Abstract

Based on the promotion and application of green and low-carbon technology, this study aims to develop a high-safety performance cement concrete incorporating a large dosage of fly ash (FA). The safety and effect of FA content on the mechanical properties of FA composited cement were studied through compressive strength, flexural strength, and microscopic tests. The results show that when the FA replaced 20% cement, the properties of concrete were the best in this study. The flexural strengths and compressive strengths of the standard cured concrete for 28 days with 20% FA content are 0.82 MPa and 4.32 MPa larger than that of the pure cement concrete. The XRD and SEM analysis suggested that the mechanical properties of the composite cement FA system are improved significantly since the replacement of cement by FA promotes secondary hydration of calcium hydroxide in the concrete, leading to a more compact and safe interface between cement and FA.

1. Introduction

Concrete is still an engineering material with the largest usage and the widest application range in construction projects since it has good plasticity, economy, high-strength, and durability [1]. Cement is an important component of concrete, and a lot of CO2 is emitted into the atmosphere during its production [2]. Cement production accounts for about 10% of the world’s current annual CO2 emissions, which is about 32.3 billion tones [3]. Ordinary Portland cement (OPC) requires a lot of energy to produce, and the manufacturing process releases toxic CO2 into the environment. Large amounts of CO2 emission leads to the greenhouse effect and aggravates global warming. A large portion of the waste produced in the manufacturing process is dumped and disposed of in landfills, damaging the soil and causing environmental pollution [4]. Since the sustainable development model of the social economy has been proposed, the protection of the environment and ecology is required in the production, use, maintenance, and reuse of concrete [5]. Meanwhile, climate anomalies caused by greenhouse gas emissions have become the focus of global attention, and the concrete industry is responsible for excessive emission of CO2 and other greenhouse gases [6]. The low carbon life aims to achieve the lower energy consumption and lower CO2 emission, which has received people’s response and recognition [7]. The concept of green high-performance concrete can be summarized as saving resources and energy, not damaging the environment, helpong the environment, aiding sustainable development, and ensuring the healthy and happy survival of human offspring [8]. This philosophy has raised attention of the performance improvement and energy conservation of concrete [9,10]. Therefore, it is an inevitable choice for the future development of engineering materials to make the cement concrete industry moving towardslow-carbon and sustainable development.

As an important link in sustainable development, the preparation methods of green and low-carbon concrete have been developed and promoted successively. The mechanical properties of concrete are affected by many factors, such as temperature and loading ratio [11,12]. Previous studies demonstrated that the reasonable composition ratio of mineral admixtures and recycled aggregates can greatly improve the performance of composite admixtures [13,14,15]. On the one hand, the compaction method and microstructure of concrete are also important factors affecting its performance [16]. Şengün, et al. [17] investigated the effect of four compaction techniques on the performance of concrete after 28 days through uniaxial compression and splitting tests. Results showed that the mechanical properties and mixing parameters of concrete are closely related to compacted density. On the other hand, an appropriate amount of mineral admixtures can achieve an effective supply of cement materials and improve the technical performance at a low cost [18,19]. Matar and Barhoun [20] found that the waterproofing admixture presents a strong inhibiting effect on the micro-cracking of the concrete surface by producing calcium silicate hydrates. Ji, et al. [21] performed laboratory tests to evaluate the hydration properties of concrete by adding magnesium slag, and the results suggest that a magnesium slag content of 30% can improve the working performance of concrete in frost resistance and crack resistance. Therefore, a series of mineral admixtures provide a convenient solution to enhance the mechanical properties of concrete considering the low-carbon and sustainability requirements.

