Generative Artificial Intelligence-Enabled Facility Layout Design Paradigm

Abstract

Featured Application

Abstract

1. Introduction

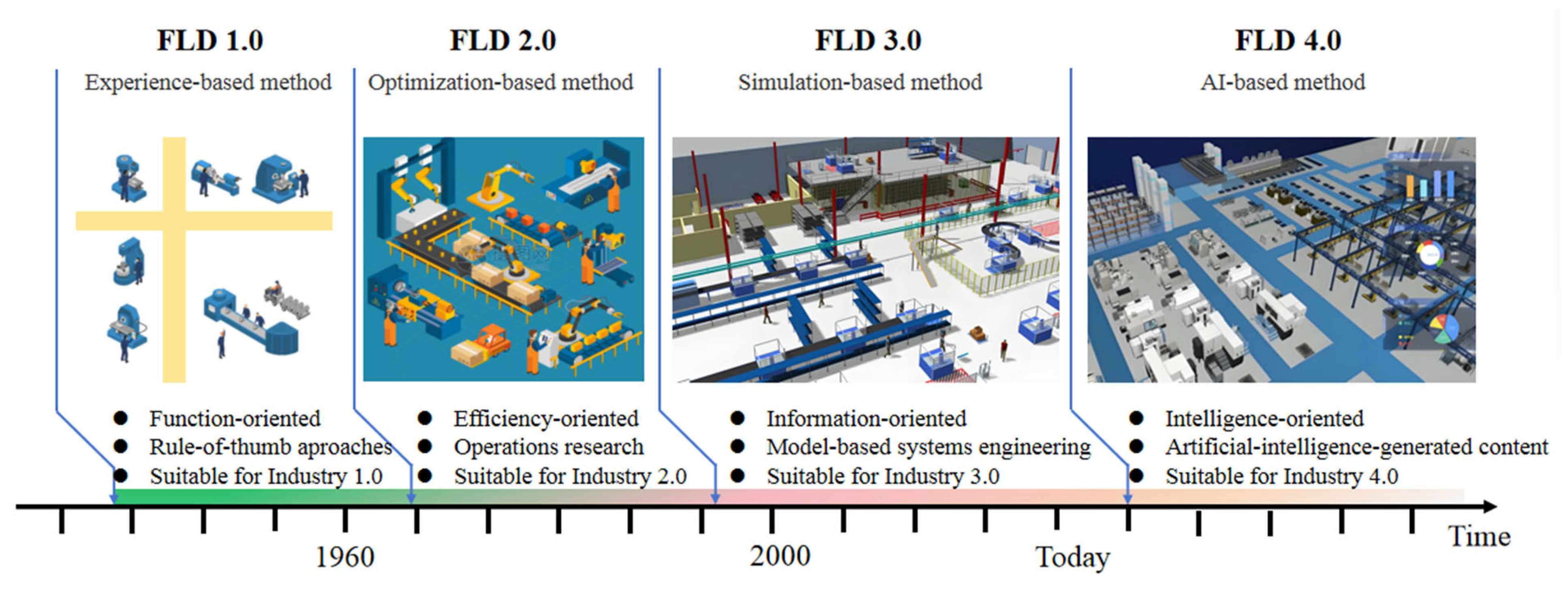

- This work outlines the evolution of facility layout design through three historical paradigms: experience-based methods (FLD 1.0), operations-research-based approaches (FLD 2.0), and simulation-based engineering (FLD 3.0), especially positioning FLD 4.0 as a generative-AI-driven and Industry 4.0-compliant approach.

