Influences of Temperature Variations Around Subway Ventilations on Fractures of Continuous Welded Rail Fractures

Abstract

1. Introduction

2. Materials and Methods

2.1. Overview

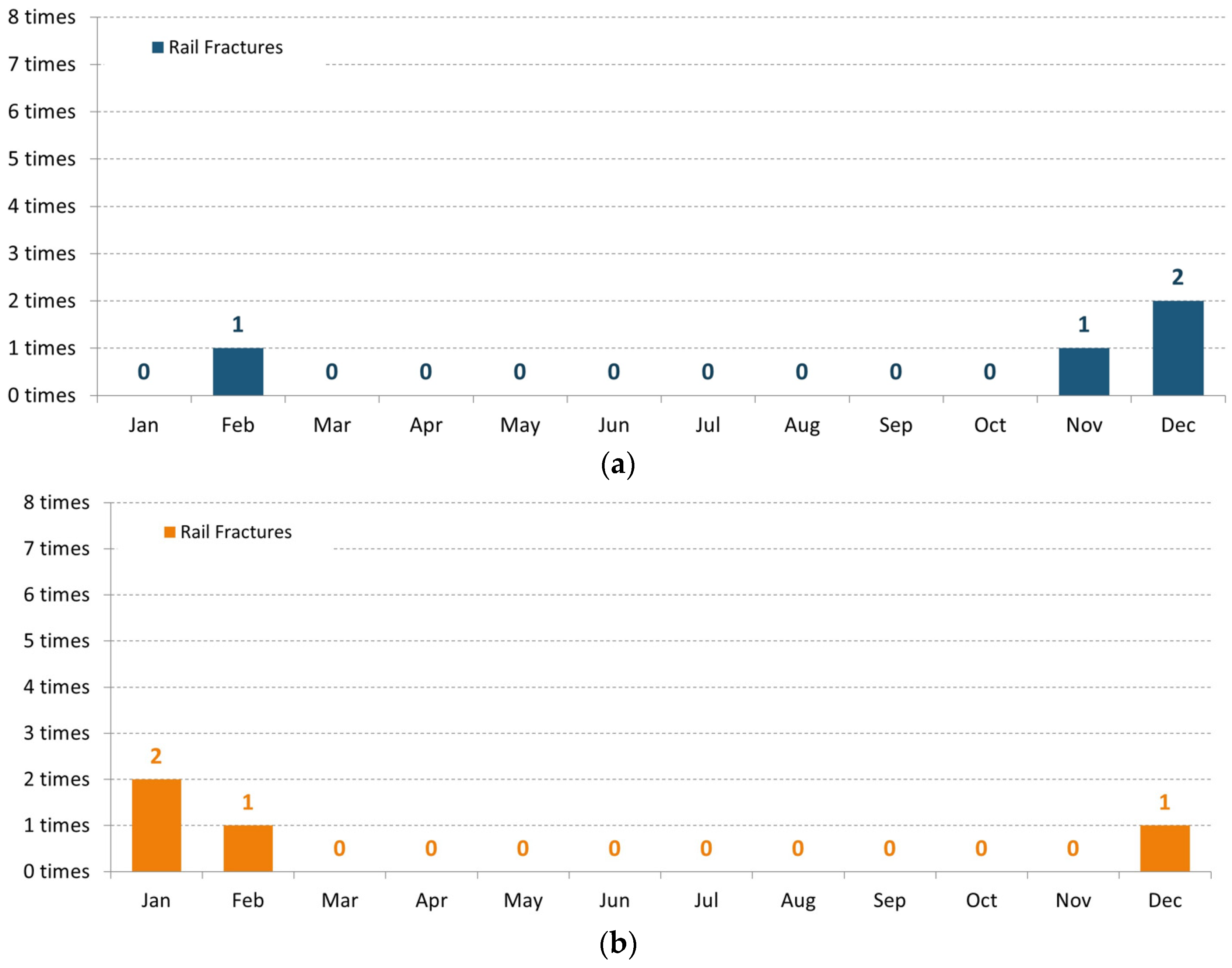

2.2. Rail Fracture Status

2.2.1. CWR Welding and Fracture Status

2.2.2. Effect of Tunnel Temperature Variations on Urban Rail CWRs

