Exploring Surface-Driven Mechanisms for Low-Temperature Sintering of Nanoscale Copper

Abstract

1. Introduction

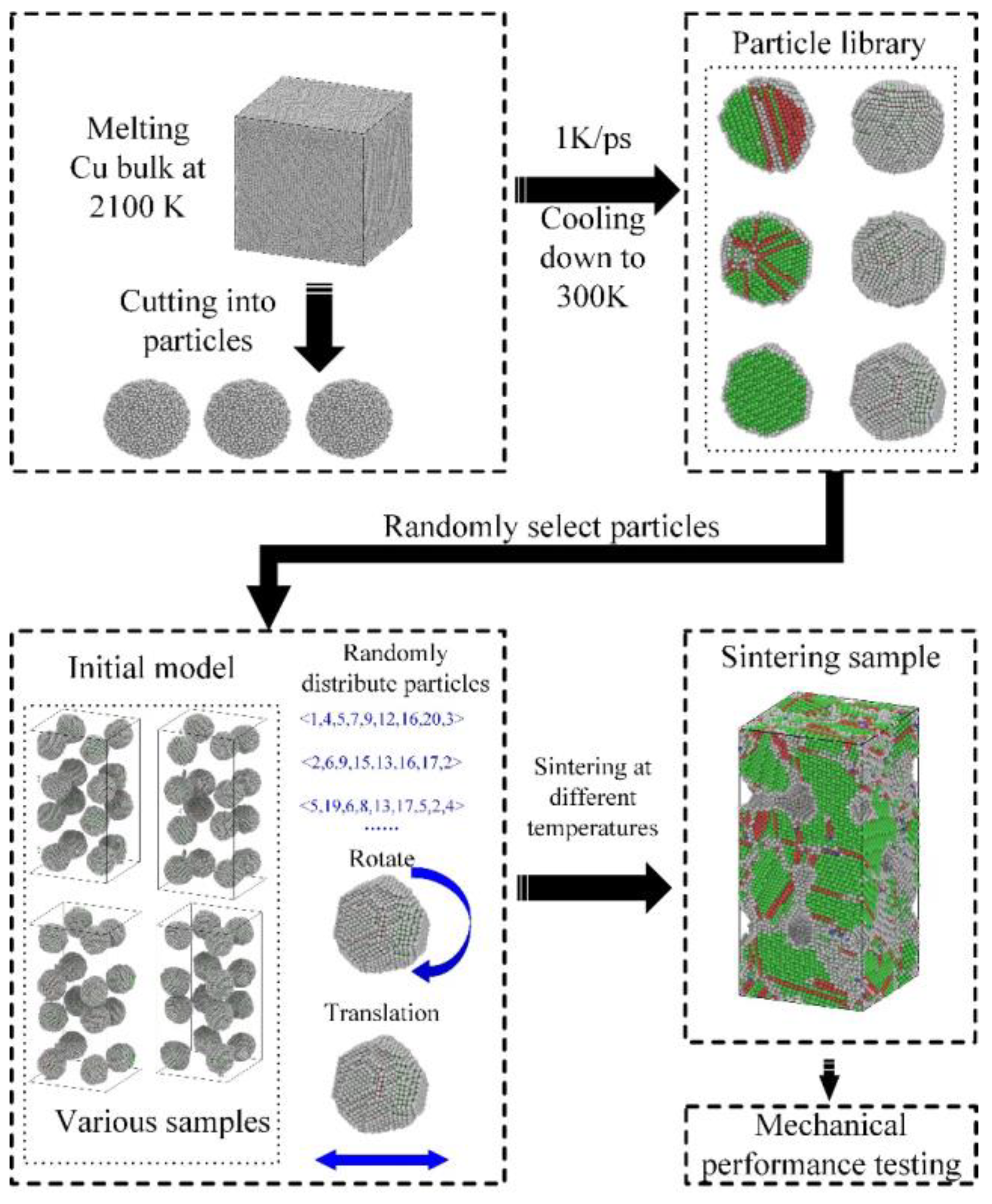

2. Methods

3. Results and Discussion

3.1. Sintering of Multiple Copper Nanoparticles

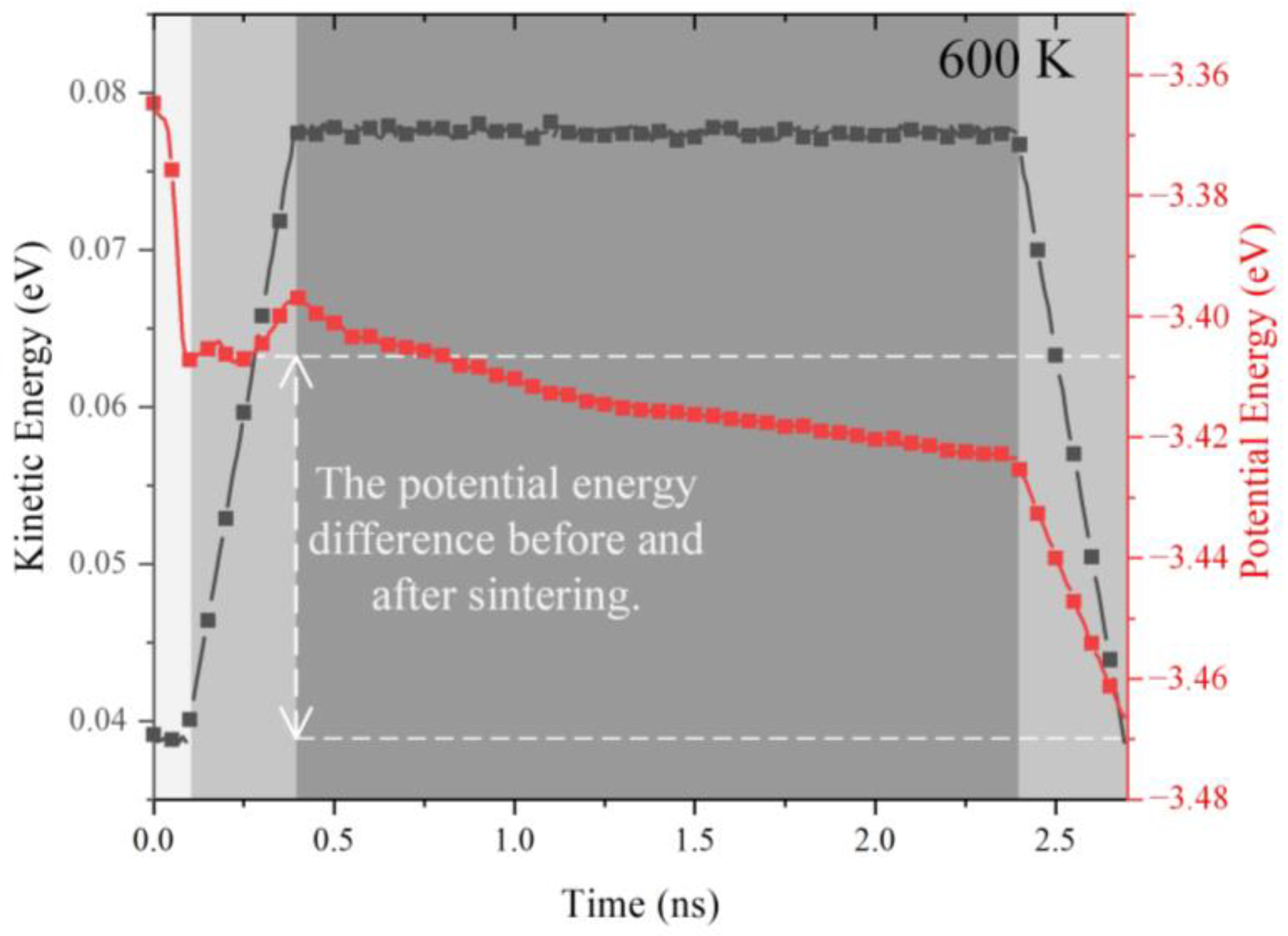

3.1.1. Energy Changing During Sintering

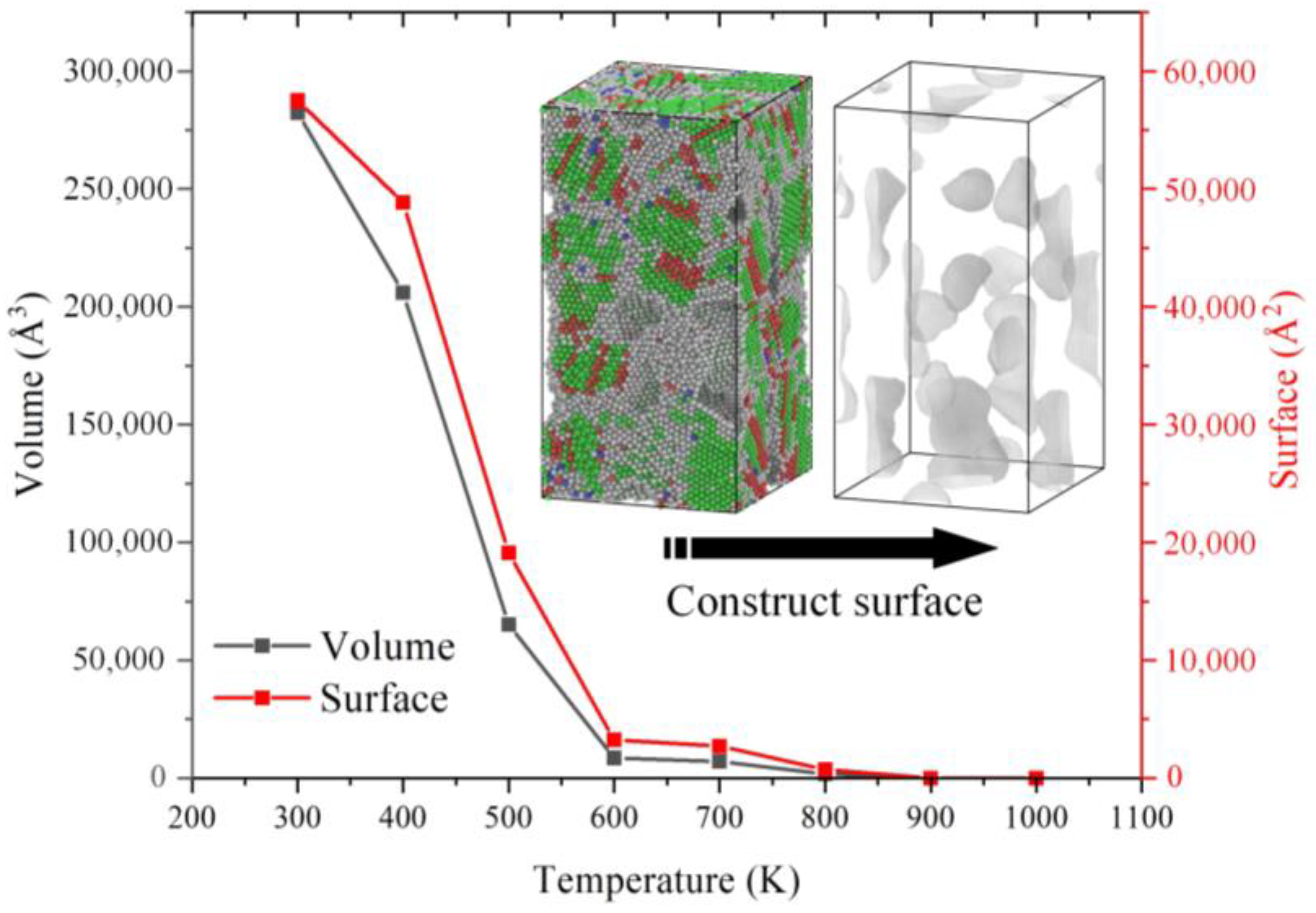

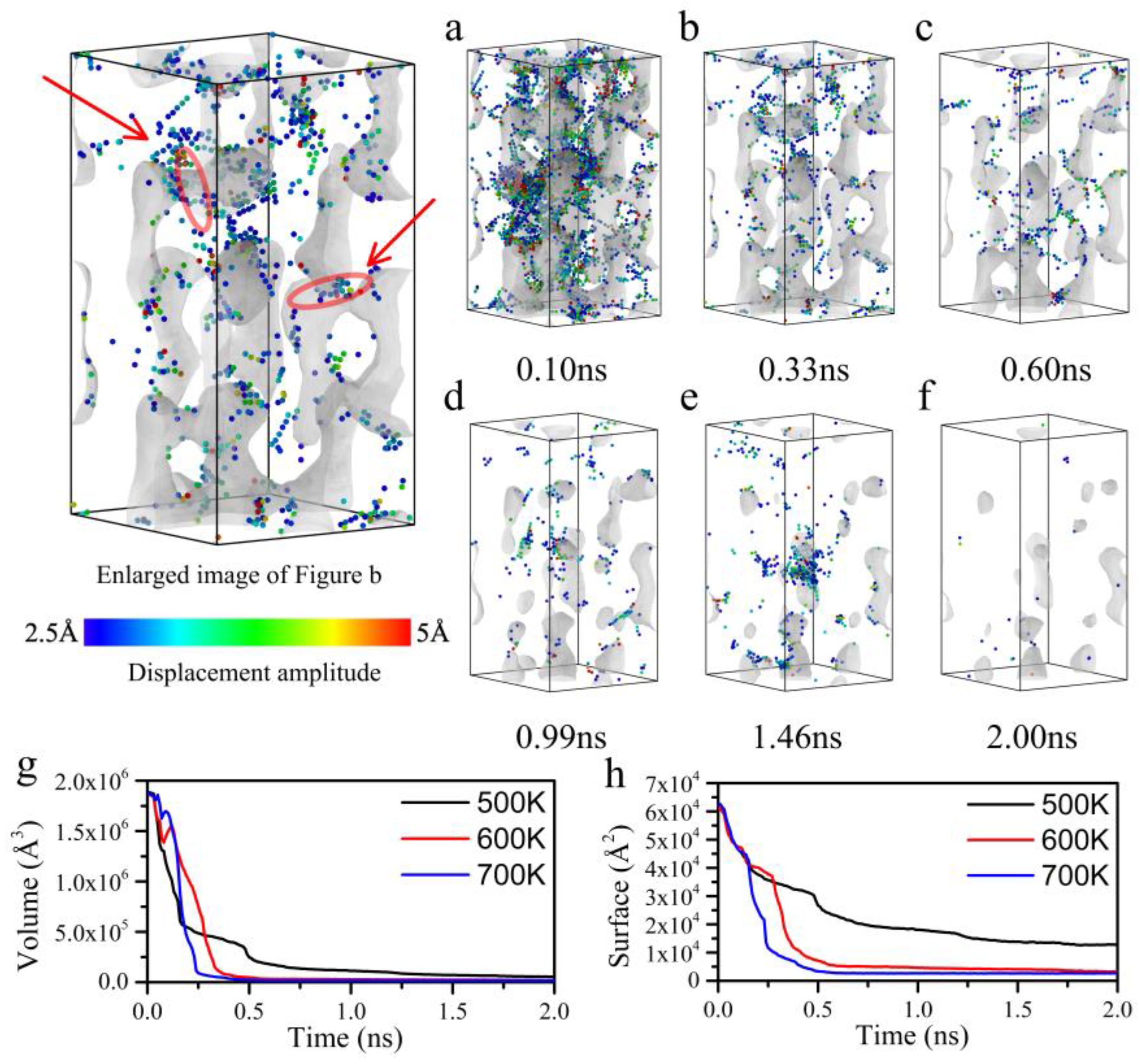

3.1.2. The Structural Evolution During Sintering

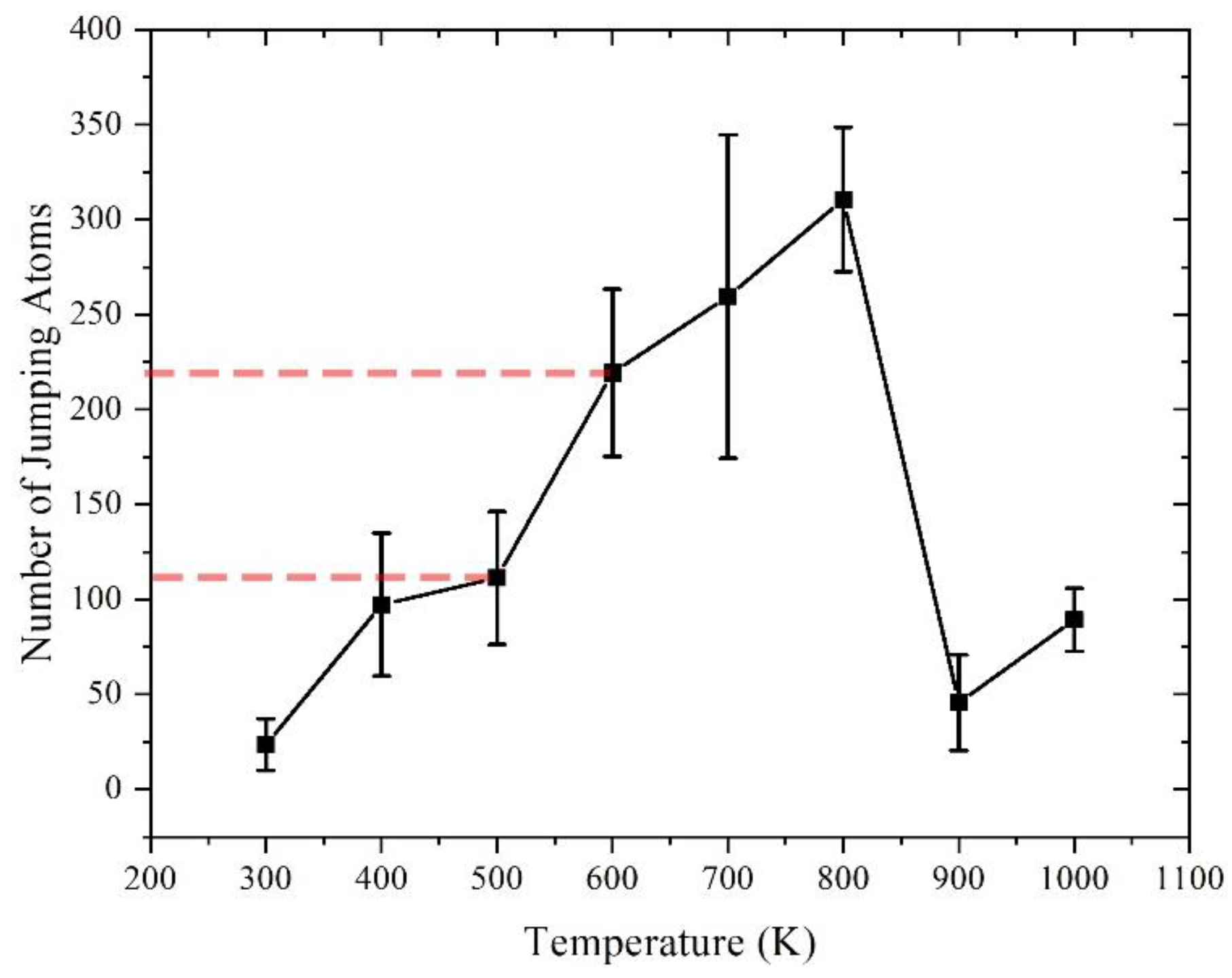

3.1.3. Surface-Driven Atomic Migration

3.2. Mechanical Properties of Sintered Samples

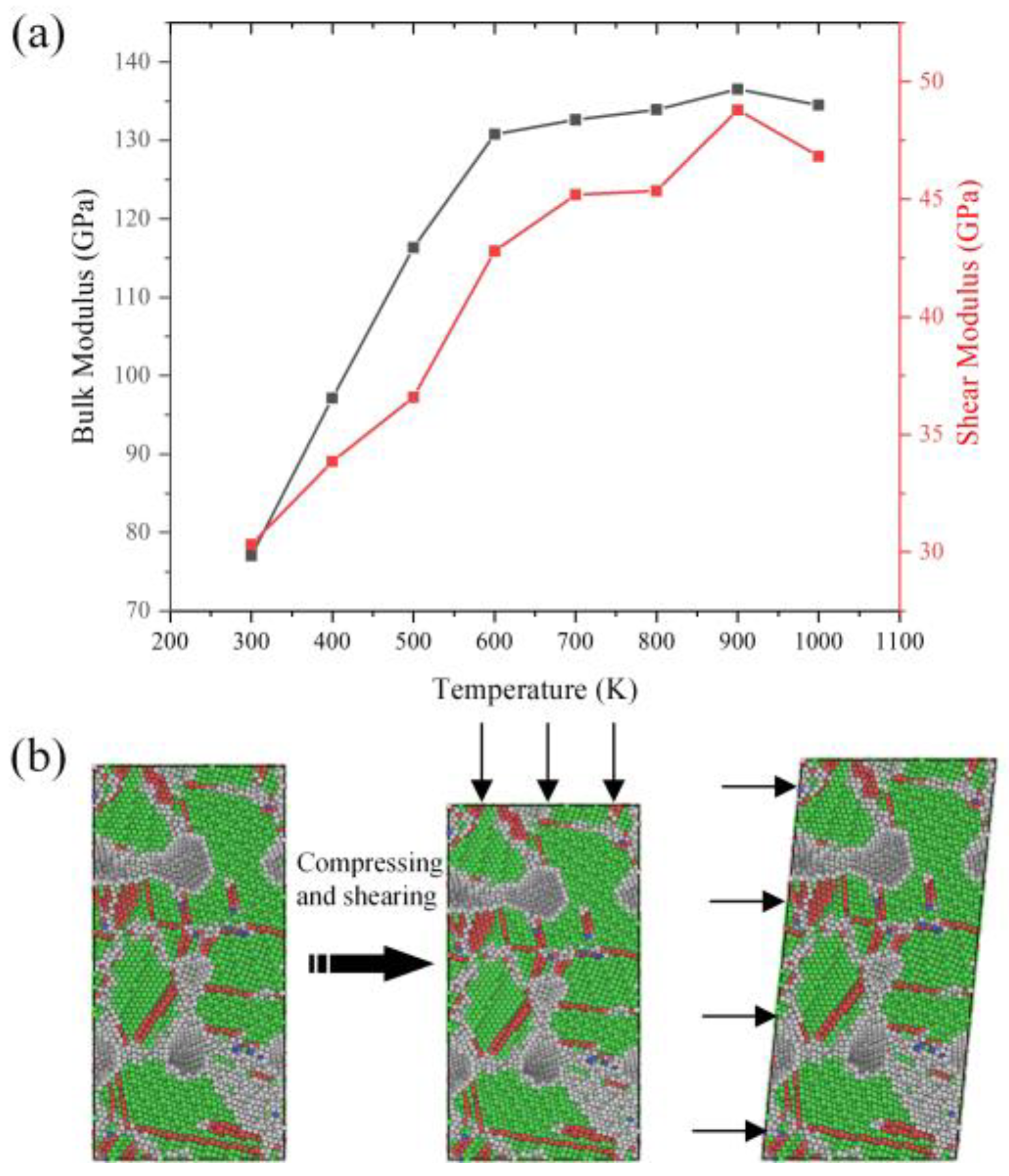

