Harnessing Secondary Resources for Sustainable and Circular Practices in the Construction Sector: A Scoping Review

Abstract

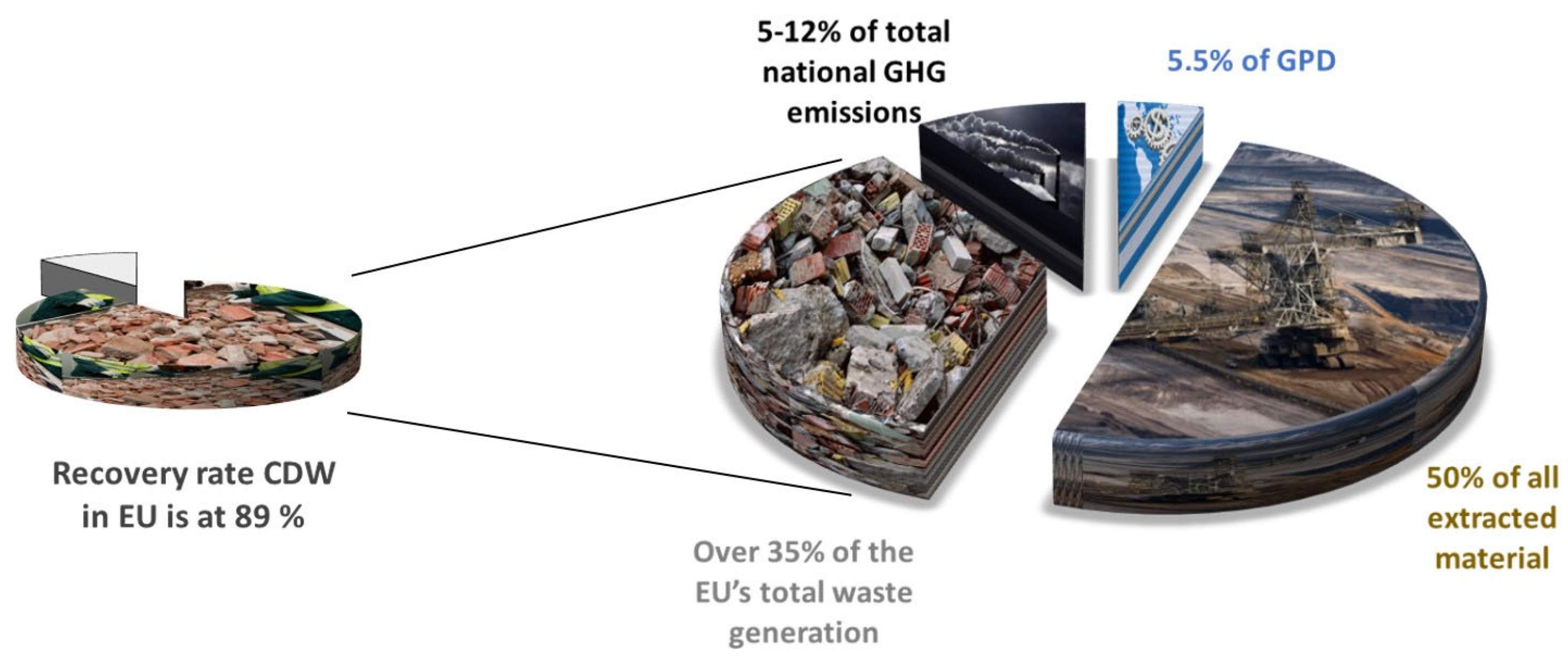

1. Introduction

Review Methodology

- -

- (“cellulose fiber” OR “cellulose waste”) AND (“insulation” OR “concrete” OR “mortar” OR “composites” OR “bio-based materials”) AND (“construction” OR “building” OR “civil engineering”)

- -

- (“mine tailings” OR “mining waste” OR “iron tailings” OR “copper tailings” OR “phosphate tailings”) AND (“geopolymer” OR “binder” OR “concrete” OR “paving blocks” OR “ceramics”) AND (“construction” OR “building materials” OR “road base”)

- -

- (“steel slag” OR “blast furnace slag” OR “copper slag” OR “ferrochrome slag” OR “ferronickel slag”) AND (“cement” OR “aggregate” OR “asphalt” OR “bricks” OR “concrete”) AND (“construction” OR “infrastructure” OR “building sector”)

2. The Role of Cellulose Waste in Sustainable Construction

2.1. Cellulose-Based Composites and Bio-Based Materials

2.2. Cellulose Insulation Products

2.3. Sustainable Concrete Alternatives

3. The Role of Mining Tailings in Advancing Sustainable Construction Practices

3.1. Mining Tailings as Aggregates in Concrete

3.2. Mining Tailings in Cement Production

3.3. Mining Tailings in Ceramic and Brick Manufacturing

3.4. Tailings-Based Geopolymer

3.5. Mining Tailings: Other Uses

4. The Role of Metallurgy Slags in Sustainable Construction

4.1. Metallurgy Slags in Concrete Production

4.2. Slags in Road Construction

4.3. Innovative Uses in Bricks and Ceramics

4.4. Slags in Cement Production

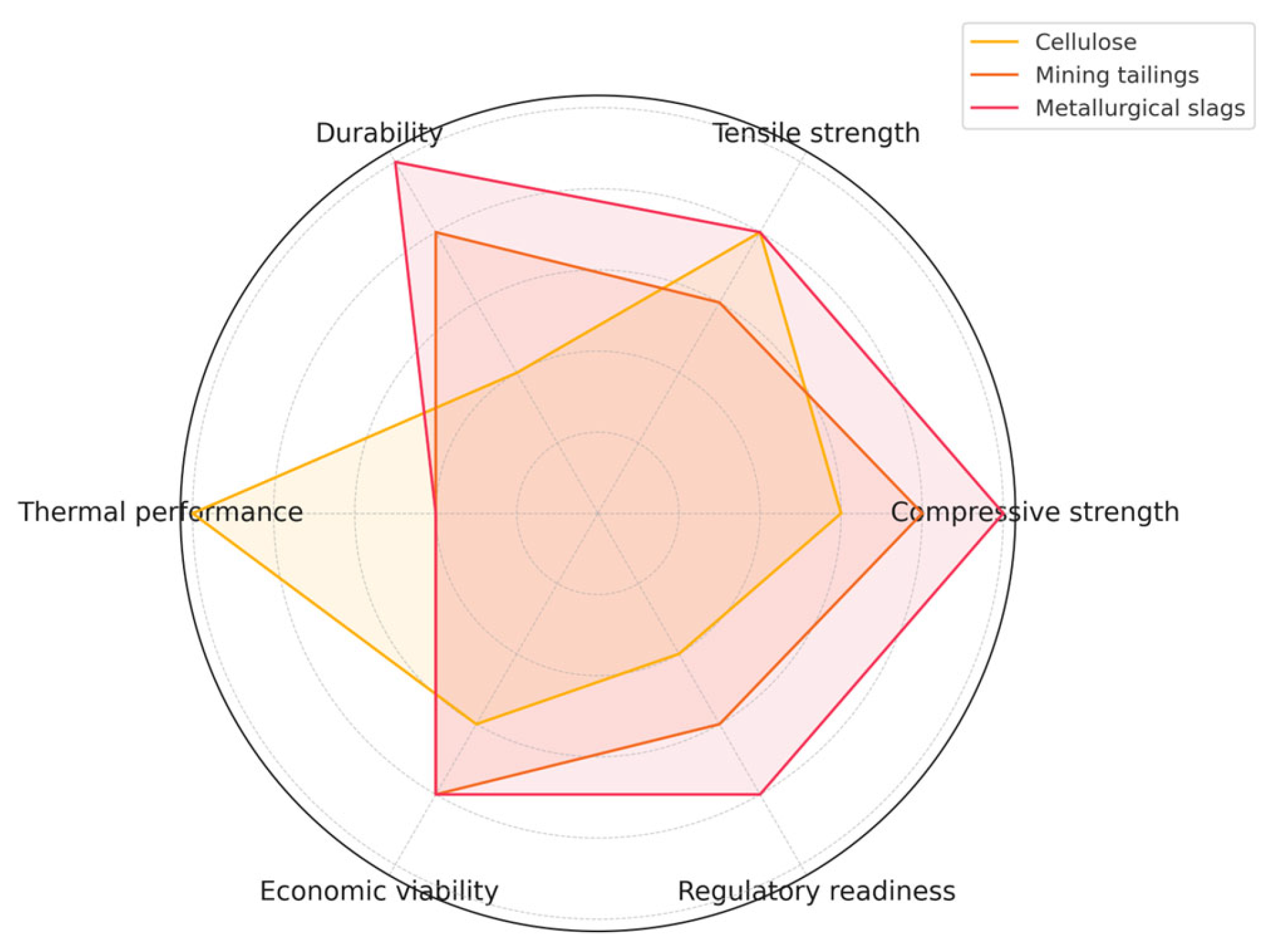

5. Mechanical and Durability Performance of Construction Materials Incorporating Secondary Raw Materials

6. Overcoming Barriers to Integration

6.1. Economic Challenges

6.2. Technological Limitations

6.3. Regulatory Barriers

6.4. Policy Recommendations and Stakeholder Collaboration

7. Future Perspectives and Sustainability Goals

7.1. Technological Innovations in Waste Valorization

7.2. Digital Technologies for Optimization

7.3. Circular Business Models and Environmental Assessment

8. Conclusions

Comparative Synthesis and Evaluation Framework

Author Contributions

Funding

Conflicts of Interest

References

- Domljan, I.; Domljan, V. Major challenges in the construction industry. In New Technologies, Development and Application VII; Karabegovic, I., Kovačević, A., Mandzuka, S., Eds.; Lecture Notes in Networks and Systems; Springer: Cham, Switzerland, 2024; Volume 1070. [Google Scholar] [CrossRef]

- Norouzi, M.; Chàfer, M.; Cabeza, L.F.; Jiménez, L.; Boer, D. Circular economy in the building and construction sector: A scientific evolution analysis. J. Build. Eng. 2021, 44, 102704. [Google Scholar] [CrossRef]

- Elhegazy, H.; Zhang, J.; Amoudi, O.; Zaki, J.N.; Yahia, M.; Eid, M.; Mahdi, I. An exploratory study on the impact of the construction industry on climate change. J. Ind. Integr. Manag. 2023, 9, 397–418. [Google Scholar] [CrossRef]

- Bulkeley, H.; Chan, S.; Fransen, A.; Landry, J.; Seddon, N.; Deprez, A.; Kok, M. Building Synergies Between Climate Biodiversity Governance: A Primer for COP28. 2023. Available online: https://shorturl.at/tCNZ0 (accessed on 28 August 2024).

- Husgafvel, R.; Sakaguchi, D. Circular economy development in the wood construction sector in Finland. Sustainability 2023, 15, 7871. [Google Scholar] [CrossRef]

- Purchase, C.K.; Al Zulayq, D.M.; O’Brien, B.T.; Kowalewski, M.J.; Berenjian, A.; Tarighaleslami, A.H.; Seifan, M. Circular economy of construction and demolition waste: A literature review on lessons, challenges, and benefits. Materials 2022, 15, 76. [Google Scholar] [CrossRef]

- Xu, F.; Lin, X.; Zhou, A. Effect of recycled ceramic aggregate on hydration heat and permeability of high performance concrete. Cement Concr. Compos. 2023, 137, 104930. [Google Scholar] [CrossRef]

- Cozzarini, L.; De Lorenzi, L.; Barago, N.; Sbaizero, O.; Bevilacqua, P. Expanded glass for thermal and acoustic insulation from recycled post-consumer glass and textile industry process waste. Materials 2023, 16, 1721. [Google Scholar] [CrossRef]

- Bostanci, S.C. Use of waste marble dust and recycled glass for sustainable concrete production. J. Clean. Prod. 2020, 251, 119785. [Google Scholar] [CrossRef]

- Papamichael, I.; Voukkali, I.; Loizia, P.; Zorpas, A.A. Construction and demolition waste framework of circular economy: A mini review. Waste Manag. Res. 2023, 41, 1728–1740. [Google Scholar] [CrossRef]

- Valois, M. UNECE/FAO Data Brief 2023–Pulp, Paper and Paperboard. 2024. Available online: https://unece.org/forestry-timber/documents/2023/11/informal-documents/2023-data-brief-pulp-paper-and-paperboard (accessed on 28 August 2024).

