, Australia, 2009. [Google Scholar]

- Saville, B.P. Physical Testing of Textiles; Elsevier: Cambridge, UK, 1999. [Google Scholar]

- Llinares Berenguer, J.; Díaz-García, P.; Miró Martínez, P. Calculation of Interlock, 1×1 Rib, and Single Jersey Knitted Fabrics Shrinkage During the Dyeing Process After Determining Loop Shape. Text. Res. J. 2021, 91, 2588–2599. [Google Scholar] [CrossRef]

| Knit Macrostructure | Sample 1 | Sample 2 | Sample 3 | Sample 4 | Sample 5 |

|---|---|---|---|---|---|

| Threads | Cotton 100%, NE 60/4 | Cotton 100%, NE 20/2 | Cotton 100%, NE 20/2 | Cotton 100%, NE 60/4 | Cotton 100%, NE 20/2 |

| Cotton 100%, NE 20/2 |

| Knit Macrostructure | Sample 1 | Sample 2 | Sample 3 | Sample 4 | Sample 5 |

|---|---|---|---|---|---|

| Number of needles | 172 | 170 | 74 | 120 | 140 |

| Number of rows | 274 | 218 | 132 | 377 | 187 |

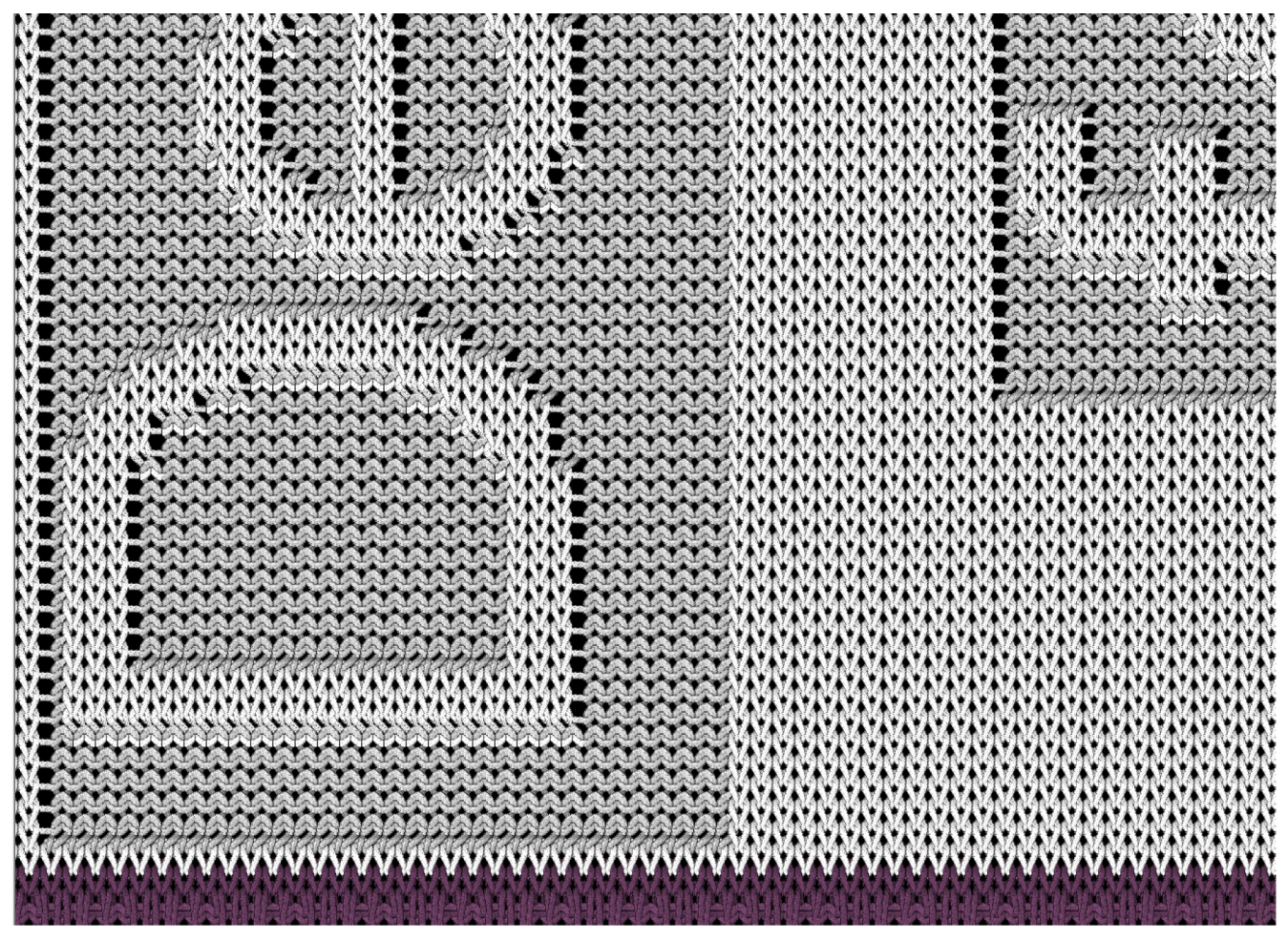

| Parameter | Setting |

|---|---|

| Rib binding setting | Stoll with protection thread |

| Needle binding type | Standard |

| Number of knitting systems for binding | 1 system |

| Type of thread/stitch for binding | With elastic thread |

| Type of transition row | Transition DJ (for rib to double-faced knit) |