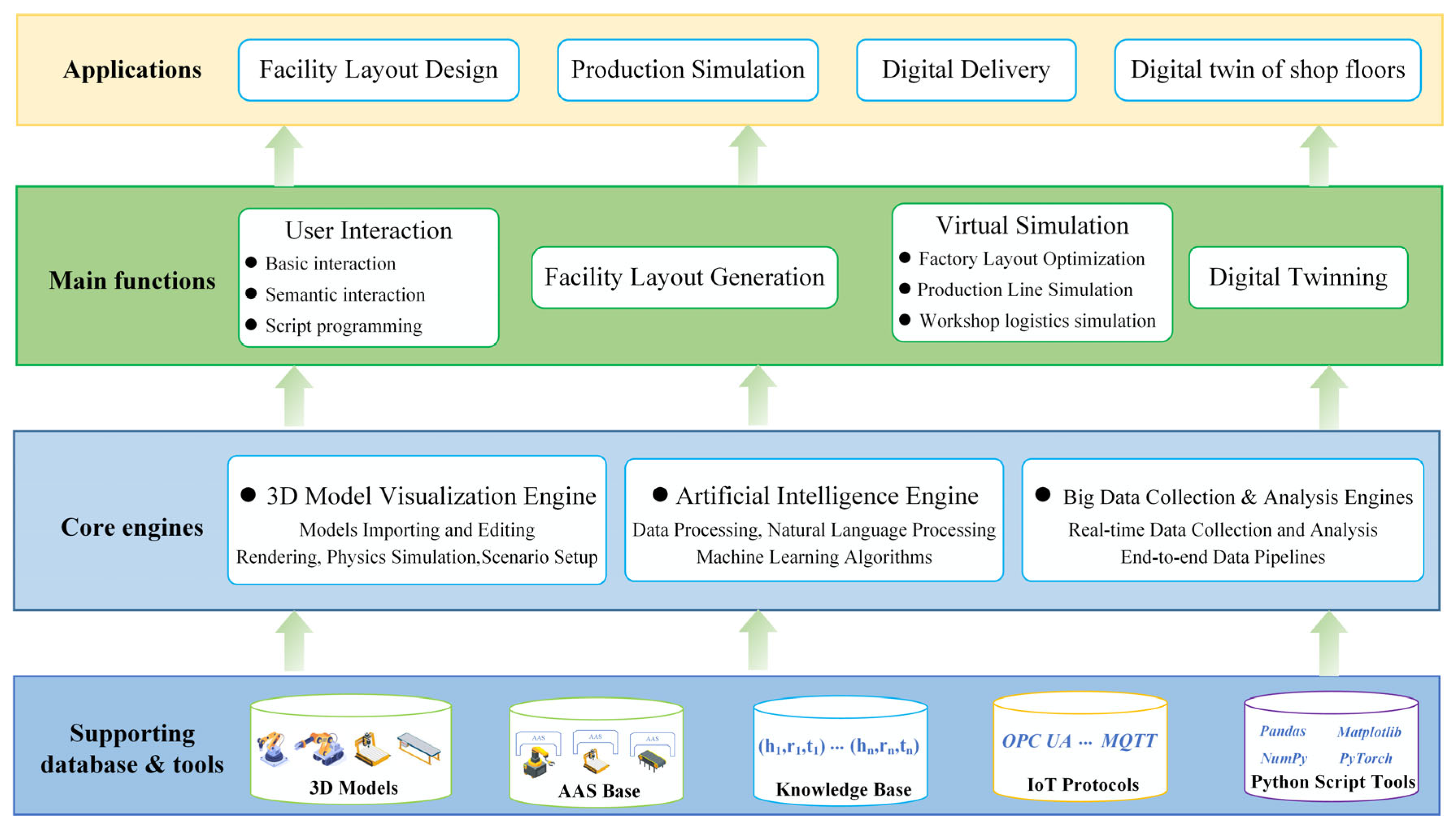

- This research introduces a basic reference architecture for the FLD 4.0 paradigm that integrates the Asset Administration Shell (AAS), knowledge graphs, and generative AI, emphasizing interoperability, real-time adaptability, and human–AI collaboration.

