Compressive Characteristics and Energy Absorption Capacity of Automobile Energy-Absorbing Box with Filled Porous TPMS Structures

Abstract

1. Introduction

2. Materials and Methods

2.1. TPMS Unit Design

2.2. Quasi-Static Compression Experiments

2.3. Low-Speed Impact Experiments of Automobile Energy-Absorbing Box

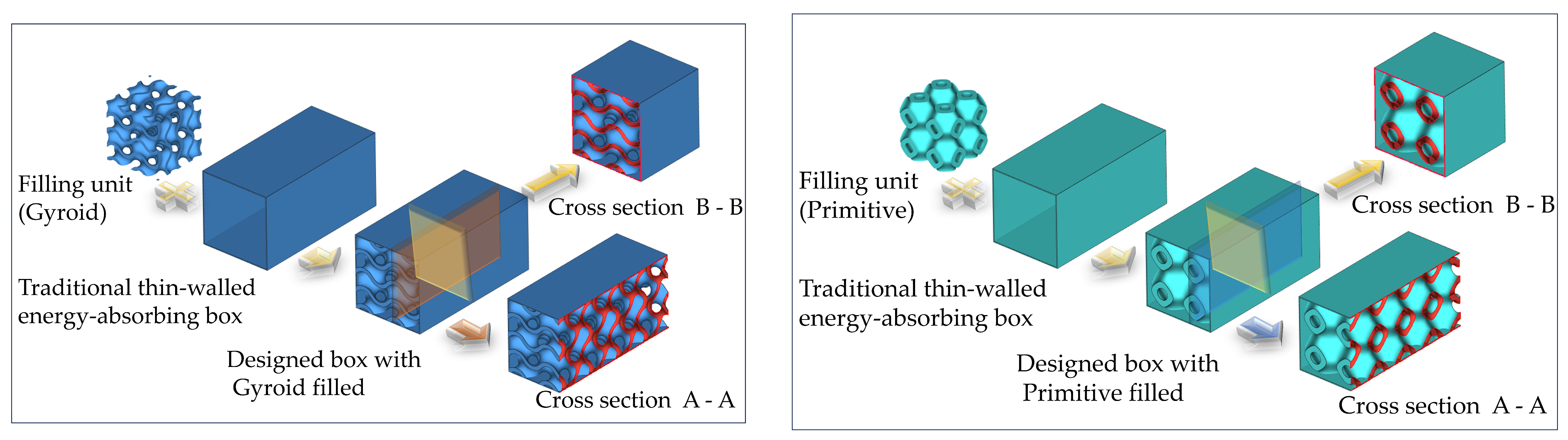

2.3.1. Structural Design

2.3.2. Properties Characterization

2.3.3. Experimental Testing and Numerical Simulation

3. Results and Discussion

3.1. Mechanical Characterization of TPMS Structures

3.1.1. Deformation Mechanism

3.1.2. Mechanical Response

3.1.3. Energy Absorption Evaluation Indexes Comparison

3.2. Low-Speed Impact Analysis of Designed Energy-Absorbing Box

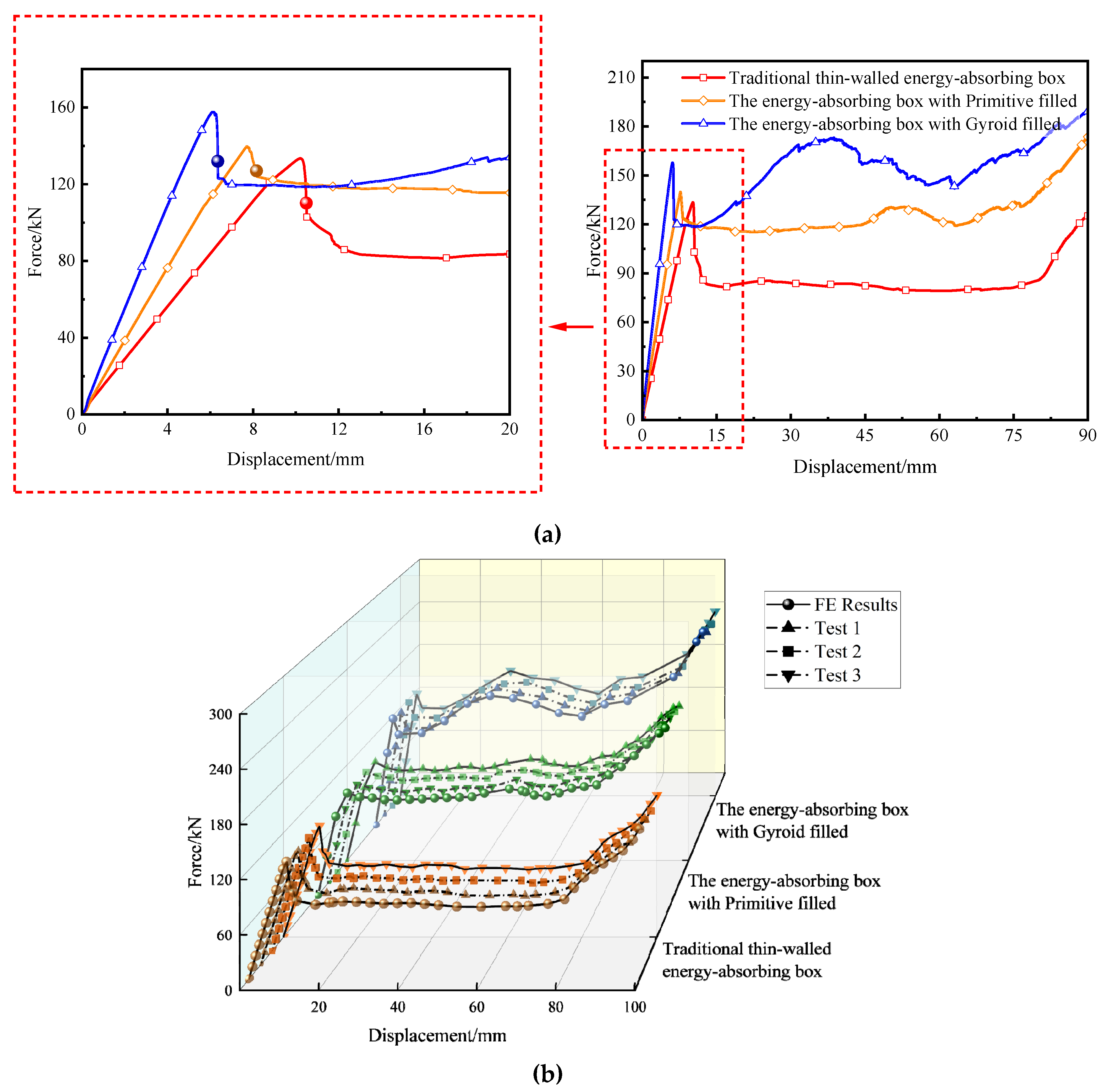

3.2.1. Deformation Mechanism and Mechanical Response

3.2.2. Energy Absorption Evaluation Indexes Comparison

4. Conclusions

- Structural failure of the porous TPMS structure along the surface shear bands under axial quasi-static compressive loading conditions. Deformation is dominated by layered bending collapse, which stabilizes structural deformation while reducing peak loads.

- The load–displacement curves of the porous TPMS structures (Gyroid and Primitive) subjected to external loads fluctuate smoothly. The more prominent the shear deformation of the porous TPMS structure, the less the fluctuation degree of the platform section affected by the single load.

- The energy-absorbing box filled with porous TPMS structures is attributed to a particular deformation behavior. The failure form of layer-by-layer collapse provides it with high-quality energy absorption capacity, and its peak load and load fluctuation are significantly reduced compared with traditional thin-walled energy-absorbing boxes. On the premise of ensuring lightweight and energy absorption requirements, a new solution is provided for solving the problems of excessive peak load and unstable load fluctuation of traditional thin-walled energy-absorbing boxes.

- Comprehensive analysis shows that the porous TPMS structure has the advantages of eliminating stress concentration and improving mechanical strength. Automobile energy absorbing boxes filled with porous TPMS structures have excellent impact resistance and energy absorption characteristics compared with traditional thin-walled energy-absorbing boxes. The porous TPMS structure is an ideal candidate for lightweight multifunctional structures.