3. Analysis of CWR Fracture Parameters near Ventilation Shafts Using Machine Learning

3.1. Overview

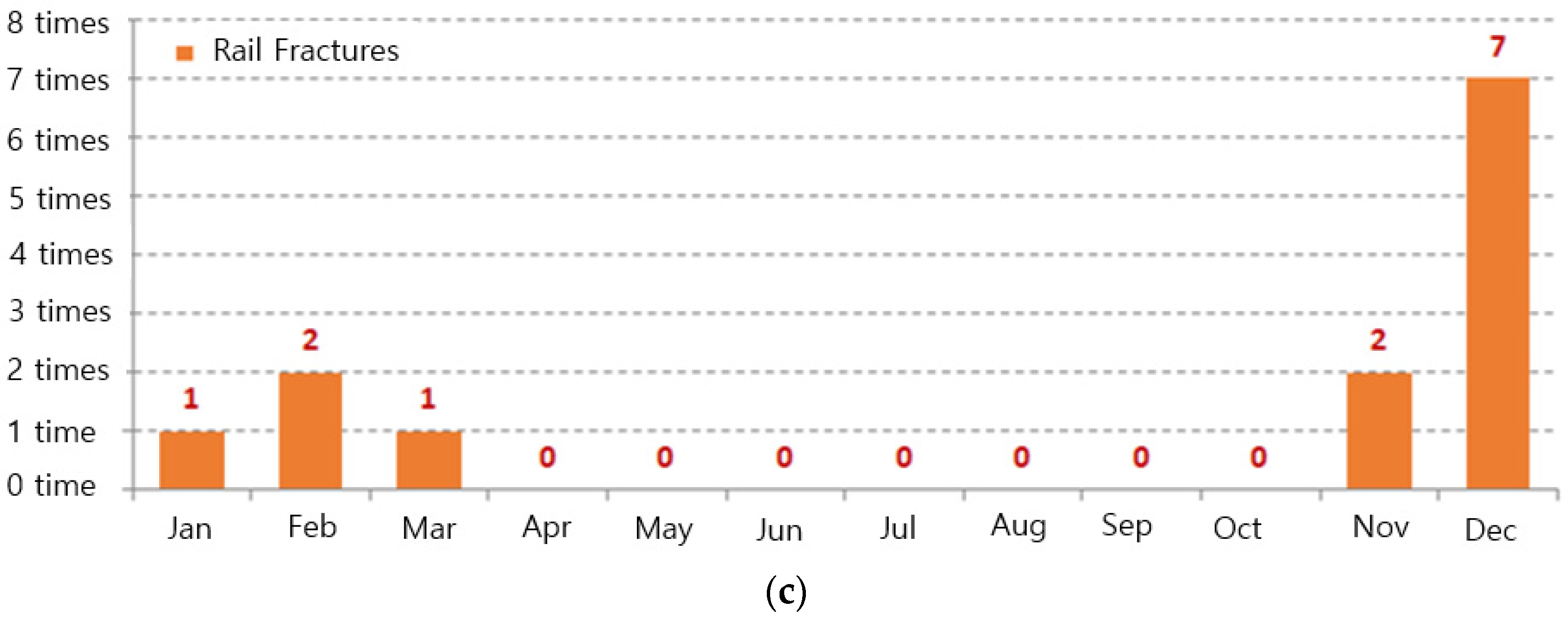

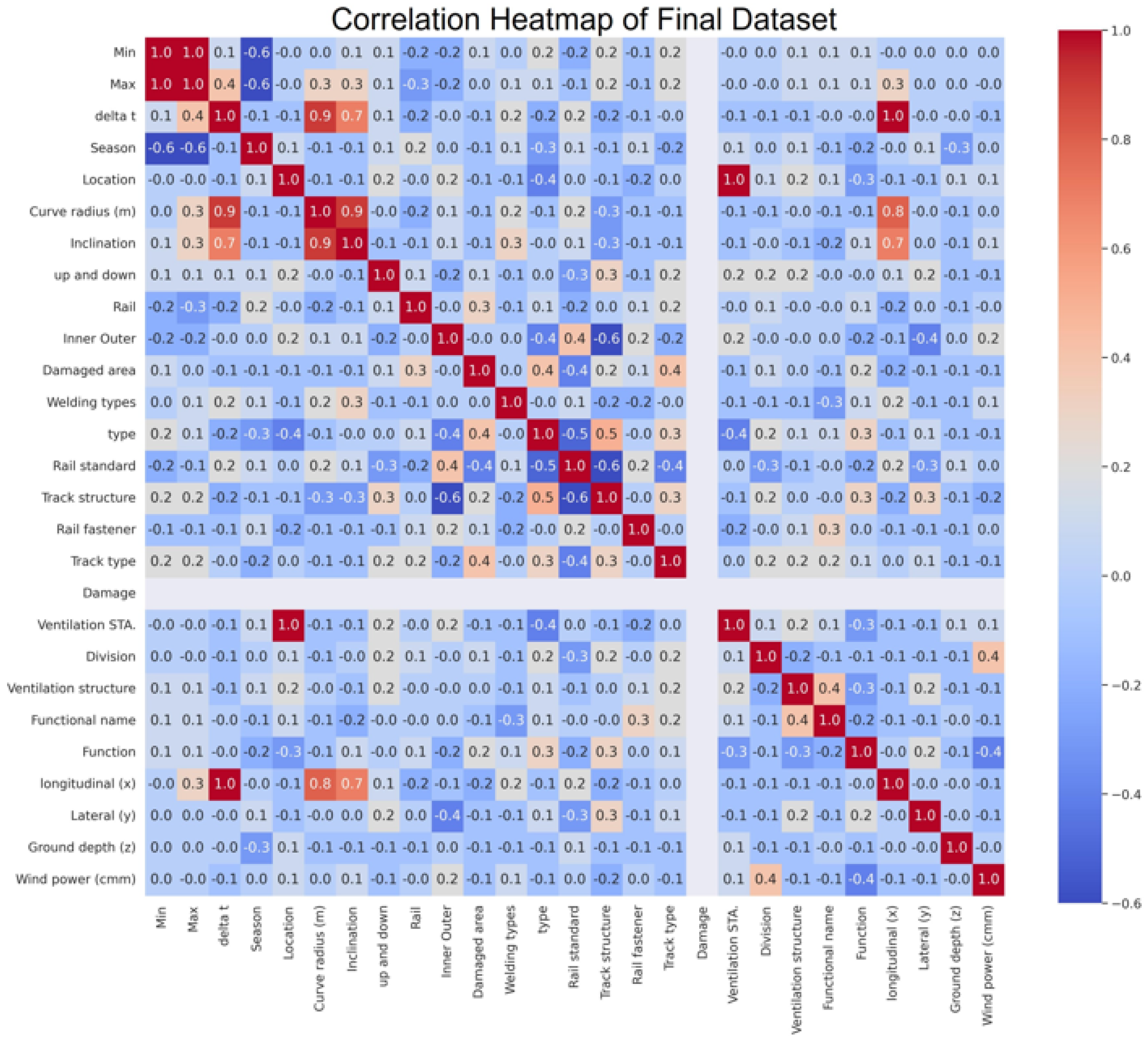

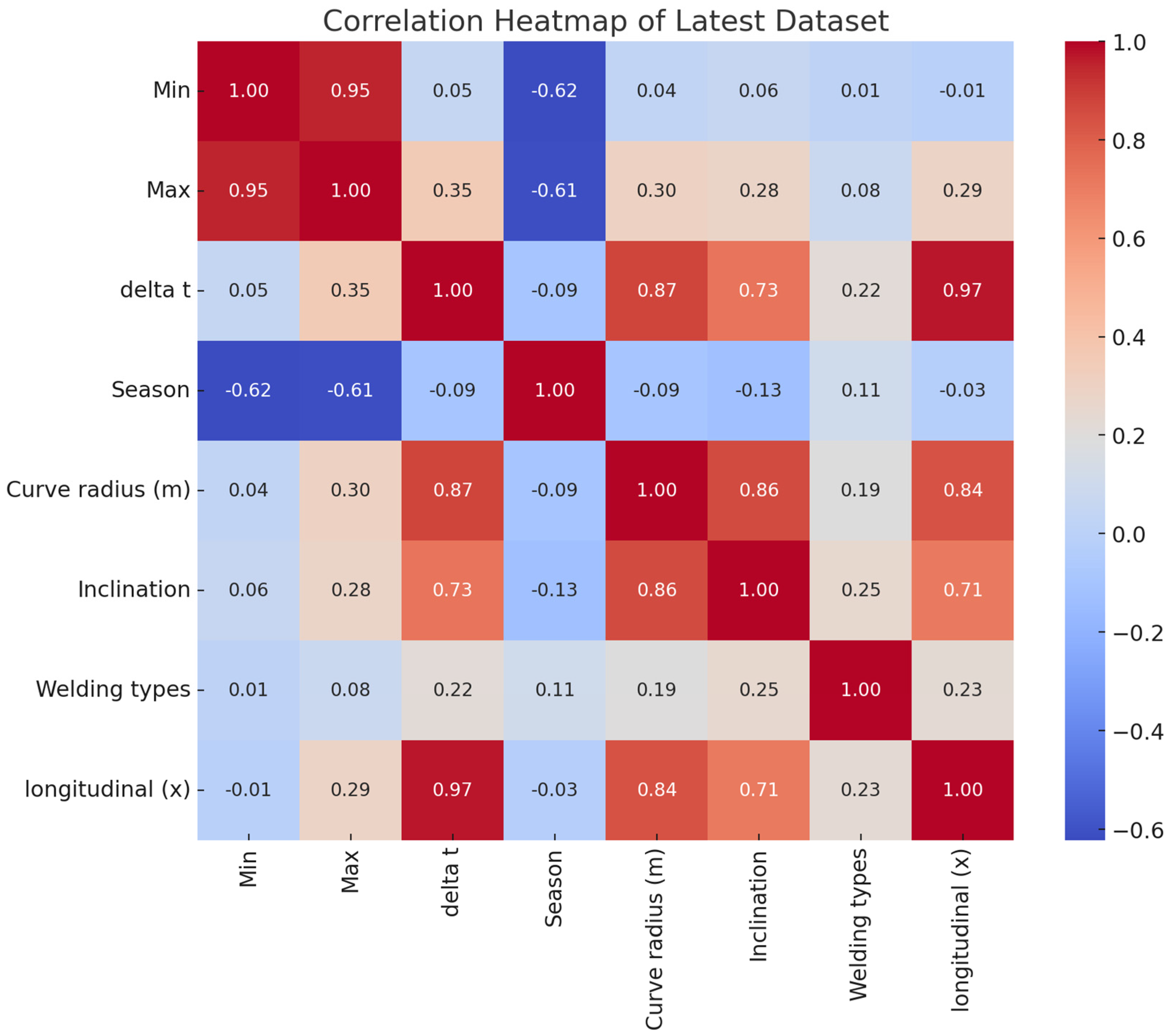

3.2. Analysis of Parameter-Influencing Factors

3.2.1. Classification of Training Datasets

3.2.2. Machine Learning Analysis Using All Parameters