- Bamigboye, G.O.; Bassey, D.E.; Olukanni, D.O.; Ngene, B.U.; Adegoke, D.; Odetoyan, A.O.; Kareem, M.A.; Enabulele, D.O.; Nworgu, A.T. Waste materials in highway applications: An overview on generation and utilization implications on sustainability. J. Clean. Prod. 2021, 283, 124581. [Google Scholar] [CrossRef]

- Ji, R.; Liu, T.J.; Kang, L.L.; Wang, Y.T.; Li, J.G.; Wang, F.P.; Yu, Q.; Wang, X.M.; Liu, H.; Guo, H.W.; et al. A review of metallurgical slag for efficient wastewater treatment: Pretreatment, performance and mechanism. J. Clean. Prod. 2022, 380, 135076. [Google Scholar] [CrossRef]

- Rbihi, S.; Neggaoui, H.; Laallam, L.; Jouaiti, A. Cellulose waste for making sustainable cellulose/concrete biocomposite: Functional and environmental value for the thermal insulation. Biomass Convers. Biorefinery 2024, 14, 2333–2340. [Google Scholar] [CrossRef]

- Wang, J.; Wang, L.; Gardner, D.J.; Shaler, S.M.; Cai, Z. Towards a cellulose-based society: Opportunities and challenges. Cellulose 2021, 28, 4511–4543. [Google Scholar] [CrossRef]

- Kumar, V.; Verma, P. Pulp-paper industry sludge waste biorefinery for sustainable energy and value-added products development: A systematic valorization towards waste management. J. Environ. Manag. 2024, 352, 120052. [Google Scholar] [CrossRef] [PubMed]

- Kethiri, M.A.; Chikhi, M.; Belghar, N.; Chekired, F.; Guerira, B. A thermophysical investigation of the potential for the use of wastepaper for insulation building materials. Int. Wood Prod. J. 2024, 15, 63–71. [Google Scholar] [CrossRef]

- Khalife, E.; Sabouri, M.; Kaveh, M.; Szymanek, M. Recent advances in the application of agricultural waste in construction. Appl. Sci. 2024, 14, 2355. [Google Scholar] [CrossRef]

- Sharma, R.; Jha, P.; Bansal, T.; Sharma, D.; Pathak, A. Sustainable construction: Unveiling the potential of hempcrete in the modern era. Asian J. Civ. Eng. 2024, 25, 4157–4167. [Google Scholar] [CrossRef]

- Fode, T.A.; Jande, Y.A.C.; Kivevele, T. Physical, mechanical, and durability properties of concrete containing different waste synthetic fibers for green environment—A critical review. Heliyon 2024, 10, e32950. [Google Scholar] [CrossRef]

- Yang, L.; Liu, J.; Ma, X.; Hu, X.; Wu, Z.; Shi, C. Use of bauxite tailing for the production of fine lightweight aggregates. J. Clean. Prod. 2022, 372, 133603. [Google Scholar] [CrossRef]

- Deng, H.; Ran, C.; Liu, Y. Properties of cement thermal insulation materials containing tailing waste for connecting mines assessed using the orthogonal method with the response surface method. Processes 2023, 11, 2652. [Google Scholar] [CrossRef]

- Lage, G.T.; Bessa, S.A. Soil stabilization with Brazilian iron ore tailings to produce rammed earth. In International Conference on Earthen Construction; Springer Nature: Cham, Switzerland, 2024; pp. 206–215. [Google Scholar] [CrossRef]

- Kurniati, E.O.; Pederson, F.; Kim, H.J. Application of steel slags, ferronickel slags, and copper mining waste as construction materials: A review. Resour. Conserv. Recycl. 2023, 198, 107175. [Google Scholar] [CrossRef]

- Meshram, S.; Raut, S.P.; Ansari, K.; Madurwar, M.; Daniyal, M.; Khan, M.A.; Katare, V.; Khan, A.H.; Khan, N.A.; Hasan, M.A. Waste slags as sustainable construction materials: A compressive review on physico mechanical properties. J. Mater. Res. Technol. 2023, 23, 5821–5845. [Google Scholar] [CrossRef]

- Ramón-Álvarez, I.; Sánchez-Delgado, S.; Torres-Carrasco, M. Viability of hybrid and alkali-activated slag materials for thermal energy storage: Analysis of the evolution of mechanical and thermal properties. J. Build. Eng. 2024, 95, 110073. [Google Scholar] [CrossRef]

- Wang, Y.; Hu, Y.; Yang, J.; He, Y.; He, X.; Su, Y.; Strnadel, B. Performance of cement-based materials incorporating ultra-fine copper slag. Constr. Build. Mater. 2023, 402, 132949. [Google Scholar] [CrossRef]

- Gaus, A.; Rauf, I.; Siregar, F.; Heryanto, H. Proximity porosity and crystallinity analysis as clay/nickel slag characteristics for material stabilization application. Trends Sci. 2024, 21, 7970. [Google Scholar] [CrossRef]

- Ababio, B.K.; Lu, W. Barriers and enablers of circular economy in construction: A multi-system perspective towards the development of a practical framework. Constr. Manag. Econ. 2023, 41, 3–21. [Google Scholar] [CrossRef]

- Caro, D.; Lodato, C.; Damgaard, A.; Cristóbal, J.; Foster, G.; Flachenecker, F.; Tonini, D. Environmental and socio-economic effects of construction and demolition waste recycling in the European Union. Sci. Total Environ. 2024, 908, 168295. [Google Scholar] [CrossRef]

- European Commission. Construction Sector. Available online: https://ec.europa.eu/eurostat/cache/digpub/housing/bloc-3a.html?lang=en (accessed on 8 May 2025).

- European Commission. Internal Market, Industry, Entrepreneurship and SMEs. Available online: https://single-market-economy.ec.europa.eu/industry/sustainability/buildings-and-construction_en (accessed on 8 May 2025).

- Jing, L.; Shi, T.; Chang, Y.; Meng, X.; He, S.; Xu, H.; Yang, S.; Liu, J. Cellulose-based materials in environmental protection: A scientometric and visual analysis review. Sci. Total Environ. 2024, 929, 172576. [Google Scholar] [CrossRef]

- Zhang, Z.; Scherer, G.W. Measuring chemical shrinkage of ordinary Portland cement pastes with high water-to-cement ratios by adding cellulose nanofibrils. Cem. Concr. Compos. 2020, 111, 103625. [Google Scholar] [CrossRef]

- Gorzelańczyk, T.; Schabowicz, K.; Szymków, M. Tests of fiber cement materials containing recycled cellulose fibers. Materials 2020, 13, 2758. [Google Scholar] [CrossRef]

- Feng, H.; Zheng, Z.; Guo, A.; Sun, Z.; Yu, Z.; Yao, C.; Du, Y. Mechanical properties and microstructure of cellulose nanocrystal modified cement pastes subject to chloride erosion. J. Build. Eng. 2025, 112670. [Google Scholar] [CrossRef]

- Ghahari, S.; Assi, L.N.; Alsalman, A.; Alyamaç, K.E. Fracture properties evaluation of cellulose nanocrystals cement paste. Materials 2020, 13, 2507. [Google Scholar] [CrossRef] [PubMed]

- Xu, H.; Wang, Z.; Shao, Z.; Cai, L.; Jin, H.; Zhang, Z.; Chen, T. Experimental study on durability of fiber reinforced concrete: Effect of cellulose fiber, polyvinyl alcohol fiber and polyolefin fiber. Constr. Build. Mater. 2021, 306, 124867. [Google Scholar] [CrossRef]

- Arslan, C.; Gencel, O.; Borazan, I.; Sutcu, M.; Erdogmus, E. Effect of waste-based micro cellulose fiber as pore maker on characteristics of fired clay bricks. Constr. Build. Mater. 2021, 300, 124298. [Google Scholar] [CrossRef]

- Chopperla, K.S.T.; Ramanathan, S.; Moon, R.J.; Isgor, O.B.; Weiss, W.J. Field demonstrations using cellulose nanomaterials as concrete additives. Concr. Int. 2023, 45, 33–38. Available online: https://www.fpl.fs.usda.gov/documnts/pdf2023/fpl_2023_chopperla001.pdf (accessed on 8 May 2025).

- Barabanshchikov, Y.; Pham, H.; Usanova, K. Influence of microfibrillated cellulose additive on strength, elastic modulus, heat release, and shrinkage of mortar and concrete. Materials 2021, 14, 6933. [Google Scholar] [CrossRef]

- Ma, W.; Qin, Y.; Li, Y.; Chai, J.; Zhang, X.; Ma, Y.; Liu, H. Mechanical properties and engineering application of cellulose fiber-reinforced concrete. Mater. Today Commun. 2020, 22, 100818. [Google Scholar] [CrossRef]

- Nassiri, S.; Chen, Z.; Jian, G.; Zhong, T.; Haider, M.M.; Li, H.; Wolcott, M. Comparison of unique effects of two contrasting types of cellulose nanomaterials on setting time, rheology, and compressive strength of cement paste. Cem. Concr. Compos. 2021, 123, 104201. [Google Scholar] [CrossRef]

- de Souza, L.O.; Cordazzo, M.; de Souza, L.M.S.; Tonoli, G.; de Andrade Silva, F.; Mechtcherine, V. Investigation of dispersion methodologies of microcrystalline and nano-fibrillated cellulose on cement pastes. Cem. Concr. Compos. 2022, 126, 104351. [Google Scholar] [CrossRef]

- Aziz, M.A.; Zubair, M.; Saleem, M. Development and testing of cellulose nanocrystal-based concrete. Case Stud. Constr. Mater. 2021, 15, e00761. [Google Scholar] [CrossRef]

- de Souza, L.O.; Liebscher, M.; de Souza, L.M.S.; de Andrade Silva, F.; Mechtcherine, V. Effect of microcrystalline and nano-fibrillated cellulose on the mechanical behaviour and microstructure of cement pastes. Constr. Build. Mater. 2023, 408, 133812. [Google Scholar] [CrossRef]

- Choi, H.; Choi, Y.C. Setting characteristics of natural cellulose fiber reinforced cement composite. Constr. Build. Mater. 2021, 271, 121910. [Google Scholar] [CrossRef]

- Singh, H.; Gupta, R. Influence of cellulose fiber addition on self-healing and water permeability of concrete. Case Stud. Constr. Mater. 2020, 12, e00324. [Google Scholar] [CrossRef]

- Zhang, Z.; Angst, U. Microstructure and moisture transport in carbonated cement-based materials incorporating cellulose nanofibrils. Cem. Concr. Res. 2022, 162, 106990. [Google Scholar] [CrossRef]

- Goncalves, J.; Boluk, Y.; Bindiganavile, V. Cellulose nanofibers mitigate chloride ion ingress in cement-based systems. Cem. Concr. Compos. 2020, 114, 103780. [Google Scholar] [CrossRef]

- Gwon, S.; Shin, M. Rheological properties of cement pastes with cellulose microfibers. J. Mater. Res. Technol. 2021, 10, 808–818. [Google Scholar] [CrossRef]

- Onuaguluchi, O.; Banthia, N. Sulfate resistance of cement composites containing Nano-Fibrillated Cellulose (NFC). Cem. Concr. Compos. 2023, 135, 104831. [Google Scholar] [CrossRef]

- Terrones-Saeta, J.M.; Suárez-Macías, J.; Iglesias-Godino, F.J.; Corpas-Iglesias, F.A. Development of porous asphalt with bitumen emulsion, electric arc furnace slag and cellulose fibers for medium traffic roads. Minerals 2020, 10, 872. [Google Scholar] [CrossRef]

- Castro, M.P.P.; Effects of Cellulose Nano-Fiber as an Additive on Performance of Asphalt Binders and Mixes. South Dakota State University. 2020. Available online: https://www.proquest.com/openview/9d7cb9eca3df40f17be867250d12623f/1?pq-origsite=gscholar&cbl=18750&diss=y (accessed on 8 May 2025).

