A Categorization of Digital Twin and Model-Based System Engineering Interactions

Abstract

1. Introduction

- Mirroring: all data and information that characterize the physical object are present in the digital counterpart.

- Virtualization: the capability to virtualize complete systems using software and run them on general-purpose hardware.

- Entanglement: the communication relationship between a physical object and its digital counterpart.

- Representativeness: how accurately the digital object reflects the physical object that it represents.

- Contextualization: only the attributes of the physical object that influence its behavior and performance in a given context are included in the digital object.

- How can DT and MBSE interact?

- Can these interactions be categorized?

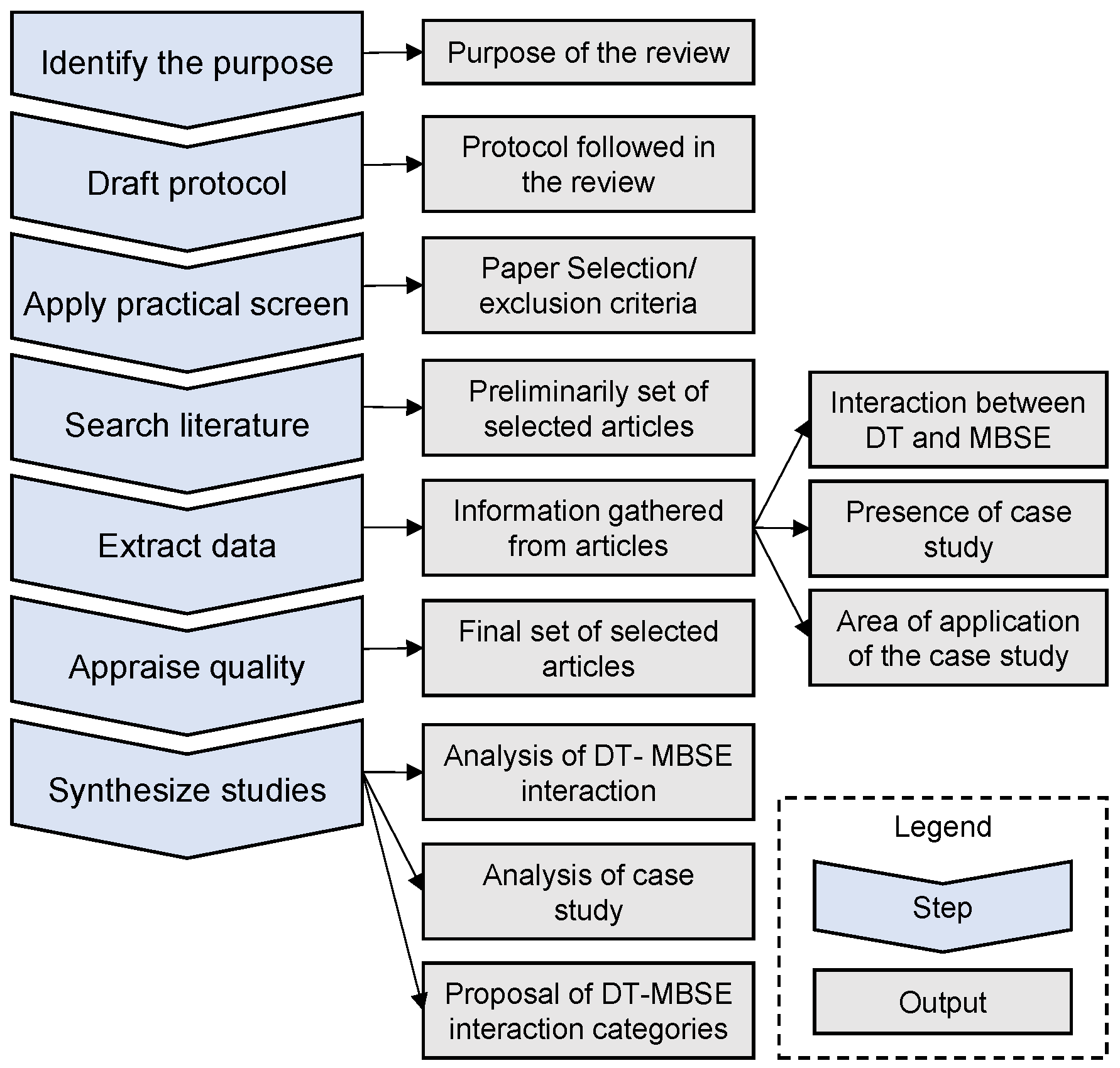

2. Materials and Methods

2.1. Identify the Purpose

2.2. Draft Protocol

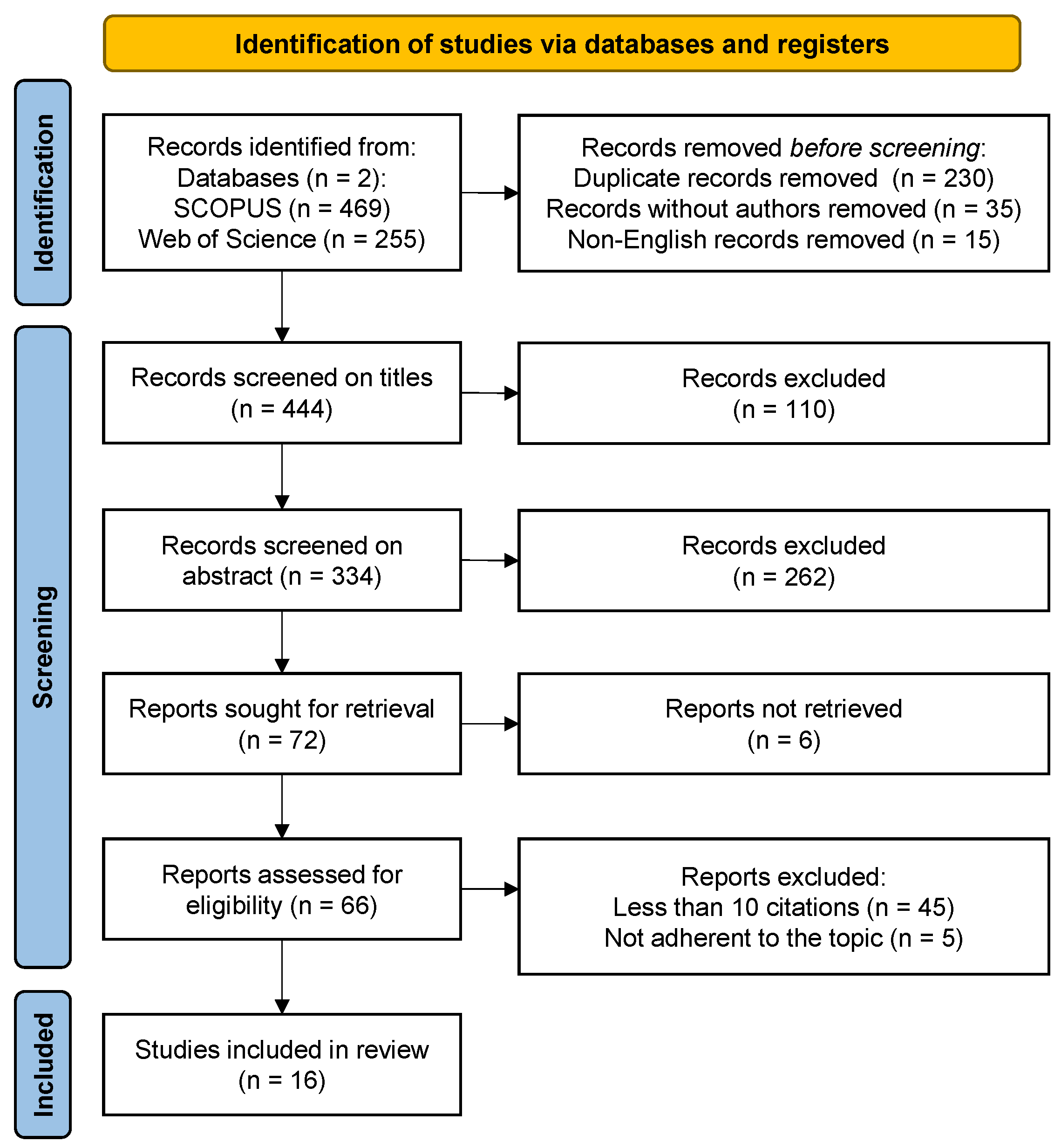

2.3. Apply Practical Screening

- The article must be written in English;

- The article must have at least 10 citations according to an indexed database;

- The article must be available as a full text.

