Condition Monitoring and Predictive Maintenance in Industrial Equipment: An NLP-Assisted Review of Signal Processing, Hybrid Models, and Implementation Challenges

Abstract

1. Introduction

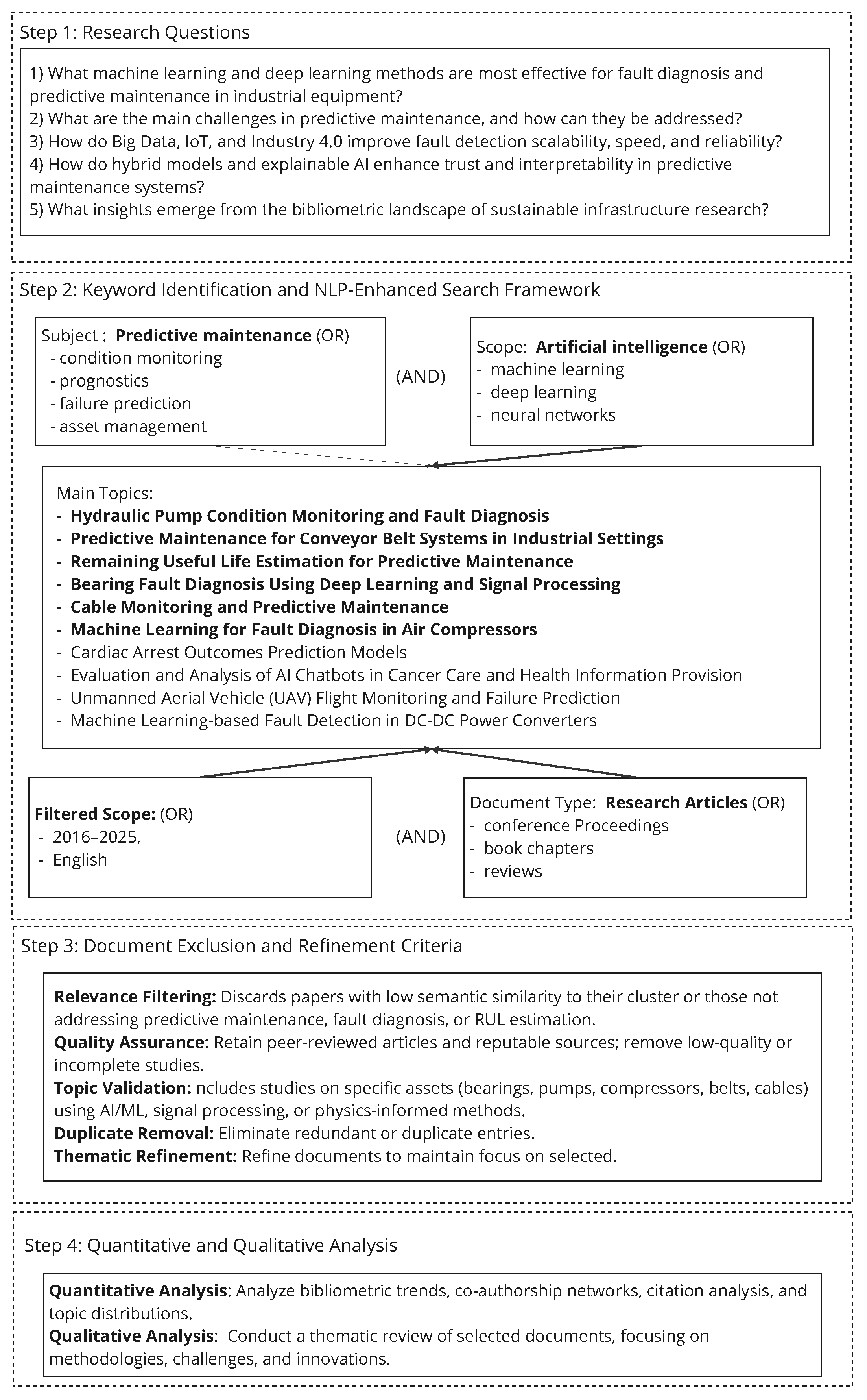

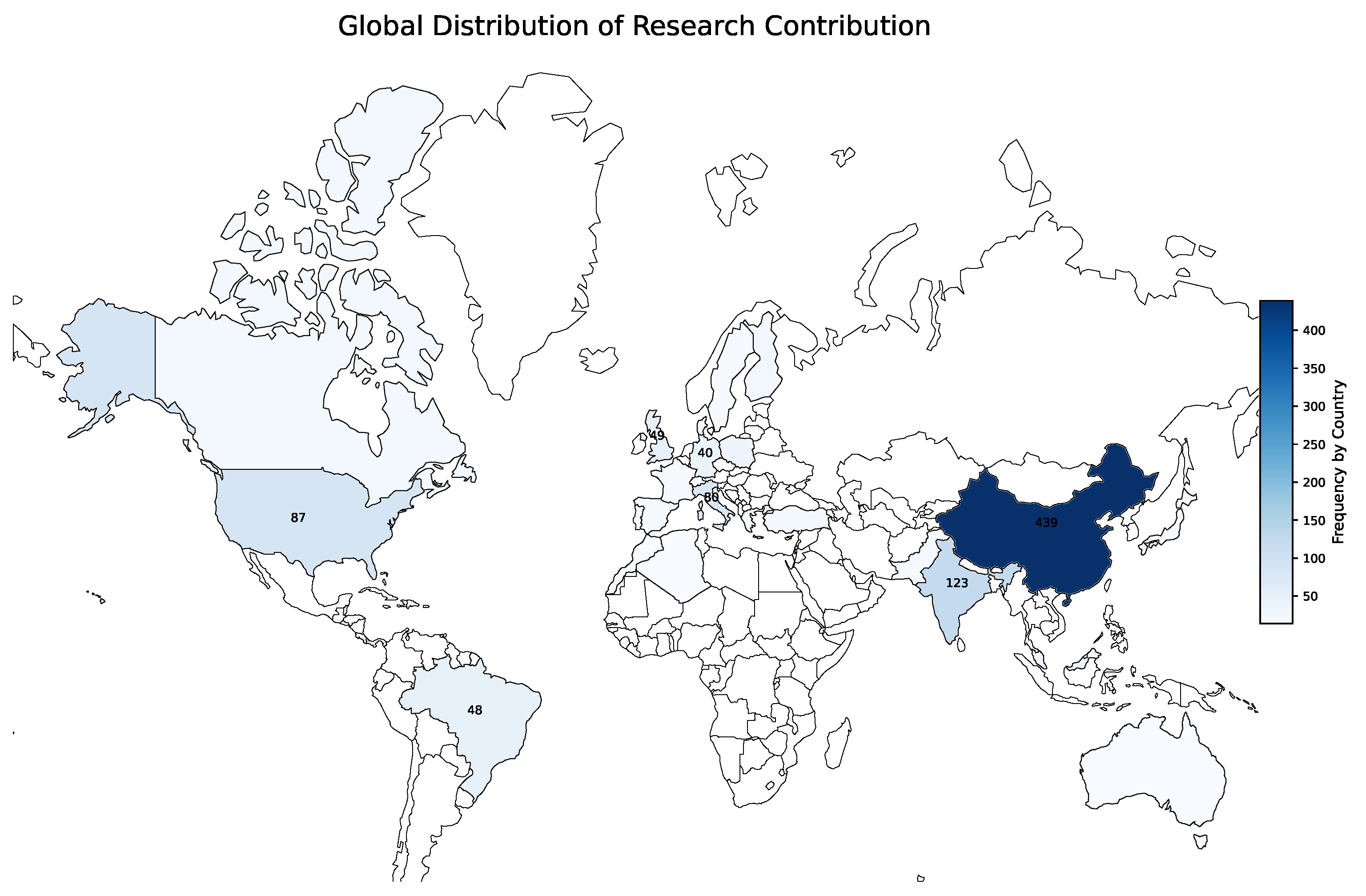

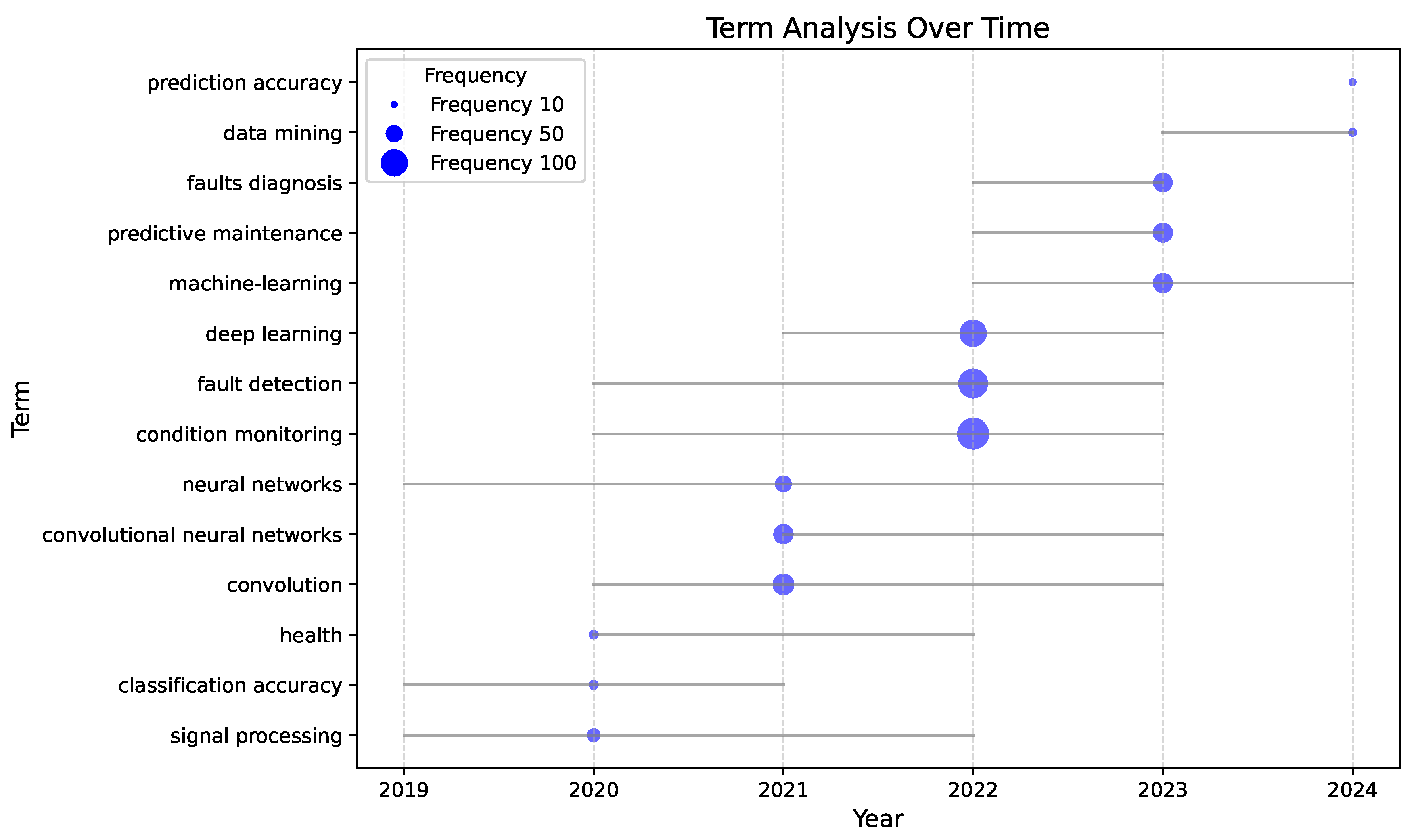

2. Methodology

TITLE-ABS-KEY("predictive maintenance" OR "condition monitoring" OR

"prognostics" OR "failure prediction" OR "asset management")

AND ("machine learning" OR "artificial intelligence" OR

"deep learning" OR "neural networks")

AND PUBYEAR > 2016 AND PUBYEAR < 2025

AND LIMIT-TO(LANGUAGE,"English")

AND LIMIT-TO(DOCTYPE,"ar","cp","ch","re")

- Citation strength. A dynamic threshold is applied to avoid bias against recent work: an article must be in at least the 60th percentile of citations for its publication year and document type (journal, conference, or review). For articles published in 2023–2024—where absolute counts are still low—we accept ≥3 citations in Web of Science.