- Guha, A.H.; Assaf, G.J. Effects of different fillers on pavement deformation of hot mix asphalt in hot climates. Constr. Build. Mater. 2020, 261, 119898. [Google Scholar] [CrossRef]

- Li, M.; Zheng, F.; Xiao, Y.; Guan, Y.; Wang, J.; Zhen, Q.; Yu, Y. Utilization of residual heat to prepare high performance foamed glass-ceramic from blast furnace slag and its reinforce mechanism. Process Saf. Environ. Prot. 2021, 156, 391–404. [Google Scholar] [CrossRef]

- Aljubory, A.; Teama, Z.T.; Salman, H.T.; Abd Alkareem, H.M. Effects of cellulose fibers on the properties of asphalt mixtures. Mater. Today Proc. 2021, 42, 2941–2947. [Google Scholar] [CrossRef]

- Ghabchi, R.; Castro, M.P.P. Effect of laboratory-produced cellulose nanofiber as an additive on performance of asphalt binders and mixes. Constr. Build. Mater. 2021, 286, 122922. [Google Scholar] [CrossRef]

- Nambiar, R.A.; Haridharan, M.K. Mechanical and durability study of high performance concrete with addition of natural fiber (jute). Mater. Today Proc. 2021, 46, 4941–4947. [Google Scholar] [CrossRef]

- Zhou, C.; Cai, L.; Chen, Z.; Li, J. Effect of kenaf fiber on mechanical properties of high-strength cement composites. Constr. Build. Mater. 2020, 263, 121007. [Google Scholar] [CrossRef]

- Guo, A.; Sun, Z.; Satyavolu, J. Impact of modified kenaf fibers on shrinkage and cracking of cement pastes. Constr. Build. Mater. 2020, 264, 120230. [Google Scholar] [CrossRef]

- Candamano, S.; Crea, F.; Coppola, L.; De Luca, P.; Coffetti, D. Influence of acrylic latex and pre-treated hemp fibers on cement based mortar properties. Constr. Build. Mater. 2021, 273, 121720. [Google Scholar] [CrossRef]

- Affan, M.; Ali, M. Experimental investigation on mechanical properties of jute fiber reinforced concrete under freeze-thaw conditions for pavement applications. Constr. Build. Mater. 2022, 323, 126599. [Google Scholar] [CrossRef]

- Sáez-Pérez, M.P.; Brümmer, M.; Durán-Suárez, J.A. Effect of the state of conservation of the hemp used in geopolymer and hydraulic lime concretes. Constr. Build. Mater. 2021, 285, 122853. [Google Scholar] [CrossRef]

- Gencel, O.; Bayraktar, O.Y.; Kaplan, G.; Benli, A.; Martinez-Barrera, G.; Brostow, W.; Bodur, B. Characteristics of hemp fiber reinforced foam concretes with fly ash and Taguchi optimization. Constr. Build. Mater. 2021, 294, 123607. [Google Scholar] [CrossRef]

- Poletanovic, B.; Dragas, J.; Ignjatovic, I.; Komljenovic, M.; Merta, I. Physical and mechanical properties of hemp fiber reinforced alkali-activated fly ash and fly ash/slag mortars. Constr. Build. Mater. 2020, 259, 119677. [Google Scholar] [CrossRef]

- Juradin, S.; Boko, I.; Grubeša, I.N.; Jozić, D.; Mrakovčić, S. Influence of different treatment and amount of Spanish broom and hemp fibers on the mechanical properties of reinforced cement mortars. Constr. Build. Mater. 2021, 273, 121702. [Google Scholar] [CrossRef]

- Poletanovic, B.; Janotka, I.; Janek, M.; Bacuvcik, M.; Merta, I. Influence of the NaOH-treated hemp fibers on the properties of fly-ash based alkali-activated mortars prior and after wet/dry cycles. Constr. Build. Mater. 2021, 309, 125072. [Google Scholar] [CrossRef]

- Kouta, N.; Saliba, J.; Saiyouri, N. Effect of flax fibers on early age shrinkage and cracking of earth concrete. Constr. Build. Mater. 2020, 254, 119315. [Google Scholar] [CrossRef]

- Rahimi, M.; Hisseine, O.A.; Tagnit-Hamou, A. Effectiveness of treated flax fibers in improving the early age behavior of high-performance concrete. J. Build. Eng. 2022, 45, 103448. [Google Scholar] [CrossRef]

- Page, J.; Amziane, S.; Gomina, M.; Djelal, C.; Audonnet, F. Using linseed oil as flax fiber coating for fiber-reinforced cementitious composite. Ind. Crops Prod. 2021, 161, 113168. [Google Scholar] [CrossRef]

- Rahimi, M.; Omran, A.; Tagnit-Hamou, A. Role of homogenization and surface treatment of flax fiber on performance of cement-based composites. Clean. Mater. 2022, 3, 100037. [Google Scholar] [CrossRef]

- Zhang, D.; Tan, G.Y.; Tan, K.H. Combined effect of flax fibers and steel fibers on spalling resistance of ultra-high-performance concrete at high temperature. Cem. Concr. Compos. 2021, 121, 104067. [Google Scholar] [CrossRef]

- Kouta, N.; Saliba, J.; Saiyouri, N. Fracture behavior of flax fibers reinforced earth concrete. Eng. Fract. Mech. 2021, 241, 107378. [Google Scholar] [CrossRef]

- Page, J.; Khadraoui, F.; Gomina, M.; Boutouil, M. Enhancement of the long-term mechanical performance of flax fiber-reinforced cementitious composites by using alternative binders. J. Build. Eng. 2021, 40, 102323. [Google Scholar] [CrossRef]

- Czajkowski, Ł.; Kocewicz, R.; Weres, J.; Olek, W. Estimation of thermal properties of straw-based insulating panels. Materials 2022, 15, 1073. [Google Scholar] [CrossRef]

- Parmar, N.; Vats, A.; Devi, V.; Kwatra, S.; Srivastava, R.K.; Singh, S.B. Assessing sustainability and performance of hempcrete. Int. J. Environ. Clim. Change 2024, 14, 609–622. [Google Scholar] [CrossRef]

- Walker, R.; Pavia, S. Moisture transfer and thermal properties of hemp–lime concretes. Constr. Build. Mater. 2014, 64, 270–276. [Google Scholar] [CrossRef]

- Ayati, B.; Gutierrez, A.; Chandler, A. Mechanical and hygrothermal properties of hemp-silica bio-composites. Constr. Build. Mater. 2024, 425, 136077. [Google Scholar] [CrossRef]

- Fernando, S.; Gunasekara, C.; Shahpasandi, A.; Nguyen, K.; Sofi, M.; Setunge, S.; Mendis, P.; Rahman, M.T. Sustainable cement composite integrating waste cellulose fibre: A comprehensive review. Polymers 2023, 15, 520. [Google Scholar] [CrossRef] [PubMed]

- Rubino, C.; Liuzzi, S.; Stefanizzi, P.; Martellotta, F. Characterization of sustainable building materials obtained from textile waste: From laboratory prototypes to real-world manufacturing processes. J. Clean. Prod. 2023, 390, 136098. [Google Scholar] [CrossRef]

- Abdulmunem, A.R.; Hussein, N.F.; Samin, P.M.; Sopian, K.; Hussien, H.A.; Ghazali, H. Integration of recycled waste paper with phase change material in building enclosure. J. Energy Storage 2023, 64, 107140. [Google Scholar] [CrossRef]

- Sangmesh, B.; Patil, N.; Jaiswal, K.K.; Gowrishankar, T.P.; Selvakumar, K.K.; Jyothi, M.S.; Jyothilakshmi, R.; Kumar, S. Development of sustainable alternative materials for the construction of green buildings using agricultural residues: A review. Constr. Build. Mater. 2023, 368, 130457. [Google Scholar] [CrossRef]

- Ayed, R.; Bouadila, S.; Skouri, S.; Boquera, L.; Cabeza, L.F.; Lazaar, M. Recycling textile waste to enhance building thermal insulation and reduce carbon emissions: Experimentation and model-based dynamic assessment. Buildings 2023, 13, 535. [Google Scholar] [CrossRef]

- Petcu, C.; Hegyi, A.; Stoian, V.; Dragomir, C.S.; Ciobanu, A.A.; Lăzărescu, A.V.; Florean, C. Research on thermal insulation performance and impact on indoor air quality of cellulose-based thermal insulation materials. Materials 2023, 16, 5458. [Google Scholar] [CrossRef]

- Song, M.; Ripoll, K. A comparative study: Exploring diverse paper-based fabrics for innovative soundproofing solutions. J. Stud. Res. 2023, 12, 1–8. [Google Scholar] [CrossRef]

- Jefferson Andrew, J.; Sain, M.; Ramakrishna, S.; Jawaid, M.; Dhakal, H.N. Environmentally friendly fire retardant natural fibre composites: A review. Int. Mater. Rev. 2024, 69, 267–308. [Google Scholar] [CrossRef]

- Wang, Z.; Wang, D. Can paper waste be utilised as an insulation material in response to the current crisis. Sustainability 2023, 15, 15939. [Google Scholar] [CrossRef]

- Ali, M.; Al-Suhaibani, Z.; Almuzaiqer, R.; Albahbooh, A.; Al-Salem, K.; Nuhait, A. New composites derived from the natural fiber polymers of discarded date palm surface and pineapple leaf fibers for thermal insulation and sound absorption. Polymers 2024, 16, 1002. [Google Scholar] [CrossRef] [PubMed]

- Rodríguez Neira, K.; Cárdenas-Ramírez, J.P.; Rojas-Herrera, C.J.; Haurie, L.; Lacasta, A.M.; Torres Ramo, J.; Sánchez-Ostiz, A. Assessment of elaboration and performance of rice husk-based thermal insulation material for building applications. Buildings 2024, 14, 1720. [Google Scholar] [CrossRef]

- Di Canto, J.A.; Malfait, W.J.; Wernery, J. Turning waste into insulation–a new sustainable thermal insulation board based on wheat bran and banana peels. Build. Environ. 2023, 244, 110740. [Google Scholar] [CrossRef]

- Babenko, M.; Estokova, A.; Unčik, S.; Savytskyi, M. Comparative study of lightweight concretes based on hemp and flax straw. Slovak. J. Civ. Eng. 2022, 30, 11–16. [Google Scholar] [CrossRef]

- Agnihotri, S.; Sheikh, J.N.; Singh, S.P.; Behera, B.K. Flame-retardant textile structural composites for construction application: A review. J. Mater. Sci. 2024, 59, 1788–1818. [Google Scholar] [CrossRef]

- Samardzioska, T.; Jovanoska, M.; Grujoska, V. Sustainable thermal insulation derived from recycled textile waste. Adv. Environ. Eng. Res. 2023, 4, 1–8. [Google Scholar] [CrossRef]

- Kamaruzzaman, A.S.; Jusoh, W.A.W.; Zin, F.S.; Roslan, N.H. A study on thermal insulation of cement bricks incorporate with cellulose fiber. Prog. Eng. Appl. Technol. 2023, 4, 701–710. [Google Scholar] [CrossRef]

- Salahuddin, B.; Sha, Z.; Aziz, S.; Faisal, S.N.; Islam, M.S. Durability against fatigue and moisture of natural fibre composite. Sustain. Nat. Fiber Compos. 2022, 122, 128–153. [Google Scholar] [CrossRef]

- Wang, R.; Jin, P.; Dong, H.; Liu, Y.; Ding, Z.; Zhang, W. Effect of moist content on the bio-carbonated steel slag bricks. Constr. Build. Mater. 2021, 269, 121313. [Google Scholar] [CrossRef]

- Ahmad, J.; Zhou, Z. Mechanical properties of natural as well as synthetic fiber reinforced concrete: A review. Constr. Build. Mater. 2022, 333, 127353. [Google Scholar] [CrossRef]

- Dias, S.; Almeida, J.; Tadeu, A.; de Brito, J. Alternative concrete aggregates—Review of physical and mechanical properties and successful applications. Cem. Concr. Compos. 2024, 152, 105663. [Google Scholar] [CrossRef]

- Kilani, A.; Fapohunda, C.; Adeleke, O.; Metiboba, C. Evaluating the effects of agricultural wastes on concrete and composite mechanical properties: A review. Res. Eng. Struct. Mater. 2021, 8, 307–336. [Google Scholar] [CrossRef]

- Chabannes, M.; Bénézet, J.C.; Clerc, L.; Garcia-Diaz, E. Use of raw rice husk as natural aggregate in a lightweight insulating concrete: An innovative application. Constr. Build. Mater. 2014, 70, 428–438. [Google Scholar] [CrossRef]

- Marques, B.; Tadeu, A.; Almeida, J.; António, J. Experimental characterisation of cement-based composites with rice husk. Int. J. Des. Nat. Ecodynamics 2019, 14, 147–153. [Google Scholar] [CrossRef]

- Maruthupandian, S.; Chaliasou, N.A.; Kanellopoulos, A. Recycling mine tailings for a sustainable future built environment. In Energy and Sustainable Futures: Proceedings of 2nd ICESF 2020; Springer International Publishing: Cham, Switzerland, 2021. [Google Scholar] [CrossRef]

- Araujo, F.S.; Taborda-Llano, I.; Nunes, E.B.; Santos, R.M. Recycling and reuse of mine tailings: A review of advancements and their implications. Geosciences 2022, 12, 319. [Google Scholar] [CrossRef]

- Amrani, M.; Taha, Y.; El Haloui, Y.; Benzaazoua, M.; Hakkou, R. Sustainable reuse of coal mine waste: Experimental and economic assessments for embankments and pavement layer applications in Morocco. Minerals 2020, 10, 851. [Google Scholar] [CrossRef]

