Natural Ventilation to Manage Ammonia Concentration and Temperature in a Rabbit Barn in Central Mexico

Abstract

1. Introduction

2. Materials and Methods

2.1. Experiment Description

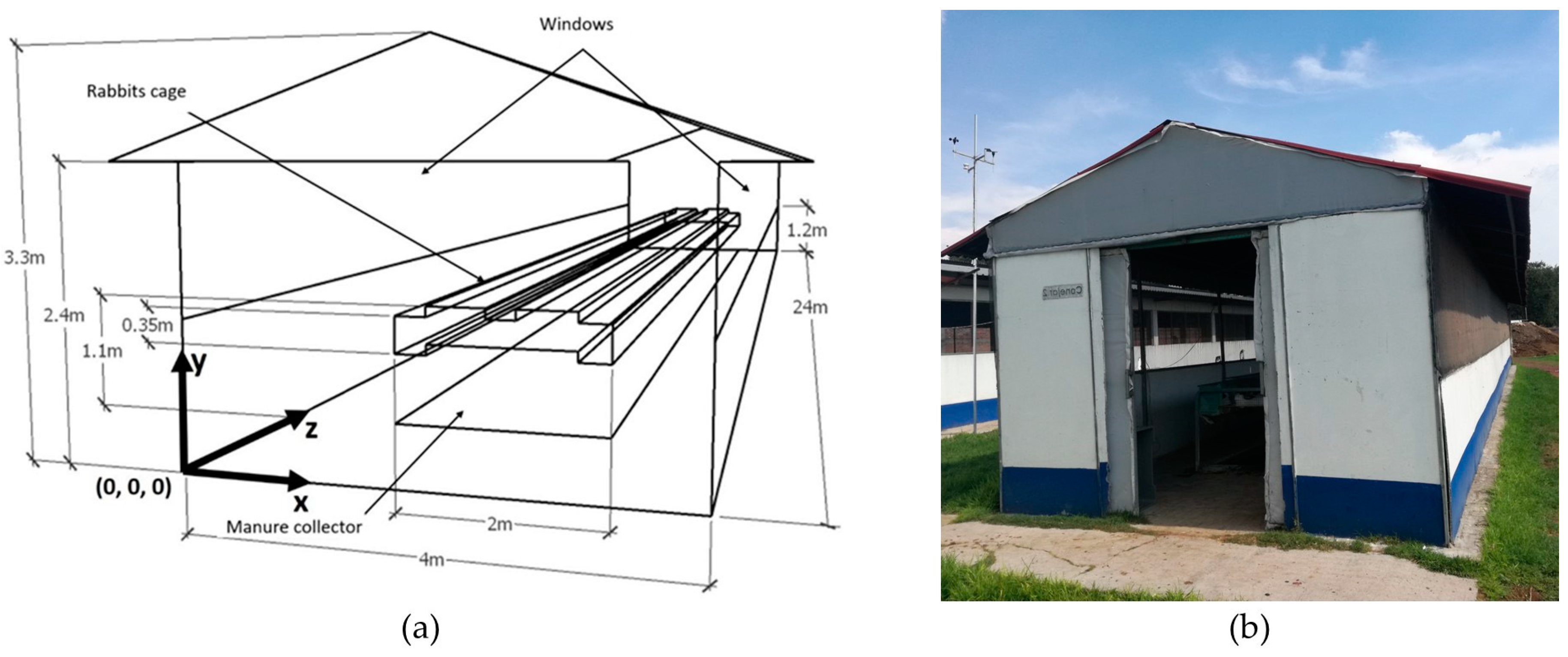

2.2. Geometry and Computational Domain

2.3. Fundamental Equations for the Simulation of the Numerical Model

3. Results and Discussion

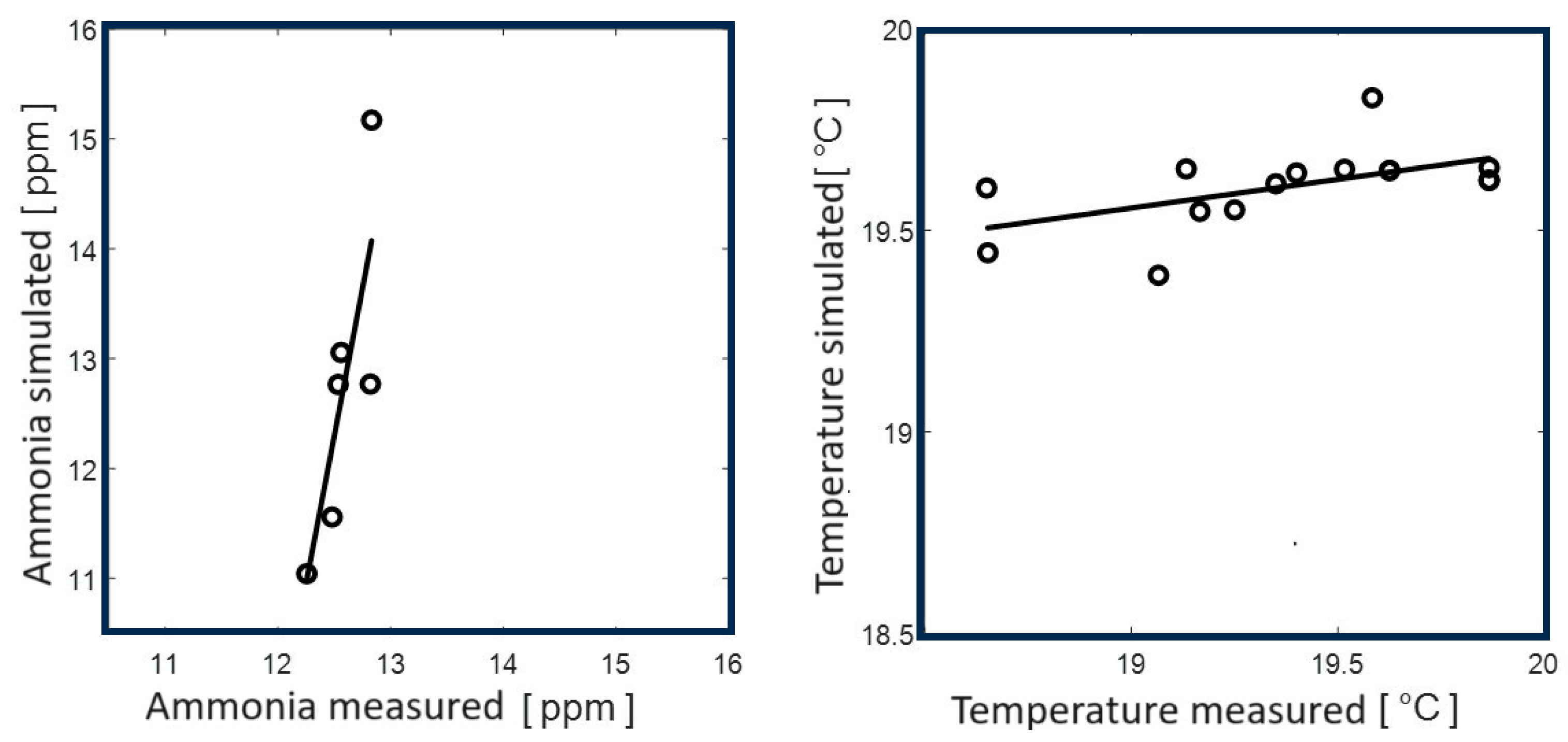

3.1. Evaluation of the Numerical Model

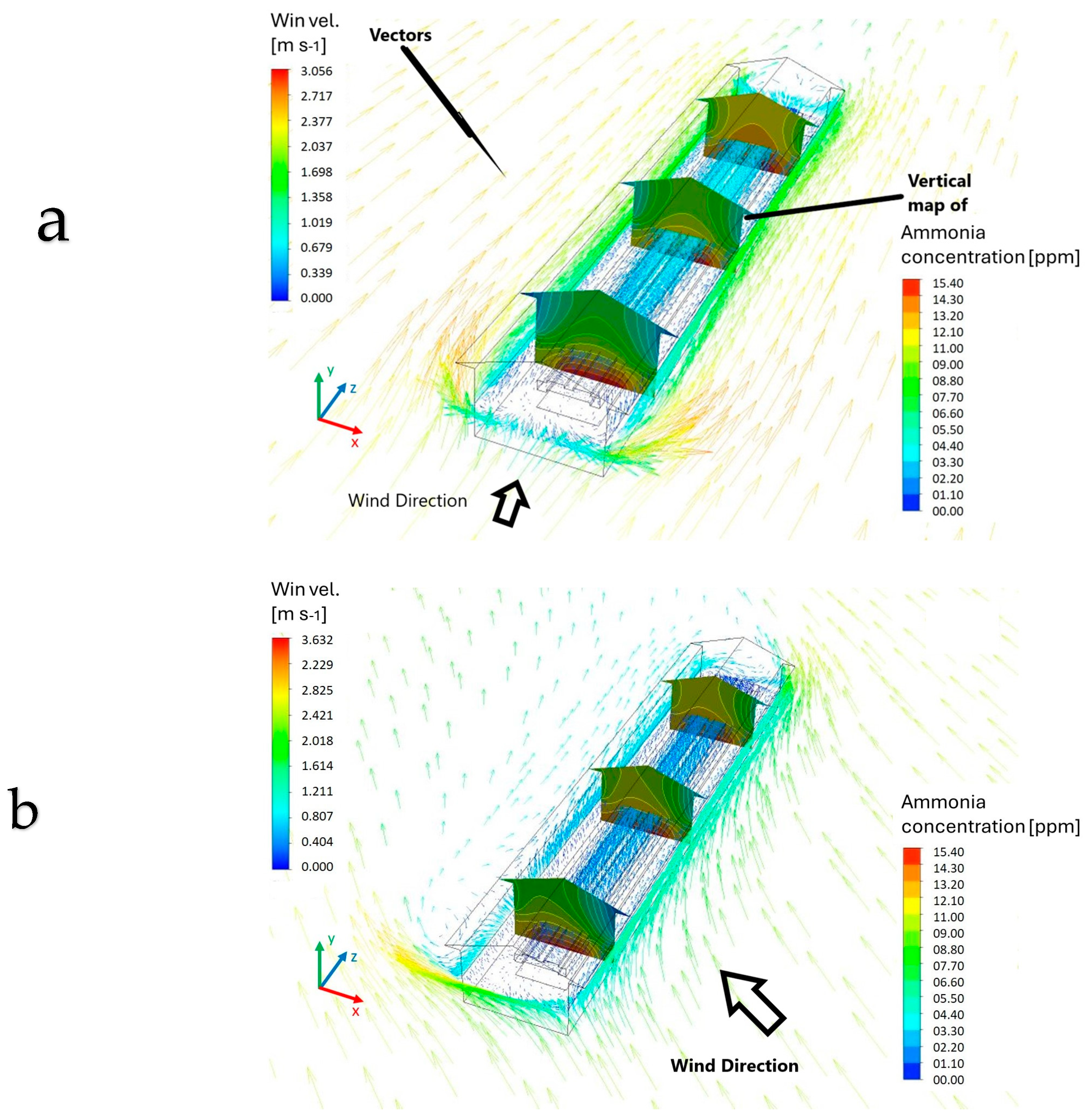

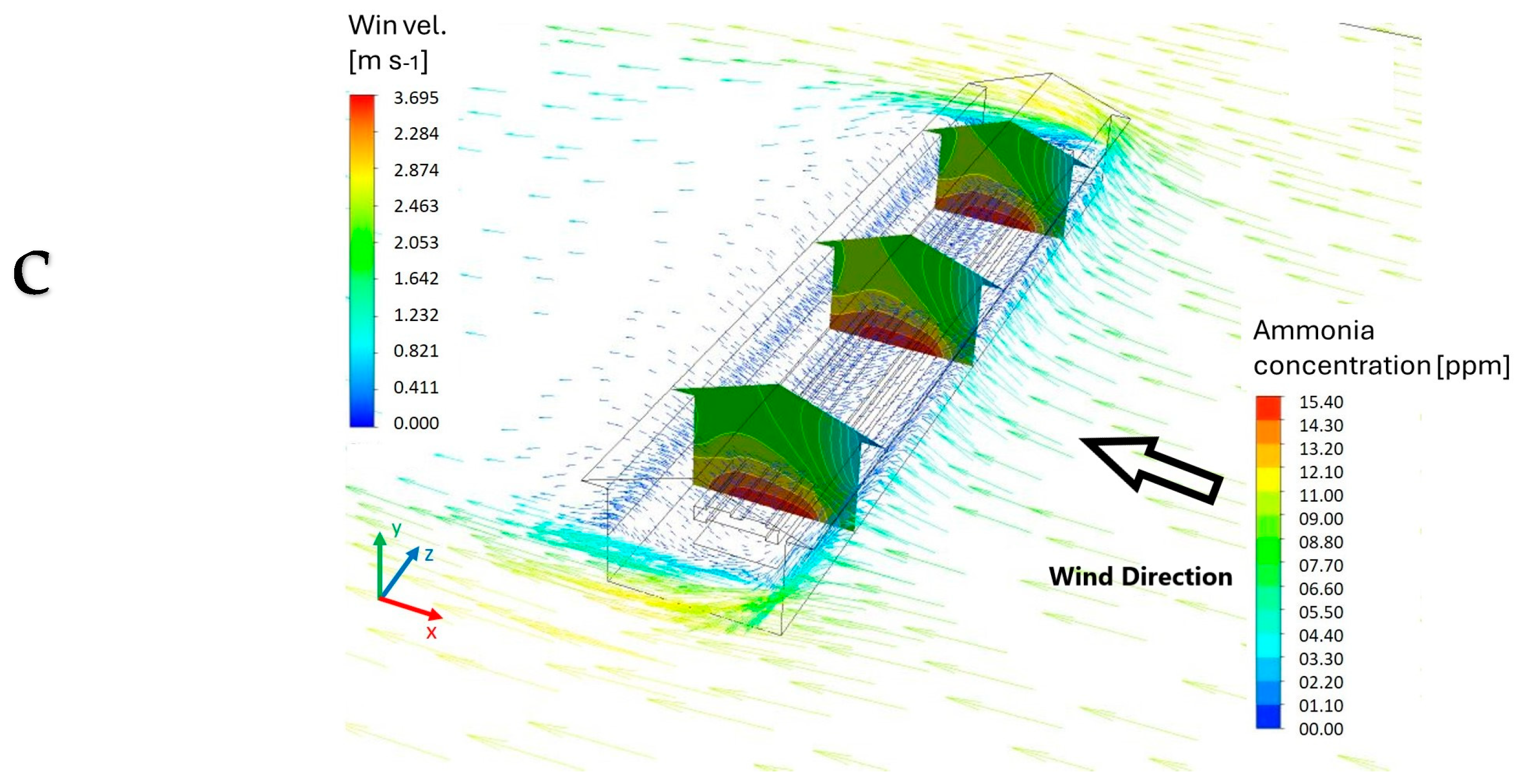

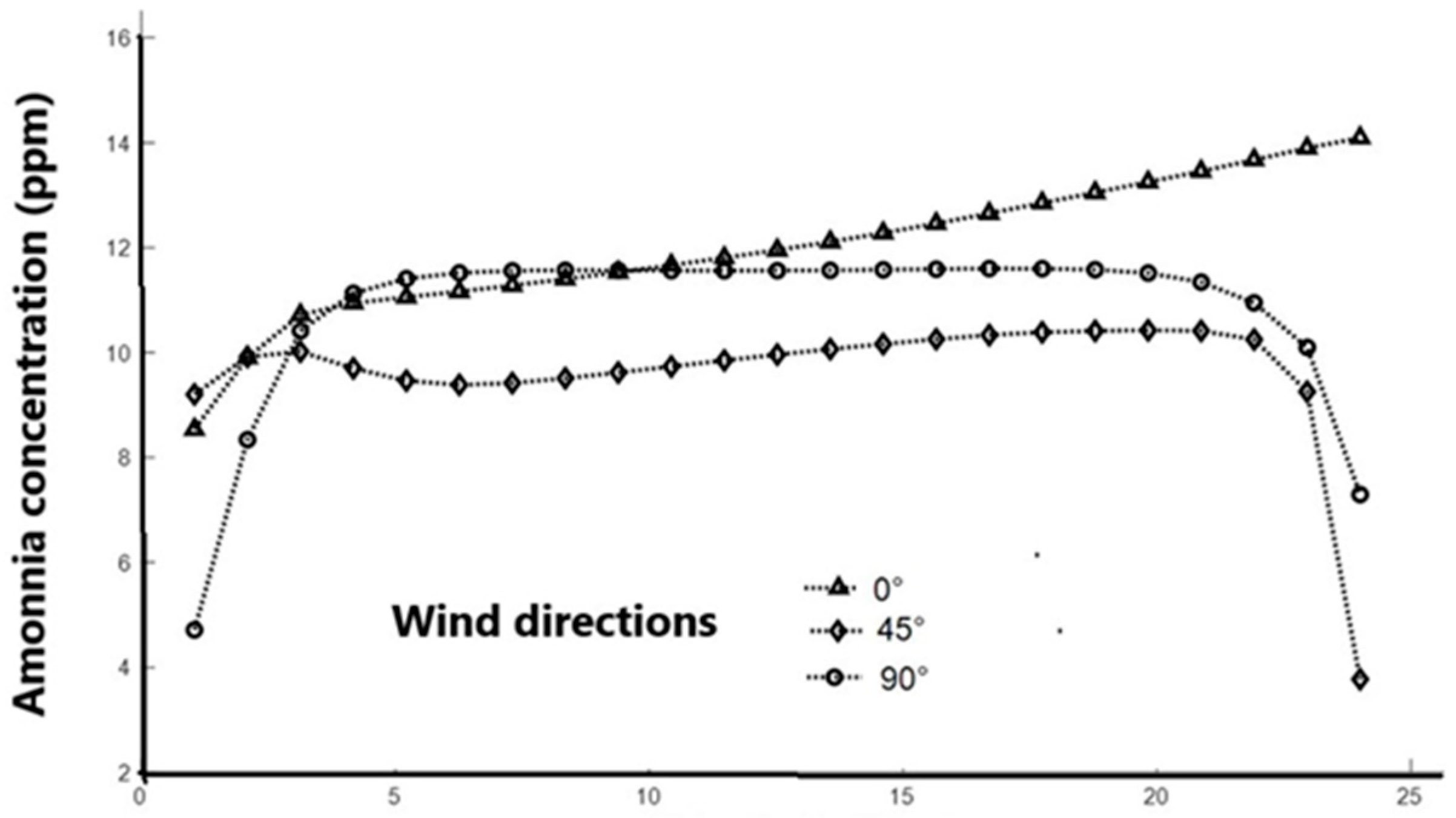

3.2. Variation of Air Speed and Ammonia Concentration in the AOR

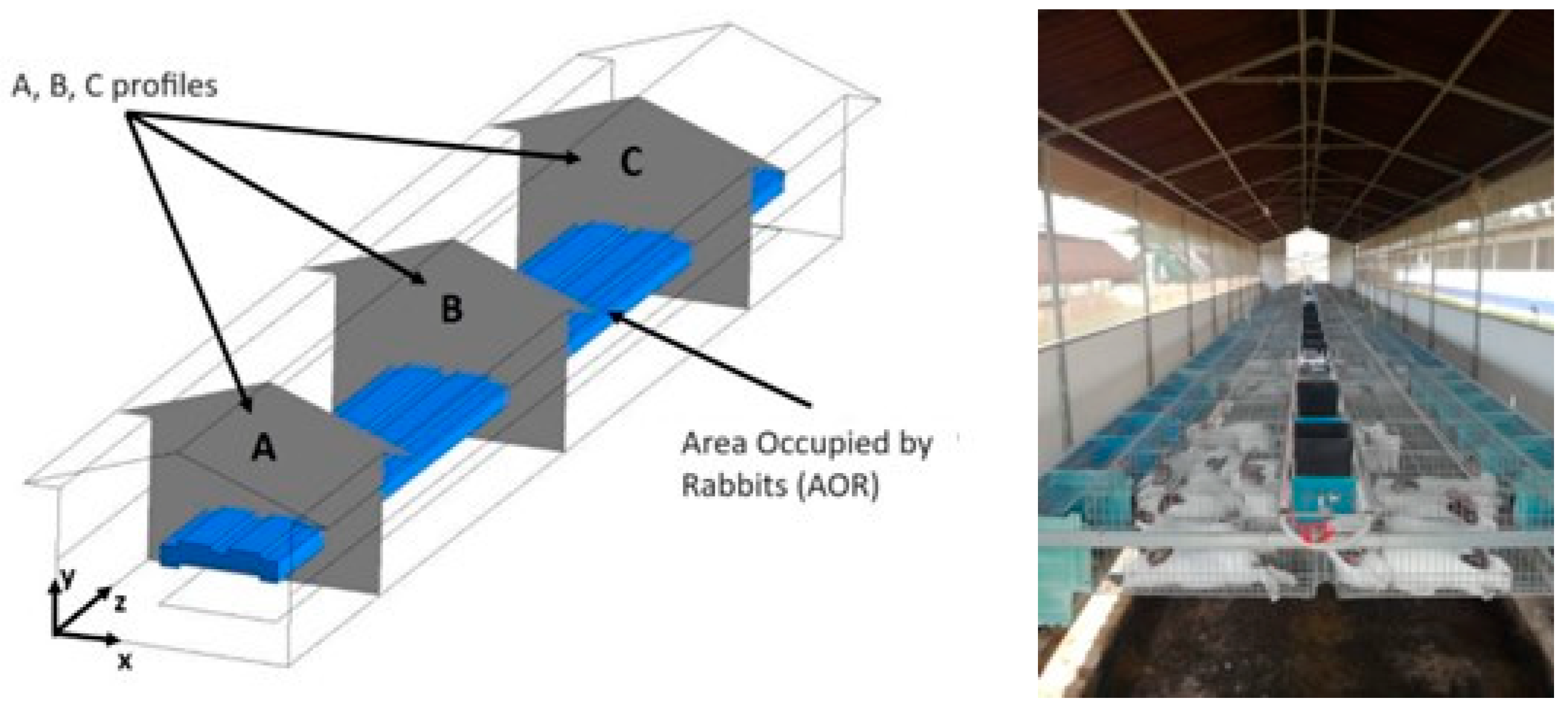