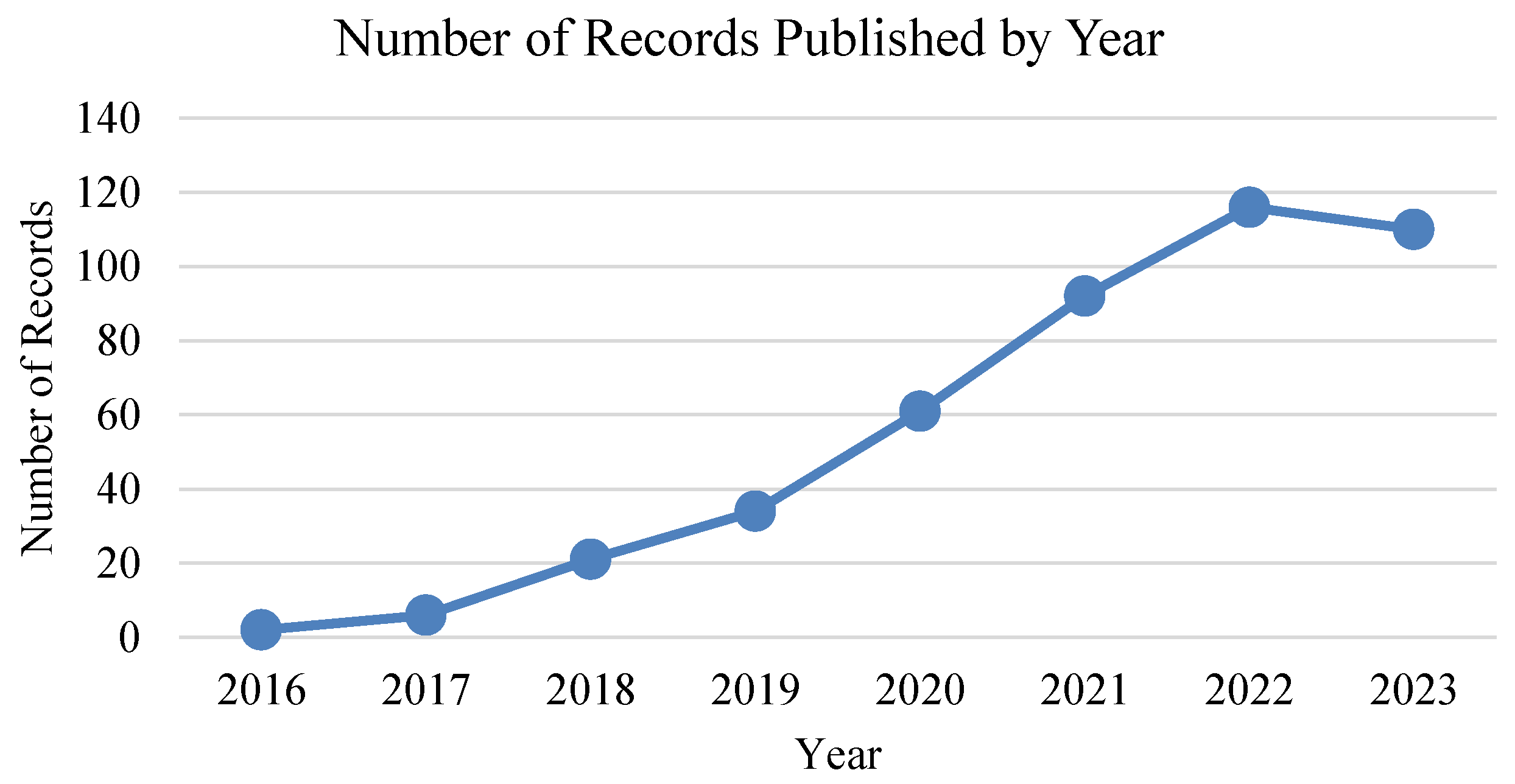

2.4. Search the Literature

2.5. Extract Data

- Type of relationship between DT and MBSE;

- Presence of case study;

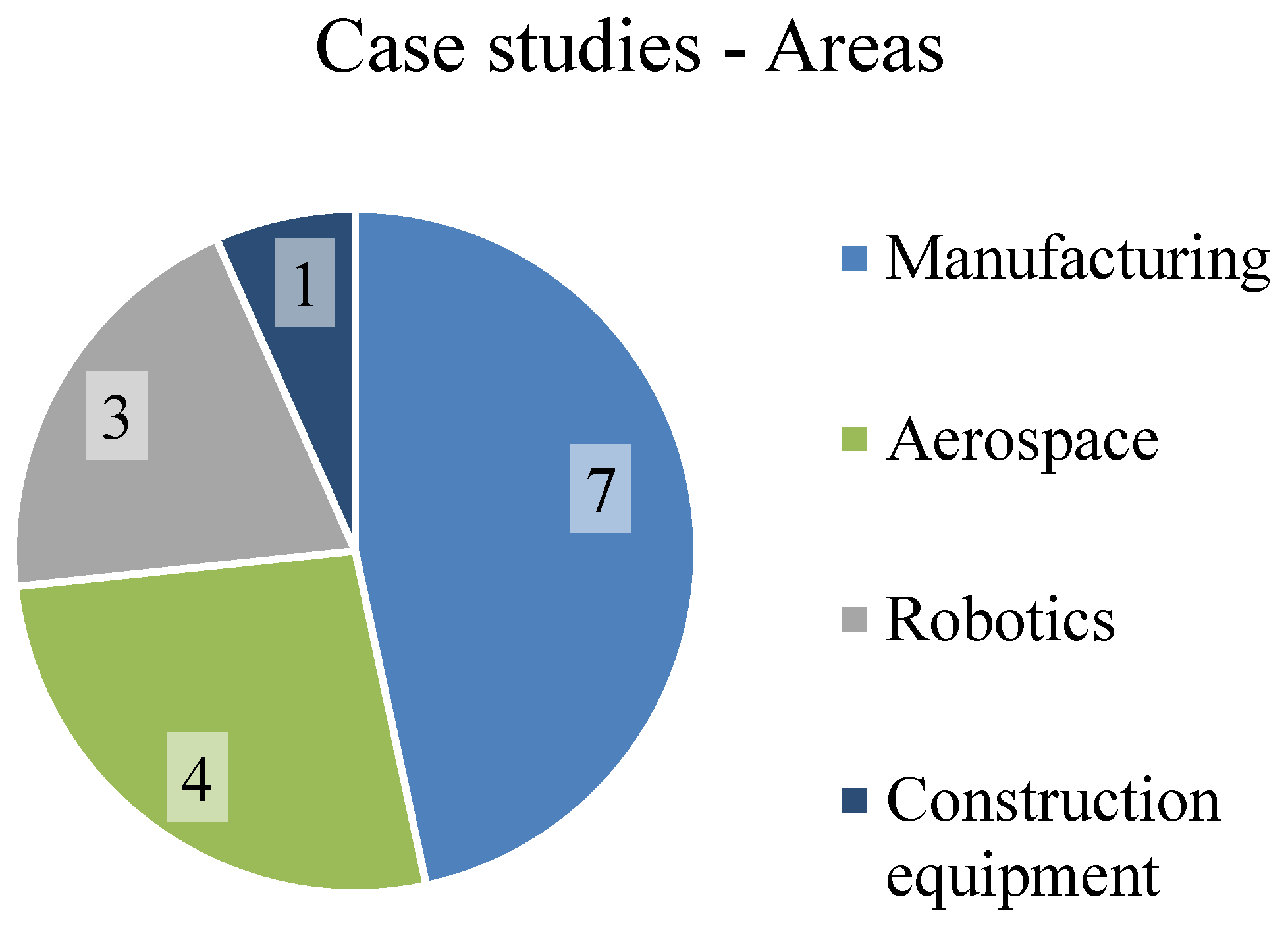

- Area of application of case study.