3.2.3. Machine Learning Analysis Using Proposed Parameters

4. Numerical Analysis

4.1. Overview

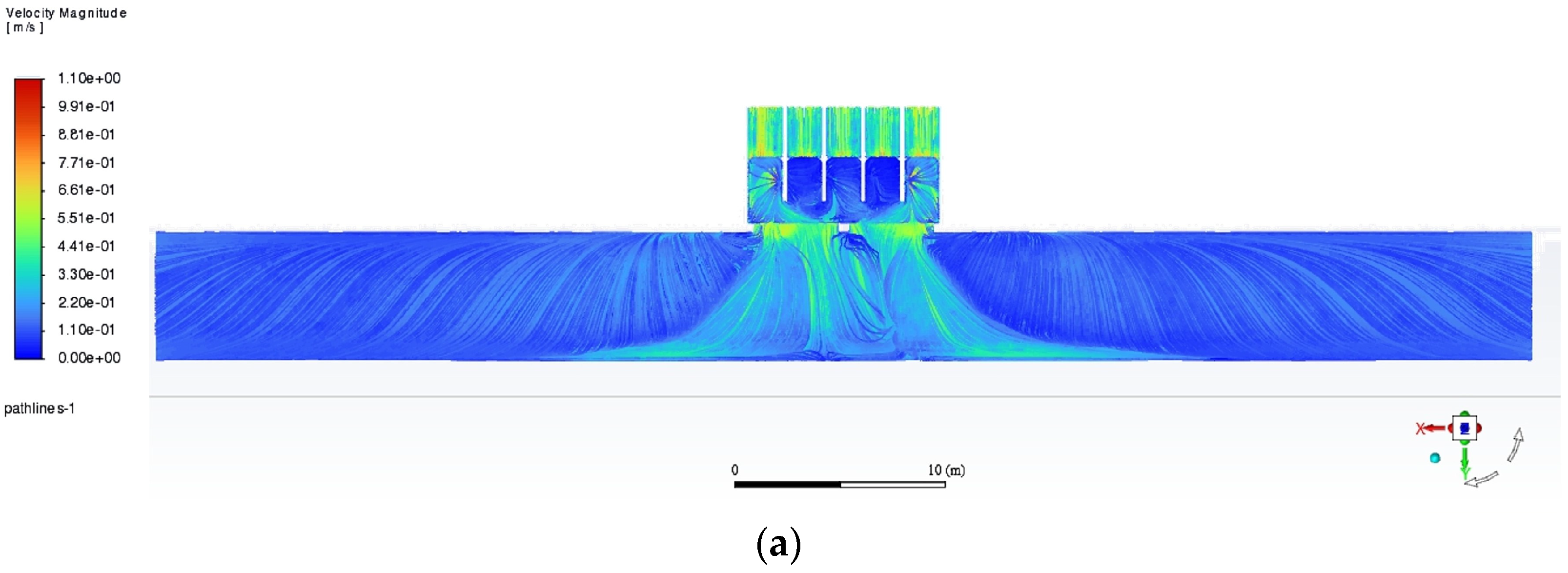

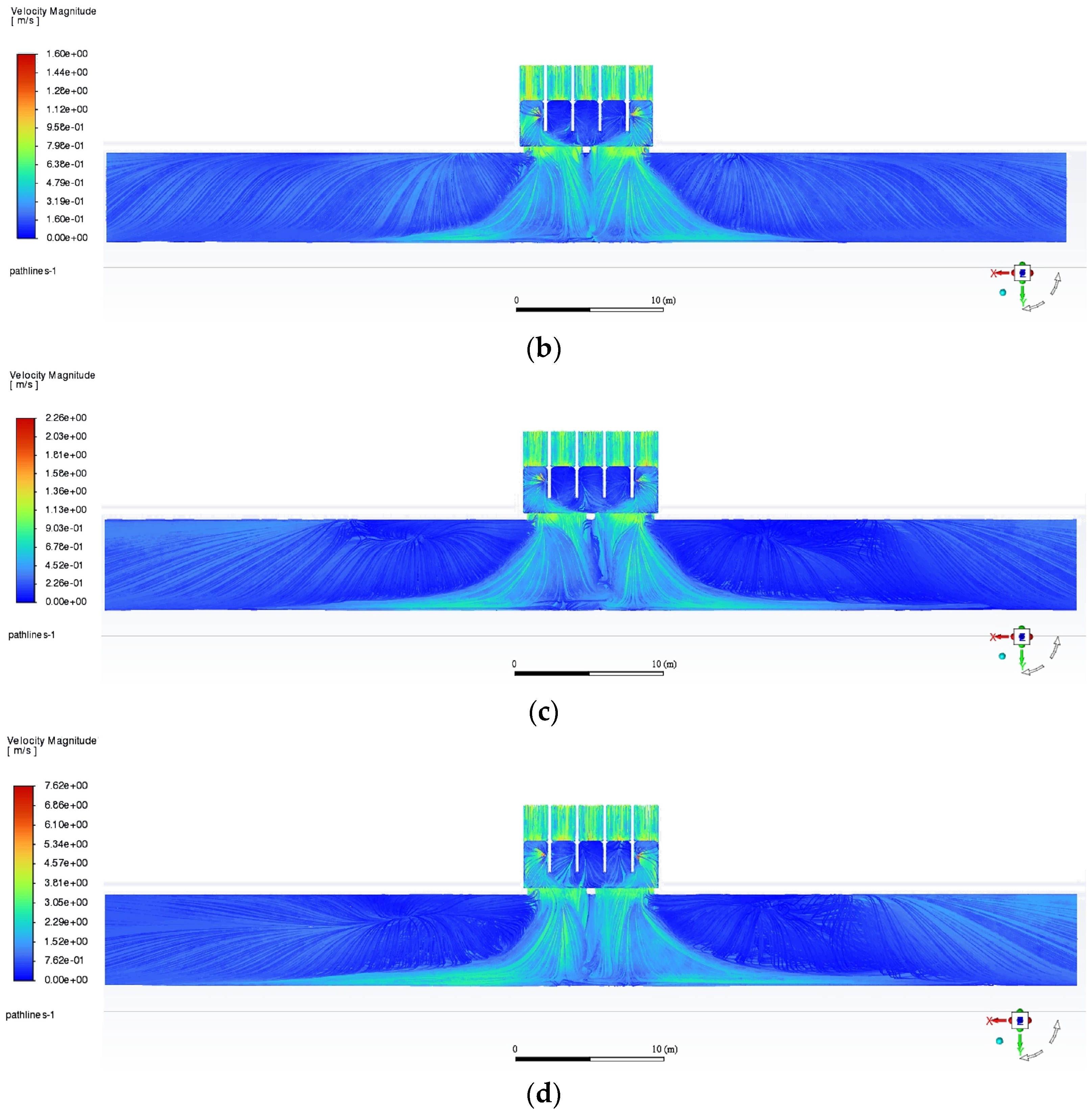

4.2. Analysis Results

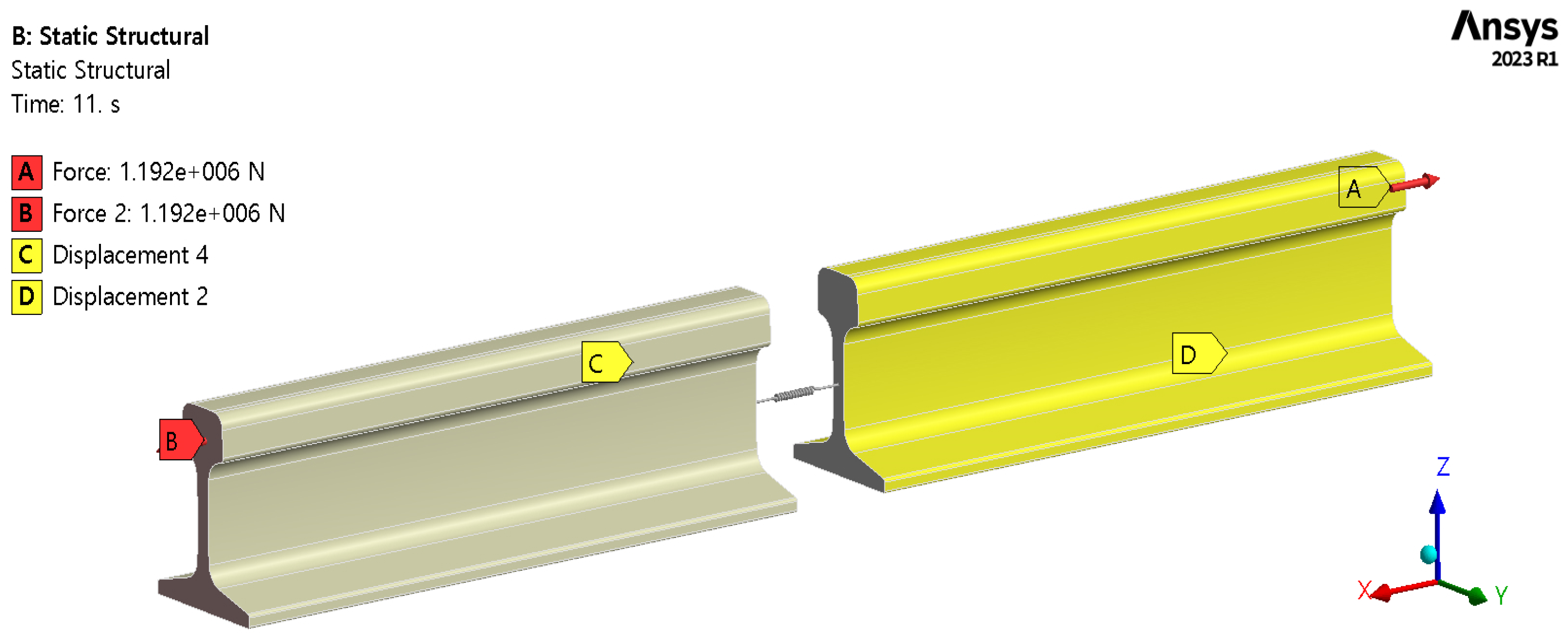

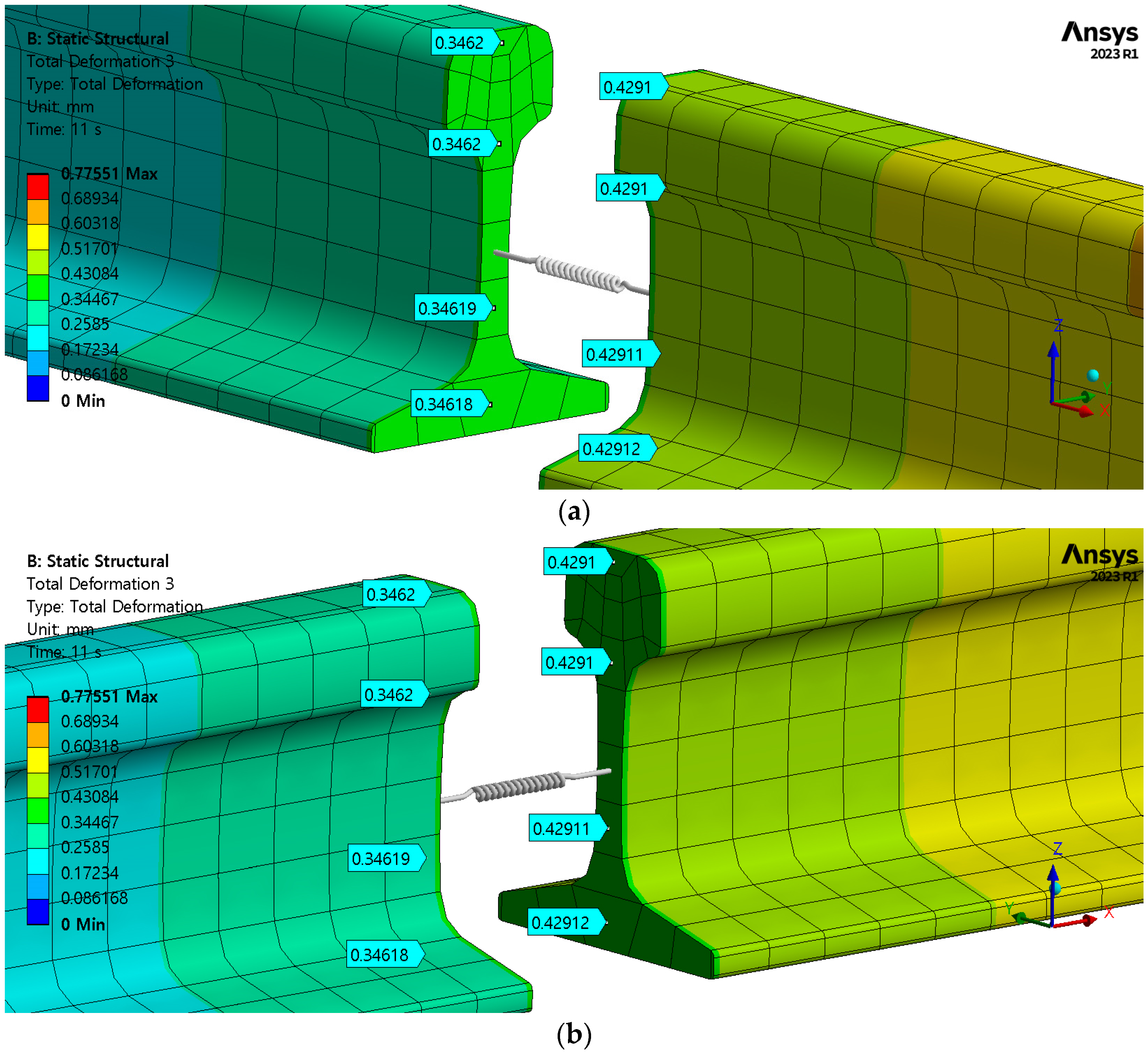

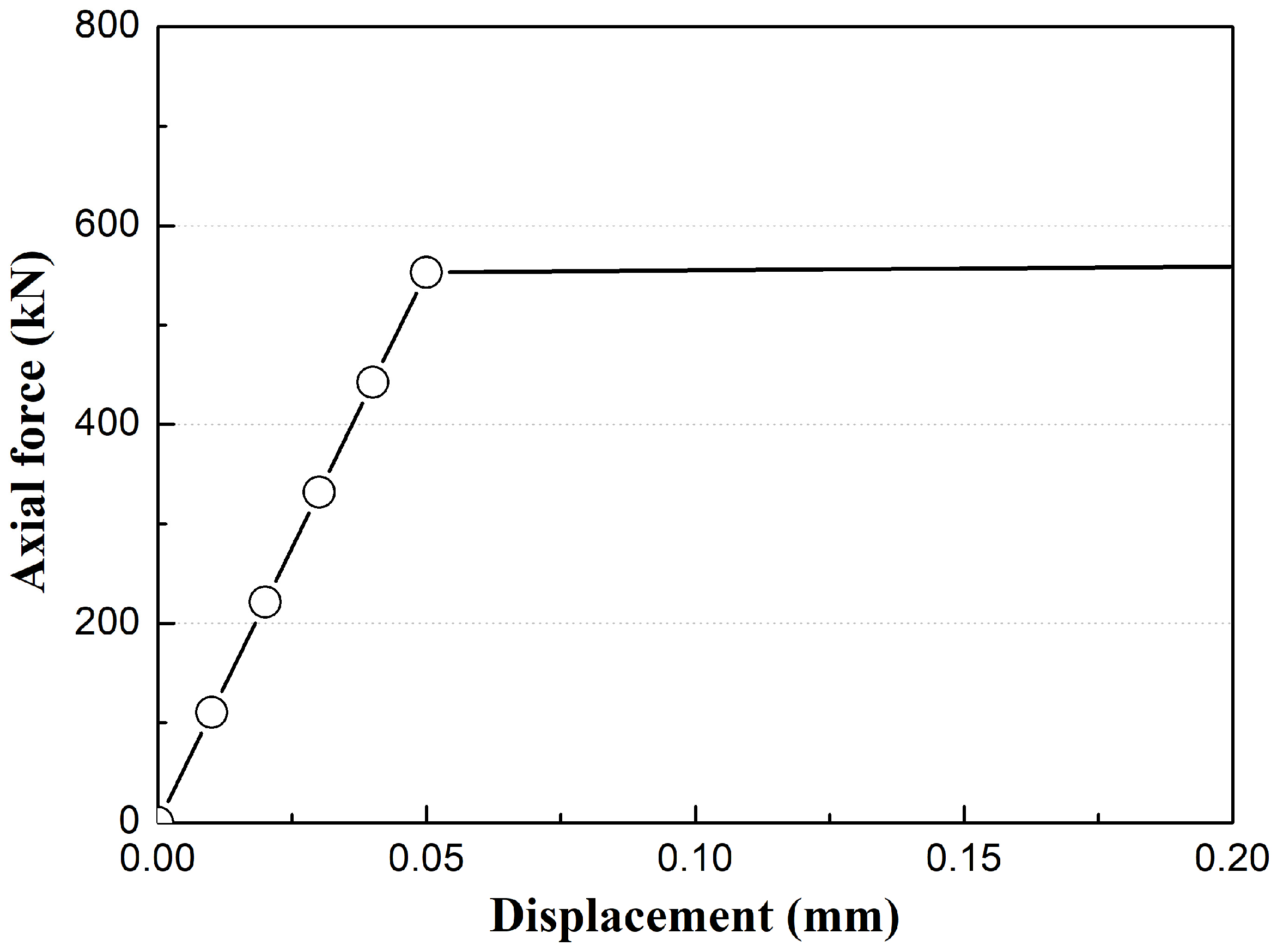