3.3. Vertical Variation of Ammonia Concentration and Air Temperature

3.3.1. Ammonia and Temperature in Cross Section A

3.3.2. Ammonia and Temperature in Cross Section B

3.3.3. Ammonia and Temperature in Cross Section C

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ngwabie, N.M.; Jeppsson, K.-H.; Nimmermark, S.; Swensson, C.; Gustafsson, G. Multi-location measurements of greenhouse gases and emission rates of methane and ammonia from a naturally-ventilated barn for dairy cows. Biosyst. Eng. 2009, 103, 68–77. [Google Scholar] [CrossRef]

- Calvet, S.; Campelo, J.C.; Estellés, F.; Perles, A.; Mercado, R.; Serrano, J.J. Suitability evaluation of multipoint simultaneous CO2 sampling wireless sensors for livestock buildings. Sensors 2014, 14, 10479–10496. [Google Scholar] [CrossRef] [PubMed]

- Kwon, K.S.; Lee, I.B.; Ha, T. Identification of key factors for dust generation in a nursery pig house and evaluation of dust reduction efficiency using a CFD technique. Biosyst. Eng. 2016, 151, 28–52. [Google Scholar] [CrossRef]

- Bodnar, K.; Makra, L.; Bodnar, G.; Privoczki, Z.I. A review on environmental management of rabbit production. Agricultural Management/Lucrari Stiintifice Seria I. Manag. Agricol. 2019, XXI, 5–12. [Google Scholar]

- Marai, I.F.; Habeeb, A.A.; Gad, A. Rabbits’ productive, reproductive and physiological performance traits as affected by heat stress: A review. Livest. Prod. Sci. 2002, 78, 71–90. [Google Scholar] [CrossRef]