- Susanto, I.; Fransisco, S.; Firdaus, Y.; Ronny, Y. Utilization of tailing waste as aggregate for road pavement. IOP Conf. Ser. Earth Environ. Sci. 2021, 802, 012020. [Google Scholar] [CrossRef]

- Tong, J.; Niu, X.; Wang, Y.; Lu, Y. Strength characteristics of iron tailings blended soil as a road base material. Appl. Sci. 2021, 11, 7587. [Google Scholar] [CrossRef]

- Mashifana, T.; Sithole, T. Clean production of sustainable backfill material from waste gold tailings and slag. J. Clean. Prod. 2021, 308, 127357. [Google Scholar] [CrossRef]

- Solouki, A.; Fathollahi, A.; Viscomi, G.; Tataranni, P.; Valdrè, G.; Coupe, S.J.; Sangiorgi, C. Thermally treated waste silt as filler in geopolymer cement. Materials 2021, 14, 5102. [Google Scholar] [CrossRef] [PubMed]

- Solouki, A.; Tataranni, P.; Sangiorgi, C. Mixture optimization of concrete paving blocks containing waste silt. Sustainability 2022, 14, 451. [Google Scholar] [CrossRef]

- Solouki, A.; Viscomi, G.; Tataranni, P.; Sangiorgi, C. Preliminary evaluation of cement mortars containing waste silt optimized with the design of experiments method. Materials 2021, 14, 528. [Google Scholar] [CrossRef]

- Solouki, A.; Tataranni, P.; Tarsi, G.; Sangiorgi, C. Waste silt as filler in hot mix asphalt: A laboratory characterization. Appl. Sci. 2023, 13, 3473. [Google Scholar] [CrossRef]

- Ipekyol, A.; Tortum, A.; Rasouli, R.; Yazdani, M. Evaluating fatigue and crack resistance of asphalt mixture containing zinc tailing aggregates. Case Stud. Constr. Mater. 2022, 17, e01384. [Google Scholar] [CrossRef]

- Ikotun, J.; Adeyeye, R.; Otieno, M. Application of mine tailings sand as construction material—A review. MATEC Web Conf. 2022, 364, 05008. [Google Scholar] [CrossRef]

- Cao, L.; Zhou, J.; Zhou, T.; Dong, Z.; Tian, Z. Utilization of iron tailings as aggregates in paving asphalt mixture: A sustainable and eco-friendly solution for mining waste. J. Clean. Prod. 2022, 375, 134126. [Google Scholar] [CrossRef]

- Baldo, N.; Rondinella, F.; Daneluz, F.; Pasetto, M. Foamed bitumen mixtures for road construction made with 100% waste materials: A laboratory study. Sustainability 2022, 14, 6056. [Google Scholar] [CrossRef]

- Calandra, P.; Quaranta, S.; Figueira, B.A.M.; Caputo, P.; Porto, M.; Rossi, C.O. Mining wastes to improve bitumen performances: An example of circular economy. J. Colloid. Interface Sci. 2022, 614, 277–287. [Google Scholar] [CrossRef]

- Sá, T.S.W.; Oda, S.; Machado, V.K.C.B.L.; Toledo Filho, R.D. Use of iron ore tailings and sediments on pavement structure. Constr. Build. Mater. 2022, 342, 128072. [Google Scholar] [CrossRef]

- Wei, Z.; Jia, Y.; Wang, S.; Li, Z.; Li, Y.; Wang, X.; Gao, Y. Utilization of iron ore tailing as an alternative mineral filler in asphalt mastic: High-temperature performance and environmental aspects. J. Clean. Prod. 2022, 335, 130318. [Google Scholar] [CrossRef]

- Xiao, Y.; Ju, X.; Li, C.; Wang, T.; Wu, R. Research on recycling of phosphorus tailings powder in open-graded friction course asphalt concrete. Materials 2023, 16, 2000. [Google Scholar] [CrossRef] [PubMed]

- Singh, S.; Kumar, A.; Sitharam, T.G. Experimental study on strength, durability, hydraulic and toxicity characteristics of soil treated with mine tailings based geopolymers for sustainable road subgrade application. Constr. Build. Mater. 2024, 414, 134894. [Google Scholar] [CrossRef]

- Lei, B.; Li, X.; Guo, Y.; Qu, F.; Zhao, C.; Tam, V.W.; Li, W. Recycling of copper tailing as filler material in asphalt paving mastic: A sustainable solution for mining waste recovery. Case Stud. Constr. Mater. 2024, 20, e03237. [Google Scholar] [CrossRef]

- Li, J.; Sha, A.; Wang, Z.; Song, R.; Cao, Y. Investigation of the self-healing, road performance and cost–benefit effects of an iron tailing/asphalt mixture in pavement. Constr. Build. Mater. 2024, 422, 135788. [Google Scholar] [CrossRef]

- Vargas, F.; Rigamonti, L. Environmental evaluation of treated tailing as supplementary cementitious material. Procedia CIRP 2020, 90, 280–284. [Google Scholar] [CrossRef]

- Yao, G.; Wang, Q.; Wang, Z.; Wang, J.; Lyu, X. Activation of hydration properties of iron ore tailings and their application as supplementary cementitious materials in cement. Powder Technol. 2020, 360, 863–871. [Google Scholar] [CrossRef]

- Magalhaes, L.F.; França, S.; dos Santos Oliveira, M.; Peixoto, R.A.F.; Bessa, S.A.L.; da Silva Bezerra, A.C. Iron ore tailings as a supplementary cementitious material in the production of pigmented cements. J. Clean. Prod. 2020, 274, 123260. [Google Scholar] [CrossRef]

- Bezerra, C.G.; Rocha, C.A.A.; de Siqueira, I.S.; Toledo Filho, R.D. Feasibility of iron-rich ore tailing as supplementary cementitious material in cement pastes. Constr. Build. Mater. 2021, 303, 124496. [Google Scholar] [CrossRef]

- Zhang, Y.; Liu, B.; Gu, X.; Nehdi, M.L.; Zhang, L.V. Mechanochemical activation of iron ore tailing-based ternary supplementary cementitious materials. Constr. Build. Mater. 2022, 346, 128420. [Google Scholar] [CrossRef]

- Zhang, Y.; Yang, D.; Gu, X.; Chen, H.; Li, Z. Application of iron tailings-based composite supplementary cementitious materials (SCMs) in green concrete. Materials 2022, 15, 3866. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Li, Z.; Jin, Q.; Zhang, M.; Zhou, Z. High-efficiency utilization of limestone tailings: Used as cementitious materials and fine aggregate to prepare karst structure filling material. Constr. Build. Mater. 2022, 316, 125841. [Google Scholar] [CrossRef]

- Ghazi, A.B.; Jamshidi-Zanjani, A.; Nejati, H. Utilization of copper mine tailings as a partial substitute for cement in concrete construction. Constr. Build. Mater. 2022, 317, 125921. [Google Scholar] [CrossRef]

- Yun-Hong, C.; Si-hui, Y.; Jing-yu, Z.; Xiao-hui, S. Test research on hydration process of cement-iron tailings powdercomposite cementitious materials. Powder Technol. 2022, 399, 117215. [Google Scholar] [CrossRef]

- Duarte, M.S.; Almada, B.S.; dos Santos, W.J.; Bessa, S.A.L.; da Silva Bezerra, A.C.; Aguilar, M.T.P. Influence of mechanical treatment and magnetic separation on the performance of iron ore tailings as supplementary cementitious material. J. Build. Eng. 2022, 59, 105099. [Google Scholar] [CrossRef]

- Zhang, K.; Xu, H.; Kong, X.X.; Zhang, C.Y.; Lu, H.F.; He, D. Study on the influence mechanism of micro-mechanical properties of heterogeneous geopolymer gels. J. Build. Eng. 2023, 76, 107164. [Google Scholar] [CrossRef]

- Singh, A.; Wang, Y.; Zhou, Y.; Sun, J.; Xu, X.; Li, Y.; Wang, X. Utilization of antimony tailings in fiber-reinforced 3D printed concrete: A sustainable approach for construction materials. Constr. Build. Mater. 2023, 408, 133689. [Google Scholar] [CrossRef]

- Chen, B.; Pang, L.; Zhou, Z.; Chang, Q.; Fu, P. Study on the hydration properties of a ternary cementitious material system containing activated gold tailings and granulated blast furnace slag. J. Build. Eng. 2023, 63, 105574. [Google Scholar] [CrossRef]

- Sepúlveda-Vásquez, C.; Carrasco-Astudillo, N.; Muñoz, L.; Molina, P.; Ringuedé, A.; Guerra, C.; Sancy, M. Electrochemical analysis of carbon steel embedded in mortars with pretreated copper tailings as supplementary cementitious material. Int. J. Electrochem. Sci. 2024, 19, 100584. [Google Scholar] [CrossRef]

- Hernández-Ramos, S.M.; Trejo-Arroyo, D.L.; Cholico-González, D.F.; Rodríguez-Torres, G.M.; Zárate-Medina, J.; Vega-Azamar, R.E.; Ortíz-Lara, N. Characterization and effect of mechanical and thermal activation in mining tailings for use as supplementary cementitious material. Case Stud. Constr. Mater. 2024, 20, e02770. [Google Scholar] [CrossRef]

- Hu, Z.; Gu, X.; Cheng, B.; Wang, Q.; Liu, J.; Ge, X.; Yin, S. The role of chemical activation in strengthening iron ore tailings supplementary cementitious materials. Buildings 2024, 14, 963. [Google Scholar] [CrossRef]

- Hu, Z.; Gu, X.; Liu, J.; Ge, X.; Wang, S.; Yin, S. Mechanical properties and hydration mechanism of iron tailings–cement-based supplementary cementitious materials. Buildings 2024, 14, 1044. [Google Scholar] [CrossRef]

- Fernandes, J.V.; Guedes, D.G.; da Costa, F.P.; Rodrigues, A.M.; Neves, G.D.A.; Menezes, R.R.; Santana, L.N.L.D.L. Sustainable ceramic materials manufactured from ceramic formulations containing quartzite and scheelite tailings. Sustainability 2020, 12, 9417. [Google Scholar] [CrossRef]

- Figueirêdo, J.M.R.D.; Costa, F.P.D.; Fernandes, J.V.; Rodrigues, A.M.; Neves, G.D.A.; Menezes, R.R.; Santana, L.N.L.D.L. Development of scheelite tailings-based ceramic formulations with the potential to manufacture porcelain tiles, semi-stoneware and stoneware. Materials 2020, 13, 5122. [Google Scholar] [CrossRef]

- Suvorova, O.V.; Selivanova, E.A.; Mikhailova, J.A.; Masloboev, V.A.; Makarov, D.V. Ceramic products from mining and metallurgical waste. Appl. Sci. 2020, 10, 3515. [Google Scholar] [CrossRef]

- Baziz, A.; Bouzidi, N.; Eliche-Quesada, D. Recycling of gold mining reject from Amesmessa mine as ceramic raw material: Microstructure and mechanical properties. Environ. Sci. Pollut. Res. 2021, 28, 46738–46747. [Google Scholar] [CrossRef]

- Paiva, H.; Simões, F.; Maljaee, H.; Yliniemi, J.; Illikainen, M.; Ferreira, V.M. Production of ceramic construction materials as an environmental management solution for sulfidic mine tailings. SN Appl. Sci. 2021, 3, 1–10. [Google Scholar] [CrossRef]

- Almeida, E.P.; Carreiro, M.E.A.; Rodrigues, A.M.; Ferreira, H.S.; Santana, L.N.L.D.L.; Menezes, R.R.; Neves, G.A. A new eco-friendly mass formulation based on industrial mining residues for the manufacture of ceramic tiles. Ceram. Int. 2021, 47, 11340–11348. [Google Scholar] [CrossRef]

- Simão, F.V.; Chambart, H.; Vandemeulebroeke, L.; Cappuyns, V. Incorporation of sulphidic mining waste material in ceramic roof tiles and blocks. J. Geochem. Explor. 2021, 225, 106741. [Google Scholar] [CrossRef]

- Simão, F.V.; Chambart, H.; Vandemeulebroeke, L.; Nielsen, P.; Cappuyns, V. Turning mine waste into a ceramic resource: Plombières tailing case. J. Sustain. Metall. 2021, 7, 1469–1482. [Google Scholar] [CrossRef]

- Ferreira, J.F.; Costa, F.P.D.; Borborema, L.F.D.; Arimateia, R.R.; Leite, R.S.; Apolinário, R.C.; Menezes, R.R. Incorporation of bentonite mining waste in ceramic formulations for the manufacturing of porcelain stoneware. Sustainability 2022, 14, 15973. [Google Scholar] [CrossRef]

