1. Introduction

An urgent task in modern construction in the Republic of Kazakhstan is to increase the durability and operational reliability of hydraulic structures and irrigation systems, on which the degree of wear reaches about 70%. Such structures operate under complex impacts from aggressive factors, including water with high mineralization, the cavitation effect of flows, and sharp daily and seasonal temperature fluctuations that involve multiple transitions through 0 °C during the autumn–winter period. These factors provoke the intensive development of destructive processes in the concrete matrix, contributing to leaching, carbonation, frost destruction, and the effects of salt solutions, which inevitably lead to a decrease in the strength and durability of structures [

1,

2]. In light of the need to extend the service life of hydraulic structures, special attention is given to materials with improved operating characteristics, among which the use of SCC is considered a promising direction. This material is characterized by high homogeneity, structural density, and resistance to external influences. However, despite the significant potential for the use of SCC, its implementation in Kazakhstan remains limited due to insufficient scientific development, the absence of mass production of modern modified additives, a weak technological base of enterprises, and a lack of practical experience in calculating and designing structures using such materials, resulting in non-compliance with the requirements of current regulatory documents, such as SP RK EN 1992-1-1:2004 and ST RK EN 206-2017 [

3].

Increasing the durability and operational reliability of structures made of SCC is possible through the use of protective coatings and polymer compositions, but these have several limitations. In particular, thin protective layers (about 0.2 mm) are susceptible to mechanical damage, which reduces their effectiveness in aggressive conditions [

4]. Furthermore, while polymer compositions exhibit high resistance to external influences, their use is economically impractical in mass construction due to the high cost of components [

5]. Thus, the most rational solution for enhancing the operational reliability of SCC is to modify the structure of the cement stone itself by utilizing multicomponent chemical–mineral additives that promote the formation of a dense and durable structure resistant to aggressive environments [

6]. Additionally, Lang et al. demonstrated that ternary binder systems combining industrial by-products (slag and manganese residue) with cement can significantly reduce environmental impact while maintaining or enhancing concrete durability [

7].

Previous studies have shown that using mineral additives in heavy concretes can reduce shrinkage deformations by 20% and increase frost and water resistance by up to 25% [

8]. This highlights the potential for further research into improving the performance characteristics of concrete by optimizing its microstructure and permeability. An analysis of scientific and technical literature allowed us to formulate a hypothesis that increasing the resistance of concrete to aggressive impacts can be achieved through mathematical optimization of the grain composition of the cement binder. This approach is based on forming a polydisperse structure of the cement matrix with efficient particle packing, which helps enhance the characteristics of concrete throughout its entire service life [

9]. Optimization of the binder structure involves a detailed study of structure formation processes using topological analysis methods, which treat the binder as a spatial system of dispersed particles and phase formations interacting during the hydration process [

10]. The most common method for studying the packing of dispersed systems is mathematical modeling using a complex sphere model, which enables the analysis of the packing density and interaction of particles of different sizes [

11]. For monodisperse systems, the maximum packing density reaches F = π/√18 ≈ 0.74 with simple cubic or hexagonal packing (

Figure 1). However, with a rational selection of the ratios of diameters and volume fractions of the components, it is possible to form a polydisperse structure with an even higher packing density, which ensures an increase in the strength and durability characteristics of the material [

12].

The present study proposes a sequential volume-filling model with spherical particles to form a thermodynamically stable, polydisperse cement–stone structure. This model enables denser packing than traditional approaches based on similar structures. An analysis of the scientific publications on the structural topology of cement binders, the corrosion resistance of concrete, and the mechanisms of destruction of the cement matrix under the influence of aggressive environments shows there has been insufficient study of the issues related to the creation and practical application of polydisperse cement systems in modern building materials [

13].

At the same time, existing studies mainly focus on monodisperse mixtures or limited polydisperse systems, and the possibilities of using software and computational complexes based on three-dimensional modeling to optimize the binder composition remain insufficiently explored. The lack of a systematic approach to the experimental substantiation of the optimal parameters of polydisperse cement matrices underscores the relevance of this study, which aims to improve the operational reliability of SCCs used in aggressive environments by integrating mathematical modeling, theoretical analysis, and experimental data.

2. Materials and Methods

The research involved both theoretical and applied methods. The theoretical aspect was grounded in mathematical principles, considering mathematics, construction materials science, and colloid chemistry, along with analysis and modeling. This facilitated a deeper exploration of the topology of dispersed systems and a comparison of results with those from previous research groups, concentrating on the durability and operational reliability of SCC. The applied research aimed to validate the theoretical hypothesis regarding the feasibility of using polydisperse binders in SCC. Experiments were carried out to evaluate the theoretical conclusions about the durability and operational reliability of the resulting SCC, as well as to process and document the results obtained in accordance with standards. All materials used in the study were sourced and produced in Kazakhstan. All studies and tests adhered to the regulatory documentation in effect in Kazakhstan.

