Research on the Mechanical Properties of Fiber-Reinforced Bamboo Board and Numerical Simulation Analysis of the Structural Mechanical Properties of Products

Abstract

1. Introduction

2. Test of Binder Ratio and Mechanical Properties of Fiber-Reinforced Bamboo Substrate

2.1. Test Materials

2.2. Optimum Ratio of MOC Mortar

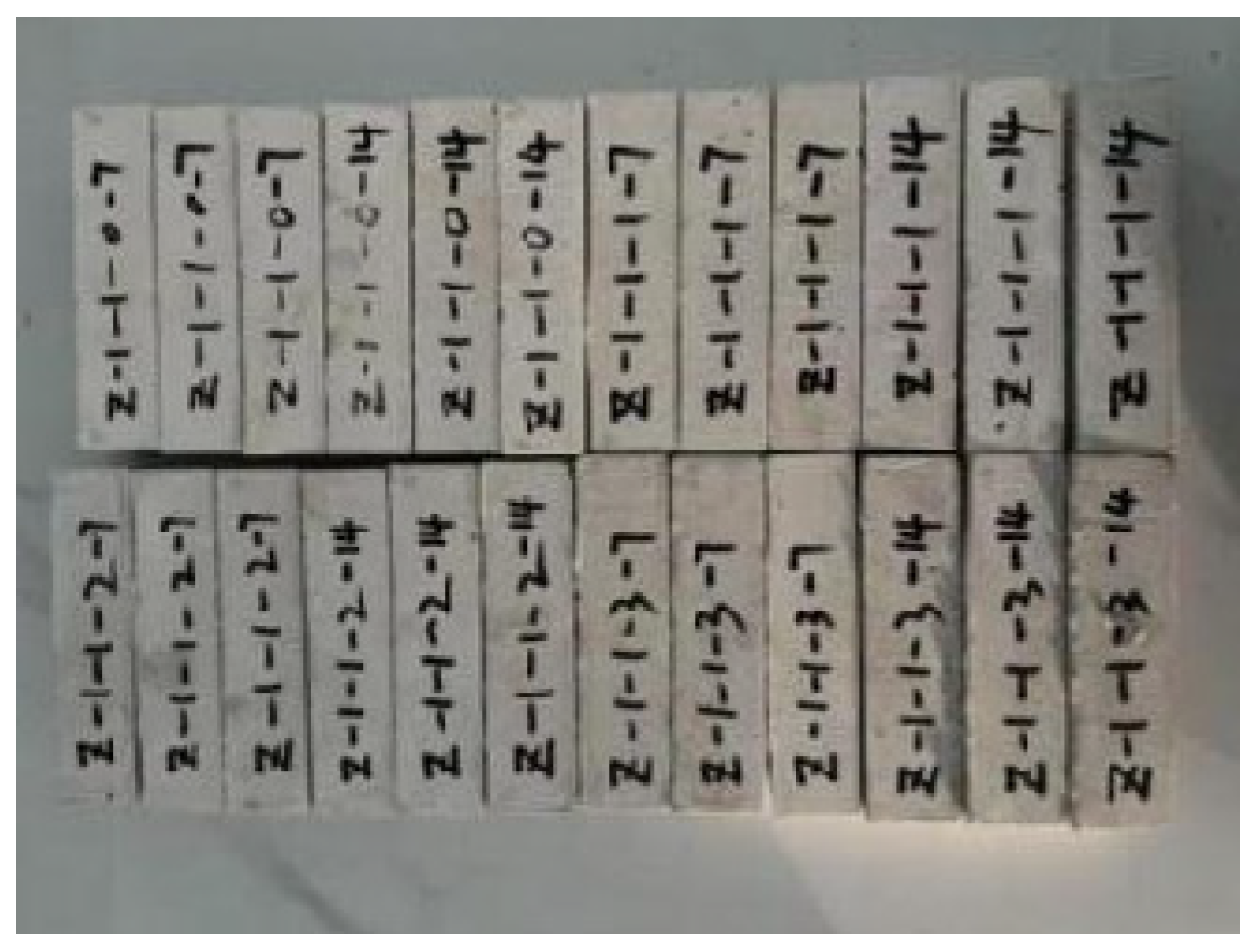

2.2.1. Ratio of MOC Specimen

2.2.2. MOC Specimen Production

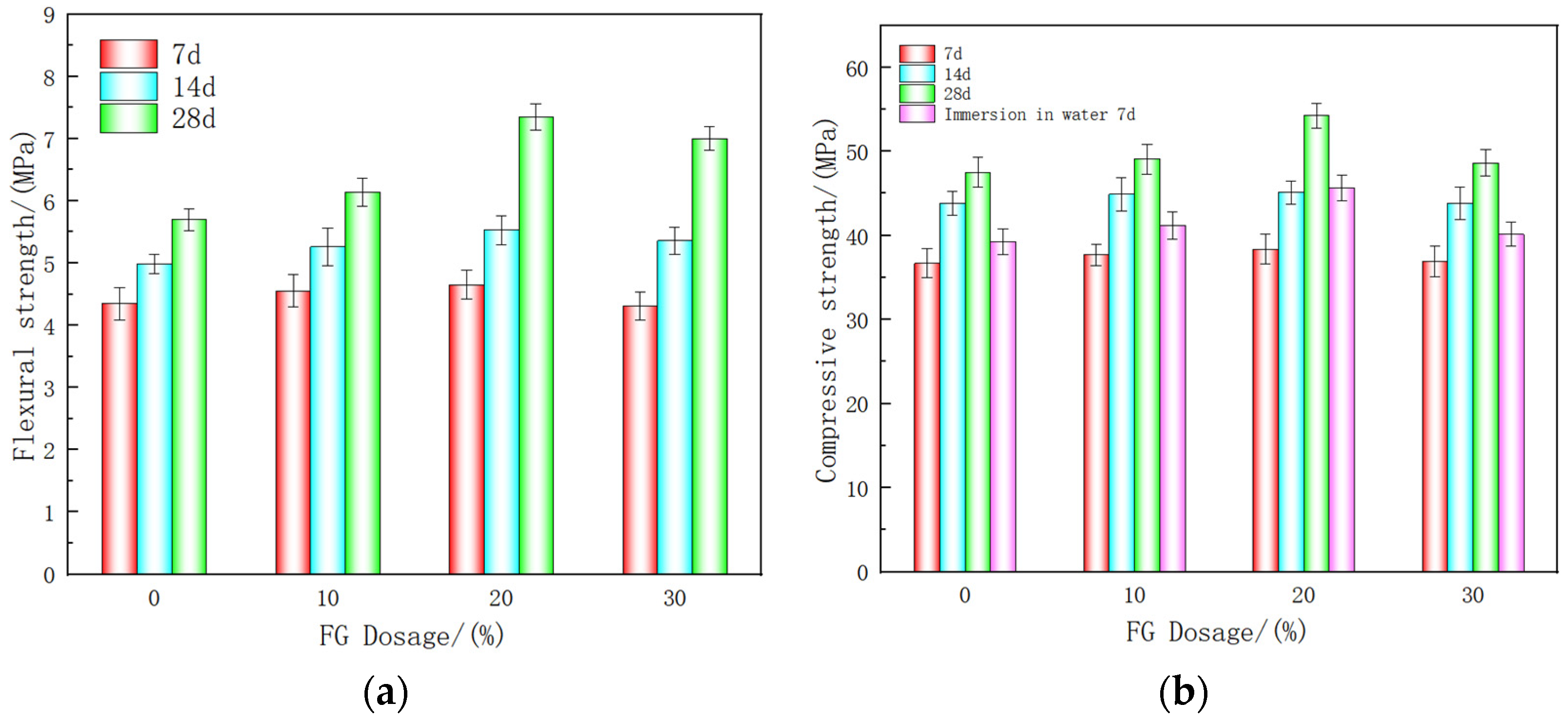

2.2.3. Mechanical Property Test of MOC Specimen

2.2.4. Analysis of Experimental Results of MOC Material Properties

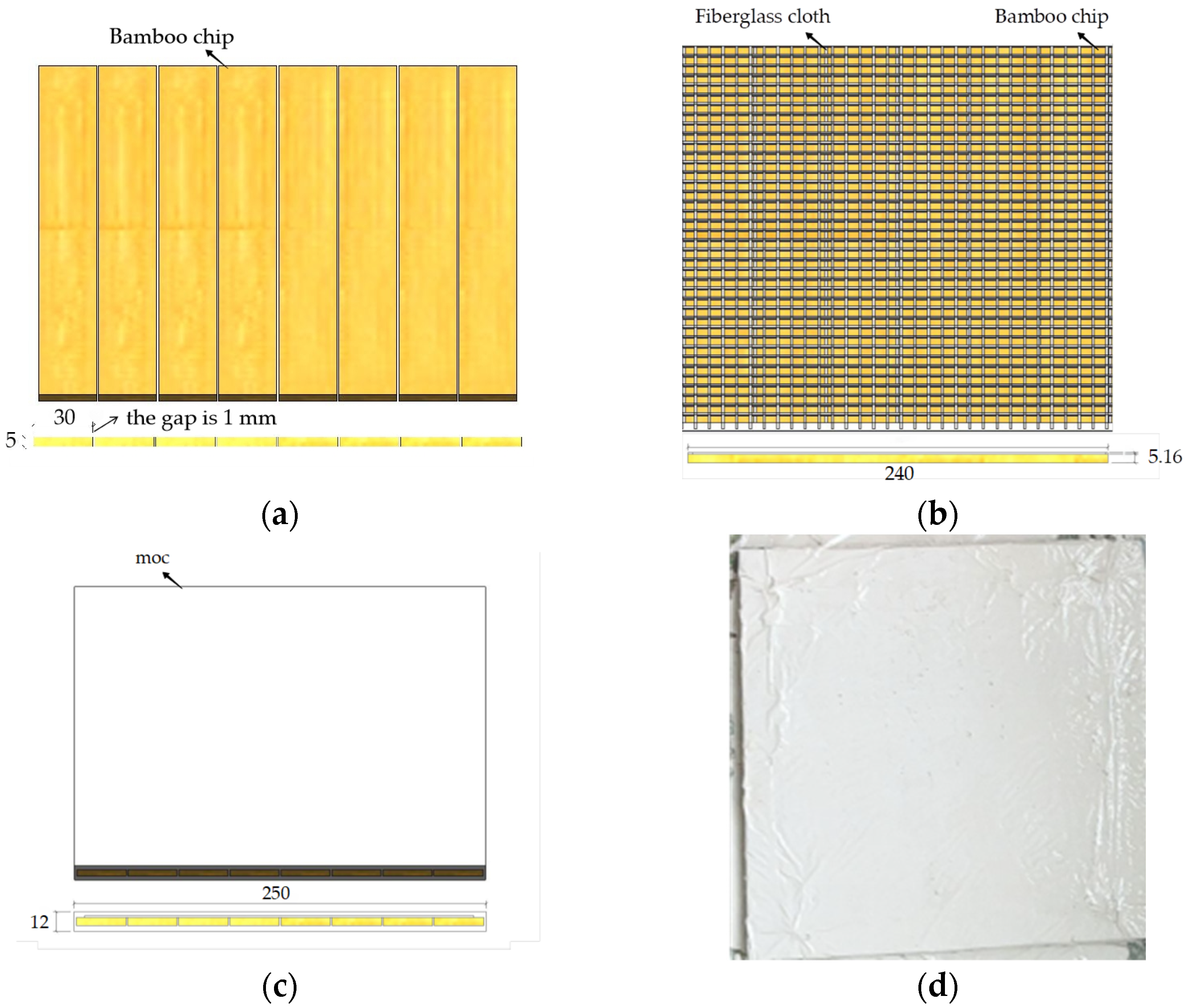

2.3. Fabrication and Performance Test Analysis of Fiber-Reinforced Bamboo Substrate

2.3.1. Fabrication of Fiber-Reinforced Bamboo Board

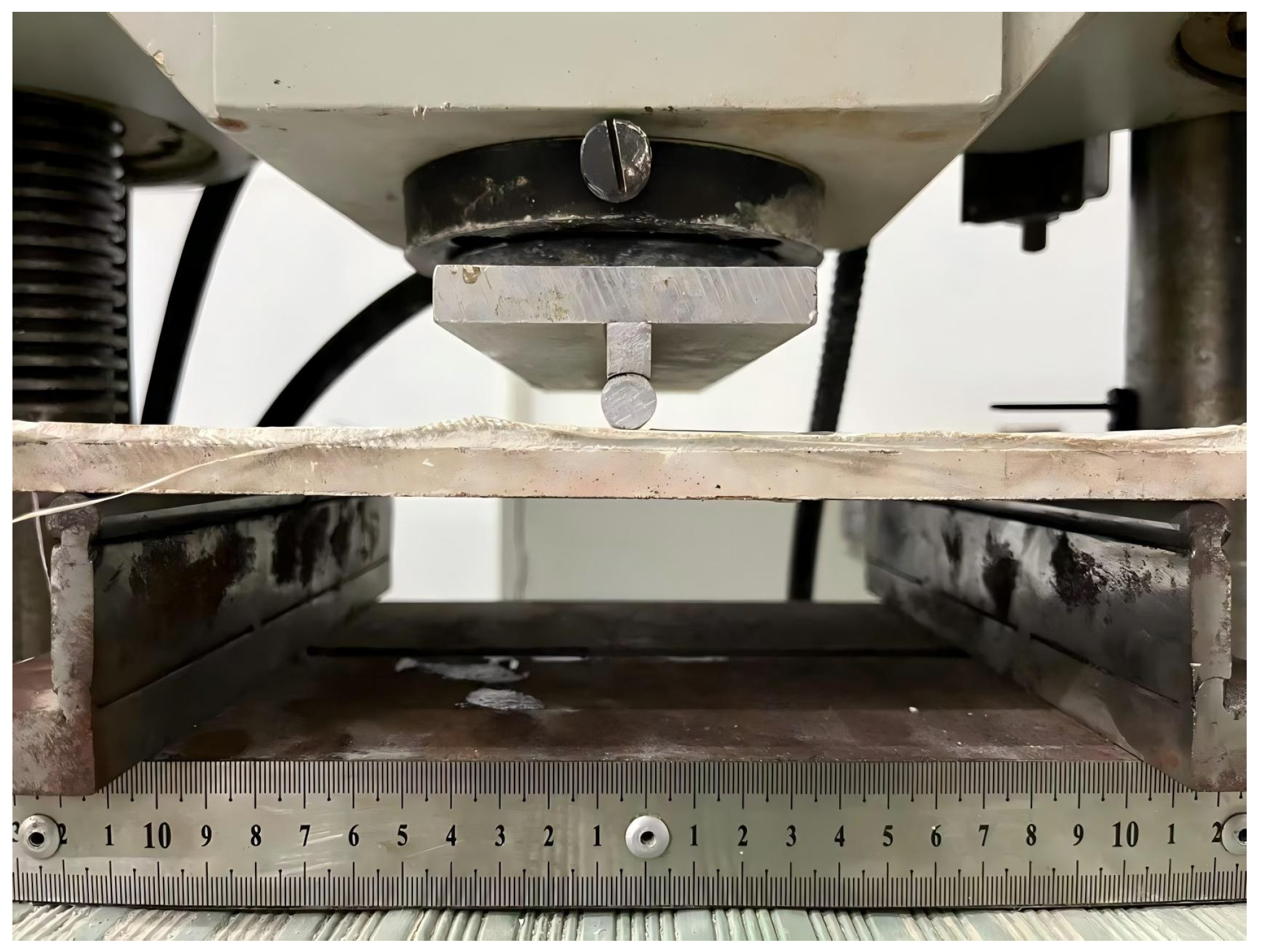

2.3.2. Performance Test and Results of Fiber-Reinforced Bamboo Substrate

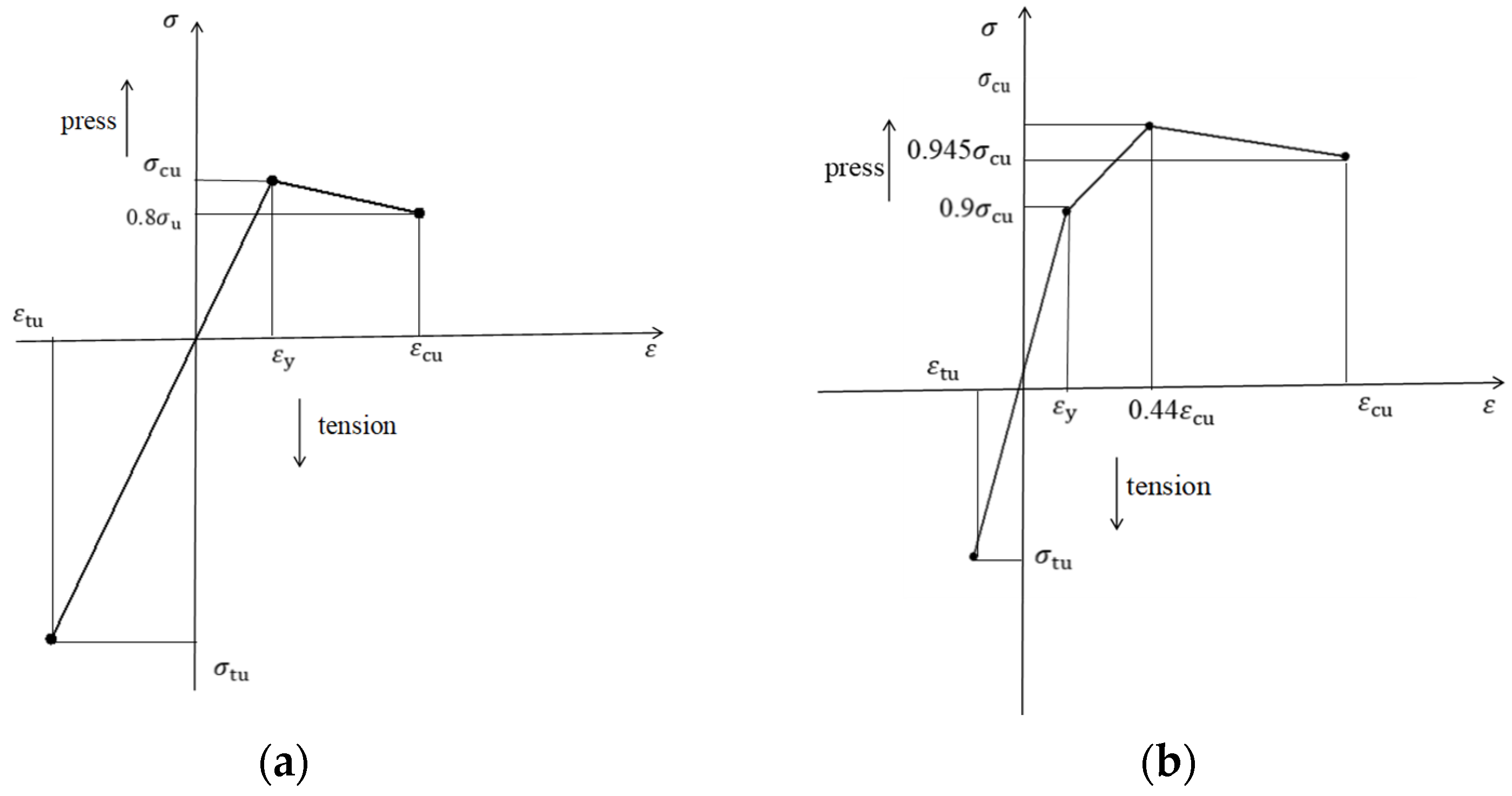

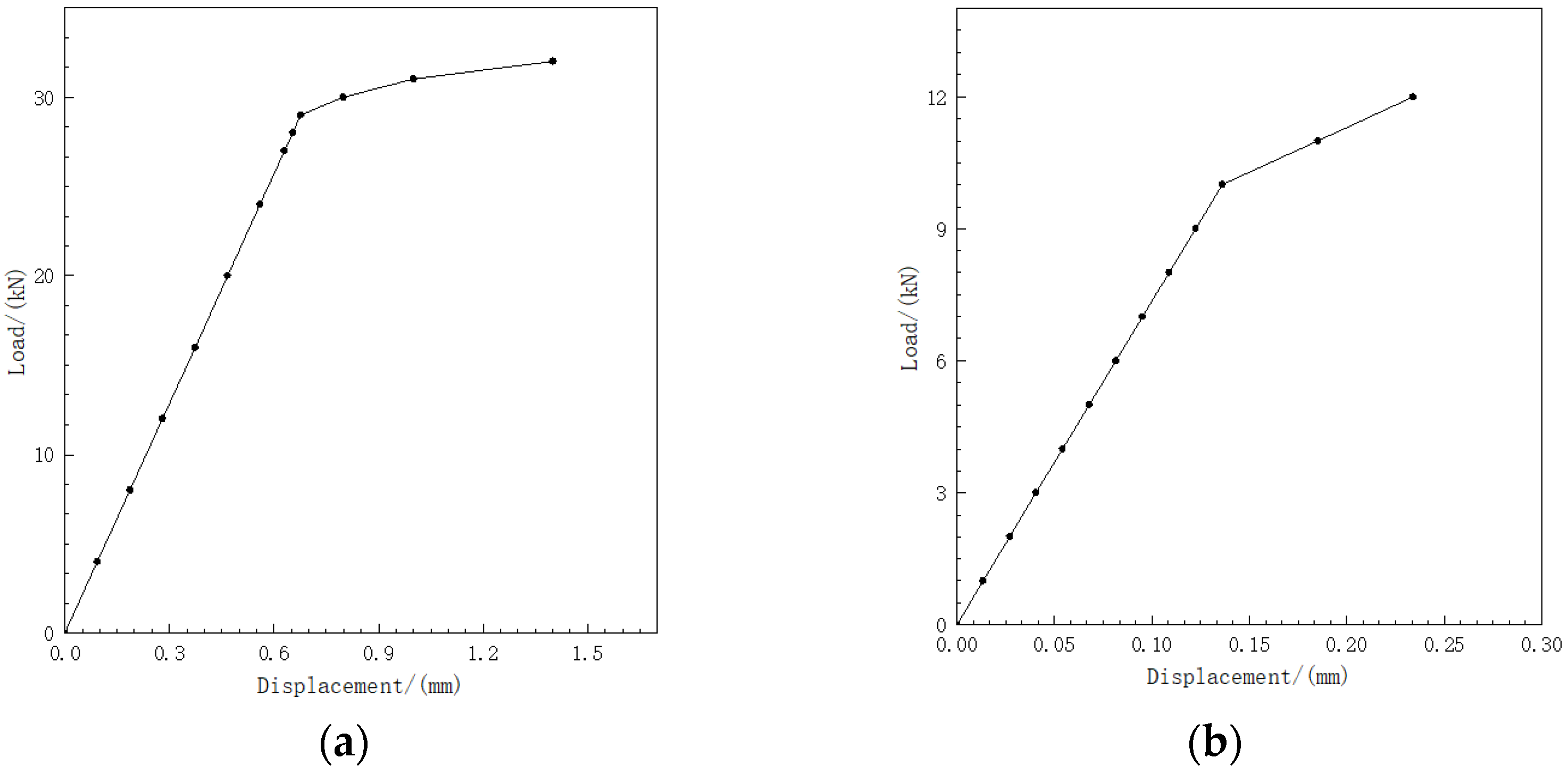

3. Numerical Simulation of Fiber-Reinforced Bamboo Substrate and Comparison with Experimental Results

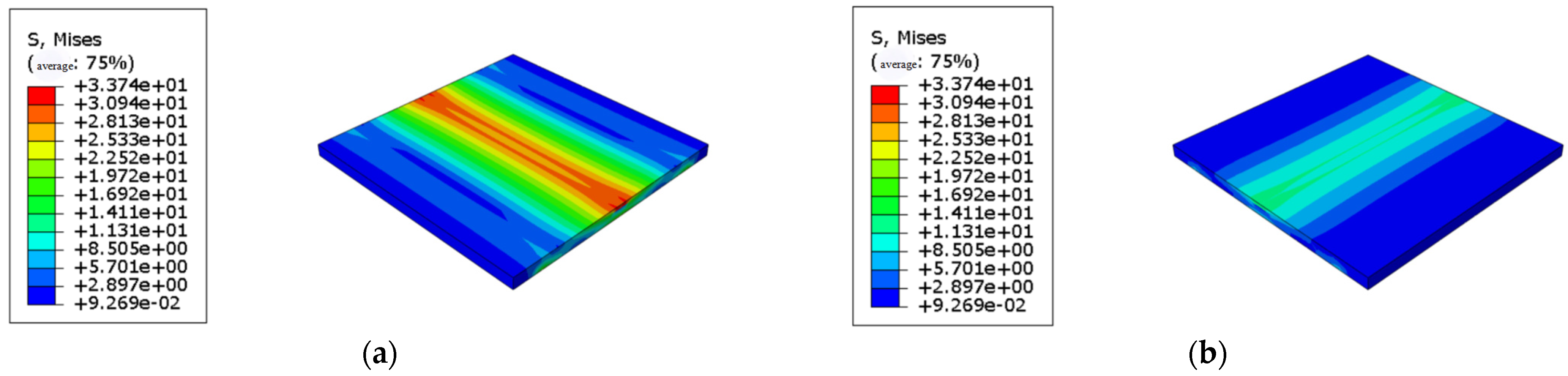

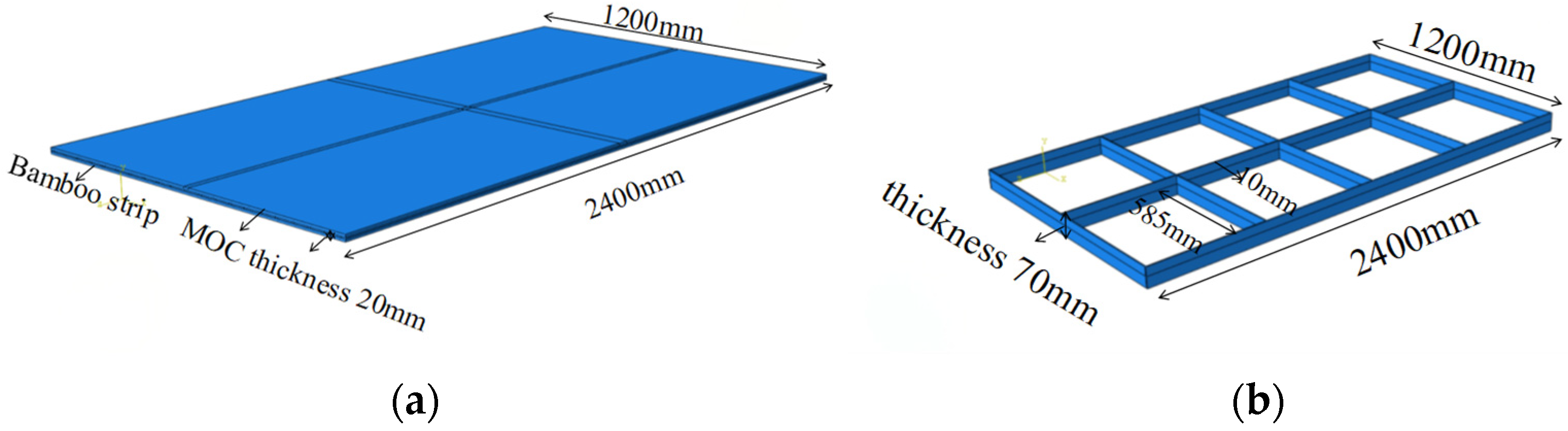

4. Numerical Simulation Analysis of Fiber-Reinforced Bamboo Floor