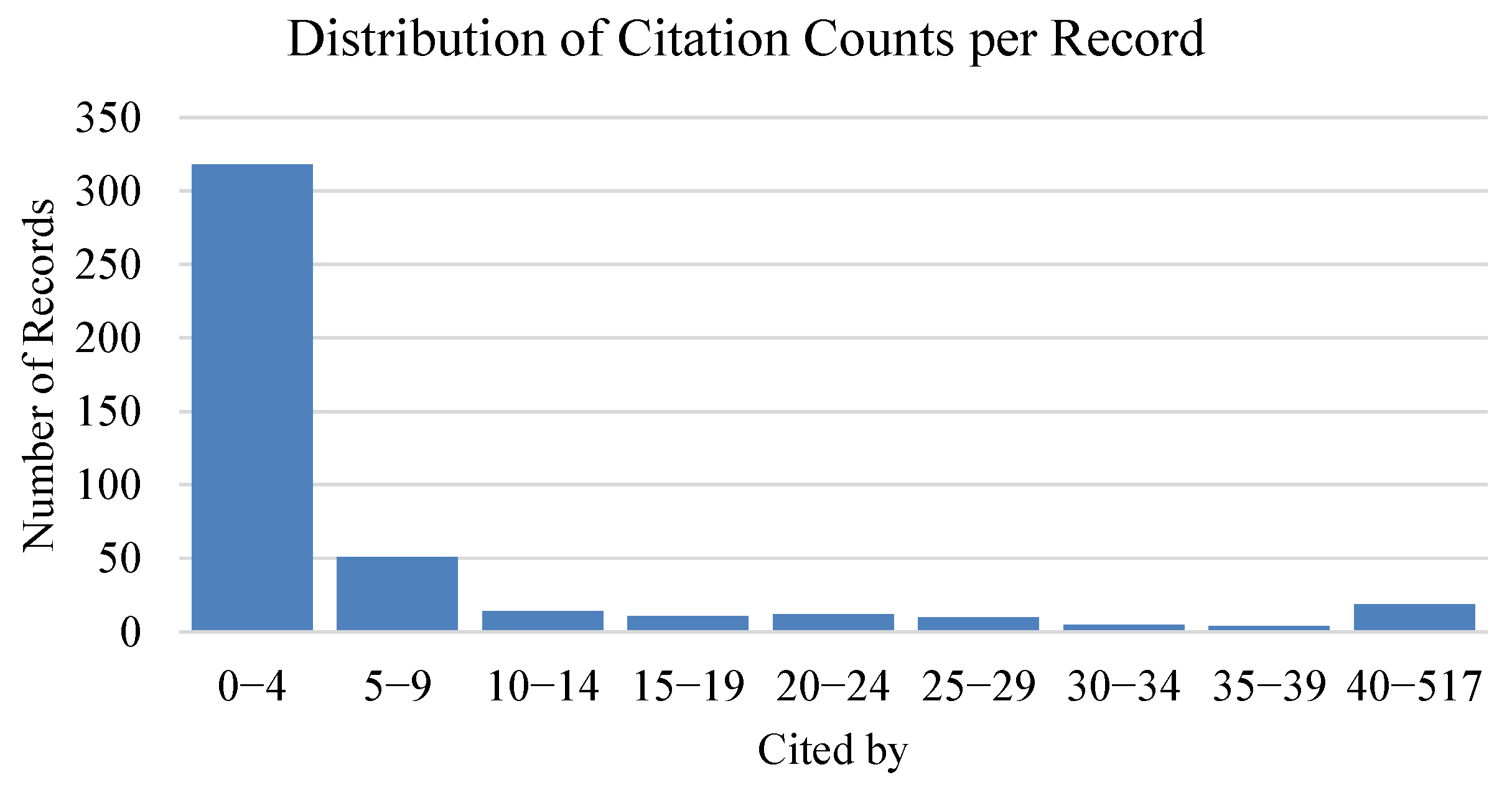

2.6. Appraise Quality

2.7. Synthesize Studies

3. Results

3.1. Interaction Between DT and MBSE

3.2. Case Study

3.3. Categorization

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| AUV | Autonomous underwater vehicle |

| CAM | Computer-aided manufacturing |

| CAPP | Computer-aided process planning |

| CLOSE | Closed-loop engineering |

| DTD | Digital twin data |

| DT | Digital twin |

| EDT | Experimentable digital twin |

| IM | Injection molding |

| INCOSE | International Council on Systems Engineering |

| INPA | National Amazon Research Institute |

| LBA | Large-Scale Biosphere–Atmosphere Program in the Amazon |

| LODESTAR | Aerospace Systems Simulation and Control Laboratory |

| MBSE | Model-based system engineering |

| MT | Micrometeorological tower |

| OCL | Object Constraint Language |

| PDM | Product data management |

| PE | Physical entity |

| SS | Service system |

| STK | Systems tool kit |

| SysML | Systems Modeling Language |

| UML | Unified Modeling Language |

| UnB | University of Brasília |

| USV | Unmanned surface vehicle |

| VE | Virtual entity |

| VTB | Virtual testbed |

| WoDT | Web of digital twins |

References

- Tao, F.; Zhang, H.; Liu, A.; Nee, A.Y. Digital Twin in Industry: State-of-the-Art. IEEE Trans. Ind. Inform. 2019, 15, 2405–2415. [Google Scholar] [CrossRef]