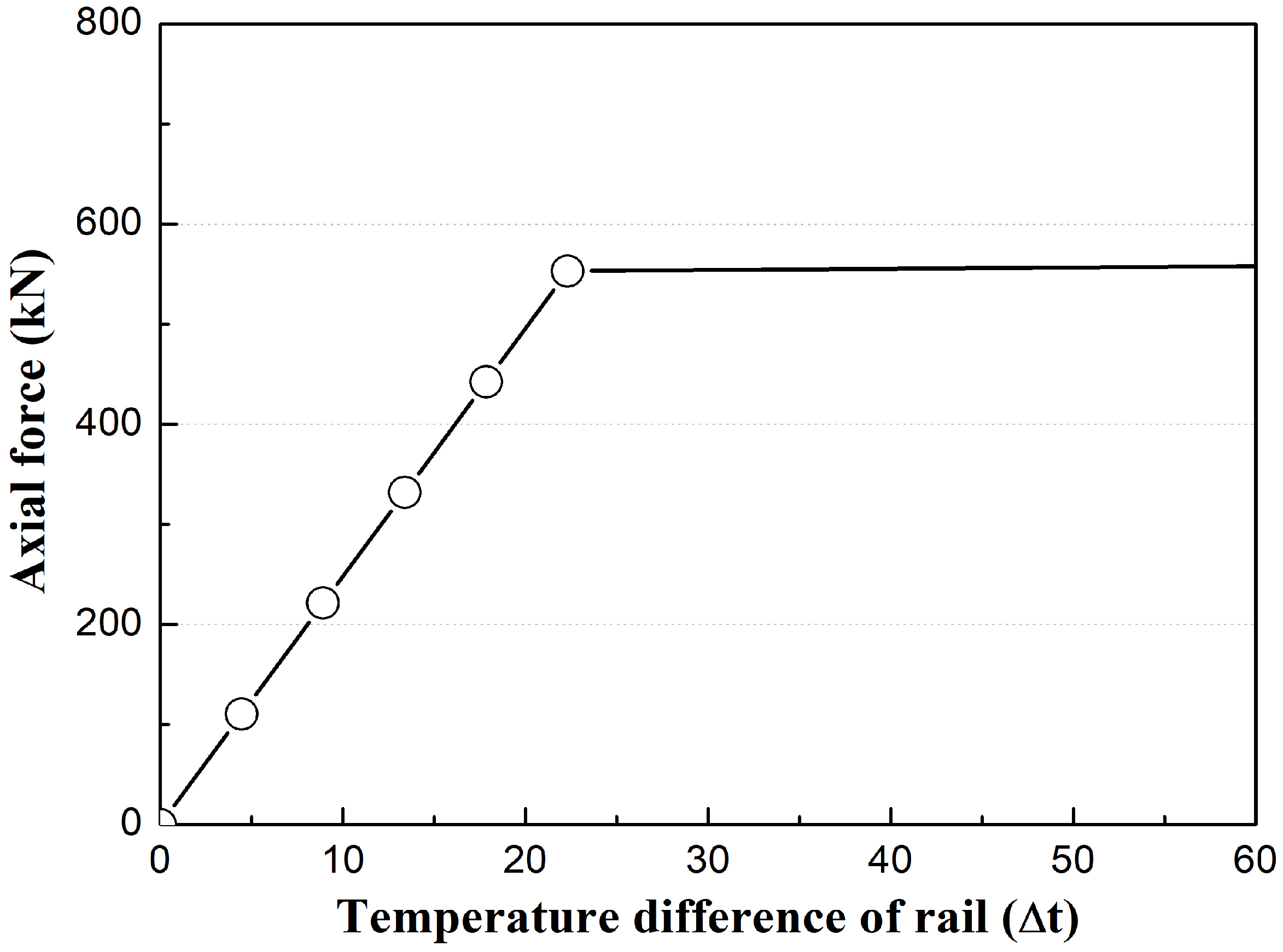

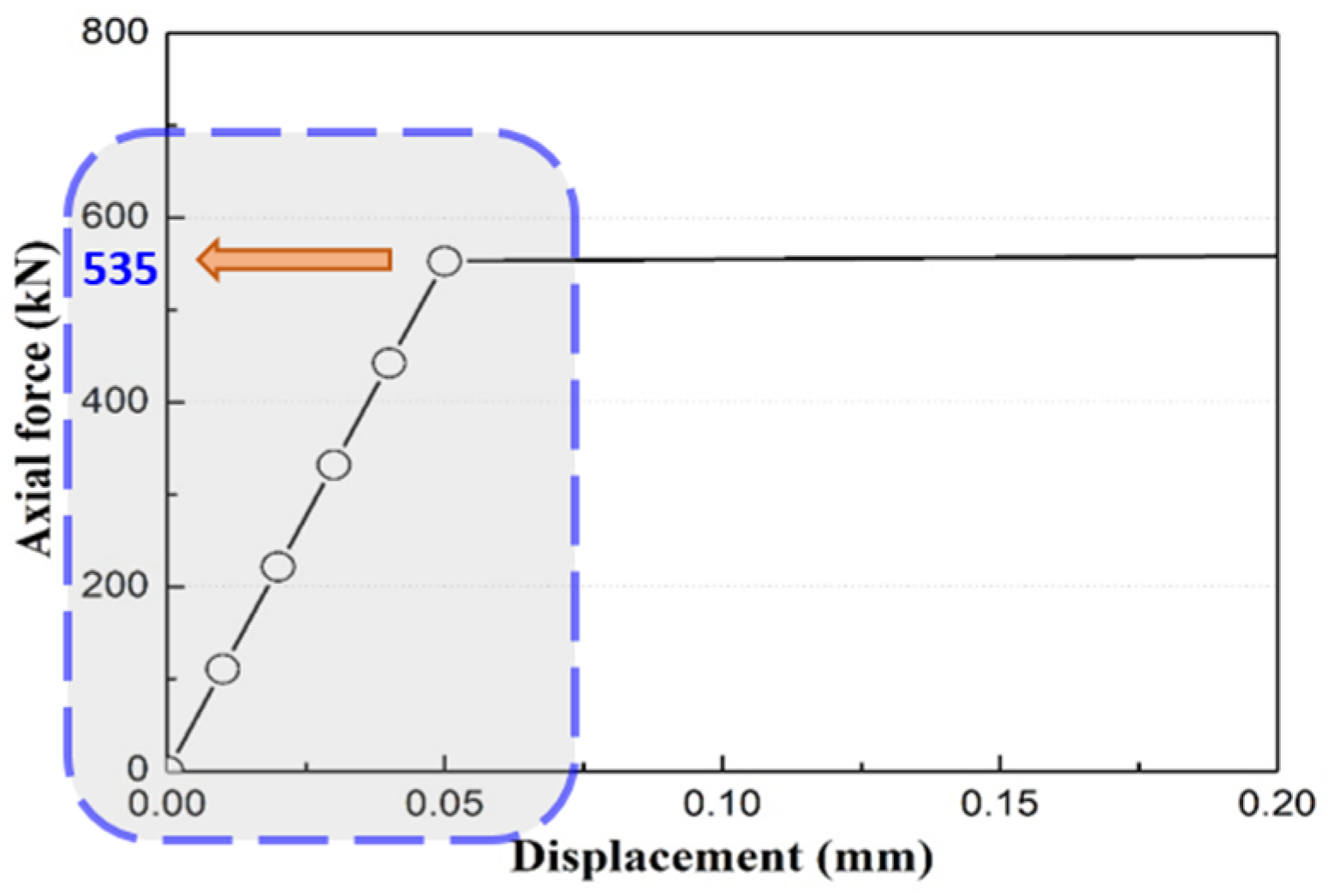

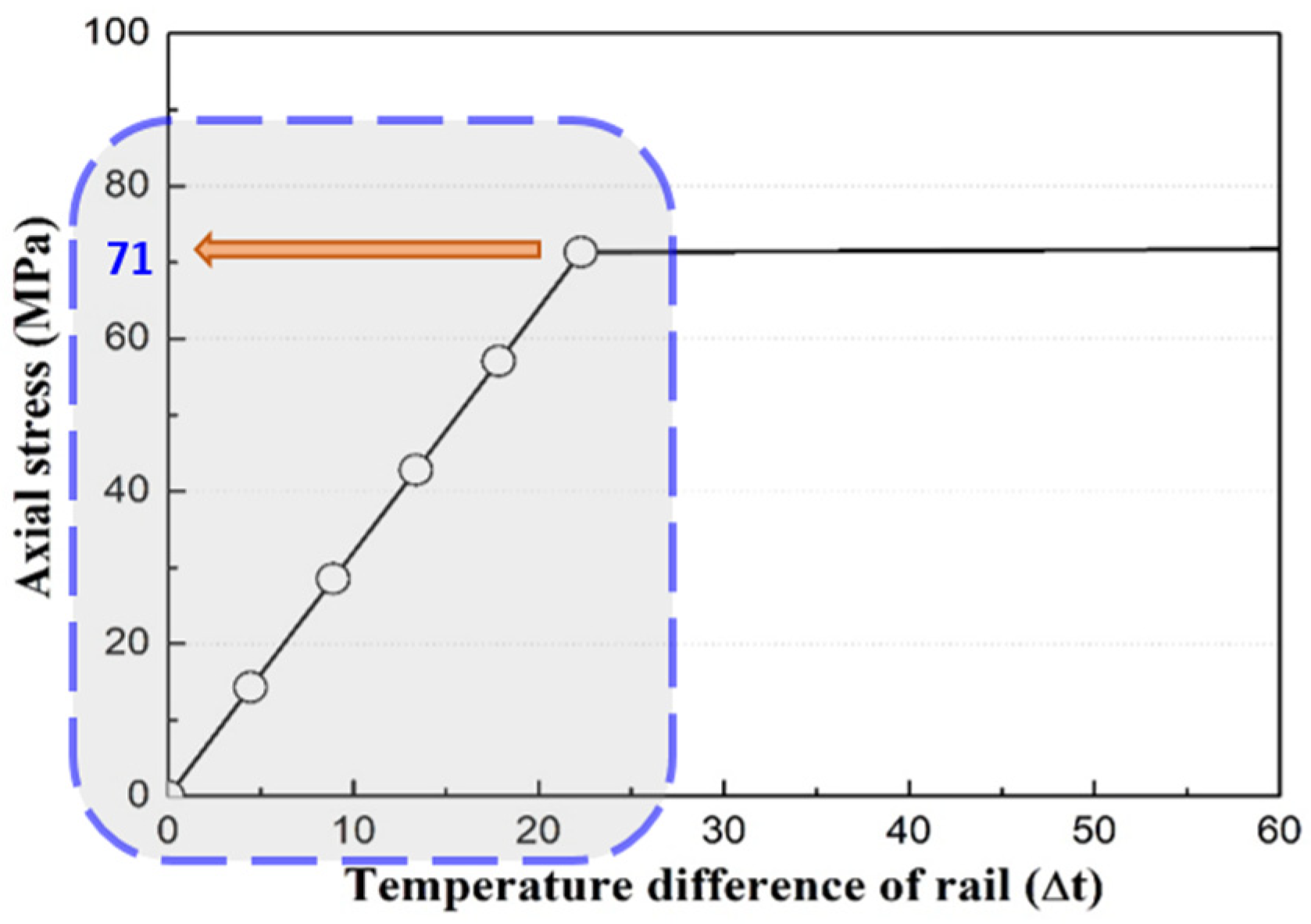

4.3. Axial Force Analysis of CWR Fractures Using FEA

4.3.1. Numerical Analysis Modeling

- α—thermal expansion coefficient of the rail steel [1/°C];

- E—Young modulus of steel [MPa];

- Δt—temperature difference in the rail about the neutral temperature (the temperature at which there is no thermal stress in the rail) [°C];

- A—cross-section area of the rail [m2].

4.3.2. CWR Axial Force Analysis Results

5. Analysis and Discussion

5.1. Correlation Analysis Between CWR Fractures and Parameter Analysis

5.2. Analysis of Temperature Variation Influence Range near Ventilation Shafts

5.3. Analysis of Axial Force During CWR Fractures Caused by Temperature Variations

6. Conclusions

- CWR installation guidelines:

- (1)

- Avoid extreme cold or extreme heat during construction of the track;

- (2)

- The location of the CWR field welding part (thermite welding, etc.) should be located ±20.0 m away from the center of the ventilation shaft.