- Marai, I.F.M.; Ayyat, M.S.; Abd El-Monem, U.M. Growth performance and reproductive traits at first parity of New Zealand White female rabbits as affected by heat stress and its alleviation under Egyptian conditions. Trop. Anim. Health Prod. 2001, 33, 451–462. [Google Scholar] [CrossRef] [PubMed]

- Drewry, J.L.; Choi, C.Y.; Powell, J.M.; Luck, B.D. Computational model of methane and ammonia emissions from dairy barns: Development and validation. Comput. Electron. Agric. 2018, 149, 80–89. [Google Scholar] [CrossRef]

- Krupa, S. Effects of atmospheric ammonia (NH3) on terrestrial vegetation: A review. Environ. Pollut. 2003, 124, 179–221. [Google Scholar] [CrossRef] [PubMed]

- Norton, T.; Grant, J.; Fallon, R.; Sun, D.W. Assessing the ventilation effectiveness of naturally ventilated livestock buildings under wind dominated conditions using computational fluid dynamics. Biosyst. Eng. 2009, 103, 78–99. [Google Scholar] [CrossRef]

- Wu, W.; Zhai, J.; Zhang, G.; Nielsen, P.V. Evaluation of methods for determining air exchange rate in a naturally ventilated dairy cattle building with large openings using computational fluid dynamics (CFD). Atmos. Environ. 2012, 63, 179–188. [Google Scholar] [CrossRef]

- Bjerg, B.; Svidt, K.; Zhang, G.; Morsing, S. SE–Structures and Environment: The Effects of Pen Partitions and Thermal Pig Simulators on Airflow in a Livestock Test Room. J. Agric. Eng. Res. 2000, 77, 317–326. [Google Scholar] [CrossRef]

- Li, H.; Rong, L.; Zong, C.; Zhang, G. Assessing response surface methodology for modelling air distribution in an experimental pig room to improve air inlet design based on computational fluid dynamics. Comput. Electron. Agric. 2017, 141, 292–301. [Google Scholar] [CrossRef]

- Bjerg, B.; Rong, L.; Zhang, G. Computational prediction of the effective temperature in the lying area of pig pens. Comput. Electron. Agric. 2018, 149, 71–79. [Google Scholar] [CrossRef]

- Li, H.; Rong, L.; Zhang, G. Numerical study on the convective heat transfer of fattening pig in groups in a mechanical ventilated pig house. Comput. Electron. Agric. 2018, 149, 90–100. [Google Scholar] [CrossRef]