- Thematic pertinence. A paper must (i) explicitly address at least one target asset class (bearings, pumps, compressors, conveyor belts, or cables) and (ii) apply an AI/ML, signal processing, or hybrid physics–data technique to condition monitoring, fault diagnosis, or RUL estimation.

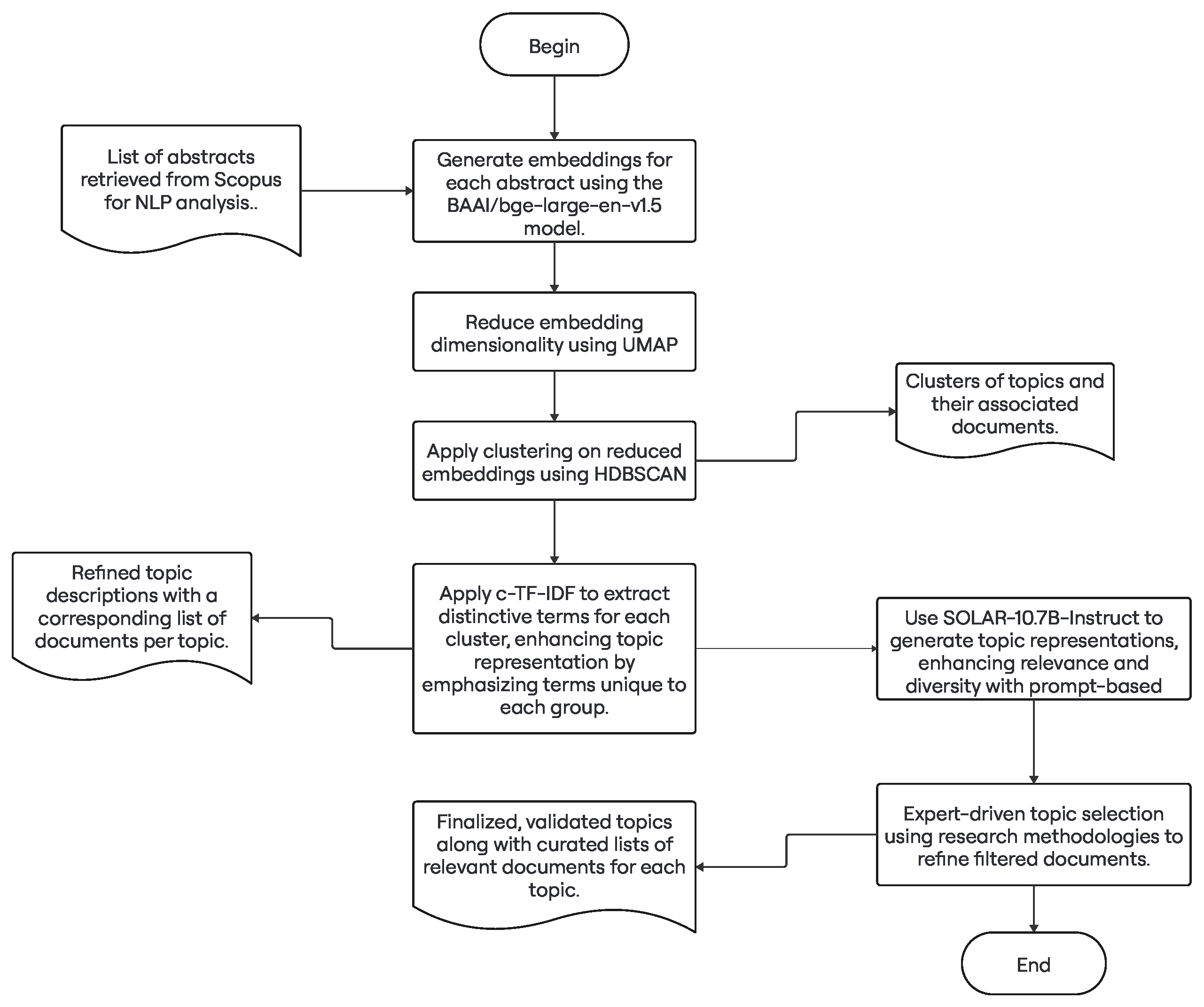

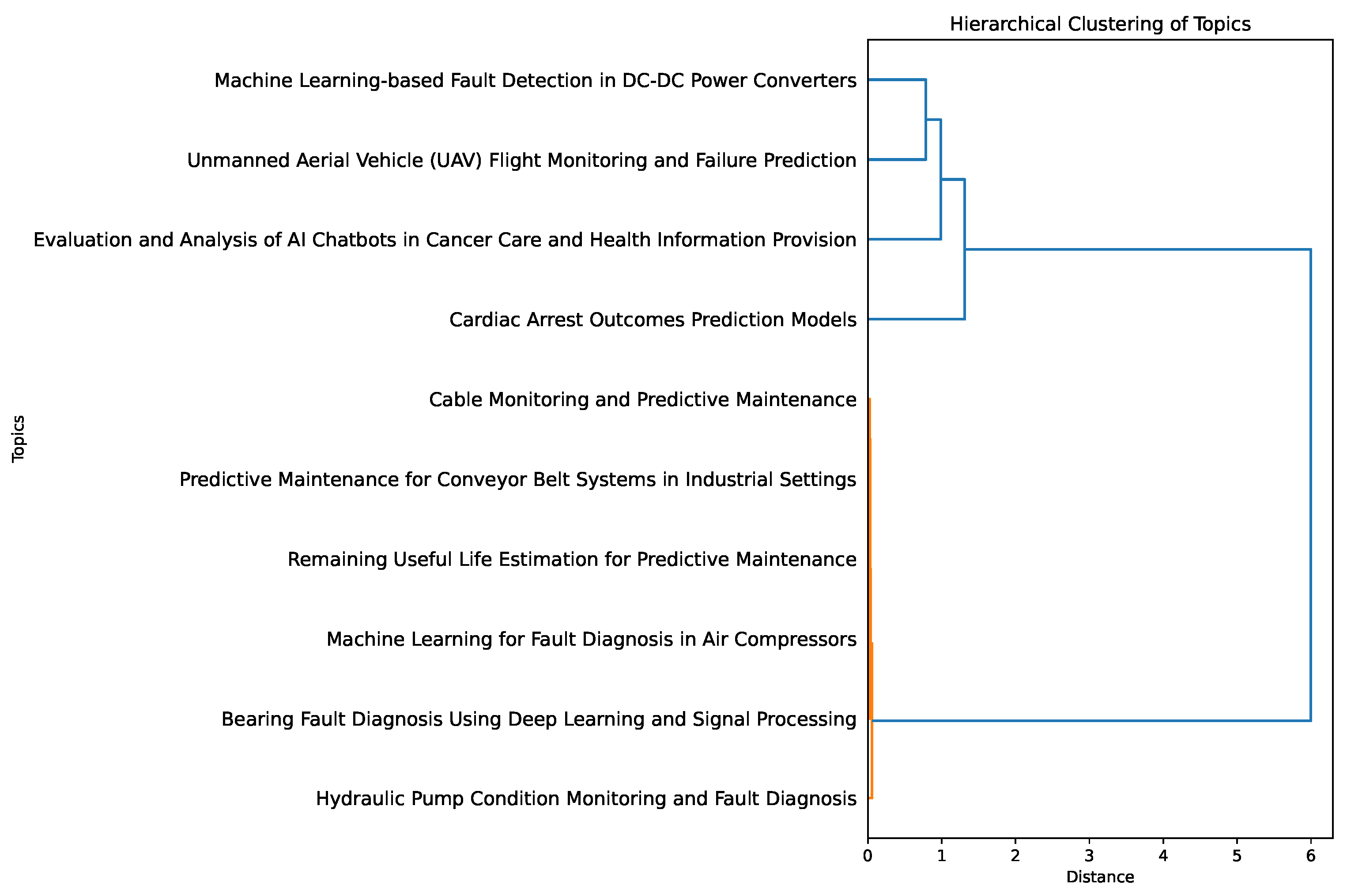

Embedding Generation and NLP Approaches in the SLR Framework

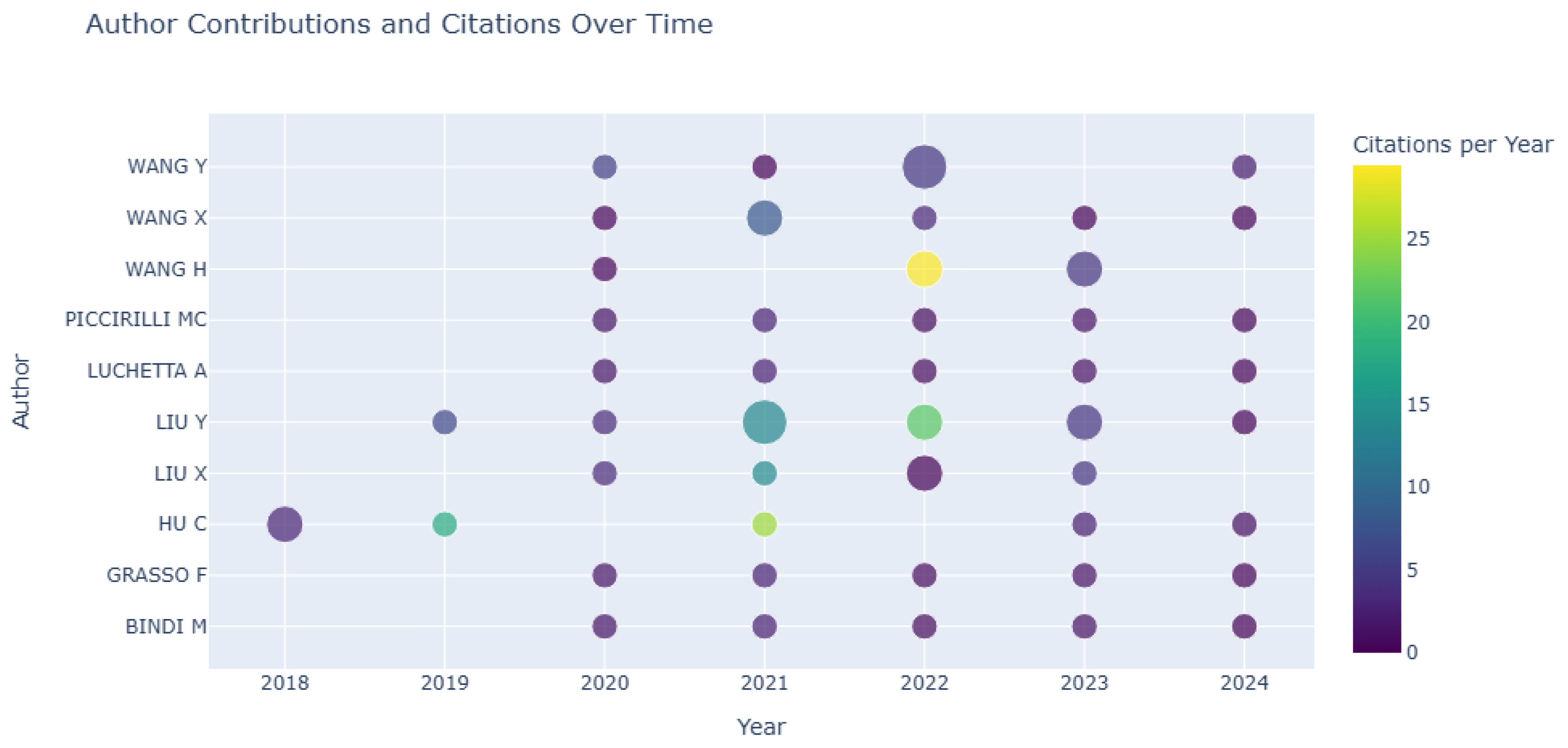

3. Quantitative Analysis of Condition Monitoring and Predictive Maintenance

4. Qualitative Analysis of Fault Diagnosis and Predictive Maintenance

4.1. Industrial Compressors: State of the Art and Emerging Trends

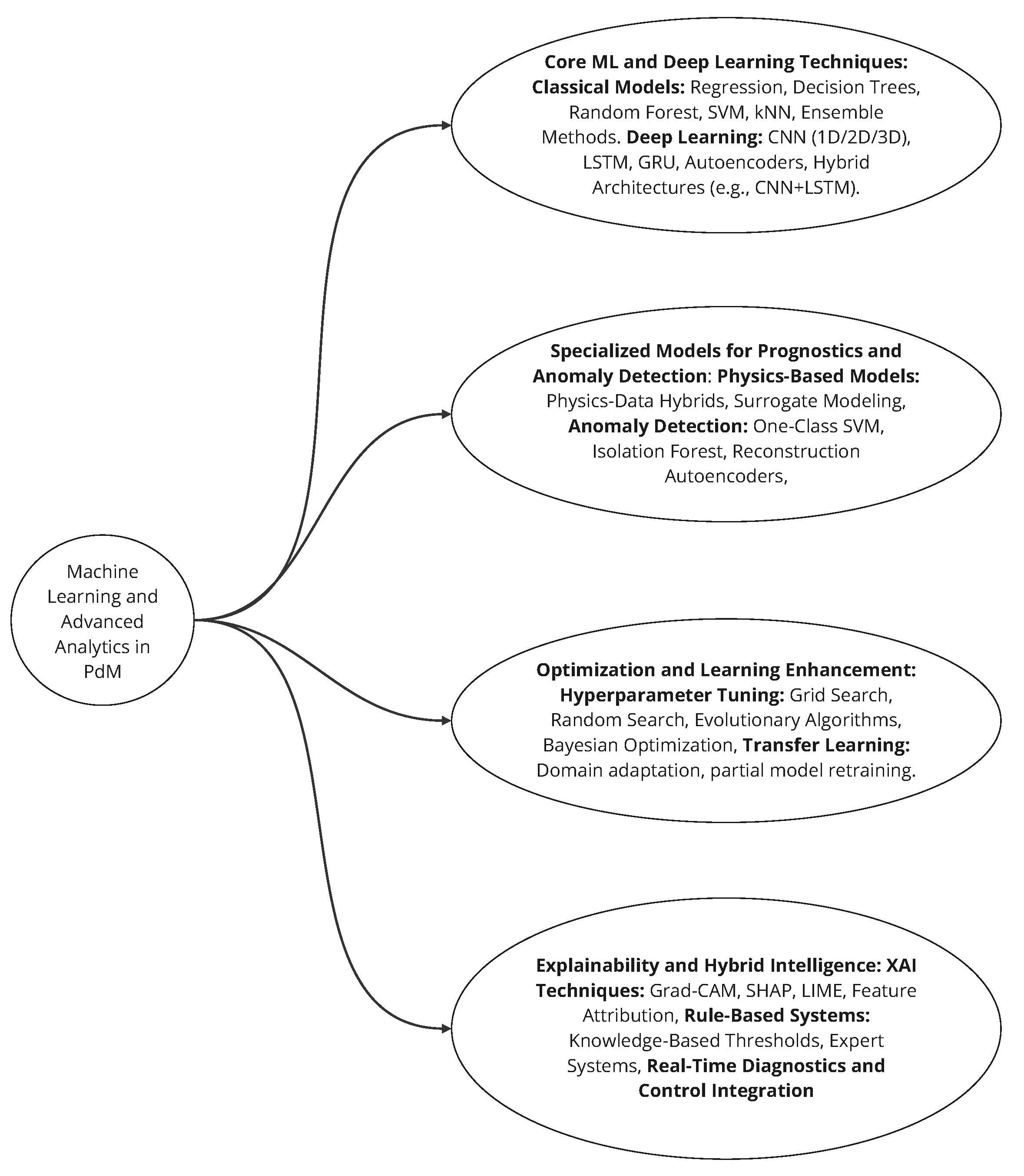

- Machine learning (ML). Classical models—linear/polynomial regression, random forest, gradient boosting, kNN, decision trees, SVM, and LDA/QDA—and neural baselines such as MLP and PNN dominate early-stage deployments [29,30,31,32]. Recent studies favour ensembles or stacking (e.g., kNN + gradient boosting with a ridge meta-learner) and anomaly pipelines that combine isolation forest with regression refinements.

- Deep learning (DL). CNNs extract hierarchical features from raw vibration or spectrogram inputs, sequence models (LSTM, GRU) capture temporal dependencies, and hybrid layouts—TCN–LSTM and attention-augmented autoencoders—boost sensitivity to subtle degradation patterns [33,34,35]. Transfer learning from large acoustic datasets is gaining traction where labelled compressor data are scarce.