- Lam, E.J.; Zetola, V.; Ramírez, Y.; Montofré, Í.L.; Pereira, F. Making paving stones from copper mine tailings as aggregates. Int. J. Environ. Res. Public Health 2020, 17, 2448. [Google Scholar] [CrossRef] [PubMed]

- Zhou, Y.; Duan, X.; Chen, T.; Yan, B.; Li, L. Mechanical properties and toxicity risks of lead-zinc sulfide tailing-based construction materials. Materials 2021, 14, 2940. [Google Scholar] [CrossRef] [PubMed]

- Cechin, L.; Mymrine, V.; Avanci, M.A.; Povaluk, A.E. Ceramics composites from iron ore tailings and blast furnace slag. Ceram. Int. 2022, 48, 10506–10515. [Google Scholar] [CrossRef]

- Huang, H.; Li, S.; Gou, H.; Zhang, N.; Liu, L. Efficient recovery of feldspar, quartz, and kaolin from weathered granite. Minerals 2024, 14, 300. [Google Scholar] [CrossRef]

- Lv, X.; Lin, Y.; Chen, X.; Shi, Y.; Liang, R.; Wang, R.; Peng, Z. Environmental impact, durability performance, and interfacial transition zone of iron ore tailings utilized as dam concrete aggregates. J. Clean. Prod. 2021, 292, 126068. [Google Scholar] [CrossRef]

- Vallejos, C.M.C.; Rodríguez, J.S.T.; Janet, L.; Reyes, C.; Serrano, J.C.E.; Lindo, M.A.S.; Giraldo, R.D.L.; Huerta, D.M.; González, C.G.P. Copper and zinc mining tailings as a partial replacement for cement to increase the compressive strength of concrete. Int. J. Membr. Sci. Technol. 2023, 10, 1543–1550. [Google Scholar] [CrossRef]

- Junior, P.; Franks, D.M. Construction materials and sustainable development. In Routledge Handbook of the Extractive Industries and Sustainable Development; Routledge: Abingdon-on-Thames, UK, 2022; pp. 228–246. [Google Scholar]

- Adiguzel, D.; Tuylu, S.; Eker, H. Utilization of tailings in concrete products: A review. Constr. Build. Mater. 2022, 360, 129574. [Google Scholar] [CrossRef]

- Gou, M.; Zhou, L.; Then, N.W.Y. Utilization of tailings in cement and concrete: A review. Sci. Eng. Compos. Mater. 2019, 26, 449–464. [Google Scholar] [CrossRef]

- Jian, S.; Gao, W.; Lv, Y.; Tan, H.; Li, X.; Li, B.; Huang, W. Potential utilization of copper tailings in the preparation of low heat cement clinker. Constr. Build. Mater. 2020, 252, 119130. [Google Scholar] [CrossRef]

- Faria, N.C.; Pereira, V.M.; Nobre, T.R.; Romano, R.C.D.O.; Coelho, A.C.V.; Angulo, S.C. Clinker Portland with iron ore tailing and its characterization by integrated laboratory methods. Constr. Build. Mater. 2023, 402, 132958. [Google Scholar] [CrossRef]

- Wang, Z.; Wang, Q.; Zhao, W.; Xia, C.; Tian, X.; Jiang, Y.; Zhou, X.; Chen, G.; Wang, L.; Chen, M. Influence of carlin-type gold mine tailings addition on the synthesis temperature, alkali-resistant performance, and hydration mechanism of Portland cement. Constr. Build. Mater. 2022, 359, 129458. [Google Scholar] [CrossRef]

- Da, Y.; He, T.; Shi, C. Unveiling the cooperation effects of fluorine and copper on tricalcium silicate (C3S) during cement kiln co-processing hazardous wastes containing Cu. Constr. Build. Mater. 2022, 337, 127612. [Google Scholar] [CrossRef]

- Barbosa, P.D.C.; Mau, J.P.M.; Cheloni, L.M.D.M.S.; Cota, T.G.; Reis, É.L. Briquetting of manganese ore fines with cement as binder. REM-Int. Eng. J. 2024, 77, e230047. [Google Scholar] [CrossRef]

- Tian, X.; Wang, C.; Asrah, H.; Han, L.C.; Zheng, Y. Investigating the grinding characteristics of vanadium-titanium iron ore tailings for sustainable utilization in cementitious material preparation. Alex. Eng. J. 2024, 101, 78–89. [Google Scholar] [CrossRef]

- Tai, W.; Tong, X.; Zhang, K.; Luo, Z. Effect of Iron Tailings Fine Powder as Admixture on the Properties of Cement Mortar and Concrete. In Advanced Construction Technology and Research of Deep-Sea Tunnels; Springer Nature: Singapore, 2024; pp. 283–300. [Google Scholar]

- Eid, M.S.; Saleh, H.M. Characterizations of cement and modern sustainable concrete incorporating different waste additives. In Sustainability of Concrete with Synthetic and Recycled Aggregates, 1st ed.; IntechOpen: London, UK, 2021; pp. 3–18. [Google Scholar]

- Pell, R.; Tijsseling, L.; Goodenough, K.; Wall, F.; Dehaine, Q.; Grant, A.; Deak, D.; Yan, X.; Whattoff, P. Towards sustainable extraction of technology materials through integrated approaches. Nat. Rev. Earth Environ. 2021, 2, 665–679. [Google Scholar] [CrossRef]

- DeCeanne, A.V.; Rodrigues, L.R.; Wilkinson, C.J.; Mauro, J.C.; Zanotto, E.D. Examining the role of nucleating agents within glass-ceramic systems. J. Non Cryst. Solids 2022, 591, 121714. [Google Scholar] [CrossRef]

- Smirnov, A.D.; Kholodkova, A.A.; Rybalchenko, V.V.; Tarasovskii, V.P. Porous alumina-bentonite ceramics: Effects of fillers and molding technique. Ceramics 2023, 6, 132–145. [Google Scholar] [CrossRef]

- Khanam, J.; Hasan, M.R.; Biswas, B.; Jahan, S.A.; Sharmin, N.; Ahmed, S.; Al-Reza, S.M. Development of ceramic grade red iron oxide pigment from waste iron source. Heliyon 2023, 9, e12854. [Google Scholar] [CrossRef]

- Ozturk, S. Optimization of thermal conductivity and lightweight properties of clay bricks. Eng. Sci. Technol. Int. J. 2023, 48, 101566. [Google Scholar] [CrossRef]

- Yilmaz, E.; Koohestani, B.; Cao, S. Recent practices in mine tailings’ recycling and reuse. In Managing Mining and Minerals Processing Wastes: Concepts, Design and Applications, 1st ed.; Elsevier: Amsterdam, The Netherlands, 2023; pp. 271–304. [Google Scholar] [CrossRef]

- Hua, S.; Wu, D.; Wu, J.; Li, S.; Liu, G.; Pei, D. Characterization of the physical chemistry properties of iron-tailing-based ceramsite. Molecules 2023, 28, 2258. [Google Scholar] [CrossRef] [PubMed]

- Kinnunen, P.; Ismailov, A.; Solismaa, S.; Sreenivasan, H.; Räisänen, M.L.; Levänen, E.; Illikainen, M. Recycling mine tailings in chemically bonded ceramics—A review. J. Clean. Prod. 2018, 174, 634–649. [Google Scholar] [CrossRef]

- Kang, X.; Li, Y.; Li, W.; Zhou, Y.; Cui, J.; Cai, B.; Zi, Y.; Fang, J.; Chen, Y.; Li, S.; et al. Synthesis and characterization of sustainable eco-friendly alkali-activated high-content iron ore tailing bricks. Buildings 2023, 13, 2743. [Google Scholar] [CrossRef]

- Li, W.; Lei, G.; Xu, Y.; Huang, Q. The properties and formation mechanisms of eco-friendly brick building materials fabricated from low-silicon iron ore tailings. J. Clean. Prod. 2018, 204, 685–692. [Google Scholar] [CrossRef]

- Thejas, H.K.; Hossiney, N. A short review on environmental impacts and application of iron ore tailings in development of sustainable eco-friendly bricks. Mater. Today Proc. 2022, 61, 327–331. [Google Scholar] [CrossRef]

- Chen, H.; Wang, Z.; Pei, L.; Xue, Z.; Yu, C.; Fan, C. Fabrication of baking-free bricks from iron ore tailings. Curr. Mater. Sci. 2020, 13, 97–110. [Google Scholar] [CrossRef]

- Nikvar-Hassani, A.; Hodges, R.; Zhang, L. Production of green bricks from low-reactive copper mine tailings: Durability and environmental aspects. Constr. Build. Mater. 2022, 337, 127571. [Google Scholar] [CrossRef]

- Huang, X.; Tian, Y.; Jiang, J.; Lu, X.; He, Z.; Jia, K. Mechanical properties and enhancement mechanism of iron ore tailings as aggregate for manufacturing ultra-high performance geopolymer concrete. Constr. Build. Mater. 2024, 439, 137362. [Google Scholar] [CrossRef]

- Das, D.; Gołąbiewska, A.; Rout, P.K. Geopolymer bricks: The next generation of construction materials for sustainable environment. Constr. Build. Mater. 2024, 445, 137876. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhang, L.; Wang, Q.; Han, D.; Li, Z. Iron ore tailings, phosphate slags, and lithium slags as ternary supplementary cementitious materials for concrete: Study on compression strength and microstructure. Mater. Today Commun. 2023, 36, 106644. [Google Scholar] [CrossRef]

- Zhang, J.; Sun, N.; Huo, Z.; Chen, J. Understanding the synergistic geopolymerization mechanism of multiple solid wastes in ternary geopolymers. J. Build. Eng. 2024, 95, 110295. [Google Scholar] [CrossRef]

- Kriven, W.M.; Leonelli, C.; Provis, J.L.; Boccaccini, A.R.; Attwell, C.; Ducman, V.S.; Ferone, C.; Rossignol, S.; Luukkonen, T.; Van Deventer, J.S.; et al. Why geopolymers and alkali-activated materials are key components of a sustainable world: A perspective contribution. J. Am. Ceram. Soc. 2024, 107, 5159–5177. [Google Scholar] [CrossRef]

- Palma, G.; Bolaños, H.; Huamani, R.; Clements, C.; Hedayat, A. Optimization of geopolymers for sustainable management of mine tailings: Impact on mechanical, microstructural and toxicological properties. Minerals 2024, 14, 997. [Google Scholar] [CrossRef]

- Manaviparast, H.R.; Miranda, T.; Pereira, E.; Cristelo, N. A comprehensive review on mine tailings as a raw material in the alkali activation process. Appl. Sci. 2024, 14, 5127. [Google Scholar] [CrossRef]

- Wang, H.; Wang, L.; Ren, Z.; Liu, S. Optimizing raw material composition and alkali content in low silicon-aluminum tailings-based geopolymers. Constr. Build. Mater. 2023, 404, 133339. [Google Scholar] [CrossRef]

- Asadizadeh, M.; Hedayat, A.; Tunstall, L.; Gonzalez, J.A.V.; Alvarado, J.W.V.; Neira, M.T. The impact of slag on the process of geopolymerization and the mechanical performance of mine-tailings-based alkali-activated lightweight aggregates. Constr. Build. Mater. 2024, 411, 134347. [Google Scholar] [CrossRef]

- Das, D.; Neupane, K.; Gołąbiewska, A.; Rout, P.K. Utilization of iron tailings in alkali-activated binders: A review. Case Stud. Constr. Mater. 2023, 18, e02050. [Google Scholar] [CrossRef]

- Okereafor, U.; Makhatha, M.; Mekuto, L.; Mavumengwana, V. Gold mine tailings: A potential source of silica sand for glass making. Minerals 2020, 10, 448. [Google Scholar] [CrossRef]

- Alfonso, P.; Tomasa, O.; Domenech, L.M.; Garcia-Valles, M.; Martinez, S.; Roca, N. The use of tailings to make glass as an alternative for sustainable environmental remediation: The case of Osor, Catalonia, Spain. Minerals 2020, 10, 819. [Google Scholar] [CrossRef]

- Fu, F.; Hu, N.; Ye, Y.; Chen, G.; Guan, W.; Yang, S.; Li, Q. Production of high-value-added lightweight glass ceramics based on phosphorus tailings and coal gangue. Ceram. Int. 2024, 50, 16725–16735. [Google Scholar] [CrossRef]

- Sangiorgi, C.; Lantieri, C.; Tataranni, P.; Castro-Gomes, J.; Gabriel, M. Reuse of mining waste into innovative alkali-activated-based materials for road pavement applications. In Functional Pavement Design; CRC Press: Boca Raton, FL, USA, 2016. [Google Scholar]

- Segui, P.; Safhi, A.E.M.; Amrani, M.; Benzaazoua, M. Mining wastes as road construction material: A review. Minerals 2023, 13, 90. [Google Scholar] [CrossRef]

- Jahandari, S.; Tao, Z.; Chen, Z.; Osborne, D.; Rahme, M. Coal wastes: Handling, pollution, impacts, and utilization. In The Coal Handbook; Woodhead Publishing: Sawston, UK, 2023; pp. 97–163. [Google Scholar] [CrossRef]

- Prasad, M.N.V. Resource potential of natural and synthetic gypsum waste. In Environmental Materials and Waste; Elsevier: Amsterdam, The Netherlands, 2024; pp. 369–424. [Google Scholar] [CrossRef]

- Randhawa, N.S. An overview of sustainable solutions towards recycling of metallurgical slags. In iConFIRM: International Conference on Fundamental and Industrial Research in Materials; Springer Nature: Singapore, 2023; pp. 47–56. [Google Scholar] [CrossRef]

- Baalamurugan, J.; Ganesh Kumar, V.; Naveen Prasad, B.S.N.; Padmapriya, R.; Karthick, V.; Govindaraju, K. Recycling of induction furnace steel slag in concrete for marine environmental applications towards ocean acidification studies. Int. J. Environ. Sci. Technol. 2022, 19, 5039–5048. [Google Scholar] [CrossRef]

- USGS. US Geological Survey, Mineral Commodity Summaries. Iron and Steel Slag. 2024. Available online: https://www.usgs.gov/centers/national-minerals-information-center/mineral-commodity-summaries (accessed on 8 May 2025).

