Abstract

Additive manufacturing (AM) technologies provide significant design freedom, which is highly desirable in today’s fast-paced product design processes. However, most of the parametric CAD software tools used today do not fully utilize this potential for freedom of form and design. Design mechanisms, such as topology optimization (TO), generative design (GD), and lattice structures, are available on the market to help designers minimize weight and material cost while maximizing the stiffness and flexibility of planned designs. This paper proposes a benchmarking approach for designers and engineers to select a suitable software tool for lattice structure generation for their specific applications. The approach includes preselecting software tools based on a weighted point evaluation of seven significant criteria. The tools are then evaluated based on key metrics such as computing time and file size of exported structures, as well as the following six distinctive attributes: usability, reliability, availability, performance, support, and cost. The evaluation process considers a total of 32 defined features. The investigation produced clear recommendations regarding overall performance, reliability, and user experience. The findings indicate that the option of a comprehensive support offering, as well as the initial and operational costs, are significant drivers in the decision-making process.

1. Introduction

Additive manufacturing (AM) technologies are leading many different industries to rethink traditional production possibilities and enable even small batches to be manufactured in a cost- and material-efficient manner. Compared with traditional manufacturing processes such as machining, the use of fewer primary materials, thereby being more resource-efficient, as well as the elimination of chips and harmful process additives, such as cutting fluids—a major source of hazardous production waste threatening terrestrial, atmospheric, and aquatic systems—makes AM a state-of-the-art manufacturing solution compatible with future goals such as sustainability and increased environmental protection [1]. The evolution of various AM processes has both disruptive and industry–evolutionary implications [2,3,4]. With the help of AM, fundamental changes in society in the areas of consumer behavior, industrial manufacturing, and education can be triggered. AM has implications for society both in terms of industry and in terms of the manufacturing of components by so-called “makers” in their own home spaces [3]. In the industry sector, on the one hand, employees at all levels of the supply chain must be retrained. On the other hand, because of the high level of automation and the continuous digital process chain, many manual, labor-intensive jobs will be lost. This effect can be compensated for by highly qualified training, which is required for new jobs in the AM industry [5]. However, because of patent restrictions on many AM processes, the actual impact on the manufacturing industry as well as on society as a whole cannot (yet) be estimated at this point in time [2].

The rapid development of new, innovative, and alternative manufacturing methods, which have made great strides in recent years, particularly in the area of additive manufacturing, has likewise opened up new possibilities for component design and part construction [6,7]. The continuously growing variety of materials [8,9,10] and the ability to rapidly manufacture geometries and designs that cannot be produced conventionally make it possible to integrate new design structures into part volumes to be manufactured.

Similar to truss constructions in the building industry, which use wood or steel, in order to achieve the desired product properties in additive manufacturing, lattice and support structures are used [11,12]. Lattice structures are an important tool for providing larger, normally massive volumes with a certain porosity in order to save weight while maintaining the same load-bearing capacity [13,14]. These make it possible to manufacture free-hanging, thin, or heavily protruding features with the least possible additional material input. These structures, usually built from strut-based lattices, are added to the given part manually by the user or automatically by the corresponding software program during part preparation. This support method, which allows for the most stable and warp-free manufacturing possible, is often used in Powder Bed Fusion (PBF) of metals (e.g., Selective Laser Melting—SLM, Direct Laser Metal Sintering—DLMS, Electron Beam Melting—EBM, etc.) [15,16,17,18,19] and Vat Photopolymerisation (VPP, e.g., Stereolithography—SLA, Digital Light Processing—DLP, etc.). Similar is the case of the filling of bodies with larger volumes, or the connection of two separate walls. It is possible to determine the degree of filling of the volume in order to save manufacturing time, material, and weight. Generated lattice structures can either be uniform, with identical cubic geometries, regardless of the imported body’s shape (constant, non-conformal, and strut-based) [20,21], or gradient cubic-based structures that adjust the distance between vertices or the thickness of connecting struts to more closely conform to the original model’s shape, thereby allowing for local density variations (conformal or gradient lattice structures) [22,23,24,25,26,27].

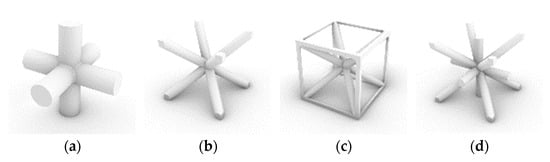

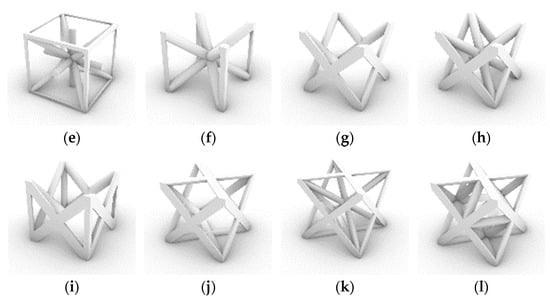

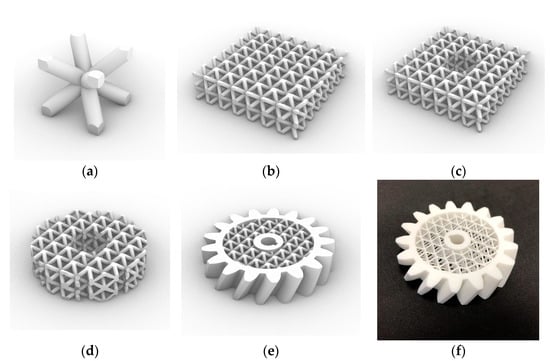

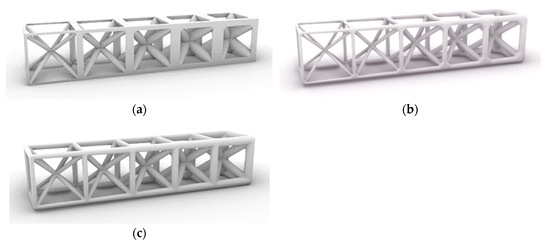

Cell structures are an attractive option for many design applications, especially for lightweight applications, because of the high specific strength and stiffness offered by their porous structure [28,29,30,31]. Figure 1 shows the most commonly studied strut-based cell topologies. Lattice structures, consisting of innumerable unit cells, can vary in strut thickness, unit cell size, and unit cell shape. The cell propagation can also be constant or gradient (Figure 2) and their geometry load matched [25,32,33].

Figure 1.

Different types of strut-based base cells most commonly used in lattice structure design, (a) centered cubic (CC), (b) body-centered cubic (BCC), (c) simple cubic body-centered cubic (SCBCC), (d) centered body-centered cubic (CBCC), (e) Iso truss, (f) body-centered cubic with Z-struts (BCCZ), (g) simple face-centered cubic (S-FCC), (h) simple face- and body-centered cubic (S-FBCC), (i) simple face-centered cubic with Z-struts (S-FCCZ), (j) face-centered cubic (FCC), (k) face- and body-centered cubic (FBCC), (l) octet truss based on [32,34,35,36].

Figure 2.

Lattice structure design variables, based on [24].

By finely tuning these specific parameters, lattice structures can produce unique mechanical, electrical, thermal, and acoustic properties and have thus garnered significant research interest. Consequently, the application range of these structures in parts, components, and entire products is continuously expanding, particularly in highly technologized sectors [37,38,39].

New ways of thinking and approaches can help to simplify and partly automate what can be very complicated and lengthy implementations, thus opening up access to new technologies and concepts to a wider range of potential users [40,41,42].

Beyond aerospace, the medical sector represents a potentially very large area of application for lattice structures, owing to their customization capabilities. Medical products that can be easily and quickly customized and adapted offer a decisive advantage for patients and their quality of life, especially in the field of prostheses, insoles, and splints [11,43,44].

Although TO and GD are becoming increasingly common in CAD, creating lattices remains a complex process and is not often implemented in currently available tools. This contribution aims to help designers and engineers choose the right software tool for the implementation of lattice structures into their designs. For this purpose, a number of software tools were first preselected from a variety of different developers on the market. These were then refined to a shortlist through a rigorous weighted point evaluation process (Table 1). After the evaluation process, five representative software tools were selected and analyzed with the help of two example geometries of varying complexity, and data such as computing time, export time, and file size were analyzed and compared. Additionally, comprehensive key attributes such as usability, reliability, availability, performance, support, and cost, consisting of a total of 32 features, were considered for an overall benchmarking of the selected software applications.

Table 1.

Shortlist of CAD software tools for lattice structure generation.

2. Materials and Methods

To narrow down the selection of suitable software for the design of lattice structures, the first eight different CAD systems were short-listed. The reason for the selection of these software tools was, on the one hand, their already proven use in the field of AM at the university of applied sciences and, on the other hand, the short-term availability on the market due to trial versions for research for students as well as faculty. In terms of origin, all except one software tool is being developed in the USA. Considering functionality, most of the short-listed software tools offer an integrated module for the generation of lattice structures, although more stand-alone solutions are entering the market. For the eight CAD systems, seven different significant criteria including lattice toolbox functionality, repair functionality, AM process integration, visualization and rendering options, materials database, meshing tools, and additional tools available were defined in order to be able to preselect five CAD systems by means of a weighted point evaluation.