3.2.1. The Bulk Modulus and Shear Modulus

3.2.2. Young’s Modulus and Tensile Strength

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Theis, T.N.; Wong, H.-S.P. The end of moore’s law: A new beginning for information technology. Comput. Sci. Eng. 2017, 19, 41–50. [Google Scholar] [CrossRef]

- Shalf, J. The future of computing beyond Moore’s Law. Philos. Trans. R. Soc. A 2020, 378, 20190061. [Google Scholar] [CrossRef] [PubMed]

- Pal, M.K.; Bajaj, V. Nucleation and Location of Kirkendall Voids at the Tin-Based Solder/Copper Joint: A Review. Adv. Eng. Mater. 2023, 25, 2300671. [Google Scholar] [CrossRef]

- Wang, J.; Chen, J.; Zhang, L.; Zhang, Z.; Han, Y.; Hu, X.; Lu, H.; Zhang, S. Forming mechanism and growth of Kirkendall voids of Sn/Cu joints for electronic packaging: A recent review. J. Adv. Join. Process. 2022, 6, 100125. [Google Scholar] [CrossRef]

- Wu, C.-D.; Liu, K.-W.; Cheng, P.-C. Atomistic simulation of mechanical behavior of Cu/Cu3Sn solder interface with Kirkendall void under shear and tensile deformation. Appl. Phys. A 2023, 129, 255. [Google Scholar] [CrossRef]

- Delhaise, A.M.; Bagheri, Z.; Meschter, S.; Snugovsky, P.; Kennedy, J. Tin whisker growth on electronic assemblies soldered with Bi-containing, Pb-free alloys. J. Electron. Mater. 