Laser Sintering of Nano-Graphite-Reinforced Polyamide Composites for Next-Generation Smart Materials: A Preliminary Investigation of Processability and Electromechanical Properties

Abstract

1. Introduction

2. Materials and Methods

2.1. Flowability and Sintering Window

2.2. Sample Preparation

2.3. Electrical Characterization

2.4. Mechanical Characterization

3. Results and Discussion

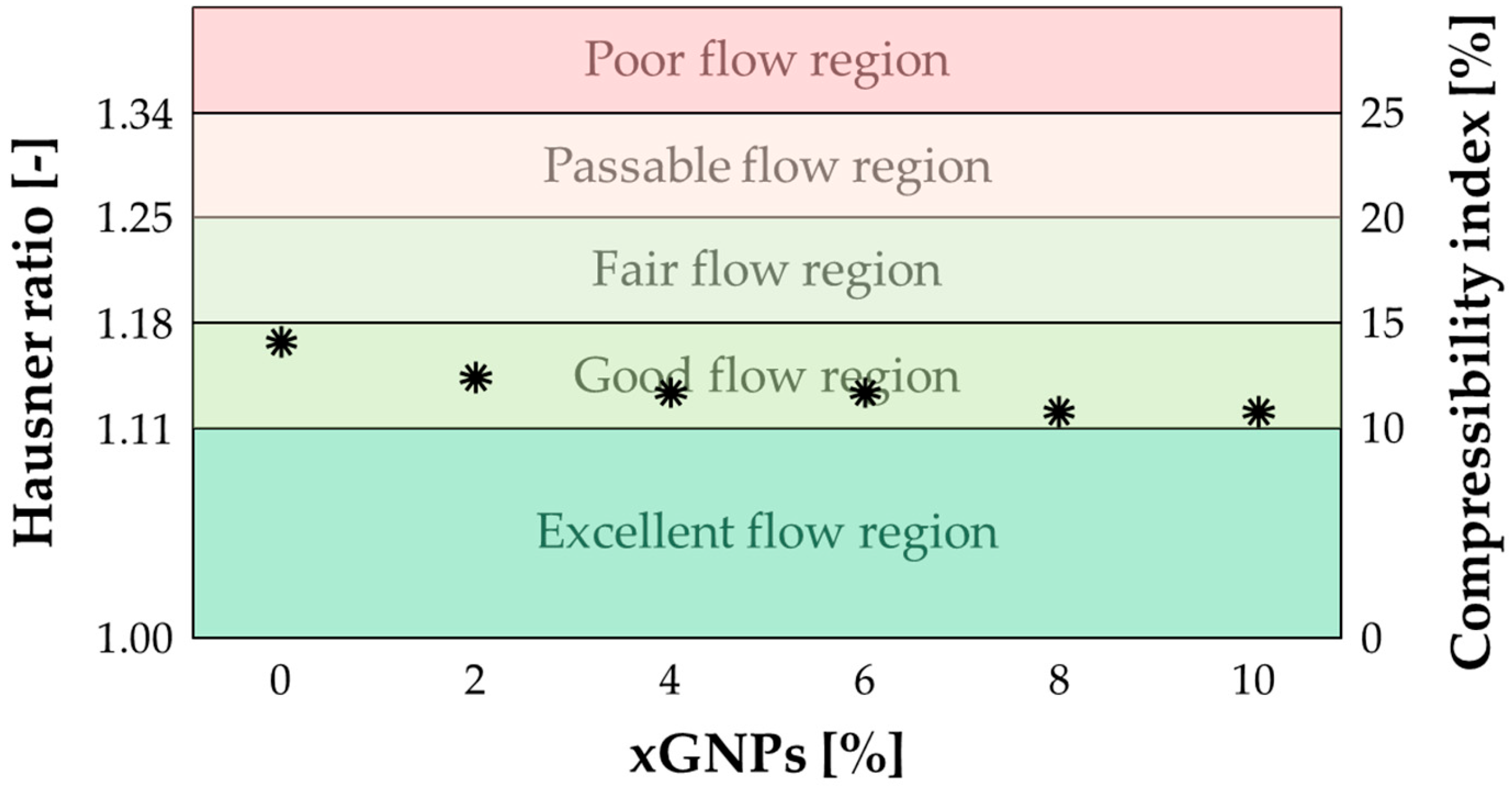

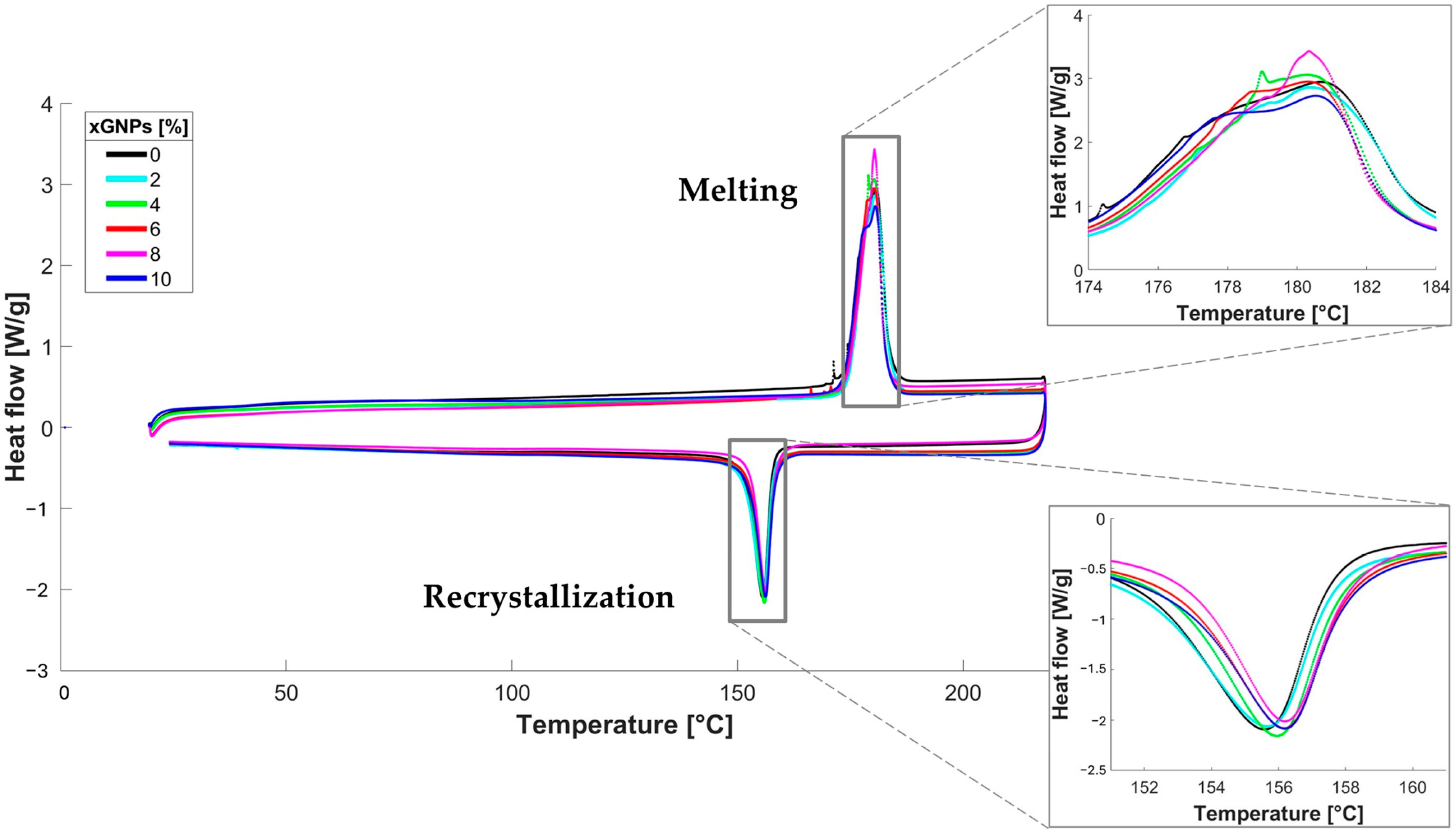

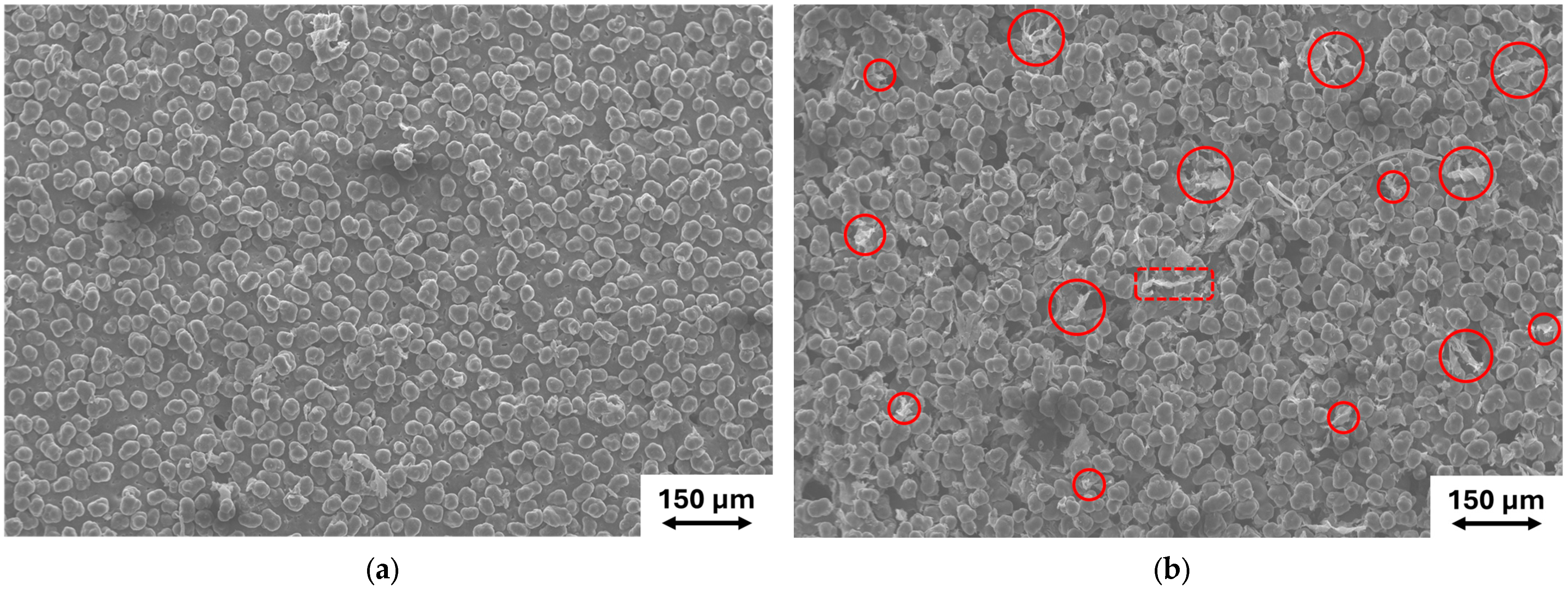

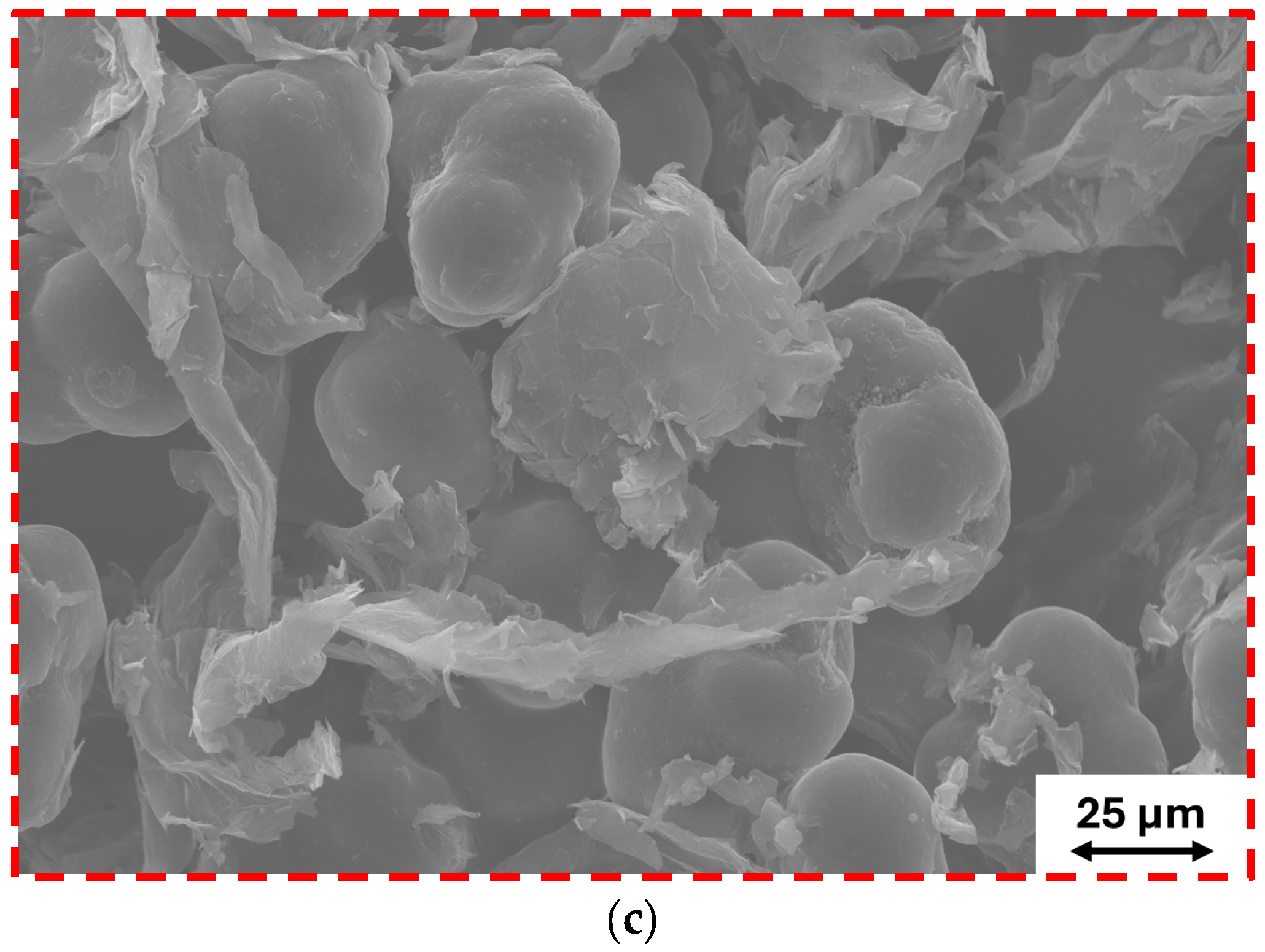

3.1. Filler Content, Flowability, and Sintering Window

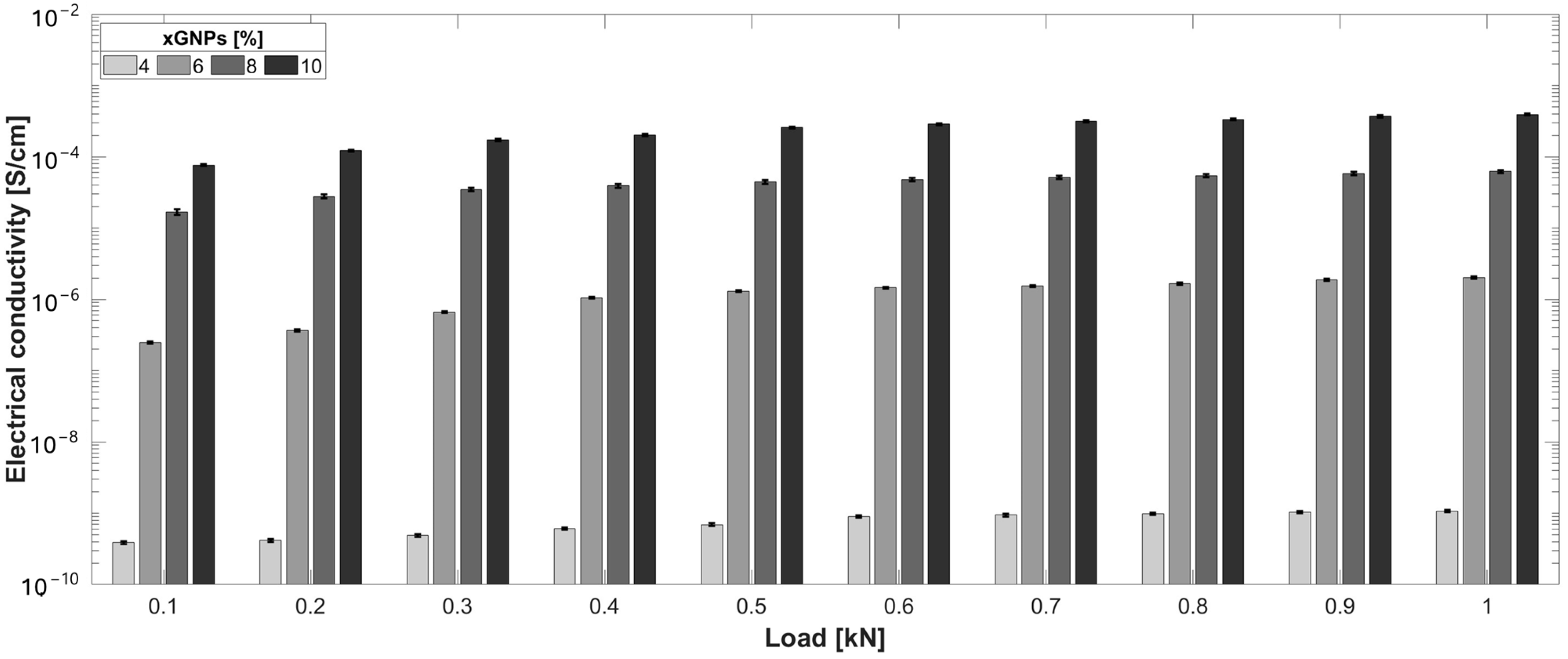

3.2. Electrical Characterization

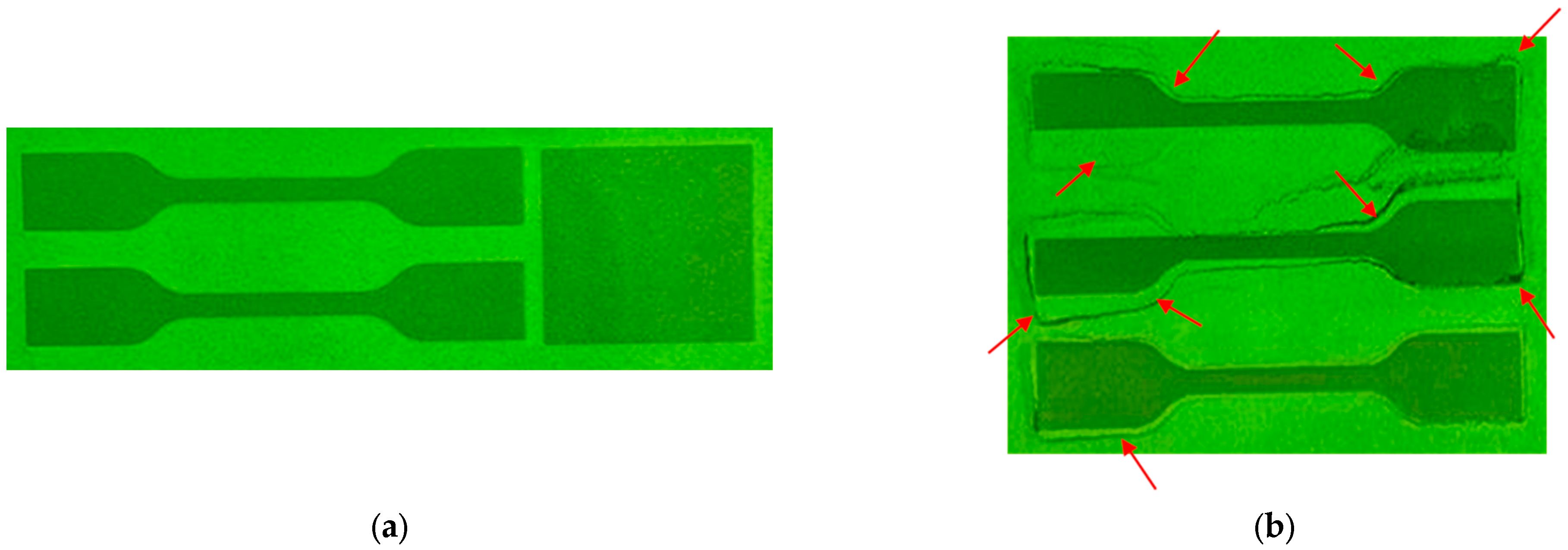

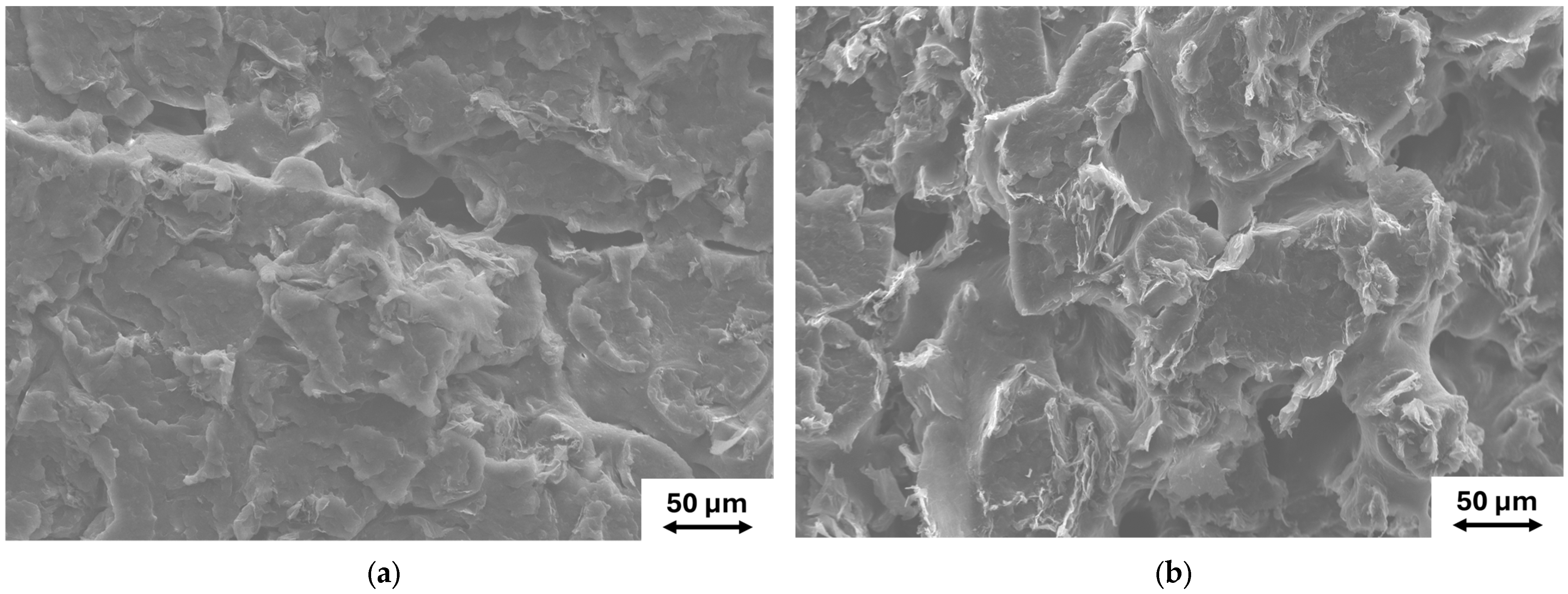

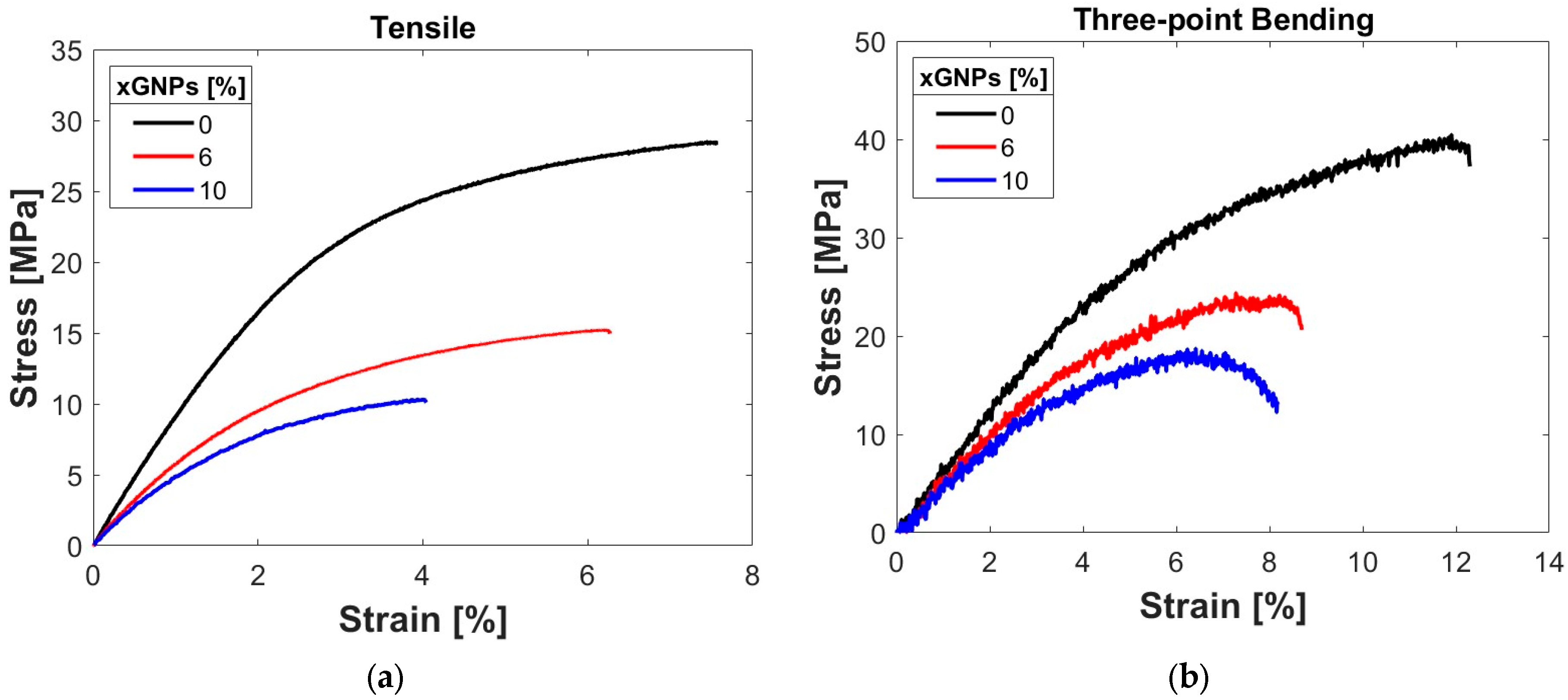

3.3. Mechanical Characterization

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Alami, A.H.; Ghani Olabi, A.; Alashkar, A.; Alasad, S.; Aljaghoub, H.; Rezk, H.; Abdelkareem, M.A. Additive Manufacturing in the