- The research is based on SLM to realize the lightweight design of automotive energy-absorbing boxes and to provide the basis for the selection of other parts. Additional research should be carried out on the influence of the parameters of additive manufacturing and the selection of raw materials on the mechanical behavior of porous TPMS structures. Through the matching of different additive manufacturing technologies and excellent raw materials, combined with the topological optimization of porous TPMS structure, the integrated design of goal–material–structure–function can be achieved.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Du, Y.; Zhao, Y.; Li, H. Subsidy policy and carbon quota mechanism of the Chinese vehicle industry. Transp. Res. Part D Transp. Environ. 2023, 121, 103806. [Google Scholar] [CrossRef]

- Zhang, W.; Xu, J. Advanced lightweight materials for Automobiles: A review. Mater. Des. 2022, 221, 110994. [Google Scholar] [CrossRef]

- Lv, X.; Xiao, Z.; Fang, J.; Li, Q.; Lei, F.; Sun, G. On safety design of vehicle for protection of vulnerable road users: A review. Thin-Walled Struct. 2023, 182, 109990. [Google Scholar] [CrossRef]

- Yoo, S.H.; Chang, S.H.; Sutcliffe, M.P.F. Compressive characteristics of foam-filled composite egg-box sandwich panels as energy absorbing structures. Compos. Part A Appl. Sci. Manuf. 2010, 41, 427–434. [Google Scholar] [CrossRef]

- Liu, W.; Zhang, Y.; Guo, Z.; Li, D.; Zhao, S.; Xie, W. Analyzing in-plane mechanics of a novel honeycomb structure with zero Poisson’s ratio. Thin-Walled Struct. 2023, 192, 111134. [Google Scholar] [CrossRef]

- Montgomery-Liljeroth, E.; Schievano, S.; Burriesci, G. Elastic properties of 2D auxetic honeycomb structures- a review. Appl. Mater. Today 2023, 30, 101722. [Google Scholar] [CrossRef]

- Peng, X.; Liu, G.; Li, J.; Wu, H.; Jia, W.; Jiang, S. Compression property and energy absorption capacity of 4D-printed deformable honeycomb structure. Compos. Struct. 2023, 325, 117591. [Google Scholar] [CrossRef]

- Shen, X.; Hu, Q.; Zhu, D.; Qi, S.; Huang, C.; Yuan, M.; Qian, X.; Guo, R. Dynamic mechanical response prediction model of honeycomb structure based on machine learning method and finite element method. Int. J. Impact Eng. 2024, 184, 104825. [Google Scholar] [CrossRef]

- Jongpradist, P.; Tongthong, S.; Kongwat, S.; Ruangjirakit, K.; Thongchom, C.; Hasegawa, H. Optimizing functionally graded hexagonal crash boxes with honeycomb filler for enhanced crashworthiness. Structures 2024, 59, 105775. [Google Scholar] [CrossRef]

- Wei, W.; Zhang, F.; Xing, Y.; Wang, H.; Liu, R. Research on Mechanical Properties of Origami Aluminum Honeycomb for Automobile Energy Absorbing Box. Materials 2023, 16, 141. [Google Scholar] [CrossRef]

- Li, X.; Yu, W.; Liu, J.; Zhu, X.; Wang, H.; Sun, X.; Liu, J.; Yuan, H. A mechanics model of hard-magnetic soft rod with deformable cross-section under three-dimensional large deformation. Int. J. Solids Struct. 2023, 279, 112344. [Google Scholar] [CrossRef]

- Moosavian, H.; Tang, T. Statistical mechanics of coil–rod structure in biopolymer gels. J. Mech. Phys. Solids 2023, 175, 105272. [Google Scholar] [CrossRef]

- Browne, C.; Raghuwanshi, V.S.; Garnier, G.; Batchelor, W. Modulating the chiral nematic structure of cellulose nanocrystal suspensions with electrolytes. J. Colloid. Interface. Sci. 2023, 650, 1064–1072. [Google Scholar] [CrossRef] [PubMed]

- Li, X.; Cheng, S.; Wang, R.; Yan, Q.; Wang, B.; Sun, Y.; Yan, H.; Zhao, Q.; Xin, Y. Design of novel two-dimensional single-phase chiral phononic crystal assembly structures and study of bandgap mechanism. Results Phys. 2023, 48, 106431. [Google Scholar] [CrossRef]