2021, 50, 842–854. [Google Scholar] [CrossRef]

- Illés, B.; Medgyes, B.; Dušek, K.; Bušek, D.; Skwarek, A.; Géczy, A. Numerical simulation of electrochemical migration of Cu based on the Nernst-Plank equation. Int. J. Heat. Mass. Tran. 2022, 184, 122268. [Google Scholar] [CrossRef]

- Lee, E.L.; Goh, Y.S.; Haseeb, A.; Wong, Y.H.; Sabri, M.F.M.; Low, B.Y. Electrochemical migration in electronic materials: Factors affecting the mechanism and recent strategies for inhibition. J. Electrochem. Soc. 2023, 170, 021505. [Google Scholar] [CrossRef]

- Liu, W.; Wang, H.; Huang, K.-S.; Wang, C.-M.; Wu, A.T. Low temperature and pressureless Cu-to-Cu direct bonding by green synthesized Cu nanoparticles. J. Taiwan Inst. Chem. Eng. 2021, 125, 394–401. [Google Scholar] [CrossRef]

- Mittal, J.; Lin, K.-L. Exothermic low temperature sintering of Cu nanoparticles. Mater. Charact. 2015, 109, 19–24. [Google Scholar] [CrossRef]

- Li, J.; Shi, T.; Feng, C.; Liang, Q.; Yu, X.; Fan, J.; Cheng, S.; Liao, G.; Tang, Z. The novel Cu nanoaggregates formed by 5 nm Cu nanoparticles with high sintering performance at low temperature. Mater. Lett. 2018, 216, 20–23. [Google Scholar] [CrossRef]

- Zhang, M.; Gao, L.-Y.; Li, J.-J.; Sun, R.; Liu, Z.-Q. Characterization of Cu-Cu direct bonding in ambient atmosphere enabled using (111)-oriented nanotwinned-copper. Mater. Chem. Phys. 2023, 306, 128089. [Google Scholar] [CrossRef]

- Shie, K.-C.; Gusak, A.; Tu, K.-N.; Chen, C. A kinetic model of copper-to-copper direct bonding under thermal compression. J. Mater. Res. Technol. 2021, 15, 2332–2344. [Google Scholar] [CrossRef]

- Seo, H.; Park, H.S.; Kim, S.E. Two-step plasma treatment on sputtered and electroplated Cu surfaces for Cu-to-Cu bonding application. Appl. Sci. 2019, 9, 3535. [Google Scholar] [CrossRef]

