Research Progress of Enhanced Thermal Evacuation and Cooling Technology for High-Speed Motors

Abstract

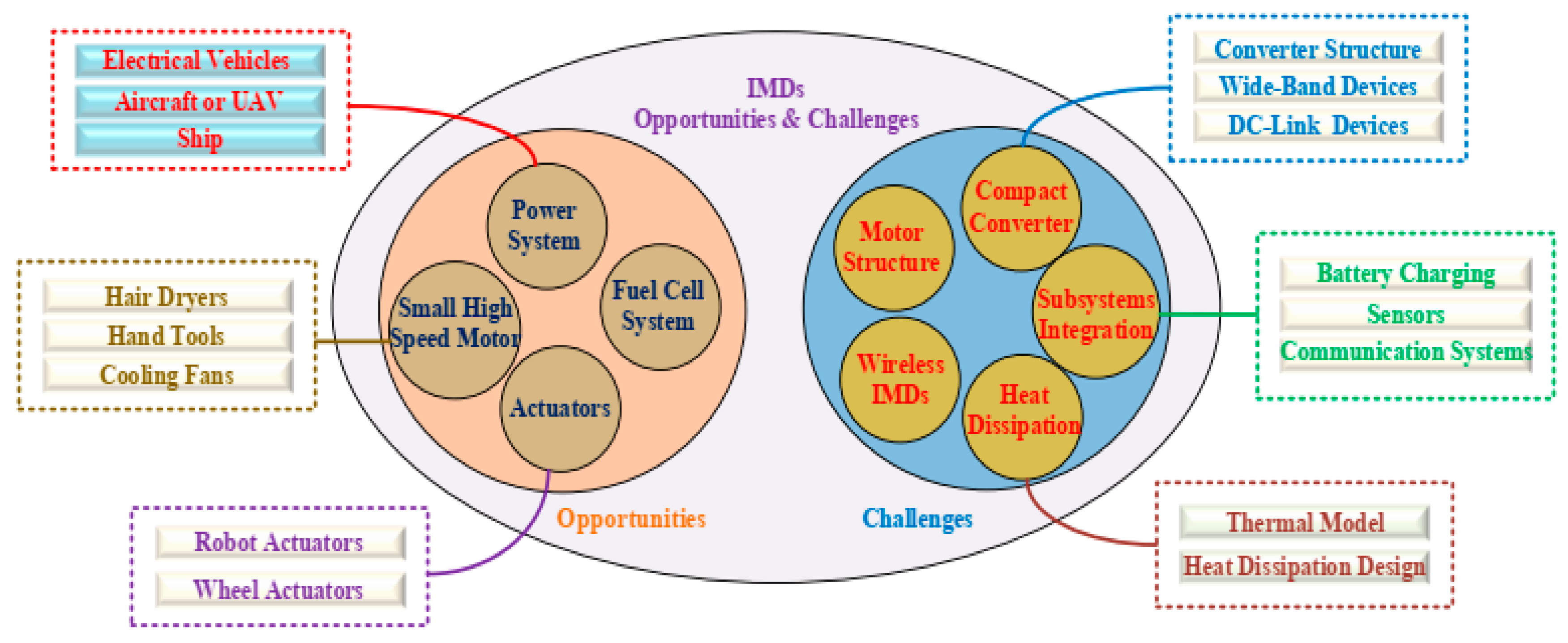

1. Introduction

2. Different Application and Cooling Requirements for High-Speed Motors

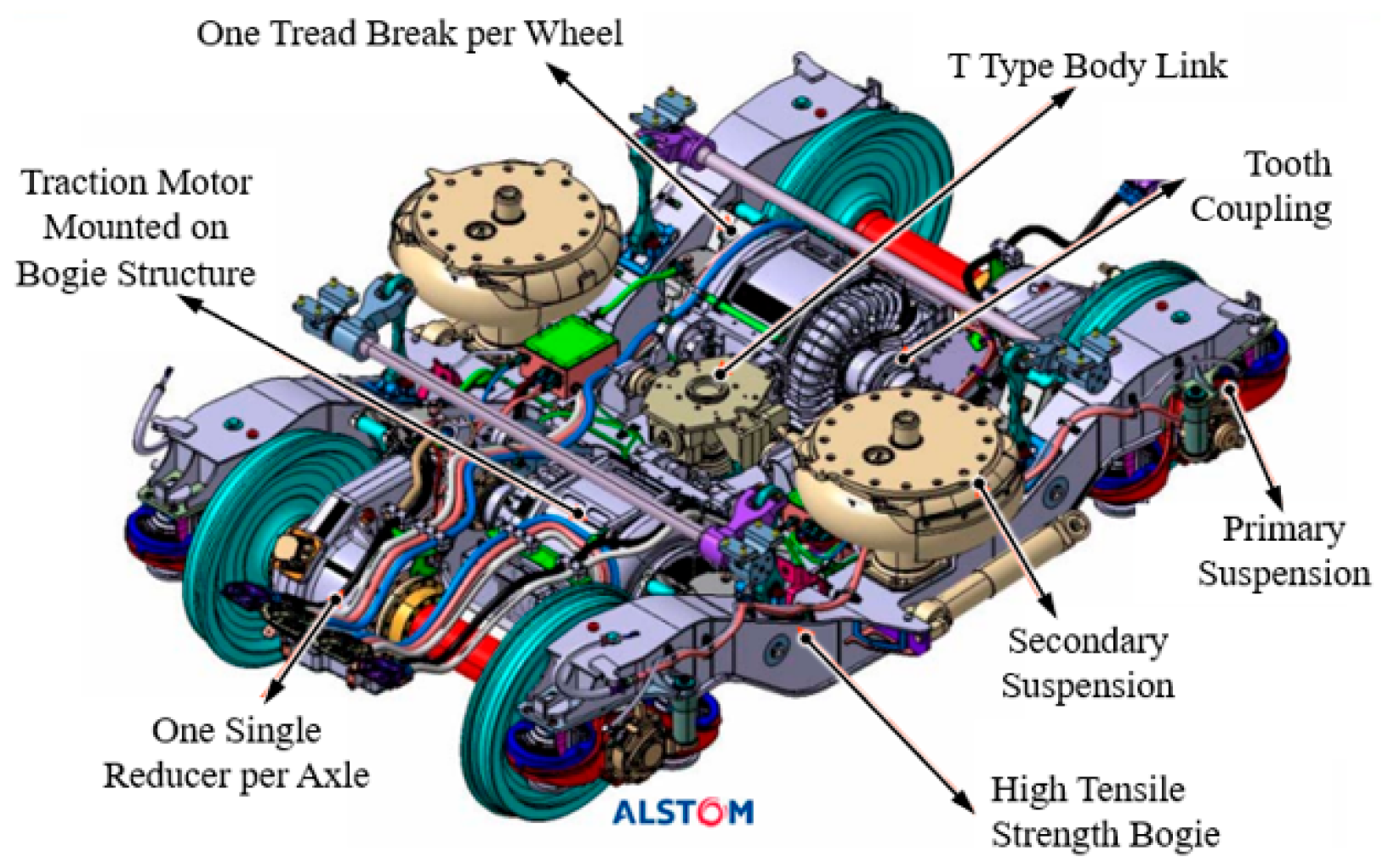

2.1. Electric Devices

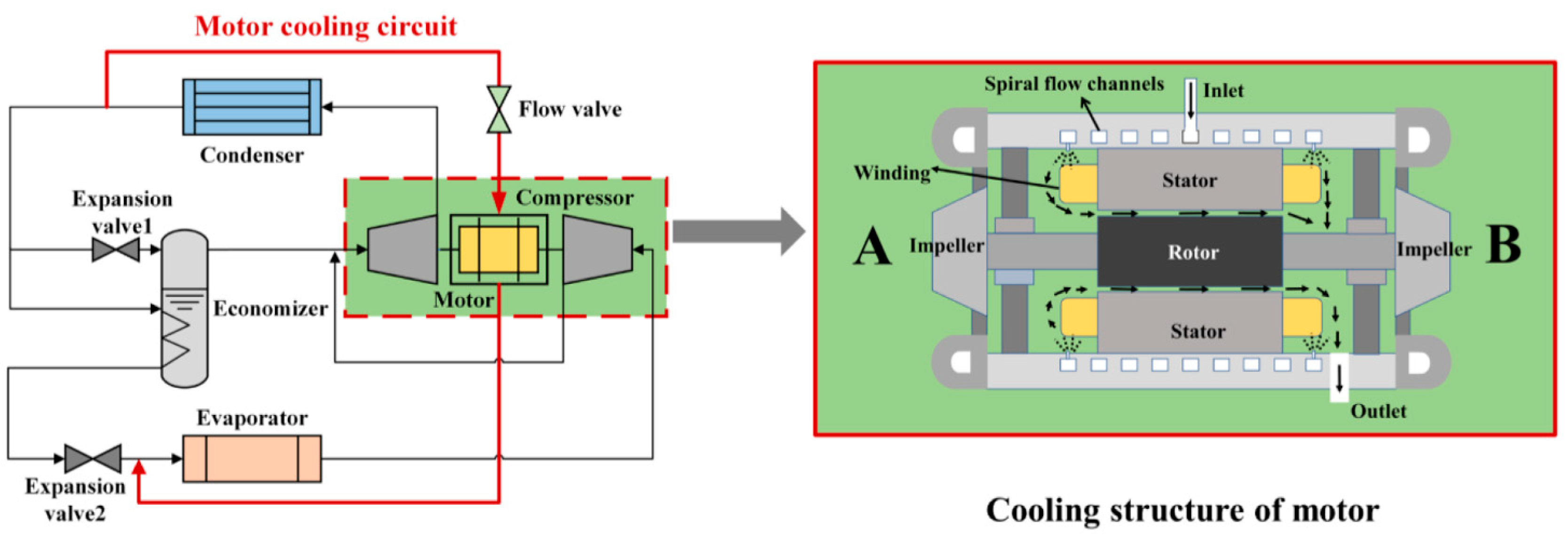

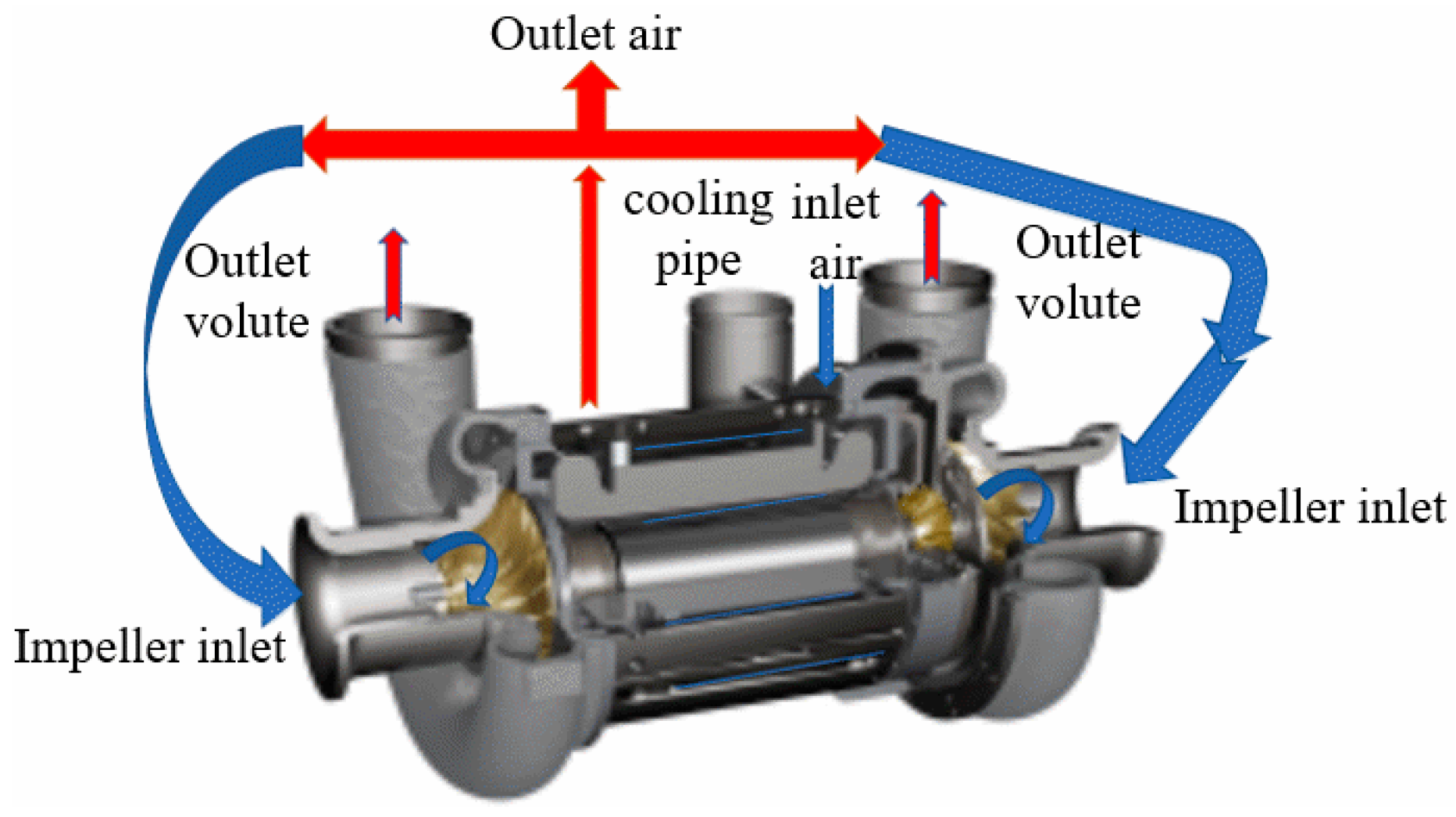

2.2. Turbo-Machinery

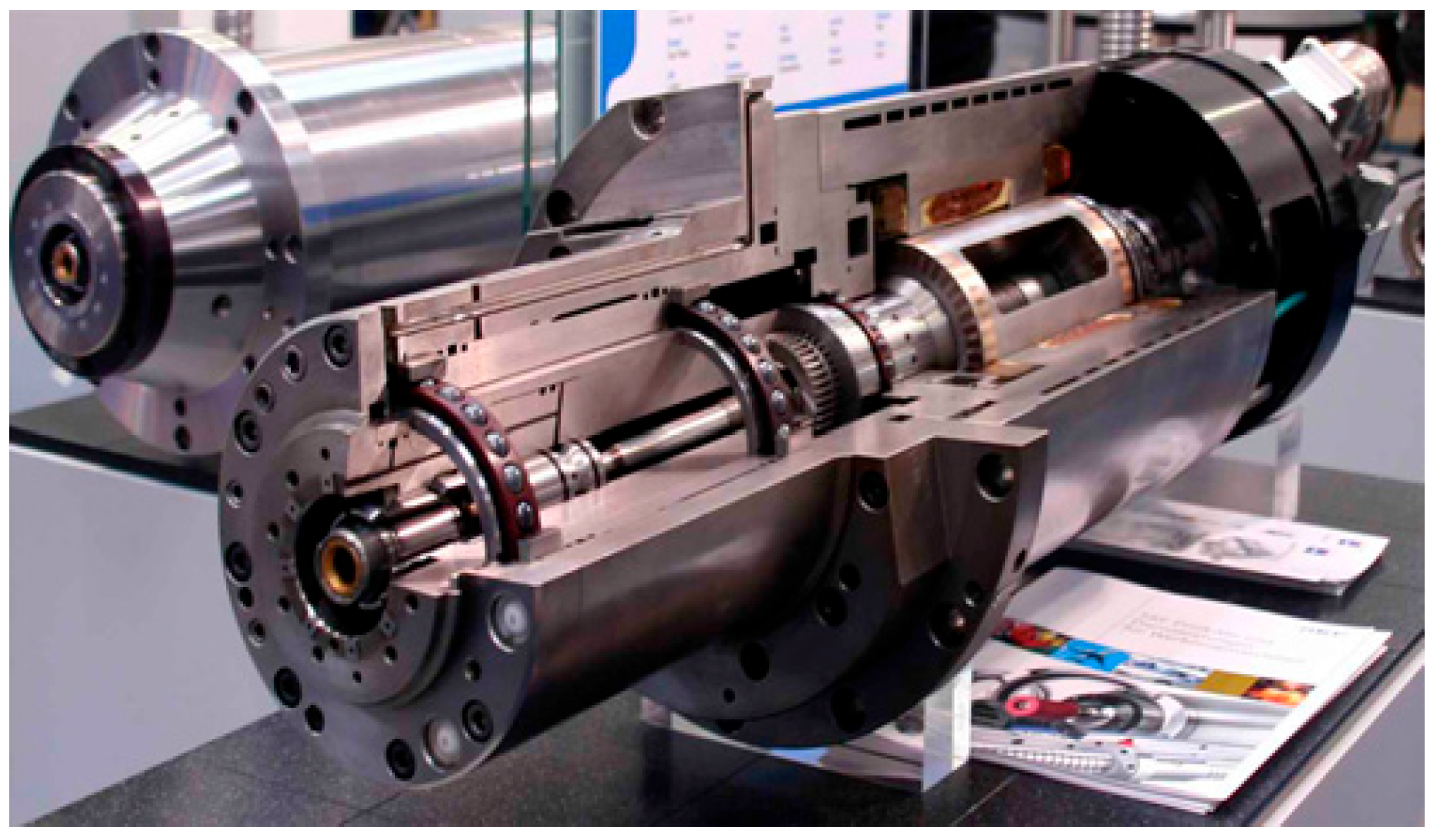

2.3. High-Speed Machine Tools

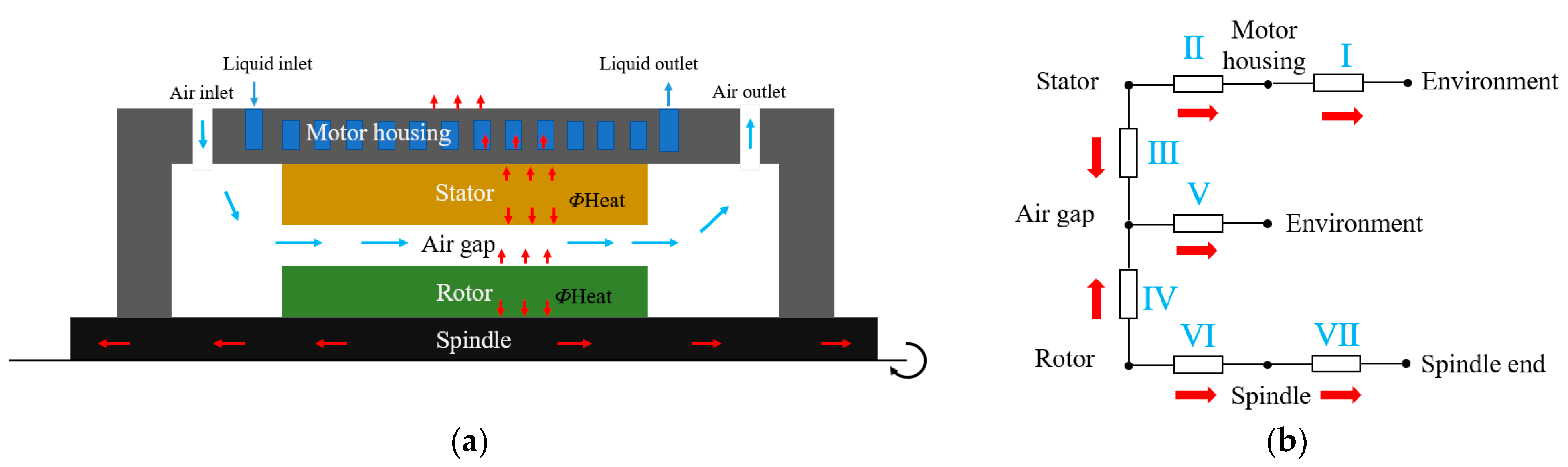

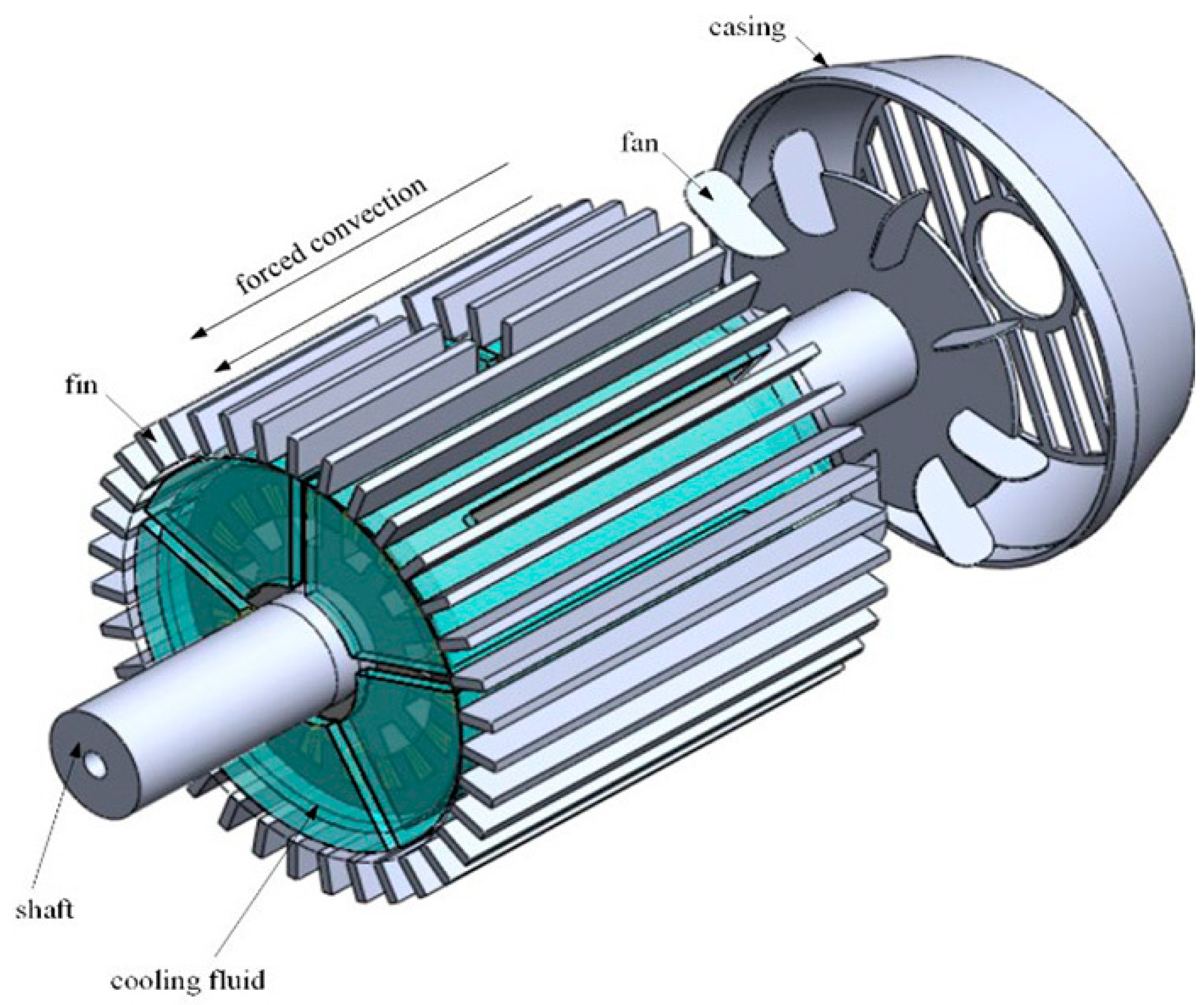