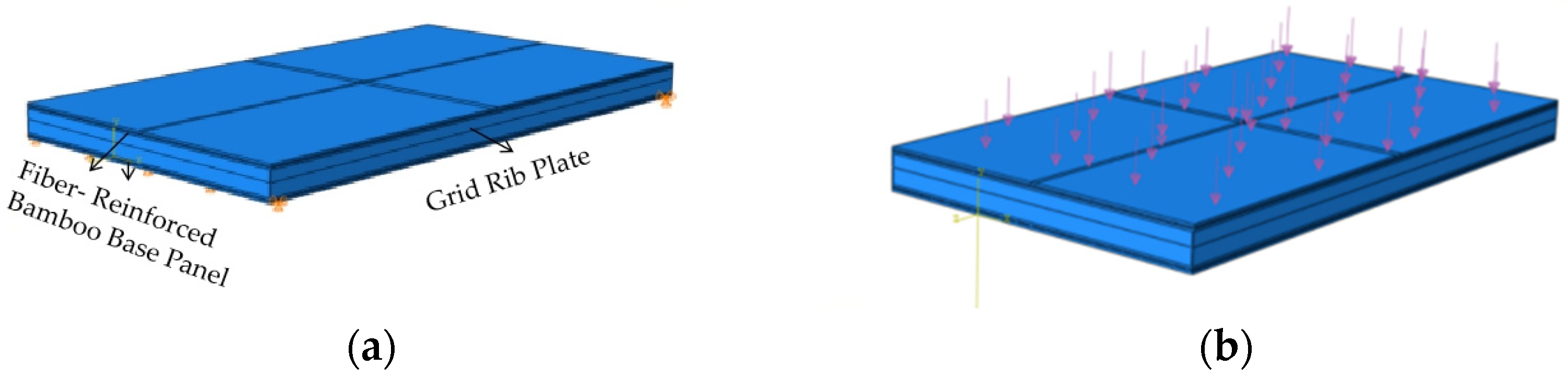

4.1. Numerical Modeling

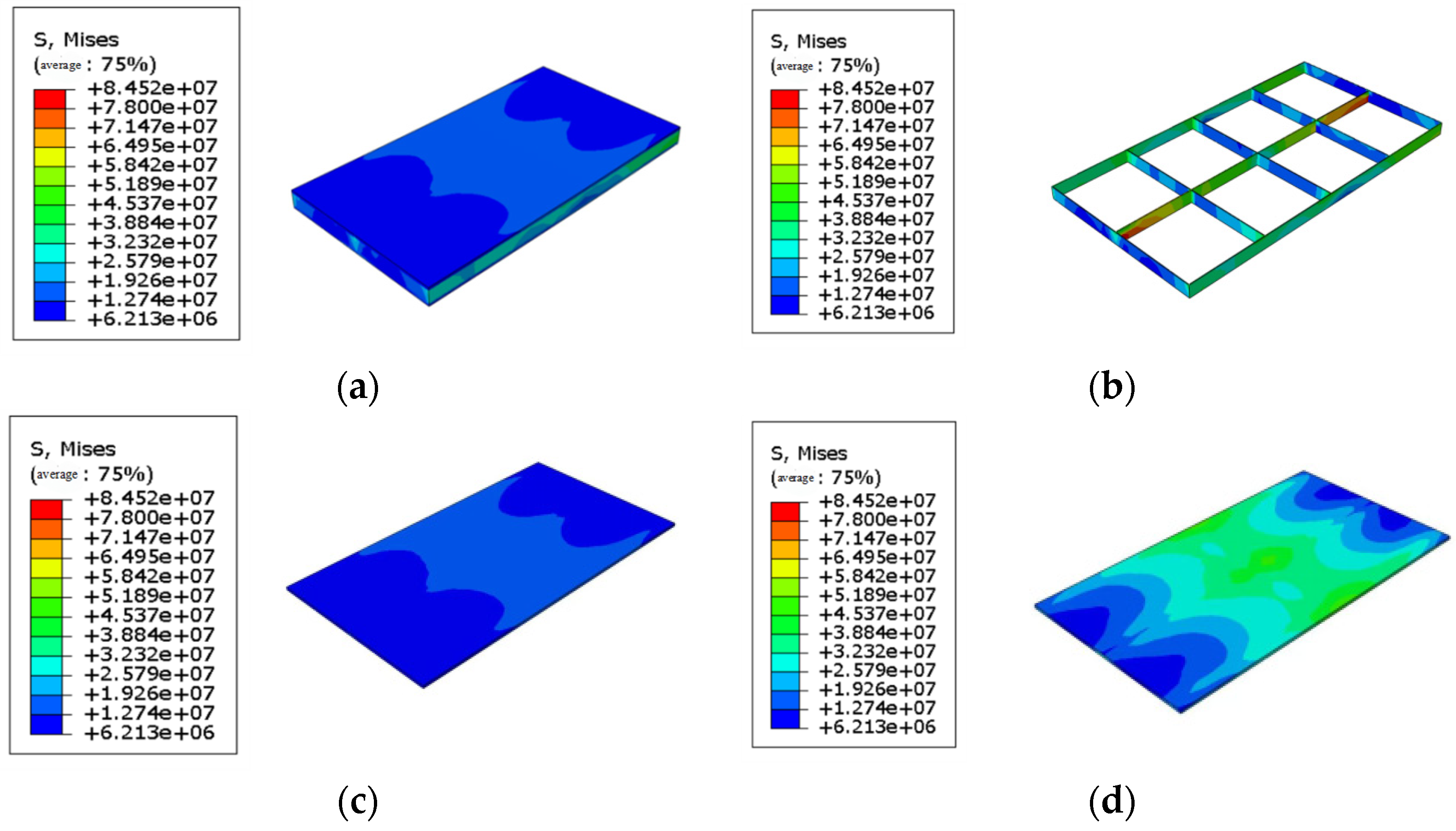

4.2. Result of Analysis

5. Numerical Simulation of Fiber-Reinforced Bamboo Wallboard

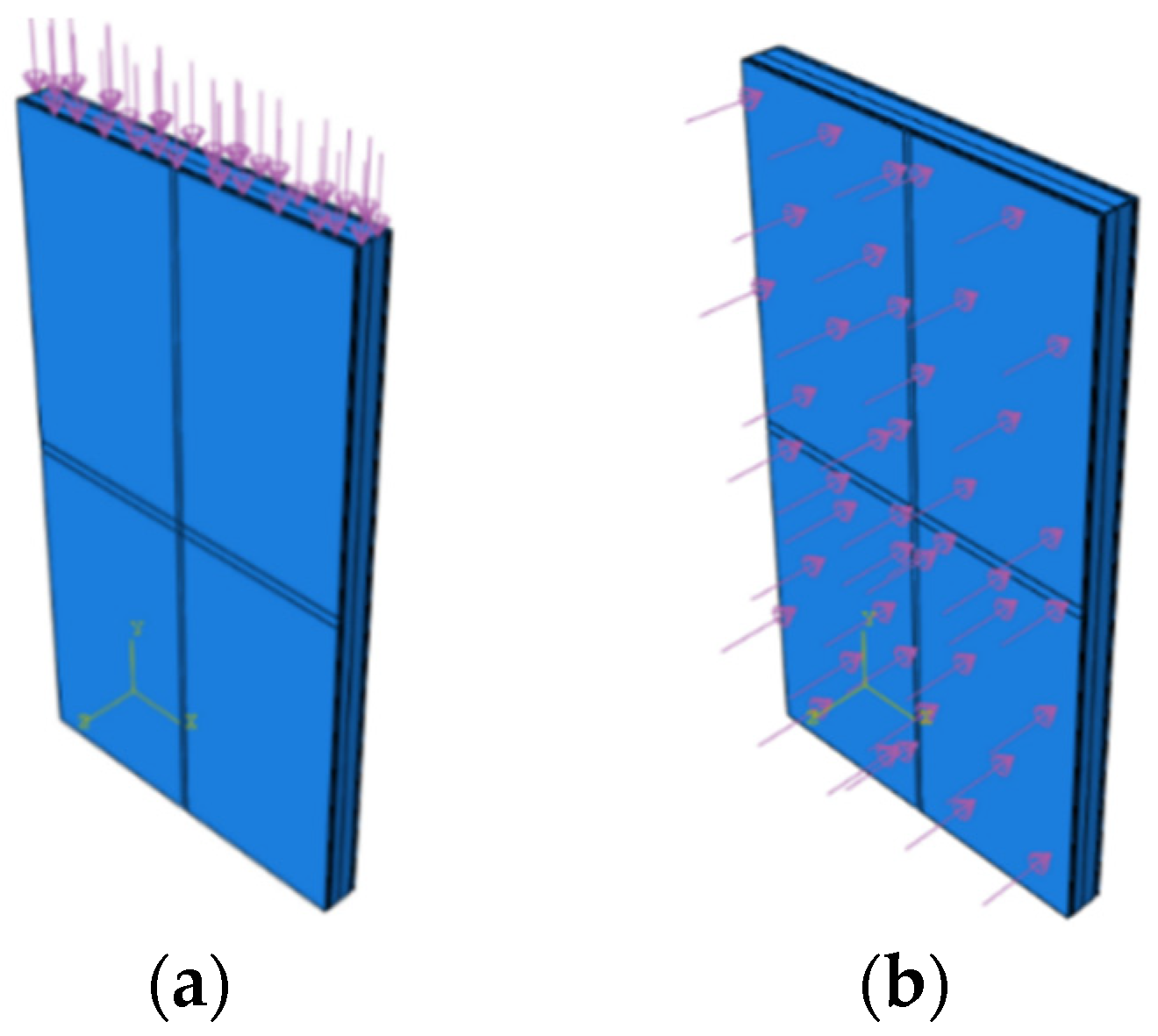

5.1. Numerical Modeling

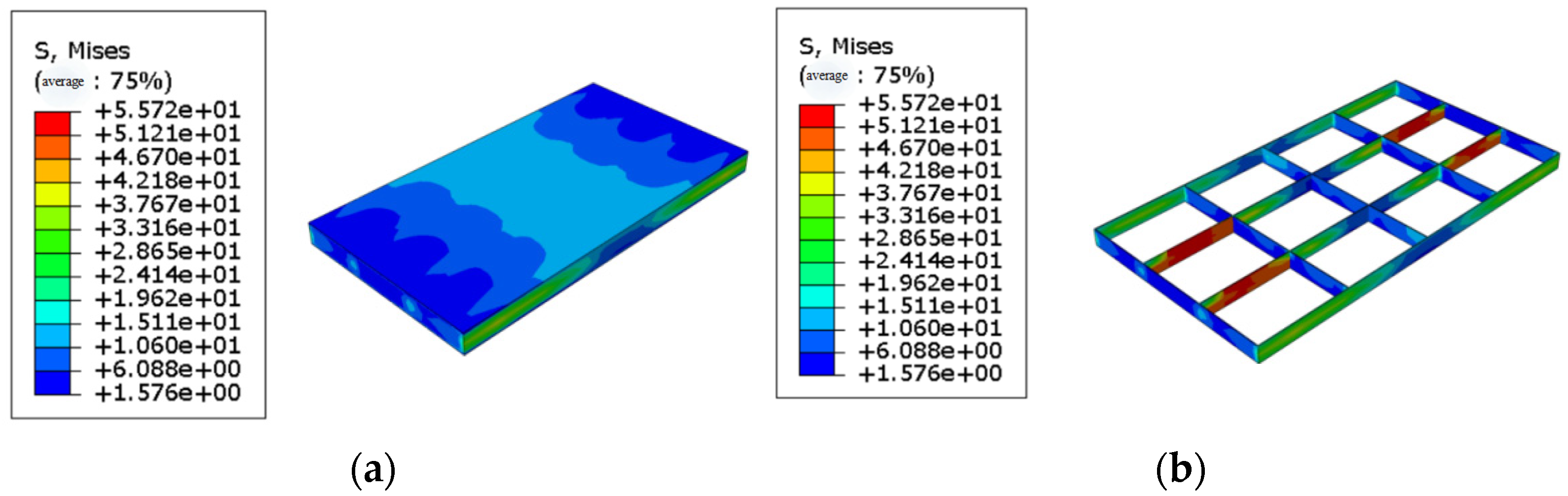

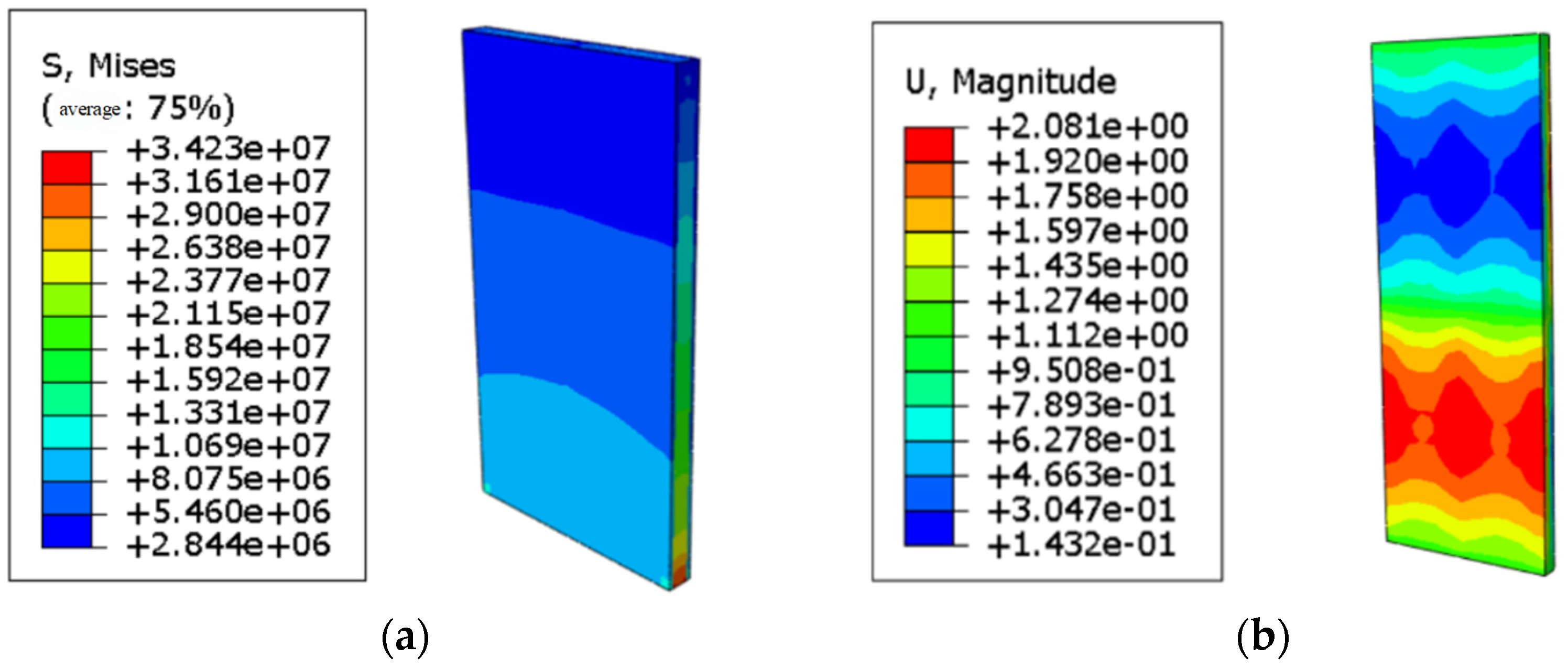

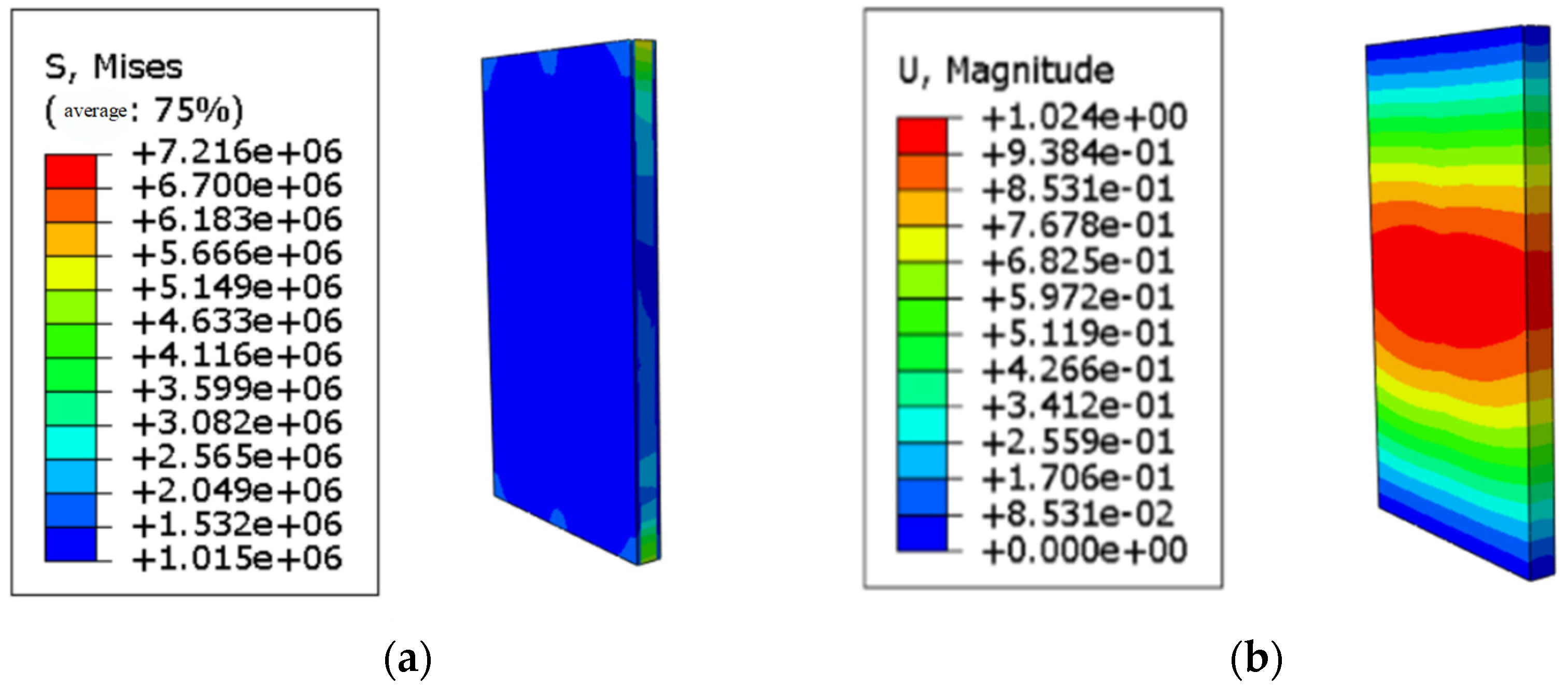

5.2. Result of Analysis

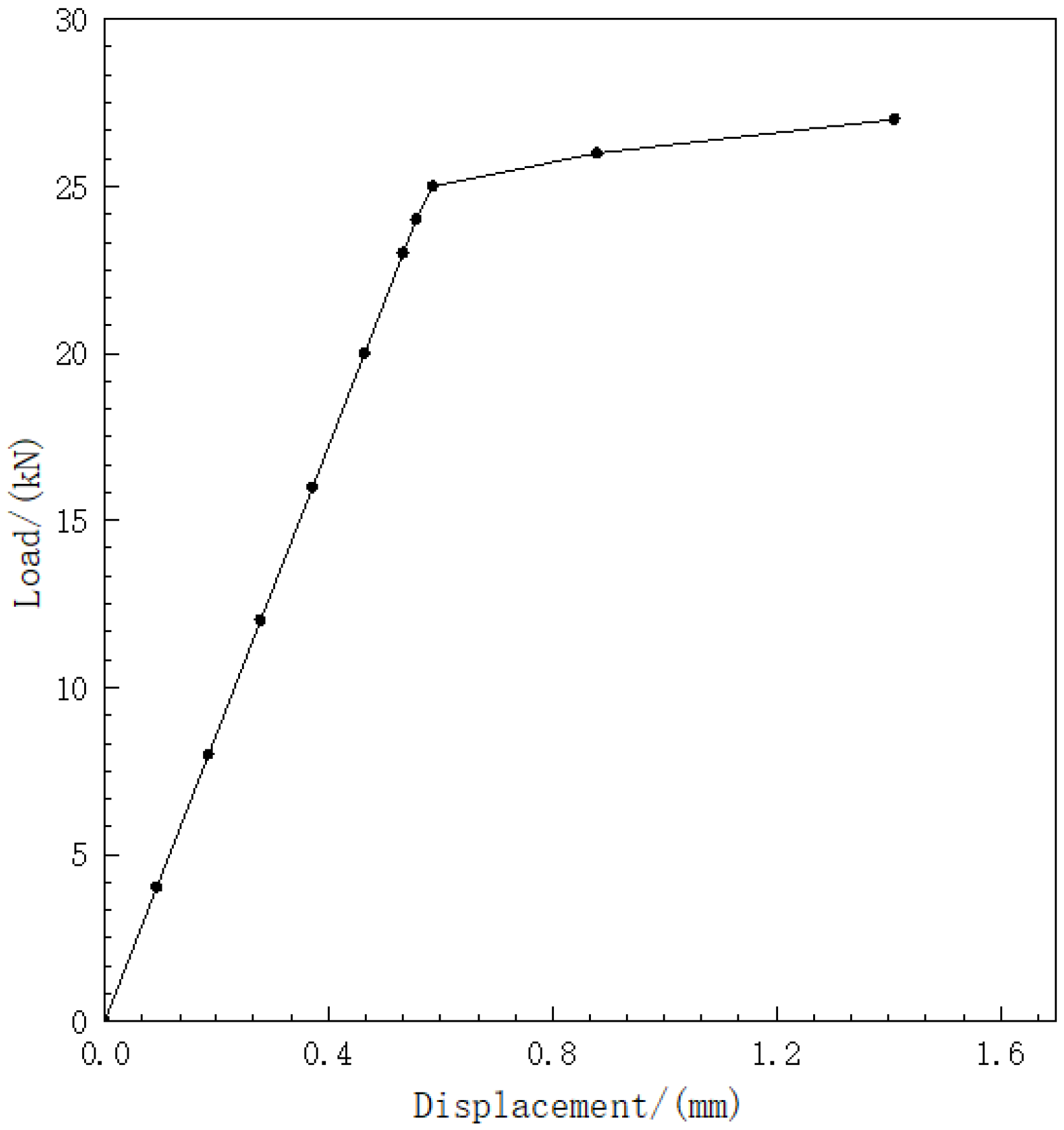

5.3. Analysis of Lateral Force Resistance of Fiber-Reinforced Bamboo Wallboard

6. Conclusions

- In the mechanical property test of MOC, the mechanical properties of MOC were optimized when FG content reached 20%. At this moment, the bending strength and compressive strength of the specimen cured for 28 days were 7.35 MPa and 54.25 MPa. This paper does not analyze the integration situation and physical properties of glass fibers but only studies the mechanical property tests of the composite. The experimental results show that the bending strengths of the plate section in the direction of and perpendicular to the bamboo fiber were 15.71 MPa and 34.64 MPa, respectively. The mechanical properties of the plate thus exhibit anisotropy.