- Xu, W.; Zhang, L.; Zhang, B.; Zhang, H.; Liu, Z.; Zhu, P. Crushing behavior of contact-aided AlSi10Mg sandwich structure based on chiral mechanical metamaterials. Int. J. Mech. Sci. 2023, 260, 108636. [Google Scholar] [CrossRef]

- Ma, X.; Zhang, N.; Chang, Y.; Tian, X. Analytical model of mechanical properties for a hierarchical lattice structure based on hierarchical body-centered cubic unit cell. Thin-Walled Struct. 2023, 193, 111217. [Google Scholar] [CrossRef]

- Deshpande, V.S.; Fleck, N.A.; Ashby, M.F. Effective properties of the octet-truss lattice material. J. Mech. Phys. Solids 2001, 49, 1747–1769. [Google Scholar] [CrossRef]

- Kooistra, G. Compressive behavior of age hardenable tetrahedral lattice truss structures made from aluminium. Acta Mater. 2004, 52, 4229–4237. [Google Scholar] [CrossRef]

- Moongkhamklang, P.; Deshpande, V.S.; Wadley, H.N.G. The compressive and shear response of titanium matrix composite lattice structures. Acta Mater. 2010, 58, 2822–2835. [Google Scholar] [CrossRef]

- Sun, G.; Chen, D.; Zhu, G.; Li, Q. Lightweight hybrid materials and structures for energy absorption: A state-of-the-art review and outlook. Thin-Walled Struct. 2022, 172, 108760. [Google Scholar] [CrossRef]

- Li, N.; Xue, C.; Chen, S.; Aiyiti, W.; Khan, S.B.; Liang, J.; Zhou, J.; Lu, B. 3D Printing of Flexible Mechanical Metamaterials: Synergistic Design of Process and Geometric Parameters. Polymers 2023, 15, 4523. [Google Scholar] [CrossRef]

- Rico-Baeza, G.; Pérez-Soto, G.I.; Morales-Hernández, L.A.; Cuan-Urquizo, E.; Camarillo-Gómez, K.A. Additively Manufactured Foot Insoles Using Body-Centered Cubic (BCC) and Triply Periodic Minimal Surface (TPMS) Cellular Structures. Appl. Sci. 2023, 13, 12665. [Google Scholar] [CrossRef]

- Xue, C.; Li, N.; Chen, S.; Liang, J.; Aiyiti, W. The Laser Selective Sintering Controlled Forming of Flexible TPMS Structures. Materials 2023, 16, 7565. [Google Scholar] [CrossRef]

- Du Plessis, A.; Yadroitsava, I.; Yadroitsev, I.; le Roux, S.G.; Blaine, D.C. Numerical comparison of lattice unit cell designs for medical implants by additive manufacturing. Virtual Phys. Prototyp. 2018, 13, 266–281. [Google Scholar] [CrossRef]

- Zargarian, A.; Esfahanian, M.; Kadkhodapour, J.; Ziaei-Rad, S.; Zamani, D. On the Fatigue Behavior of Additive Manufactured Lattice Structures. Theor. Appl. Fract. Mech. 2019, 100, 225–232. [Google Scholar] [CrossRef]

- Wu, R.; Roberts, P.C.; Lyu, S.; Zheng, F.; Soutis, C.; Diver, C.; Zhou, D.; Li, L.; Deng, Z. Lightweight Self-Forming Super-Elastic Mechanical Metamaterials with Adaptive Stiffness. Adv. Funct. Mater. 2020, 31, 2008252. [Google Scholar] [CrossRef]

- Sychov, M.M.; Lebedev, L.A.; Dyachenko, S.V.; Nefedova, L.A. Mechanical properties of energy-absorbing structures with triply periodic minimal surface topology. Acta Astronaut. 2018, 150, 81–84. [Google Scholar] [CrossRef]

- Berger, J.B.; Wadley, H.N.G.; Mcmeeking, R.M. Mechanical metamaterials at the theoretical limit of isotropic elastic stiffness. Nature 2017, 543, 533. [Google Scholar] [CrossRef]

