Evolution Law and Grouting Treatment of Water Inrush in Hydraulic Tunnel Approaching Water-Rich Fault: A Case Study

Abstract

1. Introduction

2. Tunnel Description and Geological Conditions

3. DEM-Based Analysis of the Catastrophic Process of Water Inrush at the Face of the Tunnel Adjacent to the Water-Rich Fault

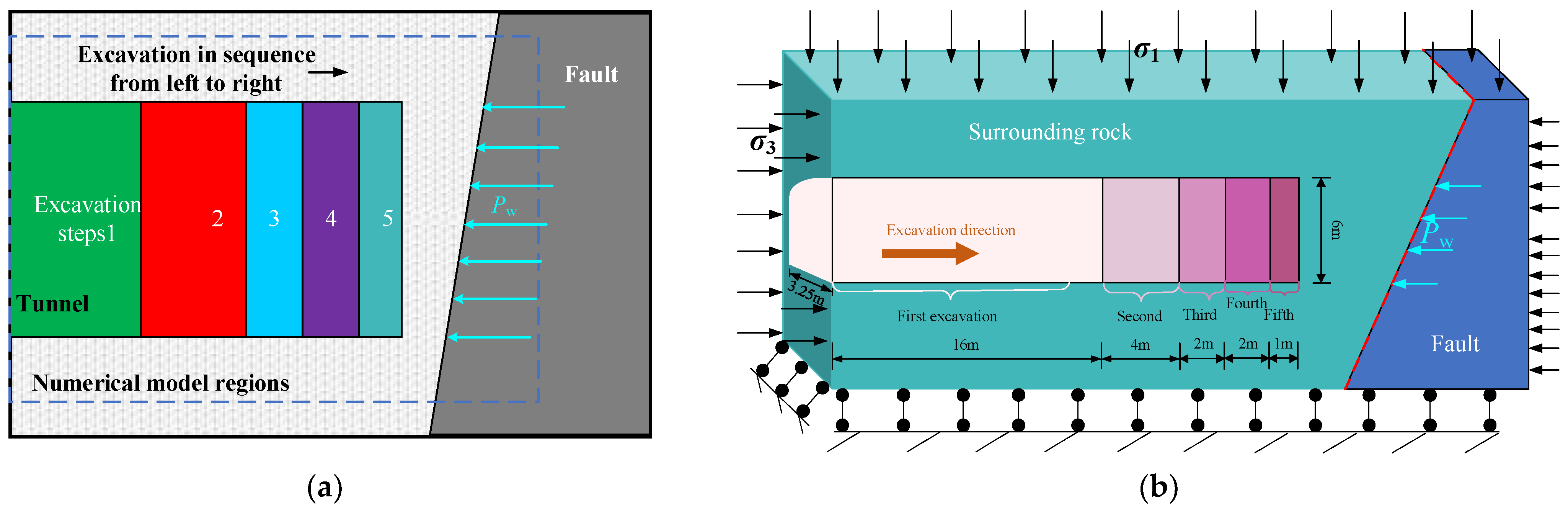

3.1. DEM-Based Numerical Simulation

3.2. Establishment of the DEM-Based Computational Model

3.3. Catastrophic Law of Water Inrush of the Water-Resistant Rock Mass at the Tunnel Face Induced by Water-Rich Fault

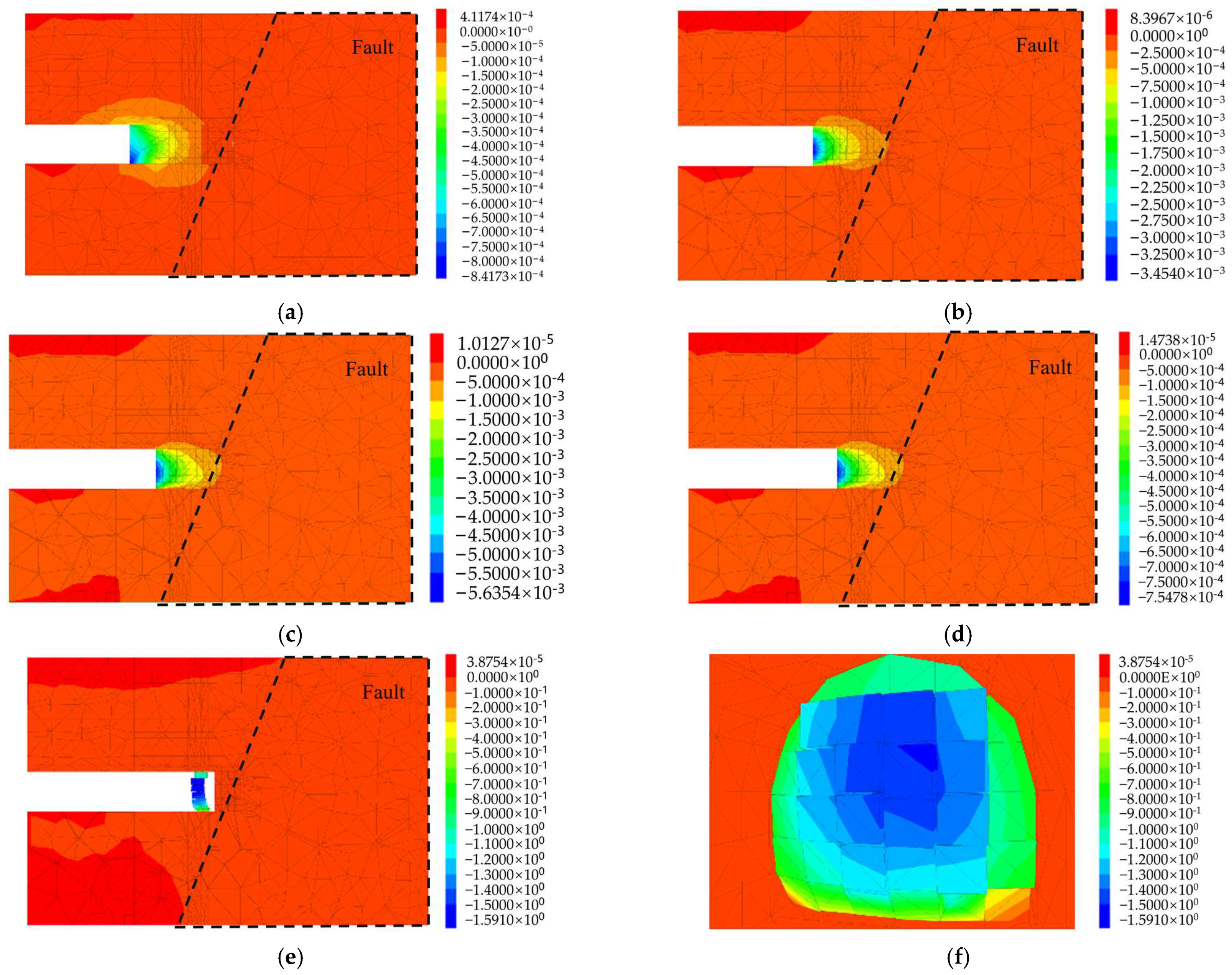