- The numerical simulation of the board and the wall and floor modules indicates that when a 25 kN/m line load is applied in the vertical direction of the board bamboo fiber, the maximum Mises value is 33.74 MPa, with an error of approximately 2.6% compared to the test. When a 10 kN/m line load is applied to the board along the bamboo fiber direction, the maximum Mises value is 14.52 MPa, with an error of about 7.6% compared to the test. Additionally, the strain distribution of the components obtained by finite element simulation aligns well with that in the test.

- The simulation of the fiber-reinforced bamboo floor slab shows that the maximum deflection in the span of the floor slab meets the requirements. However, the maximum Mises stress is located on the grid plates, which is the weak part of the structure, making it difficult to meet the corresponding strength requirements. Given that there are no relevant specifications for this type of structure as a reference, high professional quality is required of engineering designers. Therefore, it is not recommended to use it as a floor. If there are relevant requirements, structural design should be completed by a professional design team, along with material experiments and structural loading tests.

- The simulation results indicate that the Mises stress at the bottom of the wall reaches 34.25 MPa when a compressive load is applied, meeting the design value of the compressive strength obtained from MOC testing. Under wind load conditions, the maximum Mises stress reaches 7.216 MPa, which does not exceed the ultimate strength, indicating that the board can function normally under gusty wind loads. The maximum deflection of the wall under wind load is 1.024 mm, which can align with the normal use requirements. This suggests that the wall modules made from this material can be applied as a load-bearing wall in buildings up to two stories high.

- The analysis of lateral force resistance reveals that structural stiffness decreases when the lateral concentrated force reaches 29 kN. Considering the material characteristics of the fiber-reinforced bamboo board, the yield displacement is defined as the maximum displacement at the end of the elastic stage, with a value of 0.6773 mm. The ultimate lateral resistance of the fiber-reinforced bamboo wallboard is 29 kN, indicating significant lateral force resistance.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Li, K.; Zhou, Y.; Huang, X.; Xiao, H.; Shan, Y. Low-carbon development pathways for resource-based cities in China under the carbon peaking and carbon neutrality goals. Environ. Sci. Pollut. Res. 2024, 31, 10213–10233. [Google Scholar] [CrossRef] [PubMed]