A large amount of fly ash (FA) is produced in the coal industry every year as a by-product with a low utilized value [22]. At present, given that the utilization rate of FA is about 50% in the world, a lot of FA waste is piled up in landfills, occupying much arable land and space [23]. Zhang, et al. [24] calculated the CO2 emissions and cost of the concrete with FA addition and suggested that the effect of FA content on CO2 emissions is more obvious for higher-strength concrete. Uliasz-Bocheńczyk and Mokrzycki [25] reported the relative contribution of FA to reduce CO2 emissions is higher than 15% in the production process. Based on the above consideration, many studies declared that FA can be applied suitably as a substitute for cement to meet the needs of hydration products in concrete preparation, which is also an effective measure to produce low-carbon concrete [26]. Therefore, the exploration of FA admixture has become a research topic of green low-carbon concrete [27]. In addition, the usage of FA in concrete not only improves concrete performance but also provides an economical and effective way to consume FA [28]. The existing study found that the main chemical components of FA, as a pozzolanic material, are SiO2, Al2O3, CaO, Fe2O3, and a small number of unburned carbon particles [29]. Its major phases are vitreous aluminum silica and a small amount of quartz, mullite, and other minerals. A large number of vitreous substances are the main source of the gelling activity of FA and have potential hydration reactivity [30]. The activation methods of FA mainly include calcium treatment, single alkali excitation (lime, sodium silicate), sulfate excitation (CaSO4, Na2SO4), physical fine grinding or physical fine grinding combined with chemical activators, etc. Hwang and Huynh [31] obtained fine ash with a particle size of less than 45 μm by a wind separation method, which can improve the strength and working performance of concrete. Fan, et al. [32] demonstrated that the slurry fluidity and backfill strength of the cement material mixed with FA can meet the mining requirements of filling cement. Karakurt and Bayazıt [33] suggested that the strength of FA concrete may be obviously improved by activating the activity of FA with chemical admixtures. Poletanovic, et al. [34] found that the method of the combination of composite activation, mechanical activation, and chemical activator could enhance the activity of FA more significantly. Concrete consumption creates a large carbon footprint in the environment. Fly ash (FA), rice husk ash (RHA), and silica fume (SF) can replace cement in proper proportions to reduce CO2 emissions. FA affects the set-up time and sulfate resistance of concrete and can improve the workability of concrete mixtures. Conversely, the high surface area of SF particles reduces workability. A high LOI ratio indicates that RHA may evaporate when the concrete is exposed to high temperatures. FA and RHA, as substitutes for cement, have no adverse effect on the compressive strength of concrete, whereas the incorporation of SF into concrete can improve the overall compressive strength, tensile strength, and elastic modulus of concrete. SF not only improves the bond between the cement paste and the aggregate but also has a key advantage as an alternative to cement due to its ability to reduce the permeability of concrete [35]. It has been established that the mechanical strength of concrete will be affected when the replacement level of RHA and SF synergies is above 30%, and that concrete with a continued increase in RHA content will have lower mechanical strength than ordinary concrete. When the RHA content is increased to a certain extent, higher flexural strength can be obtained, and the durability of the concrete can be improved [36]. The combination of FA and nS is adopted to replace ordinary Portland cement (OPC), which significantly improves the mechanical properties of environmentally friendly concrete and the form of the cement matrix. At the same time, homogenization of the cement matrix promotes structural alignment of the composite materials mixed with FA and nS and reduces the carbon footprint of cement-based materials [37]. In addition, the research on the properties of FA concrete mainly focuses on the physical and chemical properties of the material, whereas the research and test data on the mechanical properties of concrete are relatively few. Therefore, the mechanical properties of FA concrete are investigated in depth in this study.

This study aimed to explore the high safety performance of green and low-carbon concrete. The improvement effect of FA on the performance of the composite Portland-cement–FA system was investigated. Under the condition that the amount of binder and water, the ratio of water to the binder, and the total amount of material used in the specimen are equal, the concrete was prepared by adding the FA content instead of cement. Through the mechanical properties test, XRD, and SEM analysis, the influence law of FA content on the road performance of concrete was comprehensively discussed. The research results provide support for the future study of FA content in concrete from both theoretical and data aspects and obtains the optimal FA content.

2. Materials and Methods

2.1. Materials

This study used Portland cement, which comes from a cement plant in Ningxia.

Cement is a type of binder that can bond at room temperature. It can set and harden to adhere to sand, brick, stone, and other building materials. The chemical composition of cement contains the most Fe2O3 content and quite a lot of SiO2.

Fe2O3 in cement is responsible for the cement’s acting as a flux in the high-temperature manufacturing process. It combines with Ca and Al2O3 to form C2F, which is the main component of cement hardness. SiO2 is responsible for reacting with lime to form 2CaO·SiO2 and 3CaO·SiO2, and the correct proportion of SiO2 plays an important role in improving cement strength.

Table 1 presents the test results of physical and mechanical properties, which meet the requirements of construction performance.

Table 1.

Physical and mechanical properties of tested cement.

Table 2 displays the chemical compositions of Portland Cement.

Table 2.

Chemical compositions of cement.

The coarse sand produced in Xiamen was used as the fine aggregate. With a fineness modulus of 3.4, the coarse sand is in zone Ⅱ. The water content is 3%. The apparent density is 2590 kg/m3, and the mud content is 1.8%.

Crude FA comes from Tianjin. The specific surface area is 252 m2/kg, and the fineness (0.044 mm square hole sieve residue) is 20.2%. The water demand ratio is 98%. Table 3 lists the main chemical composition of FA.

Table 3.

Chemical composition of FA.

Clean drinking water or fresh water is used in the design of the concrete mix in this study. The water quality must be tested as the following requirements to ensure it is available for concrete preparation.

- (1)

- Sulfate content (measured by SO42−) should be less than 0.0027 mg/mm3;

- (2)

- Salt content should not exceed 0.005 mg/mm3;

- (3)

- PH should not be less than 4.6;

- (4)

- Do not contain oil, mud, and other harmful impurities.