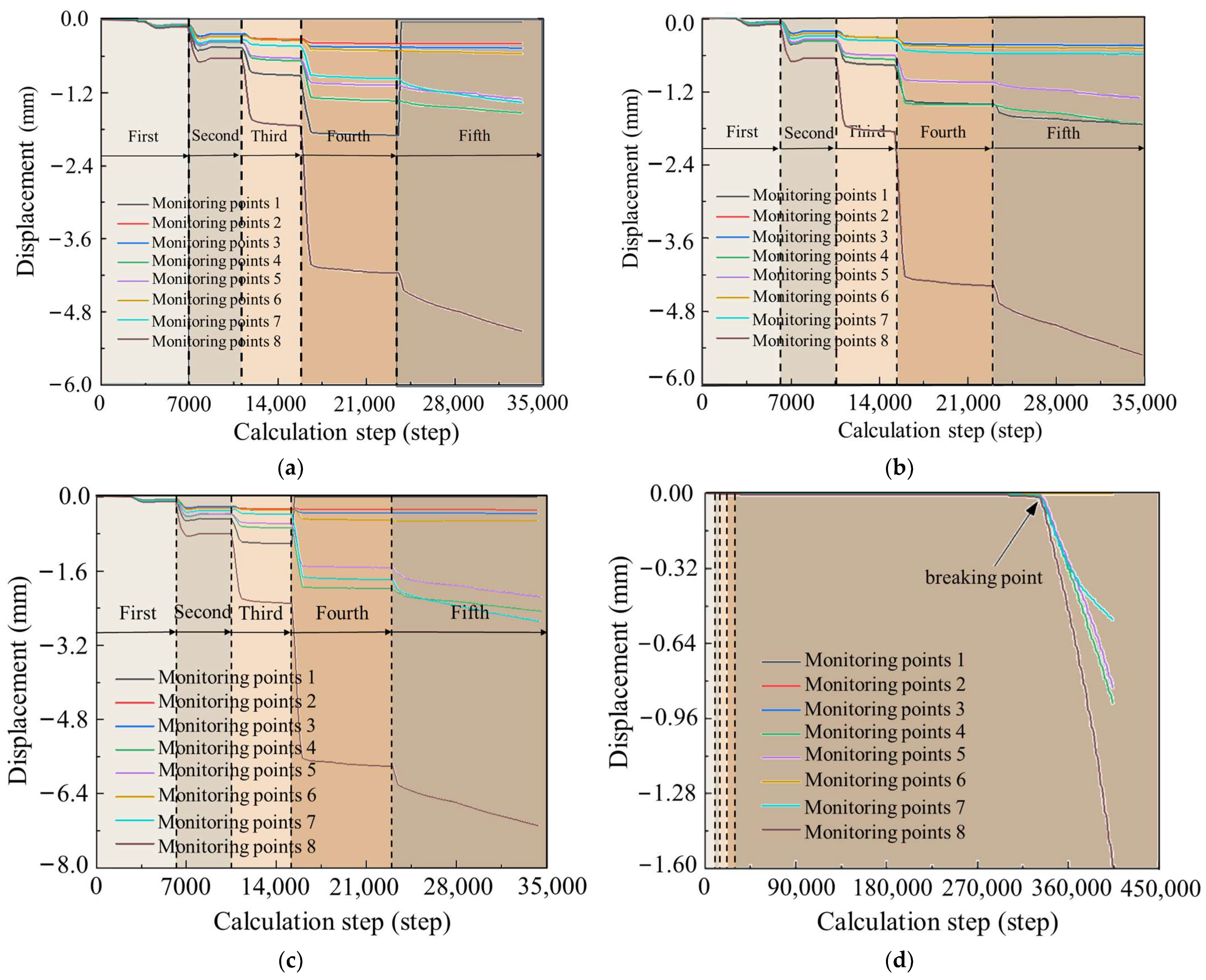

3.3.1. Change Rule of Displacement Field

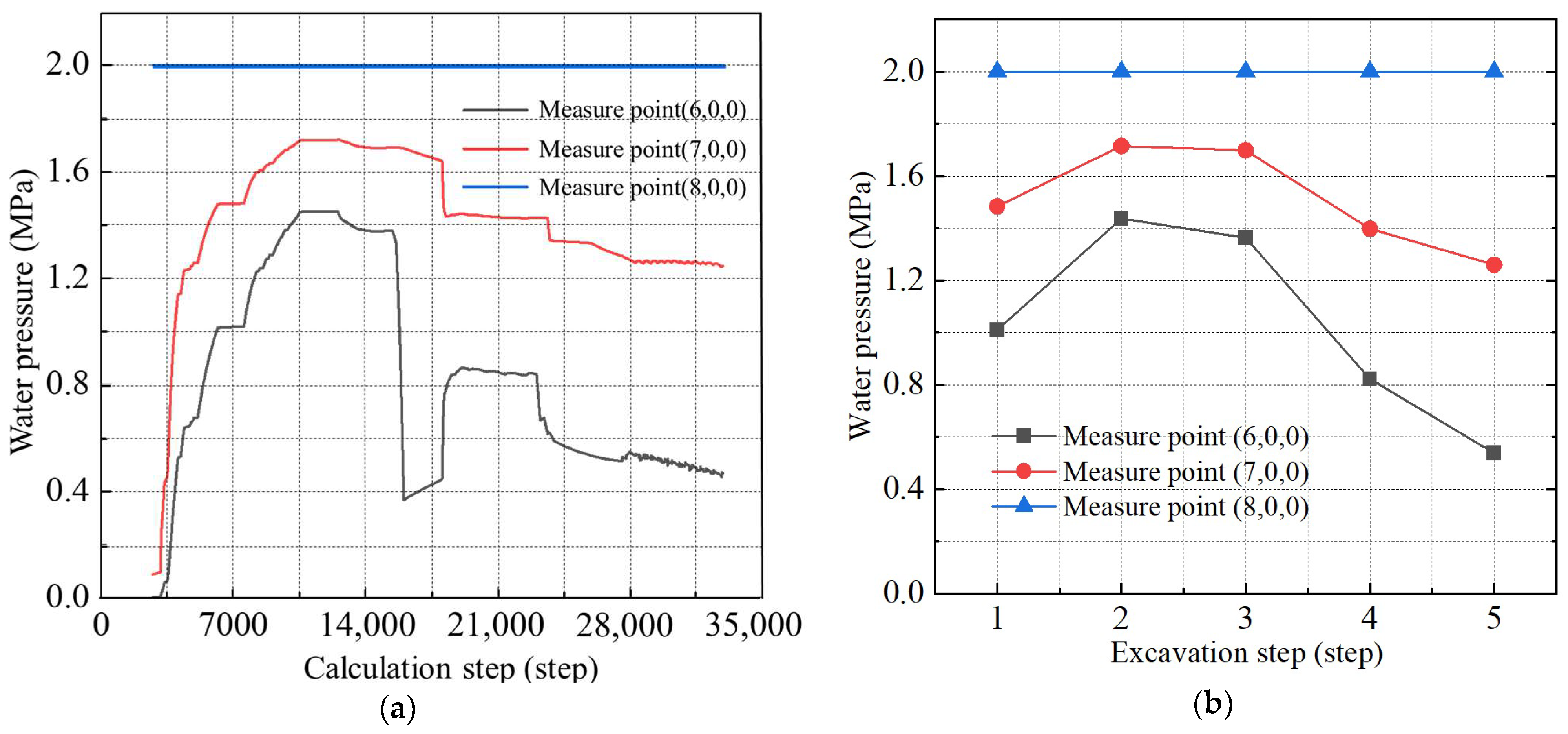

3.3.2. Change Rule of Seepage Pressure Field

4. Prevention and Control Measures for Water Inrush at the Face of the Tunnel Adjacent to the Water-Rich Fault and Its Effectiveness