The distributed point values ranged from 1 (very poor) to 10 (very good) and were assigned to the respective properties of the CAD software tools. All assigned point values were weighted and summed up to identify the most suitable software tools taken into consideration in the next phase of this research project. The weight of each criterion was determined based on its significance. The importance of a well-designed lattice toolbox was considered a key factor and was therefore given a weight of 25%. Similarly, the integration of the respective CAD data output into the AM process chain was given a weight of 20%. This includes the integration of standardized output file types such as STL, AMF, or 3MF, as well as integration into the next process step, such as slicing or support structure generation. The significance of additional tools such as FEA, GD, or TO in the development process of the lattice structures was given a weight of 15%. The remaining criteria were each given a weight of 10% as they were considered less significant.

The evaluation showed that five software tools including Rhino7 [45]/Grasshopper® [46], nTopology nTop [47], Altair® SulisTM [48], Altair® InpireTM [49], and Carbon® Design Engine Pro [50] yielded more than half of the ten points possible and were therefore preselected for the benchmarking in this paper.

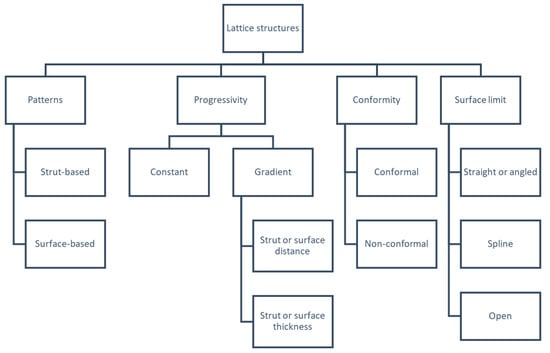

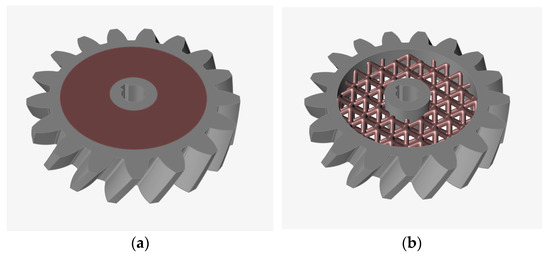

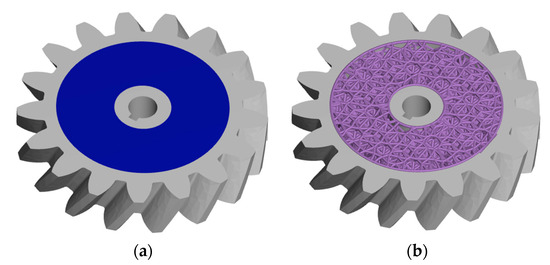

To further test the capabilities of the preselected software tools, two example geometries were devised. The first geometry represents a fundamental machine element: a helical gear. The proposed model consists of three parts including (1) the outer solid volume with a helically toothed surface, (2) the inner volume with a center bore and keyway, and (3) the design space in between (see Figure 3). The purpose of this model is to test the intersection between multiple solid volumes and a generated lattice structure. The design space is a hollow cylindrical shape, chosen to further test the software tools’ capabilities in creating a periodic cubic strut-based lattice structure and its overlap with the curved solid volumes. Often, these sections pose challenges for tools to perform clean Boolean and trimming operations.

Figure 3.

Proposed model of a helical gear consisting of three individual geometries.

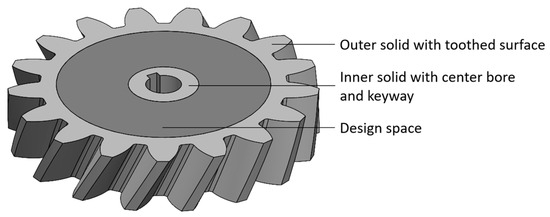

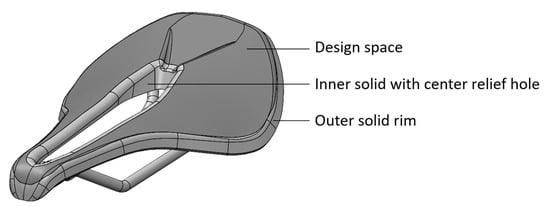

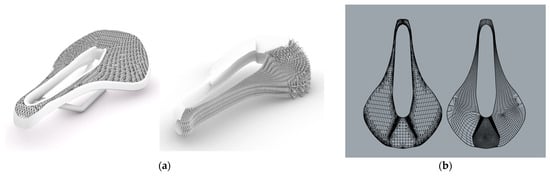

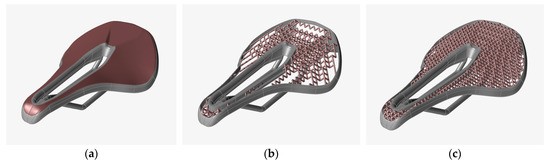

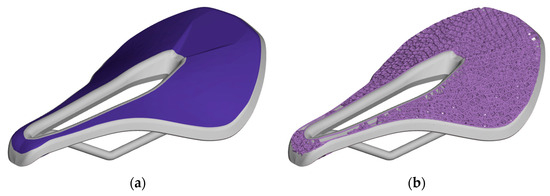

The second geometry is of a more complex character, featuring freeform surfaces and thin-walled structures. This model of a road bike seat, the “specialized power saddle” by Max Morozov, was downloaded from the GrabCAD Community homepage and used as a reference geometry for use with all the preselected software tools [51]. The original design was modified to limit the use of lattice structures in a given design space, sandwiched between an outer and an inner solid volume (Figure 4). The inner volume incorporates a cutout to help relieve stress and pressure onto the pelvic floor during riding. The purpose of selecting this type of model was to evaluate the capabilities of the preselected software tools in performing complex lattice operations such as progressivity (constant or gradient) and conformity (conformal or non-conformal). When using non-conformal constant lattice structures, the algorithms face an additional challenge because of the presence of freeform surfaces during Boolean or trimming operations.

Figure 4.

Modified CAD model of the bike seat, based on [51].

The outer and inner volumes help to protect the otherwise open ends of the lattice structure and add rigidity to the overall design. The software tools’ capabilities were tested by evaluating these two geometries. If the respective tools were able to generate these geometries, there should be no obstacle to using more complex ones in the future.

In order to sample the chosen software tools and present a comprehensive benchmark of the respective capabilities, computing times and file sizes for specified lattice structure types and sizes were evaluated. The following hardware was used to compute the calculation times and resulting file sizes:

- Processor: Intel® Core™ i9-9880H CPU @ 2.30 GHz.

- RAM: 32.0 GB (31.7 GB usable).

- Graphics: Nvidia Quadro T2000, 5 GB RAM @ 1575 MHz.

- HDD: Intel SSD 1 TB.

To measure the calculation times, a digital stopwatch was used. The measured times were defined from the start of the computation until the end of the computation and the following display of a graphical representation on the screen. In order to compare the calculation times and file sizes in the different software tools, the following lattice structure modalities were used for the helical gear:

- Unit Cell Type: BCC (body-centered cubic) and FCC (face-centered cubic).

- Unit cell dimensions: 8 × 8 × 8 mm.

- Strut thickness: 1 mm.

- Lattice dimensions: 7 × 7 × 2 (X/Y/Z).

For the bike seat, the following lattice structure modalities were used:

- Unit Cell Type: BCC (body-centered cubic) and FCC (face-centered cubic).

- Unit cell dimensions: 8 × 8 × 8 mm.

- Strut thickness: 1 mm.

- Lattice dimensions: 13 × 23 × 4 (X/Y/Z).

The base cell topologies BCC and FCC are not available in Carbon®’s Design Engine Pro. Therefore, tetrahedral as well as icosahedral lattice topologies were investigated and evaluated. All exported geometries except the bike seat in SULIS were saved as binary STL-Files with a geometric resolution of 0.1 mm.

3. Results

The subsequent sections describe the procedures for designing lattice structures for the two proposed example geometries using the respective software tools. Representative parameters like cell and lattice dimensions, computing time as well as corresponding file sizes were determined and compared to one another. In addition to the procedures and specifications, further functionalities as well as limitations of the respective software tools for the generation of lattice structures are discussed.

3.1. Rhino 7/Grasshopper®

Rhino 7 is a 3D CAD program focused on the creation of 3D freeform models based on NURBS-curves, NURBS-surfaces subdivision surfaces (SubD), point clouds, and polygon meshes. With the help of the Grasshopper® plugin, which is available in the basic scope of functions of Rhino 7, it is possible to develop models by combining different sets of function blocks. These different parametrized function blocks, each having a certain function on the geometry of the model, can be linked together to generate algorithms based on mathematical functions and expressions. Grasshopper® enables the user to fully use the potential of modern AM technologies in terms of manufacturability such as lattice structure, selective Voronoi tessellation, and many more [29,31,37,38,52,53,54,55]. The student version of Rhino 7 and Grasshopper® was used to visually program fully parameterizable algorithms to model base cells and simple geometry to help with the processes as well as to import models from SolidWorks®, which was used to both model and prepare CAD data from both the helical gear as well as the bike seat.