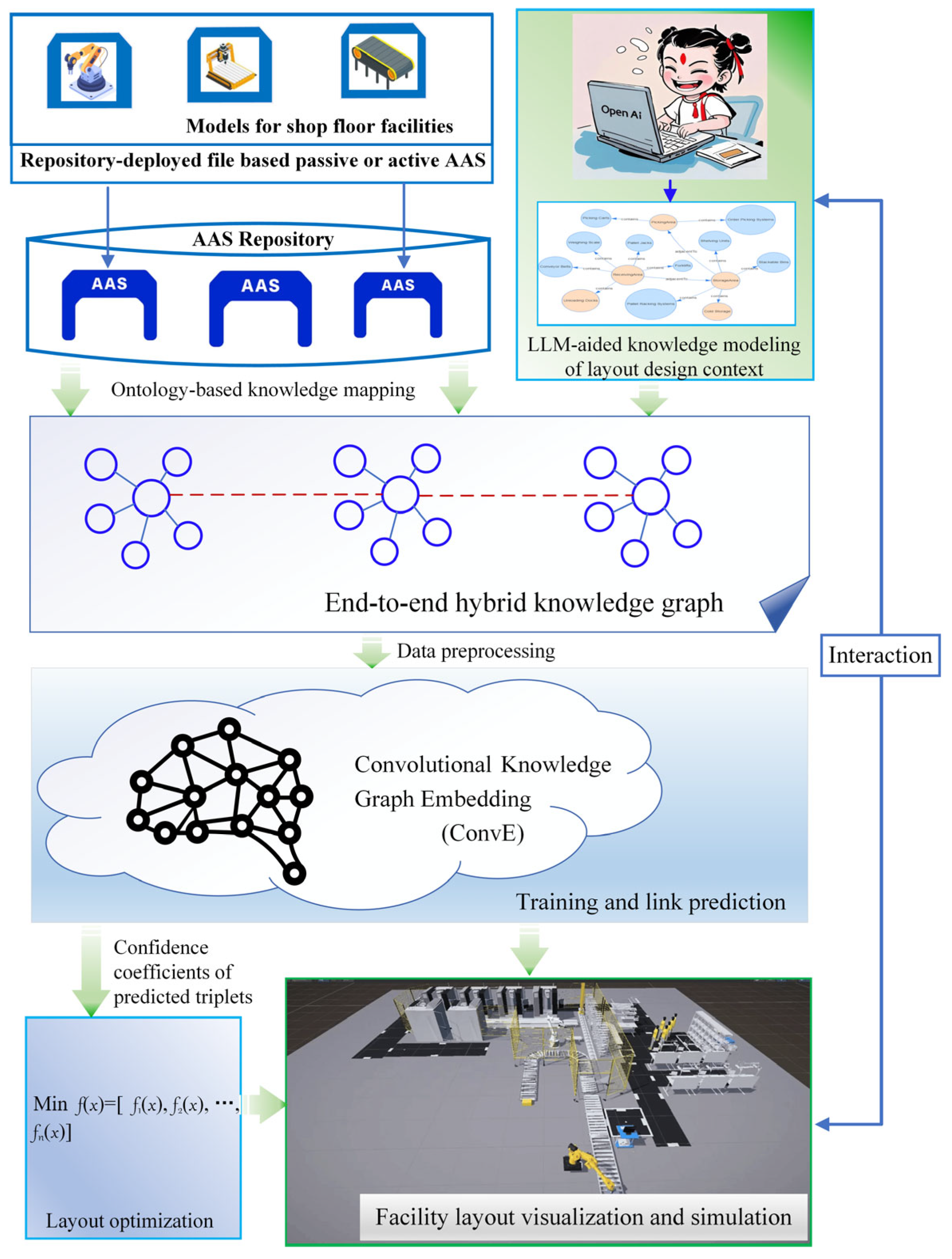

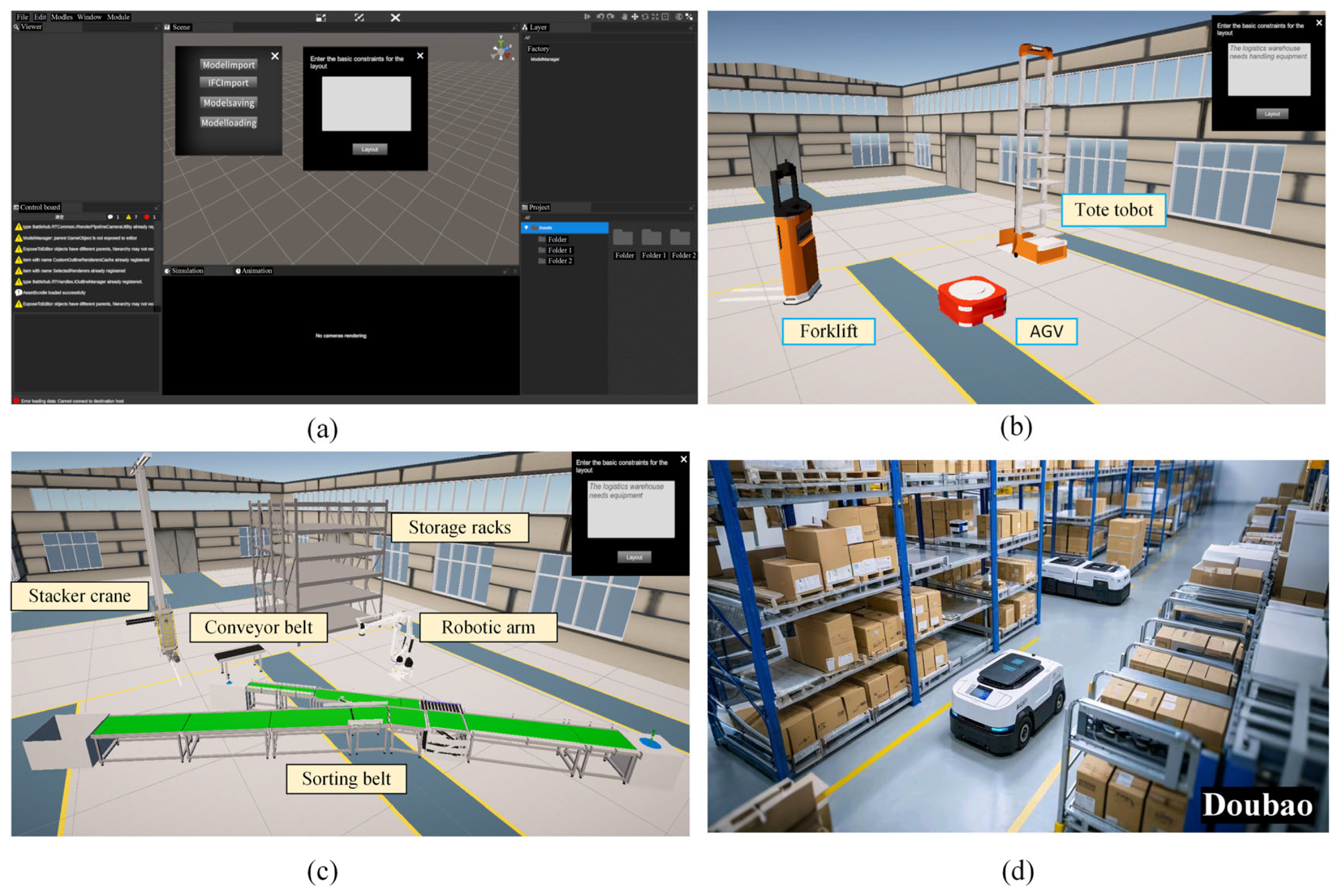

- We developed a functional prototype that combines AAS, large language models (LLMs), embedding-based knowledge graph reasoning, and 3D visualization tools to enable end-to-end facility layout generation.