2.2. FA Addition

The objective is to study the impact of FA content on the working performance of concrete, based on the same water–cement ratio, water–binder ratio, water consumption, the amount of cementing material, and the total amount of material used in specimens, according to the equal substitution method adopted in concrete mix design, the FA content was, respectively, compared with the total content of 0, 5%, 10%, 15%, 20%, 25%, 30%, 35%, 40%, 45%, and 50% in this test.

2.3. Testing Design

The slump and density of the specimen were measured before assembling. Then, a standard test mold, according to the Method of Test method of mortar strength (ISO method), was used to make concrete test specimens, and the mold was removed after 24 h. After the test pieces were made, they were placed in a standard curing box (relative humidity 98%, temperature 20 °C) for curing. After the standard curing for 3 days, 7 days, and 28 days, respectively, concrete test specimens with a size of 40 mm × 40 mm × 160 mm were applied to obtain the compressive strength and flexural strength. According to the Chinese Standard for test method of mechanical properties on ordinary concrete (GB/T 50081-2002), the concrete specimens were prepared and standard cured as shown in Figure 1. Table 4 lists the mix ratio design scheme of concrete specimens. Concrete was prepared by substituting cement schemes with different FA content according to the test schemes shown in Table 4. Three identical test specimens were poured in each group, and 11 control groups of concrete test specimens were tested after standard curing at 3, 7, and 28 days.

Figure 1.

Concrete specimens in the preparation process: (a) test piece to be cured, (b) cured sample.

Table 4.

Experimental scheme of cement replaced by FA.

2.4. Mechanical Property Evaluation Parameters

The mechanical behavior of concrete is obviously dependent on FA content, cement type, cement grade, aggregate type, concrete placement, age, the porosity of cement stone, and field conditions [38]. Experimental evaluation is an important tool to understand the changes in mechanical properties of concrete with material design. The laboratory tests of the same concrete mix design under different FA content were performed in this study. According to the measured data, the mechanical property evaluation parameters can be reasonably determined. Through the above comprehensive analysis, the flexural strength can be calculated as shown in Equation (1). The flexural strength of concrete test specimens is key evaluation index of concrete in mechanical properties.

where ff is the flexural strength of concrete cube specimen (MPa); F is the failure load under flexure (N); L is the distance between two fulcrums (mm); b is the section width of the specimen (mm); h is the section height of the specimen (mm).

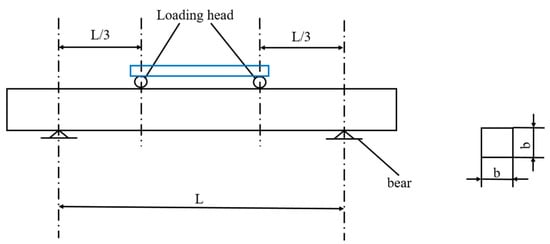

In the flexural strength test, the specimen was installed according to Figure 2. The b and h of the sample are 40 mm, and the loading head is a rigid cylinder with a diameter of 25 mm and hinged support. The average of the three specimens in each group is taken as the test result. After being removed from the curing place, the specimen should be tested in time and the surface of the specimen should be wiped clean. The application of loads should be uniform and continuous. The loading rate was 0.05–0.08 mm/s.

Figure 2.

Test scheme of flexural strength.

After standard curing to the specified age, tested specimens were taken out for determination. The strength of the compression test is obtained by Equation (2).

where: fcc is the compressive strength (MPa); F is the failure load (N); A is the bearing area of the specimen (mm2).

The compressive strength of each test group was treated as required by the Chinese standard for the evaluation of concrete compressive strength (GB/T 50107-2010). After removal from the curing site, the specimen shall be tested in time, and the surface of the specimen and the upper and lower bearing plates shall be wiped clean. In the test process, the load should be continuous and uniform, and the loading rate was 0.5–0.8 MPa/s. When the loading value was recorded after the failure, the testing data was obtained from three specimens.

The X-ray diffraction (XRD) test was measured by a SHIMADZU (Kyoto, Japan) X-ray diffractometer, as shown in Figure 3. Mainly for the test of concrete ground into powder, the test range is −3–150°, the full spectrum of <±0.02° deviation, and the concrete can withstand up to 120 kg. The scanning speed of the equipment is 0.01~120°/min. In this test, the scanning speed of 80°/min can be used to determine the phase composition of permeable concrete samples.

Figure 3.

FRINGE CLASS diffraction instrument.

Scanning electron microscopy (SEM) was used in this study. The scanning electron microscope was produced by SHIMADZU, and the instrument model was ZEISS Merlin Compact (Jena, Germany). The reaction products of FA, mineral powder, and silica fume at different ages in pervious concrete were tested from a microscopic point of view. The microscopic mechanism of the influence of admixture on the performance of pervious concrete was analyzed. The magnification of the SEM image was 10,000 times, and the scale was 10 μm.