Aerospace and Automotive Industries: Recent Trends and Role in Achieving Sustainable Development Goals. Ain Shams Eng. J. 2023, 14, 102516. [Google Scholar] [CrossRef]

- Rezvani Ghomi, E.; Khosravi, F.; Neisiany, R.E.; Singh, S.; Ramakrishna, S. Future of Additive Manufacturing in Healthcare. Curr. Opin. Biomed. Eng. 2021, 17, 100255. [Google Scholar] [CrossRef]

- Dhinesh, S.K.; Joshua Robert, J.; Tushar Nair, S.; Sharne Moni, D.H.; Sona Fowzeya, S.; Senthil Kumar, K.L.; Raghunath, M.; Nagarajan, P. Recent Trends in Additive Manufacturing of Electronics Devices. Mater. Today Proc. 2022, 66, 928–941. [Google Scholar] [CrossRef]

- Xiong, Y.; Tang, Y.; Zhou, Q.; Ma, Y.; Rosen, D.W. Intelligent Additive Manufacturing and Design: State of the Art and Future Perspectives. Addit. Manuf. 2022, 59, 103139. [Google Scholar] [CrossRef]

- Ponticelli, G.S.; Tagliaferri, F.; Venettacci, S.; Horn, M.; Giannini, O.; Guarino, S. Re-Engineering of an Impeller for Submersible Electric Pump to Be Produced by Selective Laser Melting. Appl. Sci. 2021, 11, 7375. [Google Scholar] [CrossRef]

