Experimental Study on the Forced Ventilation Safety during the Construction of a Large-Slope V-Shaped Tunnel

Abstract

1. Introduction

2. Experimental Study

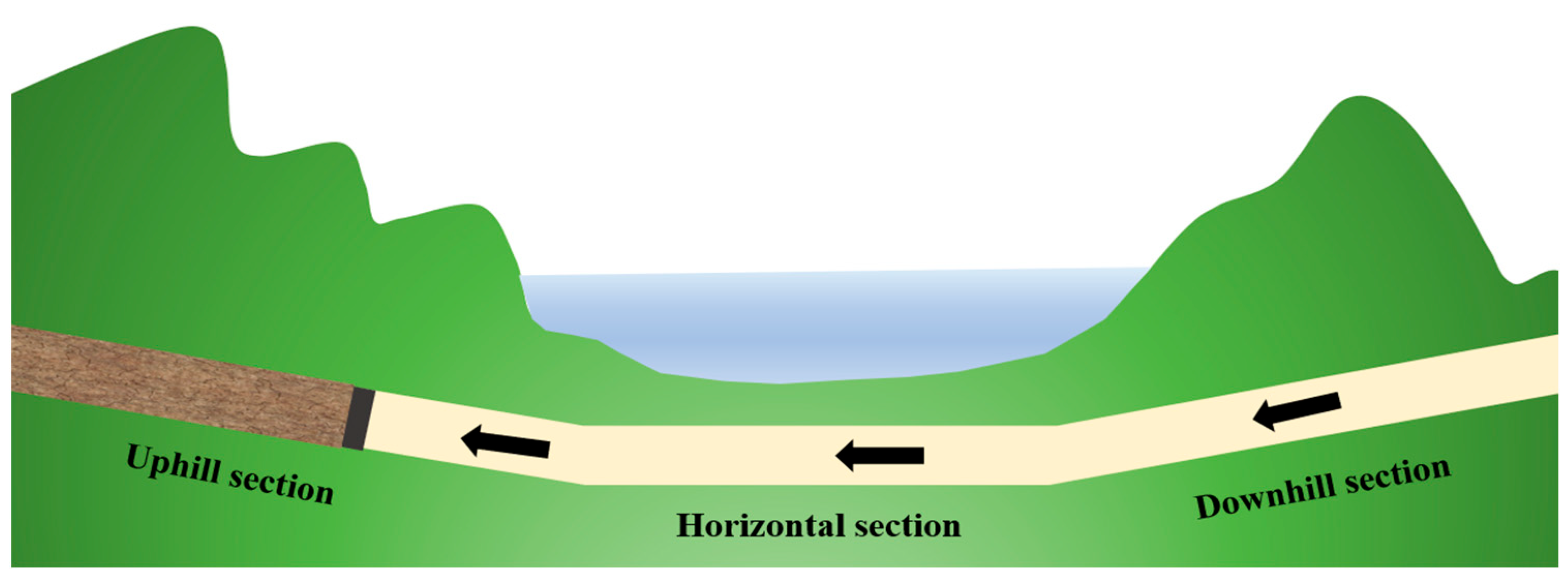

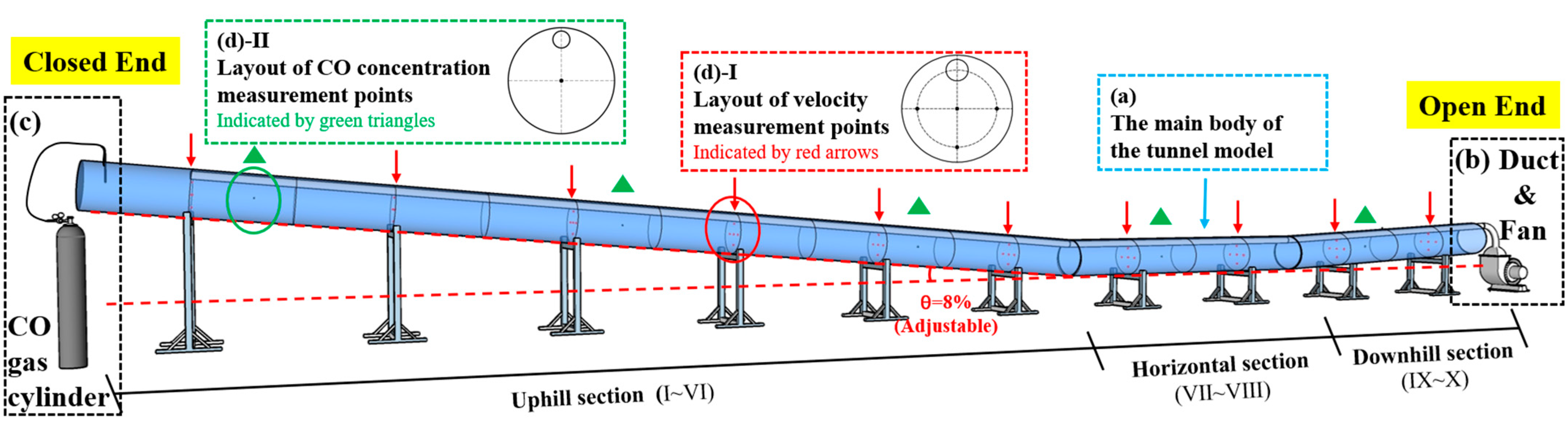

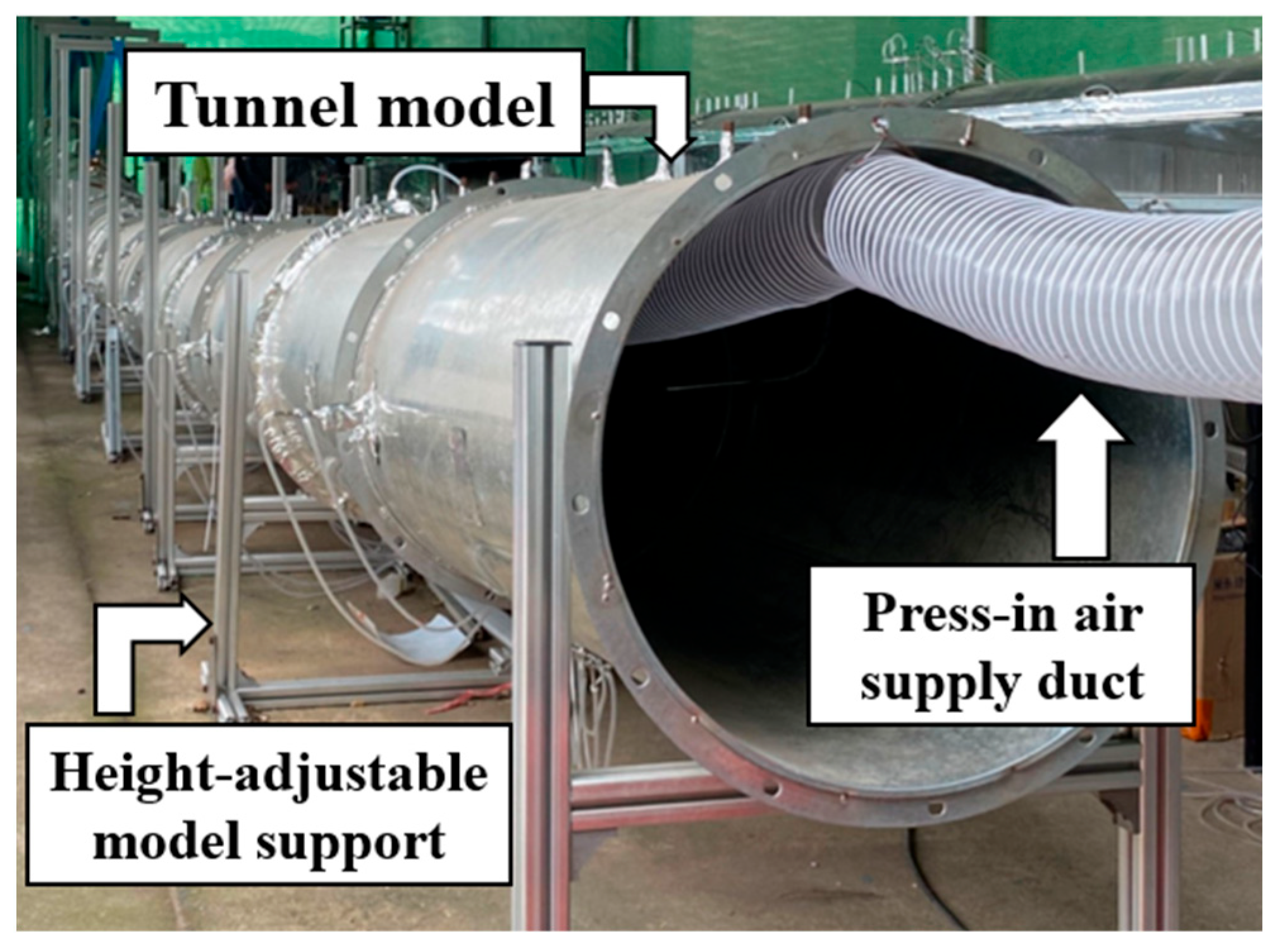

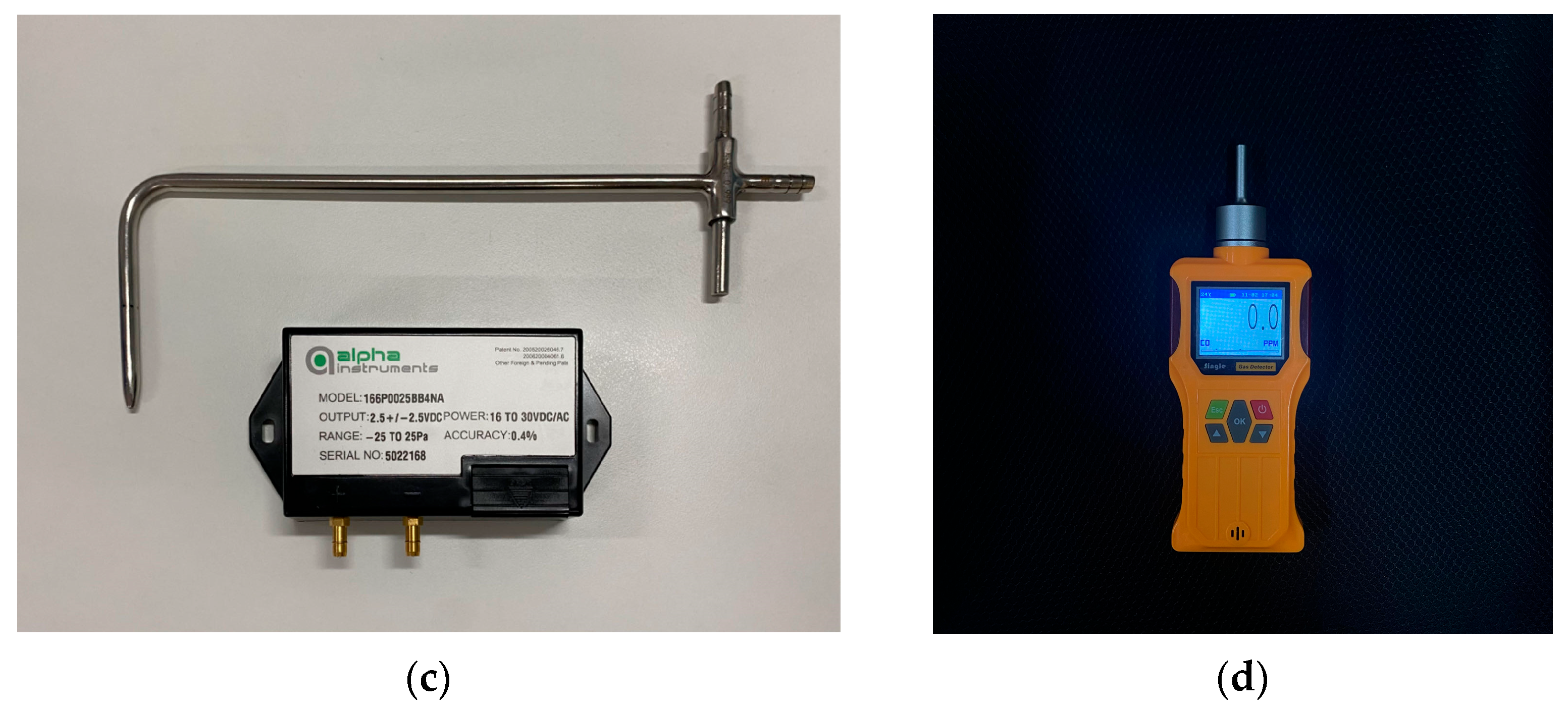

2.1. Tunnel Model

2.2. Working Conditions and Experimental Procedures

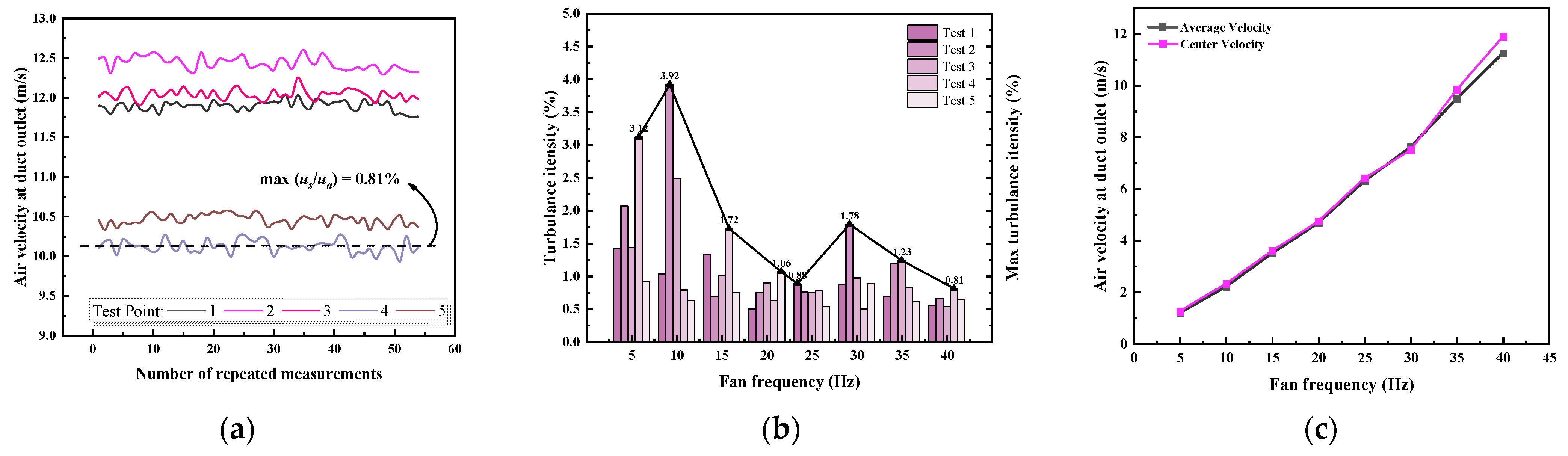

2.3. Repeatability Verification and Error Analysis

2.3.1. Repeatability Verification

2.3.2. Error Analysis

3. Results and Discussion

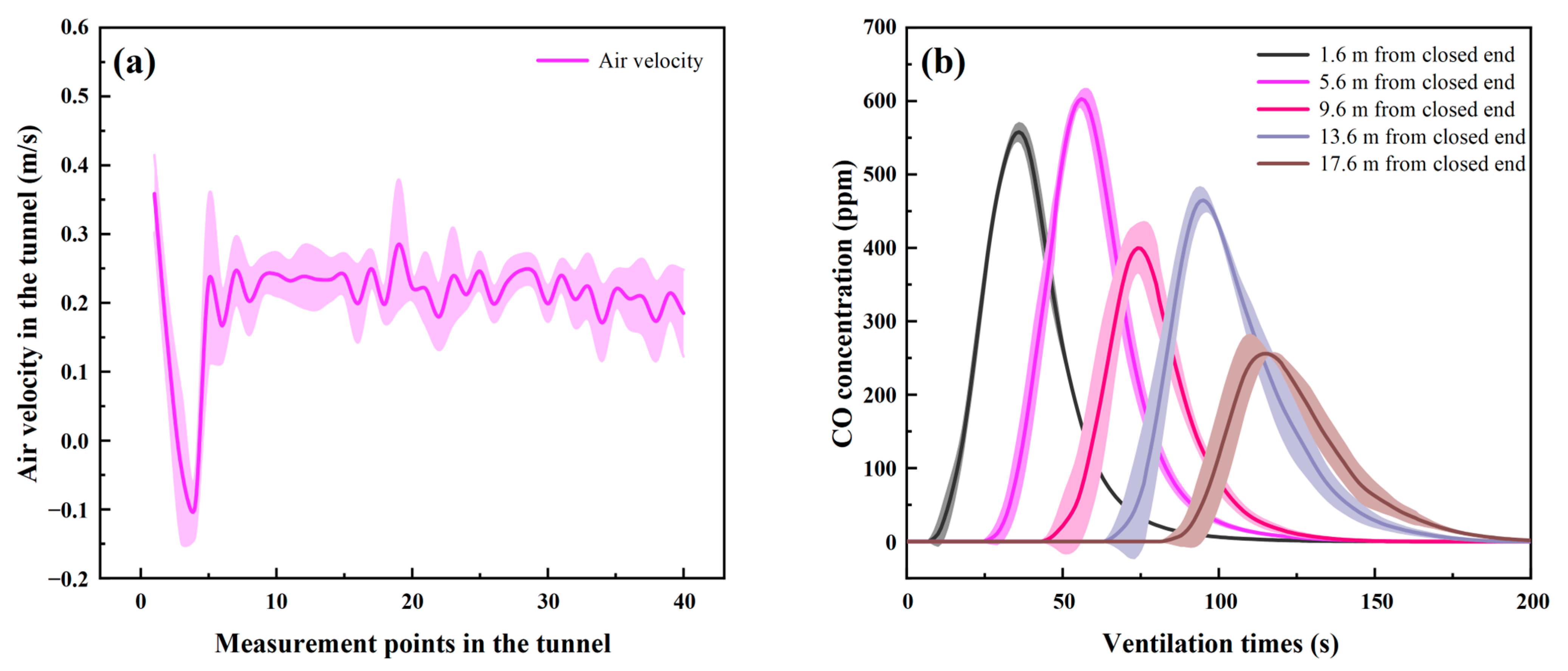

3.1. Flow Field

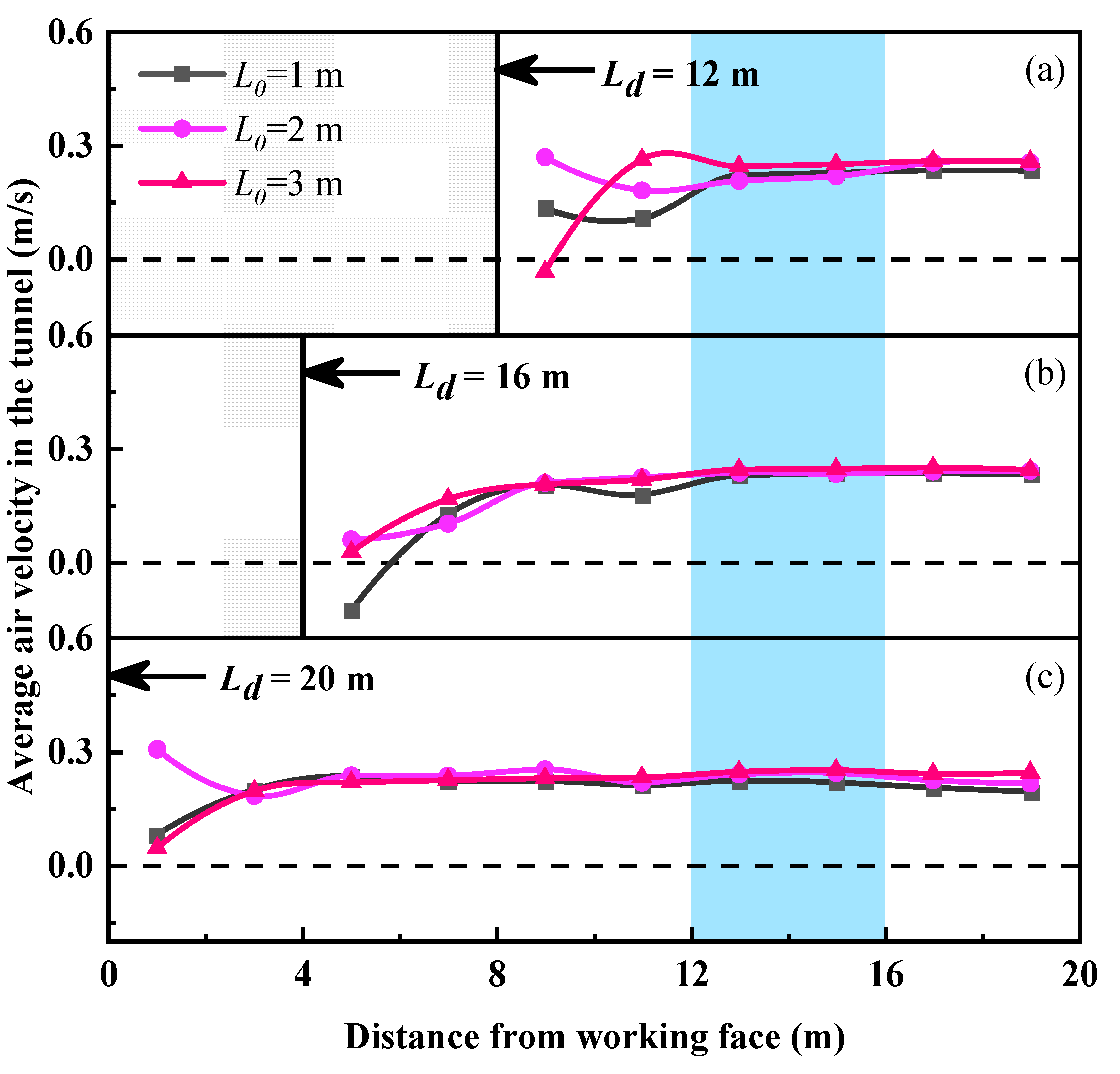

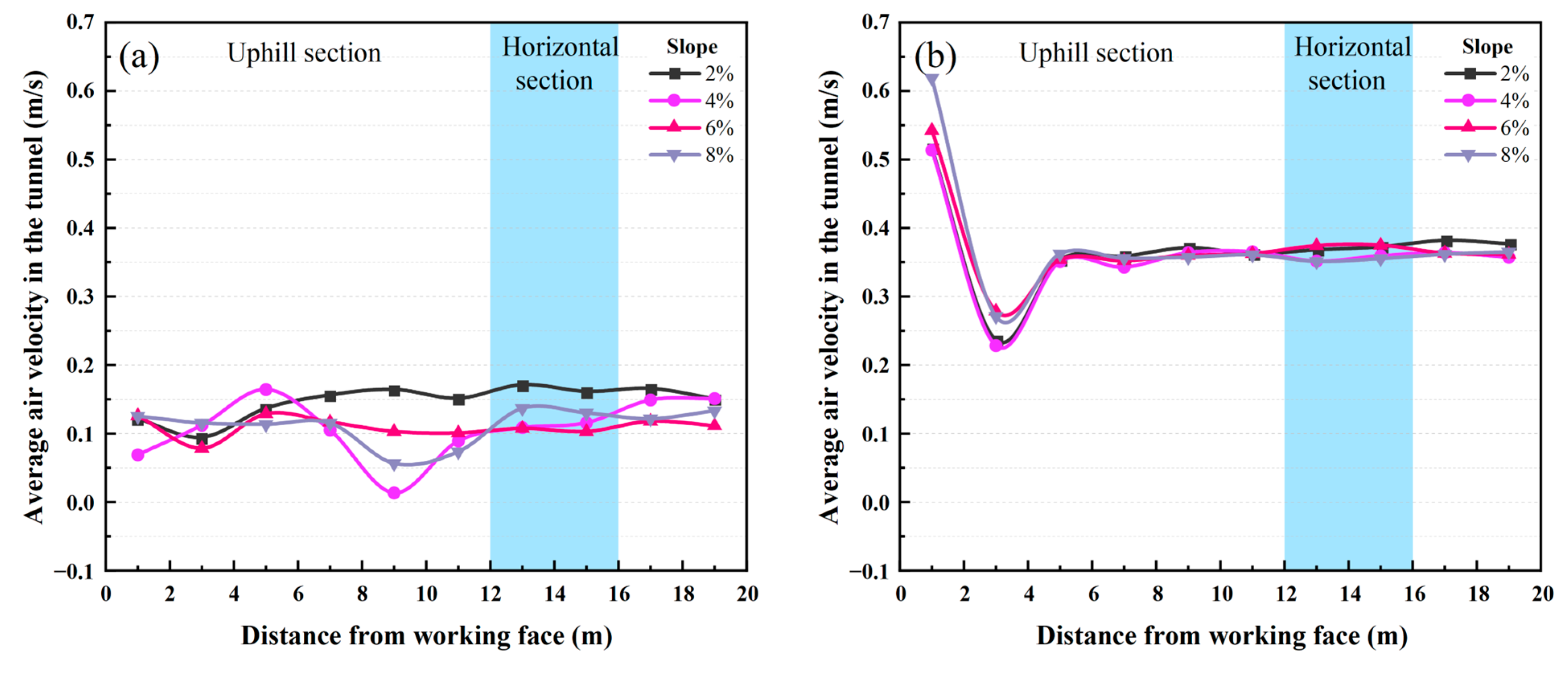

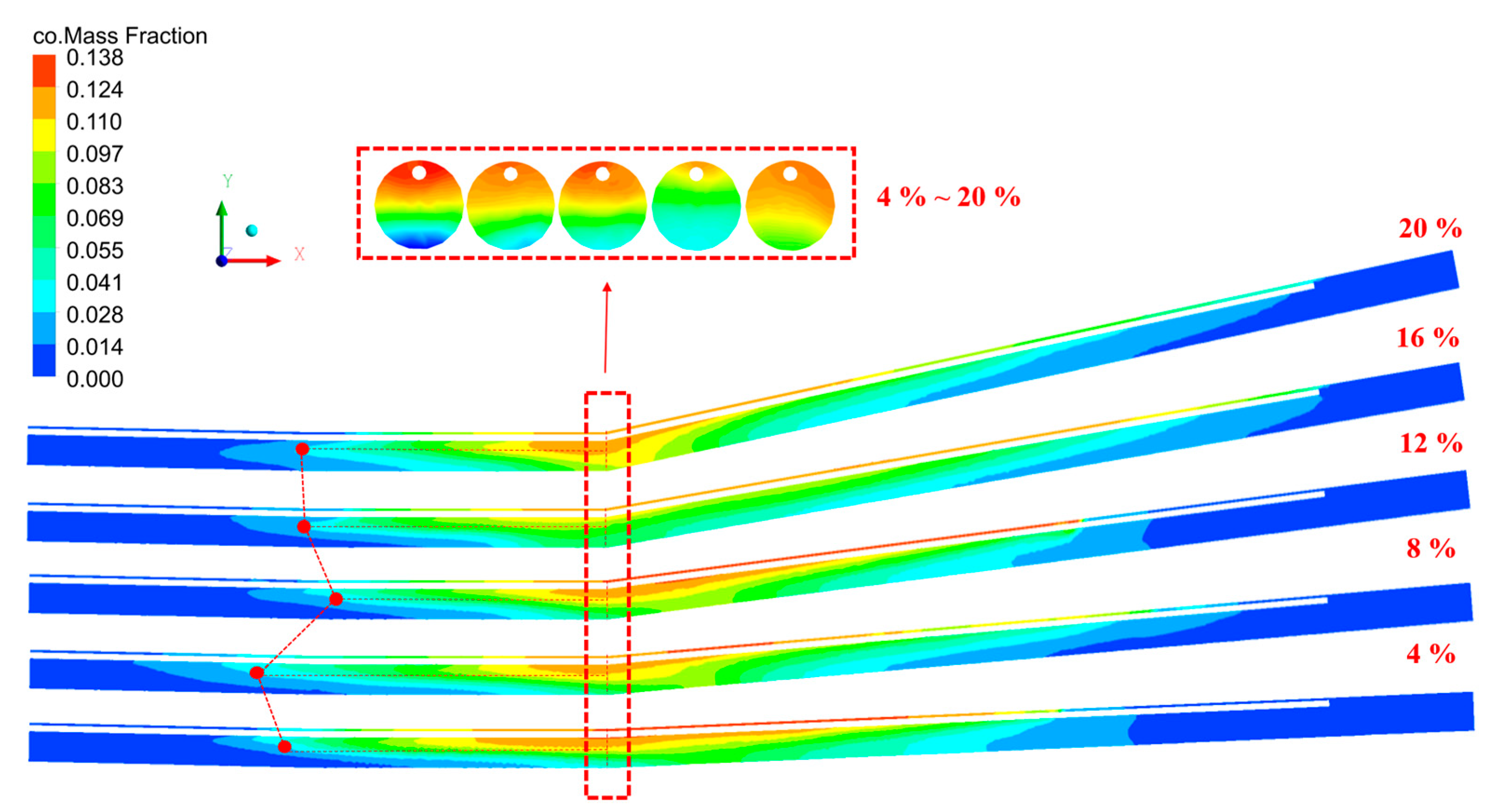

3.1.1. Effect of on the Flow Field

3.1.2. Effect of on the Flow Field

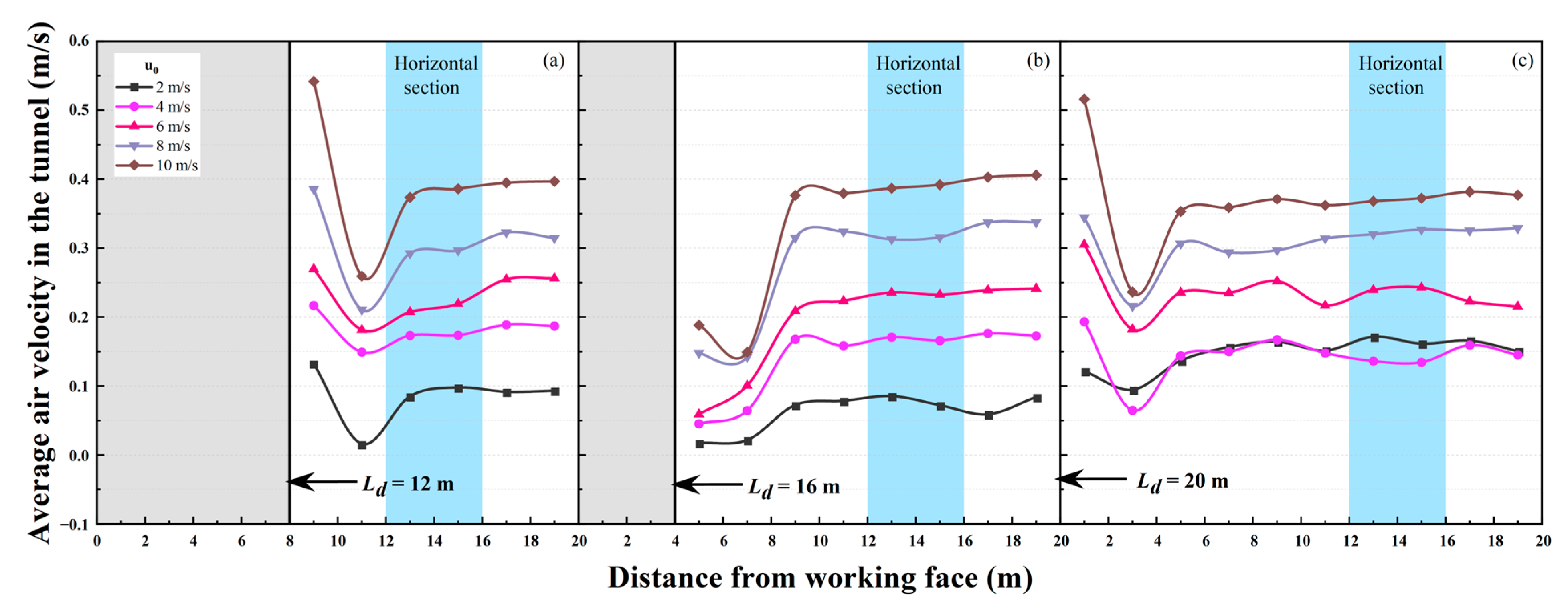

3.1.3. Effect of on the Flow Field

3.1.4. Effect of on the Flow Field

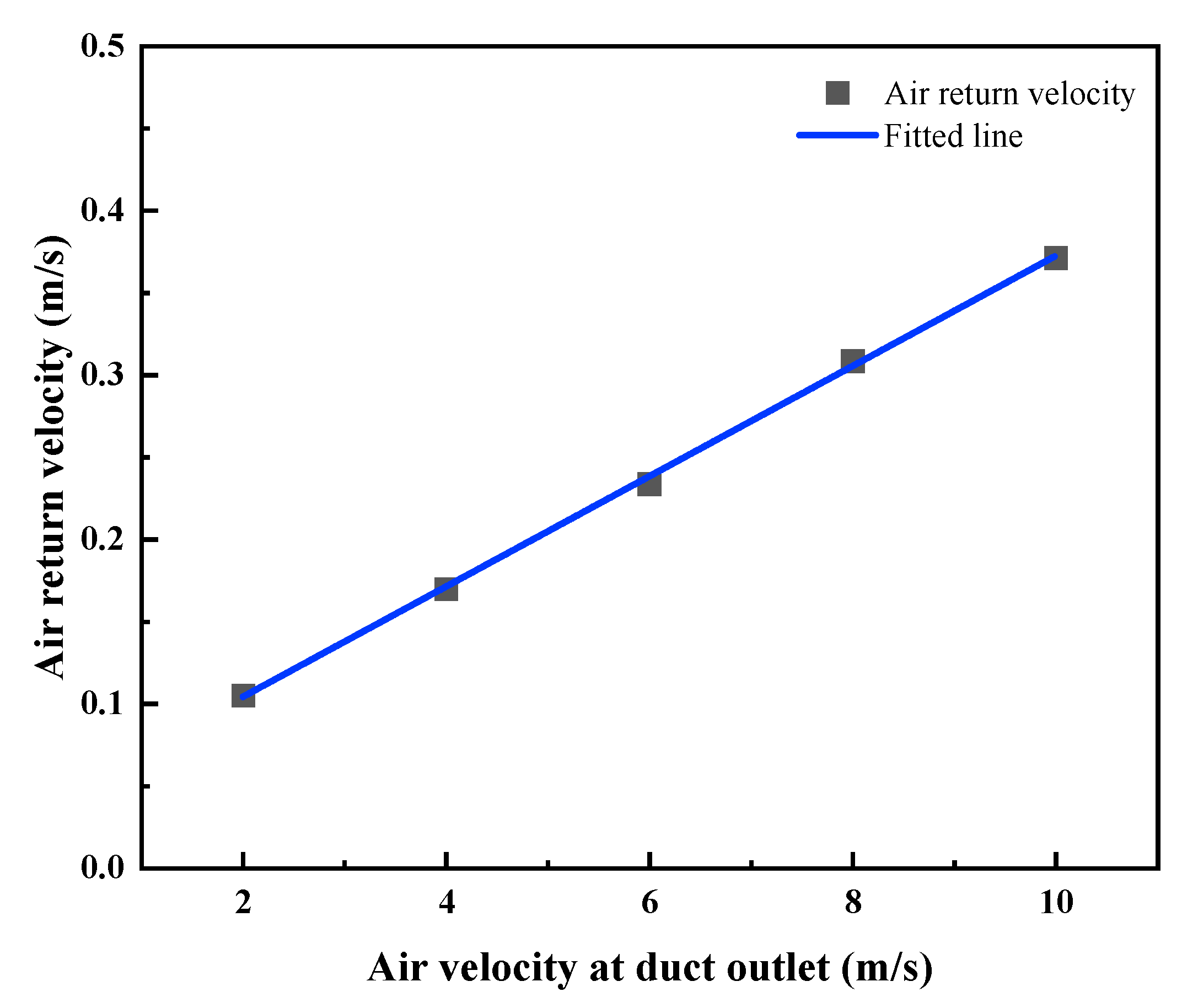

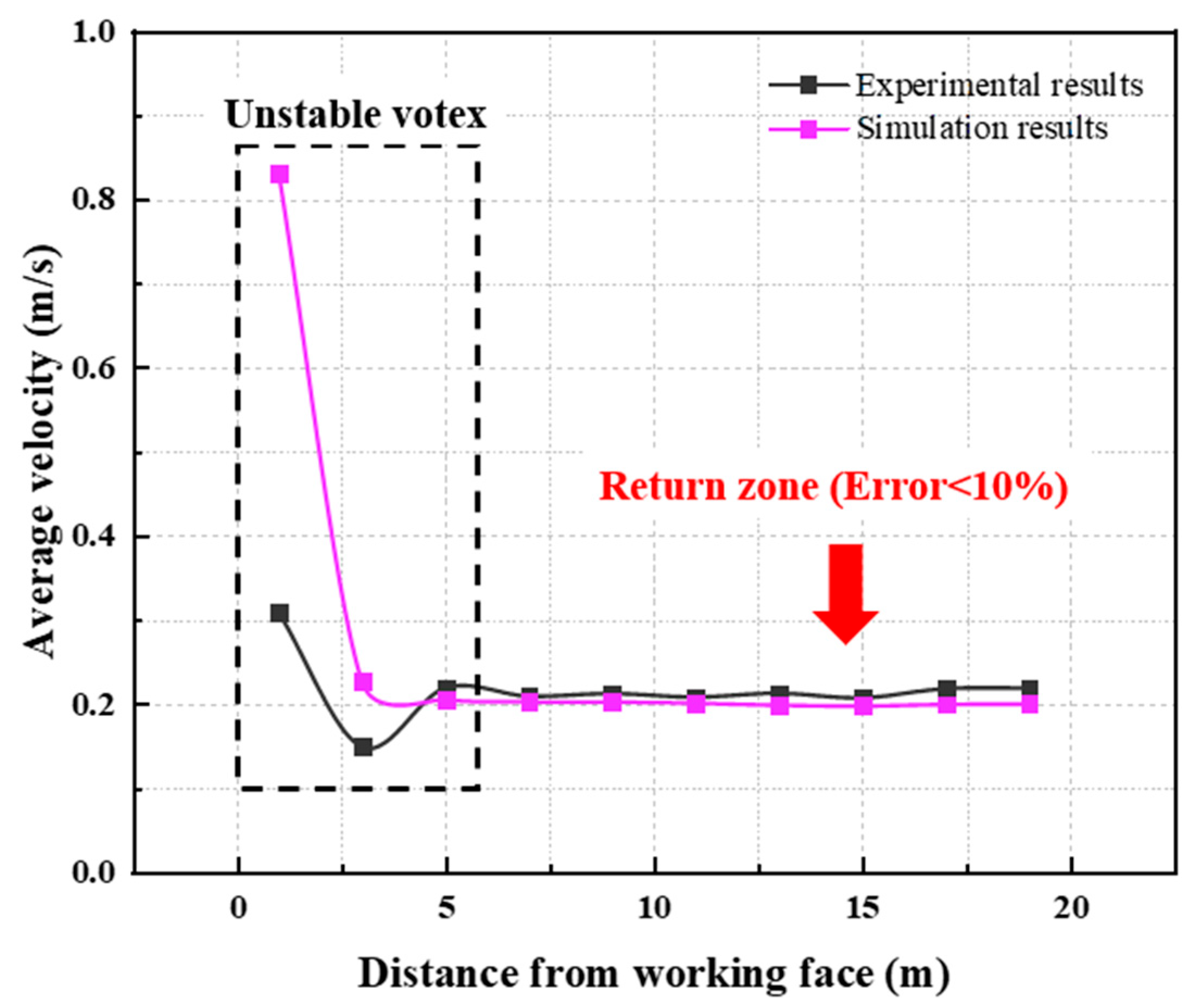

3.1.5. Derivation of the Air Return Velocity

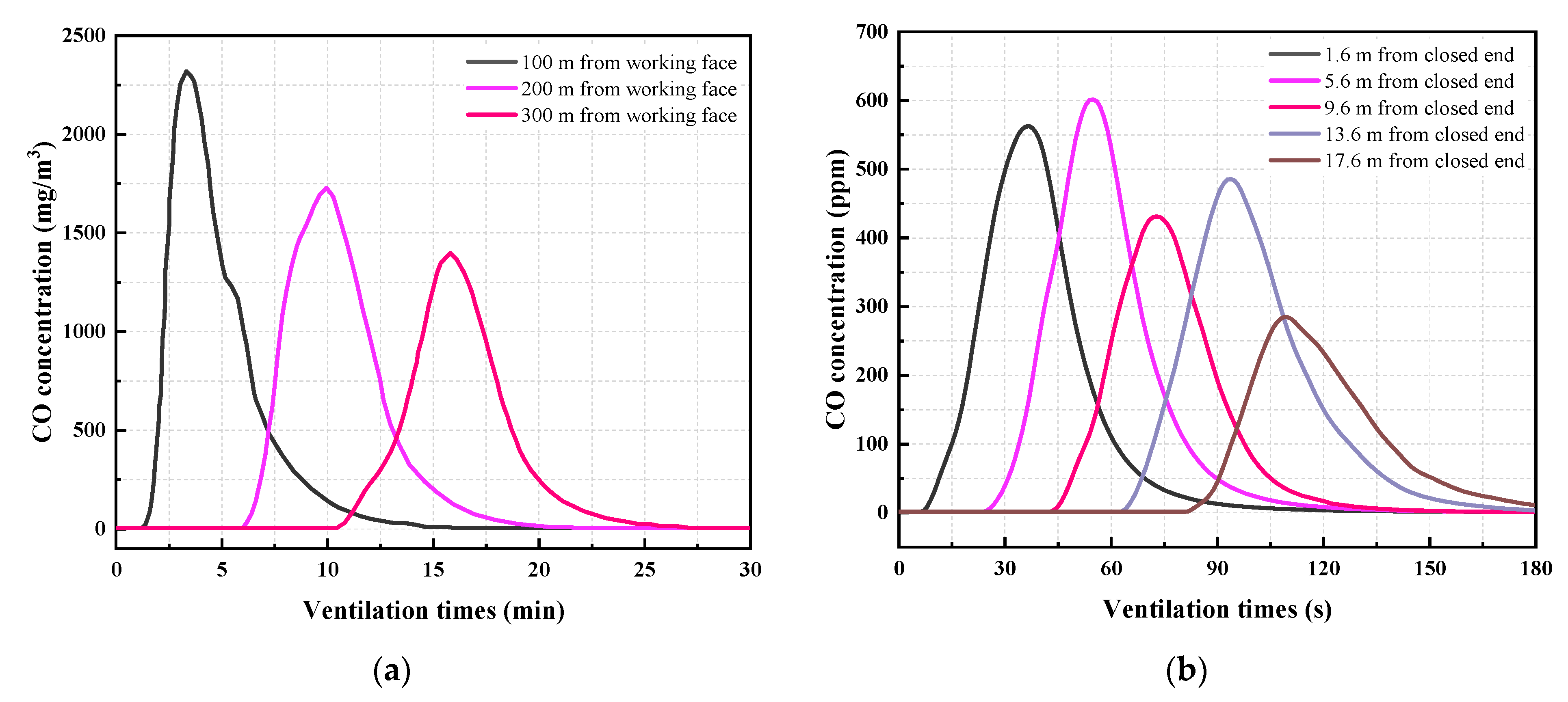

3.2. CO Diffusion Law

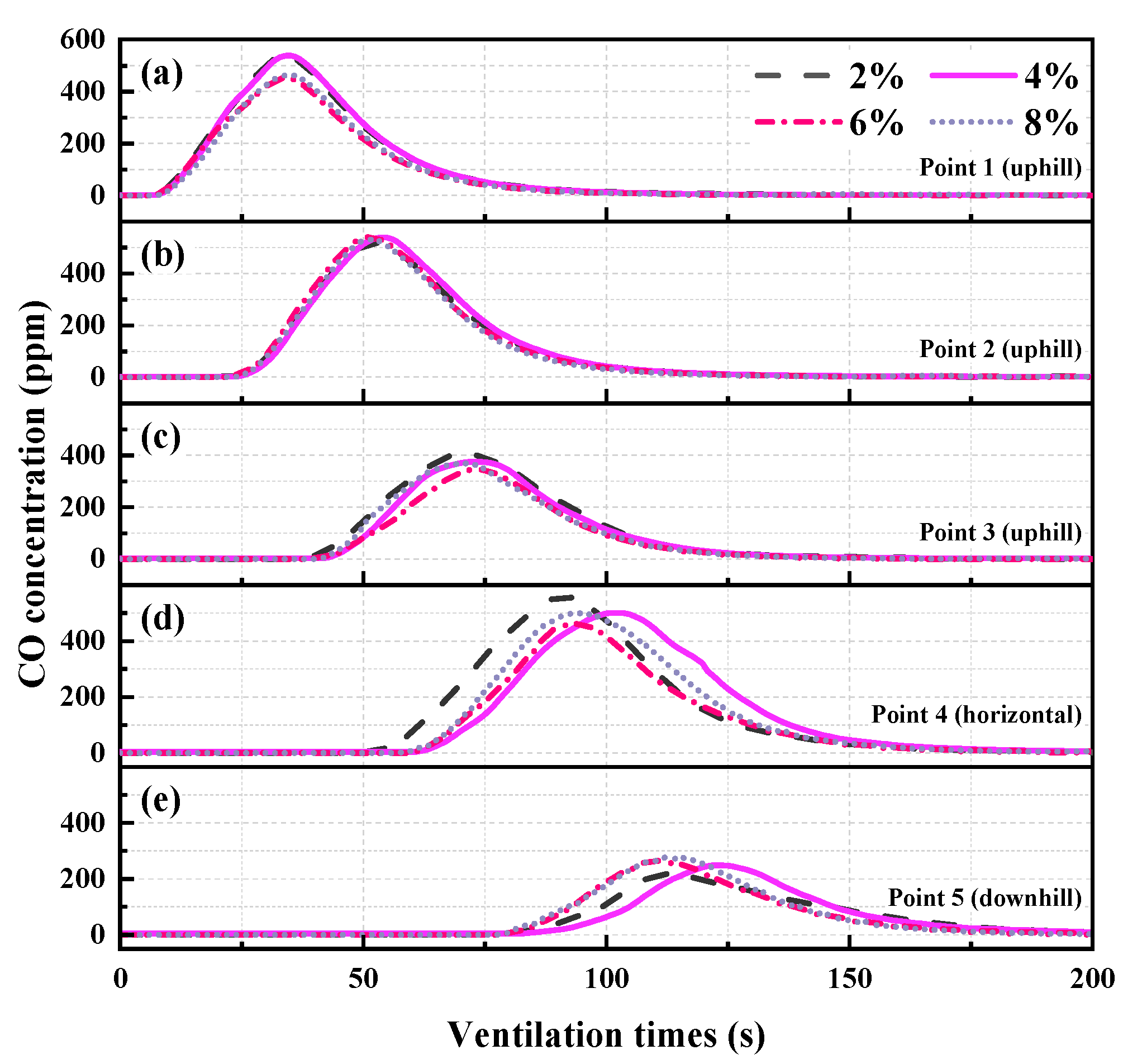

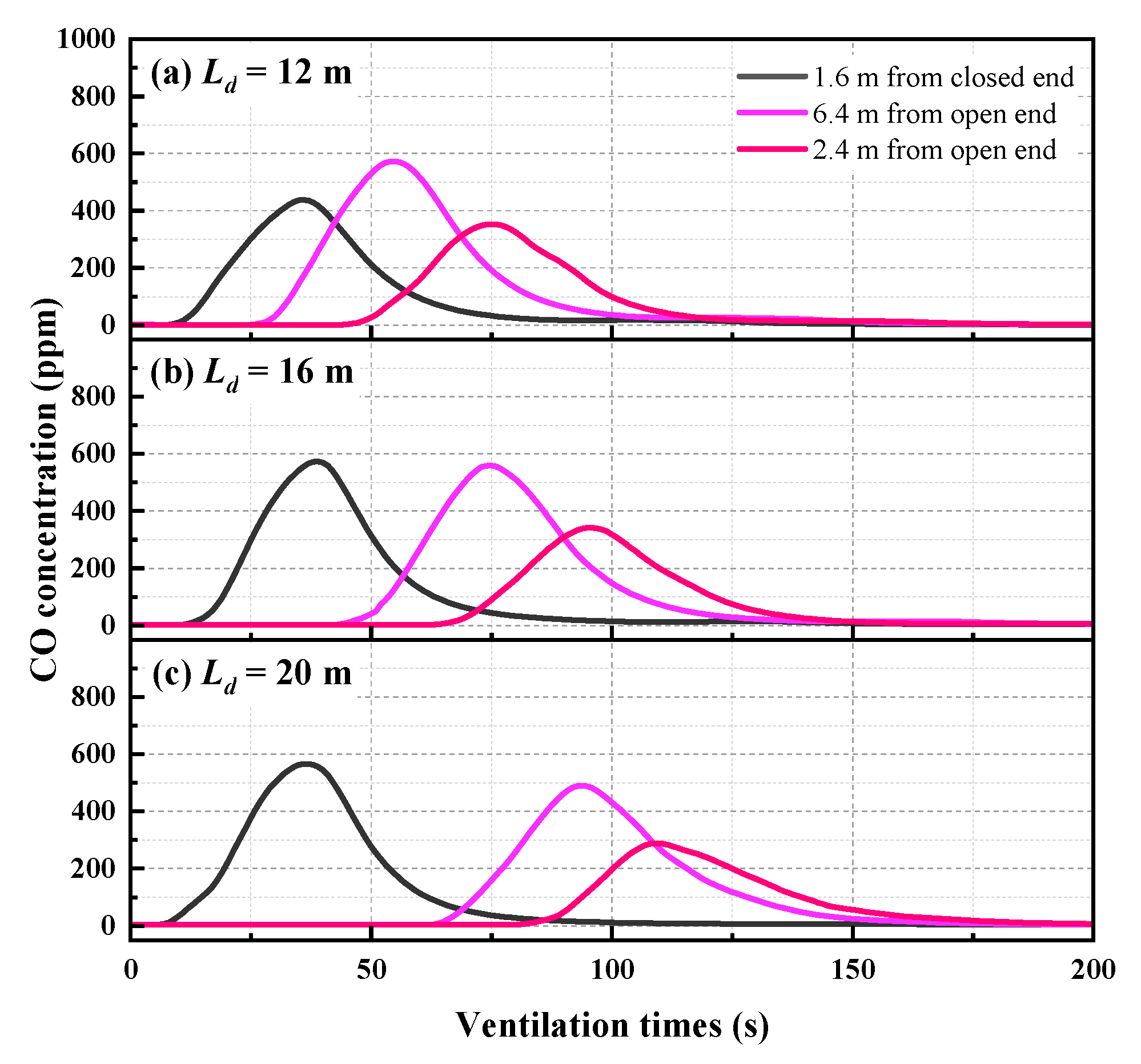

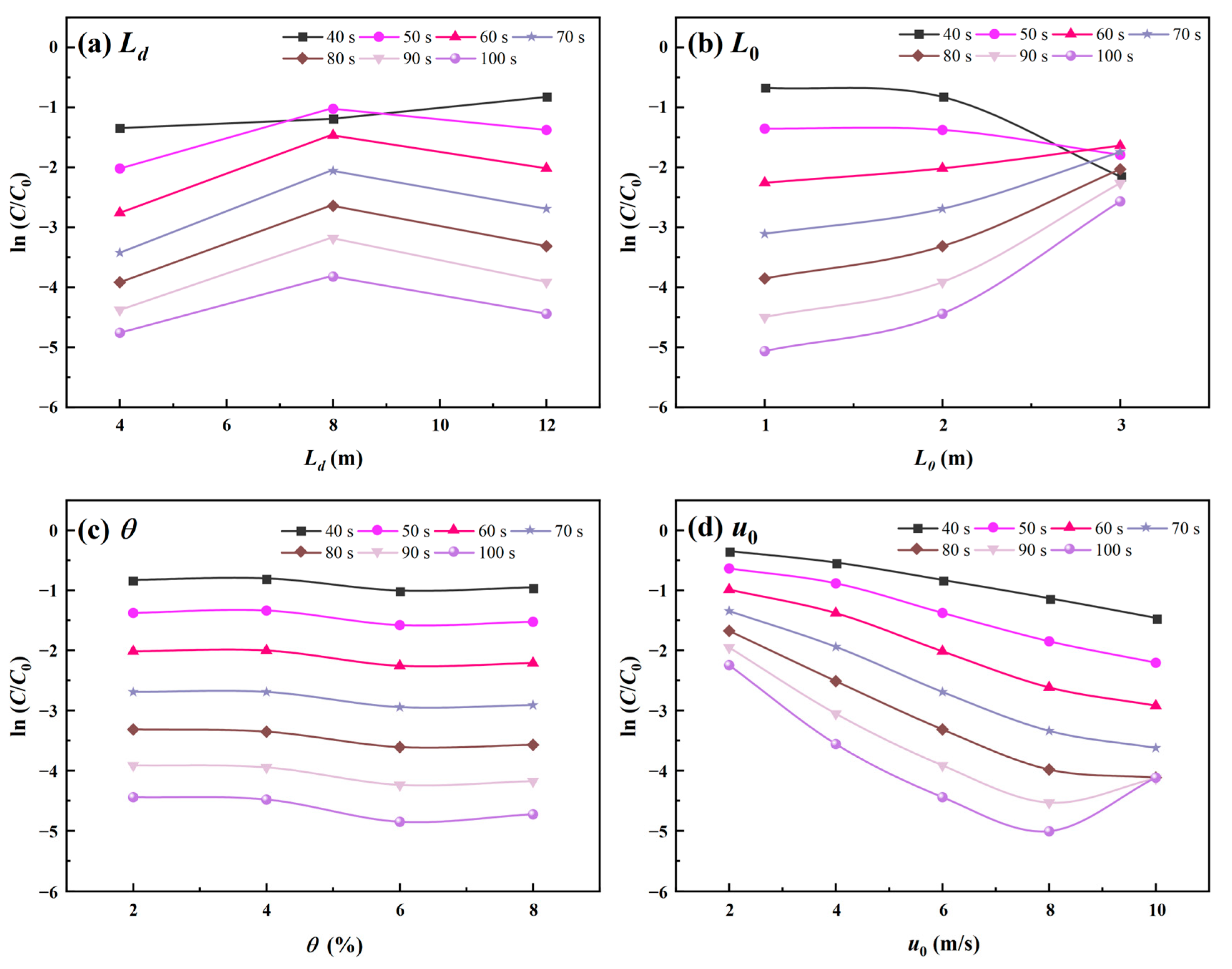