3. Results and Discussions

3.1. Influence of FA Content on Mechanical Properties of Concrete

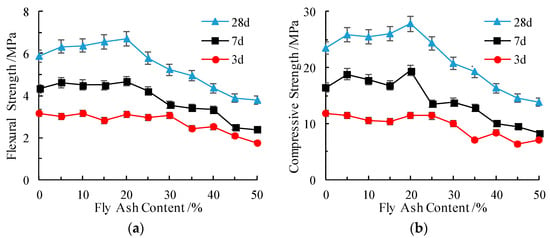

After the standard curing for 3, 7, and 28 days, the concrete specimens were tested for flexural strength and compressive strength based on different FA content (0–50%). The results are shown in Figure 4. In addition, the standard error lines were added in Figure 4, to describe the differences in the results of the three parallel tests.

Figure 4.

Effect curve of FA content on mechanical properties of concrete: (a) flexural strength; (b) compressive strength.

Results show that under the condition of keeping the concrete mix unchanged, and the standard curing for 3 days flexural strength of concrete slowly decreased with the increase of FA content. In particular, the flexural strength of the curve decreases rapidly after the inflection point of 20% content. When the FA content is 20%, the flexural strength is 3.09 MPa. When the FA content is 50%, the flexural strength is 1.76 MPa, which is also the minimum flexural strength of concrete after 3 days of standard curing. The flexural strength of concrete after 7 days of standard curing increases slowly with the increase of the FA content and then decreases rapidly. When the FA content is 20%, the flexural strength is 4.68 MPa, which is also the maximum flexural strength of concrete after 7 days of standard curing. As can be seen from Figure 4b, after the incorporation of FA, the variation law of concrete’s compressive strength is consistent with that of its SF on the whole. Basically, it showed a trend of a slow increase at first and then a gradual decrease. When the FA content is 20%, compressive strength at 3 days of standard curing age is 11.48 MPa, at 7 days of standard curing age is 19.46 Mpa, and at 28 days of standard curing age is 27.81 MPa. When the FA content is 50%, compressive strength at 3 days of standard curing age is 7.08 MPa, compressive strength at 7 days of standard curing age is 8.31 Mpa, and compressive strength at 28 days of standard curing age is 13.87 MPa.

Compared with the concrete specimens without FA, the flexural strength of concrete after 3 days of standard curing and the compressive strength of concrete after FA incorporation show little change. Compared with the untreated concrete, after 28 days of standard curing, the flexural strength and the compressive strength of concrete with 20% FA increased by 0.82 MPa and 4.32 MPa, respectively. With the increase of the standard curing age, the volcanic ash effect of FA is further released, which can not only keep the flexural strength of concrete but also improve the overall mechanical properties of concrete due to the active characteristics of FA. Therefore, from the perspective of industrial solid waste utilization and reducing carbon emissions in cement production, the experimental results show that the optimal content of FA is 20%.

FA as an admixture of concrete has been extensively studied, and most of the studies are consistent with the law of change in the compressive and flexural strength of concrete after the addition of FA. As the age increases, it basically shows a trend of fast growth at the beginning and slow growth at the end. At the same time, the experimental results show that the relative percentage values of the compressive strength of cement concrete, Portland concrete, and high-performance concrete with FA content of 15% and 20% are significantly larger than those of the other mixtures. The optimal FA content in this study is 20%, which is in line with most experimental results on the mechanical properties of concrete materials with FA content [39,40].

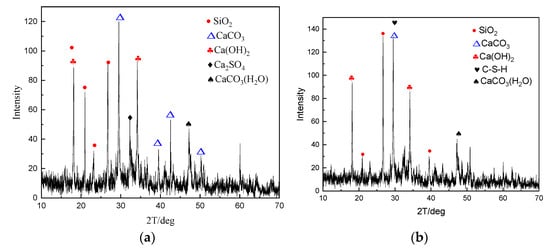

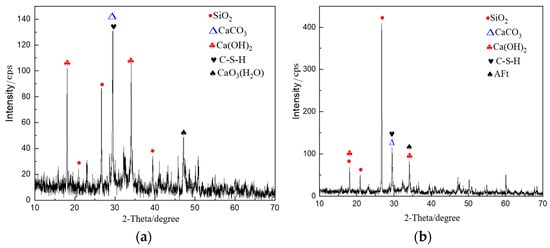

3.2. Phase Analysis of FA after Incorporation

After the standard curing for 3 days and 7 days, the concrete XRD test was conducted based on the FA content of 0% and 20%, respectively, to observe their micromorphology and qualitatively study their hydration products. Then the macroscopic difference is explained from the microscopic mechanism, and the impact of FA on the road performance of concrete is further explored. The XRD test was used to analyze and determine the content of amorphous calcium silicate hydrate (C-S-H) gel, and the test results are shown in Figure 5.