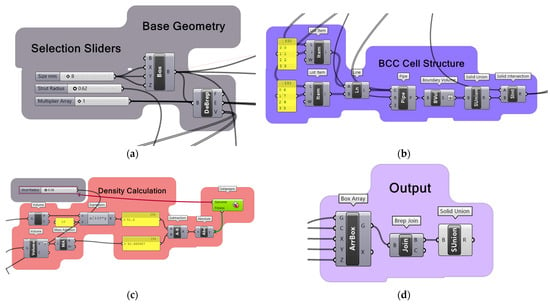

The overall algorithm for the lattice formulation within the design space of the helical gear consists of the four subroutines including base geometry, BCC cell structure, density calculation, and output (Figure 5).

Figure 5.

Grasshopper® algorithms, (a) cubic base geometry, (b) BCC Base Cell formulation by connecting defined vertices and adding round cross sections as well as volumes, (c) Genome-based density calculation to 25% density of base cell geometry with strut radius as controlled value, and (d) output of the lattice structure array with Boolean operation solid union.

The base geometry (Figure 5a) consists of a domain box that is fully parametrically adjustable via number sliders. In this case, an edge length of 8 mm in all principal directions was chosen. The box was dismantled into faces, edges, and vertices via the DeBrep command. With the help of the resulting vertices, line connections in the shape of a BCC base cell were formulated and a pipe-shaped volume was applied in the BCC cell structure subroutine (Figure 5b).

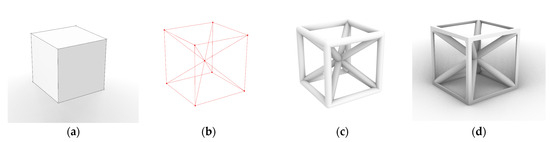

The resulting shape was intersected with the original domain box to cut away excess material on the outside of the base cell. Figure 6 exemplarily illustrates the formulation process using a SCBCC base cell. It is crucial that the solid intersection with the original domain box takes place in order to be able to repeat the base cells in all three principal directions of a given volume or design space. Otherwise, the connection between the base cells would be zero. The density calculation subroutine (Figure 5c) enables the user to choose the desired relative density value of a given base cell. In this case, 25% density was chosen, and the subroutine calculated the matching strut radius of the BCC base cell with the help of the Galapagos genetic solver accordingly.

Figure 6.

Generation of a SCBCC base cell in Grasshopper®, (a) domain box, (b) vertices and lines, (c) pipe volume, and (d) SCBCC base cell after solid intersection with domain box.

In the fourth subroutine—output (Figure 5d)—the output of the subroutine BCC cell structure was used to formulate the needed lattice structure with respect to the given design space. The actual size of the lattice structure was set with the help of the number sliders—in this case, a 7 × 7 × 2 lattice structure was formulated (Figure 7b). After a series of geometry inputs and Boolean operations (Figure 7c,d), the resulting gear can be examined in Figure 7e. The calculations of the BCC as well as FCC lattice-filled helical gear are shown in Table 2.

Figure 7.

BCC simple lattice structure generation for parts of a gear’s solid domain: (a) 8 × 8 × 8 mm BCC base cell, (b) 7 × 7 × 2 lattice structure, (c) lattice structure after inner cutout, (d) lattice structure after solid intersection with BRep_design_space, (e) finished gear after solid intersection of BRep_Gear with lattice structure BRep_design_space, and (f) manufactured gear using LPBF.

Table 2.

BCC and FCC lattice generation values of the helical gear in Rhino7/Grasshopper®.

The basic functionality of the program was used to define a 13 × 23 × 4 non-conformal lattice structure based on an 8 × 8 × 8 mm BCC, as well as an FCC base cell. In Figure 8a, left, the resulting model with BCC cell topology can be observed after a series of Boolean operations, including the design space as well as the inner and outer solid structures, were performed.

Figure 8.

Different types of tessellations of the bike seat’s design space: (a) non-conformal BCC lattice structure (left) and conformal tessellation with quadratic lattice structure (right) and (b) mesh representation of the upper bike saddle surface (left) and quadratic mesh (right).

Another approach had to be used to formulate a conformal lattice structure inside the given design space or between two sets of surfaces when using the plugin Crystallon [56] (Figure 8a, right). The plugin is only able to formulate lattice structures between two non-trimmed surfaces. When using a BRep—the design space of the bike seat—as boundary volume, the Deconstruct BRep command only yields trimmed surfaces. It is not possible to convert trimmed surfaces to non-trimmed surfaces easily; thus, a detour through additional functionality was taken. The top surface of the bike seat’s design space was extracted from the BRep and formulated as quadratic mesh, as can be seen in Figure 8b, right. In order to enable the formulation of a lattice structure using quadratic meshes, two identical surfaces were required. The previously extracted top surface was copied and moved by a thickness value of 15 mm, and voxels between the two resulting surfaces were created with Crystallon’s MBM command and filled (CLF command) with a BCC unit cell (CT command). The resulting lattice was thickened with the Pipe command with a diameter of 1 mm (Figure 8a, right). Table 3 shows the calculated as well as the measured values for both the BCC and FCC lattice structures of the bike seat. These were the longest processing times among all the software tools investigated.

Table 3.

BCC and FCC lattice generation values of the bike seat in Rhino7/Grasshopper®.

Additional capabilities

- A large collection of plugins for Grasshopper® is available.

- Many different possibilities to achieve the desired outcome (formulation of tailored algorithms).

Limitations

- Long computing times.

- Often, all hardware resources (RAM) were used, resulting in program crashes.

- No automated solutions for lattice structure generation are available. Tailored algorithms must be formulated.

Discussion

While Rhino 7 used in conjunction with Grasshopper® produced unexpected results with the formulated algorithms, the limitations of the programs stem from the open-source nature of the software, which offers a broad spectrum of design and calculation applications. The formulated algorithms with or without the Crystallon plugin are not suitable for complex and demanding AM applications when using lattice structure design. This is also evident when comparing the calculation times, which were the longest for the bike seat among all the investigated software tools.

3.2. nTop

The lattice structure module of the nTop design software is used to either build strut-based or surface-based base cells on a rectangular, cylindrical, spherical, or chosen periodic pattern [57,58,59,60]. The program also offers functionality to build conformal lattice structures from a surface mesh or a volume mesh. Apart from the possibility of forming constant lattice structures, nTop offers the option to implement stochastic structures such as 2D and 3D Voronoi lattices as well as branched-, Delaunay-, and Orthofoam-Lattices. nTop is therefore seen as an engineering design software specifically developed to aid in the design and optimization process of products for AM. The software is developed by nTopolgy Inc. in New York City. Unlike proven CAD tools that are used in the industry today, which use B-Reps and NURBS to represent a specific design, this software is based on the use of implicit model representations, which is advantageous with respect to increased computing speed, scalability, reliability, and control [61]. Nonetheless, the software tool offers all possible interfaces to import CAD and other representations of geometry such as meshes, voxels, and point clouds.

The formulation of the lattice structure in nTop is similar with respect to model treatment, although the handling inside the tool is very different from the other investigated software tools. The outer and inner volumes of the helical gear (Figure 9) were considered as solids, and the design space in between was populated with the previously defined lattice characteristics.

Figure 9.

Workflow for the helical gear in nTop: (a) design space and solid volumes and (b) generated lattice structure.

The overall process within nTop, although intuitive, requires additional time to manage correctly. The formulation of the lattice structure was achieved without complications. Because of the fact that nTop works with implicit body representations, calculation times are often longer compared with other software tools. The computing time of the BCC lattice structure required 2 min and 41 s, whereas the calculation of the FCC lattice required 3 min and 22.1 s, both of which were the longest of all the investigated software tools (see Table 4). The building of the “implicit body view” for the lattice representation was broken down into the following steps: outer solid, design space, inner solid, full body, and implicit body.

Table 4.

BCC and FCC lattice generation calculation times of the helical gear in nTop.

In order to export the generated lattice structure into the desired STL-File, the formulated implicit body had to be converted into a mesh. For the BCC lattice, this additional operation took a further 3 min 44.41 s. After the conversion, the mesh was finally exported as binary STL, which took 30.53 s, adding to a grand total of 4 min 14.95 s of export time for the helical gear with the BCC lattice structure (see Table 5).

Table 5.

BCC and FCC lattice generation values of the helical gear in nTop.

The same approach was used to formulate the lattice structures within the design space of the bike seat (Figure 10).

Figure 10.

Workflow for the bike seat in nTop: (a) design space and solid volumes and (b) generated lattice structure.

The computing times for the lattice structures of the bike seat were 8 min and 41.15 s for the BCC lattice structure and 8 min and 57 s for the FCC lattice structure. These times were among the longest of all the investigated software tools, except for Rhino/Grasshopper® (refer to Table 6). The building of the “implicit body view” for the lattice representation was broken down into the following steps: outer solid, full body, and implicit body.

Table 6.

BCC and FCC lattice generation calculation times of the bike seat in nTop.

The meshing operation failed after a total calculation time of 10 h. Unfortunately, no valid solution was calculated and, therefore, no mesh and no subsequent STL-File was generated or exported for either the BCC or FCC lattice structures (see Table 7).

Table 7.

BCC and FCC lattice generation values of the bike seat in nTop.

Additional capabilities

- Topology optimization implemented.

- Generative design implemented.

- Finite element analysis implemented.