- Maintenance guidelines:

- (1)

- Avoid extreme cold or extreme heat when performing rail welding work in a tunnel during operation;

- (2)

- When performing field welding work, perform the work within the medium temperature range (urban railway 13 ± 5 °C) if possible.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Jung, C.M. A Study on Influencing Factors of Urban Railway Concrete Ballast Rail Defect and Its Reduction Measures. Master’s Thesis, Seoul National University of Science and Technology, Seoul, Republic of Korea, February 2015. [Google Scholar]

- Nam, J.G. The Influence Factors of Rail Damage in Seoul Metro Lines. Master’s Thesis, National University of Science and Technology, Seoul, Republic of Korea, February 2015. [Google Scholar]

- Bong, J.K. A Study on Analyze the Cause of Seoul Urban Railway Continuous Welded Rail Broken. Master’s Thesis, Dong-yang University, Yeongju-si, Republic of Korea, August 2018. [Google Scholar]

- Lee, K.B. A Study on the Estimation of Natural Ventilation by Train-Induced Wind in a Subway Tunnel. Master’s Thesis, University of Seoul, Seoul, Republic of Korea, August 2010. [Google Scholar]

- Song, J.H. A Study on Train-Induced Wind Control and Its Influence on the Ventilation in Subway Tunnel and Station Environments. Ph.D. Thesis, University of Incheon, Incheon, Republic of Korea, February 2012. [Google Scholar]

- Zheng, S.; Liu, Y.; Zhang, N.; Li, X.; Gao, L. Experimental studies on shape and size effects on particle breakage of railway ballast. Transp. Geotech. 2022, 37, 100883. [Google Scholar] [CrossRef]

- Zhu, H.Y.; Lian, S.R.; Jin, M.Z.; Wang, Y.; Yang, S.J.; Lu, Q.D.; Tao, Z.Y.; Xiao, Q. Review of research on the influence of vibration and thermal fatigue crack of brake disc on rail vehicles. Eng. Fail. Anal. 2023, 153, 107603. [Google Scholar] [CrossRef]

- Xu, W.; Zhang, B.; Deng, Y.; Wang, Z.; Jiang, Q.; Yang, L.; Zhang, J. Corrosion of rail tracks and their protection. Corros. Rev. 2021, 39, 1–13. [Google Scholar] [CrossRef]

- Yasin, S.; Osman, S.T.; Can, C. Influence of welding on microstructure and strength of rail steel. Constr. Build. Mater. 2020, 243, 118220. [Google Scholar] [CrossRef]

- Kim, C.S.; Kim, J.K. Fatigue crack growth behavior of a gas pressure welded part of rail steel under mixed mode loading. Key Eng. Mater. 2007, 345–346, 473–476. [Google Scholar] [CrossRef]

- Hajime, I.; Ryu-ichi, Y. Thermal deformation analysis for pressure welding of rail. Q. Rep. RTRI 2022, 63, 257–262. [Google Scholar] [CrossRef]

- Kim, K.S. A experimental study on strength safety of rail steel using gas pressure welding. J. Korean Soc. Railw. 2012, 15, 266–271. [Google Scholar] [CrossRef]

- Abdulsameea, J. Welding of Rail Steels. Ph.D. Thesis, University of Manchester, Manchester, UK, 2015. [Google Scholar]

- Trushil, A.P.; Vishvesh, B. Rail welding technology: Processes and welding quality. Recent Adv. Mech. Infrastruct. 2022, 369–381. [Google Scholar] [CrossRef]

- Ranit, D.; Gregor, K.; David, S. Feature Selection with Distance Correlation. arXiv 2022, arXiv:2212.00046. [Google Scholar] [CrossRef]

- Baptiste, G.; Bertrand, M.; Philippe, S.P. Correlation and Variable Importance in Random Forests. Stat. Comput. 2016, 27, 659–678. [Google Scholar] [CrossRef]

- Chen, S.B.; Ding, C.H.Q.; Zhou, Z.L.; Luo, B. Feature Selection Based on Correlation Deflation. Neural Comput. Appl. 2018, 31, 6383–6392. [Google Scholar] [CrossRef]

- Gong, H.H.; Li, Y.Y.; Zhang, J.N.; Zhang, B.S.; Wang, X.L. A New Filter Feature Selection Algorithm for Classification Task by Ensembling Pearson Correlation Coefficient and Mutual Information. Eng. Appl. Artif. Intell. 2024, 131, 107865. [Google Scholar] [CrossRef]

- Swope, R.; Khanna, A.; Doldo, P.; Roy, S.; Raff, E. Feature Selection from Differentially Private Correlations. arXiv 2024, arXiv:2408.10862. [Google Scholar] [CrossRef]

- Makhsuda, J.; Ryu, K.J.; Jeong, S.H.; Song, D.J. A computational analysis of the airflow in a twin-track subway tunnel with a sliding-curtain to improve ventilation performance. J. Mech. Sci. Technol. 2013, 27, 2359–2365. [Google Scholar] [CrossRef]

- Yuan, F.D.; You, S.J. CFD simulation and optimization of the ventilation for subway side-platform. Tunn. Undergr. Space Technol. 2007, 22, 474–482. [Google Scholar] [CrossRef]

- Mohamed, M.A.; Abdelrasoul, E.I.; Hamed, S.R. Numerical simulation of airflow distribution in the tunnel of Cairo Metro Line 3 using CFD. Int. J. Multidiscip. Res. Anal. 2023, 6, 3827–3837. [Google Scholar] [CrossRef]

- Huang, Y.D. A Numerical analysis of the ventilation performance for different ventilation strategies in a subway tunnel. J. Hydrodyn. 2012, 24, 193–201. [Google Scholar] [CrossRef]

- Mohamed, M.A.; Abdelrasoul, E.I.; Hamed, S.R. CFD application to estimate air flow rate for normal ventilation in metro trains and stations. Am. J. Sci. Eng. Technol. 2023, 8, 226–234. [Google Scholar] [CrossRef]

- ANSYS Workbench 2023 R1; ANSYS Inc.: Canonsburg, PA, USA, 2023.

- ANSYS Fluent 2025 R1; ANSYS Inc.: Canonsburg, PA, USA, 2025.

- Gao, Y.; Wang, P.; Wang, K.; Xu, J.; Dong, Z. Damage tolerance of fractured rails on continuous welded rail track for high-speed railways. Railw. Eng. Sci. 2021, 29, 59–73. [Google Scholar] [CrossRef]

- Lee, S.H.; Kim, S.H.; Chang, Y.S.; Jun, H.K. Fatigue life assessment of railway rail subjected to welding residual and contact stresses. J. Mech. Sci. Technol. 2015, 28, 4483–4491. [Google Scholar] [CrossRef]

- Xu, X.; Xie, L.; Zhou, S.; An, J.; Huang, Y.; Li, D. Fatigue crack propagation behavior and life prediction of welded joints of SMA490BW steel for bogies. Processes 2023, 11, 1984. [Google Scholar] [CrossRef]

- Gao, R.; Liu, M.; Wang, B.; Wang, Y.; Shao, W. Influence of stress intensity factor on rail fatigue crack propagation by finite element method. Materials 2021, 14, 5720. [Google Scholar] [CrossRef] [PubMed]

- Wu, X.; Zhang, Z.; Qi, W.; Tian, R.; Huang, S.; Shi, C. Corrosion behavior of SMA490BW steel and welded joints for high-speed trains in atmospheric environments. Materials 2019, 12, 3043. [Google Scholar] [CrossRef] [PubMed]

- Xiang, L.; Alexander, L.; Tyler, D.; Rapik, S.M.; Christopher, P.; Barkan, L. Optimization of ultrasonic rail-defect inspection for improving railway transportation safety and efficiency. J. Transp. Eng. 2014, 140, 1–10. [Google Scholar] [CrossRef]