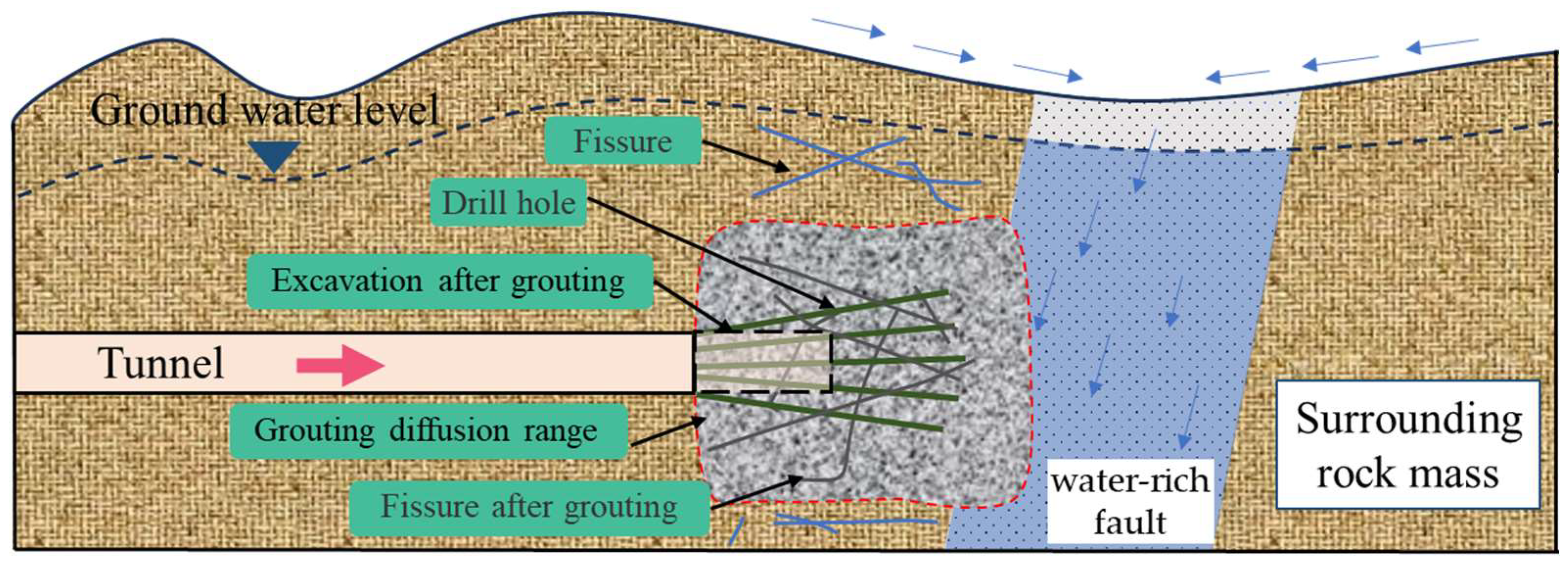

4.1. Prevention and Control Measures of Water Inrush in the 2# Adit of Xianglushan Tunnel

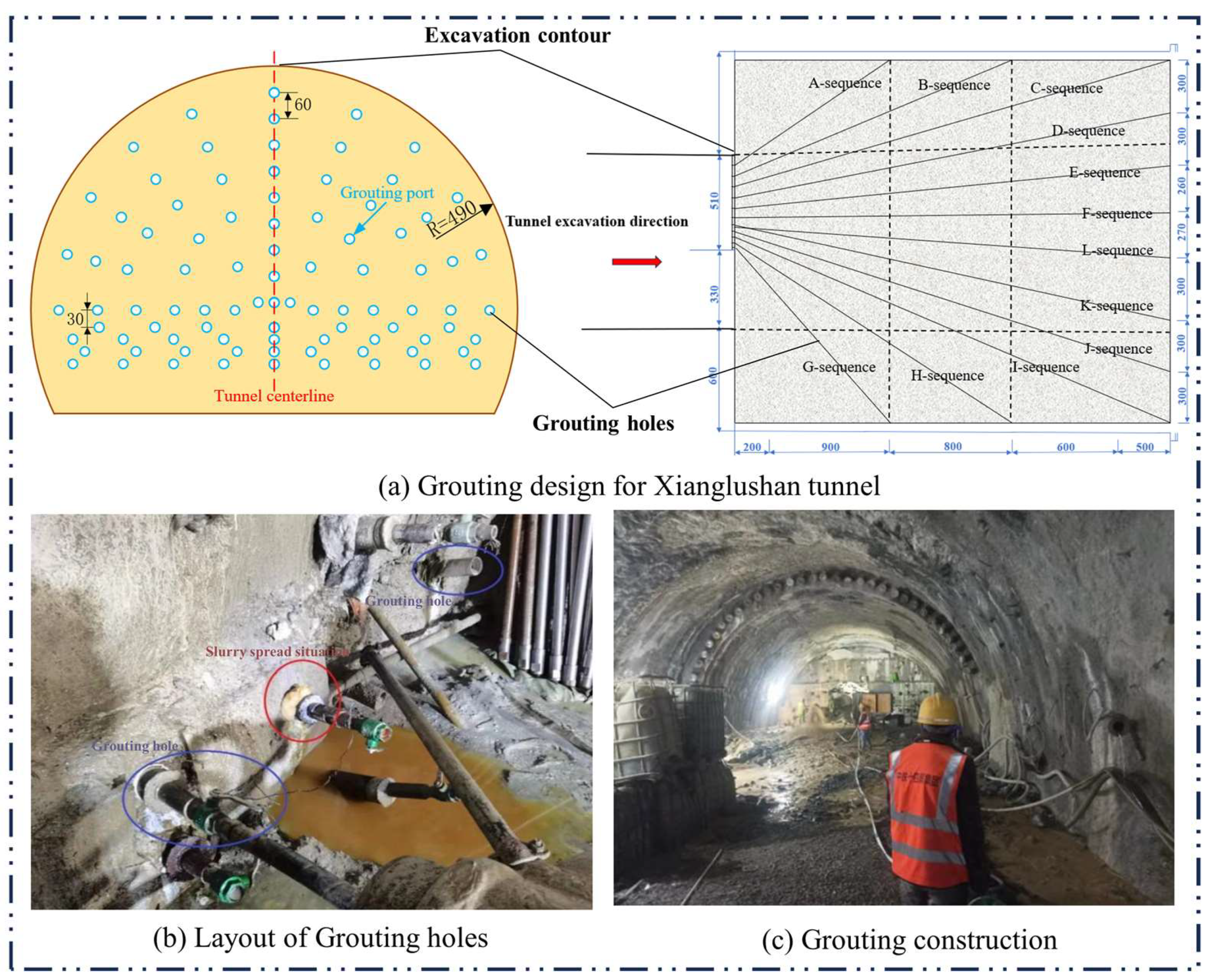

4.2. Grouting Scheme for 2# Adit of Xianglushan Tunnel

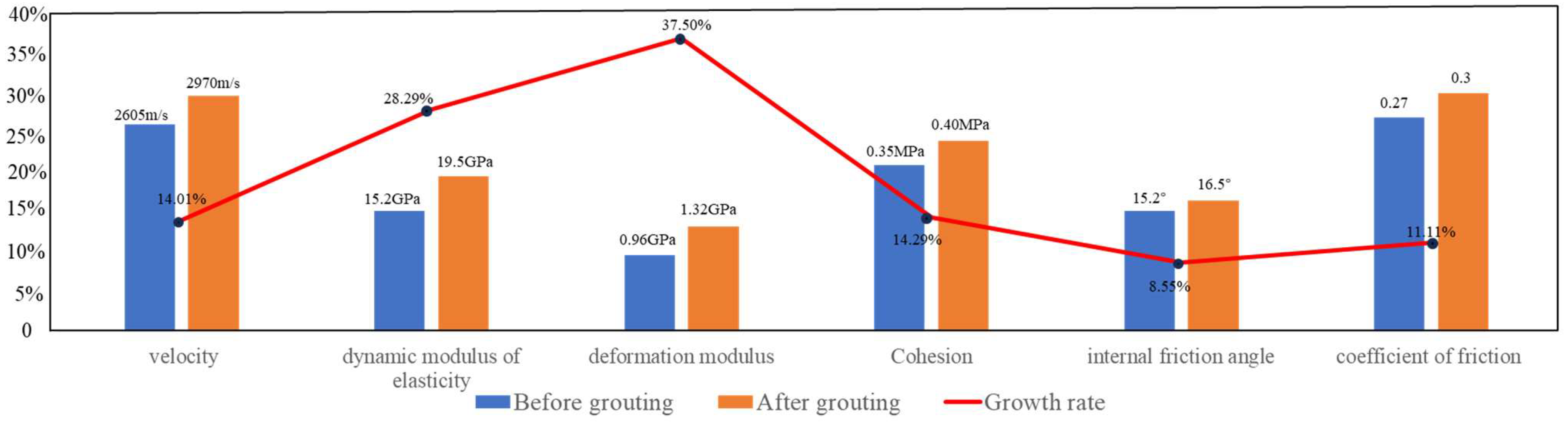

4.3. Effectiveness Analysis of Grouting Treatment

5. Discussion

5.1. The Spatial Effect of the Tunnel Approaching Water-Rich Fault

5.2. Disposal Measures for the Tunnel Approaching the Water-Rich Fault

5.2.1. Advanced Geological Prediction and Detection

5.2.2. Advance Support

5.2.3. Advance Pressure Relief

5.2.4. Advanced Grouting

6. Conclusions

- (1)

- As the tunnel face approached the water-rich fault fracture zone, the displacement at each monitoring point in the water-resistant rock mass increased continuously. The closer the tunnel was to the fault, the greater the increase rate of the displacement was at each monitoring point in the water-resistant rock mass. When the tunnel was excavated to the position 5 m from the fault, a sudden displacement of the center of the face was observed. The water-resistant rock mass ahead of the face was damaged, and the tunnel was subjected to a water inrush disaster. The recommended safety thickness of the water-resistant rock mass was 5–6 m.

- (2)

- When the tunnel face was far away from the fault, the water-resistant rock mass at the face was less affected by the water pressure, and it was in a relatively stable state. As the tunnel face approached the fault, water seepage from the fault occurred, and