- Esther, L.A.; Pedro, L.G.; Irune, I.V.; Gerardo, F. Comprehensive analysis of the environmental impact of electric arc furnace steel slag on asphalt mixtures. J. Clean. Prod. 2020, 275, 123121. [Google Scholar] [CrossRef]

- Dondi, G.; Mazzotta, F.; Lantieri, C.; Cuppi, F.; Vignali, V.; Sangiovanni, C. Use of steel slag as an alternative to aggregate and filler in road pavements. Materials 2021, 14, 345. [Google Scholar] [CrossRef]

- Díaz-Piloneta, M.; Terrados-Cristos, M.; Álvarez-Cabal, J.V.; Vergara-González, E. Comprehensive analysis of steel slag as aggregate for road construction: Experimental testing and environmental impact assessment. Materials 2021, 14, 3587. [Google Scholar] [CrossRef]

- Georgiou, P.; Loizos, A. Characterization of sustainable asphalt mixtures containing high reclaimed asphalt and steel slag. Materials 2021, 14, 4938. [Google Scholar] [CrossRef]

- Chen, W.; Wei, J.; Xu, X.; Zhang, X.; Han, W.; Yan, X.; Lu, Z. Study on the optimum steel slag content of SMA-13 asphalt mixes based on road performance. Coatings 2021, 11, 1436. [Google Scholar] [CrossRef]

- Swathi, M.; Andiyappan, T.; Guduru, G.; Reddy, M.A.; Kuna, K.K. Design of asphalt mixes with steel slag aggregates using the Bailey method of gradation selection. Constr. Build. Mater. 2021, 279, 122426. [Google Scholar] [CrossRef]

- Zhao, X.; Sheng, Y.; Lv, H.; Jia, H.; Liu, Q.; Ji, X.; Meng, J. Laboratory investigation on road performances of asphalt mixtures using steel slag and granite as aggregate. Constr. Build. Mater. 2022, 315, 125655. [Google Scholar] [CrossRef]

- Goli, A. The study of the feasibility of using recycled steel slag aggregate in hot mix asphalt. Case Stud. Constr. Mater. 2022, 16, e00861. [Google Scholar] [CrossRef]

- Wang, Z. Quantitative assessment of road performance of recycled asphalt mixtures incorporated with steel slag. Materials 2022, 15, 5005. [Google Scholar] [CrossRef] [PubMed]

- Chen, H.; Liu, Y.; Cui, H.; Zhang, W.; Hu, L.; Mao, L. Effects of electric arc furnace slag on promoting quality and environmental safety of fired bricks incorporating municipal solid waste incineration fly ash. Constr. Build. Mater. 2022, 345, 128327. [Google Scholar] [CrossRef]

- Liu, J.; Jing, H.; Wang, Z.; Wang, X.; Zhang, L. Recycling of steel slag in sustainable bituminous mixtures: Self-healing performance, mechanism, environmental and economic analyses. J. Clean. Prod. 2023, 429, 139496. [Google Scholar] [CrossRef]

- Liu, J.; Wang, W.; Wang, Y.; Zhou, X.; Wang, S.; Liu, Q.; Yu, B. Towards the sustainable utilization of steel slag in asphalt pavements: A case study of moisture resistance and life cycle assessment. Case Stud. Constr. Mater. 2023, 18, e01722. [Google Scholar] [CrossRef]

- Sun, J.; Luo, S.; Wang, Y.; Dong, Q.; Zhang, Z. Pre-treatment of steel slag and its applicability in asphalt mixtures for sustainable pavements. Chem. Eng. J. 2023, 476, 146802. [Google Scholar] [CrossRef]

- Tangadagi, R.B.; Manjunatha, M.; Bharath, A.; Preethi, S. Utilization of steel slag as an eco-friendly material in concrete for construction. J. Green. Eng. 2020, 10, 2408–2419. [Google Scholar]

- Sha, F.; Liu, P.; Ding, Y. Application investigation of high-phosphorus steel slag in cementitious material and ordinary concrete. J. Mater. Res. Technol. 2021, 11, 2074–2091. [Google Scholar] [CrossRef]

- Lee, J.I.; Choi, S.J. Effect of replacement ratio of ferronickel slag aggregate on characteristics of cementitious mortars at different curing temperatures. Case Stud. Constr. Mater. 2023, 18, e01882. [Google Scholar] [CrossRef]

- Fares, A.I.; Sohel, K.M.A.; Al-Jabri, K.; Al-Mamun, A. Characteristics of ferrochrome slag aggregate and its uses as a green material in concrete—A review. Constr. Build. Mater. 2021, 294, 123552. [Google Scholar] [CrossRef]

- Wang, D.; Wang, Q.; Huang, Z. Reuse of copper slag as a supplementary cementitious material: Reactivity and safety. Resour. Conserv. Recycl. 2020, 162, 105037. [Google Scholar] [CrossRef]

- Chen, Y.; Ji, T.; Yang, Z.; Zhan, W.; Zhang, Y. Sustainable use of ferronickel slag in cementitious composites and the effect on chloride penetration resistance. Constr. Build. Mater. 2020, 240, 117969. [Google Scholar] [CrossRef]

- Gupta, N.; Siddique, R. Durability characteristics of self-compacting concrete made with copper slag. Constr. Build. Mater. 2020, 247, 118580. [Google Scholar] [CrossRef]

- Beaucour, A.L.; Pliya, P.; Faleschini, F.; Njinwoua, R.; Pellegrino, C.; Noumowé, A. Influence of elevated temperature on properties of radiation shielding concrete with electric arc furnace slag as coarse aggregate. Constr. Build. Mater. 2020, 256, 119385. [Google Scholar] [CrossRef]

- Luo, Z.; Ma, Y.; Mu, W.; Liu, J.; He, J.; Zhou, X. Magnesium phosphate cement prepared with electric furnace ferronickel slag: Properties and its hydration mechanism. Constr. Build. Mater. 2021, 300, 123991. [Google Scholar] [CrossRef]

- Nuruzzaman, M.; Kuri, J.C.; Sarker, P.K. Strength, permeability and microstructure of self-compacting concrete with the dual use of ferronickel slag as fine aggregate and supplementary binder. Constr. Build. Mater. 2022, 318, 125927. [Google Scholar] [CrossRef]

- Shoukry, H.; Perumal, P.; Abadel, A.; Alghamdi, H.; Alamri, M.; Abdel-Gawwad, H.A. Performance of limestone-calcined clay cement mortar incorporating high volume ferrochrome waste slag aggregate. Constr. Build. Mater. 2022, 350, 128928. [Google Scholar] [CrossRef]

- Liu, J.; Lin, C.; Liu, T.; Han, L.; Shen, X.; Li, C.; Lu, A. An eco-friendly permeable brick with excellent permeability and high strength derived from steel slag wastes. Int. J. Appl. Ceram. Technol. 2020, 17, 584–597. [Google Scholar] [CrossRef]

- Liu, Y.; Zhang, Z.; Hou, G.; Yan, P. Preparation of sustainable and green cement-based composite binders with high-volume steel slag powder and ultrafine blast furnace slag powder. J. Clean. Prod. 2021, 289, 125133. [Google Scholar] [CrossRef]

- Islam, M.Z.; Sohel, K.M.; Al-Jabri, K.; Al Harthy, A. Properties of concrete with ferrochrome slag as a fine aggregate at elevated temperatures. Case Stud. Constr. Mater. 2021, 15, e00599. [Google Scholar] [CrossRef]

- Yang, H.J.; Lee, C.H.; Shim, S.H.; Kim, J.H.J.; Lee, H.J.; Park, J. Performance evaluation of cement paste incorporating ferro-nickel slag powder under elevated temperatures. Case Stud. Constr. Mater. 2021, 15, e00727. [Google Scholar] [CrossRef]

- Jena, S.; Panigrahi, R. Feasibility study of the properties of geopolymer concrete with ferrochrome slag and silica fume. Mater. Today Proc. 2021, 38, 2476–2480. [Google Scholar] [CrossRef]

- Maharishi, A.; Singh, S.P.; Gupta, L.K. Strength and durability studies on slag cement concrete made with copper slag as fine aggregates. Mater. Today Proc. 2021, 38, 2639–2648. [Google Scholar] [CrossRef]

- Roslan, N.H.; Ismail, M.; Khalid, N.H.A.; Muhammad, B. Properties of concrete containing electric arc furnace steel slag and steel sludge. J. Build. Eng. 2020, 28, 101060. [Google Scholar] [CrossRef]

- Ruan, W.; Ma, Y.; Liao, J.; Ma, T.; Zhu, Y.; Zhou, A. Effects of steel slag on the microstructure and mechanical properties of magnesium phosphate cement. J. Build. Eng. 2022, 49, 104120. [Google Scholar] [CrossRef]

- Pang, L.; Liao, S.; Wang, D.; An, M. Influence of steel slag fineness on the hydration of cement-steel slag composite pastes. J. Build. Eng. 2022, 57, 104866. [Google Scholar] [CrossRef]

- Fang, M.; Fang, G.; Xia, Y.; Wang, H. Study on compressive strength of concrete mixed by steel slag powder and fly ash. IOP Conf. Ser. Earth Environ. Sci. 2020, 508, 012183. [Google Scholar] [CrossRef]

- Wu, Q.; Huang, Z. Preparation and performance of lightweight porous ceramics using metallurgical steel slag. Ceram. Int. 2021, 47, 25169–25176. [Google Scholar] [CrossRef]

- Rahou, J.; Rezqi, H.; El Ouahabi, M.; Fagel, N. Characterization of Moroccan steel slag waste: The potential green resource for ceramic production. Constr. Build. Mater. 2022, 314, 125663. [Google Scholar] [CrossRef]

- Ji, Y.; Li, E.; Zhu, G.; Wang, R.; Sha, Q. Preparation and performance of ceramic tiles with steel slag and waste clay bricks. Materials 2024, 17, 1755. [Google Scholar] [CrossRef]

- Liu, J.; Yu, B.; Wang, Q. Application of steel slag in cement treated aggregate base course. J. Clean. Prod. 2020, 269, 121733. [Google Scholar] [CrossRef]

- Weng, Y.; Liu, Y.; Liu, J. Study on mathematical model of hydration expansion of steel slag-cement composite cementitious material. Environ. Technol. 2021, 42, 2776–2783. [Google Scholar] [CrossRef] [PubMed]

- Li, N.; Zhan, H.; Yu, X.; Tang, W.; Xue, Q. Investigation of the aging behaviour of cellulose fiber in reclaimed asphalt pavement. Constr. Build. Mater. 2021, 271, 121559. [Google Scholar] [CrossRef]

- Mikhailenko, P.; Piao, Z.; Poulikakos, L.D. Electric arc furnace slag as aggregates in semi-dense asphalt. Case Stud. Constr. Mater. 2023, 18, e02049. [Google Scholar] [CrossRef]

- Piemonti, A.; Conforti, A.; Cominoli, L.; Sorlini, S.; Luciano, A.; Plizzari, G. Use of iron and steel slags in concrete: State of the art and future perspectives. Sustainability 2021, 13, 556. [Google Scholar] [CrossRef]