- Jacek, K.; Andrzej, R. Concept of thermal shrinkage-resistant railroad rail for use in continuous welded rail track. Appl. Sci. 2024, 14, 6172. [Google Scholar] [CrossRef]

- Park, S.Y. Evaluation of Fracture of Continuous Welded Rails According to Temperature Changes Around Urban Railway Ventilations. Ph.D. Thesis, Dong-yang University, Yeongju-si, Republic of Korea, February 2025. [Google Scholar]

| Category | Cumulative Tonnage (ton) | Annual Tonnage (ton) | ||

|---|---|---|---|---|

| Average | Maximum | Minimum | ||

| Line 1 | 353,564,757 | 1,166,542,899 | 46,534,472 | 37,985,936 |

| Line 2 | 429,770,051 | 1,409,051,143 | 43,191,733 | 35,412,833 |

| Line 3 | 308,694,055 | 1,009,647,703 | 24,793,729 | 25,783,785 |

| Line 4 | 371,380,412 | 1,116,506,539 | 25,250,378 | 30,590,571 |

| Line 5 | 543,161,448 | 714,882,321 | 15,016,651 | 17,210,184 |

| Line 6 | 398,654,404 | 424,788,449 | 117,362,310 | 16,346,463 |

| Line 7 | 538,070,364 | 624,131,400 | 202,664,753 | 21,690,988 |

| Line 8 | 336,416,626 | 369,261,145 | 291,078,661 | 11,304,729 |

| Average | 409,964,015 | 854,351,450 | 95,736,586 | 24,540,686 |

| Category | Depot Gas Pressure Welding | On-Site Gas Pressure Welding | Thermite Welding |

|---|---|---|---|

| Quantity (locations) | 1114 | 306 | 222 |

| Application rate | 67.9% | 18.6% | 13.5% |

| Category | Maximum (°C) | Minimum (°C) |

|---|---|---|

| Magok–Balsan | 27.0 | 2 |

| Mapo–Gongdeok | 29.6 | −2 |

| Haengdang–Wangsimni | 27.3 | 0 |

| Mapo-gu Office–Mangwon | 27.1 | 3 |

| Itaewon–Hangangjin | 33.6 | 5 |

| Sangwolgok–Dolgoji | 30.1 | −8 |

| Banpo–Express Bus Terminal | 30.2 | −6 |

| Cheonwang–Onsu | 30.0 | −4 |

| Gulpocheon–Bupyeong-gu Office | 26.8 | −5 |

| Mongchontoseong–Jamsil | 27.8 | 0 |

| Dandaeogeori–Shinheung | 28.3 | 1.1 |

| Independent variables | Temperature (°C) | −18–27.1 |

| Temperature variation over time (△t) | 2.4–38.1 °C | |

| Curve radius (m) | 0–3000 | |

| Season | Spring, summer, fall, winter | |

| Inclination (‰) | −34–32 | |

| Rail upper/lower, inner/outer | - | |

| Distance between fracture location and ventilation shaft (m) | 2–344 | |

| Effect of ventilation shafts on rail fractures | Field investigation results | |

| Dependent variable | Rail fracture occurrence | - |

| No. | Ambient Temperature (△t) | Curve Radius (m) | Inclination (‰) | Welding Type | Rail Fracture Occurrence | Ventilation Shaft Position | Ventilation Shaft Function | Distance Between Fracture Location and Ventilation Shaft Center (m) | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Upper/Middle/Lower | Connection Type | Ventilation Shaft Entrance Area | Longitudinal (x) | Transverse (y) | Depth (z) | |||||||

| 1 | 9 | 299 | 7 | Gas | Rail fracture | Lower | Ceiling | 24 | Exhaust | 160 | 1.794 | 23.73 |

| 2 | 8 | 296 | 3 | Gas | Rail fracture | Upper | Ceiling | 27 | Exhaust | −41 | 0.75 | 19,450 |

| 3 | 8.6 | 249 | 10 | Gas | Rail fracture | Upper | Wall | 22.4 | Intake | 240 | 1.85 | 29.32 |

| · · · | · · · | · · · | · · · | · · · | · · · | · · · | · · · | · · · | · · · | · · · | · · · | · · · |

| 50 | 8.1 | 250 | 32 | Ther mite | Rail fracture | Lower | Ceiling | 59.60 | U-type | −46 | 7.3 | 10.5 |

| 51 | 8.6 | 300 | −32 | Ther mite | Rail fracture | Upper | Ceiling | 72.73 | Natural | −45 | 4.4 | 16.94 |

| · · · | · · · | · · · | · · · | · · · | · · · | · · · | · · · | · · · | · · · | · · · | · · · | · · · |

| 83 | 7.1 | 265 | −10 | Ther mite | Rail fracture | Lower | Ceiling | 22.40 | Intake | 282 | 2.34 | 29.32 |

| 84 | 9.3 | Straight | −1.4 | HAZ | Rail fracture | Upper | Ceiling | 44.10 | Intake | −114 | 1.277 | 20.22 |

| Output Input | Minimum Temperature | Maximum Temperature | Δt | Season | Curve Radius | Inclination | Welding Type | Distance (x) |

|---|---|---|---|---|---|---|---|---|

| Minimum temperature | - | 1.97 | 1.36 | inf | inf | inf | inf | inf |

| Maximum temperature | 1.97 | - | 1.25 | inf | inf | inf | inf | inf |

| Δt | 1.36 | 1.25 | - | 2.54 | 1.28 | 1.40 | 2.14 | 1.19 |

| Season | inf | inf | 2.54 | - | 2.38 | 1.54 | 1.20 | 2.12 |

| Curve radius | inf | inf | 1.28 | 2.38 | - | 1.45 | 1.48 | 1.54 |

| Inclination | inf | inf | 1.40 | 1.54 | 1.45 | - | 1.40 | 1.67 |

| Welding type | inf | inf | 2.14 | 1.20 | 1.48 | 1.40 | - | 2.47 |

| Distance (x) | inf | inf | 1.19 | 2.12 | 1.54 | 1.67 | 2.47 | - |

| Category | Airflow (m/s) | Temperature Setting (Δt) |

|---|---|---|

| Case A | 0.5 m/s | 35 °C |

| Case B | 1.0 m/s | |

| Case C | 2.0 m/s | |

| Case D | 4.0 m/s |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Choi, J.-Y.; Park, S.-Y.; Kim, S.-H.; Chung, J.-S. Influences of Temperature Variations Around Subway Ventilations on Fractures of Continuous Welded Rail Fractures. Appl. Sci. 2025, 15, 5391. https://doi.org/10.3390/app15105391

Choi J-Y, Park S-Y, Kim S-H, Chung J-S. Influences of Temperature Variations Around Subway Ventilations on Fractures of Continuous Welded Rail Fractures. Applied Sciences. 2025; 15(10):5391. https://doi.org/10.3390/app15105391

Chicago/Turabian StyleChoi, Jung-Youl, Sang-Yeol Park, Sun-Hee Kim, and Jee-Seung Chung. 2025. "Influences of Temperature Variations Around Subway Ventilations on Fractures of Continuous Welded Rail Fractures" Applied Sciences 15, no. 10: 5391. https://doi.org/10.3390/app15105391

APA StyleChoi, J.-Y., Park, S.-Y., Kim, S.-H., & Chung, J.-S. (2025). Influences of Temperature Variations Around Subway Ventilations on Fractures of Continuous Welded Rail Fractures. Applied Sciences, 15(10), 5391. https://doi.org/10.3390/app15105391