- ISO/ASTM 52900; Standard Terminology for Additive Manufacturing–General Principles–Terminology. ASTM International: West Conshohocken, PA, USA, 2015.

- Bănică, C.F.; Sover, A.; Anghel, D.C. Printing the Future Layer by Layer: A Comprehensive Exploration of Additive Manufacturing in the Era of Industry 4.0. Appl. Sci. 2024, 14, 9919. [Google Scholar] [CrossRef]

- Thiede, S.; Wiese, M.; Herrmann, C. Upscaling Strategies for Polymer Additive Manufacturing: An Assessment from Economic and Environmental Perspective for SLS, MJF and DLP. Procedia CIRP 2021, 104, 653–658. [Google Scholar] [CrossRef]

- Tagliaferri, V.; Trovalusci, F.; Guarino, S.; Venettacci, S. Environmental and Economic Analysis of FDM, SLS and MJF Additive Manufacturing Technologies. Materials 2019, 12, 4161. [Google Scholar] [CrossRef]

- Tinajero, C.; Palmara, G.; Zanatta, M.; Sans, V. New Frontiers in Sustainable Process Engineering with Additive Manufacturing for Continuous-Flow Applications. Chem. Eng. J. 2025, 505, 159442. [Google Scholar] [CrossRef]

- Eshraghi, S.; Karevan, M.; Kalaitzidou, K.; Das, S. Processing and Properties of Electrically Conductive Nanocomposites Based on Polyamide-12 Filled with Exfoliated Graphite Nanoplatelets Prepared by Selective Laser Sintering. Int. J. Precis. Eng. Manuf. 2013, 14, 1947–1951. [Google Scholar] [CrossRef]

- Lim, S.; Park, H.; Yamamoto, G.; Lee, C.; Suk, J.W. Measurements of the Electrical Conductivity of Monolayer Graphene Flakes Using Conductive Atomic Force Microscopy. Nanomaterials 2021, 11, 2575. [Google Scholar] [CrossRef] [PubMed]

- Shulga, Y.M.; Melezhik, A.V.; Kabachkov, E.N.; Milovich, F.O.; Lyskov, N.V.; Irzhak, A.V.; Dremova, N.N.; Gutsev, G.L.; Michtchenko, A.; Tkachev, A.G.; et al. Characterisation and Electrical Conductivity of Polytetrafluoroethylene/Graphite Nanoplatelets Composite Films. Appl. Phys. A Mater. Sci. Process 2019, 125, 460. [Google Scholar] [CrossRef]

- Lawal, A.T. Graphene-Based Nano Composites and Their Applications. A Review. Biosens. Bioelectron. 2019, 141, 111384. [Google Scholar] [CrossRef] [PubMed]