3. Heat Evacuation Paths and Enhancement

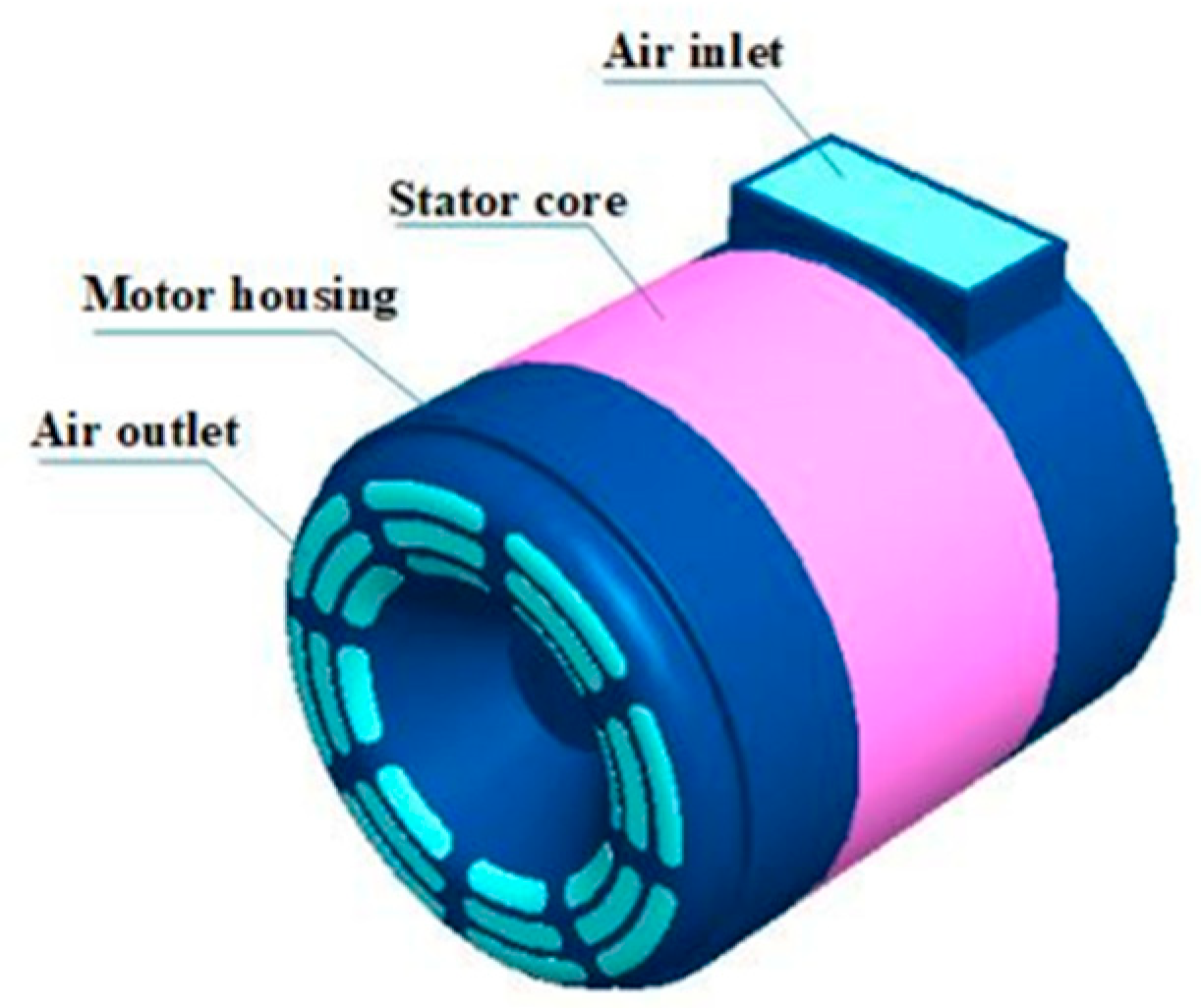

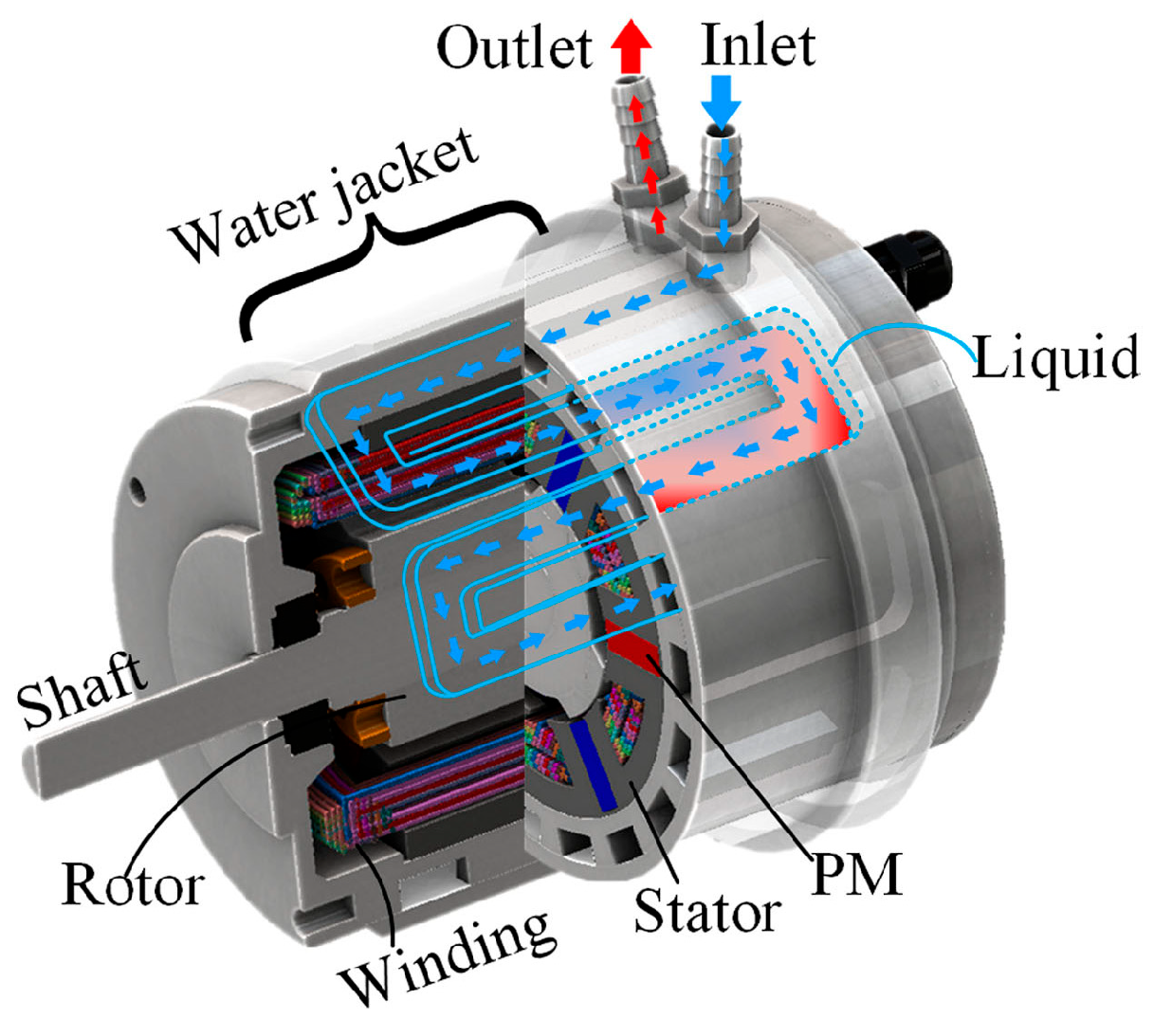

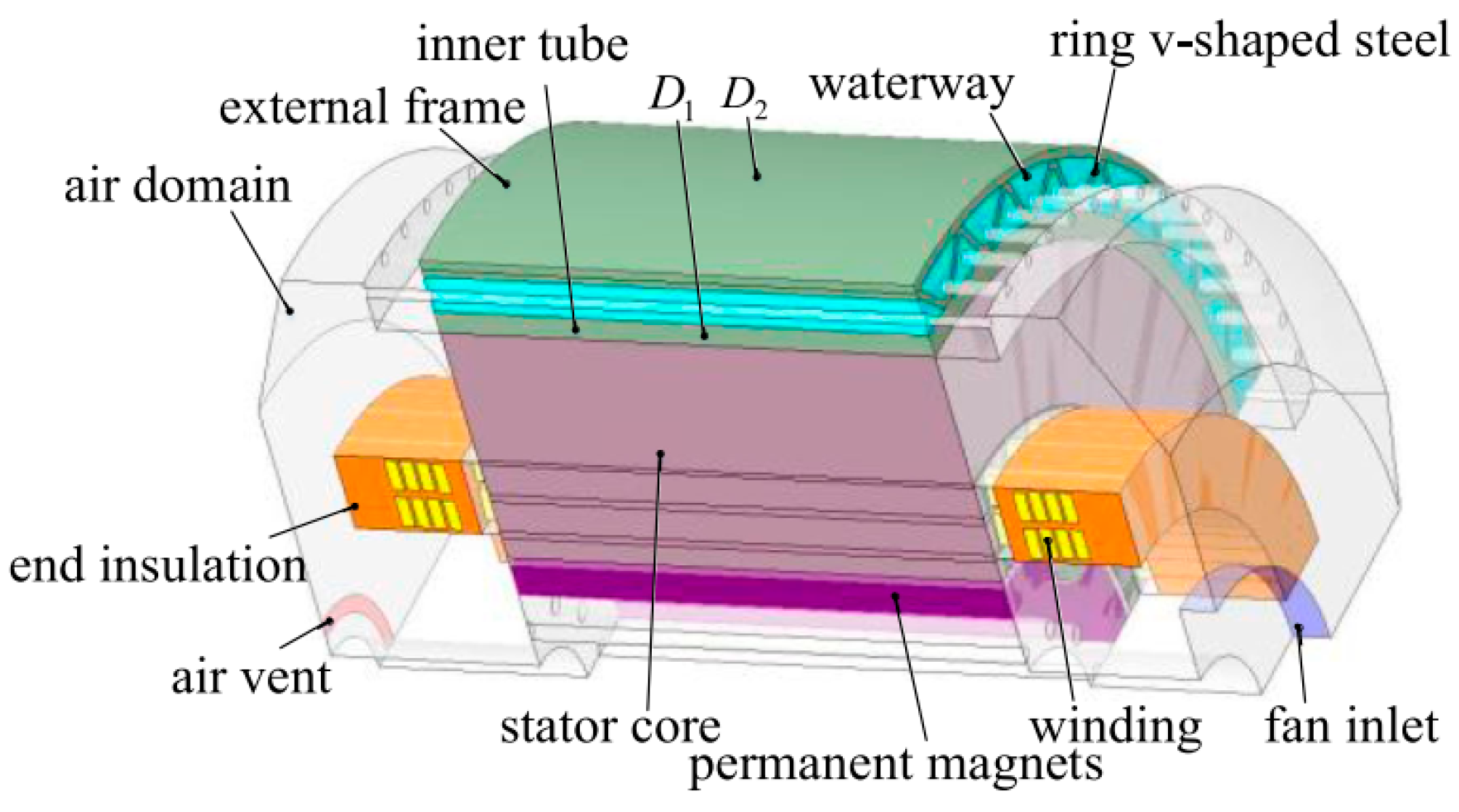

3.1. Motor Housing

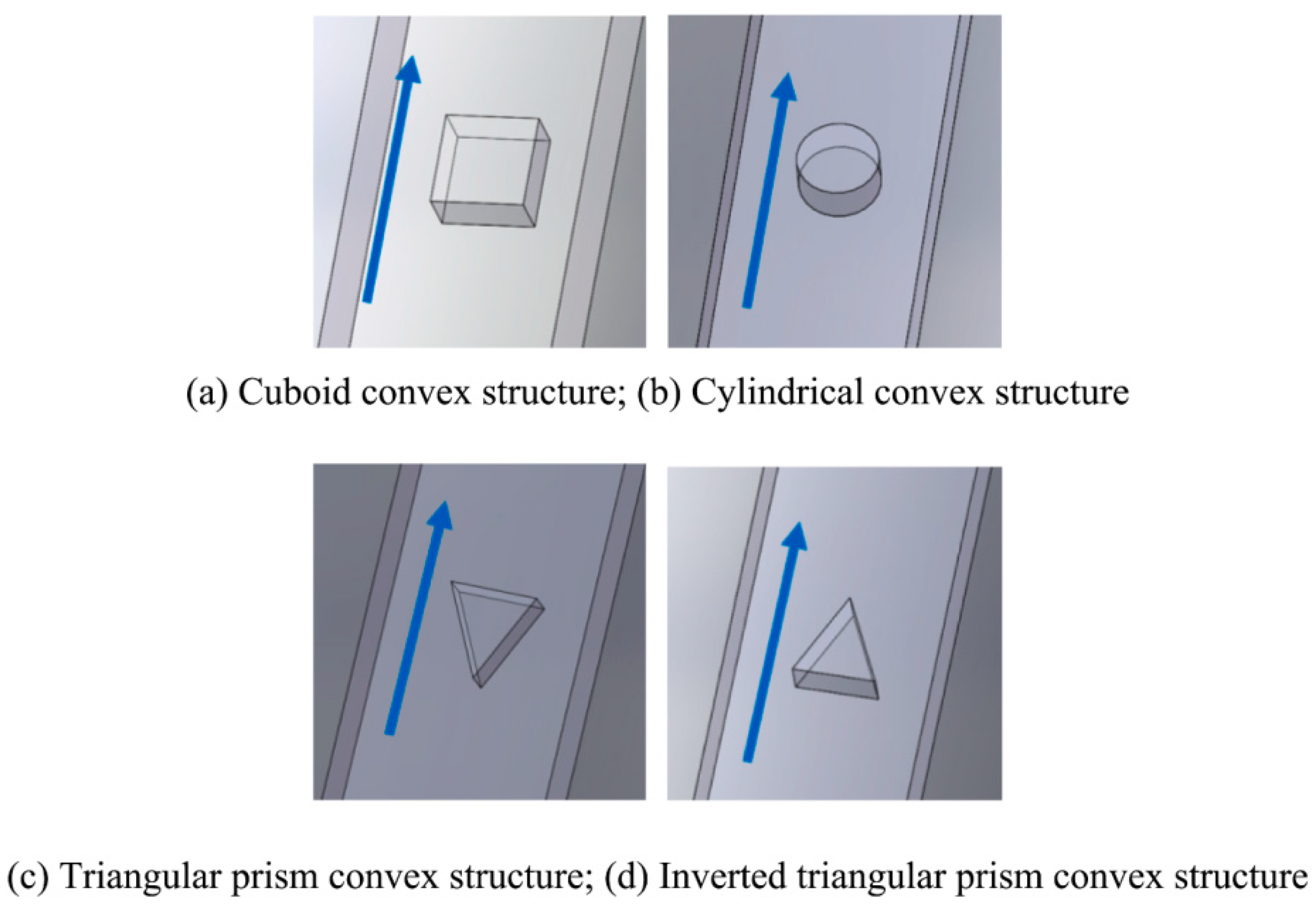

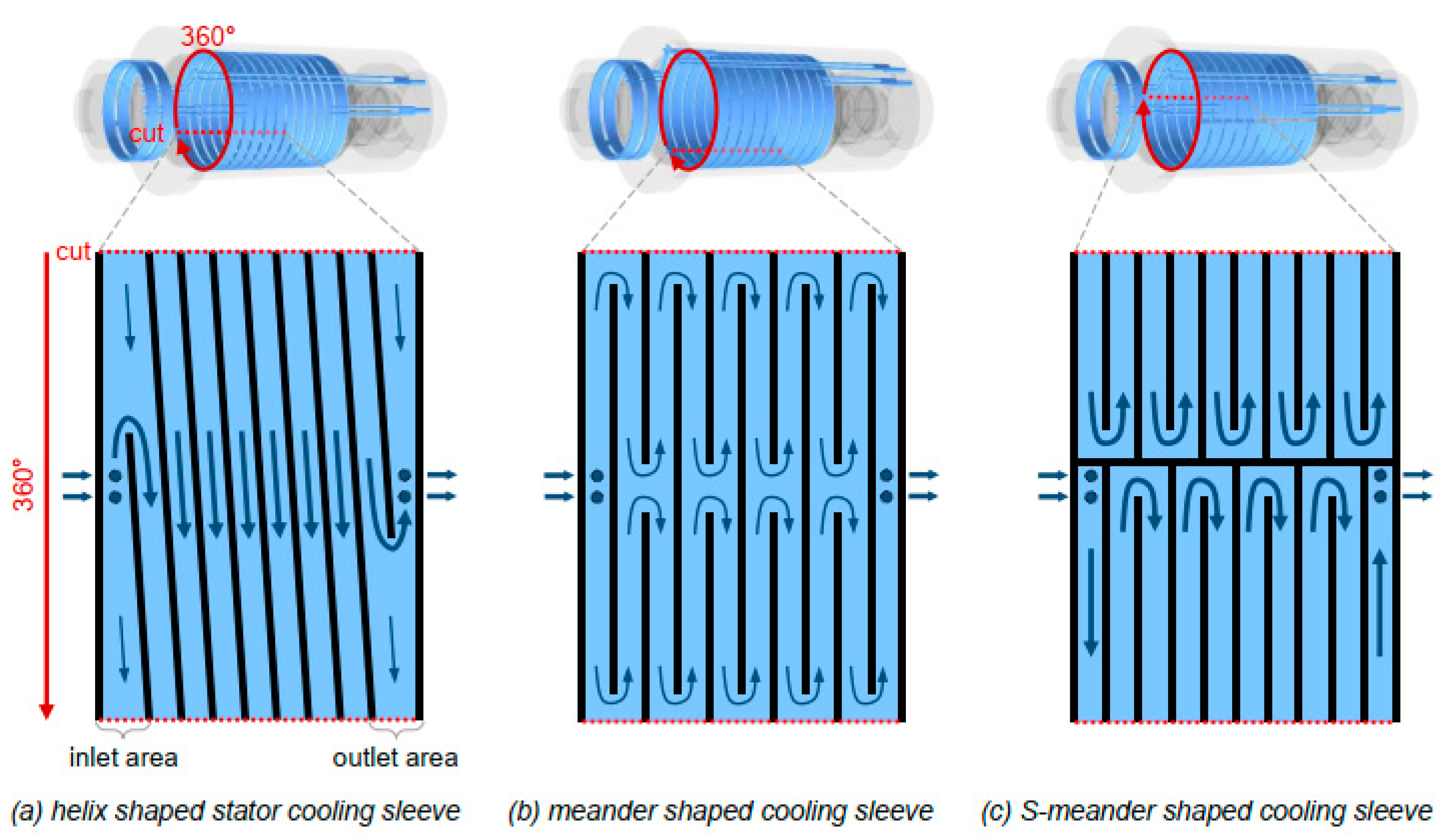

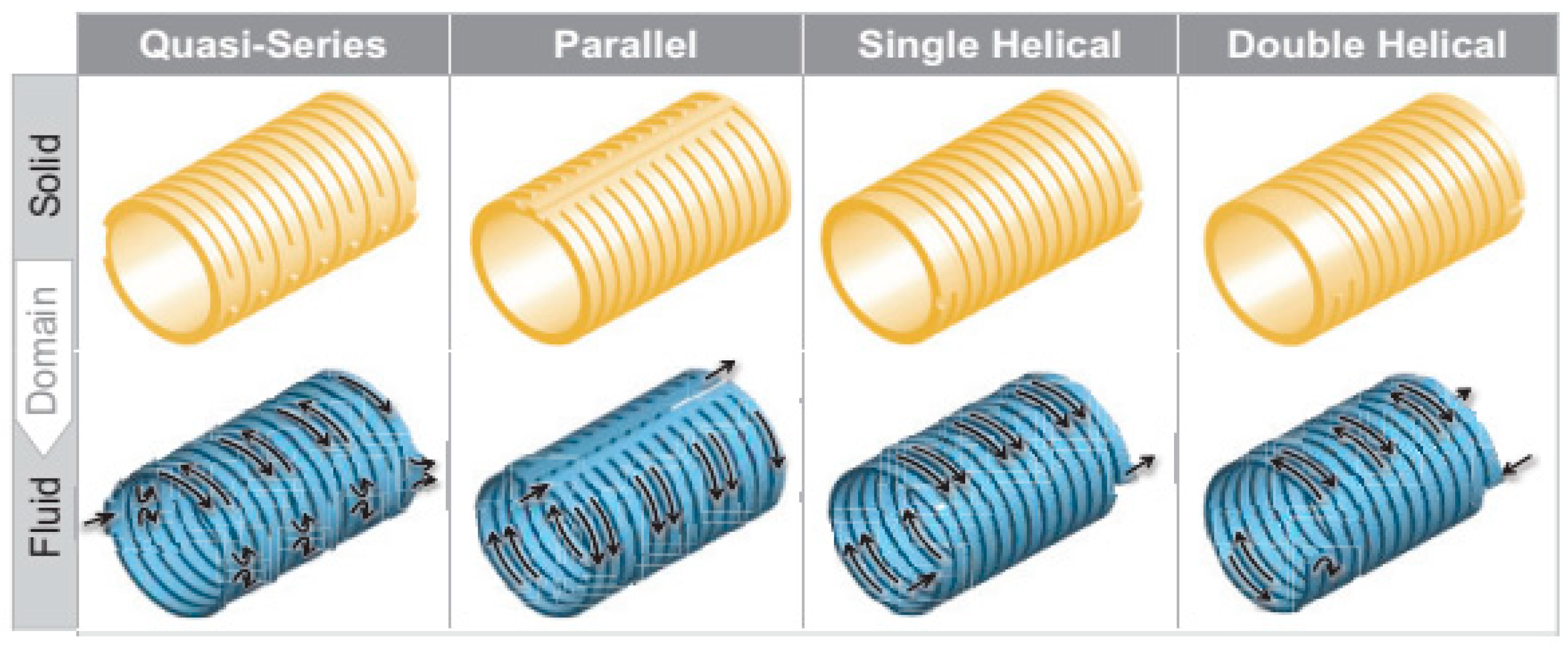

3.1.1. Flow Channel Configuration

3.1.2. Coolant Flow Status

3.2. Stator

3.3. Air Gap Convection

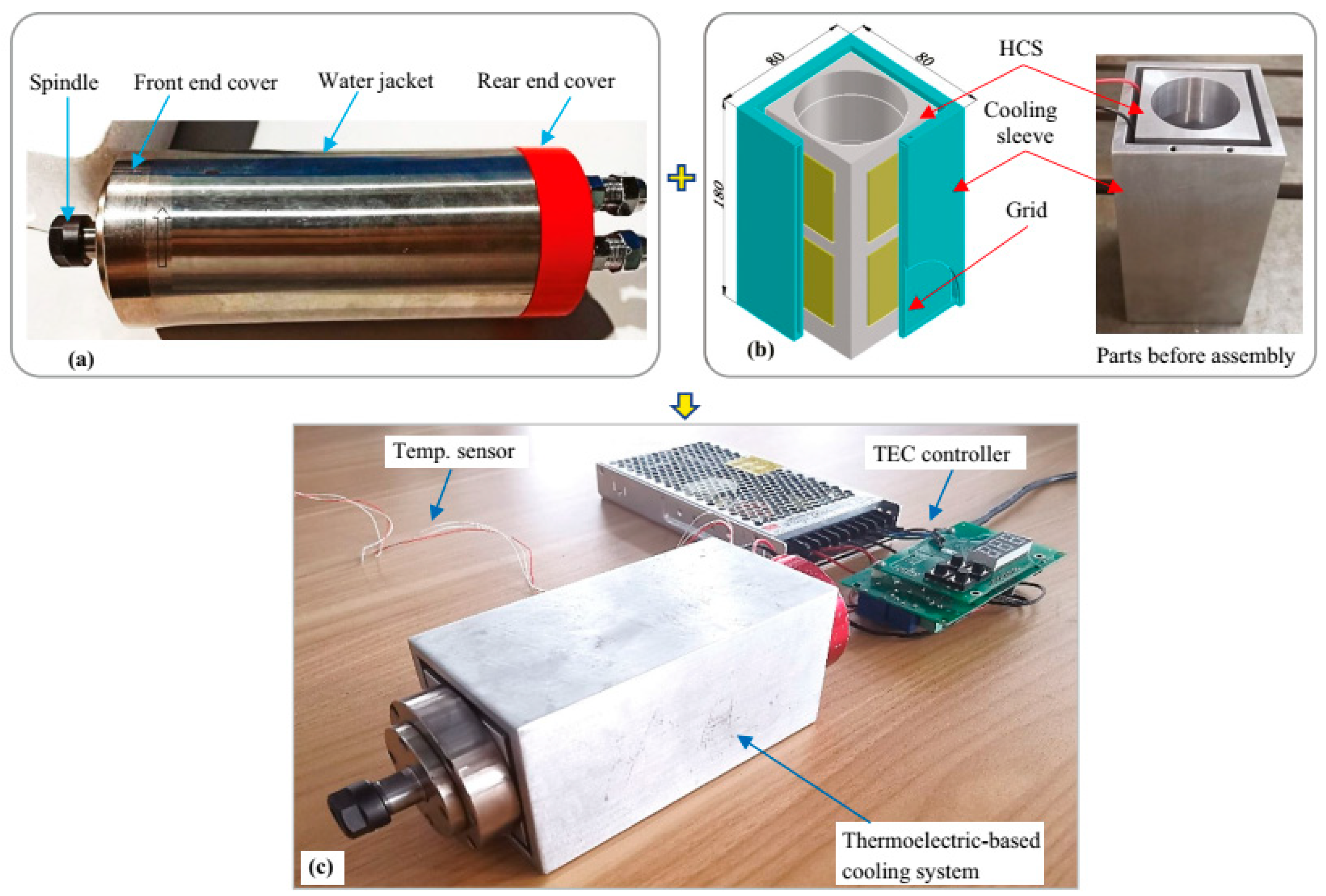

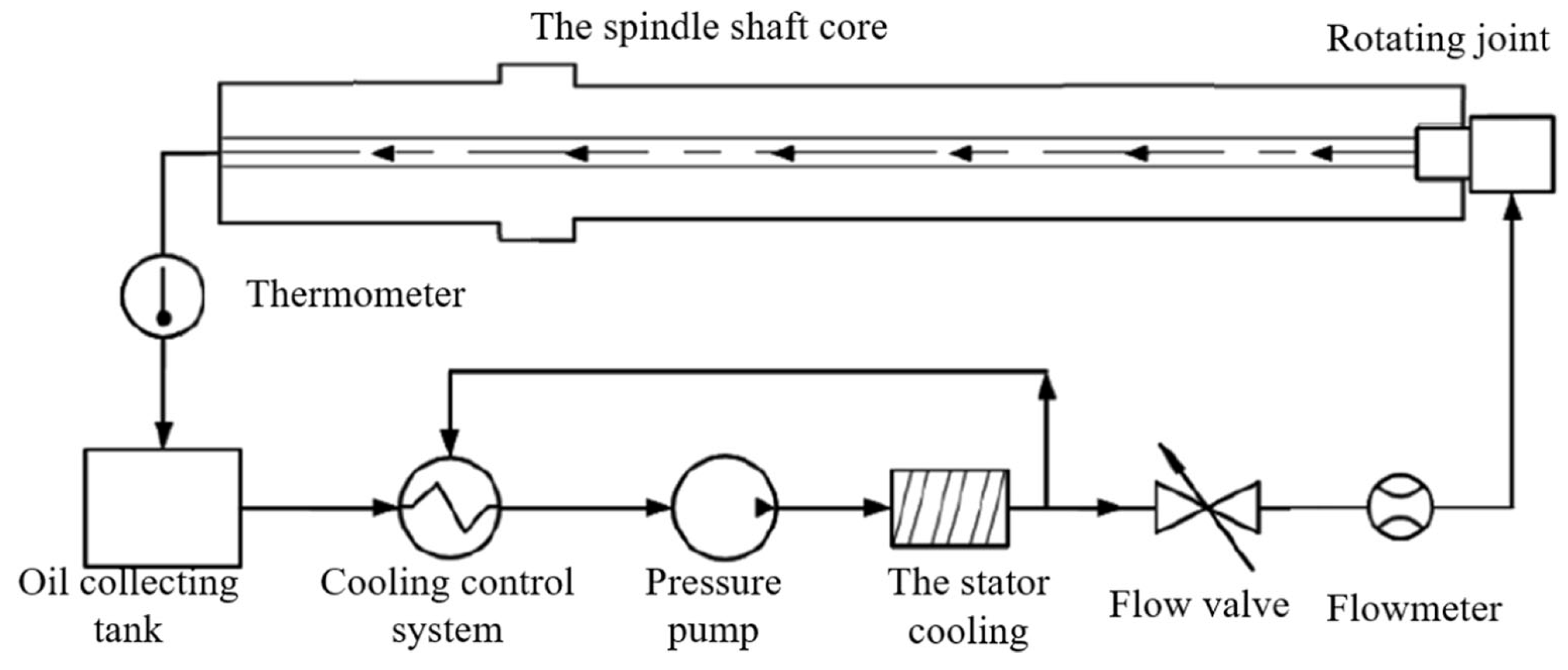

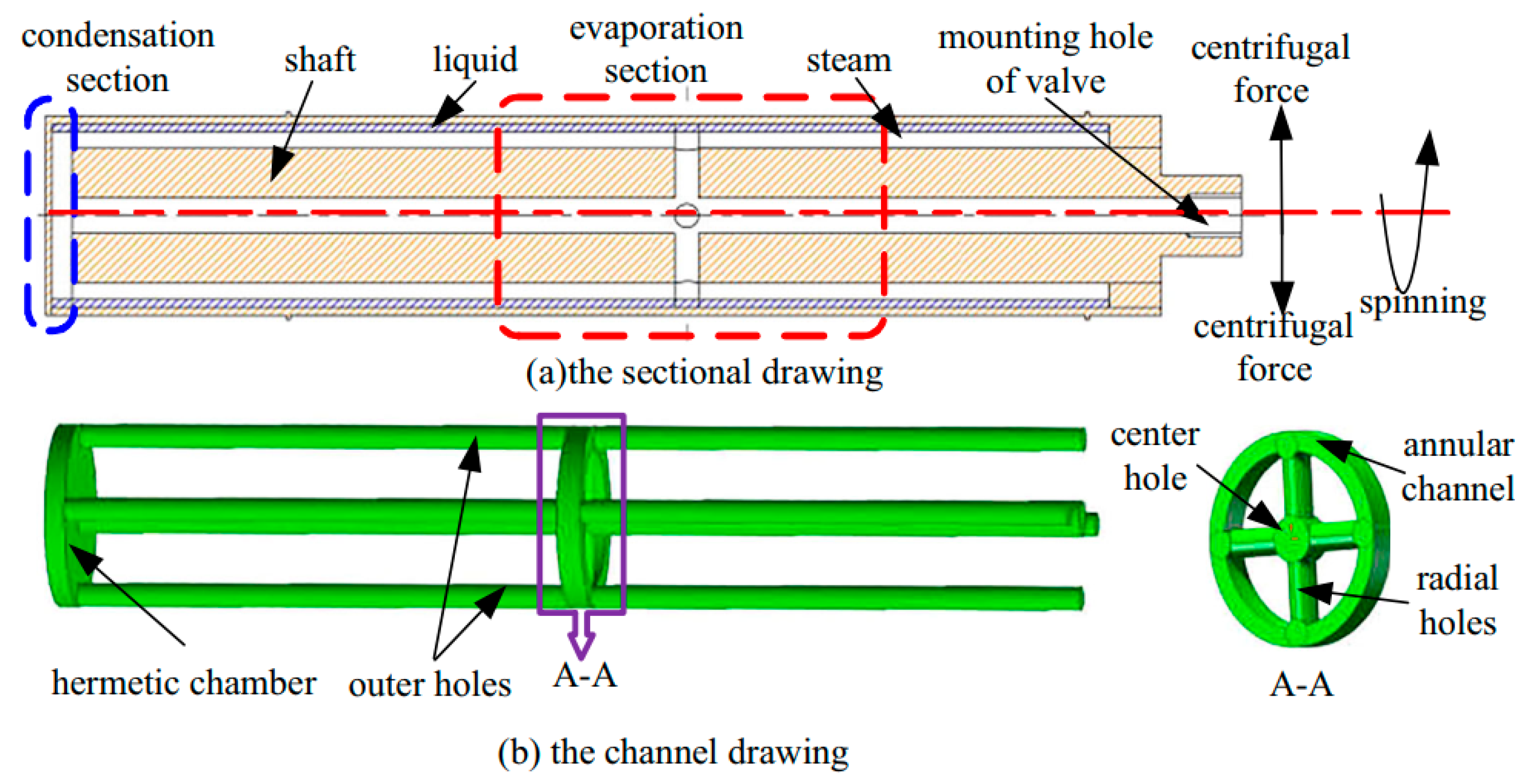