| Rib type | 2 × 2 |

| Section | Applied Modules and Structure |

|---|---|

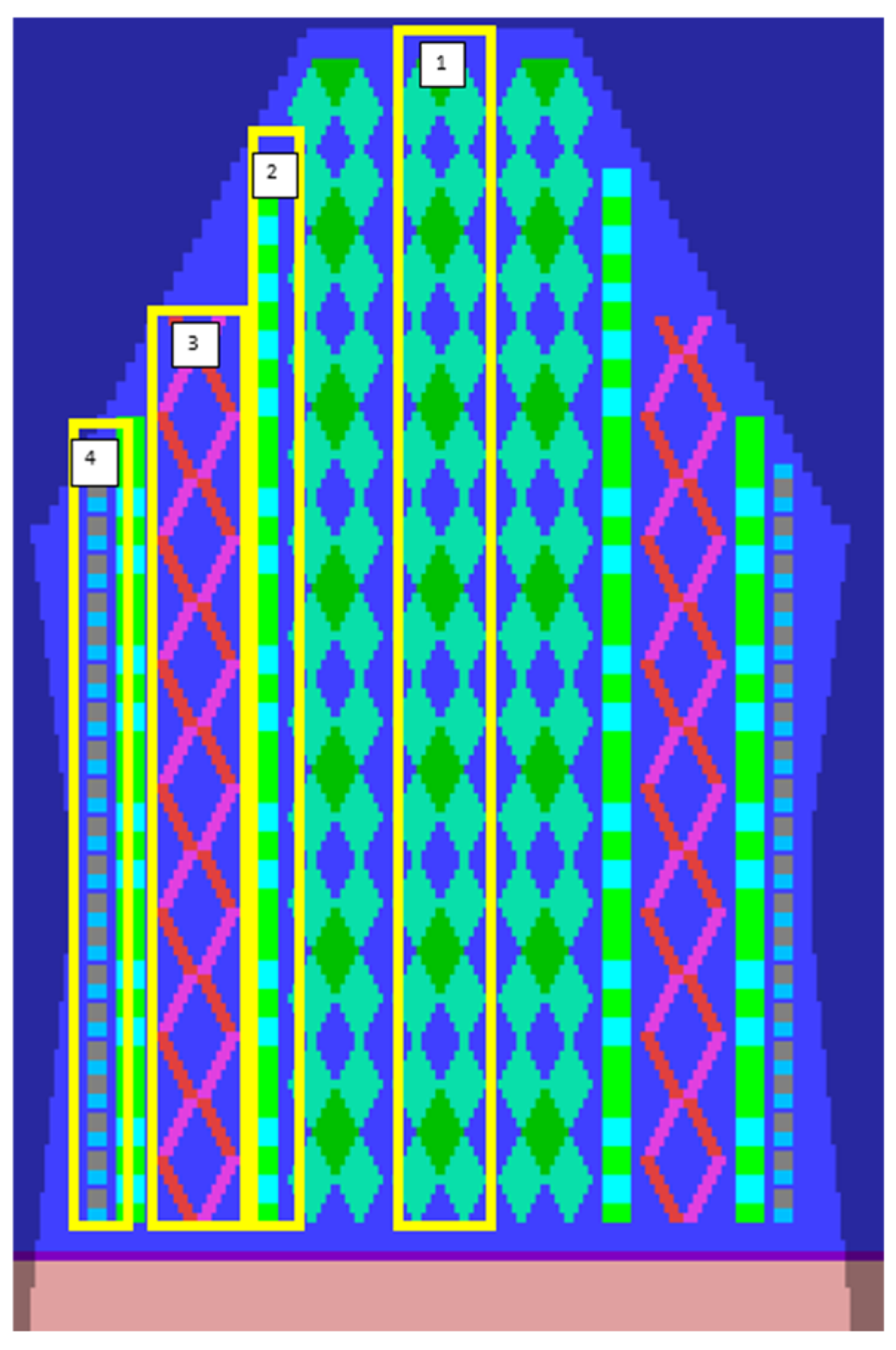

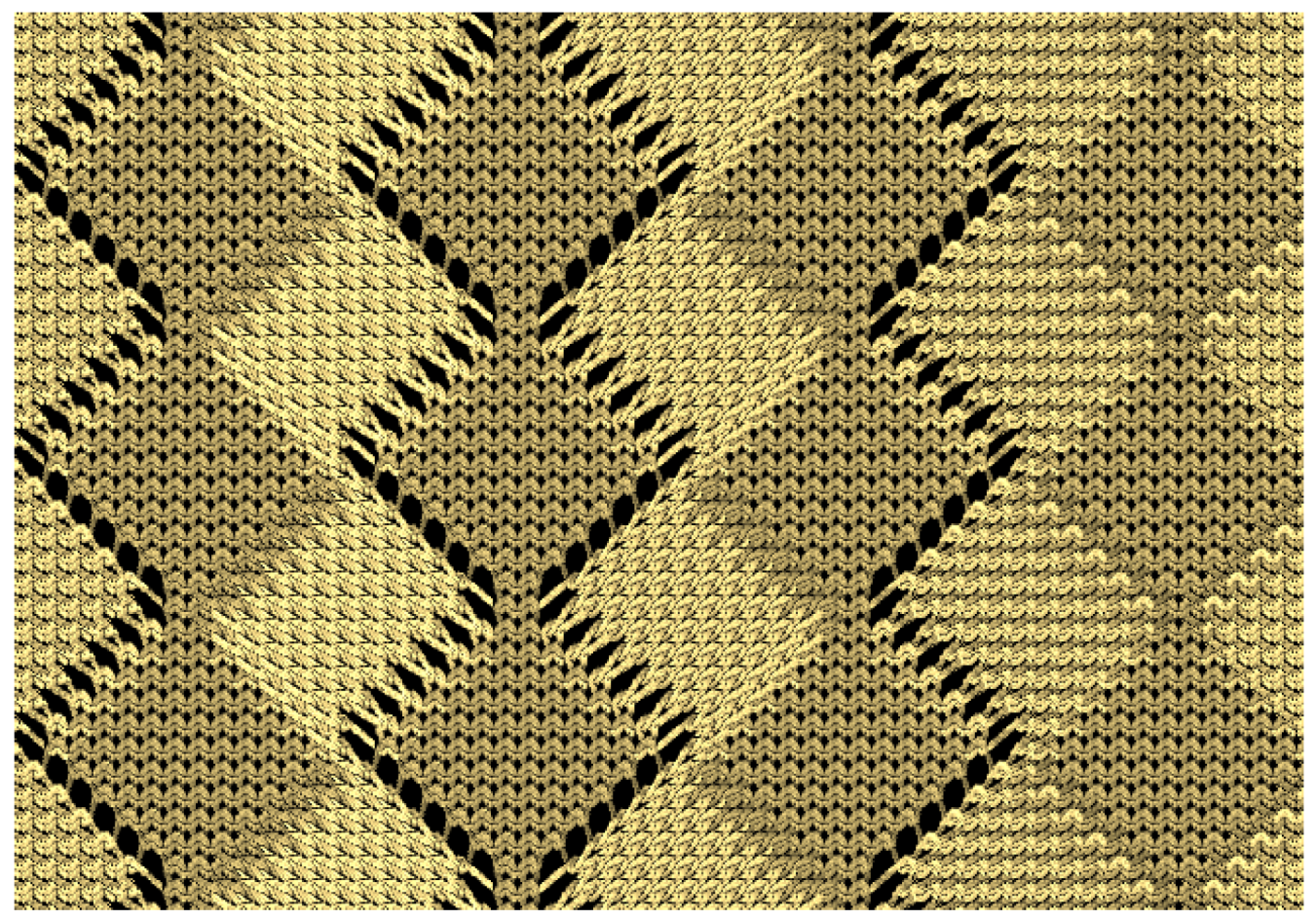

| 1 | Aran modules “Aran” type mesh, forming multiple diamonds that create “X” patterns arranged in three columns. |

| 2 | Cable modules “Cable 3 × 3<” and “Cable 3 × 3>”, forming embossed wave-like lines. |

| 3 | Aran modules “Aran 2 × 1 <” and “Aran 2 × 1 >”, resulting in embossed broken lines where the peaks touch, forming diamonds. The pattern continues with wave-like lines, using Cable modules “Cable 3 × 3<” and “Cable 3 × 3>”. |