3.2.1. Effect of on the CO Diffusion

3.2.2. Effect of on the CO Diffusion

3.2.3. Effect of on the CO Diffusion

3.2.4. Effect of on the CO Diffusion

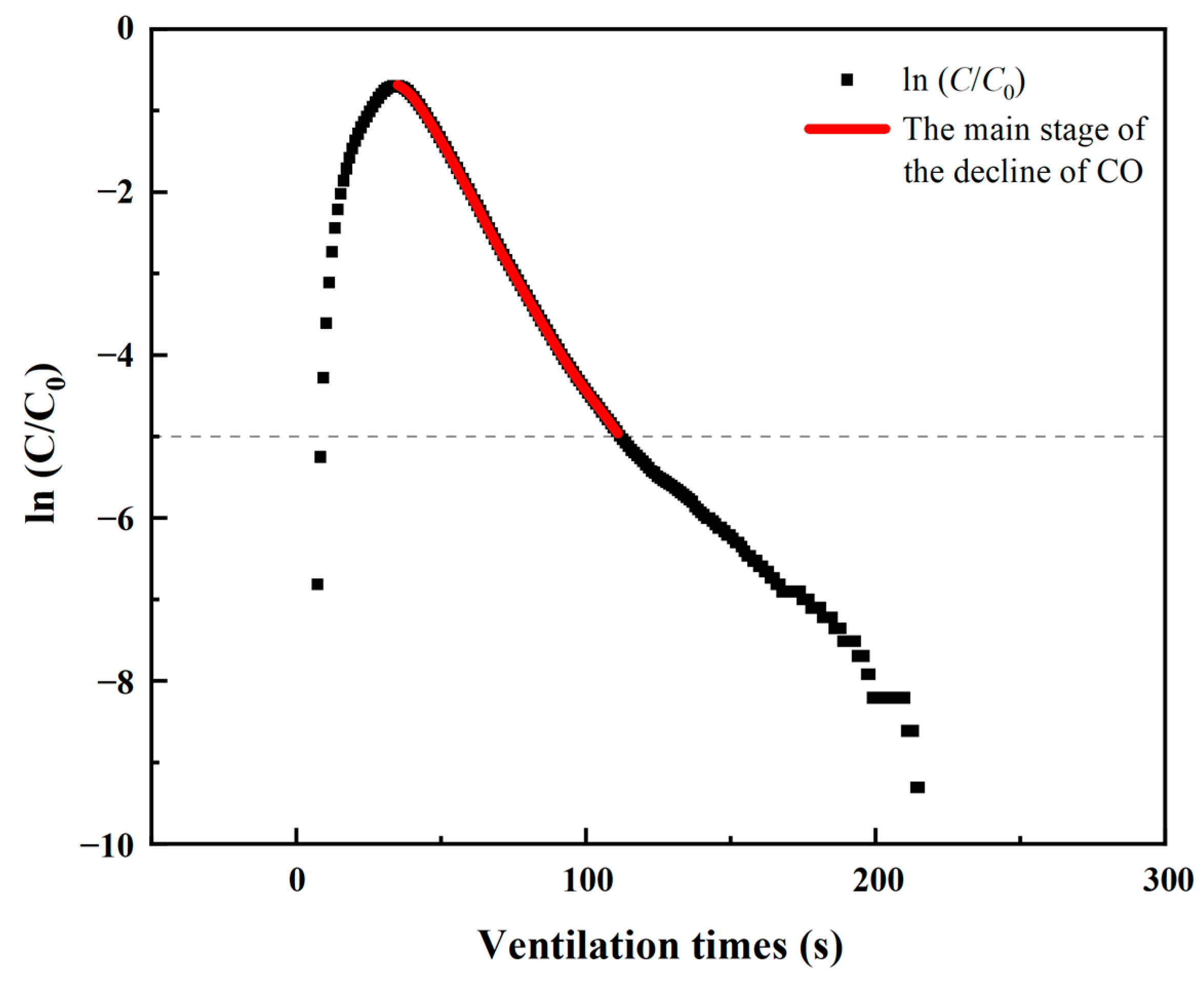

3.3. Derivation of the CO Distribution Function

3.3.1. Control Zone

3.3.2. Diffusion Zone

4. Conclusions

- The order of importance of the effect on the magnitude of the air return velocity is: . Where increases in and cause to increase and decrease, respectively. and have no significant effect on to a limited extent. The as a function of is derived.

- Pollutant transport characteristics of V-shaped tunnels and flat tunnels were compared. The peak of CO concentration along the longitudinal direction of the model does not decay unidirectionally as in the case of flat tunnels but shows fluctuating decay. Unconventionally high pollutant concentration occurs in the horizontal section of the model, making the V-shaped tunnel have critical ventilation areas other than the working area.

- Excessive levels of and lead to a significant increase in the time required for pollutant emission. In contrast, increasing without considering the flow field stabilization in the work area has the opposite effect. The discharge of pollutants is more favorable when the value is smaller. Conversely, a larger value results in a wider spread of pollutants.