- Field-driven design implemented.

- Thermal simulation implemented.

- Buckling analysis implemented.

- Modal analysis of lattice structures implemented.

Limitations

- Very long calculation times.

- Extensive program with many settings options.

Discussion

The program’s functionality is highly regarded in the market. When given the correct input, the software produces functional and visually appealing results. The different approach using building blocks that contain certain design features and functionality, which are stacked on top of each other, however, makes it challenging for beginners to become familiar with the program. The calculation times were significantly higher compared with the other software tools such as Altair® SulisTM and Carbon® Design Studio Pro. Furthermore, the failed calculation of a more sophisticated geometry raises questions regarding the program’s reliability.

3.3. Altair® SulisTM

Altair® SulisTM is a design software for AM that is designed to create complex lattice structures as well as fluid channels. Altair Sulis offers integrated manufacturability analyses and compensation tools to reduce the risk of costly manufacturing errors. Currently, Altair® Sulis™ is a standalone program, but it will be integrated into the Altair Inspire software in the future. The program can be used to create simple geometries like cuboids and cylinders or modify imported geometries, such as creating a wall or mirroring. Altair® SulisTM provides 17 tools under the Lattice tab, which can be divided into three groups as follows: surface lattices (such as TPMS or shell lattice structures), strut lattices, and planar lattices.

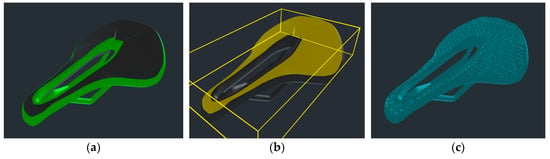

The program is intuitive, and only a few steps are required to fill a geometry with lattice structures. Individual areas can be separated from the rest of the model and defined as a solid. The area to be populated can then be filled using a variety of tools. These include surface-based, strut-based, and planar lattice structures. Within each subset, a number of different unit cell designs can be selected, and parameters such as cell size and strut thickness can be set. Altair® SulisTM allows the user to import a variety of file formats. However, the easiest way is to import STL representations of a model. Although the user can manually select areas of interest in the imported model, a more practical approach is to separate the solid model areas from the design space that the lattice will later fill. The example geometry “helical gear” was prepared in SolidWorks® beforehand to obtain the outer and inner solids as well as the design space in between (see Figure 3). Geometries were set in SulisTM accordingly. The inner and outer volumes were defined as solids, and the inner design space was defined with the exact same settings as in Grasshopper® and nTop.

After the formulation of all parameters, the lattice generation was started, and the results shown in Table 8 were computed as well as measured.

Table 8.

BCC and FCC lattice generation values of the helical gear in Altair® Sulis™.

Figure 11 displays the workflow of the helical gear in Sulis™ for the BCC base cell geometry.

Figure 11.

Workflow for the helical gear in Sulis™: (a) solid areas of the model, (b) design space, and (c) generated lattice structure.

The imported seat geometry was processed in a similar manner (Figure 12), except for the size of the lattice structure (13 × 23 × 4).

Figure 12.

Workflow for the bike seat in SulisTM: (a) solid areas of the model, (b) design space, and (c) generated lattice structure.

The computed as well as the measured results are shown in Table 9. To decrease calculation times for the bike seat, the resolution was reduced from 0.1 mm to 0.5 mm. This change was made because the calculation times for the lattice structures with 0.1 mm resolution would be 20 times longer than those with 0.5 mm resolution.

Table 9.

BCC and FCC lattice generation values of the bike seat in Altair® Sulis™.

Additional capabilities

- Fluid channel design with real-time feedback.

- Self-supporting fluid channels.

- Simple design of offset walls and lattice infill.

- Gradient cell sizing and gradient density across multiple axes.

- Conformal geometry is possible.

Limitations

- No FEA toolbox.

- The operation of the program is not clear at once.

- No frequent updates (latest version: 1.12, Release Date: 1 December 2022).

Discussion

Overall, SulisTM is a reliable tool for generating lattice structures on geometry. Once the workflow of importing geometry and assigning solids and design spaces is understood, the process becomes straightforward. It is important to note that increasing the resolution by a factor of 5 can significantly increase calculation times and file sizes. There is a discussion about whether SulisTM should be integrated into Inspire to combine the two functionalities for lattice structure design into one more powerful software tool. It is possible that the software tool may not be available in the future.

3.4. Altair® InspireTM

Altair® Inspire™ is a software suite that accelerates simulation-driven design throughout the product development lifecycle, from concept to reality, while reducing product time-to-market. InspireTM enables the creation of designs focused on both performance and manufacturability. It empowers users to develop and manufacture high-performance products in a single, intuitive environment. Inspire offers various design features to help users shift their focus from traditional CAD modeling to AM-oriented parts and product development. These include topology and structure optimization tools, as well as lattice structure filling for geometry. InspireTM also provides motion simulation, FEA, and frequency analysis and provides pre-processing and simulation tools, as well as compensation for metal additive manufacturing processes, to facilitate a seamless transition to AM technologies.

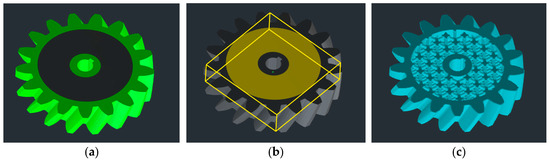

The formulation of the lattice fill process was similar to the other investigated software tools (Figure 13). The outer and inner volumes of the helical gear were considered solid, whereas the design space was populated with a lattice.

Figure 13.

Workflow for the helical gear in Inspire: (a) design space and (b) generated lattice structure.

To export the finished helical gear, the outer and inner solid volumes were combined with the generated lattice structure using a Boolean unify command. The geometry can be saved as binary STL through the context menu of InpireTM. The computed as well as measured values can be seen in Table 10.

Table 10.

BCC and FCC lattice generation values of the helical gear in Altair® Inspire™.

The same approach was used to populate the design space of the bike seat (Figure 14). However similar limitations occurred concerning the exact dimension of the formulated BCC and FCC lattice structures. No information on the dimensions of the lattices was given by the program.

Figure 14.

Workflow for the bike seat in Inspire: (a) design space, (b), failed population of design space, and (c) generated lattice structure.

The computed as well as measured values can be observed in Table 11.

Table 11.

BCC and FCC lattice generation values of the bike seat in Altair® Inspire™.

Additional capabilities

- Topology optimization implemented.

- A materials database is available (primarily common materials for AM of metals).

- Finite element analysis integrated.

- Computational fluid dynamics implemented.

- Frequency analysis implemented.

- Motion simulation implemented.

- Manufacturing constraints are given automatically.

- Poly-NURBS fit for AM.

Limitations

- Only one layer of the lattice structure near the top surface of the design space was created.

- No information concerning the size of the lattice structure was provided by the program.

- Only strut-based lattice structures are available.

- The materials database is predominantly for metal applications—only two polymer materials (ABS and PA).

- Process integration for AM solely for SLM- and Binder–Sinter processes.

Discussion

Altair® InspireTM is a software tool designed for AM applications. It optimizes parts in terms of motion, mechanical loads, and natural frequency, taking into account the surrounding parts of an assembly or mechanical subsystem. However, it is limited to simple strut-based lattice structures where both cell size and strut thickness can be adjusted. Furthermore, the orientation and angular alignment of lattice generation cannot be easily manipulated. While populating the design space of the helical gear geometry was straightforward, it was not possible to do the same for the bike seat with an 8 × 8 × 8 mm base cell. This limitation hindered the comparability of the design approach with the rest of the software tools investigated. Furthermore, it is evident that the file size of the helical gear increased fourfold when transitioning from a basic BCC cell to an FCC cell topology. Similarly, the file size of the bike seat increased by a factor of 2.4.

3.5. Carbon® Design Studio Pro

The program Design Studio Pro is proprietary software to help designers and engineers construct lattice structures with respect to the available AM machines as well as resins developed by Carbon® Inc. Unlike all the previously examined programs, this application runs directly in the browser, which is an advantage with respect to usability. All geometries, however, must be uploaded into the browser to produce the desired lattice structure design. Upon upload, the geometry can only be filled with a small number of different types of lattices such as icosahedral, Kagome, rhombic, tetrahedral, and Voronoi.

The operation of the program is intuitive, and all necessary commands to form a lattice structure are clearly presented in an uncluttered workspace. The import of the geometry was performed in the form of STEP files. It is important to point out that the geometry of the helical gear was divided into the outer solid, the inner solid, and the design space in between (as described in Section 2). However, Design Studio Pro merged the three geometries into one single geometry upon import. Therefore, all three bodies had to be imported separately in order to fill only the design space with lattice structures (Figure 15a). As mentioned, before it was not possible to choose the lattice type in accordance with the previously defined BCC lattice type. Therefore, the tetrahedral and icosahedral lattice topologies with 8 × 8 × 8 mm cell size and 1 mm strut thickness were chosen (see Table 12). After the lattice generation, two additional operations, including solidify lattice and combine, had to be performed to generate unified meshes.

Figure 15.

Workflow for the helical gear in Design Studio Pro: (a) design space and (b) generated lattice structure.

Table 12.

Tetrahedral and icosahedral lattice generation calculation times of the helical gear in Design Engine Pro.