- Rong, L.; Bjerg, B.; Zhang, G. Assessment of modeling slatted floor as porous medium for prediction of ammonia emissions—Scaled pig barns. Comput. Electron. Agric. 2015, 117, 234–244. [Google Scholar] [CrossRef]

- Rong, L.; Aarnink, A.J.A. Development of ammonia mass transfer coefficient models for the atmosphere above two types of the slatted floors in a pig house using computational fluid dynamics. Biosyst. Eng. 2019, 183, 13–25. [Google Scholar] [CrossRef]

- Norton, T.; Grant, J.; Fallon, R.; Sun, D.W. Improving the representation of thermal boundary conditions of livestock during CFD modelling of the indoor environment. Comput. Electron. Agric. 2010, 73, 17–36. [Google Scholar] [CrossRef]

- Rojano, F.; Mondaca, M.; Choi, C.Y. Feasibility of a dual cooling system for dairy cows in arizona. In Proceedings of the ASABE Meeting, Louisville, KY, USA, 7–10 August 2011. [Google Scholar] [CrossRef]

- Mondaca, M.R.; Choi, C.Y.; Cook, N.B. Understanding microenvironments within tunnel-ventilated dairy cow freestall facilities: Examination using computational fluid dynamics and experimental validation. Biosyst. Eng. 2019, 183, 70–84. [Google Scholar] [CrossRef]

- Gebremedhin, K.G.; Wu, B.; Perano, K. Modeling conductive cooling for thermally stressed dairy cows. J. Therm. Biol. 2016, 56, 91–99. [Google Scholar] [CrossRef]

- Fidaros, D.; Baxevanou, C.; Bartzanas, T.; Kittas, C. Numerical study of mechanically ventilated broiler house equipped with evaporative pads. Comput. Electron. Agric. 2018, 149, 101–109. [Google Scholar] [CrossRef]

- Rojano, F.; Bournet, P.E.; Hassouna, M.; Robin, P.; Kacira, M.; Choi, C.Y. Computational modelling of thermal and humidity gradients for a naturally ventilated poultry house. Biosyst. Eng. 2016, 151, 273–285. [Google Scholar] [CrossRef]

- Rojano, F.; Bournet, P.E.; Hassouna, M.; Robin, P.; Kacira, M.; Choi, C.Y. Modelling the impact of air discharges caused by natural ventilation in a poultry house. Biosyst. Eng. 2019, 180, 168–181. [Google Scholar] [CrossRef]

- Blanes-Vidal, V.; Guijarro, E.; Balasch, S.; Torres, A.G. Application of computational fluid dynamics to the prediction of airflow in a mechanically ventilated commercial poultry building. Biosyst. Eng. 2008, 100, 105–116. [Google Scholar] [CrossRef]

- Du, L.; Yang, C.; Dominy, R.; Yang, L.; Hu, C.; Du, H.; Li, Q.; Yu, C.; Xie, L.; Jiang, X. Computational Fluid Dynamics aided investigation and optimization of a tunnel-ventilated poultry house in China. Comput. Electron. Agric. 2019, 159, 1–15. [Google Scholar] [CrossRef]

- Tong, X.; Hong, S.W.; Zhao, L. CFD modeling of airflow, thermal environment, and ammonia concentration distribution in a commercial manure-belt layer house with mixed ventilation systems. Comput. Electron. Agric. 2019, 162, 281–299. [Google Scholar] [CrossRef]

- Flores-Velázquez, J.; Villarreal-Guerrero, F.; Ojeda, W.; Ruíz-García, A. Thermal and ammonia concentration gradients in a rabbit barn with two ventilation system designs. Rev. Bras.Eng. Agric. Ambirnt. 2017, 21, 134–140. [Google Scholar] [CrossRef][Green Version]

- Jin, N.; Zheng, M.; Chen, J.; Duan, E.; Kong, D.; Wang, H.; Fang, P. Study on the indoor environmental simulation and optimal design of rabbit houses in winter based on CFD. In Proceedings of the 2018 ASABE Annual International Meeting, Detroit, MI, USA, 29 July–1 August 2018; p. 1. [Google Scholar] [CrossRef]

- Jáuregui Ostos, E.; Vidal Bello, J. Investigaciones geográficas: Boletín del Instituto de Geografía. En Investigaciones geográficas. 1990. Available online: http://www.scielo.org.mx/scielo.php?script=sci_arttext&pid=S0188-46111981000100002 (accessed on 16 November 2023).

- COLPOS. Normales Climatológicas. 2019. Available online: http://www.cm.colpos.mx/meteoro/repor2/nrm15c.htm (accessed on 12 February 2019).