- The functional relationship between CO concentration and each influencing factor in the control zone and diffusion zone is derived. The formula can be used to find the ventilation time required for similar projects.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| cross-sectional area of the wind duct, m2 | |

| area of each region after equal-area division, m2 | |

| initial CO concentration, ppm | |

| CO concentration, ppm | |

| equivalent diameter of the tunnel model, m | |

| distance from the outlet of wind duct to the closed end of the model, m | |

| digging distance/model length, m | |

| air volume at the outlet of wind duct, m3/s | |

| ventilation time, s | |

| the moment of peak CO concentration transport to the open end of the model, , s. | |

| air velocity at the outlet of wind duct, m/s | |

| air velocity in each area after equal-area division, m/s | |

| average air velocity at the outlet of wind duct, m/s | |

| air return velocity within the model, m/s | |

| minimum air return velocity to be satisfied in the tunnel, m/s | |

| velocity of movement of peak CO concentration, m/s | |

| volume of the control zone, m3 | |

| distance of a position from the closed end of the model, m | |

| slope of the uphill section of the model, % |

References

- Chen, K.S.; Chung, C.Y.; Wang, S.W. Measurement and three-dimensional Modeling of airflow and pollutant dispersion in an undersea traffic tunnel. J. Air Waste Manag. Assoc. 2002, 52, 349–363. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.; Wang, M.N.; Yu, L.; Tian, Y.; Yan, G.F. Influence of high humidity and salt-rich spray environment on ventilation effect in urban undersea road tunnel. Tunn. Undergr. Space Technol. 2019, 94, 103109. [Google Scholar] [CrossRef]

- Huang, L.Z.; Bohne, R.A.; Bruland, A.; Jakobsen, P.D.; Lohne, J. Environmental impact of drill and blast tunnelling: Life cycle assessment. J. Clean. Prod. 2015, 86, 110–117. [Google Scholar] [CrossRef]

- Tang, S.H.; Zhang, X.P.; Liu, Q.S.; Xie, W.Q.; Wu, X.L.; Chen, P.; Qian, Y.H. Control and prevention of gas explosion in soft ground tunneling using slurry shield TBM. Tunn. Undergr. Space Technol. 2021, 113, 103963. [Google Scholar] [CrossRef]

- Chow, W.K.; Wong, K.Y.; Chung, W.Y. Longitudinal ventilation for smoke control in a tilted tunnel by scale modeling. Tunn. Undergr. Space Technol. 2010, 25, 122–128. [Google Scholar] [CrossRef]