After the lattice generation, the model was exported as an STL-File, and the values are presented in Table 13.

Table 13.

Tetrahedral and icosahedral lattice generation values of the helical gear in Design Engine Pro.

The same approach was used to generate a lattice within the design space of the bike seat, as seen in Figure 16. It is noticeable that in the narrow areas at the front of the seat, where the design space touches the inner and outer solids, the software was unable to generate a lattice. However, this is due to the fact that the cell dimensions were defined too large to fit these specific areas of the seat.

Figure 16.

Workflow for the bike seat in Design Studio Pro: (a) design space and (b) generated lattice structure.

Table 14.

Tetrahedral and icosahedral lattice generation calculation times of the bike seat in Design Engine Pro.

Table 15.

Tetrahedral and icosahedral lattice generation values of the bike seat in Design Engine Pro.

Additional capabilities

- Basic shapes can be added to the uploaded geometry (cube, cylinder, sphere).

- Lattices can be populated uniformly or with point clouds (*.csv-files).

- Gradient lattices can be generated.

- Structures can be trimmed, and individual struts can be removed.

- Lattice performance can be analyzed (limited to Carbon’s resin materials).

Limitations

- Design analysis is only possible with Carbon’s resin materials.

- A browser-based application that raises questions about data protection.

Discussion

Design Studio Pro is a very capable user-friendly software that is not overly complicated to learn. Very good and appealing results are possible after just a few minutes of use. Carbon Academy provides E-learning courses for easier entry into the software. The software itself incorporates sample files for orientation as well as a simplified benchmarking function for generated lattice structures. This function however is only limited to Carbon’s generic AM materials.

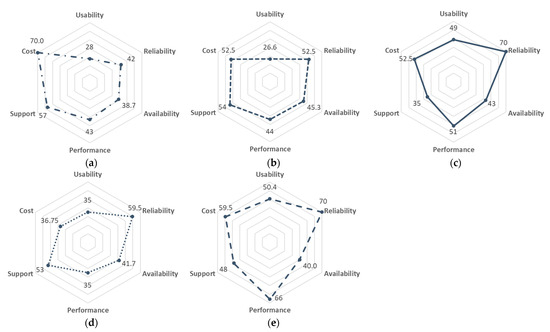

3.6. Benchmarks

Benchmarking was conducted to enable users of the examined software tools to compare their individual advantages and disadvantages. Interested users should have prior experience in CAD. Basic knowledge of FEA simulation and AM is recommended. The attributes of usability, reliability, availability, performance, support, and cost were identified for this purpose. Each of these six attributes contains between two and seven features, which are rated on a scale of 1 (very poor) to 10 (very good). The following sections provide a detailed explanation of the features, some of which are rated on a binary scale of either 1 or 10. At the end of the benchmarking process, the software tool’s final results are compared and displayed graphically.

3.6.1. Usability

The usability attribute refers to the program’s general use from a user’s perspective. The features are usually rated on a scale of 1 (very poor) to 10 (very good). The rating for the “special training required” feature decreases as the amount of required training increases. The same principle is applied when determining the previous experience that is required for handling the program.

Table 16 shows that the usability of the investigated software tools ranges from 19 to 36 out of 50 points. The tools exhibit a wide range of usability, from not very intuitive workflows and complicated operations in Rhino/Grasshopper® or nTop to the very intuitive workflow and easy operation in Design Engine Pro.

Table 16.

Evaluation of the selected features for the usability benchmarking.

3.6.2. Reliability

The importance of software tool reliability cannot be overstated. Any crashes or long computing times can have a negative impact on the user experience and lead to the conclusion that another software tool may be a better choice. Table 17 shows that SulisTM and Design Engine Pro performed well in this category, showing no weaknesses when tested with the sample geometry.

Table 17.

Evaluation of the selected features for the reliability benchmarking.

Rhino7/Grasshopper® software has limitations in terms of stability, particularly when dealing with large computing loads, which can result in crashes or insufficient RAM.

3.6.3. Availability

To effectively test and utilize a software tool, it is crucial to consider its availability. The availability attribute in Table 18 is categorized into the following four stakeholders: students, faculty, trial version, and classroom version, in order to cover a broad range of applications. Apart from these stakeholders, all investigated software tools are widely accessible through their respective developing companies or licensed vendors and distributors. The attribute “availability” comprises mostly binary features. For instance, a rating of 10 is assigned when a student version is available, and a rating of 1 is assigned when there is no student version available. The “OS compatibility” feature has the following three levels: a rating of 3.3 was assigned to software that is available for only one operating system, 6.6 for two, and 9.9 for three. Furthermore, software accessible via a desktop version was scored at 5, whereas web-based versions were rated at 10 points. This is because the web-based version does not require advanced hardware and does not need to be installed, making life easier for the user.

Table 18.

Evaluation of the selected features for the availability benchmarking.

Rhino7/Grasshopper® software is available as student and faculty versions, but these require a license costing EUR 195 each. A classroom version is also available for EUR 975, which includes 30 licenses. A trial version is available for 90 days. The software is regularly updated and can be used on both Windows® 10 and macOS. nTop is available to students and faculty without limitations for at least one year. Upon request, the license can be extended. To do so, an extensive license request form must be completed. A trial version is available for 30 days, but no classroom versions have been identified. Frequent updates are available, but the software is only compatible with Windows®. Both software products from Altair® are available to students and faculty, but classroom versions must be ordered through a distributor. In contrast to InspireTM, which frequently receives software updates, Sulis™ is only available in version 1.12, released on 1 December 2022. Both versions are available for Windows® and macOS, while a Linux version is available for SulisTM only. Carbon®’s Design Studio Pro is accessible through a browser, making it independent of users’ hardware and operating systems. However, student and faculty versions may be limited and available upon request. A trial version is typically valid for 30 days. However, after contacting support, the license duration was extended to 6 months.

3.6.4. Performance

The evaluation process is fundamentally dependent on the performance of the selected software tool. It is crucial to assess both the capabilities of each software tool and the compatibility with the available hardware. The first three features of the performance attribute in Table 19 describe the overall hardware requirements of the software tool. The feature “cloud computing support” is graded on a binary scale. Cloud computing support is either available or not. For Rhino7/Grasshopper® software, this depends on whether a plugin is used to offer this functionality. Therefore, a rating of five was given. Among the investigated tools, only Design Studio Pro offers cloud computing support.

Table 19.

Evaluation of the selected features for the performance benchmarking.

The last four features describe the overall capabilities of the software tools. The integrity of closed lattice structures is crucial for the functional viability of a design. In the case of Inspire™, it was not always possible to achieve a closed structure without gaps. As demonstrated in Section 3.1, Section 3.2, Section 3.3, Section 3.4 and Section 3.5, all programs were capable of producing strut-based lattice structures. However, not every tool investigated was capable of generating other lattice types, such as surface-based, Voronoi, or volumetric structures. Inspire™ and Design Engine Pro are limited to strut-based lattice structures. However, Design Studio Pro can generate more sophisticated structures, such as tetrahedral, icosahedral, and Kagome structures.

3.6.5. Support

To become familiar with a chosen software tool and handle complex program functionality, such as importing sensor data in the form of point clouds or fields, generating meshes, exporting certain file formats, or utilizing FEA and TO functionality, additional information is often necessary. The support attribute is a vital component of information flow. All the investigated software tools offer different support capabilities (Table 20).

Table 20.

Evaluation of the selected features for the support benchmarking.

Rhino7/Grasshopper® provides a wide range of user forums, such as “Rhinoceros Forums”, as well as knowledge bases like Food4Rhino. Rhino3D Education also offers a collection of webinars, video documentation, and user manuals. Because of the extensive community of Rhino/Grasshopper® users, there is a wealth of documentation available on dedicated websites and YouTube. nTopLearn and nTopLive are offered from nTopology to assist users in getting started. Additionally, nTop provides a knowledge base, engineering guides, and a wide range of sample parts that can be modified and studied. However, the nTop YouTube video documentation may only be partially helpful as most of the videos are posted by nTopology themselves, and the functionality of basic tools often changes between versions, which can be confusing. Altair® Community and Altair® University provide content for both SulisTM and InspireTM. The support structure for InspireTM expands to Altair® LearningTM, KnowledgeBase Articles, online courses, and webinars. Video documentation on YouTube is also available to assist users. Carbon® offers Carbon Academy, which includes blogs, case studies, courses, webinars, white papers, and sample parts for download. Video documentation on YouTube is also available.

3.6.6. Cost

The cost attribute should not be overlooked. As a faculty member or student, it may be tempting to opt for the free or discounted versions of software packages. However, obtaining precise pricing information for specific tools often presents a significant challenge. In this publication, pricing options were only available for two out of the five tools investigated including Rhino7 and Carbon® Design Engine Pro. The prices of the remaining tools were determined with the help of community forums and private conversations with vendors. Due to confidentiality, direct pricing details cannot be disclosed. Therefore, the benchmark values were approximated and compared to the prices of the software tools that were known at the time (Table 21).

Table 21.

Evaluation of the selected features for the cost benchmarking.