2. Evolution of Facility Layout Design Paradigms

2.1. Facility Layout Design 1.0: Experience-Based Methods

2.2. Facility Layout Design 2.0: Optimization-Based Methods

2.3. Facility Layout Design 3.0: Simulation-Based Systems Engineering

2.4. Facility Layout Design 4.0: AI-Based Generation Methods

3. Reference Architecture of Facility Layout Design 4.0

3.1. Overview of the Reference Architecture

3.2. Supporting Database and Tools Layer

3.3. Core Engines Layer

3.4. Main Functions Layer

3.5. Application Layer

4. Prototype of a Generative AI-Enabled Facility Layout Design Platform

4.1. Implementation Process of System Development

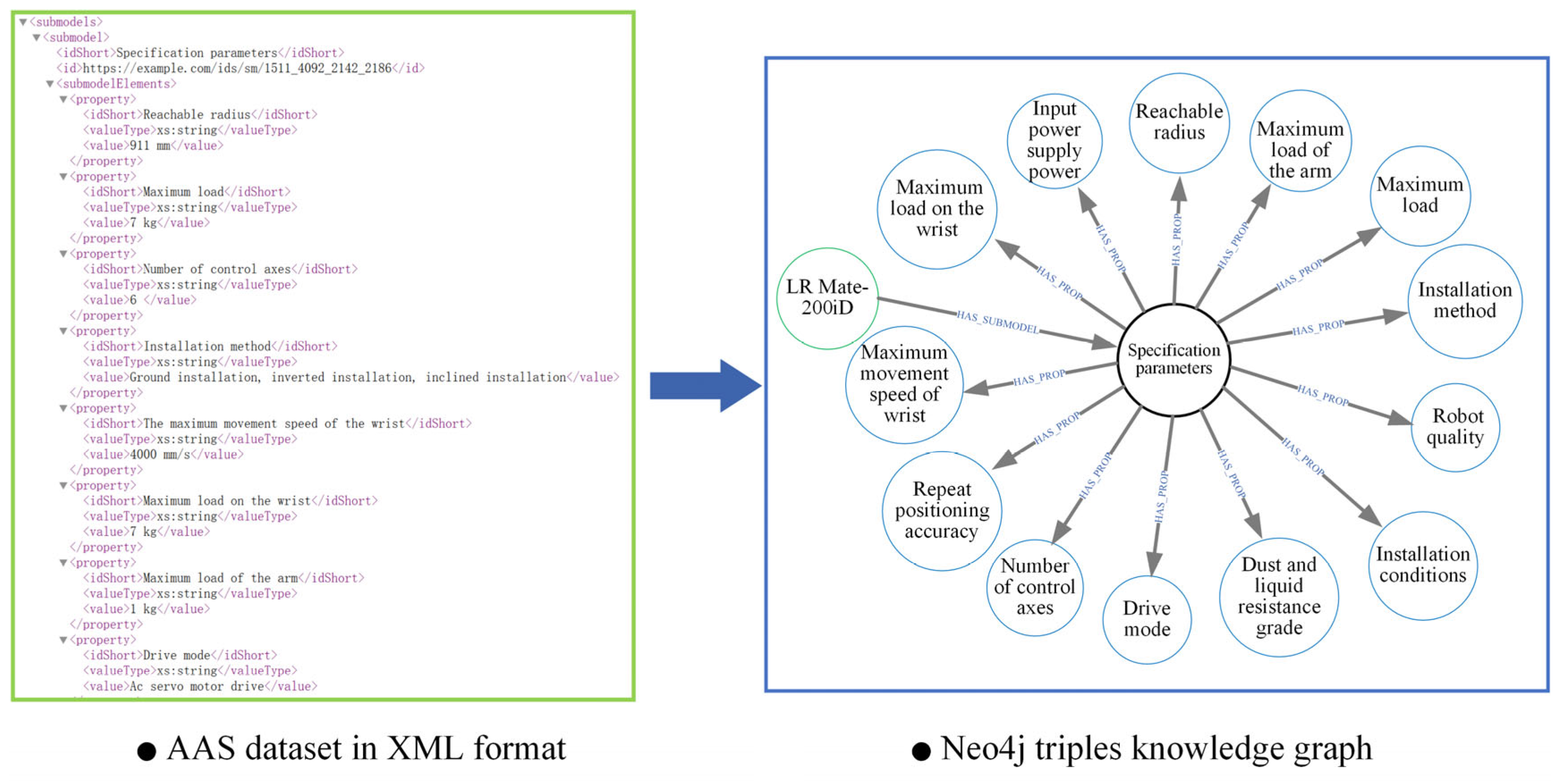

4.2. From AAS Repository to Knowledge Graph

4.3. From LLM to Knowledge Graph

4.4. Layout Reasoning Based on ConvE Model

4.5. Layout Optimization

4.6. System Development and Testing

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| AAS | Asset Administration Shell |

| AGV | Automated Guided Vehicle |

| AHP | Analytic Hierarchy Process |

| AI | Artificial Intelligence |

| AIGC | AI-Generated Content |

| API | Application Programming Interface |

| CAD | Computer-Aided Design |

| CNC | Computer Numerical Control |

| CNN | Convolutional Neural Network |

| ConvE | Convolutional Knowledge Graph Embedding |

| CPSs | Cyber–Physical Systems |

| DQNs | Deep Q Networks |

| DT | Digital Twin |

| FLD | Facility Layout Design |

| FLD 1.0 | Facility Layout Design Paradigm Based on Experience |

| FLD 2.0 | Facility Layout Design Paradigm Based on Optimization |

| FLD 3.0 | Facility Layout Design Paradigm Based on Simulation |

| FLD 4.0 | Facility Layout Design Paradigm Based on Artificial Intelligence |

| GD | Generative Design |

| GUIs | Graphical User Interfaces |

| Industry 4.0 | The Fourth Industrial Revolution |

| IoT | Internet of Things |

| JSON | JavaScript Object Notation |

| KGC | Knowledge Graph Completion |

| LLMs | Large Language Models |

| MADM | Multi-Attribute Decision Making |

| MBSE | Model-Based Systems Engineering |

| MQTT | Message Queuing Telemetry Transport |

| MRR | Mean Reciprocal Rank |

| NLP | Natural Language Processing |

| NP-Hard | Non-deterministic Polynomial-Hard |

| OPC UA | Open Platform Communications Unified Architecture |

| OR | Operations Research |

| RAMI 4.0 | Reference Architecture Model for Industry 4.0 |

| SLP | Systematic Layout Planning |

| TOPSIS | Technique for Order Preference by Similarity to Ideal Solution |

| WSM | Weighted Sum Model |

| XML | eXtensible Markup Language |

References

- Fisher, E.L. An AI-based methodology for factory design. AI Mag. 1986, 7, 72. [Google Scholar] [CrossRef]

- Hosseini-Nasab, H.; Fereidouni, S.; Fatemi Ghomi, S.M.T.; Fakhrzad, M.B. Classification of facility layout problems: A review study. Int. J. Adv. Manuf. Technol. 2018, 94, 957–977. [Google Scholar] [CrossRef]

- Constantinescu, C.; Westkämper, E. A reference model for factory engineering and design. In Proceedings of the 6th CIRP-Sponsored International Conference on Digital Enterprise Technology; Springer: Berlin/Heidelberg, Germany, 2010; pp. 1551–1564. [Google Scholar] [CrossRef]

- Monga, R.; Khurana, V. Facility layout planning: A review. Int. J. Innov. Res. Sci. Eng. Technol. 2015, 4, 976–980. [Google Scholar]

- Okpala, C.C.; Chukwumuanya, O. Plant layouts’analysis and design. Int. J. Eng. Adv. Technol. 2016, 201, 206. [Google Scholar]

- Smith, J.M.G. Dilemmas in factory design: Paradox and paradigm. In Stochastic Modeling of Manufacturing Systems: Advances in Design, Performance Evaluation, and Control Issues; Springer: Berlin/Heidelberg, Germany, 2006; pp. 3–25. [Google Scholar] [CrossRef]

- Lin, L.C.; Sharp, G.P. Quantitative and qualitative indices for the plant layout evaluation problem. Eur. J. Oper. Res. 1999, 116, 100–117. [Google Scholar] [CrossRef]

- Heinbach, B.; Burggräf, P.; Wagner, J. Deep reinforcement learning for layout planning–An MDP-based approach for the facility layout problem. Manuf. Lett. 2023, 38, 40–43. [Google Scholar] [CrossRef]

- Heinbach, B.; Burggräf, P.; Wagner, J. Gym-flp: A Python Package for Training Reinforcement Learning Algorithms on Facility Layout Problems. Oper. Res. Forum 2024, 5, 20. [Google Scholar] [CrossRef]

- Barbosa-Póvoa, A.P.; Mateus, R.; Novais, A.Q. Optimal design and layout of industrial facilities: A simultaneous approach. Ind. Eng. Chem. Res. 2002, 41, 3601–3609. [Google Scholar] [CrossRef]

- Süße, M.; Putz, M. Generative design in factory layout planning. Procedia CIRP 2021, 99, 9–14. [Google Scholar] [CrossRef]

- Anjos, M.F.; Vieira, M.V.C. Mathematical optimization approaches for facility layout problems: The state-of-the-art and future research directions. Eur. J. Oper. Res. 2017, 261, 1–16. [Google Scholar] [CrossRef]

