Influence of Baffle Location on the Diodicity of Tesla Valves

Abstract

1. Introduction

2. Problem Setup

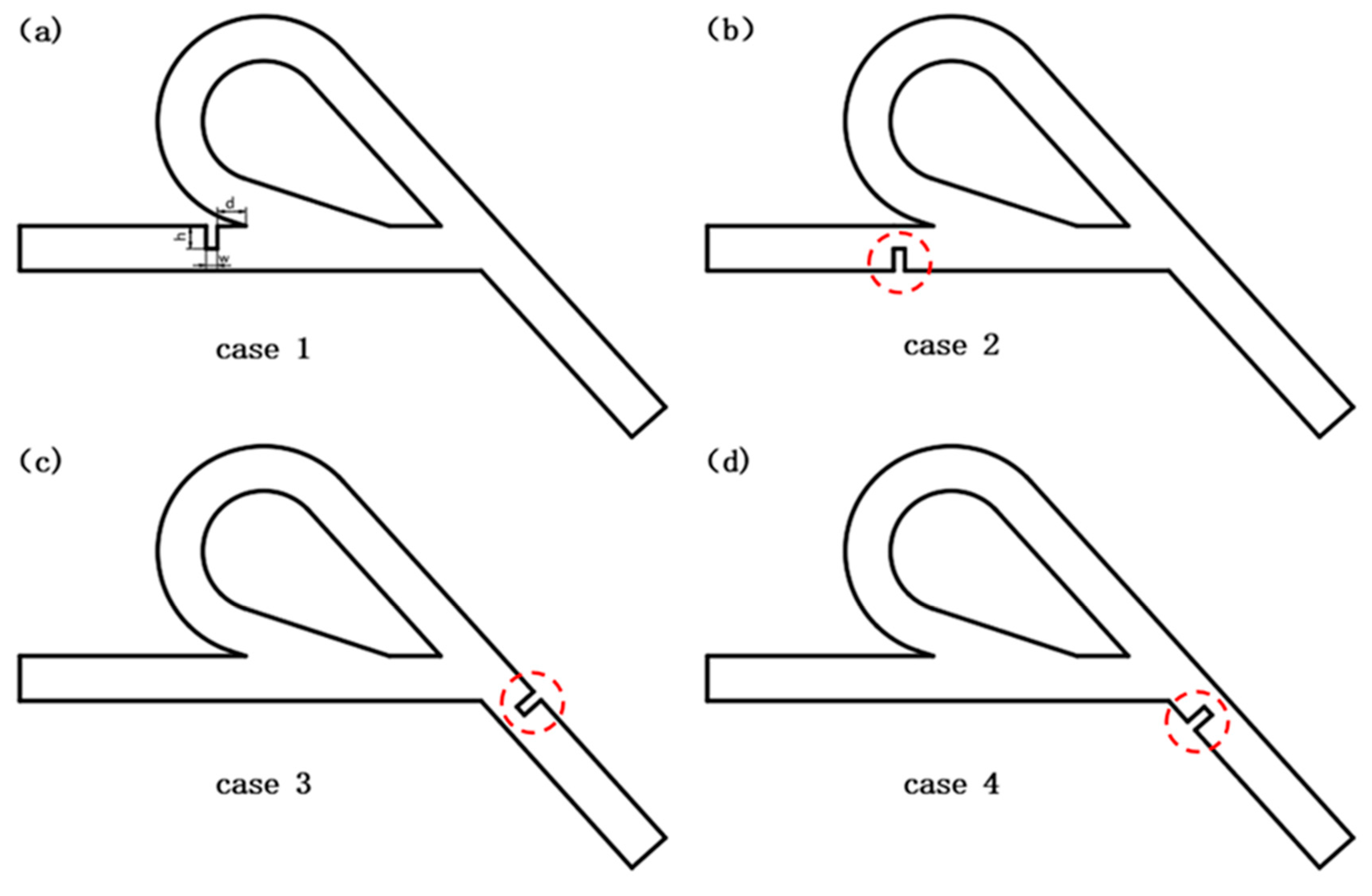

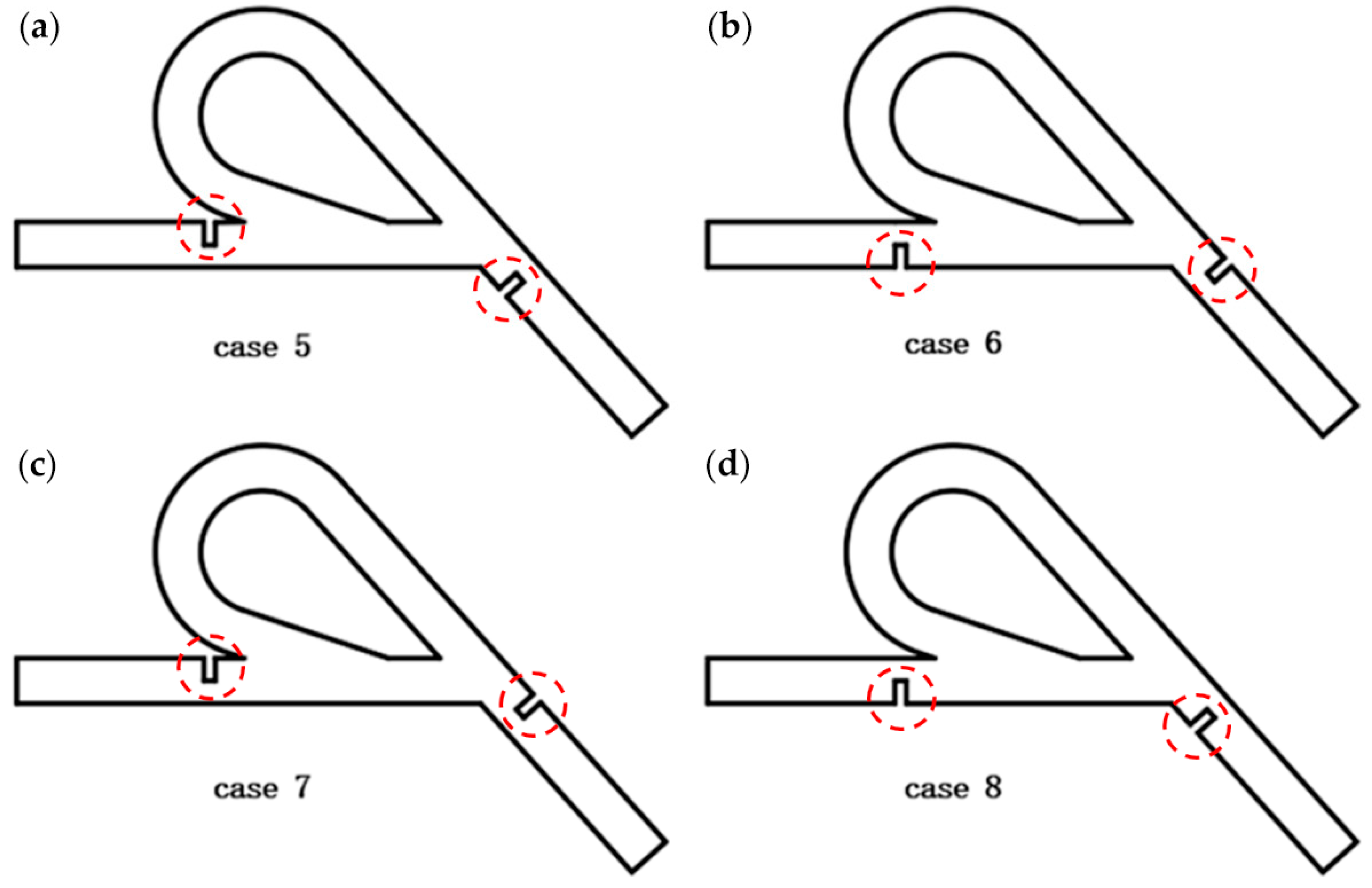

2.1. Geometric Model and Design Proposal

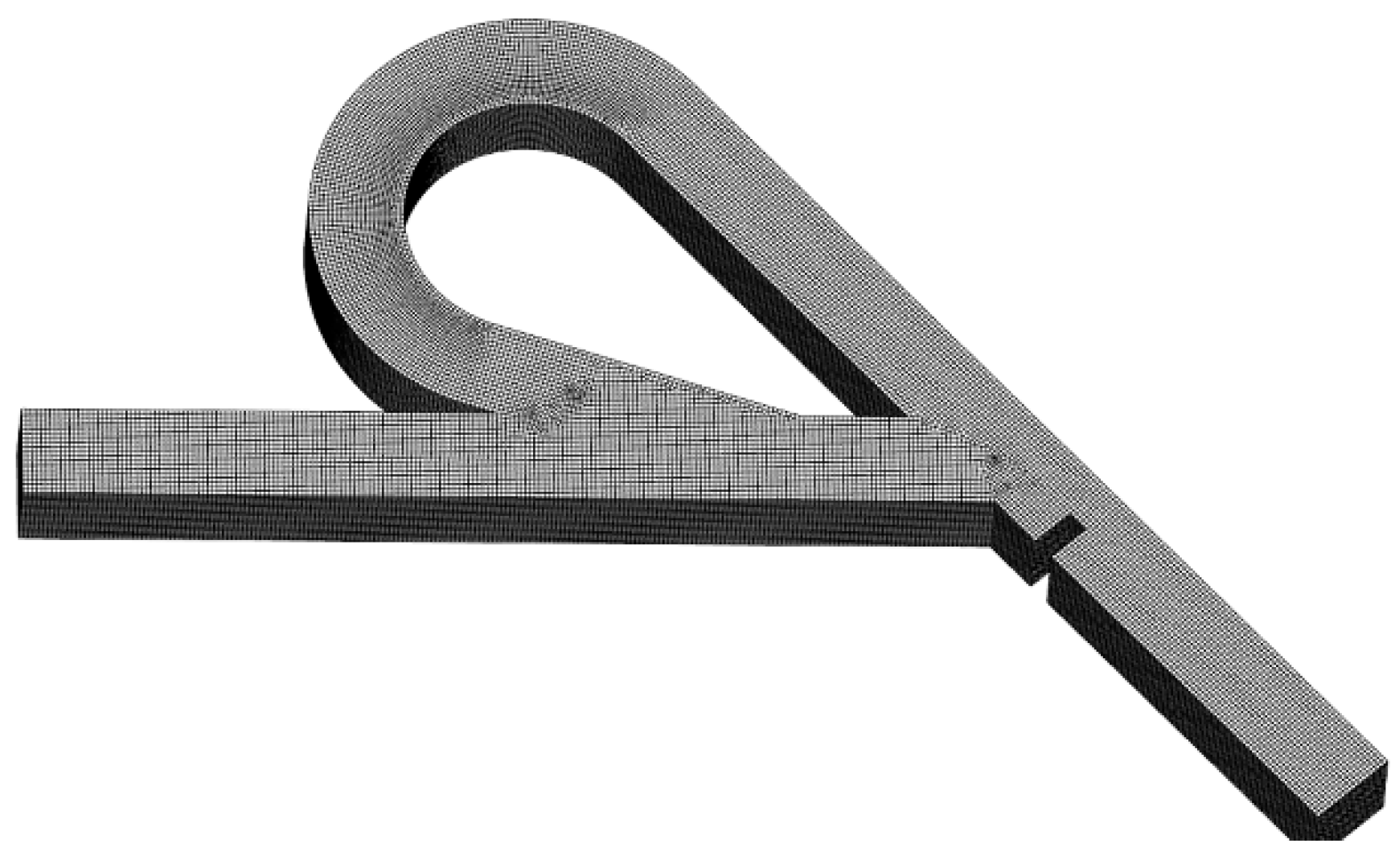

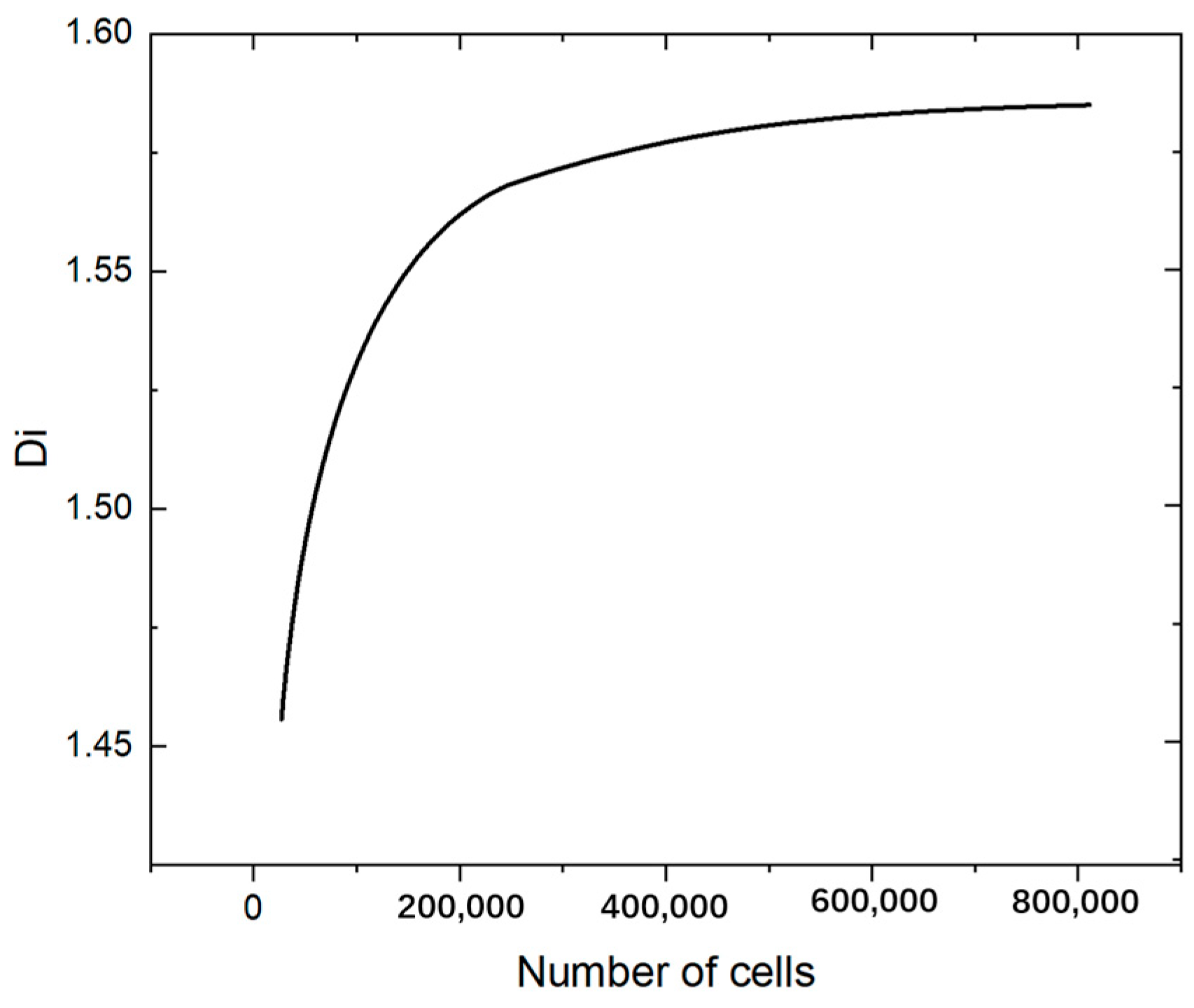

2.2. Simulation Methods

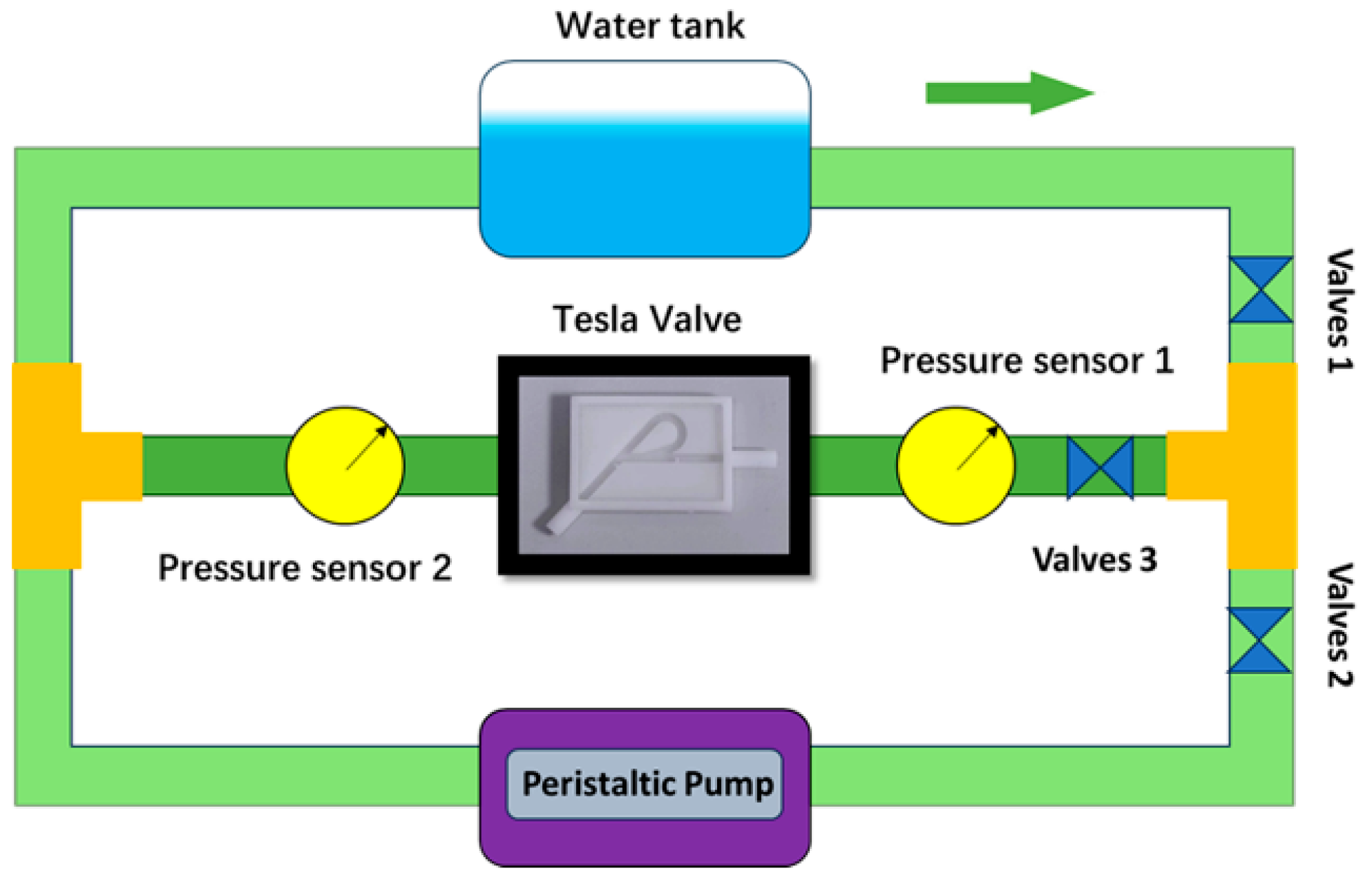

2.3. Experiment Methods

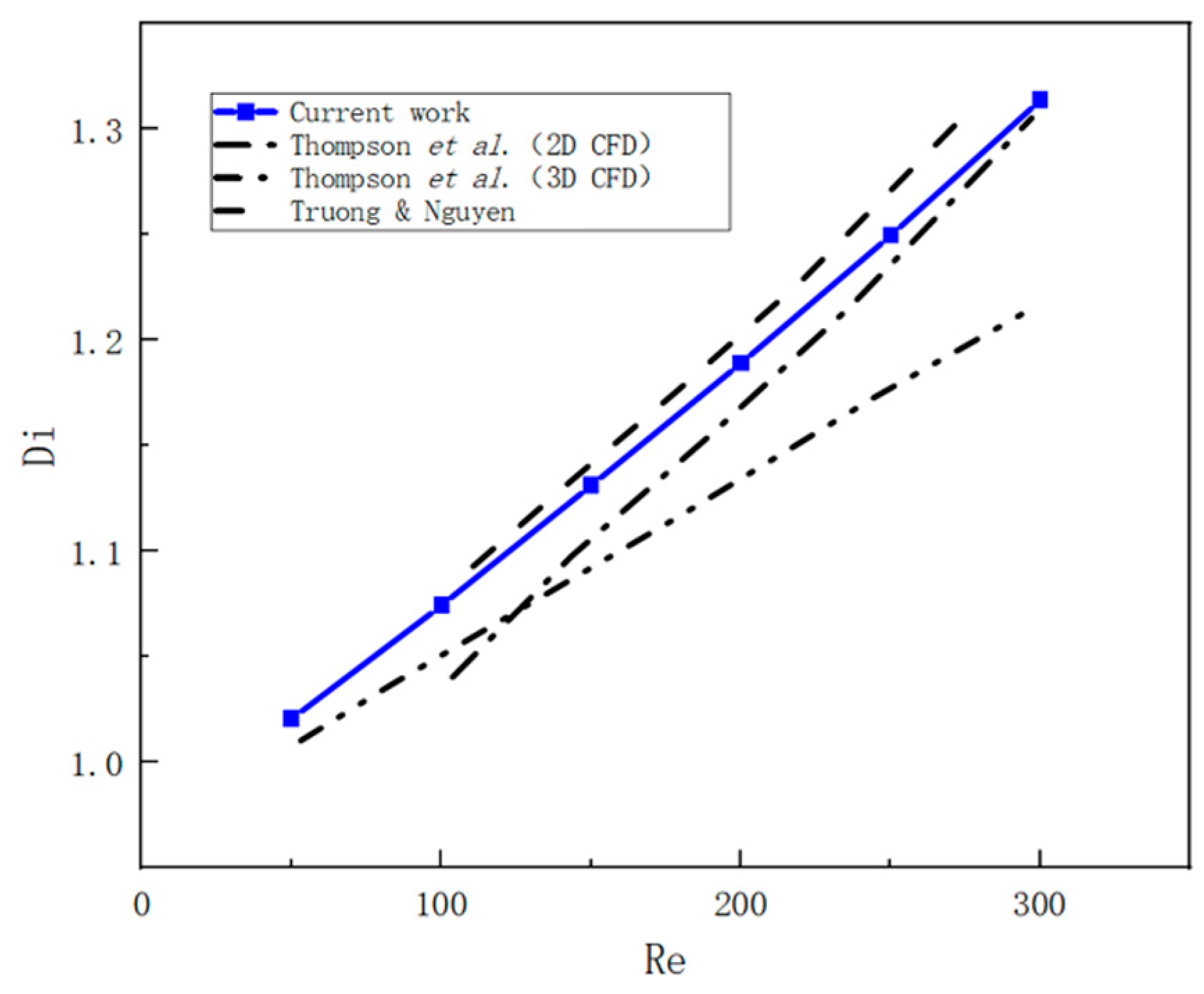

3. Results and Discussion

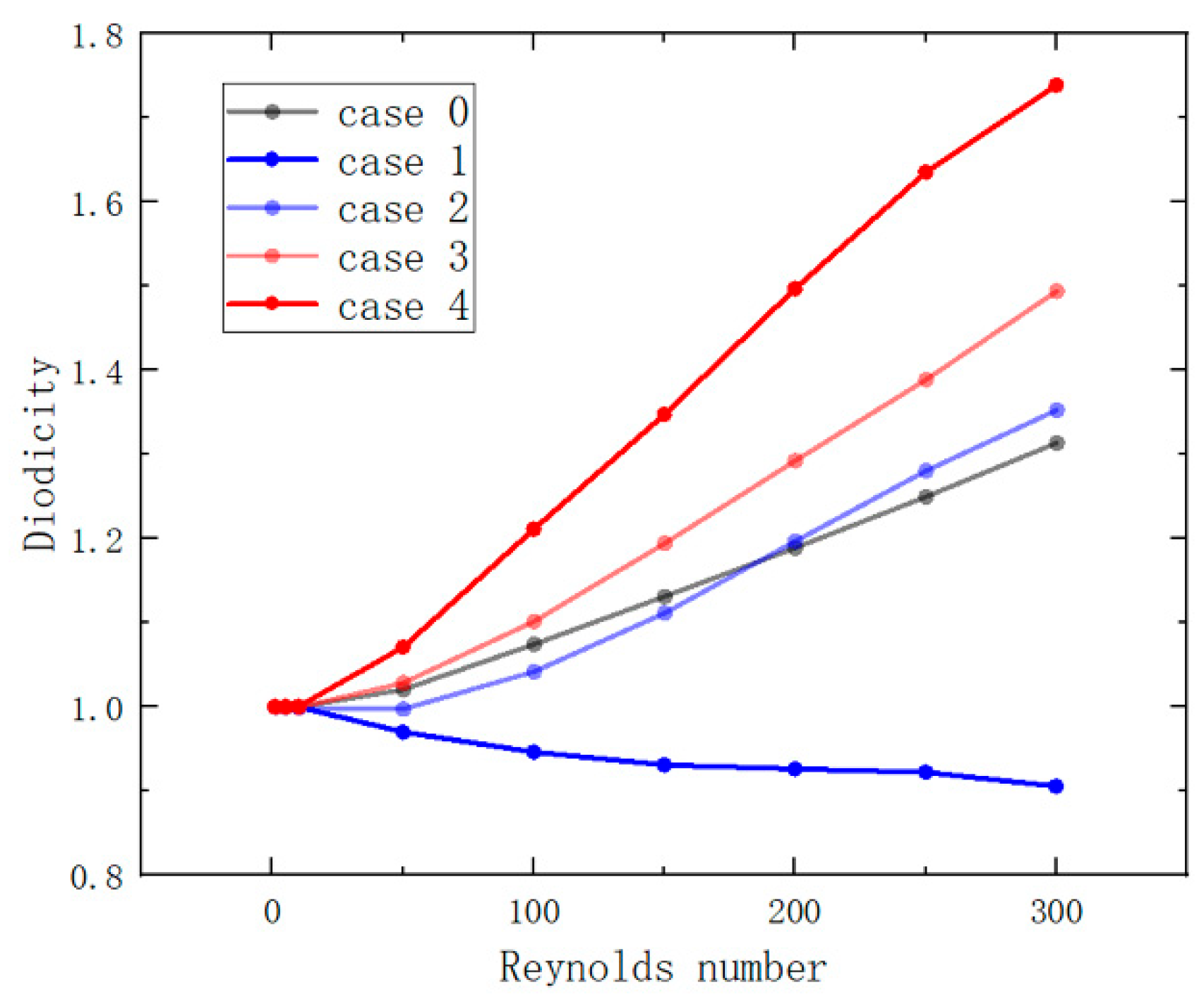

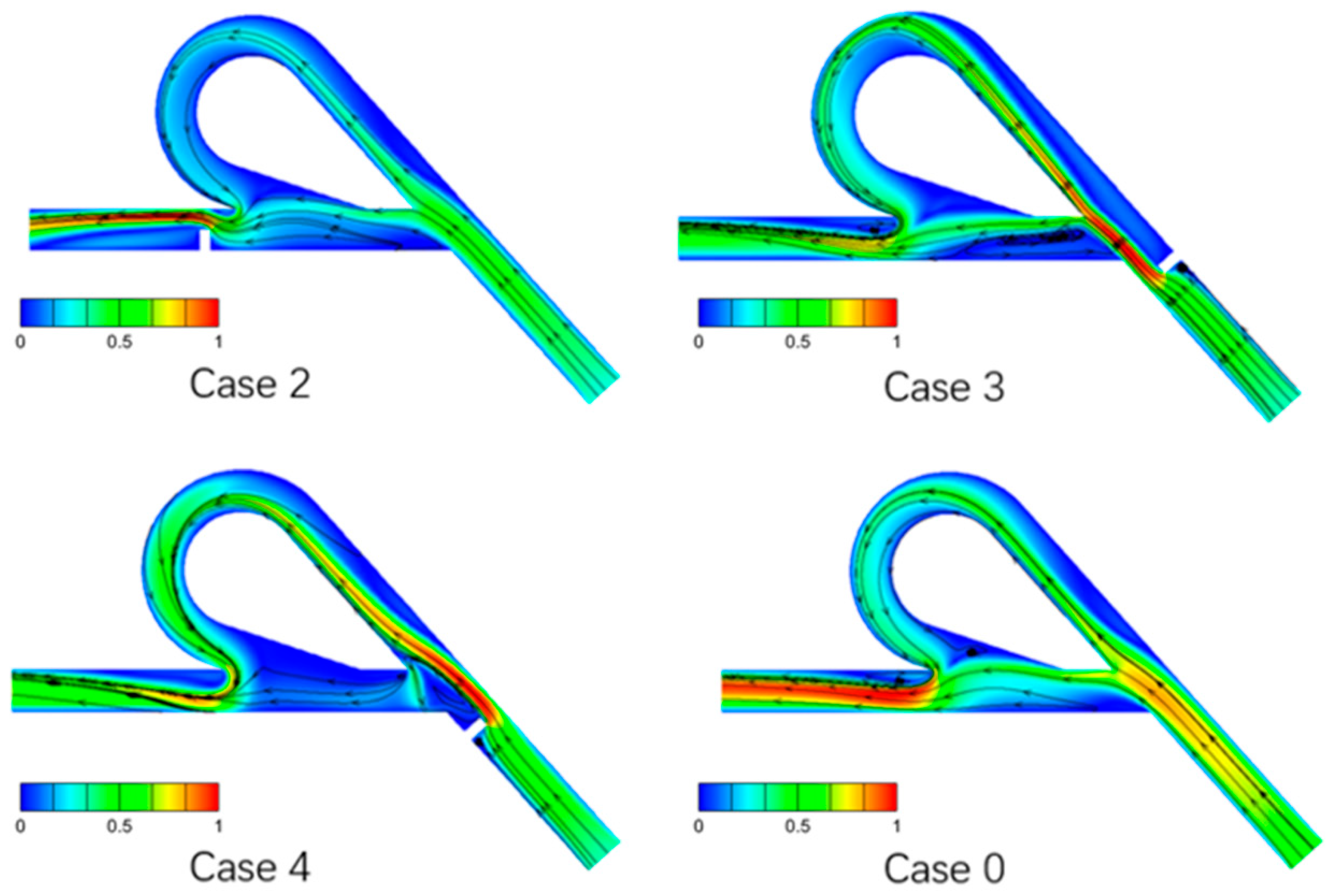

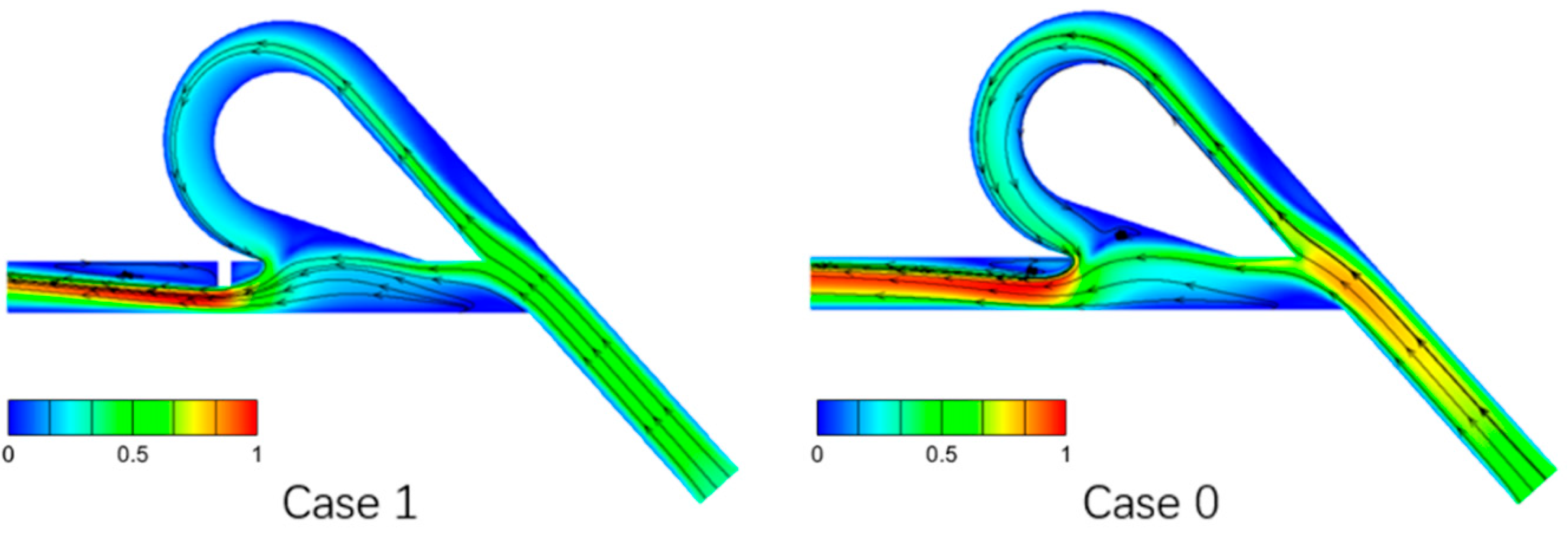

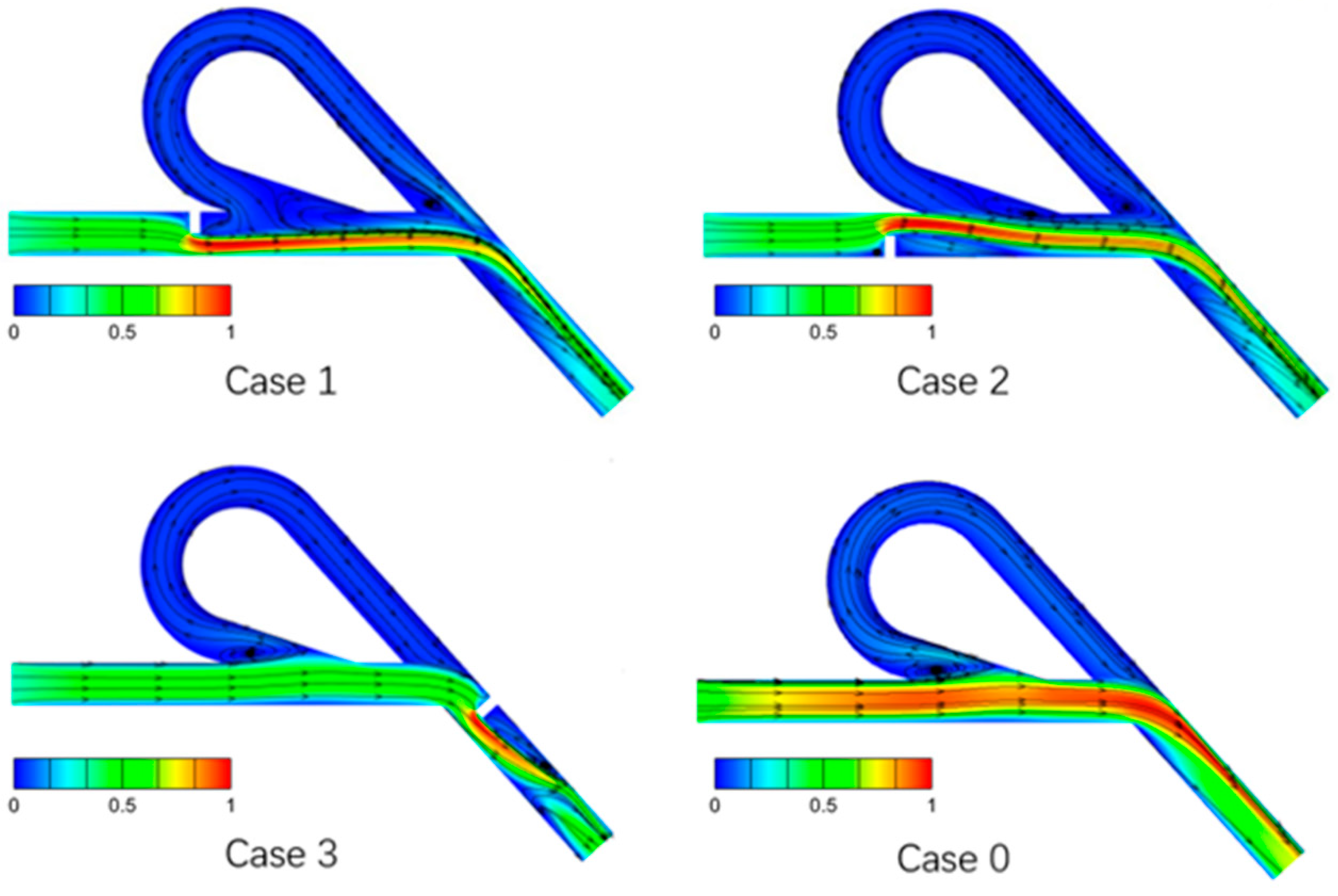