- Chen, W.; Yang, S.; Zhang, X.; Jordan, N.D.; Huang, J. Embodied energy and carbon emissions of building materials in China. Build. Environ. 2022, 207, 108434. [Google Scholar] [CrossRef]

- Wang, Z. Test and Analysis of Mechanical Properties of Full-Scale Components of Fiber-Reinforced Wood Substrate. Master’s Thesis, Southwest Jiaotong University, Chengdu, China, 2019. [Google Scholar]

- Zhang, W.; Sun, X.; Liu, C. Experimental study on seismic performance of fiber-reinforced cladding wood-based wallboard. China Civ. Eng. J. 2018, 51, 85–91. [Google Scholar]

- Pi, P. Experimental and Application Research on Fiber-Reinforced Wood-Based Components. Master’s Thesis, Xihua University, Chengdu, China, 2018. [Google Scholar]

- Kymäläinen, M.; Belt, T.; Seppäläinen, H.; Rautkari, L. Decay resistance of surface carbonized wood. Materials 2022, 15, 8410. [Google Scholar] [CrossRef] [PubMed]

- Musselman, E.S.; Dinehart, D.W.; FitzPatrick, T.; Zabel, R. Behavior of Cellulosic Fiber Board Wood-Frame Shear Walls with and without Openings under Cyclical Loading. Buildings 2024, 14, 3097. [Google Scholar] [CrossRef]