- Liu, M.; Fang, S.; Dong, H.; Xu, C. Review of digital twin about concepts, technologies, and industrial applications. J. Manuf. Syst. 2021, 58, 346–361. [Google Scholar] [CrossRef]

- Sharma, A.; Kosasih, E.; Zhang, J.; Brintrup, A.; Calinescu, A. Digital Twins: State of the art theory and practice, challenges, and open research questions. J. Ind. Inf. Integr. 2022, 30, 100383. [Google Scholar] [CrossRef]

- Grieves, M. Digital Twin: Manufacturing Excellence Through Virtual Factory Replication; White Paper; 2014; pp. 1–7. Available online: https://www.researchgate.net/publication/275211047_Digital_Twin_Manufacturing_Excellence_through_Virtual_Factory_Replication (accessed on 3 May 2025).

- Glaessgen, E.; Stargel, D. The Digital Twin Paradigm for Future NASA and U.S. Air Force Vehicles. In Proceedings of the 53rd AIAA/ASME/ASCE/AHS/ASC Structures, Structural Dynamics and Materials Conference; 20th AIAA/ASME/AHS Adaptive Structures Conference; 14th AIAA, Honolulu, HI, USA, 23–26 April 2012. [Google Scholar] [CrossRef]

- Kritzinger, W.; Karner, M.; Traar, G.; Henjes, J.; Sihn, W. Digital Twin in manufacturing: A categorical literature review and classification. IFAC-PapersOnLine 2018, 51, 1016–1022. [Google Scholar] [CrossRef]

- Tao, F.; Zhang, M.; Liu, Y.; Nee, A.Y. Digital twin driven prognostics and health management for complex equipment. CIRP Ann. 2018, 67, 169–172. [Google Scholar] [CrossRef]

- Minerva, R.; Lee, G.M.; Crespi, N. Digital Twin in the IoT Context: A Survey on Technical Features, Scenarios, and Architectural Models. Proc. IEEE 2020, 108, 1785–1824. [Google Scholar] [CrossRef]

- Hribernik, K.; Cabri, G.; Mandreoli, F.; Mentzas, G. Autonomous, context-aware, adaptive Digital Twins—State of the art and roadmap. Comput. Ind. 2021, 133, 103508. [Google Scholar] [CrossRef]

- Bellavista, P.; Bicocchi, N.; Fogli, M.; Giannelli, C.; Mamei, M.; Picone, M. Requirements and design patterns for adaptive, autonomous, and context-aware digital twins in industry 4.0 digital factories. Comput. Ind. 2023, 149, 103918. [Google Scholar] [CrossRef]

- Ricci, A.; Croatti, A.; Mariani, S.; Montagna, S.; Picone, M. Web of Digital Twins. ACM Trans. Internet Technol. 2022, 22, 101. [Google Scholar] [CrossRef]

- Tripathi, N.; Hietala, H.; Xu, Y.; Liyanage, R. Stakeholders collaborations, challenges and emerging concepts in digital twin ecosystems. Inf. Softw. Technol. 2024, 169, 107424. [Google Scholar] [CrossRef]

- Lehner, D.; Pfeiffer, J.; Tinsel, E.F.; Strljic, M.M.; Sint, S.; Vierhauser, M.; Wortmann, A.; Wimmer, M. Digital Twin Platforms: Requirements, Capabilities, and Future Prospects. IEEE Softw. 2022, 39, 53–61. [Google Scholar] [CrossRef]

- Douglass, B.P. Agile Systems Engineering; Morgan Kaufmann: Waltham, MA, USA, 2016. [Google Scholar]

- Friedenthal, S.; Griego, R.; Sampson, M. INCOSE model based systems engineering (MBSE) initiative. In Proceedings of the INCOSE 2007 Symposium, San Diego, CA, USA, 24–28 June 2007; Volume 11. [Google Scholar]

- De Saqui-Sannes, P.; Vingerhoeds, R.A.; Garion, C.; Thirioux, X. A Taxonomy of MBSE Approaches by Languages, Tools and Methods. IEEE Access 2022, 10, 120936–120950. [Google Scholar] [CrossRef]

- Rasor, R.; Göllner, D.; Bernijazov, R.; Kaiser, L.; Dumitrescu, R. Towards collaborative life cycle specification of digital twins in manufacturing value chains. Procedia CIRP 2021, 98, 229–234. [Google Scholar] [CrossRef]

- Madni, A.; Madni, C.; Lucero, S. Leveraging Digital Twin Technology in Model-Based Systems Engineering. Systems 2019, 7, 7. [Google Scholar] [CrossRef]