The study aimed to determine the optimal polyfractional composition, based on the cement clinker component, which achieves maximum or near-maximum spatial packing of polyfractional binder particles, thereby contributing to the transformation of the physical and mechanical properties of SCC. To verify the scientific hypothesis and achieve the aim of improving the structure and performance properties of SCC through the use of technology to optimize its most vulnerable component—cement stone—based on the principle of polydisperse structure formation and utilizing modern three-dimensional modeling algorithms, a set of research tasks was established as follows [

14]:

A computational validation of the potential to obtain a hardened cement matrix with an ordered fine crystalline structure by controlling the binder (cement) composition with varying dispersity and high packing density;

Laboratory studies of concrete samples of SCC with variable compositions of polyfractional cement focused on identifying the optimal composition regarding the bifurcation processes of the physical and mechanical properties of concrete.

The research included two consecutive stages: a preliminary stage of the study and the main stage.

During the preliminary studies, the following works were carried out:

Mathematical modeling of the packing density of polyfractional compositions to identify the most efficient dispersed cement powders;

Preliminary assessment of the strength of SCC based on the most efficient dispersed powders to select the most prospective compositions for the subsequent main research.

During the main studies, laboratory tests were carried out, including an assessment of the following physical and mechanical properties of concrete:

X-ray phase analysis;

Evaluation of compressive and bending strength;

Evaluation of water saturation (absorption);

Evaluation of water permeability;

Evaluation of frost resistance;

Evaluation of chemical resistance.

The composition of self-compacting concrete C35/45, developed at the Temirbeton-1 plant, is based on quick-hardening Portland cement with an additive content of no more than 5%, and was used as a reference sample. According to the basic characteristics required for SCC, the material has the following rheological indicators: workability class of the mixture SF2 (670 mm) and viscosity class VF2 (14 s), according to [

15]. Since the proposed composition includes only polyfractional cement (instead of standard cement), the rheological properties were not considered as evaluation criteria. The composition of the reference sample is presented in

Table 1.

Portland cement clinker supplied by Standard Cement LLP (Shymkent, Kazakhstan) was used in the studies. The chemical parameters of the Portland cement clinker are presented in

Table 2. The content of tricalcium and dicalcium silicates in the clinker was calculated using the following formulas:

Note: Equations (1) and (2) are based on Bogue’s formulas, which are widely used to estimate the content of the main clinker phases—alite (C

3S) and belite (C

2S)—in Portland cement. These formulas rely on the chemical oxide composition of the cement (typically obtained via XRF analysis) and provide an approximate phase analysis based on the proportions of CaO, SiO

2, Al

2O

3, and Fe

2O

3 [

16].

Sand from Arna LLP (Almaty region, Kazakhstan) was used for testing; its characteristics are presented in

Table 3.

Granite crushed stone produced by Tas Kum LLP (Almaty region, Kazakhstan) was used as a coarse aggregate; its characteristics are presented in

Table 4.

A chemical admixture based on polycarboxylate esters AR 122, produced by Arirang Group LLP (Astana, Kazakhstan), was used as a superplasticizer; its characteristics are shown in

Table 5.

Microsilica produced by Tau-Ken Temir LLP (Karaganda, Kazakhstan) was used as a finely dispersed filler for SCC. Microsilica is formed during the reduction of quartz during the production of silicon and ferrosilicon and consists of very small spherical particles containing amorphous or glassy silicon dioxide (SiO

2) in an amount of at least 95% of the additive mass. The chemical composition is given in

Table 6.

In the study we made calculations of packing density for the system of polydisperse cement binder powders of different grinding fineness (dispersity). The same Portland cement clinker of “Standard Cement” LLP (Shymkent, Kazakhstan) was used for preparation of polyfractional cement, which was used for preparation of the reference sample. Polyfractional cement is represented by three fractions of different diameters, the characteristics of which are presented in

Table 7. To create the finely dispersed fractions of the clinker component, a Fritsch Pulverisette disc vibration impact mill was used with the following characteristics: productivity—up to 250 mL, maximum size of loaded material—12 mm, final size of material—less than 10 µm, engine speed—600–1500 rpm.

For simplicity, further in the article, the mass proportion of each fraction in the composition of polyfractional cement, will be represented by the following expression: example—15/75/10, i.e., the mass proportion of the fraction F1 is 15%, F2—75% and F3—10%. Researchers argue that to reduce the influence of packing, the ratio of particle diameter to packing size should be >20 [

17]. But since the calculation of packing in 20 diameters of the largest sphere is labor-intensive and will take a very long time, the research will consider a single cell, with the ratio of the larger sphere diameter in the size 1:12. The largest diameter is 12 µm; hence, the mesh size will be 144 × 144 × 144. We take the grid spacing equal to 5% of the diameter of the smallest sphere equal to 4.9 µm; hence D = 0.245. The parameter d = 144, then we look for the tightest packing. To select the optimal composition of the fractionated binder, a software and calculation complex with a 3D modeling algorithm, based on the modified Drop and Roll method developed based on TvSTU, was used. This method consists of gradual filling of the unit volume of the package with spheres, in which they fall one by one in a random place and in a random order [

18]. The input of the program is given the initial values: parameters of the box, the number and parameters of spheres of different fractions. At the output, an array of centers of the placed spheres, their radii and indices of the spheres with which they come into contact is formed. The calculation of the density of particle packing in the compositions is based on a well-known method using the following equation:

where V

i is the particle volume, n is the number of particles, V

cell is the cell volume [

19].