the water entered the water-resistant rock mass through the fissures. Since the face was jointly affected by excavation disturbance and fissure water pressure, the water pressure encountered a slow decline trend with the excavation of the face.

- (3)

- The middle bench of the 2# adit of Xianglushan tunnel was first excavated and supported to the face, and a grouting wall was applied to the face. The range of the grouting reinforcement circle was 6 m outside the excavation profile, and the length of cyclic grouting was 30 m. The length of cyclic excavation was 25 m, and a 5 m long grouting rock disc was retained in each cycle. Grouting slurry was cement slurry with a water–cement mass ratio (W/C ratio) of 0.5–1:1.

- (4)

- The evaluation of the grouting effect by means of drilling acoustic wave, drilling TV, and radar detection confirmed that the grouting treatment scheme had an excellent reinforcement effect on the rock mass. The deformation modulus of the rock mass after grouting was increased by 37–53%. The rock mass possessed a better elastic deformation capacity to external loads, which slowed down the deformation process of the rock mass. The shear strength parameters (cohesion c and friction coefficient tanφ) were increased by 10–14%, which enhanced the overall adhesion and improved the shear and sliding resistance of the rock mass.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhang, Y.J.; Pu, S.J.; Zhou, H.; Wang, J.G.; Wu, S.C.; Ding, X.L. Research progress on key technologies for safe construction and efficient operation of the Dianzhong water diversion project-underground engineering. Chin. J. Rock Mech. Eng. 2024, 43, 333–357. [Google Scholar]