- Lopez, V.; Akundi, A. A Conceptual Model-based Systems Engineering (MBSE) approach to develop Digital Twins. In Proceedings of the 2022 IEEE International Systems Conference (SysCon), Montreal, QC, Canada, 25–28 April 2022; pp. 1–5. [Google Scholar] [CrossRef]

- Jinzhi, L.; Zhaorui, Y.; Xiaochen, Z.; Jian, W.; Dimitris, K. Exploring the concept of Cognitive Digital Twin from model-based systems engineering perspective. Int. J. Adv. Manuf. Technol. 2022, 121, 5835–5854. [Google Scholar] [CrossRef]

- Madni, A.M.; Erwin, D.; Madni, C.C. Digital Twin-enabled MBSE Testbed for Prototyping and Evaluating Aerospace Systems: Lessons Learned. In Proceedings of the 2021 IEEE Aerospace Conference (50100), Big Sky, MT, USA, 6–13 March 2021; pp. 1–8. [Google Scholar] [CrossRef]

- Gregory, C.; Mbolamananamalala, R.; Rabah, S.; Chapurlat, V. Model Based Systems Engineering applied to Digital Twin engineering: Why and how to? IFAC-PapersOnLine 2024, 58, 157–162. [Google Scholar] [CrossRef]

- Page, M.J.; McKenzie, J.E.; Bossuyt, P.M.; Boutron, I.; Hoffmann, T.C.; Mulrow, C.D.; Shamseer, L.; Tetzlaff, J.M.; Akl, E.A.; Brennan, S.E.; et al. The PRISMA 2020 statement: An updated guideline for reporting systematic reviews. BMJ 2021, 372, n71. [Google Scholar] [CrossRef]

- Okoli, C. A Guide to Conducting a Standalone Systematic Literature Review. Commun. Assoc. Inf. Syst. 2015, 37, 879–910. [Google Scholar] [CrossRef]

- Pranckutė, R. Web of Science (WoS) and Scopus: The Titans of Bibliographic Information in Today’s Academic World. Publications 2021, 9, 12. [Google Scholar] [CrossRef]

- Bao, J.; Guo, D.; Li, J.; Zhang, J. The modelling and operations for the digital twin in the context of manufacturing. Enterp. Inf. Syst. 2019, 13, 534–556. [Google Scholar] [CrossRef]

- Schluse, M.; Atorf, L.; Rossmann, J. Experimentable digital twins for model-based systems engineering and simulation-based development. In Proceedings of the 2017 Annual IEEE International Systems Conference (SysCon), Montreal, QC, Canada, 24–27 April 2017; pp. 1–8. [Google Scholar] [CrossRef]

- Bachelor, G.; Brusa, E.; Ferretto, D.; Mitschke, A. Model-Based Design of Complex Aeronautical Systems Through Digital Twin and Thread Concepts. IEEE Syst. J. 2020, 14, 1568–1579. [Google Scholar] [CrossRef]

- Heber, D.; Groll, M. Towards a digital twin: How the blockchain can foster E/E-traceability in consideration of model-based systems engineering. In Proceedings of the 21st International Conference on Engineering Design (ICED 17), Vol 3: Product, Services and Systems Design, Vancouver, BC, Canada, 21–25 August 2017; pp. 321–330. [Google Scholar]

- Wang, H.; Li, H.; Wen, X.; Luo, G. Unified modeling for digital twin of a knowledge-based system design. Robot. Comput.-Integr. Manuf. 2021, 68, 102074. [Google Scholar] [CrossRef]

- Arrichiello, V.; Gualeni, P. Systems engineering and digital twin: A vision for the future of cruise ships design, production and operations. Int. J. Interact. Des. Manuf. (IJIDeM) 2020, 14, 115–122. [Google Scholar] [CrossRef]

- Bickford, J.; Van Bossuyt, D.L.; Beery, P.; Pollman, A. Operationalizing digital twins through model-based systems engineering methods. Syst. Eng. 2020, 23, 724–750. [Google Scholar] [CrossRef]

- Delbrügger, T.; Rossmann, J. Representing adaptation options in experimentable digital twins of production systems. Int. J. Comput. Integr. Manuf. 2019, 32, 352–365. [Google Scholar] [CrossRef]

- Dickopf, T.; Apostolov, H.; Müller, P.; Göbel, J.C.; Forte, S. A Holistic System Lifecycle Engineering Approach—Closing the Loop between System Architecture and Digital Twins. Procedia CIRP 2019, 84, 538–544. [Google Scholar] [CrossRef]

- Liu, J.; Liu, J.; Zhuang, C.; Liu, Z.; Miao, T. Construction method of shop-floor digital twin based on MBSE. J. Manuf. Syst. 2021, 60, 93–118. [Google Scholar] [CrossRef]

- Laukotka, F.; Hanna, M.; Krause, D. Digital twins of product families in aviation based on an MBSE-assisted approach. Procedia CIRP 2021, 100, 684–689. [Google Scholar] [CrossRef]

- Meierhofer, J.; Schweiger, L.; Lu, J.; Züst, S.; West, S.; Stoll, O.; Kiritsis, D. Digital Twin-Enabled Decision Support Services in Industrial Ecosystems. Appl. Sci. 2021, 11, 11418. [Google Scholar] [CrossRef]