The calculations consider that if two spheres of radius r

1 and r

2 are located next to each other, then their contact can be expressed as:

where d is the distance between the centers of two spheres.

Two spheres can be arbitrarily close (d is slightly larger than r

1 + r

2) without contacting each other. It is known that the problem of contact assessment inevitably arises in experimental studies, which is due to technical approximations (d cannot be measured accurately), whereas in numerical modeling such a problem does not arise, since in this case the position and size of the spheres are precisely known. But it should be noted that the results, as in the case of measuring the packing density, are affected by the wall effect [

18]. For this reason, a distinction is always made between experiments and modeling.

The initial data and boundary conditions for calculating topological characteristics are presented by the following concept:

where F1, F2 and F3 are fractions of large, medium and small sizes.

The concentration increase factor of each fraction was 5%. First, all variations in the F2 to F3 ratios were considered, with a minimum fixed value of F1 = 5%. Then, all variations in the F2 to F3 ratios were considered, with the next fixed value of F1 = 10%, and so on, up to the maximum fixed value of F1 = 95%. The center of the corresponding cumulative distribution was adopted as the characteristic size of each composition (for each fraction).

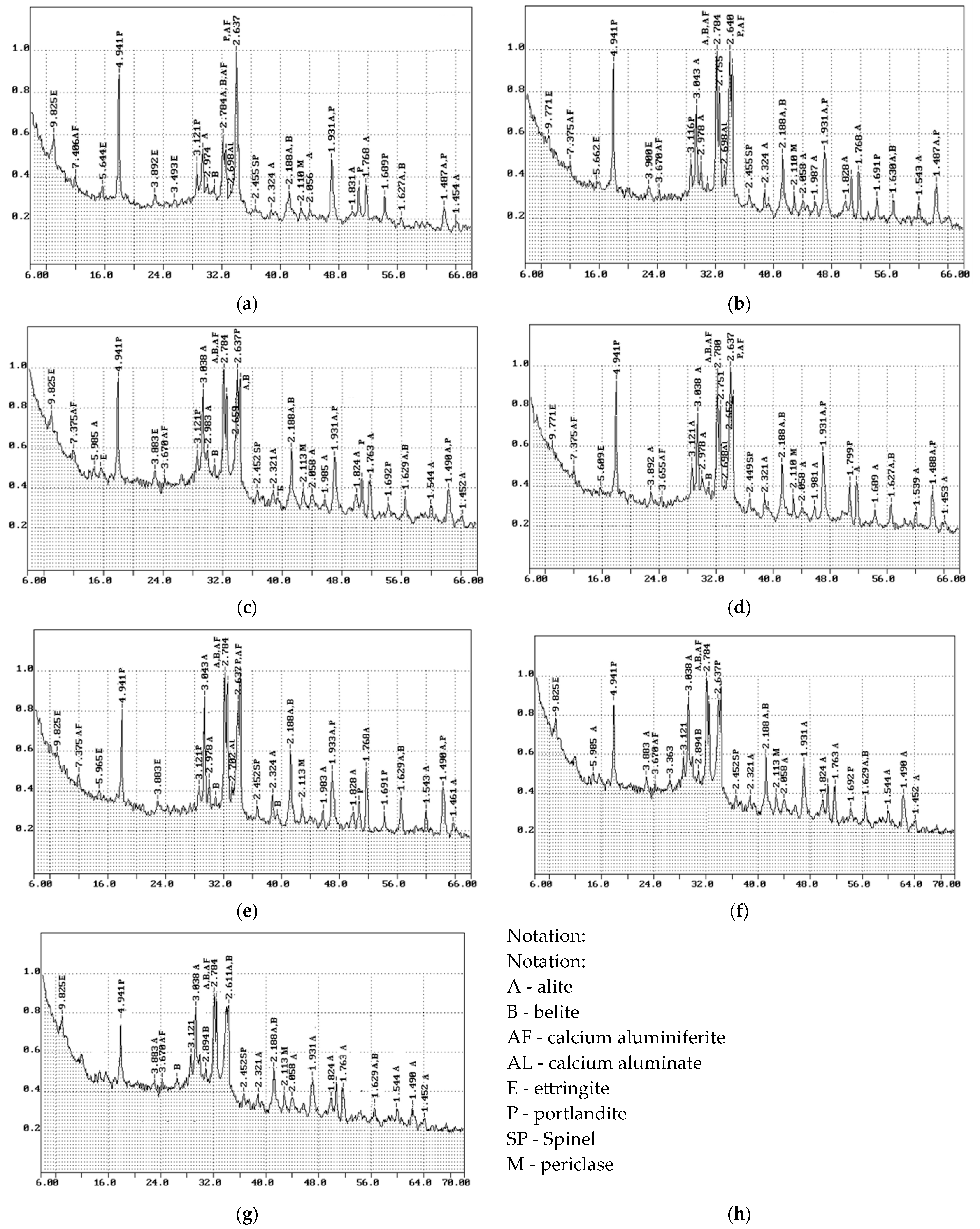

X-ray diffraction (XRD) analysis was performed using a Proto AXRD Benchtop powder X-ray diffractometer with a variable radius goniometer that can be set to 143 mm for higher line intensity or 191 mm for higher resolution of diffraction peaks, allowing the grazing incidence of diffraction (GID) technique to be implemented. The Proto AXRD Benchtop has all the functions of a sophisticated powder diffractometer due to the achievable peak resolution of FWHM < 0.04° 2θ and angular accuracy of <±0.02° 2θ over the entire angular range. A fine powder from a cement stone sample was prepared for analysis. After obtaining the X-ray diffraction pattern, it was decoded and identified [

20].