- Peng, L.; Searchinger, T.D.; Zionts, J.; Waite, R. The carbon costs of global wood harvests. Nature 2023, 620, 110–115. [Google Scholar] [CrossRef]

- Borowski, P.F.; Patuk, I.; Bandala, E.R. Innovative industrial use of bamboo as key “Green” material. Sustainability 2022, 14, 1955. [Google Scholar] [CrossRef]

- Hailemariam, E.K.; Hailemariam, L.M.; Amede, E.A.; Nuramo, D.A. Identification of barriers, benefits and opportunities of using bamboo materials for structural purposes. Eng. Constr. Archit. Manag. 2023, 30, 2716–2738. [Google Scholar] [CrossRef]

- Adier, M.F.V.; Sevilla, M.E.P.; Valerio, D.N.R.; Ongpeng, J.M.C. Bamboo as sustainable building materials: A systematic review of properties, treatment methods, and standards. Buildings 2023, 13, 2449. [Google Scholar] [CrossRef]

- Sun, X.; He, M.; Li, Z. Novel engineered wood and bamboo composites for structural applications: A state-of-the-art review of manufacturing technology and mechanical performance evaluation. Constr. Build. Mater. 2020, 249, 118751. [Google Scholar] [CrossRef]

- Zheng, Y.; Jiang, Z.; Sun, Z.; Ren, H. Effect of microwave-assisted curing on bamboo glue strength: Bonded by thermosetting phenolic resin. Constr. Build. Mater. 2014, 68, 320–325. [Google Scholar] [CrossRef]