Rhino7 is the most affordable tool, priced at EUR 195 per license. This license does not need to be renewed and remains valid as long as the developer supports the software. Upgrading to the newer version, Rhino8, costs only EUR 95. Carbon Design Engine Pro is the second most affordable option, priced at USD 799 per month. All the other tools are more expensive and therefore achieve lower ratings in the benchmark. All the tools, except Rhino7, are subject to renewal through a subscription model.

3.7. Final Assessment

The final assessment includes all previously benchmarked attributes in an overall benchmark. The values of each attribute are summed up to achieve a total of 320 points. Table 22 shows that Carbon® Design Engine Pro scored the highest with 244 points, followed by Altair® SulisTM with 214 points, Rhino/Grasshopper® with 210.66 points, nTop with 207.33 points, and InspireTM with 192.66 points. Although the difference in points between Rhino7/Grasshopper® and nTop is relatively small, it is significant in terms of the distribution of the achieved values. When comparing the end result of Rhino7/Grasshopper® with that of SulisTM, a similar assumption can be made.

Table 22.

Evaluation of the selected attributes for the overall benchmarking of the investigated software tools.

The graphical presentation of the attributes took into account the distribution of points (Figure 17). To ensure comparability, a compensation factor was created for the three attributes that have fewer than seven features (see also Table 22). This way, all attributes are distributed equally, and each can be awarded a maximum of 70 points.

Figure 17.

Evaluation of the benchmarked attributes. Rhino7/Grasshopper® (a), nTopology nTop (b), Altair® SulisTM (c), Altair® InspireTM (d), and Carbon Design Engine Pro (e).

Based on this factor, the graphical representation allows for a visual comparison of the tested software packages, leading to the following assumed classification:

Rhino7/Grasshopper® is a cost-effective option suitable for engineers and designers, offering a wide range of plugin choices and design freedom. However, it may not be the optimal choice for users seeking quick solutions to design problems.

Conversely, nTop is particularly well-suited for experts in the field of AM, catering to specialized design and engineering needs. The software provides various options for functionally grading lattice topologies based on input greyscale maps and images for lattice density. It offers a wide range of strut-based and surface-based lattice topologies. Furthermore, nTop integrates TO with geometric design and FEA to enable designers and engineers to create feedback loops for their designs. The additional functionality and the use of function blocks for building design-based algorithms make nTop less user-friendly for beginners.

Altair® SulisTM is a reliable and cost-effective solution that offers the necessary functionality to create strut-based, surface-based, and planar lattice structures, as well as simple surface and geometry offset solutions. Additionally, SulisTM provides enhanced functionality in the flow feature, which can aid in the design of cooling channels or heat exchanger functionality within parts. This feature makes Sulis an efficient application for metal AM. However, the possible integration of Sulis into Inspire and the underperforming support are disadvantages of this software tool.

Altair® InspireTM was originally designed as a parametric CAD application for TO. It offers good support through Altair®’s own offerings as well as through YouTube. However, because of the limitations described in Section 3, it may not be the right tool for lattice structure design just yet.

Carbon® Design Studio Pro outperforms other investigated tools in all categories except availability and support. The software is relatively new and was originally designed by Carbon® to prepare parts for in-house AM machines. Subsequently, it was made available industry-wide, broadening its user base beyond in-house applications. Design Engine Pro is a cost-effective solution that performs well and is available through a subscription model. It is a web-based application, so there is no need for users to invest in expensive hardware. In addition, the cloud computing service can save time when computing intricate designs and large, complex parts.

4. Discussion

This paper gives an overview of the application of strut-based lattice structures with preselected software applications. Some of these are considered parametric CAD tools such as Rhino7/Grasshopper® and Altair® InspireTM. The other three investigated, including Altair® SulisTM, nTopology nTop, and Carbon® Design Engine Pro, are categorized as AM software designed to improve part topology and characteristics, such as density, offering an optimal weight-to-stiffness ratio from the outset of the design process.

Numerous software tools for formulating lattice structures are available on the market [62]. Selecting and sampling different tools to find the most suitable one for a given situation or problem is a major task. Therefore, suitable software tools were preselected and investigated in more detail in Section 3. In the following, CAD tools that were exempt from preselection or were not even considered before are discussed.

4.1. Applications of Software Tools Exempt from Preselection

4.1.1. Parametric CAD Software Tools

SolidWorks 2023 [63] and Fusion 360 [64] are state-of-the-art CAD tools that are widely used in the industry. SolidWorks 2023 does not incorporate lattice structure functionality from the start; however, ref. [29] presents a tailored algorithm implemented into a macro-program inside the CAD environment of the software itself. Additionally, 3DXpert [65] can be used as a plugin for SolidWorks 2023 to enable AM functionality with respect to TO, TPMS, and strut-based lattice structures, texturing, conformal cooling and manifold design, implicit modeling, and dedicated heat exchanger design application.

Fusion 360 offers volumetric lattice structure capability from the January 2022 release onward. However, this functionality is incorporated into the Product Design Extension, which is commercially available for EUR 625/year or via a 7-day trial version. Creating lattice structures in Autodesk Fusion 360 is streamlined, requiring just a single command. Since there are only a few prefabricated geometries to choose from and the lattice structure area refers to a single command, the scope of functions is insufficient for a closer look.

In Grasshopper®, gradient design of lattice structures and other geometry can also be implemented using both the basic functionality as well as additional plugins such as Crystallon [56], Dendro [66], or Intralattice [67].

Crystallon contains a set of tools that break down the steps of creating a lattice structure in a modular way so that they can be used in different workflows for different applications. These tools can be used in conjunction with other plugins at any point in the process to enhance their capabilities. Each tool is an editable cluster made of native Grasshopper® components that can be modified to meet the user’s needs.

Dendro is a volumetric modeling plug-in for Grasshopper based on the OpenVDB library. It provides multiple design approaches to wrap points, curves, and meshes as a volumetric data type and perform Boolean operations. With this plugin, it is possible to dispense of the use of BReps and meshes, which are often computationally heavy on both RAM and GPU.

Intralattice is a plugin for Grasshopper used to generate solid lattice structures within a given 3D design space. Developed at McGill’s Additive Design & Manufacturing Laboratory (ADML), Intralattice is an ongoing project that offers an extensible, open-source alternative to currently available commercial solutions. The plugin comprises the following four core modules: (1) the cell module for generating a unit cell of the desired type; (2) the frame module for creating a lattice wireframe within a specified 3D design space; (3) the mesh module for converting the wireframe into a solid mesh suitable for export and 3D printing; and (4) the utility module, which facilitates pre/post-processing tasks like mesh refinement, reporting, and previewing.

With the help of basic building blocks inside Grasshopper®, it was possible to create a line attractor setting where the strut radius was gradually increased from the first BCC cell in Figure 8a (left) to the last (right). The distance between a predefined attractor point and every vertex of the subsequent base cells was measured, and each connecting line’s pipe radius was assigned a value between 0.3 and 0.8 mm.

The gradient lattice structure can be formulated using a similar approach as with Dendro, as shown in Figure 18c. The curves connecting the vertices were divided into 50 equidistant points. A random point was constructed outside the lattice structure, and the distances between it and all 4079 points of the lattice curves were measured. A list of distances was compiled. Using the Dendro command, each point was assigned a volume based on the radial value of a domain between 0.3 mm and 0.8 mm. Finally, the surface was smoothed using Dendro’s smooth surface command.

Figure 18.

Example 1 × 5 × 1 BCC lattice structures with gradient strut thickness: (a) Grasshopper basic functionality, (b) Grasshopper Intralattice plugin, and (c) Grasshopper Dendro plugin.

4.1.2. AM Software

Materialise Magics 27 [68] is a popular pre-processing tool for AM specialists. It offers data format conversion from all standards into STL, 3MF, AMF, PLY, and many more as well as a wide range of AM vendor and machine presets for easier part preparation and file transfer to AM machines (build processors). Furthermore, it includes an advanced repair toolset to facilitate the error-free manufacturing of AM parts. The software offers basic functionality for constant, non-conformal strut-based lattice structures with base cell designs such as cross, octet truss, rhombic dodecahedron, and others. Although the selection of base cells is not very extensive, the software can be used to generate attractive and, with some limitations (e.g., soft component characteristics, dampening, etc.), functional components. However, because of these limitations, the software was not subjected to detailed evaluation in this study.

Specialized lattice structure design software, such as Autodesk® Netfabb [69], places emphasis on preparing 3D models for AM during the design phase. Like most AM software applications, they employ strategies such as lightweighting that can be achieved by applying lattice infills, which reduces material usage and manufacturing time while maintaining the desired properties and improving manufacturability. For the study of mechanical performance, applications such as Autodesk® Netfabb offer numerical simulations, TO, and a library of predefined additive manufacturing materials as well as process parameters for metal AM such as PBF (SLM, DLMS, and EBM).

4.2. AM of Designed Lattice Structures

The additive manufacturing of lattice structures presents a challenge in the AM toolchain. Finding suitable AM processes that are able to manufacture strut-based and surface-based lattice structures can be demanding. These structures are primarily produced through the LPBF of metals and sometimes polymers, which do not require support structures. Many AM processes, such as MEX and VPP, are capable of producing strut-based lattice structures without the need for support structures. However, surface-based lattice structures may require additional support. It is a fact that for all additive manufacturing processes, the parts produced differ significantly from the original design models. In many cases, this behavior is observed in the LPBF of metals [70,71]. As a result, the current research is focused on predicting and virtually correcting defects in the CAD model prior to manufacturing by means of numerical simulations and statistical models. This approach ensures the production of both accurate and mechanically robust parts [70,72]. However, additional fundamental research needs to be conducted to achieve predictive models that automatically correct process parameters and help the user achieve the desired mechanical properties of the manufactured parts.