- Lal Lazar, P.J.; Subramanian, J.; Natarajan, E.; Markandan, K.; Ramesh, S. Anisotropic structure-property relations of FDM printed short glass fiber reinforced polyamide TPMS structures under quasi-static compression. J. Mater. Res. Technol. 2023, 24, 9562–9579. [Google Scholar] [CrossRef]

- Ge, J.; Huang, Q.; Wang, Y.; Zhang, C.; Liu, Q.; Lu, Z.; Yin, S. Microstructural optimization and mechanical enhancement of SLM Ti6Al4V TPMS scaffolds through vacuum annealing treatment. J. Alloys Compd. 2023, 934, 167524. [Google Scholar] [CrossRef]

- Leary, M.; Mazur, M.; Elambasseril, J.; Mcmillan, M.; Chirent, T.; Sun, Y.; Qian, M.; Easton, M.; Brandt, M. Selective laser melting (SLM) of AlSi12Mg lattice structures. Mater. Des. 2016, 98, 344–357. [Google Scholar] [CrossRef]

- Giorleo, L.; Bonaventi, M. Casting of complex structures in aluminum using gypsum molds produced via binder jetting. Rapid Prototyp. J. 2021, 27, 13–23. [Google Scholar] [CrossRef]

- Jonsson, S.; Kajberg, J. Evaluation of Crashworthiness Using High-Speed Imaging, 3D Digital Image Correlation, and Finite Element Analysis. Metals 2023, 13, 1834. [Google Scholar] [CrossRef]

- Doroszko, M. Numerical Investigation of the Defects Effect in Additive Manufactured Ti-6Al-4V Struts on Deformation Behavior Based on Microtomographic Images. Materials 2022, 15, 4807. [Google Scholar] [CrossRef]

- Guillou, E.; King, A.; Perrin, J.; Proudhon, H.; Weitkamp, T.; Shah, D.U.; Beigbeder, A.; Ouagne, P.; Bourmaud, A. Impact of flax fibre micro-structural features on composite damage observed through micro-CT characterisation. Compos. Part A Appl. Sci. Manuf. 2024, 181, 108118. [Google Scholar] [CrossRef]

- Al Ketan, O.; Abu Al Rub, R.K. MSLattice: A free software for generating uniform and graded lattices based on triply periodic minimal surfaces. Mater. Des. Process. Commun. 2021, 3, e205. [Google Scholar] [CrossRef]

- Han, D.; Ren, X.; Luo, C.; Zhang, Y.; Zhang, X.Y.; Zhang, X.G.; Jiang, W.; Hao, J.; Xie, Y.M. Experimental and computational investigations of novel 3D printed square tubular lattice metamaterials with negative Poisson’s ratio. Addit. Manuf. 2022, 55, 102789. [Google Scholar] [CrossRef]

- Nagarajan, B.; Hu, Z.; Song, X.; Zhai, W.; Wei, J. Development of Micro Selective Laser Melting: The State of the Art and Future Perspectives. Engineering 2019, 5, 702–720. [Google Scholar] [CrossRef]

- ISO 13314:2011; Mechanical Testing of Metals—Ductility Test_Ing—Compression Test for Porous and Cellular Metals. ISO: Geneva, Switzerland, 2011.

- Fan, W.; Xie, R.; Davidson, M.; Yin, H.; Lai, K.; Wu, Q. Crashworthiness and energy absorption of UHPFRC-steel composite sandwich structures under impact loading. Compos. Struct. 2023, 311, 116813. [Google Scholar] [CrossRef]

- Wu, B.; Chen, Q.; Liu, F.; Chen, M.; Lu, Y.; Jiang, D.; Yi, Y. Study on Dynamic Mechanics of Node-Enhanced Graded Lattice Structure and Application Optimization in Automobile Energy Absorbing Box. Materials 2023, 16, 6893. [Google Scholar] [CrossRef]

- Xie, C.; Wang, D.; Zong, L.; Wang, S.; Kong, D. Multi-objective crashworthiness optimization of energy-absorbing box with gradient lattice structure. Appl. Math. Model. 2023, 121, 304–320. [Google Scholar] [CrossRef]

- Djamaluddin, F. Optimization of foam-filled crash-box under axial loading for pure electric vehicle. Results Mater. 2024, 21, 100505. [Google Scholar] [CrossRef]