- Signal processing and feature engineering. Wavelet packets (MODWPT, DWT), CEEMDAN, and FFT/STFT remain indispensable for denoising and isolating fault-signature frequencies. Statistical descriptors (RMS, skewness, kurtosis, and variance) feed ML pipelines, while GA, PCA, and kernel PCA support feature selection and dimensionality reduction [36,37,38].

- Physics-based and hybrid models. Thermofluidodynamic simulations of heat-pump or refrigeration cycles provide virtual sensors for quantities that are difficult to measure in situ; polytropic-exponent or correlations help pinpoint valve and leakage defects. Neural surrogates accelerate what-if analyses, replacing expensive CFD or finite-element solvers [38,39,40].

4.2. Machine Learning-Driven Fault Detection and Maintenance in Cable Systems

4.3. Remaining-Useful-Life Estimation: A Cross-Cutting Framework and Key Examples

4.4. Emerging Trends in Hydraulic Pump Condition Monitoring and Fault Diagnosis

4.5. Bearing Fault Diagnosis as a Common Function in Rotating Equipment

4.6. Artificial Intelligence and Predictive Maintenance in Conveyor Belt Systems

5. Discussion and Future Research Directions

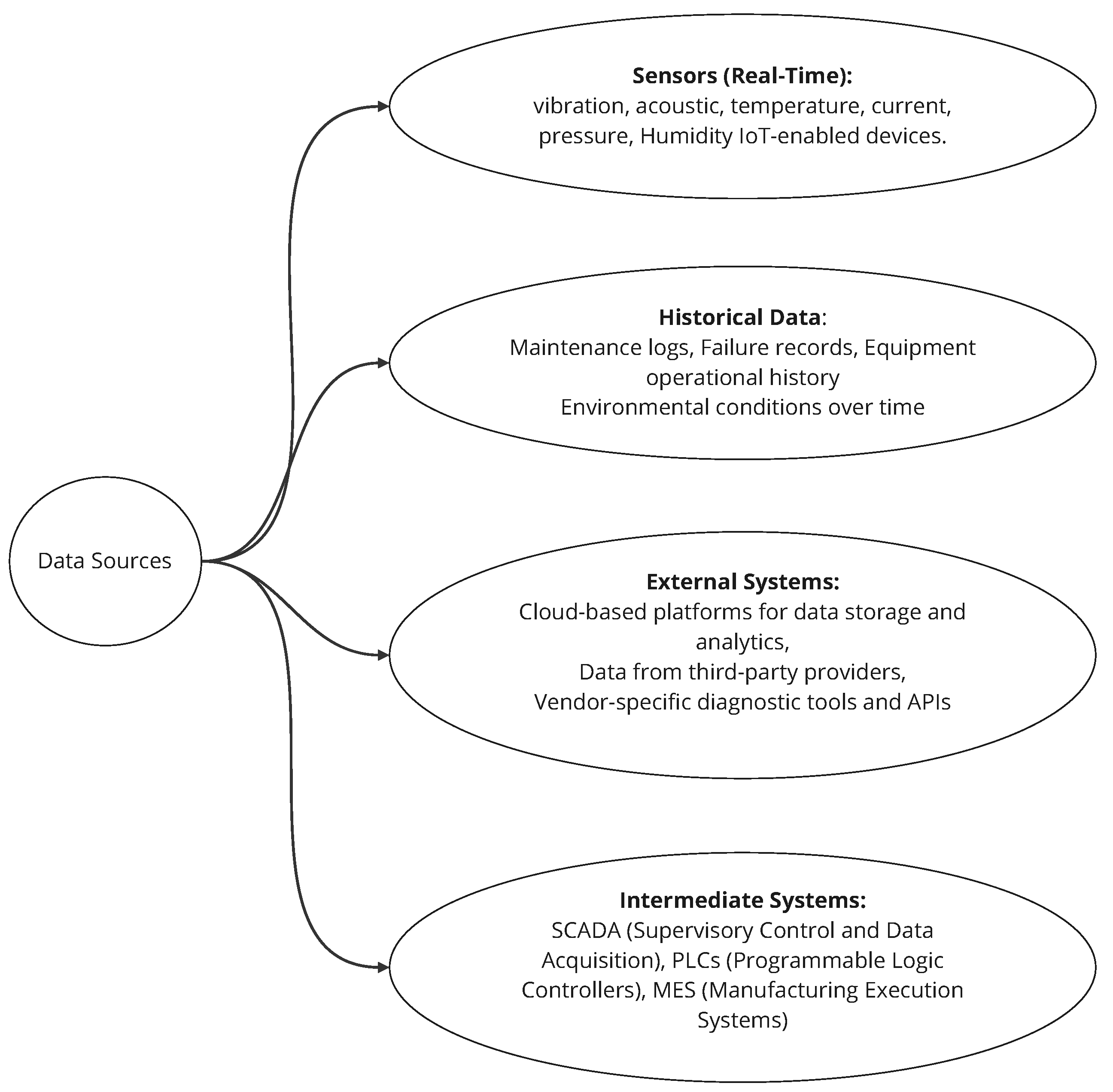

5.1. Data Sources and Their Integration

5.2. Signal Processing and Data Preparation

5.2.1. Fourier-Based Methods

5.2.2. Wavelet Transform and Time-Frequency Analysis

5.2.3. Hybrid Approaches and Emerging Perspectives

5.2.4. Challenges and Future Directions in Signal Processing

5.3. Machine Learning, Advanced Analytics, and Explainability

5.4. Hybrid Physics–Data Models: A Bridge Between First-Principles Insight and Statistical Learning

- Taxonomy of hybrid approaches.