| 4 | Cable modules “Cable 2 × 2<” and “Cable 2 × 2>” to complete the design. |

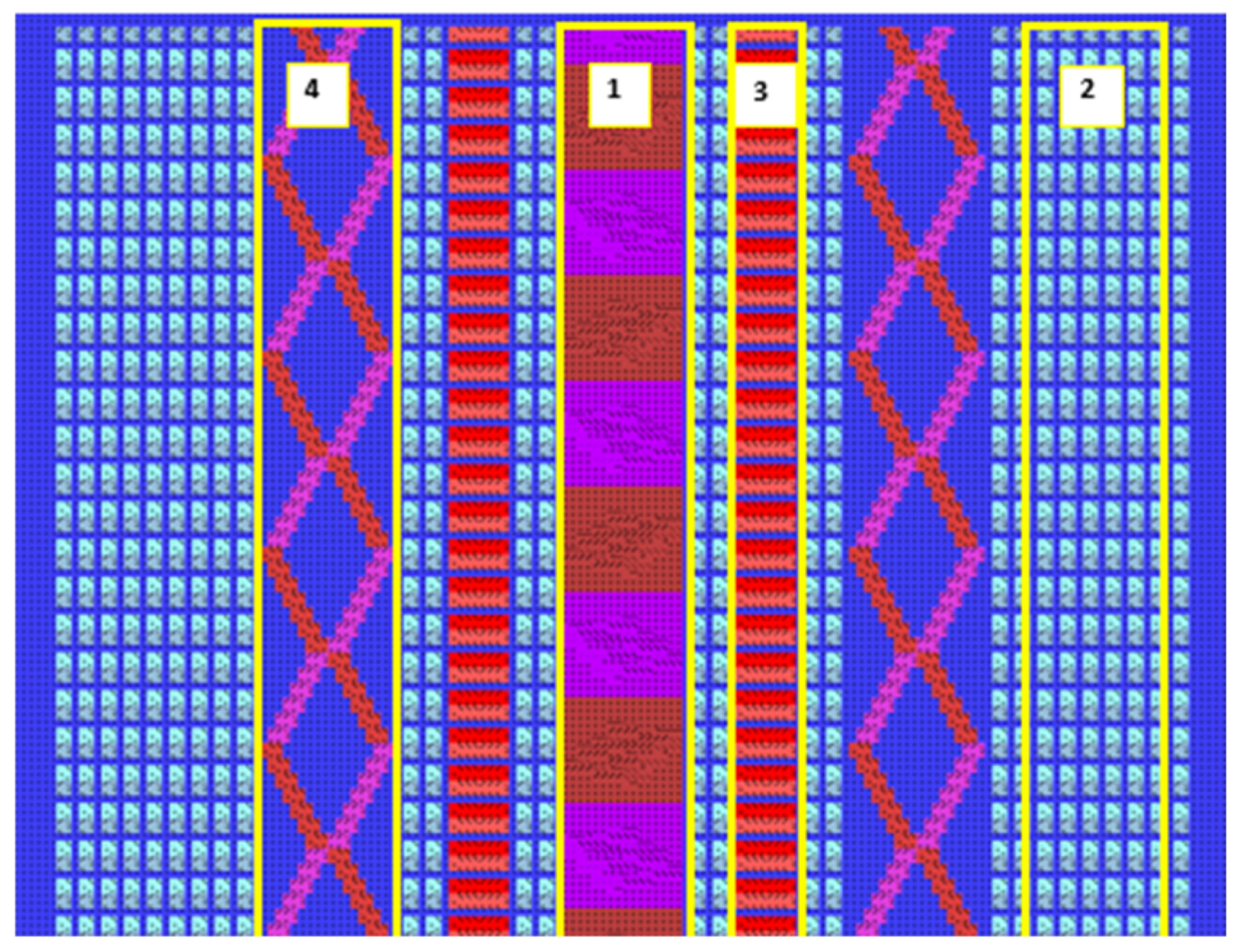

| Section | Applied Modules and Structure |

|---|---|

| 1 | Cable modules “Cable 8 × 8<” and “Cable 8 × 8>”, forming a group of embossed wave-like lines. |

| 2 | Cable modules “Cable 1 × 1<” and “Cable 1 × 1>”, forming straight embossed lines. |

| 3 | Cable modules “Cable 6 × 1<” and “Cable 6 × 1>”. |

| 4 | Cable modules “Cable 1 × 1<” and “Cable 1 × 1>”, as well as Aran modules “Aran 2 × 1 <” and “Aran 2 × 1 >”, creating embossed broken lines with touching peaks forming diamonds. “Cable 1 × 1<” and “Cable 1 × 1>” were used to complete the design. |