- Tu, W.F.; Li, L.P.; Cheng, S.; Chen, D.Y.; Yuan, Y.C.; Chen, Y.H. Evolution mechanism, monitoring, and early warning method of water inrush in deep-buried long tunnel. Geofluids 2021, 2021, e2023782. [Google Scholar] [CrossRef]

- Liu, N.; Pei, J.H.; Cao, C.Y.; Liu, X.Y.; Huang, Y.X.; Mei, G.X. Geological investigation and treatment measures against water inrush hazard in karst tunnels: A case study in Guiyang, southwest China. Tunn. Undergr. Space Technol. 2022, 124, 104491. [Google Scholar] [CrossRef]

- Wang, H.T.; Liu, P.; Liu, C.; Zhang, X.; Yang, Y.; Li, Y. Three-dimensional upper bound limit analysis on the collapse of shallow soil tunnels considering root stratification and pore water pressure. Math. Probl. Eng. 2019, 2019, 8164702. [Google Scholar] [CrossRef]

- Senent, S.; Jimenez, R. A tunnel face failure mechanism for layered ground, considering the possibility of partial collapse. Tunn. Undergr. Space Technol. 2015, 47, 182–192. [Google Scholar] [CrossRef]

- Song, R.G.; Zhang, D.L.; Wen, M. The cusp catastrophe theory analysis for instability of deep-buried tunnels surrounding rock through fault fracture zone. Chin. Civ. Eng. J. 2015, 48, 289–292. [Google Scholar]

- Zhang, L.W.; Wu, J.; Zhang, X.Y. Mechanism of water inrush from the tunnel face induced by fault and its application. J. Cent. South Univ. 2023, 30, 934–946. [Google Scholar] [CrossRef]