Figure 5.

XRD patterns of the hydration products of concrete after 3 days of the standard curing: (a) concrete without FA; (b) concrete mixed with 20% FA.

XRD is mainly used to analyze the crystal changes in the slurry before and after the hydration reaction of pervious concrete, so as to qualitatively analyze the hydration reaction effect of admixture added to pervious concrete. Figure 5 shows the XRD pattern of concrete after 3 days of the standard curing. It can be seen from Figure 5a that the main phases of concrete without FA are SiO2, CaCO3, Ca(OH)2, and Ca2SiO4, whereas the main phases of concrete mixed with 20% FA are SiO2, CaCO3, Ca(OH)2, and C-S-H, which can be seen from Figure 6b. The formation of C-S-H gel indicates that the incorporation of FA promotes the hydration of cement clinker in concrete. With the increase of C-S-H gel content, the porosity of the cementing material decreases, the material becomes dense, the connected porosity of the permeable concrete decreases, and the reaction speed in the system is improved. The content of Ca(OH)2 and SiO2 in the system was gradually reduced. The results also present the correspondence in the XRD spectrum phase peak.

Figure 6.

XRD patterns of the hydration products of concrete after 7 days of the standard curing: (a) concrete without FA; (b) concrete mixed with 20% FA.

Figure 6 shows the XRD pattern of concrete after 7 days of the standard curing, from which it can be seen that the main phases of concrete without FA are SiO2, CaCO3, Ca(OH)2, and C-S-H. The main phases of concrete mixed with 20% FA are SiO2, CaCO3, Ca(OH)2, C-S-H, and columnar ettringite (AFt). Compared with the XRD pattern of FA content in 3 days of curing standard, after 7 days of curing standard, the FA added in concrete can replace cement significantly, and exerts an active pozzolanic effect. AFt was further formed by a secondary reaction of calcium hydroxide due to the active pozzolanic effect.

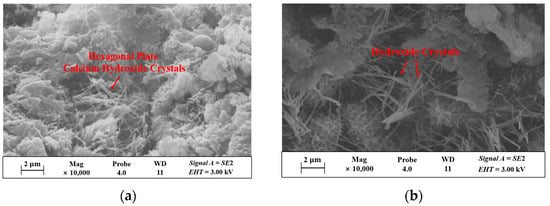

3.3. Microstructure Analysis of FA after Incorporation

The hydration of Portland cement produces many chemical compounds, including the C-S-H, the calcium aluminate hydrate gel (C-A-H), the lamellar calcium hydroxide (CH) crystals, the Aft, and the irregular petal-shaped calcium sulfide aluminate hydrate (AFm) [41]. Figure 7 shows the SEM images of the standard curing for 3 days and 7 days of concrete without FA.

Figure 7.

SEM images of concrete without FA after the standard curing for (a) 3 days and (b) 7 days.

The early hydration rate of pure cement concrete specimens is faster. In Figure 7a, there are a large number of hexagonal plate calcium hydroxide crystals, large cracks can be seen in the structure of the specimen, and the structure is loose. In Figure 7b, hydration has occurred in most of the composite Portland cement clinker minerals in the structure at the standard curing for 7 days, forming a large number of calcium hydroxide crystals, which is significantly more than at the standard curing for 3 days, and the internal structure of the concrete is denser.

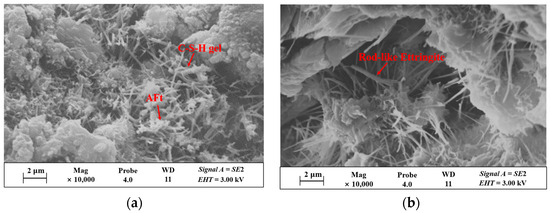

Figure 8 shows the SEM images of concrete at the standard curing for 3 days and 7 days when 20% FA is added. A large number of fibrous, network, sheet, and flocculent C-S-H gels appeared in the specimen structure, and a large number of rod-like ettringite was generated in Figure 8a. At this time, the calcium hydroxide was not obvious, and most of them were interwoven C-S-H gel and AFt. In Figure 8b, the active substance in the FA is rehydrated with calcium hydroxide, and the interface between cement colloid and FA tends to be dense. The FA in the concrete structure presents a state of approximately spherical particles, and the pores of the structure are accompanied by FA particles without hydration reaction (active reactants appear on the surface) and cube crystals. There are more rod-like ettringite in the interior. With the increase in curing time, the hydration reaction of concrete structure specimens is continuously strengthened, and the activity of FA is gradually stimulated. In Figure 8, it can be clearly seen that the specimens of concrete structures at the standard curing for 7 days contain a large number of needle-rod substances, which are denser than those at the standard curing for 3 days.