3.4. Motorized Spindle Cooling

3.5. Common Cooling Methods and Coolants

4. Future Development of High-Speed Motor Cooling

- Reduction of heat sources: Explore ways to decrease motor losses by approaching the source of heat. Reduce heat generation by optimizing stator and rotor materials as well as slot patterns to lower motor losses during operation. Achieve the purpose of reducing the overall temperature rise of the motor.

- Utilization of latent heat of coolant: Motor casing cooling generally uses liquid convection heat transfer. Considering the two-phase heat transfer of the coolant and fully utilizing the phase change latent heat of the coolant, the cooling capacity and heat dissipation efficiency of the motor can be improved.

- Optimization of the design of the shell cooling channels. According to the motor’s actual structure, the cooling channel design is optimized to reduce flow resistance and ensure uniformity of flow and temperature distribution.

- Establishment of air-cooling runners. Convection heat transfer efficiency is improved by methods such as built-in fans and enlarged leaf grilles. An external circulating air system can also be installed.

- Strengthen motorized spindle heat evacuation. Establish motorized spindle axial core cooling or heat pipe runner to reduce heat transfer thermal resistance and effectively decrease spindle temperature rise and thermal deformation.

5. Summary

- A summary of different applications and cooling requirements of high-speed motors is presented. High-speed motors are mainly used in electric devices, turbo-machinery, and high-speed machine tools. Among them, high-speed machines are more concerned with temperature rise and thermal elongation of the spindle.

- Heat evacuation paths and main thermal resistance in the motor are discussed. An overview of current research on optimizing thermal resistance is also presented. Liquid-cooling in the rotor housing is the main cooling method. Secondly, air-cooling is also used, sometimes in combination with liquid-cooling. Axial cooling of motorized spindle cores is also being investigated, among which heat pipe structures is one of the key applications.