- Munoz, P.; Troya, J.; Vallecillo, A. Using UML and OCL Models to Realize High-Level Digital Twins. In Proceedings of the 2021 ACM/IEEE International Conference on Model Driven Engineering Languages and Systems Companion (MODELS-C), Fukuoka, Japan, 10–15 October 2021; pp. 212–220. [Google Scholar] [CrossRef]

- Maio, M.D.; Kapos, G.D.; Klusmann, N.; Atorf, L.; Dahmen, U.; Schluse, M.; Rossmann, J. Closed-Loop Systems Engineering (CLOSE): Integrating Experimentable Digital Twins with the Model-Driven Engineering Process. In Proceedings of the 2018 IEEE International Systems Engineering Symposium (ISSE), Rome, Italy, 1–3 October 2018; pp. 1–8. [Google Scholar] [CrossRef]

- Fink, A. Conducting Research Literature Reviews: From the Internet to Paper; Sage Publications: Thousand Oaks, CA, USA, 2019. [Google Scholar]

- Webster, J.; Watson, R.T. Analyzing the past to prepare for the future: Writing a literature review. MIS Q. 2002, 26, xiii–xxiii. [Google Scholar]

- Borges, R.A.; dos Santos, A.C.; Silva, W.R.; Aguayo, L.; Borges, G.A.; Karam, M.M.; de Sousa, R.B.; García, B.F.A.; Botelho, V.M.d.S.; Fernández-Carrillo, J.M.; et al. The AlfaCrux CubeSat Mission Description and Early Results. Appl. Sci. 2022, 12, 9764. [Google Scholar] [CrossRef]

- Araújo, A.C.; Nobre, A.D.; Kruijt, B.; Elbers, J.A.; Dallarosa, R.; Stefani, P.; Von Randow, C.; Manzi, A.O.; Culf, A.D.; Gash, J.H.C.; et al. Comparative measurements of carbon dioxide fluxes from two nearby towers in a central Amazonian rainforest: The Manaus LBA site. J. Geophys. Res. Atmos. 2002, 107, LBA 58-1–LBA 58-20. [Google Scholar] [CrossRef]

- Roques, P. Systems Architecture Modeling with the Arcadia Method: A Practical Guide to Capella; ISTE Press: London, UK, 2018. [Google Scholar]

- de Almeida, D.P.; Graics, B.; Chagas, R.A.J.; de Sousa, F.L.; Mattiello-Francisco, F. Towards Simulation of CubeSat Operational Scenarios under a Cyber-Physical Systems View. In Proceedings of the 2021 10th Latin-American Symposium on Dependable Computing (LADC), Florianópolis, Brazil, 22–26 November 2021; pp. 1–4. [Google Scholar] [CrossRef]

- Roques, P. MBSE with the ARCADIA Method and the Capella Tool. In Proceedings of the 8th European Congress on Embedded Real Time Software and Systems, Toulouse, France, 27–29 January 2016. [Google Scholar]

- Li, L.; Aslam, S.; Wileman, A.; Perinpanayagam, S. Digital Twin in Aerospace Industry: A Gentle Introduction. IEEE Access 2022, 10, 9543–9562. [Google Scholar] [CrossRef]

- da Silva, R.C.; Ishioka, I.S.K.; Cappelletti, C.; Battistini, S.; Borges, R.A. Helmholtz Cage Design and Validation for Nanosatellites HWIL Testing. IEEE Trans. Aerosp. Electron. Syst. 2019, 55, 3050–3061. [Google Scholar] [CrossRef]

- da Silva, R.C.; Guimarães, F.C.; de Loiola, J.V.L.; Borges, R.A.; Battistini, S.; Cappelletti, C. Tabletop Testbed for Attitude Determination and Control of Nanosatellites. J. Aerosp. Eng. 2019, 32, 04018122. [Google Scholar] [CrossRef]

- da Silva, R.C.; Borges, R.A.; Battistini, S.; Cappelletti, C. A review of balancing methods for satellite simulators. Acta Astronaut. 2021, 187, 537–545. [Google Scholar] [CrossRef]

| Authors | Title | Year | Cited by | Document Type | Reference |

|---|---|---|---|---|---|

| Madni A.M., Madni C.C., Lucero S.D. | Leveraging digital twin technology in model-based systems engineering | 2019 | 422 | Article | [18] |

| Bao J., Guo D., Li J., Zhang J. | The modelling and operations for the digital twin in the context of manufacturing | 2019 | 178 | Article | [26] |

| Schluse M., Atorf L., Rossmann J. | Experimentable digital twins for model-based systems engineering and simulation-based development | 2017 | 60 | Conference Paper | [27] |

| Bachelor G., Brusa E., Ferretto D., Mitschke A. | Model-Based Design of Complex Aeronautical Systems through Digital Twin and Thread Concepts | 2020 | 44 | Article | [28] |

| Heber D., Groll M. | Towards a digital twin: How the blockchain can foster E/E-traceability in consideration of model-based systems engineering | 2017 | 31 | Conference Paper | [29] |

| Wang H., Li H., Wen X., Luo G. | Unified modeling for digital twin of a knowledge-based system design | 2021 | 33 | Article | [30] |

| Arrichiello V., Gualeni P. | Systems engineering and digital twin: a vision for the future of cruise ships design, production and operations | 2020 | 29 | Article | [31] |