Figure 8.

SEM images of FA mixed with 20% concrete after the standard curing for (a) 3 days and (b) 7 days.

In conclusion, with the increase of FA content, the volcanic ash effect is continuously intensified, spherical particles of concrete microstructure surround a large number of hydration products, and the specimen structure becomes loose. However, with the extension of the standard curing age, the types of hydration products increase, and there are unhydrated FA particles, a large number of needle-like ettringite, and a small amount of calcium hydroxide.

From the analysis of the microstructure test results, it can be seen that the internal structure density of the standard curing 7 day concrete in this study is better than that of ordinary concrete of the same age after adding 20% FA. With most FA as the concrete admixture of the micro test study, it is concluded that the holes and cracks in the internal structure of concrete are effectively filled, forming a density skeleton system, its standard curing of 7 and 28 days concrete structure is consistently denser.

In order to reduce the footprint of cement production, the cement was partially replaced by FA. Calculations based on carbon emissions in the carbon footprint suggest that the higher the FA content, the higher the low-carbon response of the concrete. Further research and optimization of FA characteristics ensure that the mechanical properties of the cement mix will correspondingly further reduce the carbon footprint.

4. Conclusions

This study aims to improve the safety performance of a green low-carbon concrete by FA content based on mechanical property tests and microscopic results of FA content. The main findings were listed as follows.

- (1)

- The optimal FA content in green low-carbon concrete is 20%. After 28 days of standard curing, the flexural strength and compressive strength of the concrete with 20% FA increased by 0.82 MPa and 4.32 MPa, respectively;

- (2)

- XRD analysis shows that the formation time of C-S-H and AFt phase in FA-doped concrete is earlier. In addition, the incorporation of FA promotes hydration reactions that rehydrate Ca(OH)2 in the system;

- (3)

- SEM analysis revealed that the microstructure of the concrete mixed with 20% FA is mainly composed of fibrous C-S-H gels and rod-like ettringite, and the cement colloids and FA between the interfaces tend to be dense, ensuring the safety properties of the concrete;

- (4)

- This study only provides a qualitative description of the carbon footprint, and computational models should be used to quantify carbon reduction capabilities in the future.

Author Contributions

Conceptualization, Z.C. and M.L.; methodology, Z.C. and M.L.; formal analysis, Z.C. and M.L.; investigation, Z.C.; validation, M.L.; data curation, Z.C. and M.L. writing—original draft, Z.C. and M.L.; writing—review and editing, Z.C. and L.G.; visualization, Z.C. and L.G.; supervision, L.G.; resources, L.G.; project administration, L.G.; funding acquisition, M.L. and L.G. All authors have read and agreed to the published version of the manuscript.

Funding

The study is supported by the Key Research and Development Program in Ningxia Hui Autonomous Region, grant number 2022BDE02002, and the Key Research and Development Program in Xinjiang Uygur Autonomous Region, grant number 2022B01050.

Data Availability Statement

The data used to support the findings of this study are included within the article.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Ren, K.; Liu, C.; Wu, Z.; An, H.; Qu, J.; Zhang, H.; Lv, S. Laboratory investigation on performance of waste-oil cutback asphalt as prime coat on cement stabilized macadam base. Constr. Build. Mater. 2023, 365, 129965. [Google Scholar] [CrossRef]

- Benhelal, E.; Zahedi, G.; Shamsaei, E.; Bahadori, A. Global strategies and potentials to curb CO2 emissions in cement industry. J. Clean. Prod. 2013, 51, 142–161. [Google Scholar] [CrossRef]

- Gao, T.; Shen, L.; Shen, M.; Liu, L.; Chen, F.; Gao, L. Evolution and projection of CO2 emissions for China’s cement industry from 1980 to 2020. Renew. Sustain. Energy Rev. 2017, 74, 522–537. [Google Scholar] [CrossRef]

- Thumrongvut, J.; Seangatith, S.; Phetchuay, C.; Suksiripattanapong, C. Comparative Experimental Study of Sustainable Reinforced Portland Cement Concrete and Geopolymer Concrete Beams Using Rice Husk Ash. Sustainability 2022, 14, 9856. [Google Scholar] [CrossRef]

- Wei, J.; Cen, K. Empirical assessing cement CO2 emissions based on China’s economic and social development during 2001–2030. Sci. Total Environ. 2019, 653, 200–211. [Google Scholar] [CrossRef] [PubMed]

- Ke, J.; Zheng, N.; Fridley, D.; Price, L.; Zhou, N. Potential energy savings and CO2 emissions reduction of China’s cement industry. Energy Policy 2012, 45, 739–751. [Google Scholar] [CrossRef]