- Jiang, Z.A.; Wang, Y.P.; Men, L.G. Ventilation control of tunnel drilling dust based on numerical simulation. J. Cent. South Univ. 2021, 28, 1342–1356. [Google Scholar] [CrossRef]

- Liu, Q.; Cheng, W.M.; Liu, L.S.; Hua, Y.; Guo, L.D.; Nie, W. Research on the control law of dust in the main ventilation system in excavated tunnels for cleaner production. Build. Environ. 2021, 205, 108282. [Google Scholar] [CrossRef]

- Parra, M.T.; Villafruela, J.M.; Castro, F.; Méndez, C. Numerical and experimental analysis of different ventilation systems in deep mines. Build. Environ. 2006, 41, 87–93. [Google Scholar] [CrossRef]

- Qi, T.Y.; Lei, B.; Wang, R.; Li, Y.; Li, Z.Y. Solid-fluid-gas coupling prediction of harmful gas eruption in shield tunneling. Tunn. Undergr. Space Technol. 2018, 71, 126–137. [Google Scholar] [CrossRef]

- Wang, H.; Nie, W.; Cheng, W.M.; Liu, Q.; Jin, H. Effects of air volume ratio parameters on air curtain dust suppression in a rock tunnel’s fully-mechanized working face. Adv. Powder Technol. 2018, 29, 230–244. [Google Scholar] [CrossRef]

- Nan, C.Z.; Ma, J.M.; Luo, Z.; Zheng, S.L.; Wang, Z.W. Numerical study on the mean velocity distribution law of air backflow and the effective interaction length of airflow in forced ventilated tunnels. Tunn. Undergr. Space Technol. 2015, 46, 104–110. [Google Scholar] [CrossRef]