- Yunus Nasution, A.; Ruzaimi Mat Rejab, M.; Parlaungan Siregar, J.; Ma, Q. Combination of frustra shapes with cross sections and trigger circles for crash box design to absorb energy. Mater. Today Proc. 2023. [Google Scholar] [CrossRef]

- Xiang, J.; Du, J. Energy absorption characteristics of bio-inspired honeycomb structure under axial impact loading. Mater. Sci. Eng. A 2017, 696, 283–289. [Google Scholar] [CrossRef]

- Hao, P.; Du, J. Energy absorption characteristics of bio-inspired honeycomb column thin-walled structure under impact loading. J. Mech. Behav. Biomed. Mater. 2018, 79, 301–308. [Google Scholar] [CrossRef]

- Zhang, Y.; Wang, J.; Wang, C.; Zeng, Y.; Chen, T. Crashworthiness of bionic fractal hierarchical structures. Mater. Des. 2018, 158, 147–159. [Google Scholar] [CrossRef]

- Hu, D.; Wang, Y.; Song, B.; Dang, L.; Zhang, Z. Energy-absorption characteristics of a bionic honeycomb tubular nested structure inspired by bamboo under axial crushing. Compos. Part B Eng. 2019, 162, 21–32. [Google Scholar] [CrossRef]

- Zhang, L.; Bai, Z.; Bai, F. Crashworthiness design for bio-inspired multi-cell tubes with quadrilateral, hexagonal and octagonal sections. Thin-Walled Struct. 2018, 122, 42–51. [Google Scholar] [CrossRef]

- Alia, R.A.; Al-Ali, O.; Kumar, S.; Cantwell, W.J. The energy-absorbing characteristics of carbon fiber-reinforced epoxy honeycomb structures. J. Compos. Mater. 2019, 53, 1145–1157. [Google Scholar] [CrossRef]

- Liu, Q.; Ma, J.; He, Z.; Hu, Z.; Hui, D. Energy absorption of bio-inspired multi-cell CFRP and aluminum square tubes. Compos. Part B Eng. 2017, 121, 134–144. [Google Scholar] [CrossRef]

- Song, Z.; Liang, H.; Ding, H.; Ma, M. Structure design and mechanical properties of a novel anti-collision system with negative Poisson’s ratio core. Int. J. Mech. Sci. 2023, 239, 107864. [Google Scholar] [CrossRef]