- Yoo, J.M.; Hwang, D.W.; Hong, B.H. Graphene-Based Nanomaterials. In Radionanomedicine: Combined Nuclear and Nanomedicine; Lee, D.S., Ed.; Springer International Publishing: Cham, Switzerland, 2018; pp. 79–103. ISBN 978-3-319-67720-0. [Google Scholar]

- Shtein, M.; Nadiv, R.; Buzaglo, M.; Kahil, K.; Regev, O. Thermally Conductive Graphene-Polymer Composites: Size, Percolation, and Synergy Effects. Chem. Mater. 2015, 27, 2100–2106. [Google Scholar] [CrossRef]

- Balcerak-Woźniak, A.; Dzwonkowska-Zarzycka, M.; Kabatc-Borcz, J. A Comprehensive Review of Stimuli-Responsive Smart Polymer Materials—Recent Advances and Future Perspectives. Materials 2024, 17, 4255. [Google Scholar] [CrossRef]

- Meng, Q.; Song, X.; Han, S.; Abbassi, F.; Zhou, Z.; Wu, B.; Wang, X.; Araby, S. Mechanical and Functional Properties of Polyamide/Graphene Nanocomposite Prepared by Chemicals Free-Approach and Selective Laser Sintering. Compos. Commun. 2022, 36, 101396. [Google Scholar] [CrossRef]