- Li, M.; Aminossadati, S.M.; Wu, C. Numerical simulation of air ventilation in super-large underground developments. Tunn. Undergr. Space Technol. 2016, 52, 38–43. [Google Scholar] [CrossRef]

- Chang, X.K.; Chai, J.R.; Luo, J.P.; Qin, Y.; Xu, Z.G.; Cao, J. Tunnel ventilation during construction and diffusion of hazardous gases studied by numerical simulations. Build. Environ. 2020, 177, 106902. [Google Scholar] [CrossRef]

- Fang, Y.; Fan, J.G.; Kenneally, B.; Mooney, M. Air flow behavior and gas dispersion in the recirculation ventilation system of a twin-tunnel construction. Tunn. Undergr. Space Technol. 2016, 58, 30–39. [Google Scholar] [CrossRef]

- Garcia-Diaz, M.; Sierra, C.; Miguel-Gonzalez, C.; Pereiras, B. A Discussion on the Effective Ventilation Distance in Dead-End Tunnels. Energies 2019, 12, 3352. [Google Scholar] [CrossRef]

- Wang, Y.P. Case study on ventilation and cooling control technology of multi heat source coupling in long distance subsea tunnel construction. Case Stud. Therm. Eng. 2021, 26, 101061. [Google Scholar] [CrossRef]