- Chung, M.-J.; Chang, T.-C.; Chang, S.-T.; Wang, S.-Y. Properties of a formaldehyde-free tannin adhesive and mechanical strength of oriented bamboo scrimber board bonded with it. Holzforschung 2021, 75, 91–100. [Google Scholar] [CrossRef]

- Zhang, X.; Zhao, M.; Zhao, E.; Liu, J.; Liu, Q.; Li, S.; Yin, H.; Yang, C.; Li, X. Experimental investigation into mechanical properties of inorganic-bonded bamboo composite for structural applications. Constr. Build. Mater. 2024, 427, 136247. [Google Scholar] [CrossRef]

- Soni, A.; Das, P.K.; Hashmi, A.W.; Yusuf, M.; Kamyab, H.; Chelliapan, S. Challenges and opportunities of utilizing municipal solid waste as alternative building materials for sustainable development goals: A review. Sustain. Chem. Pharm. 2022, 27, 100706. [Google Scholar] [CrossRef]

- Patil, M.; Boraste, S.; Minde, P. A comprehensive review on emerging trends in smart green building technologies and sustainable materials. Mater. Today Proc. 2022, 65, 1813–1822. [Google Scholar] [CrossRef]

- WB/T 1019-2002; Caustic Burned Magnesia for Magnesium Oxychloride Cement Products. Code for Design House: Beijing, China, 2002.