- Sulaiman, S.S.; Jancy, P.L.; Muthiah, A.; Janakiraman, V.; Gnanaraj, S.J.P. An evolutionary optimal green layout design for a production facility by simulated annealing algorithm. Mater. Today Proc. 2021, 47, 4423–4430. [Google Scholar] [CrossRef]

- Klar, M.; Langlotz, P.; Aurich, J.C. A framework for automated multiobjective factory layout planning using reinforcement learning. Procedia CIRP 2022, 112, 555–560. [Google Scholar] [CrossRef]

- Besbes, M.; Zolghadri, M.; Affonso, R.C.; Masmoudi, F.; Haddar, M. 3D facility layout problem. J. Intell. Manuf. 2021, 32, 1065–1090. [Google Scholar] [CrossRef]

- Kulturel-Konak, S. Approaches to uncertainties in facility layout problems: Perspectives at the beginning of the 21 st Century. J. Intell. Manuf. 2007, 18, 273–284. [Google Scholar] [CrossRef]

- Pérez-Gosende, P.; Mula, J.; Díaz-Madroñero, M. A bottom-up multi-objective optimisation approach to dynamic facility layout planning. Int. J. Prod. Res. 2024, 62, 626–643. [Google Scholar] [CrossRef]

- Benjaafar, S.; Heragu, S.S.; Irani, S.A. Next generation factory layouts: Research challenges and recent progress. Interfaces 2002, 32, 58–76. [Google Scholar] [CrossRef]

- Zha, S.; Guo, Y.; Huang, S.; Wang, F.; Huang, X. Robust facility layout design under uncertain product demands. Procedia CIRP 2017, 63, 354–359. [Google Scholar] [CrossRef]

- Zuniga, E.R.; Moris, M.U.; Syberfeldt, A.; Fathi, M.; Rubio-Romero, J.C. A simulation-based optimization methodology for facility layout design in manufacturing. IEEE Access 2020, 8, 163818–163828. [Google Scholar] [CrossRef]

- Naranje, V.; Reddy, P.V.; Sharma, B.K. Optimization of factory layout design using simulation tool. In Proceedings of the 2019 IEEE 6th International Conference on Industrial Engineering and Applications (ICIEA), Tokyo, Japan, 12–15 April 2019; pp. 193–197. [Google Scholar] [CrossRef]

- Zhang, Z.; Wang, X.; Wang, X.; Cui, F.; Cheng, H. A simulation-based approach for plant layout design and production planning. J. Ambient. Intell. Humaniz. Comput. 2019, 10, 1217–1230. [Google Scholar] [CrossRef]

- Garcia, E.F.; Zúñiga, E.R.; Bruch, J.; Moris, M.U.; Syberfeldt, A. Simulation-based optimization for facility layout design in conditions of high uncertainty. Procedia CIRP 2018, 72, 334–339. [Google Scholar] [CrossRef]

- Negahban, A.; Smith, J.S. Simulation for manufacturing system design and operation: Literature review and analysis. J. Manuf. Syst. 2014, 33, 241–261. [Google Scholar] [CrossRef]

- Jefroy, N.; Azarian, M.; Yu, H. The Application of Simulation in Facility Layout Design of an Industry 4.0 Factory. In International Workshop of Advanced Manufacturing and Automation; Springer Nature: Singapore, 2023; pp. 89–99. [Google Scholar] [CrossRef]

- Cañas, H.; Mula, J.; Díaz-Madroñero, M.; Campuzano-Bolarín, F. Implementing industry 4.0 principles. Comput. Ind. Eng. 2021, 158, 107379. [Google Scholar] [CrossRef]

- Suleiman, Z.; Shaikholla, S.; Dikhanbayeva, D.; Shehab, E.; Turkyilmaz, A. Industry 4.0: Clustering of concepts and characteristics. Cogent Eng. 2022, 9, 2034264. [Google Scholar] [CrossRef]

- Aheleroff, S.; Huang, H.; Xu, X.; Zhong, R.Y. Toward sustainability and resilience with Industry 4.0 and Industry 5.0. Front. Manuf. Technol. 2022, 2, 951643. [Google Scholar] [CrossRef]

- Pereira, A.C.; Romero, F. A review of the meanings and the implications of the Industry 4.0 concept. Procedia Manuf. 2017, 13, 1206–1214. [Google Scholar] [CrossRef]

- Gurjanov, A.V.; A Zakoldaev, D.; Shukalov, A.V.; O Zharinov, I. Formation principles of digital twins of Cyber-Physical Systems in the smart factories of Industry 4.0. In IOP Conference Series: Materials Science and Engineering; IOP Publishing Ltd.: Volgograd, Russia, 2019; Volume 483, p. 012070. [Google Scholar] [CrossRef]

- Lin, W.D.; Low, M.Y.H. Concept design of a system architecture for a manufacturing cyber-physical digital twin system. In Proceedings of the 2020 IEEE International Conference on Industrial Engineering and Engineering Management (IEEM), Singapore, 14–17 December 2020; pp. 1320–1324. [Google Scholar] [CrossRef]

- Zhang, H.; Zhang, G.; Yan, Q. Digital twin-driven cyber-physical production system towards smart shop-floor. J. Ambient. Intell. Humaniz. Comput. 2019, 10, 4439–4453. [Google Scholar] [CrossRef]

- Hu, F. Mutual information-enhanced digital twin promotes vision-guided robotic grasping. Adv. Eng. Inform. 2022, 52, 101562. [Google Scholar] [CrossRef]

- Hu, F.; Wang, W.; Zhou, J. Petri nets-based digital twin drives dual-arm cooperative manipulation. Comput. Ind. 2023, 147, 103880. [Google Scholar] [CrossRef]

- Hu, F. Digital twin-driven reconfigurable fixturing optimization for trimming operation of aircraft skins. Aerospace 2022, 9, 154. [Google Scholar] [CrossRef]

- Hu, F.; Qiu, X.; Jing, G.; Tang, J.; Zhu, Y. Digital twin-based decision making paradigm of raise boring method. J. Intell. Manuf. 2023, 34, 2387–2405. [Google Scholar] [CrossRef]

- Burggräf, P.; Adlon, T.; Schäfer, N. Towards Digital-Twin-Driven Factory Planning–A Systematic Review. Procedia CIRP 2024, 126, 248–253. [Google Scholar] [CrossRef]