- Meng, F.S.; Wang, Y.C.; Jiao, Q.L.; Wang, Y.M.; Li, C.Y. Analysis of the minimum safe thickness of water inrush in fault fracture zone based on the silo theory. J. Harb. Inst. Technol. 2020, 52, 89–95. [Google Scholar]

- Guo, J.Q.; Li, H.F.; Chen, F.; He, Z.Y. Theoretical analysis on water-resisting thickness of karst tunnel face. Chin. J. Undergr. Space Eng. 2017, 13, 1373–1380. [Google Scholar]

- Wang, M.X.; Yang, W.M.; Zhou, Z.Q.; Li, L.P.; Yang, G.; Li, Z.H.; Sun, J.W. Experimental research on the effect of particle migration of a filling medium in a fault during water and mud inrush. Arab. J. Geosci. 2021, 14, 2206. [Google Scholar] [CrossRef]

- Wang, Y.C.; Chen, F.; Sui, W.H.; Meng, F.S.; Geng, F. Large-scale model test for studying the water inrush during tunnel excavation in fault. Bull. Eng. Geol. Environ. 2022, 81, 238. [Google Scholar] [CrossRef]

- Zhang, Q.S.; Jiang, Q.C.; Zhang, X.; Wang, D.M. Model test on development characteristics and displacement variation of water and mud inrush on tunnel in fault fracture zone. Nat. Hazards 2019, 99, 467–492. [Google Scholar] [CrossRef]

- Sun, W.B.; Hao, J.B.; Dai, X.Z.; Kong, L.J. Characteristics of the development mechanism of mining-induced fault fracture zone. Coal Geol. Expl. 2024, 2024, 1–8. [Google Scholar]

- Zhang, Q.Y.; Chen, Z.W.; Yuan, J.Q.; Liu, Q.; Rong, C. Experimental study on evolution characteristics of water and mud inrush in fault fractured zone. Rock Soil Mech. 2020, 41, 1911–1922+1932. [Google Scholar]

- Wang, Y.C.; Jing, H.W.; Su, H.J.; Xie, J.Y. Effect of a fault fracture zone on the stability of tunnel-surrounding rock. Int. J. Geomech. 2017, 17, 04016135. [Google Scholar] [CrossRef]

- Zhang, J.Q.; Li, S.C.; Zhang, Q.S.; Zhang, X.; Li, P.; Wang, D.M.; Weng, X.J. Mud inrush flow mechanisms: A case study in a water-rich fault tunnel. Bull. Eng. Geol. Environ. 2019, 78, 6267–6283. [Google Scholar] [CrossRef]

- Li, X.; Xue, Y.; Zhang, Z.H. Progressive evolution model of fault water inrush caused by underground excavation based on multiphysical fields. Geofluids 2023, 2023, 8870126. [Google Scholar] [CrossRef]

- Fu, H.L.; An, P.T.; Li, K.; Li, j.; Cheng, G.W.; Zhang, G.B. Analysis on the process of tunnel passing through high-pressurefault fractured zone with abundant water rich. Mod. Tunn. Tech. 2020, 57, 458–465. [Google Scholar]

- Zhang, Y.J.; Dong, J.X.; Zhou, Z.Q.; Zhou, L.S.; Mi, J. Water and sand inrush evolution and minimum safe thickness of waterproof-resistant slab in sandy dolomite tunnels near the faults. Chin. J. Rock Mech. Eng. 2024, 43, 639–652. [Google Scholar]

- Wang, J.; Cui, J.Y.; Chen, Z.L.; Li, Q.; Guo, Z.B. Prediction formula of critical safety thickness of tunnel water inrush in water-rich fault zone. Tunn. Constr. 2021, 41, 256–264. [Google Scholar]

- Zhang, Y.J.; Zhang, Z.W.; Xiao, J.; Li, Y.W.; Yu, Q.G. Study on mining water inrush mechanism of buried fault under coal seam floor above confined water body. Coal Sci. Tech. 2023, 51, 283–291. [Google Scholar]

- Xie, Q.; Cao, Z.L.; Sun, W.C.; Fumagalli, A.; Fu, X.; Wu, Z.H.; Wu, K. Numerical simulation of the fluid-solid coupling mechanism of water and mud inrush in a water-rich fault tunnel. Tunn. Unde. Space Tech. 2023, 131, 104796. [Google Scholar] [CrossRef]

- Chen, L.L.; Wang, Y.Q.; Wang, Z.F.; Fan, F.F.; Liu, Y. Characteristics and treatment measures of tunnel collapse in fault fracture zone during rainfall: A case study. Eng. Fail. Anal. 2023, 145, 107002. [Google Scholar] [CrossRef]