- Shumuye, E.D.; Zhao, J.; Wang, Z. Effect of the curing condition and high-temperature exposure on ground-granulated blast-furnace slag cement concrete. Int. J. Concr. Struct. Mater. 2021, 15, 1–20. [Google Scholar] [CrossRef]

- Ahmad, J.; Kontoleon, K.J.; Majdi, A.; Naqash, M.T.; Deifalla, A.F.; Ben Kahla, N.; Isleem, H.F.; Qaidi, S.M. A comprehensive review on the ground granulated blast furnace slag (GGBS) in concrete production. Sustainability 2022, 14, 8783. [Google Scholar] [CrossRef]

- Asaad, M.A.; Huseien, G.F.; Memon, R.P.; Ghoshal, S.K.; Mohammadhosseini, H.; Alyousef, R. Enduring performance of alkali-activated mortars with metakaolin as granulated blast furnace slag replacement. Case Stud. Constr. Mater. 2022, 16, e00845. [Google Scholar] [CrossRef]

- Omur, T.; Miyan, N.; Kabay, N.; Özkan, H. Utilization and optimization of unweathered and weathered basic oxygen furnace slag aggregates in cement based mortar. J. Build. Eng. 2023, 64, 105634. [Google Scholar] [CrossRef]

- Zago, S.C.; Vernilli, F.; Cascudo, O. The reuse of basic oxygen furnace slag as concrete aggregate to achieve sustainable development: Characteristics and limitations. Buildings 2023, 13, 1193. [Google Scholar] [CrossRef]

- Diotti, A.; Cominoli, L.; Galvin, A.P.; Sorlini, S.; Plizzari, G. Sustainable recycling of electric arc furnace steel slag as aggregate in concrete: Effects on the environmental and technical performance. Sustainability 2021, 13, 521. [Google Scholar] [CrossRef]

- Kurecki, M.; Meena, N.; Shyrokykh, T.; Korobeinikov, Y.; Jarnerud Örell, T.; Voss, Z.; Sridhar, S. Recycling Perspectives of Electric Arc Furnace Slag in the United States: A Review. Steel Res. Int. 2024, 2300854. [Google Scholar] [CrossRef]

- Araos, P.; Aponte, D.; Barra, M. Ladle furnace slag as a new source of supplementary cementitious material: Evaluating long-term performance and environmental impact in Portland cement systems. J. Build. Eng. 2024, 95, 109995. [Google Scholar] [CrossRef]

- Ahmad, J.; Majdi, A.; Deifalla, A.F.; Isleem, H.F.; Rahmawati, C. Concrete made with partially substitutions of copper slag (CPS): State of the art review. Materials 2022, 15, 5196. [Google Scholar] [CrossRef] [PubMed]

- Sahu, A.; Kumar, S.; Srivastava, A.K.L.; Pratap, B. Performance of recycled aggregate concrete using copper slag as fine aggregate. J. Build. Eng. 2024, 82, 108364. [Google Scholar] [CrossRef]

- Yanning, S.; Qiao, H.; Qiong, F.; Chao, W.; Jianghua, Z. Application of metallurgical ferronickel slag in building materials: A review. J. Build. Eng. 2024, 96, 110632. [Google Scholar] [CrossRef]

- Nguyen, Q.D.; Castel, A. Developing geopolymer concrete by using ferronickel slag and ground-granulated blast-furnace slag. Ceramics 2023, 6, 1861–1878. [Google Scholar] [CrossRef]

- Shooshtarian, S.; Maqsood, T.; Wong, P.S.; Caldera, S.; Ryley, T.; Zaman, A.; Cáceres Ruiz, A.M. Circular economy in action: The application of products with recycled content in construction projects—A multiple case study approach. Smart Sustain. Built Environ. 2024, 13, 370–394. [Google Scholar] [CrossRef]

- He, Y.; Liu, Y.; Liu, X.; Lan, M.; Lei, B.; Chen, Q.; Xue, X. Mechanical properties of eco-cement mortar containing MgO-modified phosphorous slag. Constr. Build. Mater. 2024, 428, 136223. [Google Scholar] [CrossRef]

- Jia, R.; Wang, Q.; Luo, T. Mechanisms and differences between sodium and magnesium sulfate attacks on alkali-activated phosphorus slag. Constr. Build. Mater. 2023, 403, 133117. [Google Scholar] [CrossRef]

- Wang, H.; Qian, J.; Zhang, H.; Nan, X.; Chen, G.; Li, X. Exploring Skid Resistance Over Time: Steel Slag as a Pavement Aggregate—Comparative Study and Morphological Analysis. J. Clean. Prod. 2024, 464, 142779. [Google Scholar] [CrossRef]

- Aquib, A.R.; Probha, Z.T.; Haque, M.A. An overview on utilization of steel slag as road construction materials. In International Conference on Civil Engineering, Lecture Notes in Civil Engineering; Springer Nature: Singapore, 2023; pp. 51–68. [Google Scholar]

- Kim, K.; Haeng Jo, S.; Kim, N.; Kim, H. Characteristics of hot mix asphalt containing steel slag aggregate according to temperature and void percentage. Constr. Build. Mater. 2018, 188, 1128–1136. [Google Scholar] [CrossRef]

- Pasetto, M.; Baliello, A.; Giacomello, G.; Pasquini, E. The use of steel slags in asphalt pavements: A state-of-the-art review. Sustainability 2023, 15, 8817. [Google Scholar] [CrossRef]

- Liu, J.; Xu, J.; Liu, Q.; Wang, S.; Yu, B. Steel slag for roadway construction: A review of material characteristics and application mechanisms. J. Mater. Civ. Eng. 2022, 34, 03122001. [Google Scholar] [CrossRef]

- Yang, S.; Krayushkina, K.; Akmaldinova, O.; Ji, J.; Bieliatynskyi, A. Determination of the possibility of using phosphorus slag in the road industry. Mater. Sci. 2023, 41, 44–61. [Google Scholar] [CrossRef]

- Kong, Y.; Zhang, X.; Zhang, L.; Xu, J.; Ji, W.; Pan, L.; Lu, R.; Zuo, J.; Ma, X.; Ma, S. Investigation on utilization and microstructure of fine iron tailing slag in road subbase construction. Constr. Build. Mater. 2024, 447, 138019. [Google Scholar] [CrossRef]

- Soni, J.; Chokshi, T.; Sharma, R.; Gujar, R.; Jariwala, N.; Pitroda, J.R. Assessing the applicability of fine copper slag in road and structural fill application. Mater. Today Proc. 2022, 62, 7040–7043. [Google Scholar] [CrossRef]

- Zakaria, S.K.; Sharif, N.M.; Abu Seman, A.; Taib, M.A.A.; Mohamed, J.J.; Yusoff, M.; Yusoff, A.H.; Masri, M.N.; Ali, A.; Ter Teo, P. Recycling of metallurgical steel slag waste as partial replacement of raw materials for sustainable clay-based ceramics: A brief review. AIP Conf. Proc. 2024, 2750, 090004. [Google Scholar] [CrossRef]

- Liu, Y.; Gu, F.; Zhou, H.; Li, Q.; Shang, S. Study on the performance and reaction mechanism of alkali-activated clay brick with steel slag and fly ash. Constr. Build. Mater. 2024, 411, 134406. [Google Scholar] [CrossRef]

- Ren, Y.; Wang, Z.; Qu, G.; Kuang, L.; Ning, P.; Ren, N.; Zhang, C.; Chen, X.; Wu, F.; Hu, Y.; et al. Comprehensive performance study of aluminum ash and calcium carbide slag for brick making under ultra-high pressure. Constr. Build. Mater. 2022, 359, 129526. [Google Scholar] [CrossRef]

- Hou, G.; Yan, Z.; Sun, J.; Naguib, H.M.; Lu, B.; Zhang, Z. Microstructure and mechanical properties of CO2-cured steel slag brick in pilot-scale. Constr. Build. Mater. 2021, 271, 121581. [Google Scholar] [CrossRef]

- Chen, Z.; Leng, Z.; Jiao, Y.; Xu, F.; Lin, J.; Wang, H.; Zhang, Y. Innovative use of industrially produced steel slag powders in asphalt mixture to replace mineral fillers. J. Clean. Prod. 2022, 344, 131124. [Google Scholar] [CrossRef]

- Maierdan, Y.; Haque, M.A.; Chen, B.; Maimaitiyiming, M.; Ahmad, M.R. Recycling of waste river sludge into unfired green bricks stabilized by a combination of phosphogypsum, slag, and cement. Constr. Build. Mater. 2020, 260, 120666. [Google Scholar] [CrossRef]

- Fuchs, K.; Gaikwad, A.D.; Prokein, M.; Schieferstein, E.; Nühlen, J.; Mölders, N.; Renner, M. CO2-curing of carbon-reducing slag-based masonry bricks at elevated pressures in pre-industrial scale. J. Supercrit. Fluids 2023, 203, 106064. [Google Scholar] [CrossRef]

- Guo, Y.; Li, Z.; Liu, F.; Wang, S.; Chen, F.; Yang, L.; Li, Z. Corrosion behavior of CaO–Al2O3–SiO2–MgO-Cr2O3 slag on MgO refractory brick for smelting of chromite. J. Eur. Ceram. Soc. 2024, 44, 544–556. [Google Scholar] [CrossRef]

- Chinyama, S.R.; Wenga, T.; Gwenzi, W. Mechanical and contaminant leaching behaviour of cement-based and fired bricks incorporating ferrochrome slag. J. Build. Eng. 2023, 72, 106572. [Google Scholar] [CrossRef]

- Gao, J.; Su, W.; Song, X.; Lv, P.; Yang, J.; Yu, G. Effect of slag composition on corrosion resistance of high chromia refractory bricks for industrial entrained-flow gasifier. Chin. J. Chem. Eng. 2023, 62, 139–149. [Google Scholar] [CrossRef]

- Amran, M.; Murali, G.; Khalid, N.H.A.; Fediuk, R.; Ozbakkaloglu, T.; Lee, Y.H.; Haruna, S.; Lee, Y.Y. Slag uses in making an ecofriendly and sustainable concrete: A review. Constr. Build. Mater. 2021, 272, 121942. [Google Scholar] [CrossRef]

- Ryu, G.U.; Kim, H.J.; Yu, H.J.; Pyo, S. Utilization of steelmaking slag in cement clinker production: A review. J. CO2 Util. 2024, 84, 102842. [Google Scholar] [CrossRef]

- Demarco, M.; Vernilli, F.; Zago, S.C. Clinker-Free Cement Manufactured with Metallurgical Slags. Buildings 2024, 14, 1739. [Google Scholar] [CrossRef]

- Xie, G.; Liu, L.; Suo, Y.; Zhu, M.; Yang, P.; Sun, W. High-value utilization of modified magnesium slag solid waste and its application as a low-carbon cement admixture. J. Environ. Manag. 2024, 349, 119551. [Google Scholar] [CrossRef]

- Amarasinghe, I.; Hong, Y.; Stewart, R.A. Visualising a framework for enhancing material circularity in building construction projects: Drivers, barriers, and strategies. Build. Environ. 2024, 253, 111359. [Google Scholar] [CrossRef]

- Sajid, Z.W.; Aftab, U.; Ullah, F. Barriers to Adopting Circular Procurement in the Construction Industry: The Way Forward. Sustain. Futures 2024, 8, 100244. [Google Scholar] [CrossRef]

- Shooshtarian, S.; Maqsood, T.; Wong, P.S.; Zaman, A.; Caldera, S.; Ryley, T. Utilisation of certification schemes for recycled products in the Australian building and construction sector. Bus. Strateg. Environ. 2024, 33, 1759–1777. [Google Scholar] [CrossRef]

- Jayalath, C. Policy Instruments Fostering Site Level Application of Circular Practices in Construction. Preprints 2024, 2024, 2024061646. [Google Scholar] [CrossRef]

- Giorgi, S.; Lavagna, M.; Wang, K.; Osmani, M.; Liu, G.; Campioli, A. Drivers and barriers towards circular economy in the building sector: Stakeholder interviews and analysis of five European countries policies and practices. J. Clean. Prod. 2022, 336, 130395. [Google Scholar] [CrossRef]

- Munaro, M.R.; Tavares, S.F. A review on barriers, drivers, and stakeholders towards the circular economy: The construction sector perspective. Clean. Responsible Consum. 2023, 8, 100107. [Google Scholar] [CrossRef]