- Lind, A.; Hanson, L.; Högberg, D.; Lämkull, D.; Mårtensson, P.; Syberfeldt, A. Digital support for rules and regulations when planning and designing factory layouts. Procedia CIRP 2023, 120, 1445–1450. [Google Scholar] [CrossRef]

- Büscher, C.; Meisen, T.; Schilberg, D.; Jeschke, S. VPI-FP: An integrative information system for factory planning. Int. J. Prod. Res. 2016, 54, 2215–2226. [Google Scholar] [CrossRef]

- Wang, W.Y.; Zhang, S.; Li, G.; Lu, J.; Ren, Y.; Wang, X.; Gao, X.; Su, Y.; Song, H.; Li, J. Artificial intelligence enabled smart design and manufacturing of advanced materials: The endless Frontier in AI+ era. Mater. Genome Eng. Adv. 2024, 2, e56. [Google Scholar] [CrossRef]

- Coelho, P.; Bessa, C.; Landeck, J.; Silva, C. Industry 5.0: The arising of a concept. Procedia Comput. Sci. 2023, 217, 1137–1144. [Google Scholar] [CrossRef]

- Suhardini, D.; Septiani, W.; Fauziah, S. Design and simulation plant layout using systematic layout planning. In IOP Conference Series: Materials Science and Engineering; IOP Publishing Ltd.: Tanjung Pandan, Indonesia, 2017; Volume 277, p. 012051. [Google Scholar] [CrossRef]

- Salins, S.S.; Zaidi, S.A.R.; Deepak, D.; Sachidananda, H.K. Design of an improved layout for a steel processing facility using SLP and lean Manufacturing techniques. Int. J. Interact. Des. Manuf. (IJIDeM) 2024, 18, 3827–3848. [Google Scholar] [CrossRef]

- Sharma, P.; Singhal, S. Implementation of fuzzy TOPSIS methodology in selection of procedural approach for facility layout planning. Int. J. Adv. Manuf. Technol. 2017, 88, 1485–1493. [Google Scholar] [CrossRef]

- Singh, S.P.; Singh, V.K. Three-level AHP-based heuristic approach for a multi-objective facility layout problem. Int. J. Prod. Res. 2011, 49, 1105–1125. [Google Scholar] [CrossRef]

- Tubaileh, A.; Siam, J. Single and multi-row layout design for flexible manufacturing systems. Int. J. Comput. Integr. Manuf. 2017, 30, 1316–1330. [Google Scholar] [CrossRef]

- Chen, C.; Tiong, L.K. Using queuing theory and simulated annealing to design the facility layout in an AGV-based modular manufacturing system. Int. J. Prod. Res. 2019, 57, 5538–5555. [Google Scholar] [CrossRef]

- Burggräf, P.; Adlon, T.; Lehde, N.; Lindholm, N. Uncovering the behaviour of facility layout problem solutions in relation to factory design applications. Procedia CIRP 2024, 126, 93–98. [Google Scholar] [CrossRef]

- Gao, T.; Wang, L.; Song, W.; Cheng, Y.; Zuo, Y.; Xiang, F.; Zhang, H.; Tao, F. Ten industrial software towards smart manufacturing. J. Manuf. Syst. 2025, 79, 255–285. [Google Scholar] [CrossRef]

- Akar, N.; Turgay, S. Optimizing Cellular Manufacturing Facility Layout Design through Digital Twin Simulation: A Case Study. Ind. Eng. Innov. Manag. 2023, 6, 1–12. [Google Scholar] [CrossRef]

- Jiang, S.; Li, L.; Deng, K. Optimization and Simulation of Production Line Layout Based on Plant Simulation. In Proceedings of the 2022 IEEE 5th International Conference on Automation, Electronics and Electrical Engineering (AUTEEE), Shenyang, China, 18–20 November 2022; pp. 180–185. [Google Scholar] [CrossRef]

- Centobelli, P.; Cerchione, R.; Murino, T. Layout and material flow optimization in digital factory. Int. J. Simul. Model. 2016, 15, 223–235. [Google Scholar] [CrossRef]

- Choi, H.; Yu, S.; Lee, D.; Noh, S.D.; Ji, S.; Kim, H.; Yoon, H.; Kwon, M.; Han, J. Optimization of the Factory Layout and Production Flow Using Production-Simulation-Based Reinforcement Learning. Machines 2024, 12, 390. [Google Scholar] [CrossRef]

- Mahmood, K.; Otto, T.; Chakraborty, A. Layout planning and analysis of a Flexible Manufacturing System based on 3D Simulation and Virtual Reality. Procedia CIRP 2023, 120, 201–206. [Google Scholar] [CrossRef]

- Gyulai, D.; Szaller, Á.; Viharos, Z.J. Simulation-based flexible layout planning considering stochastic effects. Procedia CIRP 2016, 57, 177–182. [Google Scholar] [CrossRef]

- Xu, X. SLP-based technical plant layout planning and simulation analysis. In IOP Conference Series: Materials Science and Engineering; IOP Publishing Ltd.: Sanya, China, 2020; Volume 772, p. 012020. [Google Scholar] [CrossRef]

- Gabor, T.; Belzner, L.; Kiermeier, M.; Beck, M.T.; Neitz, A. A simulation-based architecture for smart cyber-physical systems. In Proceedings of the 2016 IEEE International Conference on Autonomic Computing (ICAC), Wuerzburg, Germany, 17–22 July 2016; pp. 374–379. [Google Scholar] [CrossRef]

- Hehenberger, P.; Vogel-Heuser, B.; Bradley, D.; Eynard, B.; Tomiyama, T.; Achiche, S. Design, modelling, simulation and integration of cyber physical systems: Methods and applications. Comput. Ind. 2016, 82, 273–289. [Google Scholar] [CrossRef]

- Falcone, A.; Garro, A. Distributed co-simulation of complex engineered systems by combining the high level architecture and functional mock-up interface. Simul. Model. Pract. Theory 2019, 97, 101967. [Google Scholar] [CrossRef]

- Benali, H.; Ben Saoud, N.B. Towards a component-based framework for interoperability and composability in Modeling and Simulation. Simulation 2011, 87, 133–148. [Google Scholar] [CrossRef]

- Peron, M.; Fragapane, G.; Sgarbossa, F.; Kay, M. Digital facility layout planning. Sustainability 2020, 12, 3349. [Google Scholar] [CrossRef]