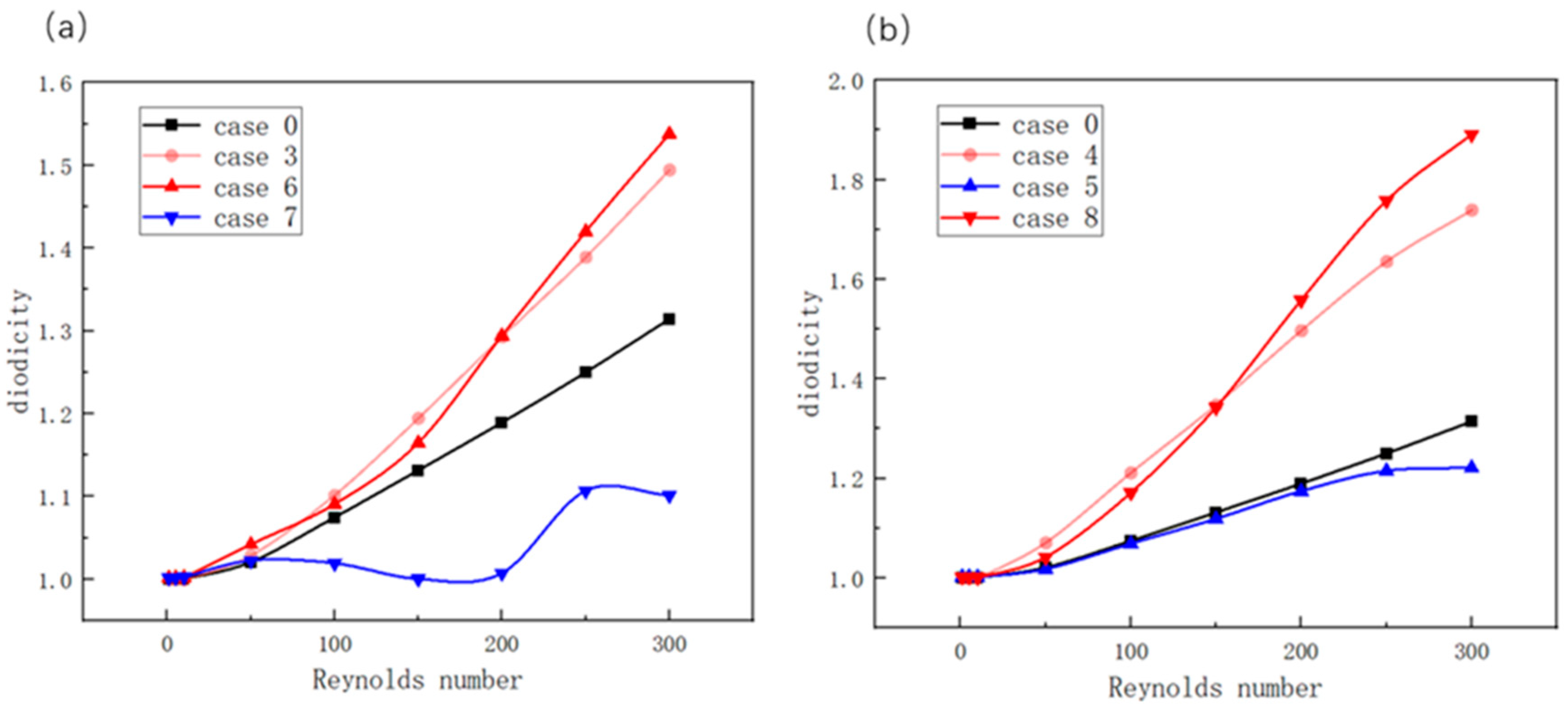

3.1. Influence of Flow Field Non-Uniformity at One Location on the Diodicity

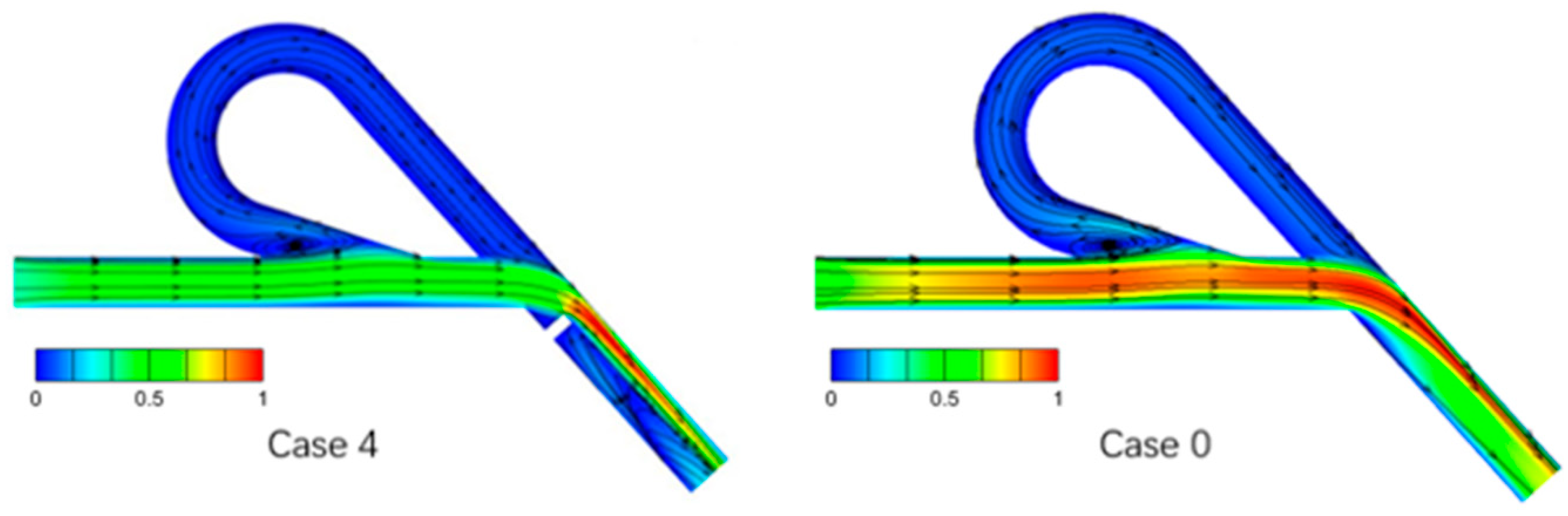

3.2. Influence of Flow Field Non-Uniformity at Two Locations on the Diodicity

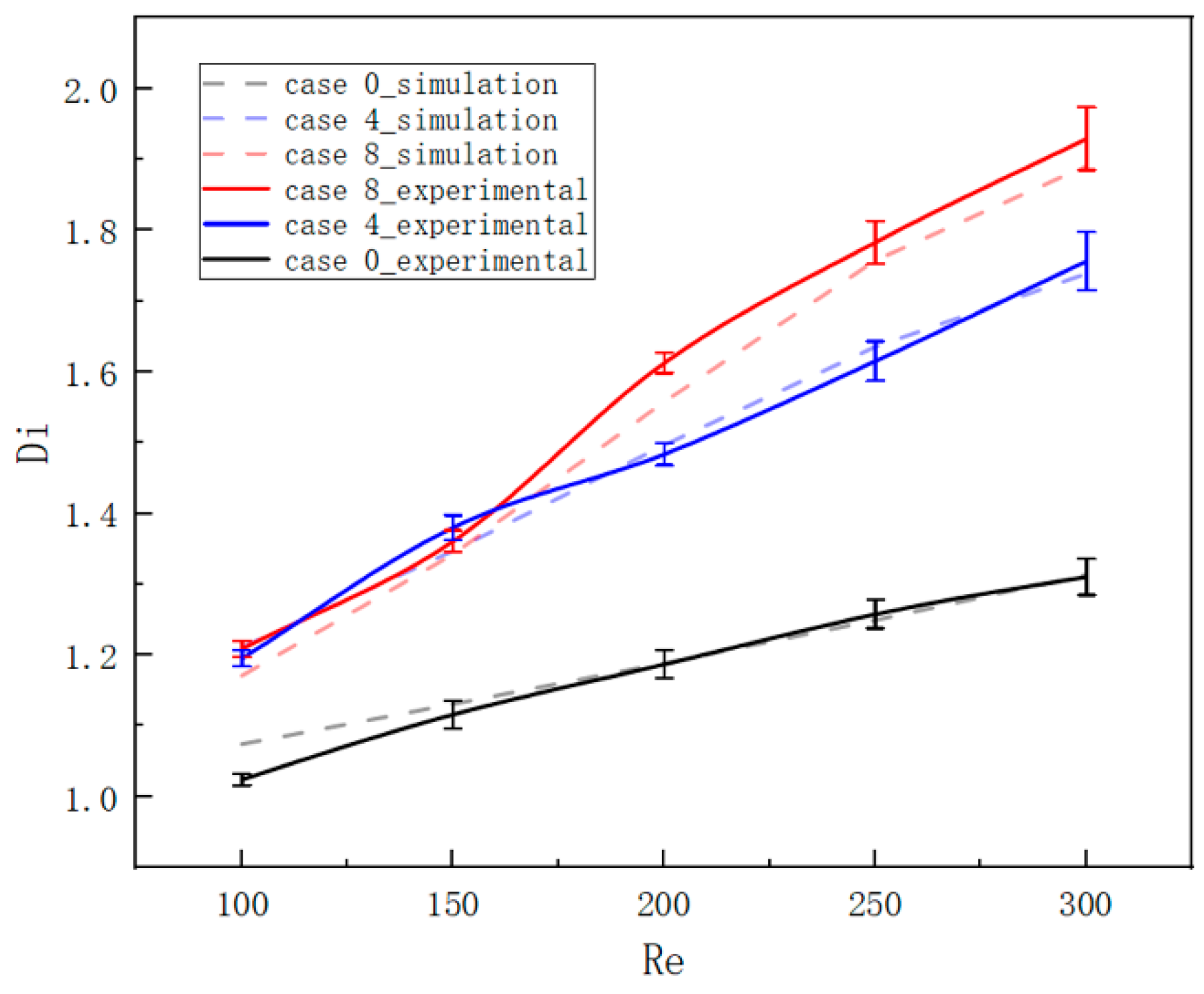

3.3. Comparison of Experimental and Simulation Results

4. Conclusions

- (1)

- This research has established that modifications to the flow field substantially affect the diodicity of the TV. The position of baffles at the outlet is instrumental in enhancing optimization, with the most significant improvements being observed when baffles are positioned below the outlet.

- (2)