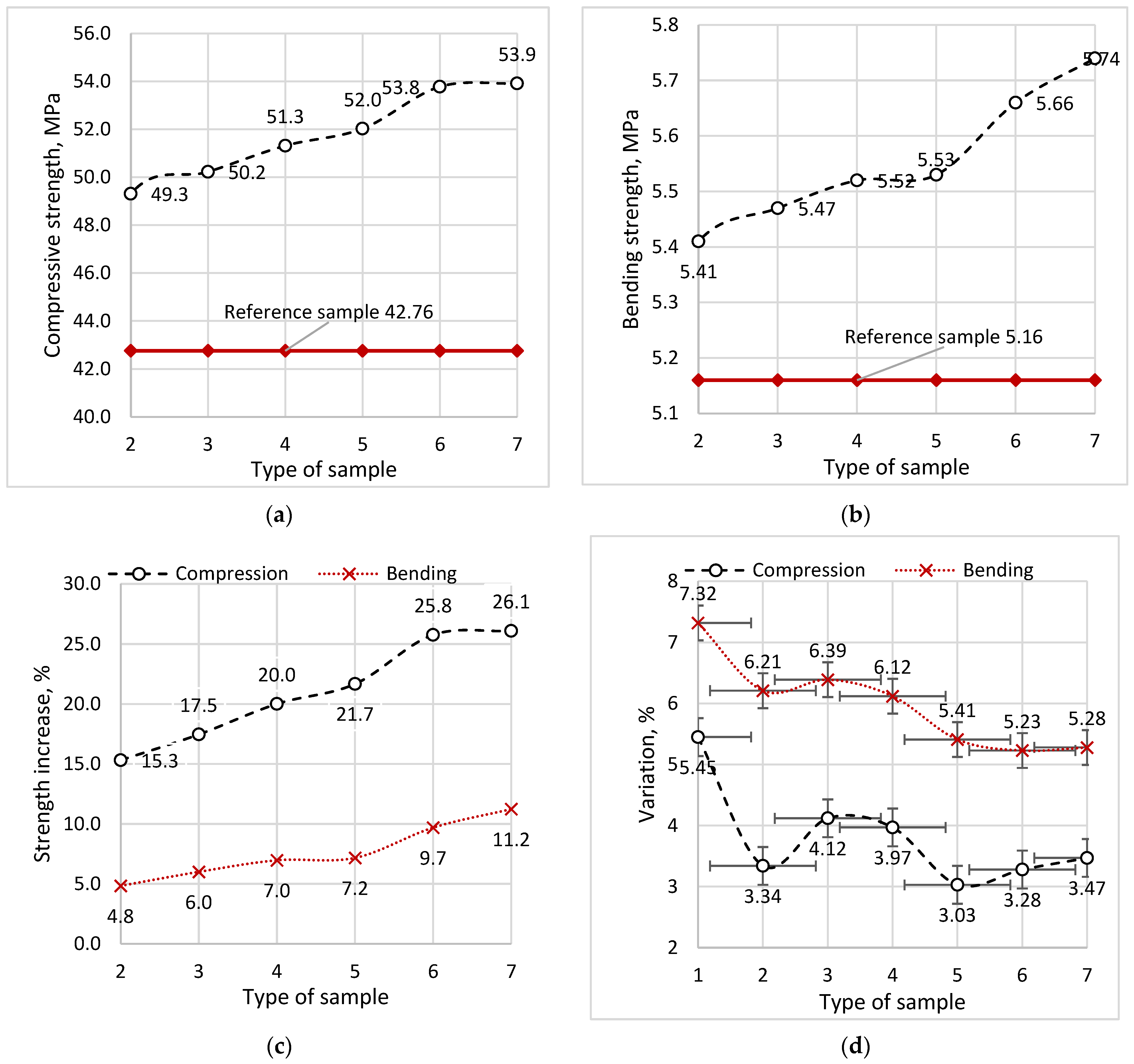

To test the SCC samples for strength according to [

21], a setup with one control (Italy) test frame was used, the maximum load of which is up to 200 MPa. To determine the compressive strength after normal hardening at the age of 28 days, cube samples with a working cross-section size of 150 × 150 × 150 mm were made, based on the fact that the largest grain size of the SCC filler is 20 mm. The experimental compositions were prepared according to the standard laboratory testing method by dosing the components by weight, followed by mixing all components in a concrete mixer [

21]. The sample was loaded until failure at a constant load increase rate of (0.6 ± 0.2) MPa/s. For bending tests, prism samples measuring 100 × 100 × 400 mm were prepared.