| TPMS | Implicit Function Expression |

|---|---|

| Gyroid | |

| Diamond | |

| I-WP | |

| Neovius | |

| Primitive | |

| Fischer-Koch S | |

| F-RD | |

| PMY |

| Property | Magnitude |

|---|---|

| Density (g/cm3) | 2.71 |

| Young’s modulus (GPa) | 70 |

| Yield strength (MPa) | 284 |

| Poisson’s ratio | 0.33 |

| Type | Weight (g) | Dimension (X × Y × Z mm) | |

|---|---|---|---|

| Gyroid | Sample 1 | 7.00 | 19.92 × 20.02 × 19.52 |

| Sample 2 | 7.03 | 19.92 × 20.00 × 19.82 | |

| Sample 3 | 7.01 | 20.02 × 19.88 × 19.62 | |

| Diamond | Sample 1 | 7.83 | 20.18 × 20.20 × 20.10 |

| Sample 2 | 7.63 | 20.12 × 20.18 × 20.16 | |

| Sample 3 | 7.47 | 20.20 × 20.00 × 20.12 | |

| I-WP | Sample 1 | 7.58 | 19.82 × 20.14 × 20.26 |

| Sample 2 | 7.58 | 20.02 × 20.12 × 20.20 | |

| Sample 3 | 7.22 | 20.12 × 19.94 × 20.18 | |

| Neovius | Sample 1 | 8.74 | 20.20 × 19.92 × 20.10 |

| Sample 2 | 8.66 | 20.12 × 19.98 × 20.08 | |

| Sample 3 | 8.66 | 20.10 × 19.94 × 20.12 | |

| Primitive | Sample 1 | 6.88 | 19.88 × 19.92 × 20.00 |

| Sample 2 | 6.76 | 19.92 × 19.42 × 19.92 | |

| Sample 3 | 6.66 | 19.92 × 19.62 × 19.94 | |

| Fischer-Koch S | Sample 1 | 8.46 | 19.72 × 19.72 × 20.02 |

| Sample 2 | 8.50 | 19.62 × 19.92 × 20.00 | |

| Sample 3 | 8.60 | 19.62 × 20.02 × 20.04 | |

| F-RD | Sample 1 | 9.07 | 20.09 × 20.12 × 19.92 |

| Sample 2 | 9.43 | 20.20 × 20.20 × 19.92 | |

| Sample 3 | 9.27 | 20.13 × 20.20 × 19.96 | |

| PMY | Sample 1 | 10.13 | 19.41 × 20.02 × 19.82 |

| Sample 2 | 10.18 | 19.62 × 20.00 × 19.92 | |

| Sample 3 | 10.33 | 19.42 × 20.40 × 20.00 | |

| Type of Automobile Energy-Absorbing Box | Weight (g) | Dimension (X × Y × Z mm) | |

|---|---|---|---|

| Traditional thin-walled box | Sample 1 | 150.83 | 49.82 × 50.12 × 99.50 |

| Sample 2 | 151.03 | 49.88 × 50.38 × 99.52 | |

| Sample 3 | 151.01 | 49.92 × 50.34 × 99.58 | |

| Gyroid filled box | Sample 1 | 228.88 | 50.01 × 50.02 × 99.62 |

| Sample 2 | 227.60 | 50.08 × 50.02 × 99.40 | |

| Sample 3 | 227.82 | 50.02 × 50.04 × 99.48 | |

| Primitive filled box | Sample 1 | 228.29 | 50.01 × 50.02 × 99.58 |

| Sample 2 | 228.36 | 50.08 × 50.08 × 99.60 | |

| Sample 3 | 228.33 | 50.02 × 50.04 × 99.60 | |

| TPMS | f (%) | m (g) | Sef (mm) | ESR (%) | Fm (kN) | SEA (J/g) |

|---|---|---|---|---|---|---|

| Gyroid | 11.27 | 7.013 | 11.88 | 59.40 | 18.38 | 31.14 |

| Diamond | 11.10 | 7.643 | 11.61 | 58.05 | 17.58 | 26.84 |

| I-WP | 10.08 | 7.460 | 10.56 | 52.80 | 17.51 | 24.79 |

| Neovius | 9.19 | 8.687 | 10.03 | 50.15 | 17.03 | 19.66 |

| Primitive | 11.68 | 6.767 | 12.28 | 61.40 | 16.09 | 29.20 |

| Fischer-Koch S | 9.61 | 8.520 | 9.99 | 49.95 | 13.58 | 15.92 |

| F-RD | 7.16 | 9.257 | 3.38 | 16.90 | 22.89 | 8.36 |

| PMY | 8.40 | 10.213 | 2.82 | 14.10 | 24.59 | 6.79 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, X.; Li, Z.; Zou, Y.; Zhao, X. Compressive Characteristics and Energy Absorption Capacity of Automobile Energy-Absorbing Box with Filled Porous TPMS Structures. Appl. Sci. 2024, 14, 3790. https://doi.org/10.3390/app14093790

Zhao X, Li Z, Zou Y, Zhao X. Compressive Characteristics and Energy Absorption Capacity of Automobile Energy-Absorbing Box with Filled Porous TPMS Structures. Applied Sciences. 2024; 14(9):3790. https://doi.org/10.3390/app14093790

Chicago/Turabian StyleZhao, Xuejin, Zhenzong Li, Yupeng Zou, and Xiaoyu Zhao. 2024. "Compressive Characteristics and Energy Absorption Capacity of Automobile Energy-Absorbing Box with Filled Porous TPMS Structures" Applied Sciences 14, no. 9: 3790. https://doi.org/10.3390/app14093790

APA StyleZhao, X., Li, Z., Zou, Y., & Zhao, X. (2024). Compressive Characteristics and Energy Absorption Capacity of Automobile Energy-Absorbing Box with Filled Porous TPMS Structures. Applied Sciences, 14(9), 3790. https://doi.org/10.3390/app14093790