- Chen, P.; Zhang, S.; Meng, J.; Lei, T.; Li, B.; Coffman, D.M. Technological solutions to China’s carbon neutrality in the steel and cement sectors. Earths Future 2023, 11, e2022EF003255. [Google Scholar] [CrossRef]

- Babalola, A.; Harinarain, N. Policy barriers to sustainable construction practice in the Nigerian construction industry: An exploratory factor analysis. J. Eng. Des. Technol. 2024, 22, 214–234. [Google Scholar] [CrossRef]

- Sorvari, J.; Wahlström, M. Industrial by-products. In Handbook of Recycling; Elsevier: Amsterdam, The Netherlands, 2024; pp. 259–285. [Google Scholar] [CrossRef]

- Assaad, R.H. Examining low-carbon material initiatives: Existing policies, impacts on the procurement of projects, current challenges, and potential solutions to reduce embodied carbon in the construction industry. J. Leg. Aff. Disput. Resolut. Eng. Constr. 2024, 16, 04523060. [Google Scholar] [CrossRef]

- Feijão, D.; Reis, C.; Marques, M.C. Comparative analysis of sustainable building certification processes. J. Build. Eng. 2024, 96, 110401. [Google Scholar] [CrossRef]

- Statsenko, L.; Samaraweera, A.; Bakhshi, J.; Chileshe, N. Construction 4.0 technologies and applications: A systematic literature review of trends and potential areas for development. Constr. Innov. 2023, 23, 961–993. [Google Scholar] [CrossRef]

- Thakur, A.; Kumar, A. Development of Novel Processes and Products from Mining Residues. In Sustainable Management of Mining Waste and Tailings; CRC Press: Boca Raton, FL, USA, 2024; pp. 301–330. [Google Scholar]

- Devarajan, P.; Kumar, R.S.; King, J.A.F. A short review on substantial role of geopolymer in the sustainable construction industry. IOP Conf. Ser. Earth Environ. Sci. 2023, 1130, 012002. [Google Scholar] [CrossRef]

- Barraza, F.P.; Thiyagarajan, D.; Ramadoss, A.; Manikandan, V.S.; Dhanabalan, S.S.; Abarzúa, C.V.; Soloaga, P.S.; Nazer, J.C.; Morel, M.J.; Thirumurugan, A. Unlocking the potential: Mining tailings as a source of sustainable nanomaterials. Renew. Sustain. Energy Rev. 2024, 202, 114665. [Google Scholar] [CrossRef]

- Geng, S.; Luo, Q.; Liu, K.; Li, Y.; Hou, Y.; Long, W. Research status and prospect of machine learning in construction 3D printing. Case Stud. Constr. Mater. 2023, 18, e01952. [Google Scholar] [CrossRef]

- Osei-Tutu, S.; Ayarkwa, J.; Osei-Asibey, D.; Nani, G.; Afful, A.E. Barriers impeding circular economy (CE) uptake in the construction industry. Smart Sustain. Built Environ. 2023, 12, 892–918. [Google Scholar] [CrossRef]

- Adrianto, L.R.; Ciacci, L.; Pfister, S.; Hellweg, S. Toward sustainable reprocessing valorization of sulfidic copper tailings: Scenarios prospective, LCA. Sci. Total Environ. 2023, 871, 162038. [Google Scholar] [CrossRef]

- Meglin, R.; Kytzia, S.; Habert, G. Regional circular economy of building materials: Environmental and economic assessment combining material flow analysis, input-output analyses, and life cycle assessment. J. Ind. Ecol. 2022, 26, 562–576. [Google Scholar] [CrossRef]

- Füchsl, S.; Rheude, F.; Röder, H. Life cycle assessment (LCA) of thermal insulation materials: A critical review. Clean. Mater. 2022, 5, 100119. [Google Scholar] [CrossRef]

- Greenfiber. Carbon Impact of Insulation: Putting Cellulose to the Test. Available online: https://www.greenfiber.com/blog/carbon-impact-of-insulation-putting-cellulose-to-the-test (accessed on 3 May 2025).

- Brekke, S.; O’Born, R. Life Cycle Assessment of Geopolymer Concrete Made with Tailings from Ilmenite Mining. In The International Conference on Net-Zero Civil Infrastructures: Innovations in Materials, Structures, and Management Practices (NTZR); Springer Nature: Cham, Switzerland, 2024; pp. 821–829. [Google Scholar]

- Crossin, E. The greenhouse gas implications of using ground granulated blast furnace slag as a cement substitute. J. Clean. Prod. 2015, 95, 101–108. [Google Scholar] [CrossRef]

- de Pedro, J.P.Q.; Lagao, J.A.T.; Ongpeng, J.M.C. Life cycle assessment of concrete using copper slag as a partial cement substitute in reinforced concrete buildings. Buildings 2023, 13, 746. [Google Scholar] [CrossRef]

| SRM | Application | Dosage | Reference |

|---|---|---|---|

| CNF | Portland cement paste | 1.5 wt% of the cement weight | [34] |

| RCF | Fiber cement board | From 10% to 50% of the total cellulose fiber content | [35] |

| RCF | Cellulose nanocrystals cement paste | 0.2% cellulose nanocrystals | [36] |

| CNC | Cement paste | 0.2 vol–1.0 vol% | [37] |

| CF | Concrete | 1.0 kg/m3 (0.09%)–1.2 kg/m3 (0.11%)–1.5 kg/m3 (0.14%)–1.8 kg/ m3 (0.16%)–2.0 kg/m3 (0.18%) | [38] |

| CF | Clay brick | 2.5–15 wt% | [39] |

| CNC | Concrete | 0.1 vol–0.2 vol% | [40] |

| MFC | Mortar and concrete | 0.4 to 4.5% by weight of the cement | [41] |

| CF | Reinforced concrete | 0.6–0.9–1.2–1.5 kg/cm3 | [42] |

| CNC/CNF | Cement | CNF 0.020–0.035–0.045–0.050–0.065–0.085–0.10–0.15 CNC 0.020–0.035–0.045–0.050–0.065–0.085–0.10–0.15–0.20–0.40–0.60 wt% | [43] |

| CF | Concrete | From 10 to 90 wt% | [14] |

| MCC/NFC | Cement pastes | MCC: 0.05–0.5–0.75–1.0% NFC: 0.05–0.5–1.0% | [44] |

| CNC | Mortar and concrete mixes | 0.25–0.50–0.75–1.00 wt% relative to the cement | [45] |

| MCC/NFC | Cement pastes | 0.050–0.075–0.100% by cement weight | [46] |

| HF/JF | Cement composite (mortar and paste) | 0.25–0.5–1–2% of the cement weight | [47] |

| CF | Concrete | 0.5 vol% | [48] |

| CNF | Cement pastes and mortars | 0.3 wt–0.8 wt% of cement mass | [49] |

| CNF | Cement based systems | 0.1–0.2–0.3–0.4–0.5 (vol%) | [50] |

| MFC | Cement pastes | 0.3–0.6–1–2 wt.% of the cement | [51] |

| CNF | Cement composites | 1.5 kg/m3 | [52] |

| CF | Asphalt | 0.5% | [53] |

| CNF | Asphalt binders and mixes | 0.2–0.3–0.5–0.7% by the weight of binder | [54] |

| CF | As filler in hot mix asphalt | 0.25–0.5–0.75% | [55] |

| CF | SMA pavement | 1.0% by weight of asphalt | [56] |

| CF | Asphalt mixtures | 2.5–5.0–7.5–10.0% by the weight of asphalt cement | [57] |

| CNF | Additive in asphalt pavements. | 0.2–0.3–0.5–0.7% by the weight of binder | [58] |

| CF | Concrete | 1–2% by the weight of cement | [59] |

| KF | Cement composites | 1–1.5–2% by mass | [60] |

| KF | Cement pastes | 0.25–0.5% by weight of cement | [61] |

| HF | Cement based mortar | 0.5 wt–1 wt–1.5 wt% on cement | [62] |

| JF | Reinforced concrete | 5% by cement mass (0.8% content by volume of concrete) | [63] |

| HF | Concrete | 51.45–60.60–64.45 by % volume | [64] |

| HF | Reinforced foam concretes | 0.75–1.5–3% by weight of cement | [65] |

| HF | Mortars | 0.5 vol–1.0 vol% | [66] |

| BF/HF | Reinforced cement mortars | 0.34–0.5–0.68–1 vol% | [67] |

| HF | Mortars | 1 vol% | [68] |

| FF | Concrete | 0.3–0.6% mass percentages | [69] |

| FF | High-performance concrete | 0.15–0.30–0.50% | [70] |

| FF | Reinforced cementitious composites | 1.0 vol% relative to the total batch volume | [71] |

| FF | Cement-based composites | 0.3–0.6–0.9–1.2–1.5–1.8 by weight of cement | [72] |

| FF | Ultra high-performance concrete | 2–4–6 (kg/m3) | [73] |

| FF | Concrete | 0.3–0.6% (5.7–11.4 kg/m3) | [74] |

| FF | Cementitious composite | 1.0–2.0–3.0% vol | [75] |

| SRM | Application | Dosage | Reference |

|---|---|---|---|

| CMWR | Road embankment or pavement layers | 80% | [105] |

| GT | Road base layer and asphalt base | by 60% tailing and 7% asphalt | [106] |

| IT | Road base material | 50% | [107] |

| GT/GBFS | Road pavement material | GBFS:GT ratios: 100–10:90–20:80–30:70–40:60–50:50 | [108] |

| SW | Cement mortars | From 2 to 20% wt% | [109] |

| SW | Concrete paving blocks | From 2 to 40% wt% | [110] |

| SW | Geopolymer cement mixture | From 53% to 81.6% | [111] |

| SW | Filler in asphalt pavement | 7 wt% | [112] |

| ZT | Asphalt mixtures | Unspecified | [113] |

| IT/GT | Concrete and asphalt mixtures | Unspecified | [114] |

| IT | Aggregates in paving asphalt mixture | Coarse aggregates: 74% Fine aggregates: 12% of the total mass of aggregates | [115] |

| SS/LFS | Aggregates in foamed bitumen-stabilized mixtures for road foundation layers | 20/10 wt% of aggregates | [116] |

| MT | Filler in bitumen | 1–3–5–10 (%w/w) | [117] |

| IT | Material in soil–cement mixtures | 10–20% | [118] |

| IT | Filler in asphalt mixtures | Filler/asphalt weight ratios: 0.6–0.8–1.0–1.2 | [119] |

| PT | Modifier for the asphalt binder and replacement for traditional limestone mineral powder | 4–7–10–12–15%. | [120] |

| RM/IT/ZT | Geopolymer binders to stabilize the soil for road subgrade application | 10–20–30% | [121] |

| CT | Filler material in asphalt paving mastic | 30–60–90–120 wt% by asphalt weight | [122] |

| IT | Filler in an asphalt mixture | 20–40–60–80% | [123] |

| CT | Supplementary cementitious material | 10–14.4–20–27.8–40–43.9% | [124] |

| IT | Supplementary cementitious materials in cement | 10–20–30–40 wt% | [125] |

| IT | Supplementary cementitious material | 10–20–30 wt% by cement weight | [126] |

| IT | Replacing cement in pastes | 5–10–15% cement in weight | [127] |

| IT/PS/SS | Concrete | IT: 6–8.5–17–25–44–63–126 (kg/m3) PS/SS: 17–32–34–41–50–60 (kg/m3) | [128] |

| IT | Cementitious materials | 30% of cement by weight replaced | [129] |

| LM | Cementitious materials | From 30% to 70% | [130] |

| CT | Substitute for cement in concrete | From 10 to 70% | [131] |

| IT | Substitute for cement in cementitious materials | 10–30–50% | [132] |

| IT | Supplementary cementitious material as partial replacement of cement | 15% | [133] |

| IT/PS/LS | Ternary supplementary cementitious materials for concrete | IT: 30–15–10% PS: 0–15–10% LS: 0–15–10. Total IOT + PS + LS = 30% replacement | [134] |

| AT | Partially replace the silica sand in the mix | 25–50–75–100% | [135] |

| GT/GBFS | Ternary cementitious material | 40.5–67.5–94.5–135 kg/m3 | [136] |

| CT | Supplementary cementitious material | Partial cement replacement, between 5 and 15 wt%, | [137] |

| GT/ST | Supplementary cementitious material | 10–15–20 wt% | [138] |

| IT/SS/GBFS | Supplementary cementitious material | IT: 2.2 wt%/SS: 1.5 wt%/GBFS: 1 wt% | [139] |

| IT/SS/GBFS | Supplementary cementitious material | IT: 2.2 wt% SS/GBFS: from 0.5 to 2 wt% | [140] |

| QT/SchT | Ceramic tiles | QT: 11 wt%/SchT: from 0 to 8 wt% | [141] |