- When augmenting the number of baffles, it is imperative to meticulously consider their layout and interactions to minimize flow losses and mitigate adverse effects on flow field structures. A setup with two baffles that generates a non-uniform flow field exerts both beneficial and deleterious effects on the optimization of the diodicity of Tesla Valves (TVs). Positioning baffles below the inlet can enhance diodicity to a certain degree, whereas positioning them above the inlet is counterproductive to the optimization process.

- (3)

- In TVs, the forward flow predominantly traverses the straight channel branches, leading to minimal variation in the drag experienced by the fluid. Consequently, a structure that directs fluid preferentially into arc channels to enhance reverse flow resistance and prevents obstructions in areas prone to vortex formation, such as above the inlet, achieves superior optimization outcomes.

- (4)

- Baffles positioned both below the inlet and the outlet yield the optimal enhancement in diodicity, with an optimization magnitude exceeding 40%. These outcomes are predicated on the specific baffle parameters delineated in the preceding text. When a single baffle is positioned, one situated below the outlet achieves a notable increase in diodicity, surpassing 30%.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Tesla, N. Valvular Conduit. U.S. Patent 1329559A, 3 February 1920. [Google Scholar]

- Wang, C.-T.; Chen, Y.-M.; Hong, P.-A.; Wang, Y.-T. Tesla valves in micromixers. Int. J. Chem. React. Eng. 2014, 12, 397–403. [Google Scholar] [CrossRef]

- Qian, J.-Y.; Hou, C.-W.; Li, X.-J.; Jin, Z.-J. Actuation mechanism of microvalves: A review. Micromachines 2020, 11, 172. [Google Scholar] [CrossRef] [PubMed]

- Lin, S.; Zhao, L.; Guest, J.K.; Weihs, T.P.; Liu, Z. Topology optimization of fixed-geometry fluid diodes. J. Mech. Des. 2015, 137, 081402. [Google Scholar] [CrossRef]

- Tesař, V. Time-Delay Circuits for Fluidic Oscillators and Pulse Shapers. Energies 2019, 12, 3071. [Google Scholar] [CrossRef]