| Bickford J., Van Bossuyt D.L., Beery P., Pollman A. | Operationalizing digital twins through model-based systems engineering methods | 2020 | 26 | Article | [32] |

| Delbrügger T., Rossmann J. | Representing adaptation options in experimentable digital twins of production systems | 2019 | 25 | Article | [33] |

| Dickopf, T; Apostolov, H; Muller, P; Gobel, JC; Forte, S | A Holistic System Lifecycle Engineering Approach—Closing the Loop between System Architecture and Digital Twins | 2019 | 23 | Conference Paper | [34] |

| Liu J., Liu J., Zhuang C., Liu Z., Miao T. | Construction method of shop-floor digital twin based on MBSE | 2021 | 23 | Article | [35] |

| Laukotka F., Hanna M., Krause D. | Digital twins of product families in aviation based on an MBSE-assisted approach | 2021 | 13 | Conference Paper | [36] |

| Meierhofer J., Schweiger L., Lu J., Züst S., West S., Stoll O., Kiritsis D. | Digital twin-enabled decision support services in industrial ecosystems | 2021 | 12 | Article | [37] |

| Rasor R., Göllner D., Bernijazov R., Kaiser L., Dumitrescu R. | Towards collaborative life cycle specification of digital twins in manufacturing value chains | 2021 | 12 | Conference Paper | [17] |

| Munoz P., Troya J., Vallecillo A. | Using UML and OCL Models to Realize High-Level Digital Twins | 2021 | 11 | Conference Paper | [38] |

| Di Maio M., Kapos G.-D., Klusmann N., Atorf L., Dahmen U., Schluse M., Rossmann J. | Closed-loop systems engineering (CLOSE): integrating experimentable digital twins with the model-driven engineering process | 2018 | 11 | Conference Paper | [39] |

| Title | DT and MBSE Interaction | Ref. |

|---|---|---|

| Leveraging digital twin technology in model-based systems engineering | DT uses MBSE system models | [18] |

| Experimentable digital twins for model-based systems engineering and simulation-based development | DT uses MBSE system models | [27] |

| Representing adaptation options in experimentable digital twins of production systems | DT uses MBSE system models | [33] |

| Systems engineering and digital twin: a vision for the future of cruise ships design, production and operations | DT uses MBSE system models | [31] |

| Operationalizing digital twins through model-based systems engineering methods | DT uses MBSE system models | [32] |

| Digital twins of product families in aviation based on an MBSE-assisted approach | DT uses MBSE system models | [36] |

| Closed-loop systems engineering (close): integrating experimentable digital twins with the model-driven engineering process | DT uses MBSE system models | [39] |

| A Holistic System Lifecycle Engineering Approach—Closing the Loop between System Architecture and Digital Twins | DT uses MBSE system models | [34] |

| The modelling and operations for the digital twin in the context of manufacturing | MBSE-based DT | [26] |

| Model-Based Design of Complex Aeronautical Systems through Digital Twin and Thread Concepts | MBSE-based DT | [28] |

| Unified modeling for digital twin of a knowledge-based system design | MBSE-based DT | [30] |

| Construction method of shop-floor digital twin based on MBSE | MBSE-based DT | [35] |

| Digital twin-enabled decision support services in industrial ecosystems | MBSE-based DT | [37] |

| Towards collaborative life cycle specification of digital twins in manufacturing value chains | MBSE-based DT | [17] |

| Using UML and OCL Models to Realize High-Level Digital Twins | MBSE-based DT | [38] |

| Towards a digital twin: How the blockchain can foster E/E-traceability in consideration of model-based systems engineering | DT and MBSE are connected to the PDM, but do not directly interact | [29] |

| DT Uses MBSE System Models | MBSE-Based DT | |

|---|---|---|

| Advantages | - The DT has knowledge of the system behaviors and rules from the system designers. | - The benefits of using MBSE for the design process. |

| - The system model can be simulated and validated in the early stages of its development. | - There is a roadmap for the development of the DT. | |

| - The DT can extend the system observation throughout the life cycle of the system further than the MBSE. | - The MBSE models can become a high-level DT. | |

| Disadvantages | - The connection between the system and the DT is not defined. | - The connection between the system and the DT is not defined. |

| - The MBSE system models must completely define the system and must be up to date. | - The information about the system must be provided by the designer. | |

| - The use of MBSE models as DTs is limited in functionality. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Oliveira, A.C.A.d.; Borges, R.A. A Categorization of Digital Twin and Model-Based System Engineering Interactions. Appl. Sci. 2025, 15, 5333. https://doi.org/10.3390/app15105333

Oliveira ACAd, Borges RA. A Categorization of Digital Twin and Model-Based System Engineering Interactions. Applied Sciences. 2025; 15(10):5333. https://doi.org/10.3390/app15105333

Chicago/Turabian StyleOliveira, Alexandre Crepory Abbott de, and Renato Alves Borges. 2025. "A Categorization of Digital Twin and Model-Based System Engineering Interactions" Applied Sciences 15, no. 10: 5333. https://doi.org/10.3390/app15105333

APA StyleOliveira, A. C. A. d., & Borges, R. A. (2025). A Categorization of Digital Twin and Model-Based System Engineering Interactions. Applied Sciences, 15(10), 5333. https://doi.org/10.3390/app15105333