- Physics-informed neural networks (PINNs). Recent studies [110,113] minimise a joint loss that combines data misfit with residuals of the underlying motion or wear equations. By forcing the latent representation to satisfy kinematic periodicity or impulse-response decay, PINNs raise diagnostic accuracy by 2–5 pp compared with purely data-driven CNN baselines while requiring only ∼50% of the original labelled samples.

- Grey-box digital twins with learned surrogates. In compressor and pump studies (e.g., those by Du et al. [40] and Rousseau et al. [39]), thermodynamic or CFD simulations generate synthetic fault trajectories that feed a lightweight surrogate network (LSTM, RBF, or autoencoder). Once calibrated, the surrogate runs three to four orders of magnitude faster than the full solver, enabling real-time residual generation for anomaly scoring.

- Physics-guided feature engineering. Works on cavitation and bearing spalls (e.g., thos eby Wu et al. [84] and Huang et al. [37]) first isolate carrier or modulated frequencies predicted by fluid–structure interaction theory, then feed those physically meaningful sub-bands to classical classifiers (RF or SVM) or to compact CNNs. This grey-box preprocessing typically cuts feature dimensionality by 60–80% and improves class-imbalance robustness.

- Why does the hybrid route matter?

- Label scarcity. Most industrial assets fail rarely; embedding conservation constraints or simulator priors substitutes for the thousands of fault cycles that deep learners usually demand.

- Extrapolation and trust. When operating conditions drift outside the training envelope, hard-coded physical laws act as safety rails that curb unphysical predictions and ease regulatory acceptance—an advantage repeatedly stressed by domain experts during our validation workshops.

- Computational frugality. Grey-box surrogates such as the self-adaptive RBF used by Du et al. [40] reduce inference latency to below 100 ms on edge-grade CPUs, satisfying the cycle times of most PLC-controlled plants.

- Frontier challenges.

- Automatic weighting of physics vs. data losses. Nearly every PINN study tunes the balance term via grid search; adaptive schemes (e.g., dynamic gradient harmonisation) remain to be tested on industrial datasets.

- Standardised benchmarks. Cross-study comparability is hampered by heterogeneous simulators and proprietary datasets. A curated, open repository pairing raw signals with physics metadata (steel grade, lubricant viscosity, and ambient pressure) would accelerate method transfer across domains.

- Research agenda and practical tips.

- Develop lightweight PINN kernels that leverage fast spectral convolutions, enabling on-device training for assets with intermittent connectivity.

- Combine active learning with simulator-in-the-loop sampling to target high-value regions of the state space, reducing synthetic data redundancy.

- Integrate explainable AI overlays such as DeepSHAP in physics-guided layers (see Keleko et al. [91]) so that operators can trace residual peaks to physically interpretable variables (e.g., pressure ratio and specific damping).

- Report energy and memory footprints alongside accuracy, following the standardization guidelines outlined in the IEEE P2802 standard [139] to facilitate deployment decisions in resource-constrained industrial environments.

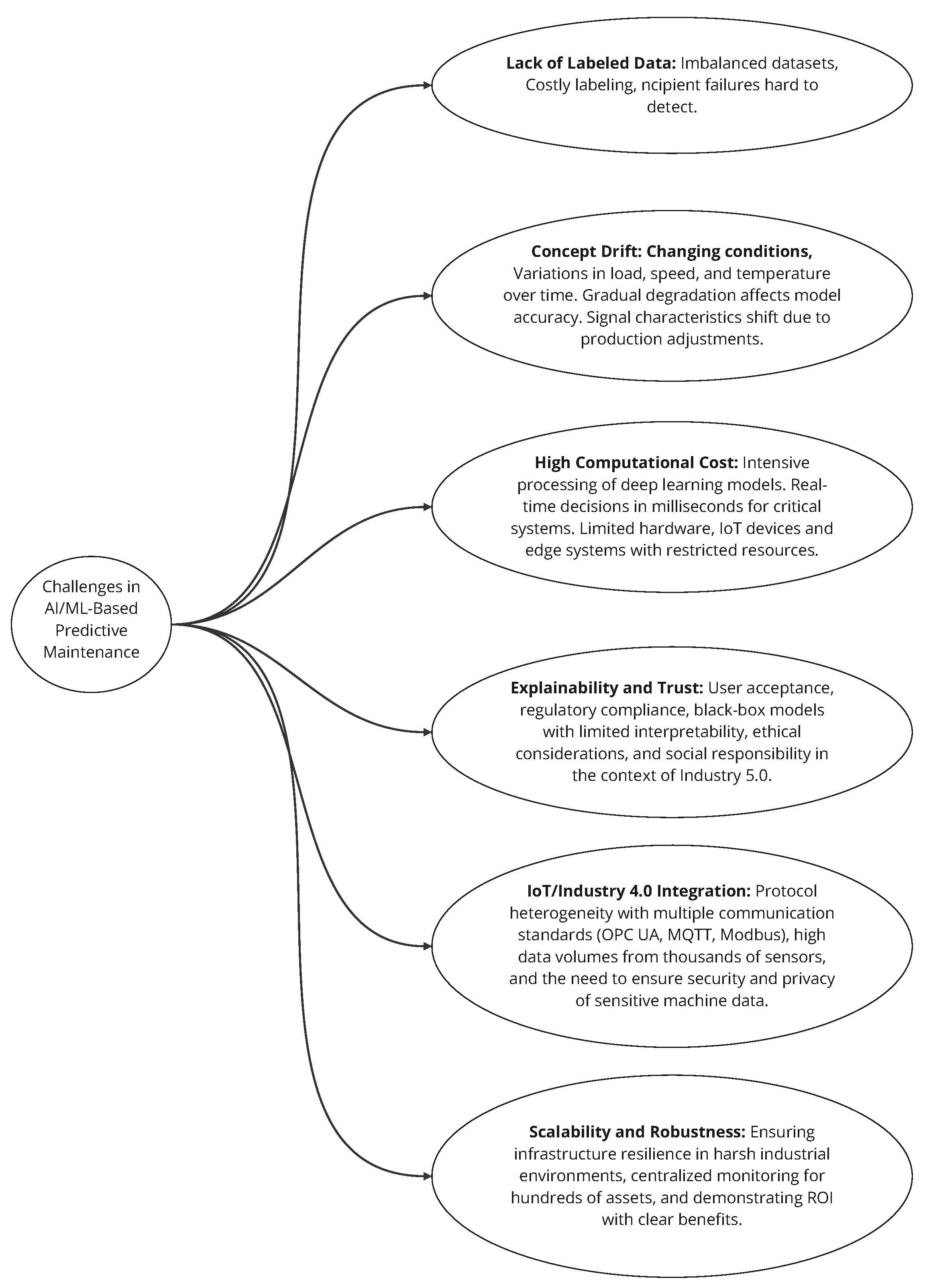

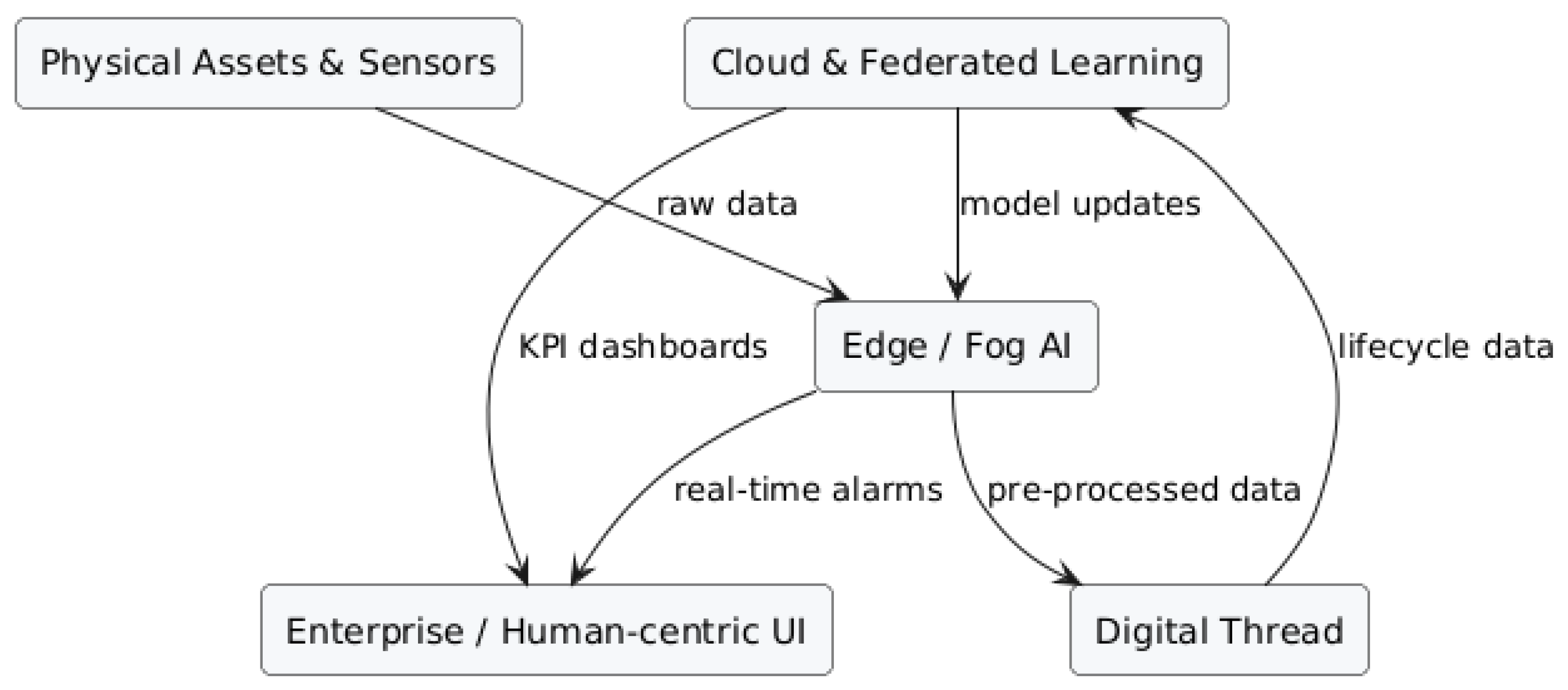

5.5. Challenges and Industry 5.0 Outlook

5.6. Concluding Remarks on Future Directions

5.7. Integration with Classical Maintenance Management Models

Future Work—Key Questions (Summary Box)

- Lightweight transforms: Can approximate wavelet/EMD variants run in real time on edge MCUs?