- Lather, J.I.; Logan, T.; Renner, K.; Messner, J.I. Implementation and evaluation of generative layout options using the graph theoretical approach for a hospital layout problem. J. Comput. Civ. Eng. 2020, 34, 04020014. [Google Scholar] [CrossRef]

- Caneparo, L. Semantic knowledge in generation of 3D layouts for decision-making. Autom. Constr. 2022, 134, 104012. [Google Scholar] [CrossRef]

- Yao, Z.; Chen, Y.; Cui, J.; Zhang, S.; Li, S.; Hao, A. Conditional room layout generation based on graph neural networks. Comput. Graph. 2024, 122, 103971. [Google Scholar] [CrossRef]

- Shi, Y.; Shang, M.; Qi, Z. Intelligent layout generation based on deep generative models: A comprehensive survey. Inf. Fusion 2023, 100, 101940. [Google Scholar] [CrossRef]

- Cohen, Y.; Aperstein, Y. Generative Shopfloor Layout Design: Challenges and Proposed Modelling Approach. IFAC-PapersOnLine 2024, 58, 748–753. [Google Scholar] [CrossRef]

- Pawletta, T.; Pascheka, D.; Schmidt, A.; Pawletta, S. Ontology-Assisted System Modeling and Simulation within MATLAB/Simulink. Simul. Notes Eur. 2014, 24, 59–68. [Google Scholar] [CrossRef]

- Arnarson, H.; Yu, H.; Olavsbråten, M.M.; Bremdal, B.A.; Solvang, B. Towards smart layout design for a reconfigurable manufacturing system. J. Manuf. Syst. 2023, 68, 354–367. [Google Scholar] [CrossRef]

- Liu, X.; Qiu, C.; Shi, J.; Huang, J.; Zhu, C.; Ni, Z.; Zhu, M.; Liu, T. A digital twin modeling method for production resources of shop floor. Int. J. Adv. Manuf. Technol. 2023, 128, 743–761. [Google Scholar] [CrossRef]

- Lee, J.; Azamfar, M.; Bagheri, B. A unified digital twin framework for shop floor design in industry 4.0 manufacturing systems. Manuf. Lett. 2021, 27, 87–91. [Google Scholar] [CrossRef]

- Cloutier, R.; Muller, G.; Verma, D.; Nilchiani, R.; Hole, E.; Bone, M. The concept of reference architectures. Syst. Eng. 2010, 13, 14–27. [Google Scholar] [CrossRef]

- Nakagawa, E.Y.; Antonino, P.O.; Schnicke, F.; Capilla, R.; Kuhn, T.; Liggesmeyer, P. Industry 4.0 reference architectures: State of the art and future trends. Comput. Ind. Eng. 2021, 156, 107241. [Google Scholar] [CrossRef]

- Burns, T.; Cosgrove, J.; Doyle, F. A review of Interoperability Standards for Industry 4.0. Procedia Manuf. 2019, 38, 646–653. [Google Scholar] [CrossRef]

- Madni, A.M.; Sievers, M. System of systems integration: Key considerations and challenges. Syst. Eng. 2014, 17, 330–347. [Google Scholar] [CrossRef]

- Wenger, M.; Zoitl, A.; Müller, T. Connecting PLCs with their asset administration shell for automatic device configuration. In Proceedings of the 2018 IEEE 16th International Conference on Industrial Informatics (INDIN), Porto, Portugal, 18–20 July 2018; pp. 74–79. [Google Scholar] [CrossRef]

- Pérez-Gosende, P.; Mula, J.; Díaz-Madroñero, M. Facility layout planning. An extended literature review. Int. J. Prod. Res. 2021, 59, 3777–3816. [Google Scholar] [CrossRef]

- Fuchs, J.; Schmidt, J.; Franke, J.; Rehman, K.; Sauer, M.; Karnouskos, S. I4. 0-compliant integration of assets utilizing the Asset Administration Shell. In Proceedings of the 2019 24th IEEE International Conference on Emerging Technologies and Factory Automation (ETFA), Zaragoza, Spain, 10–13 September 2019; pp. 1243–1247. [Google Scholar] [CrossRef]

- Platenius-Mohr, M.; Malakuti, S.; Grüner, S.; Goldschmidt, T. Interoperable digital twins in IIoT systems by transformation of information models: A case study with asset administration shell. In Proceedings of the 9th International Conference on the Internet of Things, Bilbao, Spain, 22–25 October 2019; pp. 1–8. [Google Scholar] [CrossRef]

- Tian, L.; Zhou, X.; Wu, Y.-P.; Zhou, W.-T.; Zhang, J.-H.; Zhang, T.-S. Knowledge graph and knowledge reasoning: A systematic review. J. Electron. Sci. Technol. 2022, 20, 100159. [Google Scholar] [CrossRef]

- Wang, M.; Qiu, L.; Wang, X. A survey on knowledge graph embeddings for link prediction. Symmetry 2021, 13, 485. [Google Scholar] [CrossRef]

- Aßmann, U.; Zschaler, S.; Wagner, G. Ontologies, Meta-models, and the Model-Driven Paradigm. In Ontologies for Software Engineering and Software Technology; Calero, C., Ruiz, F., Piattini, M., Eds.; Springer: Berlin/Heidelberg, Germany, 2006; pp. 249–273. [Google Scholar] [CrossRef]

- Dettmers, T.; Minervini, P.; Stenetorp, P.; Riedel, S. Convolutional 2d knowledge graph embeddings. Proc. AAAI Conf. Artif. Intell. 2018, 32, 1811–1818. [Google Scholar] [CrossRef]

- Yang, X.; Liu, X.; Zhang, H.; Fu, L.; Yu, Y. An ontology-based shop-floor digital twin configuration approach. Procedia CIRP 2023, 120, 326–331. [Google Scholar] [CrossRef]

- Xia, Y.; Xiao, Z.; Jazdi, N.; Weyrich, M. Generation of Asset Administration Shell with Large Language Model Agents: Towards Semantic Interoperability in Digital Twins in the Context of Industry 4.0. IEEE Access 2024, 12, 84863–84877. [Google Scholar] [CrossRef]