- Bohm, S.; Phi, H.B.; Moriyama, A.; Runge, E.; Strehle, S.; König, J.; Cierpka, C.; Dittrich, L. Highly efficient passive Tesla valves for microfluidic applications. Microsyst. Nanoeng. 2022, 8, 97. [Google Scholar] [CrossRef]

- Buglie, W.L.N.; Tamrin, K.F.; Sheikh, N.A.; Yasin, M.F.M.; Mohamaddan, S. Enhanced fluid mixing using a reversed multistage Tesla micromixer. Chem. Eng. Technol. 2022, 45, 1255–1263. [Google Scholar] [CrossRef]

- Wang, J.; Cui, B.; Liu, H.; Chen, X.; Li, Y.; Wang, R.; Lang, T.; Yang, H.; Li, L.; Pan, H.; et al. Tesla valve-based flexible microhybrid chip with unidirectional flow properties. ACS Omega 2022, 7, 31744–31755. [Google Scholar] [CrossRef]

- Wang, H.; Chen, X. Optimization of tesla valve-typed micromixer based on simulated annealing algorithm. Surf. Rev. Lett. 2022, 29, 2250094. [Google Scholar] [CrossRef]

- Derakhshan, S.; Beigzadeh, B.; Rashidi, M.; Pourrahmani, H. Performance improvement and two-phase flow study of a piezoelectric micropump with tesla nozzle-diffuser microvalves. J. Appl. Fluid Mech. 2019, 12, 341–350. [Google Scholar] [CrossRef]

- Yao, Y.; Zhou, Z.; Liu, H.; Li, T.; Gao, X. Valveless piezoelectric pump with reverse diversion channel. Electronics 2021, 10, 1712. [Google Scholar] [CrossRef]