- Future development of high-speed motor cooling is predicted. Reduction of heat generation from heat sources, utilization of latent heat from coolant, optimization of housing cooling flow paths, designing of axial air-cooling circulation systems and strengthening of spindle heat evacuation can be mainly considered.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Gerada, D.; Mebarki, A.; Brown, N.L.; Gerada, C.; Cavagnino, A.; Boglietti, A. High-Speed Electrical Machines: Technologies, Trends, and Developments. IEEE Trans. Ind. Electron. 2014, 61, 2946–2959. [Google Scholar] [CrossRef]

- Nategh, S.; Boglietti, A.; Liu, Y.J.; Barber, D.; Brammer, R.; Lindberg, D.; Aglen, O. A Review on Different Aspects of Traction Motor Design for Railway Applications. IEEE Trans. Ind. Appl. 2020, 56, 2148–2157. [Google Scholar] [CrossRef]

- Wang, W.S.; Shang, M.Y.; Li, Y.Z.; Yao, Z.K.; Niu, J.Z.; Juan, Z. Thermal Performance Analysis of Jet Cooling Method in a High-Power Permanent Magnet Synchronous Motor. J. Therm. Sci. Eng. Appl. 2023, 15, 011006. [Google Scholar] [CrossRef]

- Denkena, B.; Bergmann, B.; Klemme, H. Cooling of motor spindles—A review. Int. J. Adv. Manuf. Technol. 2020, 110, 3273–3294. [Google Scholar] [CrossRef]

- Shen, Q.P.; Zhou, Z.Y.; Li, S.; Liao, X.L.; Wang, T.; He, X.R.; Zhang, J.S. Design and Analysis of the High-Speed Permanent Magnet Motors: A Review on the State of the Art. Machines 2022, 10, 549. [Google Scholar] [CrossRef]

- Zhang, B.W.; Song, Z.X.; Liu, S.Y.; Huang, R.D.; Liu, C.H. Overview of Integrated Electric Motor Drives: Opportunities and Challenges. Energies 2022, 15, 8299. [Google Scholar] [CrossRef]

- Madhavan, S.; Devdatta, R.P.B.; Gundabattini, E.; Mystkowski, A. Thermal Analysis and Heat Management Strategies for an Induction Motor, a Review. Energies 2022, 15, 8127. [Google Scholar] [CrossRef]

- Grover, R.O.; Yang, X.F.; Parrish, S.; Nocivelli, L.; Asztalos, K.J.; Som, S.; Li, Y.H.; Burns, C.; Van Gilder, J.; Attal, N.; et al. CFD simulations of electric motor end ring cooling for improved thermal management. Sci. Technol. Energy Transit. 2022, 77, 17. [Google Scholar] [CrossRef]

- Pettes-Duler, M.; Roboam, X.; Sareni, B.; Lefevre, Y.; Llibre, J.F.; Fenot, M. Multidisciplinary Design Optimization of the Actuation System of a Hybrid Electric Aircraft Powertrain. Electronics 2021, 10, 1297. [Google Scholar] [CrossRef]

- Saleem, A.; Park, M.H.; Ambreen, T.; Kim, S.C. Optimization of oil flow distribution inside the in-wheel motor assembly of electric vehicles for improved thermal performance. Appl. Therm. Eng. 2022, 201, 117753. [Google Scholar] [CrossRef]

- Huang, J.K.; Naini, S.S.; Miller, R.; Rizzo, D.; Sebeck, K.; Shurin, S.; Wagner, J. A Hybrid Electric Vehicle Motor Cooling System-Design, Model, and Control. IEEE Trans. Veh. Technol. 2019, 68, 4467–4478. [Google Scholar] [CrossRef]

- Paul, S.; Lee, J.G.; Tran, V.K.; Han, P.W.; Chang, J.; Chun, Y.D. Electromagnetic Design and Thermal Analysis of Totally Enclosed Air Over Cooled Permanent Magnet Synchronous Motor for High-Speed Railway Distributed Traction. In Proceedings of the 2022 International Conference on Electrical Machines (ICEM), Valencia, Spain, 5–8 September 2022; pp. 373–379. [Google Scholar]

- Shi, H.F.; Deng, Z.G.; Zhang, B.J.; Ke, Z.H.; Pang, P.; Huang, Z.C.; Li, Z.Y.; Lu, H.; Yi, H.Y.; Liang, L.; et al. Thermal-Force Coupling Analysis of Permanent Magnet Electrodynamic Wheel System for Maglev Car. IEEE Trans. Magn. 2023, 59, 6300109. [Google Scholar] [CrossRef]

- Koster, R.; Binder, A. Medium-Speed Wind Turbine Generators with HTS Excitation Winding. In Proceedings of the 2022 International Conference on Electrical Machines (ICEM), Valencia, Spain, 5–8 September 2022; pp. 914–920. [Google Scholar]

- Karashima, T.; Nakamura, T.; Okuno, M. Multidisciplinary analysis of the transient performance of a 20 kW class HTS induction/synchronous motor cooled with a cryocooler and gaseous air-gap coolant. Cryogenics 2019, 99, 61–67. [Google Scholar] [CrossRef]

- Kepsu, D.; Kurvinen, E.; Tiainen, J.; Honkatukia, J.; Turunen-Saaresti, T.; Jastrzebski, R.P. Interdisciplinary Design of a High-Speed Drivetrain for a Kinetic Compressor in a High-Temperature Heat Pump. IEEE Access 2021, 9, 143877–143900. [Google Scholar] [CrossRef]

- Cui, H.J.; Su, X.K.; Guan, Y.; Fei, J.Y. CFD Simulation Study on the Air Side of a CO2 Evaporator in a Motor Train Unit Air Conditioning System. Energies 2023, 16, 1037. [Google Scholar] [CrossRef]

- Abubakar, U.; Wang, X.Y.; Shah, S.H.; Gao, P.; Wang, L.X. High-speed PMSM thermal analysis of totally enclosed fan cooled axial ventilation for centrifugal blower application. Int. J. Appl. Electromagn. Mech. 2022, 69, 13–43. [Google Scholar] [CrossRef]

- Li, J.; Huang, W.X.; Wang, S.Y.; Chen, Y.C.; Jiang, X.F. Design and optimization of dual-winding fault-tolerant permanent magnet motor for aviation fuel pump applications. Energy Rep. 2023, 9, 304–312. [Google Scholar] [CrossRef]

- Qi, Z.N.; Zhang, Y.; Yu, S.Y.; Xu, Z.Y. Design and Analysis of a 30 kW, 30,000 r/min High-Speed Permanent Magnet Motor for Compressor Application. Energies 2022, 15, 3923. [Google Scholar] [CrossRef]

- Weber, J.; Shabi, L.; Weber, J. State of the art and optimization of the energy flow in cooling systems of motorized high-speed spindles in machine tools. In Proceedings of the 1th CIRP Conference on Intelligent Computation in Manufacturing Engineering (CIRP ICME), Naples, Italy, 19–21 July 2017; pp. 81–86. [Google Scholar]

- Li, T.J.; Xi, G.B.; Wang, H.; Tang, W.; Shao, Z.X.; Sun, X.Z. Thermal Properties Prediction of Large-Scale Machine Tool in Vacuum Environment Based on the Parameter Identification of Fluid-Thermal Coupling Model. Machines 2022, 10, 1237. [Google Scholar] [CrossRef]

- Li, K.Y.; Luo, W.J.; Wei, S.J.; Liao, Y.S. Publishing IOP: Cooling Channel Design for a Built-in Spindle of a Machine Tool. In Proceedings of the 3rd International Conference on Forum in Research, Science, and Technology (FIRST), Makassar, Indonesia, 9–10 October 2019. [Google Scholar]

- Dai, Y.; Tao, X.S.; Li, Z.L.; Zhan, S.Q.; Li, Y.; Gao, Y.H. A Review of Key Technologies for High-Speed Motorized Spindles of CNC Machine Tools. Machines 2022, 10, 145. [Google Scholar] [CrossRef]

- Du, Z.C.; Yao, S.Y.; Yang, J.G. Thermal Behavior Analysis and Thermal Error Compensation for Motorized Spindle of Machine Tools. Int. J. Precis. Eng. Manuf. 2015, 16, 1571–1581. [Google Scholar] [CrossRef]

- Xie, B.C.; Zhang, Y.; Wang, J.Q.; Liang, B.X.; Zhang, F.G. An efficient multidisciplinary design research for the integrated low speed permanent magnet motor system based on analytical and numerical hybrid analysis. Energy Rep. 2022, 8, 199–208. [Google Scholar] [CrossRef]

- Tang, Y.; Jing, X.; Li, W.; He, Y.; Yao, J.X. Analysis of influence of different convex structures on cooling effect of rectangular water channel of motorized spindle. Appl. Therm. Eng. 2021, 198, 117478. [Google Scholar] [CrossRef]

- Koch, L.; Gross, K.; Krueger, G. Comparative analysis of fluid cooling systems in motorized spindles. Mm Sci. J. 2021, 2021, 4620–4627. [Google Scholar] [CrossRef]

- Fan, K.G.; Xu, R.F.; Wang, R.D.; Gao, R. Thermoelectric-based cooling system for high-speed motorized spindle II: Optimization and validation strategy. Int. J. Adv. Manuf. Technol. 2022, 119, 6521–6533. [Google Scholar] [CrossRef]

- Zhang, L.; Li, C.; Li, J.; Wu, Y. Influence Analysis of Cooling Water Parameters on High-speed Spindle Temperature Field. Mech. Sci. Technol. Aerosp. Eng. 2017, 36, 1414–1420. [Google Scholar]

- Zhang, L.-X.; Liu, T.; Li, C.-Q. Research on the Effects of Cooling Water Velocity on Temperature Rise of the Water-cooled Motor in Motorized Spindle. Modul. Mach. Tool Autom. Manuf. Tech. 2015, 36–38, 42. [Google Scholar]

- Zhang, Y.; Wang, L.F.; Zhang, Y.D.; Zhang, Y.D. Design and thermal characteristic analysis of motorized spindle cooling system. Adv. Mech. Eng. 2021, 13, 16878140211020878. [Google Scholar] [CrossRef]

- Liu, Y.T.; Liu, G.B.; Yang, Q.C.; Zhao, Y.Y.; Li, L.S. Research on motor cooling process of centrifugal refrigeration compressor with gas bearings. Int. J. Refrig. 2023, 145, 68–77. [Google Scholar] [CrossRef]