- Concept-drift handling: How often must models be retrained, and which incremental schemes work best in safety-critical plants?

- Physics-guided explainability: What level of physical fidelity is sufficient to gain operator trust while keeping models compact?

- Federated data sharing: Which privacy-preserving protocols are acceptable for cross-company PdM benchmarks?

- Unified ROI metrics: How should downtime, energy, and carbon savings be normalised across industries?

- Human-centric UIs: Which visual cues (e.g., causal graphs and SHAP heat maps) most effectively support TPM operators?

6. Conclusions

Reporting of Physical and Environmental Metadata

Supplementary Materials

Funding

Acknowledgments

Conflicts of Interest

Abbreviations

| AE | Acoustic Emission or Autoencoder (depending on context) |

| AI | Artificial Intelligence |

| AL | Active Learning |

| ANN | Artificial Neural Network |

| ARIMA | AutoRegressive Integrated Moving Average |

| BDL | Bayesian Deep Learning |

| BN | Bayesian Network |

| CAD | Computer-Aided Design |

| CBM | Condition-Based Maintenance |

| CFD | Computational Fluid Dynamics |

| CLAHE | Contrast-Limited Adaptive Histogram Equalization |

| CNN | Convolutional Neural Network |

| COT | Computed Order Tracking |

| CWT | Continuous Wavelet Transform |

| DT | Digital Twin or Decision Tree (depending on context) |

| DTW | Dynamic Time Warping |

| DWT | Discrete Wavelet Transform |

| EDA | Encoder–Decoder with Attention |

| EMD | Empirical Mode Decomposition |

| FDR | Frequency-Domain Reflectometry |

| FFT | Fast Fourier Transform |

| FMECA | Failure Mode, Effects, and Criticality Analysis |

| GA | Genetic Algorithm |

| GB | Gradient Boosting |

| GP | Gaussian Process |

| GRU | Gated Recurrent Unit |

| HDBSCAN | Hierarchical Density-Based Spatial Clustering |

| HI | Health Index |

| HSA | Hierarchical Symbolic Analysis |

| IoT | Internet of Things |

| JL-CNN | Joint Learning Convolutional Neural Network |

| kNN | k-Nearest Neighbours |

| KPCA | Kernel Principal Component Analysis |

| LDA | Linear Discriminant Analysis |

| LLM | Large Language Model |

| LMD | Local Mean Decomposition |

| LSTM | Long Short-Term Memory |

| MC | Monte Carlo (e.g., MC Dropout) |

| MFCC | Mel-Frequency Cepstral Coefficient |

| ML | Machine Learning |

| MLP | Multi-Layer Perceptron |

| MODWPT | Maximal Overlap Discrete Wavelet Packet Transform |

| MVN | Multi-Valued Neuron |

| NARX | Nonlinear AutoRegressive Model with eXogenous Inputs |

| NLP | Natural Language Processing |

| PCA | Principal Component Analysis |

| PIResNet | Physics-Informed Residual Network |

| PSO | Particle Swarm Optimization |

| QDA | Quadratic Discriminant Analysis |

| RBF | Radial Basis Function |

| RF | Random Forest |

| RL | Reinforcement Learning |

| RNN | Recurrent Neural Network |

| RUL | Remaining Useful Life |

| SAE | Stacked Autoencoder |

| SCR | Squared Current Ratio |

| SDMS | Self-Diagnostic Monitoring System |

| SHAP | SHapley Additive exPlanation |

| SI | State Indicator |

| SNR | Signal-to-Noise Ratio |

| SVM | Support Vector Machine |

| TDR | Time-Domain Reflectometry |

| t-SNE | t-distributed Stochastic Neighbour Embedding |

| TSA | Time Synchronous Average |

| UMAP | Uniform Manifold Approximation and Projection |

| VGG | Visual Geometry Group (CNN family) |

| VMD | Variational Mode Decomposition |

| VRBG | Variable Reluctance Bearing Generator |

| XAI | Explainable Artificial Intelligence |

| XGBoost | Extreme Gradient Boosting |

| ZSC | Zero Sequence Current |

References

- Sahu, A.R.; Palei, S.K.; Mishra, A. Data-driven fault diagnosis approaches for industrial equipment: A review. Expert Syst. 2024, 41, e13360. [Google Scholar] [CrossRef]

- Kumar, S.; Goyal, D.; Dang, R.K.; Dhami, S.S.; Pabla, B. Condition based maintenance of bearings and gears for fault detection–A review. Mater. Today Proc. 2018, 5, 6128–6137. [Google Scholar] [CrossRef]

- Sheikh, M.A.; Bakhsh, S.T.; Irfan, M.; Nor, N.b.M.; Nowakowski, G. A review to diagnose faults related to three-phase industrial induction motors. J. Fail. Anal. Prev. 2022, 22, 1546–1557. [Google Scholar] [CrossRef]

- Shahin, M.; Chen, F.F.; Hosseinzadeh, A.; Zand, N. Using machine learning and deep learning algorithms for downtime minimization in manufacturing systems: An early failure detection diagnostic service. Int. J. Adv. Manuf. Technol. 2023, 128, 3857–3883. [Google Scholar] [CrossRef]

- Nunes, P.; Santos, J.; Rocha, E. Challenges in predictive maintenance—A review. CIRP J. Manuf. Sci. Technol. 2023, 40, 53–67. [Google Scholar] [CrossRef]

- International Energy Agency. Digitalisation and Energy. 2017. Available online: https://www.iea.org/reports/digitalisation-and-energy (accessed on 7 May 2025).

- Ni, Q.; Ji, J.; Halkon, B.; Feng, K.; Nandi, A.K. Physics-Informed Residual Network (PIResNet) for rolling element bearing fault diagnostics. Mech. Syst. Signal Process. 2023, 200, 110544. [Google Scholar] [CrossRef]

- Dong, Y.; Li, Y.; Zheng, H.; Wang, R.; Xu, M. A new dynamic model and transfer learning based intelligent fault diagnosis framework for rolling element bearings race faults: Solving the small sample problem. ISA Trans. 2022, 121, 327–348. [Google Scholar] [CrossRef]

- Lu, Z.; Liang, L.; Zhu, J.; Zou, W.; Mao, L. Rotating Machinery Fault Diagnosis Under Multiple Working Conditions via A Time Series Transformer Enhanced by Convolutional Neural Network. IEEE Trans. Instrum. Meas. 2023, 72, 3533611. [Google Scholar] [CrossRef]

- Sang, K.X.; Shang, J.; Lin, T.R. Synchroextracting transform and deep residual network for varying speed bearing fault diagnostic. J. Vib. Eng. Technol. 2023, 11, 343–353. [Google Scholar] [CrossRef]

- Wang, Y.; Ning, D.; Feng, S. A novel capsule network based on wide convolution and multi-scale convolution for fault diagnosis. Appl. Sci. 2020, 10, 3659. [Google Scholar] [CrossRef]

- Chen, J.; Li, D.; Huang, R.; Chen, Z.; Li, W. Multi-Scale Dilated Convolutional Auto-Encoder Network for Weak Feature Extraction and Health Condition Detection. In Proceedings of the 2024 IEEE International Instrumentation and Measurement Technology Conference (I2MTC), Glasgow, UK, 20–23 May 2024; pp. 1–6. [Google Scholar]

- Wang, Z.; Zhang, M.; Chen, H.; Li, J.; Li, G.; Zhao, J.; Yao, L.; Zhang, J.; Chu, F. A generalized fault diagnosis framework for rotating machinery based on phase entropy. Reliab. Eng. Syst. Saf. 2025, 256, 110745. [Google Scholar] [CrossRef]

- Liu, S.; Ji, Z.; Zhang, Z.; Wang, Y. An improved deep transfer learning method for rotating machinery fault diagnosis based on time-frequency diagram and pre-training model. IEEE Trans. Instrum. Meas. 2024, 73, 2507512. [Google Scholar]

- Mushtaq, S.; Islam, M.M.; Sohaib, M. Deep learning aided data-driven fault diagnosis of rotatory machine: A comprehensive review. Energies 2021, 14, 5150. [Google Scholar] [CrossRef]

- Garcia, J.; Villavicencio, G.; Altimiras, F.; Crawford, B.; Soto, R.; Minatogawa, V.; Franco, M.; Martínez-Muñoz, D.; Yepes, V. Machine learning techniques applied to construction: A hybrid bibliometric analysis of advances and future directions. Autom. Constr. 2022, 142, 104532. [Google Scholar] [CrossRef]

- García, J.; Leiva-Araos, A.; Diaz-Saavedra, E.; Moraga, P.; Pinto, H.; Yepes, V. Relevance of Machine Learning Techniques in Water Infrastructure Integrity and Quality: A Review Powered by Natural Language Processing. Appl. Sci. 2023, 13, 12497. [Google Scholar] [CrossRef]

- McInnes, L.; Healy, J.; Melville, J. Umap: Uniform manifold approximation and projection for dimension reduction. arXiv 2018, arXiv:1802.03426. [Google Scholar]

- Campello, R.J.; Moulavi, D.; Sander, J. Density-based clustering based on hierarchical density estimates. In Proceedings of the Advances in Knowledge Discovery and Data Mining: 17th Pacific-Asia Conference, PAKDD 2013, Gold Coast, Australia, 14–17 April 2013; Proceedings, Part II 17. Springer: Berlin/Heidelberg, Germany, 2013; pp. 160–172. [Google Scholar]

- Kim, D.; Park, C.; Kim, S.; Lee, W.; Song, W.; Kim, Y.; Kim, H.; Kim, Y.; Lee, H.; Kim, J.; et al. Solar 10.7 b: Scaling large language models with simple yet effective depth up-scaling. arXiv 2023, arXiv:2312.15166. [Google Scholar]

- Mikolov, T. Efficient estimation of word representations in vector space. arXiv 2013, arXiv:1301.3781. [Google Scholar]

- Pennington, J.; Socher, R.; Manning, C.D. Glove: Global vectors for word representation. In Proceedings of the 2014 Conference on Empirical Methods in Natural Language Processing (EMNLP), Doha, Qatar, 25–29 October 2014; pp. 1532–1543. [Google Scholar]