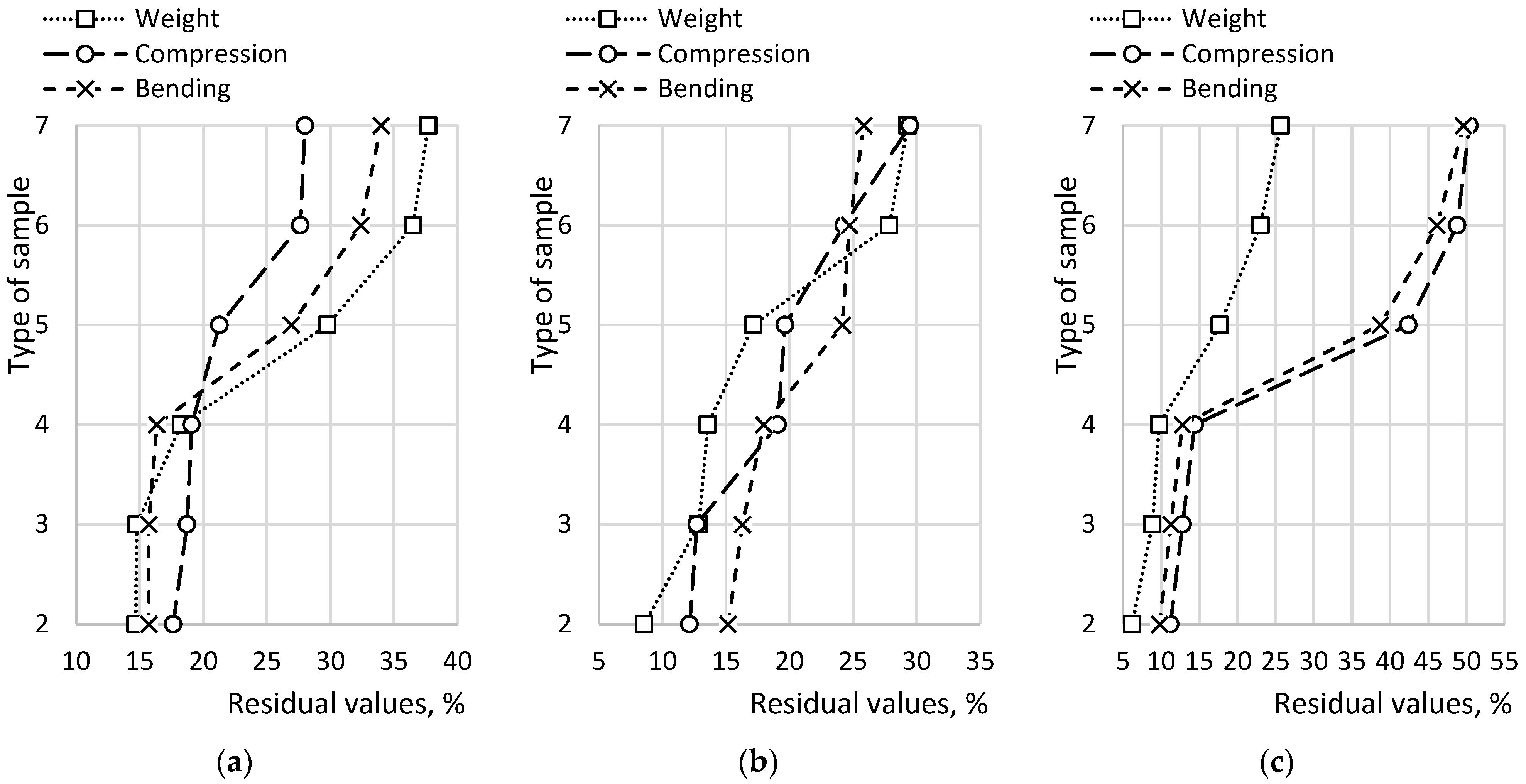

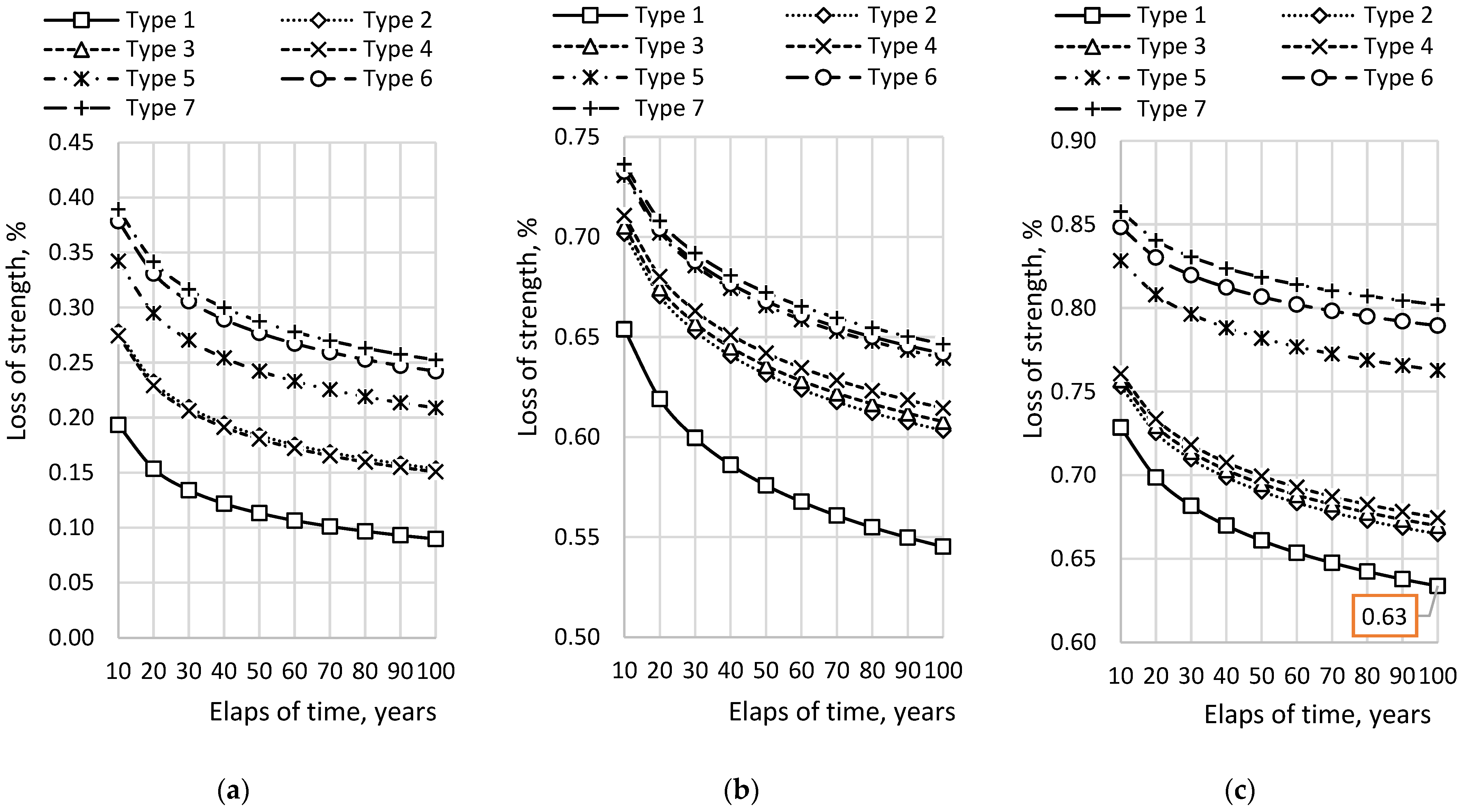

The freeze–thaw resistance tests were conducted using the basic method of repeated freezing and thawing in a water-saturated state. The test procedure and processing of the results were carried out in accordance with [

22]. Freezing was carried out for water-saturated samples at a temperature of minus 18 ± 2 °C, and thawing at a temperature of 20 ± 2 °C. The freezing time of the samples was at least 2.5 h, and the thawing time was at least 2 ± 0.5 h. After reaching a certain number of cycles (200, 300, 400, 500 and 600 cycles), control measurements of the weight loss and residual strength of the samples were performed. The tests were carried out on cube-shaped samples with dimensions similar to those for compressive strength tests. The tests were performed for 6 samples of each composition (type).