5. Conclusions

The analysis of the preselected software tools demonstrates that it is advisable to consider a wide range of features before purchasing highly specialized software, which can often be very costly. The chosen software tools include parametric CAD software and AM software. Various manufacturers of software tools and their capabilities were considered. This allowed for the examination of not only an open CAD program like Rhino7 with Grasshopper® but also technically complex and innovative tools like nTop and Design Engine Pro. The investigation focused on preselected applications using defined sample geometries and computation times. The file size of the exported lattice structures, as well as general performance and handling, were also evaluated. Benchmarking was conducted using six attributes, consisting of 32 features in total, to assess and compare all preselected applications.

The software applications were classified into three categories based on their performance and cost as follows: a performance-oriented recommendation of nTop, a low-cost recommendation of Rhino7/Grasshopper®, and Carbon® Design Engine Pro as the overall best-in-class option. Altair® SulisTM and Altair® InspireTM are both capable software tools. However, because of the possibility of SulisTM being discontinued or integrated into InspireTM, it is difficult to make a recommendation at this point. For designers and engineers, it is crucial to rely on software tools that not only perform well but are also well-supported. Additionally, InspireTM’s lattice feature, similar to Magic’s Lattice toolbox, is designed to save material, weight, and cost in a design before sending it to the AM machine. This feature is basic compared with other tools that implement simulation and verification functionality, such as FEA and TO.

Regarding the actual additive manufacturing of lattice structures, it is recognized that the inherent variability in the as-built structures and the deviation from the as-designed CAD models are important factors for both academic and industrial AM communities. Future research should aim to bridge the gap between design and manufacturing in AM. This study intentionally focuses on assessing the basic functionality and performance of CAD tools for designing lattice structures. The investigation does not cover the post-production mechanical properties of these designs. Analyzing mechanical performance and predicting it through FEA requires extensive expertise and resources, which is beyond the scope of our current research.

In conclusion, it is important to note that the presented findings were based on the experience of a small group without the support of experts in lattice structure design. The findings were obtained through extensive engagement with different software tools. Further research is necessary, and the knowledge of leading experts should be gathered in the future to facilitate entry into the domain of lattice structure design and design for AM as a whole. However, these conclusions required significant time and effort to reach and may be useful to others in the AM community.

This paper’s results will be used to conduct further research into lattice-based sports equipment design. To accomplish this, Carbon®’s Design Engine Pro will be used to produce bespoke bike seat pads that meet individual user needs, determined through pressure mapping during bike fitting.

Author Contributions

Conceptualization, S.G. and C.H.; methodology, S.G.; investigation, S.G.; data curation, S.G.; writing, S.G. and C.H.; visualization, S.G.; supervision, C.H. All authors have read and agreed to the published version of the manuscript.

Funding

The research leading to these results was partly funded under the cooperative doctoral program “Digiphot” between FH Campus Wien and TU Wien. Open Access Funding by TU Wien.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The raw data supporting the conclusions of this article will be made available by the authors on request.

Acknowledgments

I would like to thank Jürgen Stampfl for the supervision of this work and for the supervision of my dissertation at TU Wien. The authors acknowledge TU Wien Bibliothek for financial support through its Open Access Funding Programme.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Huang, S.H.; Liu, P.; Mokasdar, A.; Hou, L. Additive manufacturing and its societal impact: A literature review. Int. J. Adv. Manuf. Technol. 2013, 67, 1191–1203. [Google Scholar] [CrossRef]

- Steenhuis, H.-J.; Pretorius, L. The additive manufacturing innovation: A range of implications. J. Manuf. Technol. Manag. 2017, 28, 122–143. [Google Scholar] [CrossRef]

- Matos, F.; Godina, R.; Jacinto, C.; Carvalho, H.; Ribeiro, I.; Peças, P. Additive Manufacturing: Exploring the Social Changes and Impacts. Sustainability 2019, 11, 3757. [Google Scholar] [CrossRef]

- Jiang, R.; Kleer, R.; Piller, F.T. Predicting the future of additive manufacturing: A Delphi study on economic and societal implications of 3D printing for 2030. Technol. Forecast. Soc. Chang. 2017, 117, 84–97. [Google Scholar] [CrossRef]

- Caviggioli, F.; Ughetto, E. A bibliometric analysis of the research dealing with the impact of additive manufacturing on industry, business and society. Int. J. Prod. Econ. 2019, 208, 254–268. [Google Scholar] [CrossRef]

- Tasch, D.; Schagerl, M.; Wazel, B.; Wallner, G. Impact behavior and fractography of additively manufactured polymers: Laser sintering, multijet fusion, and hot lithography. Addit. Manuf. 2019, 29, 100816. [Google Scholar] [CrossRef]

- Gralow, M.; Weigand, F.; Herzog, D.; Wischeropp, T.; Emmelmann, C. Biomimetic design and laser additive manufacturing—A perfect symbiosis? J. Laser Appl. 2020, 32, 021201. [Google Scholar] [CrossRef]

- Steyrer, B.; Busetti, B.; Harakály, G.; Liska, R.; Stampfl, J. Hot Lithography vs. room temperature DLP 3D-printing of a dimethacrylate. Addit. Manuf. 2018, 21, 209–214. [Google Scholar] [CrossRef]

- Grunenberg, D.; Ehrmann, K.; Gorsche, C.; Steyrer, B.; Koch, T.; Stampfl, J.; Liska, R. Heterotelechelic poly(propylene oxide) as migration-inhibited toughening agent in hot lithography based additive manufacturing. Polym. Chem. 2021, 12, 1260–1272. [Google Scholar] [CrossRef]

- Le Barbenchon, L.; Lißner, M. On the dynamic performance of additively manufactured visco-elastic meta-materials. Mater. Lett. 2024, 359, 135823. [Google Scholar] [CrossRef]

- Pan, C.; Han, Y.; Lu, J. Design and Optimization of Lattice Structures: A Review. Appl. Sci. 2020, 10, 6374. [Google Scholar] [CrossRef]

- Han, Y.; Lu, W.F. A Novel Design Method for Nonuniform Lattice Structures Based on Topology Optimization. J. Mech. Des. 2018, 140, 091403. [Google Scholar] [CrossRef]

- Fontana, F.; Leutenecker-Twelsiek, B.; Omidvarkarjan, D.; Jansen, J. Entwicklung und Konstruktion für die Additive Fertigung: Grundlagen und Methoden für den Einsatz in Industriellen Endkundenprodukten; 2. Auflage. in Ein Fachbuch von Konstruktionspraxis; Vogel Communications Group: Würzburg, Germany, 2021. [Google Scholar]

- Lachmayer, R.; Ehlers, T.; Lippert, R.B. Entwicklungsmethodik für die Additive Fertigung; 2. Auflage. in Lehrbuch; Springer Vieweg: Berlin/Heidelberg, Germany, 2022. [Google Scholar]

- Wang, Z.; Zhang, Y.; Tan, S.; Ding, L.; Bernard, A. Support point determination for support structure design in additive manufacturing. Addit. Manuf. 2021, 47, 102341. [Google Scholar] [CrossRef]

- Didier, P.; Le Coz, G.; Robin, G.; Lohmuller, P.; Piotrowski, B.; Moufki, A.; Laheurte, P. Consideration of SLM additive manufacturing supports on the stability of flexible structures in finish milling. J. Manuf. Process. 2021, 62, 213–220. [Google Scholar] [CrossRef]

- Subedi, S.C.; Shahba, A.; Thevamaran, M.; Thoma, D.J.; Suresh, K. Towards the optimal design of support structures for laser powder bed fusion-based metal additive manufacturing via thermal equivalent static loads. Addit. Manuf. 2022, 57, 102956. [Google Scholar] [CrossRef]

- Yang, D.; Pan, C.; Zhou, Y.; Han, Y. Optimized design and additive manufacture of double-sided metal mirror with self-supporting lattice structure. Mater. Des. 2022, 219, 110759. [Google Scholar] [CrossRef]

- Koepf, J.A.; Pistor, J.; Markl, M.; Körner, C. Numerical Microstructure Prediction for Lattice Structures Manufactured by Electron Beam Powder Bed Fusion. Crystals 2024, 14, 149. [Google Scholar] [CrossRef]

- Babamiri, B.B.; Barnes, B.; Soltani-Tehrani, A.; Shamsaei, N.; Hazeli, K. Designing additively manufactured lattice structures based on deformation mechanisms. Addit. Manuf. 2021, 46, 102143. [Google Scholar] [CrossRef]

- Yang, L.; Mertens, R.; Ferrucci, M.; Yan, C.; Shi, Y.; Yang, S. Continuous graded Gyroid cellular structures fabricated by selective laser melting: Design, manufacturing and mechanical properties. Mater. Des. 2019, 162, 394–404. [Google Scholar] [CrossRef]