- Bridge, G.; Bouzarovski, S.; Bradshaw, M.; Eyre, N. Geographies of energy transition: Space, place and the low-carbon economy. Energy Policy 2013, 53, 331–340. [Google Scholar] [CrossRef]

- Sun, W.; Zhang, Y.; Liu, S.; Zhang, Y. The influence of mineral admixtures on resistance to corrosion of steel bars in green high-performance concrete. Cem. Concr. Res. 2004, 34, 1781–1785. [Google Scholar] [CrossRef]

- Green, B.H.; Moser, R.D.; Scott, D.A.; Long, W.R. Ultra-high performance concrete history and usage by the Corps of Engineers. Adv. Civ. Eng. Mater. 2014, 4, 132–143. [Google Scholar] [CrossRef]

- Qian, D.; Yu, R.; Shui, Z.; Sun, Y.; Jiang, C.; Zhou, F.; Ding, M.; Tong, X.; He, Y. A novel development of green ultra-high performance concrete (UHPC) based on appropriate application of recycled cementitious material. J. Clean. Prod. 2020, 261, 121231. [Google Scholar] [CrossRef]

- Wei, H.; Zhang, H.; Li, J.; Zheng, J.; Ren, J. Effect of loading rate on failure characteristics of asphalt mixtures using acoustic emission technique. Constr. Build. Mater. 2023, 364, 129835. [Google Scholar] [CrossRef]

- Ozbakkaloglu, T.; Gholampour, A.; Xie, T. Mechanical and durability properties of recycled aggregate concrete: Effect of recycled aggregate properties and content. J. Mater. Civ. Eng. 2018, 30, 04017275. [Google Scholar] [CrossRef]

- Sharma, R.; Jang, J.G.; Bansal, P.P. A comprehensive review on effects of mineral admixtures and fibers on engineering properties of ultra-high-performance concrete. J. Build. Eng. 2022, 45, 103314. [Google Scholar] [CrossRef]

- Sun, J.; Zhang, P. Effects of different composite mineral admixtures on the early hydration and long-term properties of cement-based materials: A comparative study. Constr. Build. Mater. 2021, 294, 123547. [Google Scholar] [CrossRef]

- Wang, L.; Yao, Y.; Li, J.; Tao, Y.; Liu, K. Review of Visualization Technique and Its Application of Road Aggregates Based on Morphological Features. Appl. Sci. 2022, 12, 10571. [Google Scholar] [CrossRef]

- Chang, J.; Li, J.; Hu, H.; Qian, J.; Yu, M. Numerical Investigation of Aggregate Segregation of Superpave Gyratory Compaction and Its Influence on Mechanical Properties of Asphalt Mixtures. J. Mater. Civ. Eng. 2023, 35, 04022453. [Google Scholar] [CrossRef]

- Şengün, E.; Alam, B.; Shabani, R.; Yaman, I. The effects of compaction methods and mix parameters on the properties of roller compacted concrete mixtures. Constr. Build. Mater. 2019, 228, 116807. [Google Scholar] [CrossRef]

- Langaroudi, M.A.M.; Mohammadi, Y. Effect of nano-clay on workability, mechanical, and durability properties of self-consolidating concrete containing mineral admixtures. Constr. Build. Mater. 2018, 191, 619–634. [Google Scholar] [CrossRef]

- Yu, R.; Spiesz, P.; Brouwers, H. Development of an eco-friendly Ultra-High Performance Concrete (UHPC) with efficient cement and mineral admixtures uses. Cem. Concr. Compos. 2015, 55, 383–394. [Google Scholar] [CrossRef]

- Matar, P.; Barhoun, J. Effects of waterproofing admixture on the compressive strength and permeability of recycled aggregate concrete. J. Build. Eng. 2020, 32, 101521. [Google Scholar] [CrossRef]

- Ji, G.; Peng, X.; Wang, S.; Hu, C.; Ran, P.; Sun, K.; Zeng, L. Influence of magnesium slag as a mineral admixture on the performance of concrete. Constr. Build. Mater. 2021, 295, 123619. [Google Scholar] [CrossRef]

- Herath, C.; Gunasekara, C.; Law, D.W.; Setunge, S. Performance of high volume fly ash concrete incorporating additives: A systematic literature review. Constr. Build. Mater. 2020, 258, 120606. [Google Scholar] [CrossRef]

- Sharma, V.; Akhai, S. Trends in utilization of coal fly ash in India: A review. J. Eng. Des. Anal. 2019, 2, 12–16. [Google Scholar]

- Zhang, Y.; Liu, M.; Xie, H.; Wang, Y. Assessment of CO2 emissions and cost in fly ash concrete. In Environment, Energy and Applied Technology, Proceedings of the 2014 International Conference on Frontier of Energy and Environment Engineering (ICFEEE 2014), Taipei City, Taiwan, 6–7 December 2014; Taylor & Francis Group: Oxfordshire, UK, 2014; pp. 327–331. [Google Scholar]