- Kim, Y.; Park, S.; Kim, S.E. The effect of an Ag nanofilm on low-temperature Cu/Ag-Ag/Cu chip bonding in air. Appl. Sci. 2021, 11, 9444. [Google Scholar] [CrossRef]

- Huang, Y.-C.; Lin, Y.-X.; Hsiung, C.-K.; Hung, T.-H.; Chen, K.-N. Cu-Based Thermocompression Bonding and Cu/Dielectric Hybrid Bonding for Three-Dimensional Integrated Circuits (3D ICs) Application. Nanomaterials 2023, 13, 2490. [Google Scholar] [CrossRef]

- Kuo, Y.-H.; Tran, D.-P.; Ong, J.-J.; Tu, K.-N.; Chen, C. Hybrid Cu-to-Cu bonding with nano-twinned Cu and non-conductive paste. J. Mater. Res. Technol. 2022, 18, 859–871. [Google Scholar] [CrossRef]

- Zhang, S.; Zhang, S.; Zhou, H.; Paik, K.-W.; Ding, T.; Long, W.; Zhong, S.; He, P. Preparation and characterization of Sn-3.0 Ag-0.5 Cu nano-solder paste and assessment of the reliability of joints fabricated by microwave hybrid heating. Mater. Charact. 2024, 207, 113512. [Google Scholar] [CrossRef]

- Xiao, Y.-b.; Gao, Y.; Liu, Z.-Q.; Sun, R.; Liu, Y. Cu–Cu bonding using bimodal submicron–nano Cu paste and its application in die attachment for power device. J. Mater. Sci. Mater. Electron. 2022, 33, 12604–12614. [Google Scholar] [CrossRef]

- Lv, W.; Hu, J.; Liu, J.; Xiong, C.; Zhu, F. Porosity effect on the mechanical properties of nano-silver solder. Nanotechnology 2023, 34, 165701. [Google Scholar] [CrossRef]

- Wakai, F.; Guillon, O.; Okuma, G.; Nishiyama, N. Sintering forces acting among particles during sintering by grain-boundary/surface diffusion. J. Am. Ceram. Soc. 2019, 102, 538–547. [Google Scholar] [CrossRef]

- Matsuda, T. Development of a DEM taking account of neck increments caused by surface diffusion for sintering and application to analysis of the initial stage of sintering. Comput. Mater. Sci. 2021, 196, 110525. [Google Scholar] [CrossRef]

- Kim, J.; Chung, H. Atomistic investigation of pressure effects on sintering of bimetallic core–shell nanoparticles. J. Mater. Sci. Technol. 2024, 184, 64–74. [Google Scholar] [CrossRef]

- Castro, R.H.R.; Gouvêa, D. Sintering and Nanostability: The Thermodynamic Perspective. J. Am. Ceram. Soc. 2016, 99, 1105–1121. [Google Scholar] [CrossRef]

- She, C.; Gao, J.; Wang, Z.; Jin, S.; Chen, M.; Song, L.; Chen, K. Coalescence of Al2O3/Al, MgO/Mg, and MgO/Al two nanoparticles during combustion. Appl. Surf. Sci. 2024, 649, 159157. [Google Scholar] [CrossRef]

- Zhang, L.; Shibuta, Y.; Lu, C.; Huang, X. Interaction between nano-voids and migrating grain boundary by molecular dynamics simulation. Acta Mater. 2019, 173, 206–224. [Google Scholar] [CrossRef]

- Zheng, D.W.; Zhou, M.B.; Liu, S.; Ke, C.B.; Zhang, X.P. An Intensive Study of Effects of Orientations of Cu Bumps on Cu-Cu Direct Bonding for 3D Integration by Molecular Dynamics Simulation. In Proceedings of the 2023 IEEE 73rd Electronic Components and Technology Conference (ECTC), Orlando, FL, USA, 30 May–2 June 2023; pp. 1760–1766. [Google Scholar]

- Song, Z.; Luo, W.; Fan, X.; Zhu, Y. Atomic fast dynamic motion on the Cu nanoparticle’s surface before melting: A molecular dynamics study. Appl. Surf. Sci. 2022, 606, 154901. [Google Scholar] [CrossRef]

- Wang, Z.; Song, Z.; Luo, W.; Shang, T.; Liu, Z.; Yuan, J.; Fan, X.; Zhu, Y. The effect of temperature on the mechanisms of Cu nanoparticle sintering: A molecular dynamic study. Powder Technol. 2024, 440, 119802. [Google Scholar] [CrossRef]