- Zhang, X.H.; Fu, P.; Yin, J.M.; Liu, Y.K. In-situ stress characteristics and active tectonic response of Xianglushan tunnel of Middle Yunnan Water Diversion Project. Chin. J. Geo. Eng. 2021, 43, 130–139. [Google Scholar]

- Xiao, W.B.; Xie, Y.B.; Zheng, Y.; Wu, K.; Chen, R.; Li, Q.L.; Cheng, R.Z. Deformation failure and damage evolution of urban metro tunnels under active faults. J. Shandong Univ. 2023, 53, 1–13. [Google Scholar]

- Xiao, G.Z. Problems of railway tunnel construction under some special geological conditions in China and their countermeasures. Tunn. Constr. 2019, 39, 1748–1758. [Google Scholar]

- Zhang, M.Q.; He, Z.J.; Huang, H.J.; Ren, S.Q.; Shan, H.Y. Causal analysis and governance of the water & mud bursting in Daliang tunnel on Lanzhou-Xinjiang second railway. J. Rail. Eng. Soc. 2015, 32, 77–80. [Google Scholar]

- Dai, Z.R.; Hu, R.Q.; Wang, Z.Y.; Zhao, Q.C. Mechanism and treatment measures of water and sand inrush in operational tunnel in karst area. Tunn. Constr. 2023, 43, 369–377. [Google Scholar]

- Guo, Q.J. Countermeasures and construction optimization against the water inrush event in a water-rich tunnel section. Mod. Tunn. Technol. 2020, 57, 219. [Google Scholar]

- Huang, K.; An, Y.L.; Yue, J.; Zeng, X.C.; Li, J.H.; Zhang, Y.J.; Wang, D. Influence of seepage force on tunnel face stability by new Austria tunneling method. J. Cent. South Univ. (Sci. Tech.) 2019, 50, 1221–1228. [Google Scholar]

- Ma, W.B. Development and prospect of key technology of drilling and blasting for railway mountain tunnels. J. Chin. Rail. Soc. 2022, 44, 64–85. [Google Scholar]

- Wang, B.J. Advanced geological prediction detection system for tunnel in karst areas and its application. Rail. Constr. Technol. 2023, 3, 148–151. [Google Scholar]

| Volumetric Weight γ (kN/m³) | Bulk Modulus K (GPa) | Shear Modulus G (GPa) | Poisson’s Ratio ν | Cohesion c | Internal Friction Angle φ (°) | |

|---|---|---|---|---|---|---|

| Rock mass | 2000 | 1.44 | 19.4 | 0.25 | 0.35 | 28.6 |

| Fault fracture zone | 1800 | 0.48 | 6.4 | 0.25 | 0.12 | 28.6 |

| Normal Stiffness kn (GPa) | Shear Stiffness ks (GPa) | Internal Friction Angle φ (°) | Cohesive Force (MPa) | Tensile Strength σb (MPa) | |

|---|---|---|---|---|---|

| Joint | 18.6 | 6.2 | 30 | 0.5 | 0.45 |

| Number | Segment Position/m | Segment Length/m | Permeability Rate/Lu | Reduction Rate | |

|---|---|---|---|---|---|

| Before grouting | CGJ10-32 | 1.1~3.1 | 2.0 | 3.07 | 23.14% |

| CGJ11-32 | 1.0~3.0 | 2.0 | 3.93 | ||

| After grouting | Inspection hole | 1.3~3.3 | 2.0 | 2.69 | |

| Before grouting | CGJ11-32 | 6.0~11.0 | 5.0 | 4.72 | 48.31% |

| After grouting | Inspection hole | 6.3~10.0 | 3.7 | 2.44 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gu, J.; Guo, J.; Chen, F.; Li, J. Evolution Law and Grouting Treatment of Water Inrush in Hydraulic Tunnel Approaching Water-Rich Fault: A Case Study. Appl. Sci. 2024, 14, 3407. https://doi.org/10.3390/app14083407

Gu J, Guo J, Chen F, Li J. Evolution Law and Grouting Treatment of Water Inrush in Hydraulic Tunnel Approaching Water-Rich Fault: A Case Study. Applied Sciences. 2024; 14(8):3407. https://doi.org/10.3390/app14083407

Chicago/Turabian StyleGu, Jiheng, Jiaqi Guo, Fan Chen, and Jianhe Li. 2024. "Evolution Law and Grouting Treatment of Water Inrush in Hydraulic Tunnel Approaching Water-Rich Fault: A Case Study" Applied Sciences 14, no. 8: 3407. https://doi.org/10.3390/app14083407

APA StyleGu, J., Guo, J., Chen, F., & Li, J. (2024). Evolution Law and Grouting Treatment of Water Inrush in Hydraulic Tunnel Approaching Water-Rich Fault: A Case Study. Applied Sciences, 14(8), 3407. https://doi.org/10.3390/app14083407