- Villani, V.; Ponticelli, G.S.; Venettacci, S.; Guarino, S. Effect of Water Absorption on the Properties of Selective Laser-Sintered PA12 Specimens. Prog. Addit. Manuf. 2024, 1–14. [Google Scholar] [CrossRef]

- Azam, M.U.; Schiffer, A.; Kumar, S. Piezoresistive Behavior of MWCNT/PA12 Honeycomb Composites Processed via Selective Laser Sintering. J. Mater. Res. Technol. 2023, 26, 2319–2332. [Google Scholar] [CrossRef]

- Lin, J.-C.; Liatsis, P.; Alexandridis, P. Flexible and Stretchable Electrically Conductive Polymer Materials for Physical Sensing Applications. Polym. Rev. 2023, 63, 67–126. [Google Scholar] [CrossRef]

- Chen, B.; Davies, R.; Liu, Y.; Yi, N.; Qiang, D.; Zhu, Y.; Ghita, O. Laser Sintering of Graphene Nanoplatelets Encapsulated Polyamide Powders. Addit. Manuf. 2020, 35, 101363. [Google Scholar] [CrossRef]

- Ma-Hock, L.; Strauss, V.; Treumann, S.; Küttler, K.; Wohlleben, W.; Hofmann, T.; Gröters, S.; Wiench, K.; van Ravenzwaay, B.; Landsiedel, R. Comparative Inhalation Toxicity of Multi-Wall Carbon Nanotubes, Graphene, Graphite Nanoplatelets and Low Surface Carbon Black. Part. Fibre Toxicol. 2013, 10, 23. [Google Scholar] [CrossRef] [PubMed]

- Warheit, D.B.; Hart, G.A.; Hesterberg, T.W.; Collins, J.J.; Dyer, W.M.; Swaen, G.M.H.; Castranova, V.; Soiefer, A.I.; Kennedy, G.L. Potential Pulmonary Effects of Man-Made Organic Fiber (MMOF) Dusts. Crit. Rev. Toxicol. 2001, 31, 697–736. [Google Scholar] [CrossRef] [PubMed]

- Damanhuri, A.A.M.; Hariri, A.; Alkahari, M.R.; Fauadi, M.H.F.M.; Bakri, S.F.Z. Indoor Air Concentration from Selective Laser Sintering 3D Printer Using Virgin Polyamide Nylon (PA12) Powder: A Pilot Study. Int. J. Integr. Eng. 2019, 11, 140–149. [Google Scholar] [CrossRef]

- Min, K.; Li, Y.; Wang, D.; Chen, B.; Ma, M.; Hu, L.; Liu, Q.; Jiang, G. 3D Printing-Induced Fine Particle and Volatile Organic Compound Emission: An Emerging Health Risk. Environ. Sci. Technol. Lett. 2021, 8, 616–625. [Google Scholar] [CrossRef]

- Chen, P.; Wu, H.; Zhu, W.; Yang, L.; Li, Z.; Yan, C.; Wen, S.; Shi, Y. Investigation into the Processability, Recyclability and Crystalline Structure of Selective Laser Sintered Polyamide 6 in Comparison with Polyamide 12. Polym. Test. 2018, 69, 366–374. [Google Scholar] [CrossRef]

- De, B.; Bera, M.; Bhattacharjee, D.; Ray, B.C.; Mukherjee, S. A Comprehensive Review on Fiber-Reinforced Polymer Composites: Raw Materials to Applications, Recycling, and Waste Management. Prog. Mater. Sci. 2024, 146, 101326. [Google Scholar] [CrossRef]

- Ponticelli, G.S.; Venettacci, S.; Tagliaferri, F.; Guarino, S. Fused Deposition Modelling for Aeronautics: Techno-Economic and Environmental Assessment for Overhead Locker Supports Replacement. Int. J. Adv. Manuf. Technol. 2023, 128, 3817–3840. [Google Scholar] [CrossRef]

- Singh, S.; Sachdeva, A.; Sharma, V.S. Optimization of Selective Laser Sintering Process Parameters to Achieve the Maximum Density and Hardness in Polyamide Parts. Prog. Addit. Manuf. 2017, 2, 19–30. [Google Scholar] [CrossRef]

- Karevan, M.; Eshraghi, S.; Gerhardt, R.; Das, S.; Kalaitzidou, K. Effect of Processing Method on the Properties of Multifunctional Exfoliated Graphite Nanoplatelets/Polyamide 12 Composites. Carbon 2013, 64, 122–131. [Google Scholar] [CrossRef]

- Ho, Q.B.; Osazuwa, O.; Modler, R.; Daymond, M.; Gallerneault, M.T.; Kontopoulou, M. Exfoliation of Graphite and Expanded Graphite by Melt Compounding to Prepare Reinforced, Thermally and Electrically Conducting Polyamide Composites. Compos. Sci. Technol. 2019, 176, 111–120. [Google Scholar] [CrossRef]

- Lupone, F.; Padovano, E.; Ostrovskaya, O.; Russo, A.; Badini, C. Innovative Approach to the Development of Conductive Hybrid Composites for Selective Laser Sintering. Compos. Part A Appl. Sci. Manuf. 2021, 147, 106429. [Google Scholar] [CrossRef]

- Amiri, A.; Zubir, M.N.M.; Dimiev, A.M.; Teng, K.H.; Shanbedi, M.; Kazi, S.N.; Rozali, S. Bin Facile, Environmentally Friendly, Cost Effective and Scalable Production of Few-Layered Graphene. Chem. Eng. J. 2017, 326, 1105–1115. [Google Scholar] [CrossRef]

- Azam, M.U.; Belyamani, I.; Schiffer, A.; Kumar, S.; Askar, K. Progress in Selective Laser Sintering Ofmultifunctional Polymer Composites for Strain- and Self-Sensing Applications. J. Mater. Res. Technol. 2024, 30, 9625–9646. [Google Scholar] [CrossRef]

- Sivadas, B.O.; Ashcroft, I.; Khlobystov, A.N.; Goodridge, R.D. Laser Sintering of Polymer Nanocomposites. Adv. Ind. Eng. Polym. Res. 2021, 4, 277–300. [Google Scholar] [CrossRef]

- Thakkar, R.; Pillai, A.R.; Kulkarni, V.R.; Maniruzzaman, M. Applicability of Machine Learning in Three-Dimensionally (3D) Printed Dosage Forms. In A Handbook of Artificial Intelligence in Drug Delivery; Elsevier: Amsterdam, The Netherlands, 2023; pp. 259–299. [Google Scholar]

- Baserinia, R.; Brockbank, K.; Dattani, R. Correlating Polyamide Powder Flowability to Mechanical Properties of Parts Fabricated by Additive Manufacturing. Powder Technol. 2022, 398, 117147. [Google Scholar] [CrossRef]