- Hyun, W.J.; Kumar, S.; Francis, L.F.; Frisbie, C.D. Open-channel microfluidic diodes based on two-tier junctions. Appl. Phys. Lett. 2018, 113, 193701. [Google Scholar] [CrossRef]

- Yang, C.; Li, W.; Zhao, Y.; Shang, L. Flexible liquid-diode microtubes from multimodal microfluidics. Proc. Natl. Acad. Sci. USA 2024, 121, e2402331121. [Google Scholar] [CrossRef]

- Nguyen, Q.M.; Abouezzi, J.; Ristroph, L. Early turbulence and pulsatile flows enhance diodicity of Tesla’s macrofluidic valve. Nat. Commun. 2021, 12, 2884. [Google Scholar] [CrossRef]

- Tadyszak, K.; Jäger, A.; Pánek, J.; Hrubý, M. Design and Optimization of Microfluidic Vortex Diode. Math. Comput. Appl. 2024, 29, 97. [Google Scholar] [CrossRef]

- Lin, Z.; Yin, D.; Tao, J.; Li, Y.; Sun, J.; Zhu, Z. Effect of Shaft Diameter on the Hydrodynamic Torque of Butterfly Valve Disk. J. Fluids Eng. Trans. ASME 2020, 142, 111202. [Google Scholar] [CrossRef] [PubMed]

- Lam, R.H.W.; Li, W.J. A Digitally Controllable Polymer-Based Microfluidic Mixing Module Array. Micromachines 2012, 3, 279–294. [Google Scholar] [CrossRef]

- Turowski, M.; Chen, Z.; Przekwas, A. Automated generation of compact models for fluidic microsystems. Analog Integr. Circuits Signal Process. 2001, 29, 27–36. [Google Scholar] [CrossRef]

- de Vries, S.; Florea, D.; Homburg, F.; Frijns, A. Design and operation of a Tesla-type valve for pulsating heat pipes. Int. J. Heat Mass Transf. 2017, 105, 1–11. [Google Scholar] [CrossRef]

- Zhang, S.; Winoto, S.H.; Low, H.T. Performance simulations of Tesla microfluidic valves. In Proceedings of the International Conference on Integration and Commercialization of Micro and Nanosystems, Sanya, China, 10–13 January 2007; Volume 42657, pp. 15–19. [Google Scholar] [CrossRef]

- Qian, J.-Y.; Chen, M.-R.; Liu, X.-L.; Jin, Z.-J. A numerical investigation of the flow of nanofluids through a micro Tesla valve. J. Zhejiang Univ.-Sci. A 2019, 20, 50–60. [Google Scholar] [CrossRef]

- Gamboa, A.R.; Morris, C.J.; Forster, F.K. Optimization of the Fixed-Geometry Valve for Increased Micropump Performance. In Proceedings of the ASME 2003 International Mechanical Engineering Congress and Exposition, Washington, DC, USA, 15–21 November 2003. [Google Scholar] [CrossRef]

- Liu, Z.; Shao, W.Q.; Sun, B.H. Scaling law of the one-direction flow characteristics of symmetric Tesla valve. Eng. Appl. Comput. Fluid Mech. 2022, 16, 441–452. [Google Scholar] [CrossRef]

- Dennai, B.; Belboukhari, M.E.; Chekifi, T.; Khelfaoui, R. Numerical investigation of flow dynamic in mini-channel: Case of a mini diode tesla. Fluid Dyn. Mater. Process. 2016, 12, 102–110. [Google Scholar] [CrossRef]

- Forster, F.K.; Williams, B.E. Parametric Design of Fixed-Geometry Microvalves: The Tesser Valve. In Proceedings of the ASME International Mechanical Engineering Congress & Exposition, New Orleans, LA, USA, 17–22 November 2002. [Google Scholar] [CrossRef]

- Mohammadzadeh, K.; Kolahdouz, E.M.; Shirani, E.; Shafii, M.B. Numerical study on the performance of Tesla type microvalve in a valveless micropump in the range of low frequencies. J. Micro-Bio Robot. 2013, 8, 145–159. [Google Scholar] [CrossRef]

- Raffel, J.; Ansari, S.; Nobes, D.S. An Experimental Investigation of Flow Phenomena in a Multistage Micro-Tesla Valve. J. Fluids Eng. Trans. ASME 2021, 143, 111205. [Google Scholar] [CrossRef]

- Thompson, S.M.; Paudel, B.J.; Jamal, T.; Walters, D.K. Numerical Investigation of Multistaged Tesla Valves. J. Fluids Eng. 2014, 136, 081102. [Google Scholar] [CrossRef]

- Deng, Y.; Liu, Z.; Zhang, P.; Wu, Y.; Korvink, J.G. Optimization of no-moving part fluidic resistance microvalves with low reynolds number. In Proceedings of the 2010 IEEE 23rd International Conference on Micro Electro Mechanical Systems (MEMS), Hong Kong, China, 24–28 January 2010. [Google Scholar] [CrossRef]

- Dong, X.; Liu, X. Bi-objective topology optimization of asymmetrical fixed-geometry microvalve for non-Newtonian flow. Microsyst. Technol. 2019, 25, 2471–2479. [Google Scholar] [CrossRef]

- Wang, P.; Hu, P.; Liu, L.; Xu, Z.; Wang, W.; Scheid, B. On the diodicity enhancement of multistage Tesla valves. Phys. Fluids 2023, 35, 052010. [Google Scholar] [CrossRef]

- Hu, P.; Wang, P.; Liu, L.; Ruan, X.; Zhang, L.; Xu, Z. Numerical investigation of Tesla valves with a variable angle. Phys. Fluids 2022, 34, 033603. [Google Scholar] [CrossRef]

- Nguyen, Q.M.; Oza, A.U.; Abouezzi, J.; Sun, G.; Childress, S.; Frederick, C.; Ristroph, L. Flow rectification in loopy network models of bird lungs. Phys. Rev. Lett. 2021, 126, 114501. [Google Scholar] [CrossRef]

- Van Nguyen, H.; Nguyen, H.Q.; Nguyen, V.D.; Seo, T.S. A 3D printed screw-and-nut based droplet generator with facile and precise droplet size controllability. Sens. Actuators B Chem. 2019, 296, 126676. [Google Scholar] [CrossRef]

- Naghash, T.H.; Haghgoo, A.M.; Bijarchi, M.A.; Ghassemi, M.; Shafii, M.B. Performance of microball micromixers using a programmable magnetic system by applying novel movement patterns. Sens. Actuators B Chem. 2024, 406, 135403. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhu, S.; Wang, P.; Liu, L.; Ding, C. Influence of Baffle Location on the Diodicity of Tesla Valves. Appl. Sci. 2025, 15, 5526. https://doi.org/10.3390/app15105526

Zhu S, Wang P, Liu L, Ding C. Influence of Baffle Location on the Diodicity of Tesla Valves. Applied Sciences. 2025; 15(10):5526. https://doi.org/10.3390/app15105526

Chicago/Turabian StyleZhu, Shengyu, Pengfei Wang, Li Liu, and Chuan Ding. 2025. "Influence of Baffle Location on the Diodicity of Tesla Valves" Applied Sciences 15, no. 10: 5526. https://doi.org/10.3390/app15105526

APA StyleZhu, S., Wang, P., Liu, L., & Ding, C. (2025). Influence of Baffle Location on the Diodicity of Tesla Valves. Applied Sciences, 15(10), 5526. https://doi.org/10.3390/app15105526