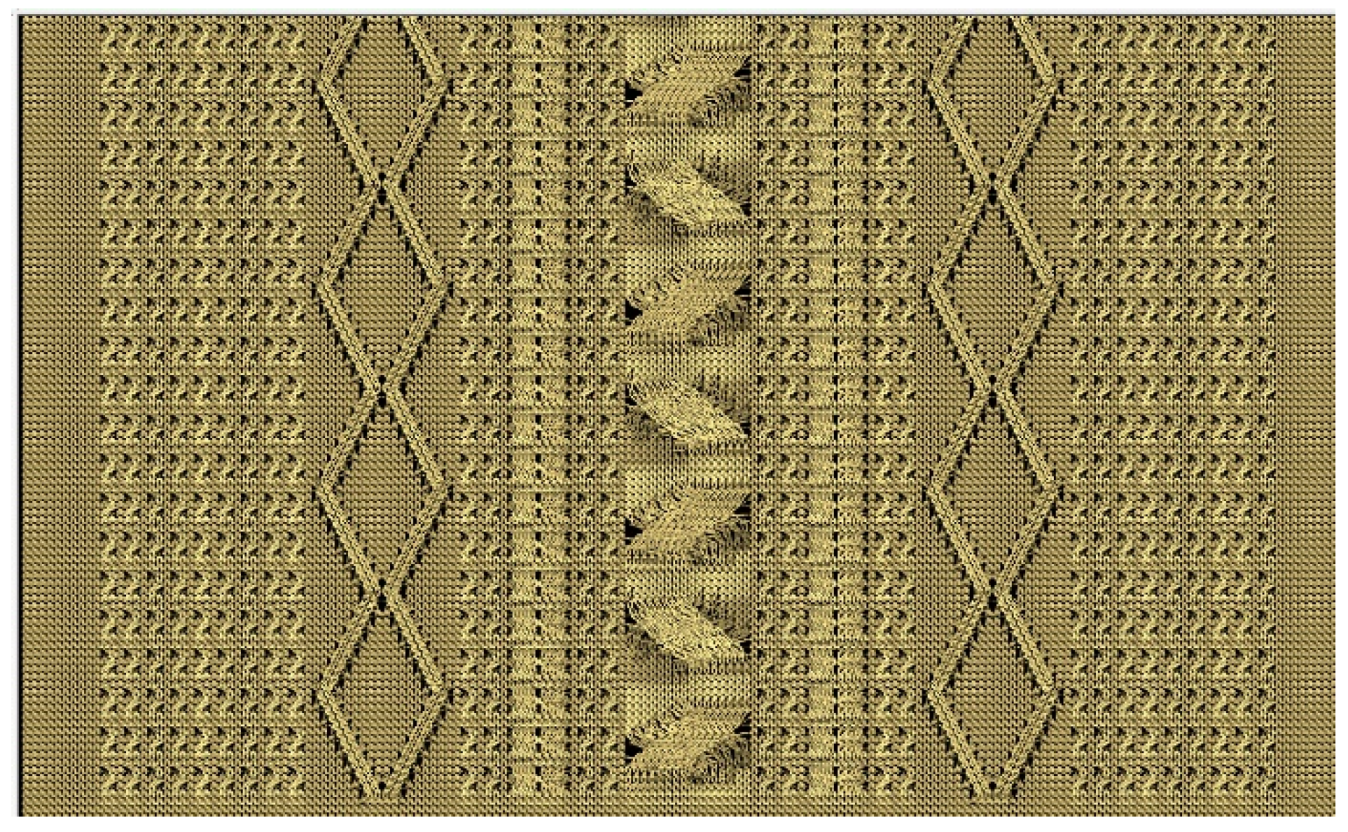

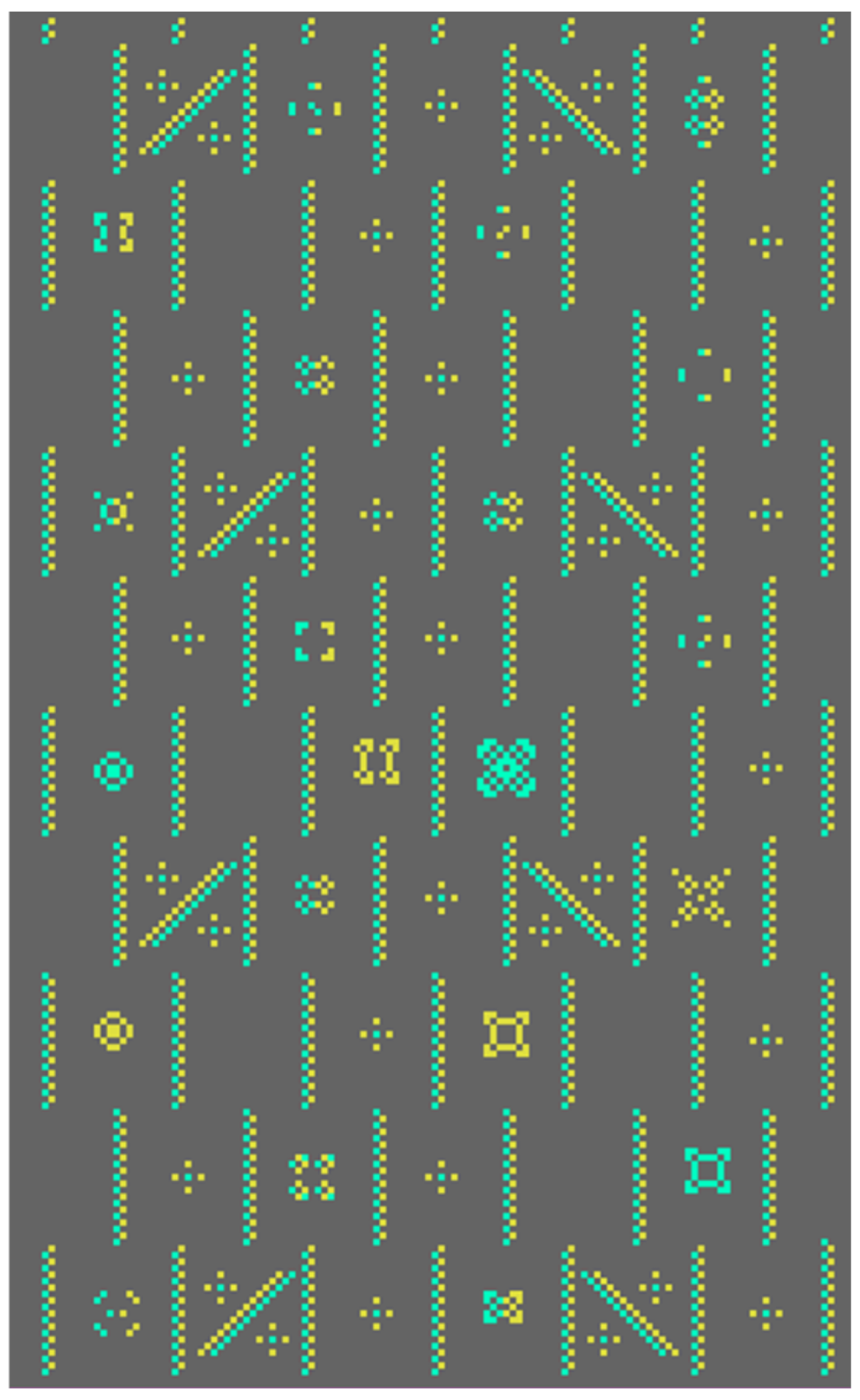

| Section | Applied Modules and Structure |

|---|---|

| 1 | Pointelle modules “Pointelle_v_Repeat <=” |

| 2 | Pointelle modules “Pointelle_v_Repeat =>” |

| 3 | Pointelle modules “Pointelle_^_Repeat <=” |

| 4 | Pointelle modules “Pointelle_^_Repeat =>” |

| Knit Macrostructure | Sample 1 | Sample 2 | Sample 3 | Sample 4 | Sample 5 |

|---|---|---|---|---|---|

| Production time, min | 3 | 9 | 3 | 10 | 5 |

| Knit Macrostructure | Sample 1 | Sample 2 | Sample 3 | Sample 4 | Sample 5 |

|---|---|---|---|---|---|

| Shrinkage Length, % | 26.170 | 4.76 | −6.52 | −7.29 | 11.11 |

| Shrinkage Width, % | 36.25 | −6.28 | −7.50 | 6.25 | 10.005 |

| Area Shrinkage, % | 30.78 | −1.22 | −14.51 | −0.58 | 20.00 |

| Sample | Main Modules Used | Visual Complexity | Production Time (min) | Shrinkage Length (%) | Shrinkage Width (%) | Area Shrinkage (%) | Dimensional Stability | Notes |