- Medeiros e Sá, A.; Mello, V.M.; Rodriguez Echavarria, K.; Covill, D. Adaptive voids: Primal and dual adaptive cellular structures for additive manufacturing. Vis. Comput. 2015, 31, 799–808. [Google Scholar] [CrossRef]

- Dong, G.; Tessier, D.; Zhao, Y.F. Design of Shoe Soles Using Lattice Structures Fabricated by Additive Manufacturing. Proc. Des. Soc. Int. Conf. Eng. Des. 2019, 1, 719–728. [Google Scholar] [CrossRef]

- Azman, A.H.; Vignat, F.; Villeneuve, F. Design Configurations and Creation of Lattice Structures for Metallic Additive Manufacturing. In 14ème Colloque National AIP PRIMECA; La Plagne: La Plagne-Tarentaise, France, 2015. [Google Scholar]

- Lei, H.-Y.; Li, J.-R.; Xu, Z.-J.; Wang, Q.-H. Parametric design of Voronoi-based lattice porous structures. Mater. Des. 2020, 191, 108607. [Google Scholar] [CrossRef]

- Santos, J.; Sohouli, A.; Suleman, A. Micro- and Macro-Scale Topology Optimization of Multi-Material Functionally Graded Lattice Structures. J. Compos. Sci. 2024, 8, 124. [Google Scholar] [CrossRef]

- Decker, T.; Kedziora, S. Optimizing the Thickness of Functionally Graded Lattice Structures for High-Performance Energy Absorption: A Case Study Based on a Bicycle Helmet. Appl. Sci. 2024, 14, 2788. [Google Scholar] [CrossRef]

- Gibson, L.J.; Ashby, M.F. Cellular Solids: Structure and Properties, 2nd ed.; Cambridge University Press: Cambridge, UK, 1997. [Google Scholar] [CrossRef]

- Gibson, L.J. Modelling the mechanical behavior of cellular materials. Mater. Sci. Eng. A 1989, 110, 1–36. [Google Scholar] [CrossRef]

- Gibson, L.J. Cellular Solids. MRS Bull. 2003, 28, 270–274. [Google Scholar] [CrossRef]

- Song, R.; Moorehead, M.; Yushu, D.; Ke, J.-H. Lattice Design and Advanced Modeling to Guide the Design of High-Performance Lightweight Structural Materials. Energies 2024, 17, 1468. [Google Scholar] [CrossRef]

- Maconachie, T.; Leary, M.; Lozanovski, B.; Zhang, X.; Qian, M.; Faruque, O.; Brandt, M. SLM lattice structures: Properties, performance, applications and challenges. Mater. Des. 2019, 183, 108137. [Google Scholar] [CrossRef]

- Robbins, J.; Owen, S.J.; Clark, B.W.; Voth, T.E. An efficient and scalable approach for generating topologically optimized cellular structures for additive manufacturing. Addit. Manuf. 2016, 12, 296–304. [Google Scholar] [CrossRef]

- Nguyen, D.S. Design of lattice structure for additive manufacturing in CAD environment. J. Adv. Mech. Des. Syst. Manuf. 2019, 13, JAMDSM0057. [Google Scholar] [CrossRef]

- Luxner, M.H.; Stampfl, J.; Pettermann, H.E. Finite element modeling concepts and linear analyses of 3D regular open cell structures. J. Mater. Sci. 2005, 40, 5859–5866. [Google Scholar] [CrossRef]

- Panesar, A.; Abdi, M.; Hickman, D.; Ashcroft, I. Strategies for functionally graded lattice structures derived using topology optimisation for Additive Manufacturing. Addit. Manuf. 2018, 19, 81–94. [Google Scholar] [CrossRef]

- Deering, J.; Dowling, K.I.; DiCecco, L.-A.; McLean, G.D.; Yu, B.; Grandfield, K. Selective Voronoi tessellation as a method to design anisotropic and biomimetic implants. J. Mech. Behav. Biomed. Mater. 2021, 116, 104361. [Google Scholar] [CrossRef] [PubMed]

- Andresen, S.; Bäger, A.; Hamm, C. Eigenfrequency maximisation by using irregular lattice structures. J. Sound Vib. 2020, 465, 115027. [Google Scholar] [CrossRef]

- Zhang, C.; Chen, F.; Huang, Z.; Jia, M.; Chen, G.; Ye, Y.; Lin, Y.; Liu, W.; Chen, B.; Shen, Q.; et al. Additive manufacturing of functionally graded materials: A review. Mater. Sci. Eng. A 2019, 764, 138209. [Google Scholar] [CrossRef]

- Richard, H.A.; Schramm, B.; Zipsner, T. (Eds.) Additive Fertigung von Bauteilen und Strukturen; Springer Fachmedien Wiesbaden: Wiesbaden, Germany, 2017. [Google Scholar] [CrossRef]

- Hussain, A.; Sakhaei, A.H.; Shafiee, M. A Data-Driven Constitutive Model for 3D Lattice-Structured Material Utilising an Artificial Neural Network. Appl. Mech. 2024, 5, 212–232. [Google Scholar] [CrossRef]

- Khan, N.; Acanfora, V.; Riccio, A. Non-Conventional Wing Structure Design with Lattice Infilled through Design for Additive Manufacturing. Materials 2024, 17, 1470. [Google Scholar] [CrossRef]

- Teufelhart, S. Belastungsoptimiertes Design von Gitterstrukturen für die Additive Fertigung nach dem bionischen Prinzip der kraftflussgerechten Gestaltung. Ph.D. Dissertation, Technische Universität München, Munich, Germany, 2016. [Google Scholar]

- Papazoglou, D.P.; Neidhard-Doll, A.T.; Pinnell, M.F.; Erdahl, D.S.; Osborn, T.H. Compression and Tensile Testing of L-PBF Ti-6Al-4V Lattice Structures with Biomimetic Porosities and Strut Geometries for Orthopedic Implants. Metals 2024, 14, 232. [Google Scholar] [CrossRef]

- Robert McNeel & Associates, Rhino 7. Available online: https://www.rhino3d.com/ (accessed on 1 April 2024).

- Grasshopper 3D, Grasshopper. Available online: https://www.grasshopper3d.com/ (accessed on 1 April 2024).

- nTopology, Inc., nTop. Available online: https://www.ntop.com/ (accessed on 1 April 2024).

- Altair Engineering Inc., Sulis. Available online: https://www.altair.com/sulis (accessed on 1 April 2024).

- Altair Engineering Inc., Inspire. Available online: https://altair.com/inspire (accessed on 1 April 2024).

- Carbon Inc., Design Engine Pro. Available online: https://www.carbon3d.com/products/carbon-design-engine (accessed on 1 April 2024).

- Max Morozov, Specialized Power Saddle. Available online: https://grabcad.com/library/specialized-power-saddle-1 (accessed on 1 April 2024).

- Ferreira, K.; Anwer, N.; Mehdi-Souzani, C. Characterization of L-PBF lattice structures geometric defects. Procedia CIRP 2021, 100, 846–851. [Google Scholar] [CrossRef]

- Hossain, U.; Ghouse, S.; Nai, K.; Jeffers, J.R. Controlling and testing anisotropy in additively manufactured stochastic structures. Addit. Manuf. 2021, 39, 101849. [Google Scholar] [CrossRef]

- Öncel, A.C.; Yaman, U. Generation of Optimized Voronoi Based Interior Structures for Improved Mechanical Properties. Procedia Manuf. 2019, 38, 42–51. [Google Scholar] [CrossRef]

- Ramírez, E.A.; Béraud, N.; Pourroy, F.; Villeneuve, F.; Museau, M. Design parameters effects on relative density of triply periodic minimal surfaces for additive manufacturing. Procedia CIRP 2021, 100, 13–18. [Google Scholar] [CrossRef]

- Aaron Porterfield, Crystallon. Available online: http://fequalsf.blogspot.com/p/crystallon.html (accessed on 1 April 2024).

- Guimarães, G.; Rocha, A.; Rego, R.; Barreiros, L.; Mascheroni, J.; Kretzer, A. Compressive Behavior of Gyroid Structures Manufactured Through SLM with Carburizing Steels: A Numerical and Experimental Study. Procedia Struct. Integr. 2021, 34, 26–31. [Google Scholar] [CrossRef]

- Jafferson, J.M.; Sharma, H. Design of 3D printable airless tyres using NTopology. Mater. Today Proc. 2021, 46, 1147–1160. [Google Scholar] [CrossRef]

- Chahid, Y.; Racasan, R.; Pagani, L.; Townsend, A.; Liu, A.; Bills, P.; Blunt, L. Parametrically designed surface topography on CAD models of additively manufactured lattice structures for improved design validation. Addit. Manuf. 2021, 37, 101731. [Google Scholar] [CrossRef]

- Cantaboni, F.; Ginestra, P.; Tocci, M.; Colpani, A.; Avanzini, A.; Pola, A.; Ceretti, E. Modelling and FE simulation of 3D printed Co-Cr Lattice Structures for biomedical applications. Procedia CIRP 2022, 110, 372–377. [Google Scholar] [CrossRef]

- Leslie Langnau, Implicit Modelling for Complex Geometry. Available online: https://www.3dcadworld.com/implicit-modelling-for-complex-geometry/ (accessed on 1 April 2024).