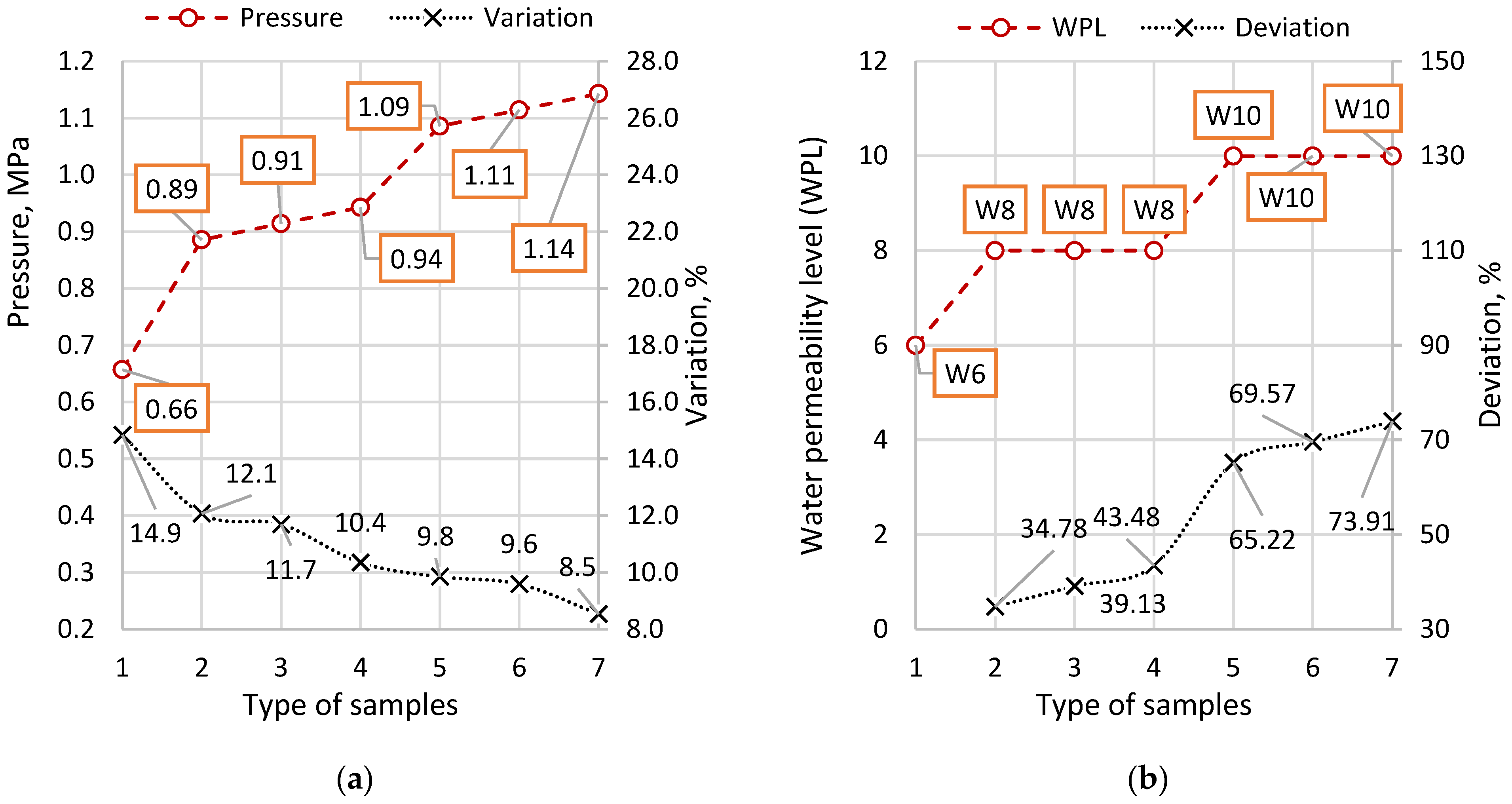

The “wet spot” method was used to determine water permeability. In accordance with the requirements of [

23], the tests were carried out on cylindrical samples, 150 mm in diameter and 150 mm in height, with the same conditions of the grain size of the SCC filler. For each composition, 6 samples were prepared, which, before testing, were kept in a curing chamber at a temperature of 20 ± 2 °C and a relative air humidity of 95 ± 5%. The testing process involved a stepwise increase in water pressure from one side of the sample until signs of water filtration from the opposite side of the sample appeared. The pressure increment was 0.2 MPa, and the holding time for each step was 12 h.