- Muennighoff, N.; Tazi, N.; Magne, L.; Reimers, N. MTEB: Massive text embedding benchmark. arXiv 2022, arXiv:2210.07316. [Google Scholar]

- Van der Maaten, L.; Hinton, G. Visualizing data using t-SNE. J. Mach. Learn. Res. 2008, 9, 2579–2605. [Google Scholar]

- Asyaky, M.S.; Mandala, R. Improving the performance of HDBSCAN on short text clustering by using word embedding and UMAP. In Proceedings of the 2021 8th International Conference on Advanced Informatics: Concepts, Theory and Applications (ICAICTA), Online, 29–30 September 2021; pp. 1–6. [Google Scholar]

- David, U.; Karabatak, M. Text clustering of covid-19 vaccine tweets. In Proceedings of the 2022 10th International Symposium on Digital Forensics and Security (ISDFS), İstanbul, Turkey, 6–7 June 2022; pp. 1–6. [Google Scholar]

- Gelar, T.; Sari, A.N. Bertopic and NER Stop Words for Topic Modeling on Agricultural Instructional Sentences. In Proceedings of the International Conference on Applied Science and Technology on Engineering Science 2023 (iCAST-ES 2023); Atlantis Press: Tarakan, Indonesia, 2024; pp. 129–140. [Google Scholar]

- Bafna, P.; Pramod, D.; Vaidya, A. Document clustering: TF-IDF approach. In Proceedings of the 2016 International Conference on Electrical, Electronics, and Optimization Techniques (ICEEOT), Chennai, India, 3–5 March 2016; pp. 61–66. [Google Scholar]

- Shar, M.A.; Muhammad, M.B.; Mokhtar, A.A.B.; Soomro, M. A Novel Energy Performance-Based Diagnostic Model for Centrifugal Compressor using Hybrid ML Model. Arab. J. Sci. Eng. 2024, 49, 14835–14853. [Google Scholar] [CrossRef]

- Lv, Q.; Yu, X.; Ma, H.; Ye, J.; Wu, W.; Wang, X. Applications of Machine Learning to Reciprocating Compressor Fault Diagnosis: A Review. Processes 2021, 9, 909. [Google Scholar] [CrossRef]

- Ahn, B.; Kim, J.; Choi, B. Artificial intelligence-based machine learning considering flow and temperature of the pipeline for leak early detection using acoustic emission. Eng. Fract. Mech. 2019, 210, 381–392. [Google Scholar] [CrossRef]

- Choi, Y.; Kwun, H.; Kim, D.; Lee, E.; Bae, H. Residual life prediction for induction furnace by sequential encoder with s-convolutional LSTM. Processes 2021, 9, 1121. [Google Scholar] [CrossRef]

- Liu, Y.; Duan, L.; Yuan, Z.; Wang, N.; Zhao, J. An intelligent fault diagnosis method for reciprocating compressors based on LMD and SDAE. Sensors 2019, 19, 1041. [Google Scholar] [CrossRef]

- Shi, Y.; Li, M.; Wen, J.; Yang, Y.; Zeng, J. Deep Learning-Based Approach for Heat Transfer Efficiency Prediction with Deep Feature Extraction. ACS Omega 2022, 7, 31013–31035. [Google Scholar] [CrossRef]

- Jeon, S.H.; Yoo, S.; Yoo, Y.S.; Lee, I.W. ML-and LSTM-Based Radiator Predictive Maintenance for Energy Saving in Compressed Air Systems. Energies 2024, 17, 1428. [Google Scholar] [CrossRef]

- Yin, Y.; Liu, X.; Huang, W.; Liu, Y.; Hu, S. Gas face seal status estimation based on acoustic emission monitoring and support vector machine regression. Adv. Mech. Eng. 2020, 12, 1687814020921323. [Google Scholar] [CrossRef]

- Huang, X.y.; Xia, H.; Liu, Y.k.; Miyombo, M.E. Improved fault diagnosis method of electric gate valve in nuclear power plant. Ann. Nucl. Energy 2023, 194, 109996. [Google Scholar] [CrossRef]

- Lv, Q.; Cai, L.; Yu, X.; Ma, H.; Li, Y.; Shu, Y. An automatic fault diagnosis method for the reciprocating compressor based on HMT and ANN. Appl. Sci. 2022, 12, 5182. [Google Scholar] [CrossRef]

- Rousseau, P.; Laubscher, R. A Condition-Monitoring Methodology Using Deep Learning-Based Surrogate Models and Parameter Identification Applied to Heat Pumps. Math. Comput. Appl. 2024, 29, 52. [Google Scholar] [CrossRef]

- Du, J.; Zhang, J.; Yang, L.; Li, X.; Guo, L.; Song, L. Mechanism analysis and self-adaptive RBFNN based hybrid soft sensor model in energy production process: A case study. Sensors 2022, 22, 1333. [Google Scholar] [CrossRef] [PubMed]

- Patil, A.; Soni, G.; Prakash, A. A BMFO-KNN based intelligent fault detection approach for reciprocating compressor. Int. J. Syst. Assur. Eng. Manag. 2022, 13, 797–809. [Google Scholar] [CrossRef]

- Mobtahej, P.; Naddaf-Sh, S.; Hamidi, M.; Zargarzadeh, H.; Liu, X. Anomaly Detection by Employing Root Cause Analysis and Machine Learning-based Approach Using Compressors Timeseries Data. In Proceedings of the IIE Annual Conference. Proceedings. Institute of Industrial and Systems Engineers (IISE), Institute of Industrial and Systems Engineers (IISE). Seattle, WA, USA, 21–24 May 2022; pp. 1–6. [Google Scholar]

- Martinez Ricardo, D.M.; Castañeda Jimenez, G.E.; Vaqueiro Ferreira, J.; de Oliveira Nobrega, E.G.; de Lima, E.R.; de Almeida, L.M. Evaluation of machine learning methods for monitoring the health of guyed towers. Sensors 2021, 22, 213. [Google Scholar] [CrossRef]

- Aizenberg, I.; Belardi, R.; Bindi, M.; Grasso, F.; Manetti, S.; Luchetta, A.; Piccirilli, M.C. Failure prevention and malfunction localization in underground medium voltage cables. Energies 2020, 14, 85. [Google Scholar] [CrossRef]

- Coutinho, M.; Novo, L.L.; De Melo, M.; De Medeiros, L.; Barbosa, D.; Alves, M.; Tarragô, V.; Dos Santos, R.; Neto, H.L.; Gama, P. Machine learning-based system for fault detection on anchor rods of cable-stayed power transmission towers. Electr. Power Syst. Res. 2021, 194, 107106. [Google Scholar] [CrossRef]

- Stanescu, D.; Digulescu, A.; Ioana, C.; Serbanescu, A. Transient power grid phenomena classification based on phase diagram features and machine learning classifiers. In Proceedings of the 2022 30th European Signal Processing Conference (EUSIPCO), Belgrade, Serbia, 29 August–2 September 2022; pp. 1676–1680. [Google Scholar]

- Belardi, R.; Bindi, M.; Grasso, F.; Luchetta, A.; Manetti, S.; Piccirilli, M. A complex neural classifier for the fault prognosis and diagnosis of overhead electrical lines. In IOP Conference Series: Earth and Environmental Science, Proceedings of the 2020 International Conference on Advanced Electrical and Energy Systems 18–21 August 2020, Osaka, Japan; IOP Publishing: Bristol, UK, 2020; Volume 582, p. 012001. [Google Scholar]

- Kim, H.; Lee, H.; Kim, S.; Kim, S.W. Attention recurrent neural network-based severity estimation method for early-stage fault diagnosis in robot harness cable. Sensors 2023, 23, 5299. [Google Scholar] [CrossRef]

- Boschetti, G.; Minto, R. A sensorless approach for cable failure detection and identification in cable-driven parallel robots. Robot. Auton. Syst. 2025, 183, 104855. [Google Scholar] [CrossRef]

- Soualhi, M.; Nguyen, K.T.; Medjaher, K.; Nejjari, F.; Puig, V.; Blesa, J.; Quevedo, J.; Marlasca, F. Dealing with prognostics uncertainties: Combination of direct and recursive remaining useful life estimations. Comput. Ind. 2023, 144, 103766. [Google Scholar] [CrossRef]

- Son, S.; Oh, K.Y. Integrated framework for estimating remaining useful lifetime through a deep neural network. Appl. Soft Comput. 2022, 122, 108879. [Google Scholar] [CrossRef]

- Solís-Martín, D.; Galán-Páez, J.; Borrego-Díaz, J. On the soundness of xai in prognostics and health management (phm). Information 2023, 14, 256. [Google Scholar] [CrossRef]

- Kim, S.; Kim, N.H.; Choi, J.H. Prediction of remaining useful life by data augmentation technique based on dynamic time warping. Mech. Syst. Signal Process. 2020, 136, 106486. [Google Scholar] [CrossRef]

- Fathi, K.; van de Venn, H.W.; Honegger, M. Predictive maintenance: An autoencoder anomaly-based approach for a 3 DoF delta robot. Sensors 2021, 21, 6979. [Google Scholar] [CrossRef] [PubMed]

- Soualhi, M.; Nguyen, K.; Medjaher, K.; Zerhouni, N. Remaining useful life estimation of turbofan engines using adaptive fault detection learning. In Proceedings of the Annual Conference of the PHM Society, London, UK, 27–29 May 2022; Volume 14. [Google Scholar]

- Nguyen, T.K.; Ahmad, Z.; Nguyen, D.T.; Kim, J.M. A remaining useful lifetime prediction model for concrete structures using Mann-Whitney U test state indicator and deep learning. Mech. Syst. Signal Process. 2025, 222, 111795. [Google Scholar] [CrossRef]

- Ellefsen, A.L.; Ushakov, S.; Æsøy, V.; Zhang, H. Validation of data-driven labeling approaches using a novel deep network structure for remaining useful life predictions. IEEE Access 2019, 7, 71563–71575. [Google Scholar] [CrossRef]

- Trinh, H.C.; Kwon, Y.K. A data-independent genetic algorithm framework for fault-type classification and remaining useful life prediction. Appl. Sci. 2020, 10, 368. [Google Scholar] [CrossRef]

- Mochammad, S.; Noh, Y.; Kim, N.H. Enhancing Realistic Remaining Useful Life Prediction through Multi-fidelity Physics-Informed Approaches. In Proceedings of the 15th Annual Conference of the Prognostics and Health Management Society, PHM 2023, Prognostics and Health Management Society, Salt Lake City, UT, USA, 28 October–2 November 2023. [Google Scholar]

- Gebraeel, N.; Lei, Y.; Li, N.; Si, X.; Zio, E. Prognostics and remaining useful life prediction of machinery: Advances, opportunities and challenges. J. Dyn. Monit. Diagn. 2023, 2, 1–12. [Google Scholar]

- Ramezani, S.B.; Cummins, L.; Killen, B.; Carley, R.; Amirlatifi, A.; Rahimi, S.; Seale, M.; Bian, L. Scalability, explainability and performance of data-driven algorithms in predicting the remaining useful life: A comprehensive review. IEEE Access 2023, 11, 41741–41769. [Google Scholar] [CrossRef]