|---|---|---|---|---|---|---|---|---|

| 1 | Aran + Cable | High | 3 | 26.17 | 6.25 | 30.69 | Low | Dense structure, vertical shrinkage |

| 2 | Cable + Aran (symmetrical) | Moderate | 9 | 4.76 | −6.28 | 1.22 | High | Most stable overall |

| 3 | Pointelle (openwork) | Moderate | 3 | −6.52 | −7.50 | −13.64 | Low | Structure expands after wash |

| 4 | Text motif (knit/purl) | Moderate–High | 10 | −7.29 | 6.25 | 0.01 | Low–Moderate | Unstable in length |

| 5 | Pointelle (geometric) | Moderate | 5 | 11.11 | 10.00 | 19.99 | Moderate | Balanced shrinkage, good control |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Angelova, R.A.; Sofronova, D.; Raycheva, V.; Borisova, E. Intelligent Automation in Knitting Manufacturing: Advanced Software Integration and Structural Optimisation for Complex Textile Design. Appl. Sci. 2025, 15, 5775. https://doi.org/10.3390/app15105775

Angelova RA, Sofronova D, Raycheva V, Borisova E. Intelligent Automation in Knitting Manufacturing: Advanced Software Integration and Structural Optimisation for Complex Textile Design. Applied Sciences. 2025; 15(10):5775. https://doi.org/10.3390/app15105775

Chicago/Turabian StyleAngelova, Radostina A., Daniela Sofronova, Violina Raycheva, and Elena Borisova. 2025. "Intelligent Automation in Knitting Manufacturing: Advanced Software Integration and Structural Optimisation for Complex Textile Design" Applied Sciences 15, no. 10: 5775. https://doi.org/10.3390/app15105775

APA StyleAngelova, R. A., Sofronova, D., Raycheva, V., & Borisova, E. (2025). Intelligent Automation in Knitting Manufacturing: Advanced Software Integration and Structural Optimisation for Complex Textile Design. Applied Sciences, 15(10), 5775. https://doi.org/10.3390/app15105775