- Miny, T.; Thies, M.; Lukic, L.; Käbisch, S.; Oladipupo, K.; Diedrich, C.; Kleinert, T. Overview and Comparison of Asset Information Model Standards. IEEE Access 2023, 11, 99189–99221. [Google Scholar] [CrossRef]

- Drath, R.; Rentschler, M.; Hoffmeister, M. The automationml component description in the context of the asset administration shell. In Proceedings of the 2019 24th IEEE International Conference on Emerging Technologies and Factory Automation (ETFA), Zaragoza, Spain, 10–13 September 2019; pp. 1278–1281. [Google Scholar] [CrossRef]

- Strakošová, S.; Novák, P.; Kadera, P. Product-Oriented Product-Process-Resource Asset Network and its Representation in AutomationML for Asset Administration Shell. In Proceedings of the 2024 IEEE 29th International Conference on Emerging Technologies and Factory Automation (ETFA), Padova, Italy, 10–13 September 2024; pp. 1–8. [Google Scholar] [CrossRef]

- Zamini, M.; Reza, H.; Rabiei, M. A review of knowledge graph completion. Information 2022, 13, 396. [Google Scholar] [CrossRef]

- Dai, Y.; Wang, S.; Xiong, N.N.; Guo, W. A survey on knowledge graph embedding: Approaches, applications and benchmarks. Electronics 2020, 9, 750. [Google Scholar] [CrossRef]

- Cao, Y.; Li, S.; Liu, Y.; Yan, Z.; Dai, Y.; Yu, P.; Sun, L. A survey of ai-generated content (aigc). ACM Comput. Surv. 2025, 57, 1–38. [Google Scholar] [CrossRef]

- Gao, R.X.; Krüger, J.; Merklein, M.; Möhring, H.-C.; Váncza, J. Artificial Intelligence in manufacturing: State of the art, perspectives, and future directions. CIRP Ann. 2024, 73, 723–749. [Google Scholar] [CrossRef]

| Design Paradigms | FLD 1.0 | FLD 2.0 | FLD 3.0 | FLD 4.0 |

|---|---|---|---|---|

| Basic principles | Rule-of-thumb | Operations research | Model- and simulation-based systems | AI-based generation |

| Starting years | 1780s | 1960s | 2000s | 2020s |

| Industrial age | Industry 1.0 | Industry 2.0 | Industry 3.0 | Industry 4.0 |

| Adaptive scenes | Simple production | Automatic large-scale production | Flexible and agile production | Intelligent production |

| Main features |

|

|

|

|

| Limitations |

|

|

|

|

| Type of Relationship | Description | Example |

|---|---|---|

| Spatial Relationships | Describes the physical location relationships between facilities, which directly affect the spatial efficiency of the layout. | |

| AdjacentTo: Facilities placed next to each other for frequent interaction. | Milling machines next to assembly lines to reduce material handling time. | |

| NearTo: Facilities located close to one another for efficient logistics. | Placing raw material storage areas near machining stations for easier replenishment. | |

| FarFrom: Certain facilities must be placed at a distance from each other for safety or environmental reasons. | High-temperature furnaces should be far from flammable chemical storage for safety. | |

| Process Relationships | Based on the dependency relationships in the production process, determining the sequence of facilities. | |

| NextProcess: Facilities that depend on each other for input/output. | Stamping machine output feeds into cleaning, then to coating. | |

| ParallelProcess: Facilities that can operate simultaneously to enhance capacity. | Multiple CNC machines placed together for parallel part processing. | |

| Material Flow Relationships | Describes the movement requirements of materials or personnel between facilities. | |

| TransportPath: There are frequent material handling paths between facilities (e.g., automated guided vehicle (AGV) routes). | A straight AGV path needs to be reserved between the storage area and the assembly line. | |

| HighFrequencyFlow: Material interactions between facilities are frequent, requiring prioritization to shorten the distance. | Stamping and quality control areas placed near each other. | |

| Constraint Relationships | Relationships created by safety, environmental, or regulatory restrictions. | |

| MinimumSafetyDistance: Some facilities must maintain a safe distance from others for safety. | High-voltage equipment placed away from operational areas. | |

| EnvironmentalConstraint: Facilities that are noisy or temperature-sensitive must be isolated. | Noisy stamping workshops should be placed away from office areas. | |

| Functional Relationships | Relationships based on the complementarity or collaboration needs of facility functions. | |

| SharesResource: Facilities requiring shared resources (e.g., electricity, cooling systems) should be placed close to reduce waste. | Machines sharing a central cooling system placed near one another. | |

| CollaboratesWith: Facilities that must work closely together should be located near each other. | Robotic welding stations near manual adjustment tables for easier adjustments. | |

| Dynamic Relationships | Considers flexibility in facility placement for optimal use of space and equipment. | |

| MobileFacility: Some facilities can be moved based on demand to improve efficiency. | AGV charging stations can be dynamically adjusted for better equipment utilization. | |

| TemporaryAdjacent: Temporary layout adjustments are made to cope with production peaks. | Additional storage areas placed near assembly lines during peak periods. | |

| Hierarchical Relationships | Describes the subordinate or grouping relationships of the facilities in the layout. | |

| ParentChild: A facility is a subunit of a certain functional module. | An assembly line with sub-stations like tightening or inspection. | |

| BelongsToZone: A facility belongs to a specific functional zone (e.g., clean area, heavy equipment area). | Precision instruments placed in cleanroom zones for accuracy. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hu, F.; Wang, C.; Wu, X. Generative Artificial Intelligence-Enabled Facility Layout Design Paradigm. Appl. Sci. 2025, 15, 5697. https://doi.org/10.3390/app15105697

Hu F, Wang C, Wu X. Generative Artificial Intelligence-Enabled Facility Layout Design Paradigm. Applied Sciences. 2025; 15(10):5697. https://doi.org/10.3390/app15105697

Chicago/Turabian StyleHu, Fuwen, Chun Wang, and Xuefei Wu. 2025. "Generative Artificial Intelligence-Enabled Facility Layout Design Paradigm" Applied Sciences 15, no. 10: 5697. https://doi.org/10.3390/app15105697

APA StyleHu, F., Wang, C., & Wu, X. (2025). Generative Artificial Intelligence-Enabled Facility Layout Design Paradigm. Applied Sciences, 15(10), 5697. https://doi.org/10.3390/app15105697