- Cofré-Martel, S.; Droguett, E.; Modarres, M. Physics-Informed Neural Networks for Remaining Useful Life Estimation of a Vapor Recovery Unit System. In Proceedings of the Probabilistic Safety Assessment and Management, PSAM 2022, Honolulu, HI, USA, 26 June–1 July 2022. [Google Scholar]

- Rebaiaia, M.L.; Ait-Kadi, D. A remaining useful life model for optimizing maintenance cost and spare-parts replacement of production systems in the context of sustainability. IFAC-PapersOnLine 2022, 55, 1562–1568. [Google Scholar] [CrossRef]

- Byun, J.; Min, S.; Kang, J. RUL Prognostics: Recursive Bayesian Ensemble Prediction with Combining Artificial Degradation Patterns. Int. J. Progn. Health Manag. 2023, 14. [Google Scholar]

- Zhang, C.; Gong, D.; Xue, G. An uncertainty-incorporated active data diffusion learning framework for few-shot equipment RUL prediction. Reliab. Eng. Syst. Saf. 2025, 254, 110632. [Google Scholar] [CrossRef]

- Crespo, M.A.; Candón, E.; Gómez, J.; Serra, J. A comparison of machine learning techniques for LNG pumps fault prediction in regasification plants. IFAC-PapersOnLine 2020, 53, 125–130. [Google Scholar]

- Rojek, M.; Blachnik, M. A Dataset and a Comparison of Classification Methods for Valve Plate Fault Prediction of Piston Pump. Appl. Sci. 2024, 14, 7183. [Google Scholar] [CrossRef]

- Borriello, P.; Tessicini, F.; Ricucci, G.; Frosina, E.; Senatore, A. A fault detection strategy for an ePump during EOL tests based on a knowledge-based vibroacoustic tool and supervised machine learning classifiers. Meccanica 2024, 59, 279–304. [Google Scholar] [CrossRef]

- Azeez, A.A.; Mazzei, P.; Minav, T.; Frosina, E.; Senatore, A. A New Approach to Study the Effect of Complexity on an External Gear Pump Model to Generate Data Source for AI-Based Condition Monitoring Application. Actuators 2023, 12, 401. [Google Scholar] [CrossRef]

- Hu, Q.; Ohata, E.F.; Silva, F.H.; Ramalho, G.L.; Han, T.; Reboucas Filho, P.P. A new online approach for classification of pumps vibration patterns based on intelligent IoT system. Measurement 2020, 151, 107138. [Google Scholar] [CrossRef]

- Indriawati, K.; Yugoputra, G.F.; Habibah, N.N.; Yudhanto, R. Artificial Neural Network-Based Fault Detection System with Residual Analysis Approach on Centrifugal Pump: A Case Study. Int. J. Automot. Mech. Eng. 2023, 20, 10285–10297. [Google Scholar] [CrossRef]

- Salim, K.; Hebri, R.S.A.; Besma, S. Classification predictive maintenance using XGboost with genetic algorithm. Rev. D’Intelligence Artif. 2022, 36, 833. [Google Scholar] [CrossRef]

- Alenany, A.; Helmi, A.M.; Nasef, B.M. Comprehensive analysis for sensor-based hydraulic system condition monitoring. Int. J. Adv. Comput. Sci. Appl. 2021, 12, 133–140. [Google Scholar] [CrossRef]

- Keller, N.; Sciancalepore, A.; Vacca, A. Condition monitoring of an axial piston pump on a mini excavator. Int. J. Fluid Power 2023, 24, 171–206. [Google Scholar] [CrossRef]

- Keller, N.; Sciancalepore, A.; Vacca, A. Demonstrating a condition monitoring process for axial piston pumps with damaged valve plates. Int. J. Fluid Power 2022, 23, 205–236. [Google Scholar] [CrossRef]

- Kim, W.; Lim, C.; Chai, J. Development of a sdms (Self-diagnostic monitoring system) with prognostics for a reciprocating pump system. Nucl. Eng. Technol. 2020, 52, 1188–1200. [Google Scholar] [CrossRef]

- Ranawat, N.S.; Kankar, P.K.; Miglani, A. Fault diagnosis in centrifugal pump using support vector machine and artificial neural network. J. Engg. Res. EMSME Spec. Issue Pp 2021, 99, 111. [Google Scholar] [CrossRef]

- Azizi, R.; Attaran, B.; Hajnayeb, A.; Ghanbarzadeh, A.; Changizian, M. Improving accuracy of cavitation severity detection in centrifugal pumps using a hybrid feature selection technique. Measurement 2017, 108, 9–17. [Google Scholar] [CrossRef]

- Orrù, P.F.; Zoccheddu, A.; Sassu, L.; Mattia, C.; Cozza, R.; Arena, S. Machine learning approach using MLP and SVM algorithms for the fault prediction of a centrifugal pump in the oil and gas industry. Sustainability 2020, 12, 4776. [Google Scholar] [CrossRef]

- Bruinsma, S.; Geertsma, R.; Loendersloot, R.; Tinga, T. Motor current and vibration monitoring dataset for various faults in an E-motor-driven centrifugal pump. Data Brief 2024, 52, 109987. [Google Scholar] [CrossRef]

- Loukatos, D.; Kondoyanni, M.; Alexopoulos, G.; Maraveas, C.; Arvanitis, K.G. On-Device Intelligence for Malfunction Detection of Water Pump Equipment in Agricultural Premises: Feasibility and Experimentation. Sensors 2023, 23, 839. [Google Scholar] [CrossRef]

- Panda, A.K.; Rapur, J.S.; Tiwari, R. Prediction of flow blockages and impending cavitation in centrifugal pumps using Support Vector Machine (SVM) algorithms based on vibration measurements. Measurement 2018, 130, 44–56. [Google Scholar] [CrossRef]

- Kim, D.; Heo, T.Y. Anomaly detection with feature extraction based on machine learning using hydraulic system IoT sensor data. Sensors 2022, 22, 2479. [Google Scholar] [CrossRef]

- Wu, K.; Xing, Y.; Chu, N.; Wu, P.; Cao, L.; Wu, D. A carrier wave extraction method for cavitation characterization based on time synchronous average and time-frequency analysis. J. Sound Vib. 2020, 489, 115682. [Google Scholar] [CrossRef]

- Kim, S.; Akpudo, U.E.; Hur, J.W. A cost-aware dnn-based fdi technology for solenoid pumps. Electronics 2021, 10, 2323. [Google Scholar] [CrossRef]

- Ali, H. Cavitation Analysis in Centrifugal Pumps Based on Vibration Bispectrum and Transfer Learning. Shock Vib. 2021, 2021, 6988949. [Google Scholar]

- Samanipour, P.; Poshtan, J.; Sadeghi, H. Cavitation detection in centrifugal pumps using pressure time-domain features. Turk. J. Electr. Eng. Comput. Sci. 2017, 25, 4287–4298. [Google Scholar] [CrossRef]

- Sunal, C.E.; Velisavljevic, V.; Dyo, V.; Newton, B.; Newton, J. Centrifugal Pump Fault Detection with Convolutional Neural Network Transfer Learning. Sensors 2024, 24, 2442. [Google Scholar] [CrossRef]

- Kim, K.; Jeong, J. Deep learning-based data augmentation for hydraulic condition monitoring system. Procedia Comput. Sci. 2020, 175, 20–27. [Google Scholar] [CrossRef]

- Karagiovanidis, M.; Pantazi, X.E.; Papamichail, D.; Fragos, V. Early detection of cavitation in centrifugal pumps using low-cost vibration and sound sensors. Agriculture 2023, 13, 1544. [Google Scholar] [CrossRef]

- Keleko, A.T.; Kamsu-Foguem, B.; Ngouna, R.H.; Tongne, A. Health condition monitoring of a complex hydraulic system using Deep Neural Network and DeepSHAP explainable XAI. Adv. Eng. Softw. 2023, 175, 103339. [Google Scholar] [CrossRef]

- Barraza, J.F.; Bräuning, L.F.G.; Droguett, E.L.; Martins, M.R. Long short-term memory network for future-state prediction in water injection pump. In Proceedings of the 30th European Safety and Reliability Conference and the 15th Probabilistic Safety Assessment and Management Conference, Venive, Italy, 1–5 November 2020; pp. 1–5. [Google Scholar]

- König, C.; Helmi, A.M. Sensitivity analysis of sensors in a hydraulic condition monitoring system using CNN models. Sensors 2020, 20, 3307. [Google Scholar] [CrossRef]

- Lee, G.H.; Akpudo, U.E.; Hur, J.W. FMECA and MFCC-based early wear detection in gear pumps in cost-aware monitoring systems. Electronics 2021, 10, 2939. [Google Scholar] [CrossRef]

- Wang, L.; Liu, Y.; Yin, H.; Sun, W. Fault diagnosis and predictive maintenance for hydraulic system based on digital twin model. AIP Adv. 2022, 12, 065213. [Google Scholar] [CrossRef]

- Taser, P.Y. An Ordinal Multi-Dimensional Classification (OMDC) for Predictive Maintenance. Comput. Syst. Sci. Eng. 2023, 44, 1499–1516. [Google Scholar] [CrossRef]

- Askari, B.; Carli, R.; Cavone, G.; Dotoli, M. Data-driven fault diagnosis in a complex hydraulic system based on early classification. IFAC-PapersOnLine 2022, 55, 187–192. [Google Scholar] [CrossRef]

- Zuo, L.; Xu, F.; Zhang, C.; Xiahou, T.; Liu, Y. A multi-layer spiking neural network-based approach to bearing fault diagnosis. Reliab. Eng. Syst. Saf. 2022, 225, 108561. [Google Scholar] [CrossRef]

- Alhams, A.; Abdelhadi, A.; Badri, Y.; Sassi, S.; Renno, J. Enhanced Bearing Fault Diagnosis Through Trees Ensemble Method and Feature Importance Analysis. J. Vib. Eng. Technol. 2024, 12, 109–125. [Google Scholar] [CrossRef]

- Velásquez, R.M.A. Bearings faults and limits in wind turbine generators. Results Eng. 2024, 21, 101891. [Google Scholar] [CrossRef]

- Liu, J.; Zuo, H. Failure prediction with statistical analysis of bearing using deep forest model and change point detection. Eng. Appl. Artif. Intell. 2024, 133, 108504. [Google Scholar] [CrossRef]

- Wang, H.; Liu, Z.; Peng, D.; Cheng, Z. Attention-guided joint learning CNN with noise robustness for bearing fault diagnosis and vibration signal denoising. ISA Trans. 2022, 128, 470–484. [Google Scholar] [CrossRef]

- Zhang, D.; Stewart, E.; Entezami, M.; Roberts, C.; Yu, D. Intelligent acoustic-based fault diagnosis of roller bearings using a deep graph convolutional network. Measurement 2020, 156, 107585. [Google Scholar] [CrossRef]