- Zeng, Y.H.; Tao, L.L.; Ye, X.Q.; Zhou, X.H.; Fang, Y.; Fan, L.; Liu, X.R.; Yang, Z.X. Temperature reduction for extra-long railway tunnel with high geotemperature by longitudinal ventilation. Tunn. Undergr. Space Technol. 2020, 99, 103381. [Google Scholar] [CrossRef]

- Rodriguez, R.; Lombardia, C. Analysis of methane emissions in a tunnel excavated through Carboniferous strata based on underground coal mining experience. Tunn. Undergr. Space Technol. 2010, 25, 456–468. [Google Scholar] [CrossRef]

- Nie, W.; Cheng, L.; Yin, S.; Liu, Q.; Hua, Y.; Guo, L.D.; Cai, X.J.; Ma, Q.X.; Guo, C. Effects of press-in airflow rate and the distance between the pressure duct and the side wall on ventilation dust suppression performance in an excavating tunnel. Environ. Sci. Pollut. Res. 2022, 29, 19404–19419. [Google Scholar] [CrossRef]

- Xia, Y.M.; Yang, D.; Hu, C.H.; Wu, C.Z.; Han, J.L. Numerical simulation of ventilation and dust suppression system for open-type TBM tunneling work area. Tunn. Undergr. Space Technol. 2016, 56, 70–78. [Google Scholar] [CrossRef]

- Zhou, W.J.; Nie, W.; Liu, C.Q.; Liu, Q.; Wang, H.T.; Wei, C.H.; Yan, J.Y.; Yin, S.; Xiu, Z.; Xu, C.W. Modelling of ventilation and dust control effects during tunnel construction. Int. J. Mech. Sci. 2019, 160, 358–371. [Google Scholar] [CrossRef]