- Uliasz-Bocheńczyk, A.; Mokrzycki, E. The potential of FBC fly ashes to reduce CO2 emissions. Sci. Rep. 2020, 10, 9469. [Google Scholar] [CrossRef]

- Cho, Y.K.; Jung, S.H.; Choi, Y.C. Effects of chemical composition of fly ash on compressive strength of fly ash cement mortar. Constr. Build. Mater. 2019, 204, 255–264. [Google Scholar] [CrossRef]

- Sandanayake, M.; Gunasekara, C.; Law, D.; Zhang, G.; Setunge, S.; Wanijuru, D. Sustainable criterion selection framework for green building materials—An optimisation based study of fly-ash Geopolymer concrete. Sustain. Mater. Technol. 2020, 25, e00178. [Google Scholar] [CrossRef]

- Elchalakani, M.; Basarir, H.; Karrech, A. Green concrete with high-volume fly ash and slag with recycled aggregate and recycled water to build future sustainable cities. J. Mater. Civ. Eng. 2017, 29, 04016219. [Google Scholar] [CrossRef]

- Xie, J.; Wang, J.; Rao, R.; Wang, C.; Fang, C. Effects of combined usage of GGBS and fly ash on workability and mechanical properties of alkali activated geopolymer concrete with recycled aggregate. Compos. Part B Eng. 2019, 164, 179–190. [Google Scholar] [CrossRef]

- Matsumoto, S.; Ogata, S.; Shimada, H.; Sasaoka, T.; Kusuma, G.J.; Gautama, R.S. Application of coal ash to postmine land for prevention of soil erosion in coal mine in Indonesia: Utilization of fly ash and bottom ash. Adv. Mater. Sci. Eng. 2016, 2016, 8386598. [Google Scholar] [CrossRef]

- Hwang, C.-L.; Huynh, T.-P. Evaluation of the performance and microstructure of ecofriendly construction bricks made with fly ash and residual rice husk ash. Adv. Mater. Sci. Eng. 2015, 2015, 891412. [Google Scholar] [CrossRef]

- Fan, C.; Wang, B.; Zhang, T. Review on cement stabilization/solidification of municipal solid waste incineration fly ash. Adv. Mater. Sci. Eng. 2018, 2018, 5120649. [Google Scholar] [CrossRef]

- Karakurt, C.; Bayazıt, Y. Freeze-thaw resistance of normal and high strength concretes produced with fly ash and silica fume. Adv. Mater. Sci. Eng. 2015, 2015, 830984. [Google Scholar] [CrossRef]

- Poletanovic, B.; Dragas, J.; Ignjatovic, I.; Komljenovic, M.; Merta, I. Physical and mechanical properties of hemp fibre reinforced alkali-activated fly ash and fly ash/slag mortars. Constr. Build. Mater. 2020, 259, 119677. [Google Scholar] [CrossRef]

- Al-Mansour, A.; Chow, C.L.; Feo, L.; Penna, R.; Lau, D. Green concrete: By-products utilization and advanced approaches. Sustainability 2019, 11, 5145. [Google Scholar] [CrossRef]

- Tayeh, B.A.; Alyousef, R.; Alabduljabbar, H.; Alaskar, A. Recycling of rice husk waste for a sustainable concrete: A critical review. J. Clean. Prod. 2021, 312, 127734. [Google Scholar] [CrossRef]

- Golewski, G.L. Combined Effect of Coal Fly Ash (CFA) and Nanosilica (nS) on the Strength Parameters and Microstructural Properties of Eco-Friendly Concrete. Energies 2023, 16, 452. [Google Scholar] [CrossRef]

- Li, J.; Zhang, J.; Yang, X.; Zhang, A.; Yu, M. Monte Carlo simulations of deformation behaviour of unbound granular materials based on a real aggregate library. Int. J. Pavement Eng. 2023, 24, 2165650. [Google Scholar] [CrossRef]

- Tosti, L.; van Zomeren, A.; Pels, J.R.; Comans, R.N. Technical and environmental performance of lower carbon footprint cement mortars containing biomass fly ash as a secondary cementitious material. Resour. Conserv. Recycl. 2018, 134, 25–33. [Google Scholar] [CrossRef]

- Gao, X.; Yu, Q.L.; Lazaro, A.; Brouwers, H.J.H. Investigation on a green olivine nano-silica source based activator in alkali activated slag-fly ash blends: Reaction kinetics, gel structure and carbon footprint. Cem. Concr. Res. 2017, 100, 129–139. [Google Scholar] [CrossRef]

- Uchechukwu, E.A. Effect of addition of sawdust ash to clay bricks. Civ. Eng. Environ. Syst. 2006, 23, 263–270. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).