- Li, Q.; Wang, M.; Liang, Y.; Lin, L.; Fu, T.; Wei, P.; Peng, T. Molecular dynamics simulations of aggregation of copper nanoparticles with different heating rates. Phys. E Low-Dimens. Syst. Nanostructures 2017, 90, 137–142. [Google Scholar] [CrossRef]

- Hu, D.; Cui, Z.; Fan, J.; Fan, X.; Zhang, G. Thermal kinetic and mechanical behaviors of pressure-assisted Cu nanoparticles sintering: A molecular dynamics study. Results Phys. 2020, 19, 103486. [Google Scholar] [CrossRef]

- Thompson, A.P.; Aktulga, H.M.; Berger, R.; Bolintineanu, D.S.; Brown, W.M.; Crozier, P.S.; in ’t Veld, P.J.; Kohlmeyer, A.; Moore, S.G.; Nguyen, T.D.; et al. LAMMPS—A flexible simulation tool for particle-based materials modeling at the atomic, meso, and continuum scales. Comput. Phys. Commun. 2022, 271, 108171. [Google Scholar] [CrossRef]

- Daw, M.S.; Baskes, M.I. Embedded-atom method: Derivation and application to impurities, surfaces, and other defects in metals. Phys. Rev. B 1984, 29, 6443–6453. [Google Scholar] [CrossRef]

- Mosavi, A.; Hekmatifar, M.; Alizadeh, A.A.; Toghraie, D.; Sabetvand, R.; Karimipour, A. The molecular dynamics simulation of thermal manner of Ar/Cu nanofluid flow: The effects of spherical barriers size. J. Mol. Liq. 2020, 319, 114183. [Google Scholar] [CrossRef]

- Wu, C.-D.; Liao, C.-F. Molecular dynamics simulation of the direct bonding of (111)-oriented nanotwinned Cu and its related mechanical behavior. J. Phys. Chem. Solids 2024, 187, 111872. [Google Scholar] [CrossRef]

- Long, Y.; He, B.; Cui, W.; Ji, Y.; Zhuang, X.; Twiefel, J. Investigations on the mechanism of microweld changes during ultrasonic wire bonding by molecular dynamics simulation. Mater. Des. 2020, 192, 108718. [Google Scholar] [CrossRef]

- Stukowski, A. Visualization and analysis of atomistic simulation data with OVITO–the Open Visualization Tool. Model. Simul. Mater. Sc. 2009, 18, 015012. [Google Scholar] [CrossRef]

- Templeton, D.H.; Dauben, C.H. Lattice Parameters of Some Rare Earth Compounds and a Set of Crystal Radii. J. Am. Chem. Soc. 1954, 76, 5237–5239. [Google Scholar] [CrossRef]

- Malti, A.; Kardani, A.; Montazeri, A. An insight into the temperature-dependent sintering mechanisms of metal nanoparticles through MD-based microstructural analysis. Powder Technol. 2021, 386, 30–39. [Google Scholar] [CrossRef]

- Wang, F.; Tang, Z.; He, H. Stress-dislocation interaction mechanism in low-temperature thermo-compression sintering of Ag NPs. AIP Adv. 2018, 8, 045012. [Google Scholar] [CrossRef]

- Zeng, Z.; Zhao, J.; Zhou, X.; Li, J.; Liang, B. Thermal stability of Al-Cu-Fe-Cr-Ni high entropy alloy bulk and nanoparticle structure: A molecular dynamics perspective. Chem. Phys. 2019, 517, 126–130. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, J.; Song, Z.; Liu, Z.; Xie, X.; Guan, P.; Zhu, Y. Exploring Surface-Driven Mechanisms for Low-Temperature Sintering of Nanoscale Copper. Appl. Sci. 2025, 15, 476. https://doi.org/10.3390/app15010476

Li J, Song Z, Liu Z, Xie X, Guan P, Zhu Y. Exploring Surface-Driven Mechanisms for Low-Temperature Sintering of Nanoscale Copper. Applied Sciences. 2025; 15(1):476. https://doi.org/10.3390/app15010476

Chicago/Turabian StyleLi, Jingyan, Zixian Song, Zhichao Liu, Xianli Xie, Penghui Guan, and Yiying Zhu. 2025. "Exploring Surface-Driven Mechanisms for Low-Temperature Sintering of Nanoscale Copper" Applied Sciences 15, no. 1: 476. https://doi.org/10.3390/app15010476

APA StyleLi, J., Song, Z., Liu, Z., Xie, X., Guan, P., & Zhu, Y. (2025). Exploring Surface-Driven Mechanisms for Low-Temperature Sintering of Nanoscale Copper. Applied Sciences, 15(1), 476. https://doi.org/10.3390/app15010476