- Rojano, F.; Bournet, P.E.; Hassouna, M.; Robin, P.; Kacira, M.; Choi, C.Y. Modelling heat and mass transfer of a broiler house using computational fluid dynamics. Biosyst. Eng. 2015, 136, 25–38. [Google Scholar] [CrossRef]

- Biswas, R.; Strawn, R.C. Tetrahedral and hexahedral mesh adaptation for CFD problems. Appl. Numer. Math. 1998, 26, 135–151. [Google Scholar] [CrossRef]

- Calvet, S.; Cambra-López, M.; Estellés Barber, F.; Torres, A.G. Characterization of the indoor environment and gas emissions in rabbit farms. World Rabbit Sci. 2011, 19, 49–61. [Google Scholar] [CrossRef]

- Beurskens, A.G.C.; Hol, J.M.G. Onderzoek naar de ammoniak- en geuremissie van stallen LXI: Stal voor vleeskalveren (witvlees productie). In Agrotechnology & Food Innovations B.V.; Agrotechnology & Food Sciences Group: Wageningen, The Netherlands, 2004. [Google Scholar]

- Versteeg, H.K.; Malalasekera, W. An Introduction to Computational Fluid Dynamics: The Finite Volume Method; Pearson Education Ltd.: Edinburgh, UK, 2007. [Google Scholar]

| Sensor | Coordinate (x, y, z) in Meters | |||

|---|---|---|---|---|

| DHT22 | 1.—(2.0, 1.1, 2.0) | 2.—(2.0, 1.1, 4.5) | 3.—(3.0, 1.1, 7.0) | 4.—(2.0, 1.1, 7.0) |

| 5.—(1.0, 1.1, 7.0) | 6.—(2.0, 1.1, 9.5) | 7.—(2.0, 2.1, 12.0) | 8.—(2.0, 1.1, 12.0) | |

| 9.—(2.0, 0.1, 12.0) | 10.—(2.0, 1.1, 14.5) | 11.—(2.0, 1.1, 17.0) | 12.—(2.0, 1.1, 19.5) | |

| 13.—(2.0, 1.1, 22.0) | ||||

| MQ-137 | 1.—(2.0, 1.1, 2.0) | 2.—(2.0, 1.1, 7.0) | 3.—(2.0, 2.1, 12.0) | 4.—(2.0, 0.1, 12.0) |

| 5.—(2.0, 1.1, 17.0) | 6.—(2.0, 1.1, 22.0) | |||

| Boundary | Type | Condition |

|---|---|---|

| Entry | Velocity inlet | Temperature: 17 °C; wind speed: 0.25 m s−1 Wind direction: 161° components (x = −0.87, y = 0, z = −0.48) |

| Exit | Pressure outlet | Pressure: 0 Pa |

| Outside air | interior | Air |

| Outside soil | Wall | Soil |

| Floor | Wall | Concrete; temperature: 19.8 °C |

| Collector | Wall | Temperature: 34.8 °C; ammonia: 15.4 ppm = 0.0154 g kg−1 |

| Indoor air | Interior | Air |

| Ceiling | Wall | Wood; thickness: 0.5 cm; temperature: 23.8 °C |

| Walls | Wall | Wood; thickness: 1 cm |

| Windows | Porous jump | Mesh; permeability: 3.98 × 10−9 (m2); thickness: 0.0032 (m) Drag coefficient: 19,185.7 (m−1) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cano, D.V.; Flores-Velazquez, J.; Garcia, A.R. Natural Ventilation to Manage Ammonia Concentration and Temperature in a Rabbit Barn in Central Mexico. Appl. Sci. 2024, 14, 3767. https://doi.org/10.3390/app14093767

Cano DV, Flores-Velazquez J, Garcia AR. Natural Ventilation to Manage Ammonia Concentration and Temperature in a Rabbit Barn in Central Mexico. Applied Sciences. 2024; 14(9):3767. https://doi.org/10.3390/app14093767

Chicago/Turabian StyleCano, David Vargas, Jorge Flores-Velazquez, and Agustín Ruiz Garcia. 2024. "Natural Ventilation to Manage Ammonia Concentration and Temperature in a Rabbit Barn in Central Mexico" Applied Sciences 14, no. 9: 3767. https://doi.org/10.3390/app14093767

APA StyleCano, D. V., Flores-Velazquez, J., & Garcia, A. R. (2024). Natural Ventilation to Manage Ammonia Concentration and Temperature in a Rabbit Barn in Central Mexico. Applied Sciences, 14(9), 3767. https://doi.org/10.3390/app14093767