- Yang, F.; Zobeiry, N.; Mamidala, R.; Chen, X. A Review of Aging, Degradation, and Reusability of PA12 Powders in Selective Laser Sintering Additive Manufacturing. Mater. Today Commun. 2023, 34, 105279. [Google Scholar] [CrossRef]

- Shah, D.S.; Moravkar, K.K.; Jha, D.K.; Lonkar, V.; Amin, P.D.; Chalikwar, S.S. A Concise Summary of Powder Processing Methodologies for Flow Enhancement. Heliyon 2023, 9, e16498. [Google Scholar] [CrossRef]

- Amankwah, N.Y.A.; Agbenorhevi, J.K.; Rockson, M.A.D. Physicochemical and Functional Properties of Wheat-Rain Tree (Samanea Saman) Pod Composite Flours. Int. J. Food Prop. 2022, 25, 1317–1327. [Google Scholar] [CrossRef]

- Yuan, S.; Shen, F.; Chua, C.K.; Zhou, K. Polymeric Composites for Powder-Based Additive Manufacturing: Materials and Applications. Prog. Polym. Sci. 2019, 91, 141–168. [Google Scholar] [CrossRef]

- ASTM D3418; Standard Test Method for Transition Temperatures and Enthalpies of Fusion and Crystallization of Polymers by Differential Scanning Calorimetry. ASTM International: West Conshohocken, PA, USA, 2021.

- Di Siena, M.; Genna, S.; Moretti, P.; Ponticelli, G.S.; Venettacci, S.; Russo, P. Study of the Laser-Material Interaction for Innovative Hybrid Structures: Thermo-Mechanical Characterization of Polyethylene-Based Polymers. Polym. Test. 2023, 120, 107947. [Google Scholar] [CrossRef]

- Calignano, F.; Giuffrida, F.; Galati, M. Effect of the Build Orientation on the Mechanical Performance of Polymeric Parts Produced by Multi Jet Fusion and Selective Laser Sintering. J. Manuf. Process. 2021, 65, 271–282. [Google Scholar] [CrossRef]

- ASTM D638; Standard Test Method for Tensile Properties of Plastics. ASTM International: West Conshohocken, PA, USA, 2014.

- ASTM D790; Standard Test Methods for Flexural Properties of nreinforced and Reinforced Plastics and Electrical Insulating Materials. ASTM International: West Conshohocken, PA, USA, 2003.

- Wang, M. Materials: Engineering, Science, Processing and Design. Mater. Today 2010, 13, 67. [Google Scholar] [CrossRef]

- Swallowe, G.M. Yield and Plastic Deformation. In Mechanical Properties and Testing of Polymers; Springer: Dordrecht, The Netherlands, 1999; pp. 281–285. [Google Scholar]

- Wang, Y.; Rouholamin, D.; Davies, R.; Ghita, O.R. Powder Characteristics, Microstructure and Properties of Graphite Platelet Reinforced Poly Ether Ether Ketone Composites in High Temperature Laser Sintering (HT-LS). Mater. Des. 2015, 88, 1310–1320. [Google Scholar] [CrossRef]

- Barbosa-Cánovas, G.V.; Ortega-Rivas, E.; Juliano, P.; Yan, H. Food Powders, 1st ed.; Food Engineering Series; Springer: Boston, MA, USA, 2005; ISBN 978-0-306-47806-2. [Google Scholar]

- Kaleem, M.A.; Alam, M.Z.; Khan, M.; Jaffery, S.H.I.; Rashid, B. An Experimental Investigation on Accuracy of Hausner Ratio and Carr Index of Powders in Additive Manufacturing Processes. Met. Powder Rep. 2021, 76, S50–S54. [Google Scholar] [CrossRef]

- Raju, A.; Rao, B.S.; Madhukar, K.; Reddy, K.R.; Sadhu, V.; Chouhan, R. Effect Irradiation on Physicochemical and Mechanical Properties of Polymers and Polymer Blends. In Green Sustainable Process for Chemical and Environmental Engineering and Science; Elsevier: Amsterdam, The Netherlands, 2022; pp. 147–163. [Google Scholar] [CrossRef]

- Pearson, G.L.; Bardeen, J. Electrical Properties of Pure Silicon and Silicon Alloys Containing Boron and Phosphorus. Phys. Rev. 1949, 75, 865–883. [Google Scholar] [CrossRef]

- Morita, N.; Yamamoto, A. Optical and Electrical Properties of Boron. Jpn. J. Appl. Phys. 1975, 14, 825–832. [Google Scholar] [CrossRef]

- Putley, E.H. The Electrical Conductivity of Germanium. Proc. Phys. Soc. Sect. A 1949, 62, 284–292. [Google Scholar] [CrossRef]

- Motaghi, A.; Hrymak, A.; Motlagh, G.H. Electrical Conductivity and Percolation Threshold of Hybrid Carbon/Polymer Composites. J. Appl. Polym. Sci. 2015, 132, 41744. [Google Scholar] [CrossRef]

- Govorov, A.; Wentzel, D.; Miller, S.; Kanaan, A.; Sevostianov, I. Electrical Conductivity of Epoxy-Graphene and Epoxy-Carbon Nanofibers Composites Subjected to Compressive Loading. Int. J. Eng. Sci. 2018, 123, 174–180. [Google Scholar] [CrossRef]

- Sahimi, M. Heterogeneous Materials I; Springer: New York, NY, USA, 2003; ISBN 978-0-387-21705-5. [Google Scholar]

- Bilisik, K.; Akter, M. Polymer Nanocomposites Based on Graphite Nanoplatelets (GNPs): A Review on Thermal-Electrical Conductivity, Mechanical and Barrier Properties. J. Mater. Sci. 2022, 57, 7425–7480. [Google Scholar] [CrossRef]

- Fang, H.; Bai, S.L.; Wong, C.P. Microstructure Engineering of Graphene towards Highly Thermal Conductive Composites. Compos. Part A Appl. Sci. Manuf. 2018, 112, 216–238. [Google Scholar] [CrossRef]

- Mardlin, K.; Osazuwa, O.; Kontopoulou, M.; Leelapornpisit, W. Polyamide Composites Containing Graphene Nanoplatelets Produced via Thermomechanical Exfoliation. Compos. Sci. Technol. 2022, 225, 109493. [Google Scholar] [CrossRef]

- Hong, R.; Zhao, Z.; Leng, J.; Wu, J.; Zhang, J. Two-Step Approach Based on Selective Laser Sintering for High Performance Carbon Black/Polyamide 12 Composite with 3D Segregated Conductive Network. Compos. B Eng. 2019, 176, 107214. [Google Scholar] [CrossRef]