- Chen, T.; Wu, Z.; Hu, X.; Aladejana, J.T.; Niu, M.; Liu, Z.; Wei, Q.; Peng, X.; Xie, Y.; Wu, B. Constructing hydrophobic interfaces in aluminophosphate adhesives with reduced graphene oxide to enhance the performance of wood-based boards. Compos. Part B 2020, 198, 108168. [Google Scholar] [CrossRef]

- Cao, F.; Qiao, H.; Li, S.; La, S.; Shao, Y. Study on the water resistance of acrylic emulsion/Barley Straw Ash modified magnesium oxychloride cement. Funct. Mater. 2022, 53, 10122–10129. [Google Scholar]

- JC/T 681-2005; Mixer for Mixing Mortars. Code for Design House: Beijing, China, 2005.

- Yang, Y.; Tan, Y.; Li, Z.; Zhou, G.; Yu, X.; Xu, D.; Yong, Q.; Zhao, H.; Xie, Z. Interaction mechanisms between polycarboxylate superplasticizers and cement, and the influence of functional groups on superplasticizer performance: A review. Polym. Bull. 2024, 81, 10415–10438. [Google Scholar] [CrossRef]

- Gu, K.; Chen, B.; Yu, H.; Zhang, N.; Bi, W.; Guan, Y. Characterization of magnesium-calcium oxysulfate cement prepared by replacing MgSO4 in magnesium oxysulfate cement with untreated desulfurization gypsum. Cem. Concr. Compos. 2021, 121, 104091. [Google Scholar] [CrossRef]

- GB/T 17671-2021; Test Method for the Strength of Cement Mortar. Code for Design House: Beijing, China, 2021.

- Zhou, W.; Ye, Q.; Zhou, Z.; Aladejana, J.T.; Cao, J.; Li, J. A high-strength, water-resistant, flame-retardant magnesium oxychloride cement-based inorganic adhesive achieved through the construction of a supramolecular system. J. Clean. Prod. 2023, 419, 138239. [Google Scholar] [CrossRef]

- Zhou, W.; Ye, Q.; Shi, S.Q.; Fang, Z.; Gao, Q.; Li, J. A robust magnesium oxychloride cement wood adhesive via an organic–inorganic hybrid approach. Constr. Build. Mater. 2021, 297, 123776. [Google Scholar] [CrossRef]

- Liu, W.; Sun, Y.; Zhang, J.; Li, W.; Wang, L.; Yu, J.; Qin, X. Influence of the H2O/MgCl2 molar ratio on the strength properties of magnesium oxychloride cement solidified soft clay and its associated mechanisms. Constr. Build. Mater. 2023, 393, 132018. [Google Scholar] [CrossRef]

- GB/T 8696-2008; Building Decoration Materials Glass Fiber Mesh Cloth. Code for Design House: Beijing, China, 2008.

- JC/T 568-2007; Boaeds of Magnesium Oxychloride Cement. Code for Design House: Beijing, China, 2007.

- GB/T 7019-2014; Test Method for Fiber Cement Products. Code for Design House: Beijing, China, 2014.

- Deng, C. Experimental Study on the Bending and Shear Stress of Fiber-Reinforced Wood-Based Components. Master’s Thesis, Xihua University, Chengdu, China, 2018. [Google Scholar]

- Yang, S.-T.; Jing, Q.-Y.; Li, J.; Luo, B.; Liu, H.-G. Study on the preparation and modification mechanism of bamboo composite magnesium oxychloride cement. Bull. Silic. 2019, 38, 3587–3591. [Google Scholar]

- JC/T 412.1-2018; Fiber Cement Flat Sheets—Part 1: Non-Asbestos Fiber Cement Flat Sheets. Code for Design House: Beijing, China, 2018.

- Wang, H.; Zhang, J.; Wang, W.; Wang, Q. Research progress in fiber-reinforced wood-plastic composites. Sci. Silvae Sin. 2016, 52, 130–139. [Google Scholar]

- GB50009-2012; Load Code for the Design of Building Structures. Code for Design House: Beijing, China, 2012.

- GB50010-2015; Code for Design of Concrete Structures. Code for Design House: Beijing, China, 2015.

- GB 50005-2017; Design Standard of Wood Structures. Code for Design House: Beijing, China, 2017.

| Sample Number | n (MgO) | n (MgCl2·6H2O) | n (Water-Resistant Modifier) | n (H2O) | n (FG) |

|---|---|---|---|---|---|

| Z-1-1-0 | 2.0 | 1 | 0.08 | 1 | 0 |

| Z-1-1-1 | 2.0 | 1 | 0.08 | 1 | 0.2 |

| Z-1-1-2 | 2.0 | 1 | 0.08 | 1 | 0.4 |

| Z-1-1-3 | 2.0 | 1 | 0.08 | 1 | 0.6 |

| Dosage of FG | Mechanical Properties | ||||||

|---|---|---|---|---|---|---|---|

| Flexural Strength/(MPa) | Compressive Strength/(MPa) | ||||||

| 7 d | 14 d | 28 d | 7 d | 14 d | 28 d | Immersion in Water 7 d | |

| 0% | 4.35 | 4.98 | 5.70 | 36.68 | 43.79 | 47.51 | 39.24 |

| 10% | 4.55 | 5.26 | 6.14 | 37.69 | 44.89 | 49.08 | 41.18 |

| 20% | 4.65 | 5.53 | 7.35 | 38.39 | 45.11 | 54.25 | 45.66 |

| 30% | 4.31 | 5.36 | 7.00 | 36.89 | 43.83 | 48.64 | 40.15 |

| Sample | Material Parameter | ||||

|---|---|---|---|---|---|

| Modulus of Elasticity (GPa) | Poisson’s Ratio | Density (kg/m3) | Compressive Strength (σcu, MPa) | Tensile Strength (σtu, MPa) | |

| Bamboo Strip | 15 | 0.3 | 780 | 50 | 165.99 |

| MOC | 50 | 0.2 | 1900 | 48.83 | 34.64 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, H.; Jiang, B. Research on the Mechanical Properties of Fiber-Reinforced Bamboo Board and Numerical Simulation Analysis of the Structural Mechanical Properties of Products. Appl. Sci. 2025, 15, 5288. https://doi.org/10.3390/app15105288

Wang H, Jiang B. Research on the Mechanical Properties of Fiber-Reinforced Bamboo Board and Numerical Simulation Analysis of the Structural Mechanical Properties of Products. Applied Sciences. 2025; 15(10):5288. https://doi.org/10.3390/app15105288

Chicago/Turabian StyleWang, Huilong, and Baoshi Jiang. 2025. "Research on the Mechanical Properties of Fiber-Reinforced Bamboo Board and Numerical Simulation Analysis of the Structural Mechanical Properties of Products" Applied Sciences 15, no. 10: 5288. https://doi.org/10.3390/app15105288

APA StyleWang, H., & Jiang, B. (2025). Research on the Mechanical Properties of Fiber-Reinforced Bamboo Board and Numerical Simulation Analysis of the Structural Mechanical Properties of Products. Applied Sciences, 15(10), 5288. https://doi.org/10.3390/app15105288