- Xu, Y.; Li, Z.; Wang, S.; Li, W.; Sarkodie-Gyan, T.; Feng, S. A hybrid deep-learning model for fault diagnosis of rolling bearings. Measurement 2021, 169, 108502. [Google Scholar] [CrossRef]

- Saravanakumar, R.; Krishnaraj, N.; Venkatraman, S.; Sivakumar, B.; Prasanna, S.; Shankar, K. Hierarchical symbolic analysis and particle swarm optimization based fault diagnosis model for rotating machineries with deep neural networks. Measurement 2021, 171, 108771. [Google Scholar] [CrossRef]

- Zuo, L.; Zhang, L.; Zhang, Z.H.; Luo, X.L.; Liu, Y. A spiking neural network-based approach to bearing fault diagnosis. J. Manuf. Syst. 2021, 61, 714–724. [Google Scholar] [CrossRef]

- Guan, Y.; Meng, Z.; Sun, D.; Liu, J.; Fan, F. Rolling bearing fault diagnosis based on information fusion and parallel lightweight convolutional network. J. Manuf. Syst. 2022, 65, 811–821. [Google Scholar] [CrossRef]

- Sinitsin, V.; Ibryaeva, O.; Sakovskaya, V.; Eremeeva, V. Intelligent bearing fault diagnosis method combining mixed input and hybrid CNN-MLP model. Mech. Syst. Signal Process. 2022, 180, 109454. [Google Scholar] [CrossRef]

- Miao, Y.; Gao, S.; Kong, Y.; Jiang, Z.; Han, Q.; Chu, F. Variable reluctance bearing generators applicable in condition monitoring of bearing cages. Mech. Syst. Signal Process. 2023, 194, 110249. [Google Scholar] [CrossRef]

- Shen, S.; Lu, H.; Sadoughi, M.; Hu, C.; Nemani, V.; Thelen, A.; Webster, K.; Darr, M.; Sidon, J.; Kenny, S. A physics-informed deep learning approach for bearing fault detection. Eng. Appl. Artif. Intell. 2021, 103, 104295. [Google Scholar] [CrossRef]

- Kumar, A.; Zhou, Y.; Gandhi, C.; Kumar, R.; Xiang, J. Bearing defect size assessment using wavelet transform based Deep Convolutional Neural Network (DCNN). Alex. Eng. J. 2020, 59, 999–1012. [Google Scholar] [CrossRef]

- Lyu, P.; Zhang, K.; Yu, W.; Wang, B.; Liu, C. A novel RSG-based intelligent bearing fault diagnosis method for motors in high-noise industrial environment. Adv. Eng. Inform. 2022, 52, 101564. [Google Scholar] [CrossRef]

- Ruan, D.; Wang, J.; Yan, J.; Gühmann, C. CNN parameter design based on fault signal analysis and its application in bearing fault diagnosis. Adv. Eng. Inform. 2023, 55, 101877. [Google Scholar] [CrossRef]

- Yang, Z.b.; Zhang, J.p.; Zhao, Z.b.; Zhai, Z.; Chen, X.f. Interpreting network knowledge with attention mechanism for bearing fault diagnosis. Appl. Soft Comput. 2020, 97, 106829. [Google Scholar] [CrossRef]

- González-Muñiz, A.; Díaz, I.; Cuadrado, A.A. DCNN for condition monitoring and fault detection in rotating machines and its contribution to the understanding of machine nature. Heliyon 2020, 6, e03395. [Google Scholar] [CrossRef]

- Wang, J.; Mo, Z.; Zhang, H.; Miao, Q. A deep learning method for bearing fault diagnosis based on time-frequency image. IEEE Access 2019, 7, 42373–42383. [Google Scholar] [CrossRef]

- Xie, J.; Du, G.; Shen, C.; Chen, N.; Chen, L.; Zhu, Z. An end-to-end model based on improved adaptive deep belief network and its application to bearing fault diagnosis. IEEE Access 2018, 6, 63584–63596. [Google Scholar] [CrossRef]

- Ding, X.; Wang, H.; Cao, Z.; Liu, X.; Liu, Y.; Huang, Z. An edge intelligent method for bearing fault diagnosis based on a parameter transplantation convolutional neural network. Electronics 2023, 12, 1816. [Google Scholar] [CrossRef]

- Dai, J.; Tian, L.; Chang, H. An Intelligent Diagnostic Method for Wear Depth of Sliding Bearings Based on MGCNN. Machines 2024, 12, 266. [Google Scholar] [CrossRef]

- Xu, G.; Liu, M.; Jiang, Z.; Söffker, D.; Shen, W. Bearing fault diagnosis method based on deep convolutional neural network and random forest ensemble learning. Sensors 2019, 19, 1088. [Google Scholar] [CrossRef]

- Li, Z.; Li, Y.; Sun, Q.; Qi, B. Bearing fault diagnosis method based on convolutional neural network and knowledge graph. Entropy 2022, 24, 1589. [Google Scholar] [CrossRef]

- van den Hoogen, J.; Bloemheuvel, S.; Atzmueller, M. Classifying multivariate signals in rolling bearing fault detection using adaptive wide-kernel cnns. Appl. Sci. 2021, 11, 11429. [Google Scholar] [CrossRef]

- Kahr, M.; Kovács, G.; Loinig, M.; Brückl, H. Condition monitoring of ball bearings based on machine learning with synthetically generated data. Sensors 2022, 22, 2490. [Google Scholar] [CrossRef]

- Mahesh, T.; Saravanan, C.; Ram, V.A.; Kumar, V.V.; Vivek, V.; Guluwadi, S. Data-driven intelligent condition adaptation of feature extraction for bearing fault detection using deep responsible active learning. IEEE Access 2024, 12, 45381–45397. [Google Scholar] [CrossRef]

- Piltan, F.; Duong, B.P.; Kim, J.M. Deep learning-based adaptive neural-fuzzy structure scheme for bearing fault pattern recognition and crack size identification. Sensors 2021, 21, 2102. [Google Scholar] [CrossRef]

- Shenfield, A.; Howarth, M. A novel deep learning model for the detection and identification of rolling element-bearing faults. Sensors 2020, 20, 5112. [Google Scholar] [CrossRef] [PubMed]

- Rumin, P.; Kotowicz, J.; Hogg, D.; Zastawna-Rumin, A. Utilization of measurements, machine learning, and analytical calculation for preventing belt flip over on conveyor belts. Measurement 2023, 218, 113157. [Google Scholar] [CrossRef]

- Elahi, M.; Afolaranmi, S.O.; Mohammed, W.M.; Lastra, J.L.M. FASTory assembly line power consumption data. Data Brief 2023, 48, 109160. [Google Scholar] [CrossRef] [PubMed]

- Elahi, M.; Afolaranmi, S.O.; Mohammed, W.M.; Martinez Lastra, J.L. Energy-based prognostics for gradual loss of conveyor belt tension in discrete manufacturing systems. Energies 2022, 15, 4705. [Google Scholar] [CrossRef]

- Martinsen, M.; Fentaye, A.D.; Dahlquist, E.; Zhou, Y. Holistic approach promotes failure prevention of smart mining machines based on Bayesian networks. Machines 2023, 11, 940. [Google Scholar] [CrossRef]

- Pulcini, V.; Modoni, G. Machine learning-based digital twin of a conveyor belt for predictive maintenance. Int. J. Adv. Manuf. Technol. 2024, 133, 6095–6110. [Google Scholar] [CrossRef]

- Dayo-Olupona, O.; Genc, B.; Celik, T.; Bada, S. Adoptable approaches to predictive maintenance in mining industry: An overview. Resour. Policy 2023, 86, 104291. [Google Scholar] [CrossRef]

- Siami, M.; Barszcz, T.; Wodecki, J.; Zimroz, R. Automated identification of overheated belt conveyor idlers in thermal images with complex backgrounds using binary classification with CNN. Sensors 2022, 22, 10004. [Google Scholar] [CrossRef]

- Souza, F.M.d.C.; Filho, G.P.R.; Guimarães, F.G.; Meneguette, R.I.; Pessin, G. Navigating Market Sentiments: A Novel Approach to Iron Ore Price Forecasting with Weighted Fuzzy Time Series. Information 2024, 15, 251. [Google Scholar] [CrossRef]

- Parmar, P.; Jurdziak, L.; Rzeszowska, A.; Burduk, A. Predictive Modeling of Conveyor Belt Deterioration in Coal Mines Using AI Techniques. Energies 2024, 17, 3497. [Google Scholar] [CrossRef]

- Siami, M.; Barszcz, T.; Wodecki, J.; Zimroz, R. Semantic segmentation of thermal defects in belt conveyor idlers using thermal image augmentation and U-Net-based convolutional neural networks. Sci. Rep. 2024, 14, 5748. [Google Scholar] [CrossRef] [PubMed]

- Robatto Simard, S.; Gamache, M.; Doyon-Poulin, P. Development and Usability Evaluation of VulcanH, a CMMS Prototype for Preventive and Predictive Maintenance of Mobile Mining Equipment. Mining 2024, 4, 326–351. [Google Scholar] [CrossRef]

- Wijaya, H.; Rajeev, P.; Gad, E.; Vivekanamtham, R. Distributed optical fibre sensor for condition monitoring of mining conveyor using wavelet transform and artificial neural network. Struct. Control Health Monit. 2021, 28, e2827. [Google Scholar] [CrossRef]

- IEEE P2802; Standard for the Performance and Safety Evaluation of Artificial Intelligence Based Medical Device: Terminology. IEEE: New York, NY, USA, 2023.

- Tan, T. Working Process Analysis of Submarine Cable Detection Robot Using Machine Vision and Reinforcement Learning. Comput.-Aided Des. Appl. 2025, S7, 285–298. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Garcia, J.; Rios-Colque, L.; Peña, A.; Rojas, L. Condition Monitoring and Predictive Maintenance in Industrial Equipment: An NLP-Assisted Review of Signal Processing, Hybrid Models, and Implementation Challenges. Appl. Sci. 2025, 15, 5465. https://doi.org/10.3390/app15105465

Garcia J, Rios-Colque L, Peña A, Rojas L. Condition Monitoring and Predictive Maintenance in Industrial Equipment: An NLP-Assisted Review of Signal Processing, Hybrid Models, and Implementation Challenges. Applied Sciences. 2025; 15(10):5465. https://doi.org/10.3390/app15105465

Chicago/Turabian StyleGarcia, Jose, Luis Rios-Colque, Alvaro Peña, and Luis Rojas. 2025. "Condition Monitoring and Predictive Maintenance in Industrial Equipment: An NLP-Assisted Review of Signal Processing, Hybrid Models, and Implementation Challenges" Applied Sciences 15, no. 10: 5465. https://doi.org/10.3390/app15105465

APA StyleGarcia, J., Rios-Colque, L., Peña, A., & Rojas, L. (2025). Condition Monitoring and Predictive Maintenance in Industrial Equipment: An NLP-Assisted Review of Signal Processing, Hybrid Models, and Implementation Challenges. Applied Sciences, 15(10), 5465. https://doi.org/10.3390/app15105465