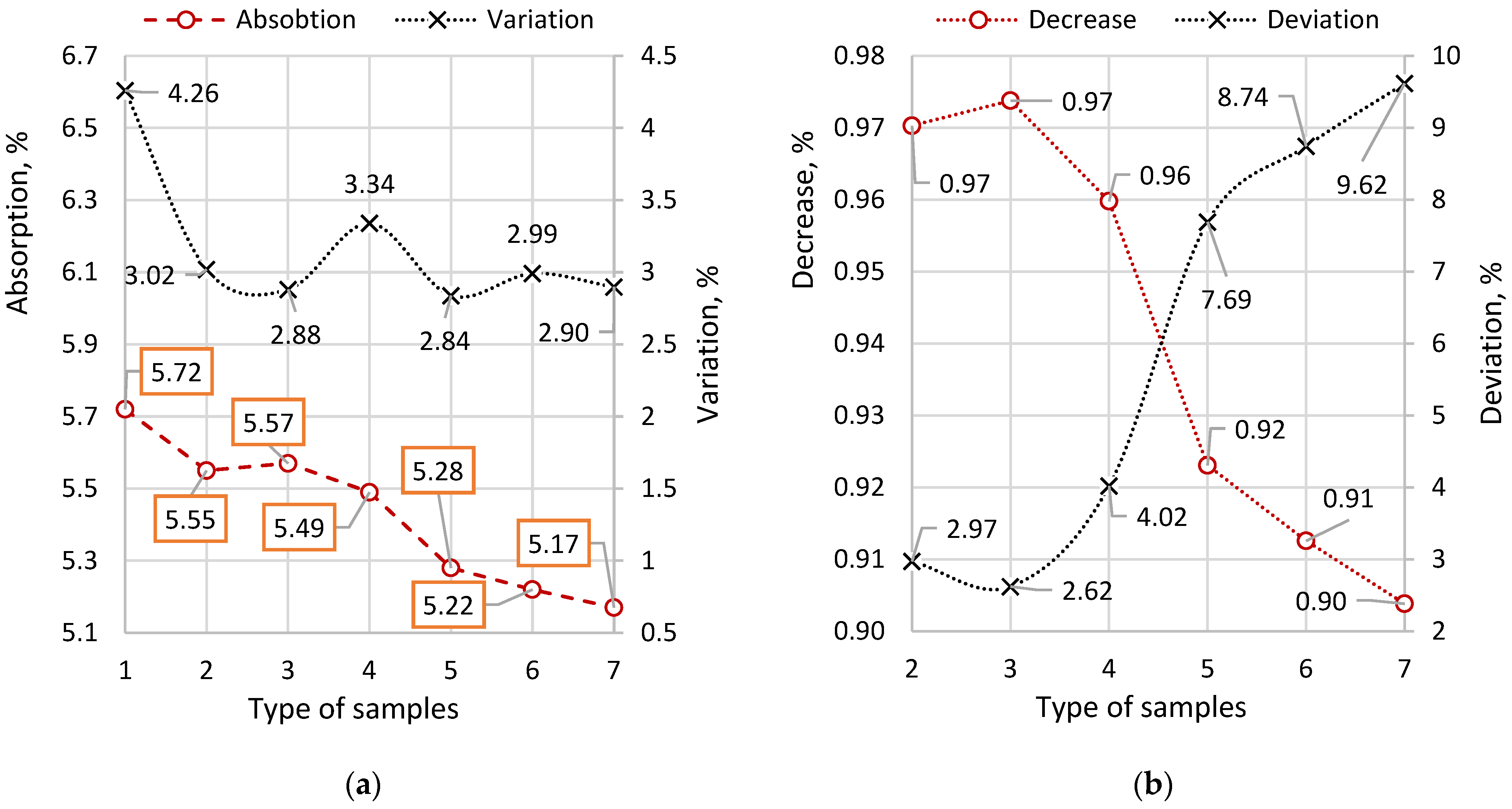

The water absorption study was conducted in accordance with the requirements of [

24]. The tests were also conducted for 6 cube samples of each series, with dimensions similar to those used for strength tests. The samples were kept in water until completely saturated at a temperature of 20 ± 2 °C. Every 24 h, the samples were weighed until constant weight, when two successive weighings did not differ by more than 0.1%. After complete water saturation, water absorption was determined, expressed as the ratio of the weight of absorbed water to the weight of the dry sample.

Chemical resistance tests were performed in accordance with [

25,

26] and consist of determining the chemical resistance coefficients of samples placed in an aggressive environment. For each composition, 18 samples were prepared (3 samples for each strength control). The studies were conducted for cube samples in three aggressive environments, represented by the following aqueous solutions: 5% sodium sulfate (Na

2SO

4), 3% sodium chloride (NaCl), and 0.01 M hydrochloric acid (HCl). The evaluation criteria were weight loss, residual compressive and bending strength, after maintaining the samples in an aggressive environment. Control measurements were carried out every 30 days for 180 days. Based on the results of the calculation of chemical resistance coefficients, the life cycle prediction of concrete structures was performed during their long-term exploitation under conditions of aggressive environments. The life cycle prediction was based on the determination of the reduction in the chemical resistance coefficient as follows:

where

—chemical resistance coefficient calculated by potentization;

—average values of the logarithm of the chemical resistance coefficient;

—average values of the logarithm of test times;

and

—logarithms of chemical resistance coefficients and test times in the i-th series of samples corresponding to intermediate (control) test periods;

—number of control tests.