- Chanklin, W.; Laowongkotr, J.; Felipe Chibante, L.P. Electrical Property Validation of Percolation Modeling in Different Polymer Structures of Carbon-Based Nanocomposites. Mater. Today Commun. 2018, 17, 153–160. [Google Scholar] [CrossRef]

- Yadav, R.; Tirumali, M.; Wang, X.; Naebe, M.; Kandasubramanian, B. Polymer Composite for Antistatic Application in Aerospace. Def. Technol. 2020, 16, 107–118. [Google Scholar] [CrossRef]

- Shariati, M.; Mafipour, M.S.; Mehrabi, P.; Bahadori, A.; Zandi, Y.; Salih, M.N.A.; Nguyen, H.; Dou, J.; Song, X.; Poi-Ngian, S. Application of a Hybrid Artificial Neural Network-Particle Swarm Optimization (ANN-PSO) Model in Behavior Prediction of Channel Shear Connectors Embedded in Normal and High-Strength Concrete. Appl. Sci. 2019, 9, 5534. [Google Scholar] [CrossRef]

- Matyas, A. Influence of Graphite Additives on Mechanical, Tribological, Fire Resistance and Electrical Properties in Polyamide 6. Teh. Vjesn.—Tech. Gaz. 2018, 25, 1014–1019. [Google Scholar] [CrossRef]

- Shariati, M.; Mafipour, M.S.; Mehrabi, P.; Ahmadi, M.; Wakil, K.; Trung, N.T.; Toghroli, A. Prediction of Concrete Strength in Presence of Furnace Slag and Fly Ash Using Hybrid ANN-GA (Artificial Neural Network-Genetic Algorithm). Smart Struct. Syst. 2020, 25, 183–195. [Google Scholar] [CrossRef]

- Satheeskumar, S.; Kanagaraj, G. Experimental Investigation on Tribological Behaviours of PA6, PA6-Reinforced Al2O3 and PA6-Reinforced Graphite Polymer Composites. Bull. Mater. Sci. 2016, 39, 1467–1481. [Google Scholar] [CrossRef]

- Zhao, P.; Li, K.; Zhou, N.; Chen, Q.; Zhou, M.; Qi, C.; Zhao, P.; Li, K.; Zhou, N.; Chen, Q.; et al. Enhanced Prediction of Occurrence Forms of Heavy Metals in Tailings: A Systematic Comparison of Machine Learning Methods and Model Integration. Int. J. Miner. Metall. Mater. 2025. [Google Scholar] [CrossRef]

| Characteristic | PA12 | xGNPs |

|---|---|---|

| Average particle size—D50 [µm] | 38 | 25 |

| Average particle size—D90 [µm] | - | 30 |

| Mean thickness [µm] | - | 14 |

| Specific surface area [m2/g] | - | 30 |

| Density [g/cm3] | 0.92 | 0.31 |

| Melting point [°C] | 185 | - |

| Carbon content [%] | - | >97 |

| C:O ratio [-] | - | 44:1 |

| Parameter | Value |

|---|---|

| Heating/cooling rate [°C/min] | 10 |

| Nitrogen flow [mL/min] | 20 |

| Temperature interval [°C] | From 20 to 225 |

| Sample weight [mg] | Between 5 and 10 |

| Feature/Parameter | Type/Value |

|---|---|

| Laser source [-] | Diode |

| Laser wavelength [nm] | 808 |

| Laser spot diameter [µm] | 400 |

| Laser nominal power [W] | 5 |

| Laser scanning speed [mm/s] | 80 |

| Maximum volume [mm3] | 110 × 160 × 230 |

| Layer thickness [µm] | 125 |

| xGNPs [%] | [°C] | [°C] | [°C] | [°C] | [°C] |

|---|---|---|---|---|---|

| 0 | 180.7 | 173.7 | 155.6 | 157.8 | 15.9 |

| 2 | 180.3 | 173.6 | 155.7 | 157.8 | 15.9 |

| 4 | 179.0 | 174.0 | 156.0 | 158.1 | 16.0 |

| 6 | 180.4 | 174.0 | 156.2 | 158.4 | 15.6 |

| 8 | 180.4 | 174.4 | 156.2 | 158.6 | 15.8 |

| 10 | 180.5 | 174.6 | 156.2 | 158.4 | 16.2 |

| xGNPs [%] | [GPa] | [GPa] | [MPa] | [MPa] | [MPa] | [MPa] | [%] | [%] |

|---|---|---|---|---|---|---|---|---|

| 0 | 1.21 ± 0.11 | 0.65 ± 0.05 | 19.40 ± 0.84 | 23.05 ± 2.68 | 30.71 ± 0.72 | 45.16 ± 2.73 | 7.19 ± 0.60 | 12.1 ± 0.43 |

| 6 | 0.86 ± 0.05 | 0.55 ± 0.06 | 10.72 ± 1.24 | 16.19 ± 2.43 | 19.48 ± 2.25 | 28.66 ± 2.74 | 6.60 ± 0.59 | 8.90 ± 0.51 |

| 10 | 0.79 ± 0.07 | 0.39 ± 0.21 | 8.75 ± 0.94 | 13.14 ± 1.96 | 13.21 ± 0.99 | 20.78 ± 2.29 | 4.11 ± 0.70 | 8.41 ± 0.14 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guarino, S.; Mingione, E.; Ponticelli, G.S.; Scuderi, A.; Venettacci, S.; Villani, V. Laser Sintering of Nano-Graphite-Reinforced Polyamide Composites for Next-Generation Smart Materials: A Preliminary Investigation of Processability and Electromechanical Properties. Appl. Sci. 2025, 15, 5708. https://doi.org/10.3390/app15105708

Guarino S, Mingione E, Ponticelli GS, Scuderi A, Venettacci S, Villani V. Laser Sintering of Nano-Graphite-Reinforced Polyamide Composites for Next-Generation Smart Materials: A Preliminary Investigation of Processability and Electromechanical Properties. Applied Sciences. 2025; 15(10):5708. https://doi.org/10.3390/app15105708

Chicago/Turabian StyleGuarino, Stefano, Emanuele Mingione, Gennaro Salvatore Ponticelli, Alfio Scuderi, Simone Venettacci, and Vittorio Villani. 2025. "Laser Sintering of Nano-Graphite-Reinforced Polyamide Composites for Next-Generation Smart Materials: A Preliminary Investigation of Processability and Electromechanical Properties" Applied Sciences 15, no. 10: 5708. https://doi.org/10.3390/app15105708

APA StyleGuarino, S., Mingione, E., Ponticelli, G. S., Scuderi, A., Venettacci, S., & Villani, V. (2025). Laser Sintering of Nano-Graphite-Reinforced Polyamide Composites for Next-Generation Smart Materials: A Preliminary Investigation of Processability and Electromechanical Properties. Applied Sciences, 15(10), 5708. https://doi.org/10.3390/app15105708