- Xie, Z.W.; Ruan, C.; Zhao, Z.T.; Huang, C.; Xiao, Y.M.; Zhao, Q.; Lin, J.Q. Effect of ventilation parameters on dust pollution characteristic of drilling operation in a metro tunnel. Tunn. Undergr. Space Technol. 2023, 132, 104867. [Google Scholar] [CrossRef]

- Fang, Y.; Yao, Z.G.; Lei, S. Air flow and gas dispersion in the forced ventilation of a road tunnel during construction. Undergr. Space 2019, 4, 168–179. [Google Scholar] [CrossRef]

- Zhou, Y.; Yang, Y.; Bu, R.W.; Ma, F.; Shen, Y.J. Effect of press-in ventilation technology on pollutant transport in a railway tunnel under construction. J. Clean. Prod. 2020, 243, 118590. [Google Scholar] [CrossRef]

- Xie, Z.W.; Xiao, Y.M.; Jiang, C.X.; Ren, Z.L.; Li, X.Q.; Yu, K.C. Numerical study on fine dust pollution characteristics under various ventilation time in metro tunnel after blasting. Build. Environ. 2021, 204, 108111. [Google Scholar] [CrossRef]

- Feng, X.; Jiang, Z.A.; Zhang, G.L.; Luo, X.; Zeng, F.B. Study on CO diffusion law and concentration distribution function under ventilation after blasting in high-altitude tunnel. J. Wind. Eng. Ind. Aerodyn. 2022, 220, 104871. [Google Scholar] [CrossRef]

- Zhang, X. Study on Ventilation Characteristic and Pollution Synergetic Control of Abnormity Structure Urban Tunnel; Zhejiang University: Hangzhou, China, 2018; Available online: https://link.cnki.net/doi/10.27461/d.cnki.gzjdx.2018.000079 (accessed on 1 January 2022).

- Ma, F. Research on the Ventilation Technology of Extra-Long Railway Tunnel under Construction; Central South University: Changsha, China, 2018. [Google Scholar]

- Liu, R.; Jiang, D.Y.; Chen, J.; Ren, S.; Fan, J.Y.; He, Y. Blasting dust diffuse characteristics of spiral tunnel and dust distribution model: Similar experiment and numerical modeling. Environ. Sci. Pollut. Res. 2023, 30, 52340–52357. [Google Scholar] [CrossRef] [PubMed]

- Jiao, A.; Shen, Y.J.; Wang, Z.Y.; Chen, T.; Tao, H.W.; Xu, Z.S.; Fan, C.G. Experimental study on the effect of canyon cross wind yaw angle on airflow and flame characteristics in a tunnel. J. Wind. Eng. Ind. Aerodyn. 2021, 213, 104616. [Google Scholar] [CrossRef]

- Tao, Y.C.; Hu, H.; Zhang, H.; Zhang, G.; Hao, Z.H.; Wang, L. A new ventilation system for extra-long railway tunnel construction by using the air cabin relay: A case study on optimization of air cabin parameters length. J. Build. Eng. 2022, 45, 103480. [Google Scholar] [CrossRef]

- Ansys Fluent, Release 20.2 © 2020 Copyright ANSYS, Inc. Available online: https://www.ansys.com/zh-cn/products/fluids/ansys-fluent (accessed on 1 October 2021).

| Types | Inner Diameter of the Tunnel (m) | Inner Diameter of the Ventilation Duct (m) | Distance from the Duct Outlet to the Closed End of the Tunnel (m) |

|---|---|---|---|

| Prototype tunnel | 12.6 | 2.0 | 25/50/75 |

| Small-scale model | 0.50 | 0.08 | 1/2/3 |

| Instruments | Range | Accuracy |

|---|---|---|

| Hot-wire anemometer | 0.3~30 m/s | 1% |

| Micro differential pressure transmitters | −25 to 25 Pa | 0.4% |

| CO flow meter | 0.1 to 1 L/min | 4% |

| CO detector | 0 to 1000 ppm | 3% |

| Test No. | Slope of the Uphill Section (%) | Tunneling Length (m) | Distance from the Duct Outlet to the Closed End (m) | Air Velocity at the Duct Outlet (m/s) |

|---|---|---|---|---|

| 1–45 | 2 | 12, 16, 20 | 1, 2, 3 | 2, 4, 6, 8, 10 |

| 46–90 | 4 | 12, 16, 20 | 1, 2, 3 | 2, 4, 6, 8, 10 |

| 91–135 | 6 | 12, 16, 20 | 1, 2, 3 | 2, 4, 6, 8, 10 |

| 136–180 | 8 | 12, 16, 20 | 1, 2, 3 | 2, 4, 6, 8, 10 |

| Parameter Type | Parameter | Parameter Setting |

|---|---|---|

| Mesh | Quantity and quality | 3.2 × 105, 0.35–0.99 |

| General | Time | Transient |

| Solver type | Pressure-based | |

| Gravity | X: 0, Y: −9.81, Z: 0 (m/s2) | |

| Model | Viscous model | Standard (2 eqn) |

| Species (Species transport model) | Mixture template (CO, air) Density: volume–weight mixing law Viscosity: constant | |

| Materials | CO (fluid) | Density: constant, 1.1233 kg/m3 |

| Air (fluid) | Density: constant, 1.225 kg/m3 | |

| Boundary | Velocity inlet | 6 m/s |

| CO inlet (mass-flow inlet) | 0.00752 kg/s (release for 25 s) | |

| Tunnel model and duct (wall) | No slip wall | |

| Open end (pressure outlet) | 101.325 kPa, Turbulence intensity 5% | |

| Solution | Pressure–velocity coupling scheme | Simple |

| Gradient | Least-squares cell-based | |

| Pressure | Second-order | |

| Momentum | Second-order upwind | |

| Turbulent kinetic energy | First-order upwind | |

| Turbulent dissipation rate | First-order upwind | |

| CO | Second-order upwind | |

| Solution controls | Pressure 0.3, Density 1, CO 1 | |

| Initialization | Initialization methods | Standard |

| Initial values | CO: 0 | |

| Calculation | Type | Fixed |

| Time steps (s) | 1 | |

| Max iterations | 50 |

| Parameter | Calculation Results |

|---|---|

| a | −0.03062 |

| b | 0.00147 |

| c | −0.072 |

| d | −5.289 |

| e | 0.0447/ |

| R2 = 0.84 |

| Stage I | ||||||

|---|---|---|---|---|---|---|

| 4 m/s | 0.011296t/T0 − 0.013823 | −0.85433t/T0 + 1.15923 | −10.0323(t/T0)2 + 20.02265t − 10.22568 | 30.48233(t/T0)2 − 63.12055t/T0 + 27.2187 | −0.03046 | 0.892 |

| 6 m/s | 0.01009t/T0 − 0.01396 | −0.13118t/T0 + 0.21549 | −2.95656(t/T0)2 + 6.12402t − 3.31801 | 16.52183(t/T0)2 − 38.29427t/T0 + 16.88465 | −0.0015 | 0.924 |

| 8 m/s | 0.08281t/T0 − 0.11163 | −0.6216t/T0 + 0.89907 | −5.59428(t/T0)2 + 12.78034t − 7.3066 | 13.52062(t/T0)2 − 33.28801t/T0 + 16.15787 | −0.0498 | 0.884 |

| 10 m/s | 0.04982t/T0 − 0.07595 | −0.30228t/T0 + 0.53842 | −4.02468(t/T0)2 + 9.31002t − 5.36407 | 9.88393(t/T0)2 − 26.43139t/T0 + 13.14085 | −0.00224 | 0.935 |

| Stage Ⅱ | |||||

|---|---|---|---|---|---|

| 4 m/s | 0.14269t/T0 − 0.19804 | −1.64291(t/T0)2 + 3.02047t/T0 − 0.26269 | 6.99498(t/T0)2 − 20.7725t/T0 + 6.82536 | −0.02483 | 0.909 |

| 6 m/s | 0.22029t/T0 − 0.29843 | −1.13271(t/T0)2+ 0.073205t/T0 + 1.67585 | 6.79006(t/T0)2 − 18.2798t/T0 + 5.34493 | −0.03139 | 0.933 |

| 8 m/s | 0.06615t/T0 − 0.09061 | −0.31577(t/T0)2 + 0.17934t/T0 + 0.808 | 2.3919(t/T0)2 − 9.71992t/T0 + 3.34618 | −0.03853 | 0.950 |

| 10 m/s | 0.02331t/T0 − 0.02105 | −0.41196(t/T0)2 + 1.18699 t/T0 − 0.60127 | 0.91471(t/T0)2 − 7.17993t/T0 + 3.69721 | −0.05098 | 0.950 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yi, L.; Wang, X.; Shen, Y. Experimental Study on the Forced Ventilation Safety during the Construction of a Large-Slope V-Shaped Tunnel. Appl. Sci. 2024, 14, 2924. https://doi.org/10.3390/app14072924

Yi L, Wang X, Shen Y. Experimental Study on the Forced Ventilation Safety during the Construction of a Large-Slope V-Shaped Tunnel. Applied Sciences. 2024; 14(7):2924. https://doi.org/10.3390/app14072924

Chicago/Turabian StyleYi, Linghong, Xiaoni Wang, and Yongjiang Shen. 2024. "Experimental Study on the Forced Ventilation Safety during the Construction of a Large-Slope V-Shaped Tunnel" Applied Sciences 14, no. 7: 2924. https://doi.org/10.3390/app14072924

APA StyleYi, L., Wang, X., & Shen, Y. (2024). Experimental Study on the Forced Ventilation Safety during the Construction of a Large-Slope V-Shaped Tunnel. Applied Sciences, 14(7), 2924. https://doi.org/10.3390/app14072924