- Liu, T.; Gao, W.G.; Tian, Y.L.; Zhang, D.W.; Zhang, Y.F.; Chang, W.F. Power matching based dissipation strategy onto spindle heat generations. Appl. Therm. Eng. 2017, 113, 499–507. [Google Scholar] [CrossRef]

- Zhang, Y.F.; Liu, T.; Gao, W.G.; Tian, Y.L.; Qi, X.Y.; Wang, P.; Zhang, D.W. Active coolant strategy for thermal balance control of motorized spindle unit. Appl. Therm. Eng. 2018, 134, 460–468. [Google Scholar] [CrossRef]

- Fang, G.Y.; Yuan, W.; Yan, Z.G.; Sun, Y.L.; Tang, Y. Thermal management integrated with three-dimensional heat pipes for air-cooled permanent magnet synchronous motor. Appl. Therm. Eng. 2019, 152, 594–604. [Google Scholar] [CrossRef]

- Zhang, Y.; Qi, Z.N.; Wang, H.J.; Zhang, H. High-speed permanent magnet machine multi-physics fields design for turbine application. Energy Rep. 2022, 8, 209–218. [Google Scholar] [CrossRef]

- Anderson, K.R.; Lin, J.; Wong, A. Experimental and Numerical Study of Windage Losses in the Narrow Gap Region of a High-Speed Electric Motor. Fluids 2018, 3, 22. [Google Scholar] [CrossRef]

- Abubakar, U.; Wang, X.Y.; Shah, S.H.; Wang, L.X.; Farouk, A. Electromagnetic and Thermal Analysis of 225 kW High-Speed PMSM for Centrifugal Blower Applications. Energies 2022, 15, 3370. [Google Scholar] [CrossRef]

- Ding, H.; Li, Y.J.; Min, S.G.; Nellis, G.; Sarlioglu, B. Design and Evaluation of the Performance of an Integrated Flux-Switching Motor-Compressor with Airfoil-Shaped Rotor. IEEE Trans. Transp. Electrif. 2021, 7, 1573–1588. [Google Scholar] [CrossRef]

- Zhang, L.X.; Li, W.X.; Gong, W.J. Analysis on the Effects of Air Gap on Cooling of Motorized Spindle. In Proceedings of the 2nd International Conference on Materials Science, Energy Technology, Power Engineering (MEP), Hangzhou, China, 14–15 April 2018. [Google Scholar]

- Wan, Y.; Li, Q.; Guo, J.; Cui, S.M. Thermal analysis of a Gramme-ring-winding high-speed permanent-magnet motor for pulsed alternator using CFD. IET Electr. Power Appl. 2020, 14, 2202–2211. [Google Scholar] [CrossRef]

- Husain, T.; Lee, S.T.; Ma, C. Design Considerations of Magnet Configurations in Interior Permanent Magnet Machines for High-Speed Traction Applications: A Comprehensive Study. IEEE Ind. Appl. Mag. 2022, 28, 14–26. [Google Scholar] [CrossRef]

- Yan, W.M.; Teng, H.Y.; Li, C.H.; Ghalambaz, M. Electromagnetic field analysis and cooling system design for high power switched reluctance motor. Int. J. Numer. Methods Heat Fluid Flow 2019, 29, 1756–1785. [Google Scholar] [CrossRef]

- Shi, X.J.; Yang, X.; Mu, Y.J.; Wang, Y.Z.; Wang, W.K. Thermal error compensation model for a motorized spindle with shaft core cooling based on exponential function. Int. J. Adv. Manuf. Technol. 2019, 103, 4805–4813. [Google Scholar] [CrossRef]

- Cui, Y.; Li, H.L.; Li, T.J.; Chen, L. An accurate thermal performance modeling and simulation method for motorized spindle of machine tool based on thermal contact resistance analysis. Int. J. Adv. Manuf. Technol. 2018, 96, 2525–2537. [Google Scholar] [CrossRef]

- Liang, F.; Gao, J.M.; Li, F.J.; Xu, L.; Wang, Z.; Jiang, H.Q. IEEE: A Central Cooling Structure for Motorized Spindles: Principle and Application. In Proceedings of the 18th IEEE InterSociety Conference on Thermal and Thermomechanical Phenomena in Electronic Systems (ITherm), Las Vegas, NV, USA, 28–31 May 2019; pp. 1204–1211. [Google Scholar]

- Li, F.J.; Gao, J.M.; Shi, X.J.; Wang, Z.F.; Wang, D.Y. Experimental investigation into rotating loop thermosyphons for cooling shafts of motorized spindles. Heat Mass Transf. 2020, 56, 3127–3134. [Google Scholar] [CrossRef]

- Shi, X.J.; Yin, B.T.; Chen, G.Q.; Zhang, X.D.; Mei, X.S. Numerical study on two-phase flow and heat transfer characteristics of loop rotating heat pipe for cooling motorized spindle. Appl. Therm. Eng. 2021, 192, 116927. [Google Scholar] [CrossRef]

- Cao, J.C.; Yan, H.; Li, D.; Wang, Y.; Li, W.L. Influence of the Variable Cross-Section Stator Ventilation Structure on the Temperature of an Induction Motor. Energies 2021, 14, 5249. [Google Scholar] [CrossRef]

- Zhang, Z.C.; Qiang, S.; Ahmed, B. IOP: Innovative Design of the Cooling Topologies for Electric Vehicle Motors. In Proceedings of the 5th International Conference on Electrical Engineering, Control and Robotics (EECR), Guangzhou, China, 12–14 January 2019. [Google Scholar]

- Yu, W.F.; Hua, W.; Zhang, Z.H. Cooling Analysis of High-Speed Stator-Permanent Magnet Flux-Switching Machines for Fuel-Cell Electric Vehicle Compressor. IEEE Trans. Veh. Technol. 2022, 71, 210–219. [Google Scholar] [CrossRef]

- Wang, L.K.; Li, Y.; Marignetti, F.; Boglietti, A. Coupled Fluid-Solid Heat Transfer of a Gas and Liquid Cooling PMSM Including Rotor Rotation. IEEE Trans. Energy Convers. 2022, 37, 443–453. [Google Scholar] [CrossRef]

- Sasa, H.; Iwakuma, M.; Yoshida, K.; Sato, S.; Sasayama, T.; Yoshida, T.; Yamamoto, K.; Miura, S.; Kawagoe, A.; Izumi, T.; et al. Experimental Evaluation of 1 kW-class Prototype REBCO Fully Superconducting Synchronous Motor Cooled by Subcooled Liquid Nitrogen for E-Aircraft. IEEE Trans. Appl. Supercond. 2021, 31, 5200706. [Google Scholar] [CrossRef]

- Du, G.G.; Huang, N. Friction Loss and Thermal Analysis of a High-Speed Permanent Magnet Machine for Waste Heat Power Generation Application. IEEE Access 2019, 7, 131710–131718. [Google Scholar] [CrossRef]

- Lee, H.S.; Hwang, M.H.; Cha, H.R. Electromagnetic Field Analysis and Design of a Hermetic Interior Permanent Magnet Synchronous Motor with Helical-Grooved Self-Cooling Case for Unmanned Aerial Vehicles. Appl. Sci. 2021, 11, 4856. [Google Scholar] [CrossRef]

- Gao, J.; Han, X.; Wang, Y.; Wang, S.; Li, H. Application analysis of forced ventilation cooling method in low-speed high-torque permanent magnet motor. Electr. Mach. Control 2022, 26, 58–64. [Google Scholar]

- Krasopoulos, C.T.; Ioannidis, A.S.; Kremmydas, A.F.; Karafyllakis, I.A.; Kladas, A.G. Convection Heat Transfer Coefficient Regression Models Construction for Fast High-Speed Motor Thermal Analysis. IEEE Trans. Magn. 2022, 58, 8206905. [Google Scholar] [CrossRef]

- Sakurai, S.; Nakamura, K. Loss reduction of outer-rotor type high-speed interior permanent magnet motors. Int. J. Appl. Electromagn. Mech. 2020, 64, 861–868. [Google Scholar] [CrossRef]

- Cao, J.C.; Yan, H.; Li, W.L.; Li, D.; Wang, Y. Optimization of stator ventilation structure of high-speed railway traction motor based on the genetic algorithm. IET Electr. Power Appl. 2023, 17, 281–292. [Google Scholar] [CrossRef]

- Du, J.J.; Li, C.J.; Zhao, J.; Huang, X.Y.; Liu, Y.P.; Lv, H.Y. Rotor Investigation of High-Speed Permanent Magnet Motor with Roundness Error and CFD-Thermal Distribution Analysis. Energies 2022, 15, 4606. [Google Scholar] [CrossRef]

- Geng, W.W.; Zhu, T.; Zhang, Y.Q.; Wu, C.Q.; Wang, Y.; Li, Q.; Zhang, Z.R. Rotor Air-Friction Loss and Thermal Analysis of IPM Rotors for High Speed Axial-Flux Machine. IEEE Trans. Ind. Appl. 2023, 59, 779–788. [Google Scholar] [CrossRef]

- Huang, J.L.; Xuan, Y.; Zhang, L.; Liu, T.G. Analysis on the design and temperature field of switched reluctance motor for electric vehicle. J. Phys. Conf. Ser. 2021, 1777, 012001. [Google Scholar] [CrossRef]

- Zou, T.; Gerada, D.; Rocca, S.L.; Rocca, A.L.; Walker, A.; Vakil, G.; Arevalo, S.L.; Xu, Z.; Cui, M.; Bardalai, A.; et al. Airgap Length Analysis of a 350 kw PM-Assisted Syn-Rel Machine for Heavy Duty EV Traction. IEEE Trans. Ind. Appl. 2023, 59, 1557–1570. [Google Scholar] [CrossRef]

- Kovacik, M.; Rafajdus, P.; Stano, M. Analysis of Loss and Thermal Performance of High Speed PMSM for Automotive Application. In Proceedings of the 2022 Elektro (Elektro), Krakow, Poland, 23–26 May 2022; p. 4. [Google Scholar]

- Zhang, F.Y.; Gerada, D.; Xu, Z.Y.; Zhang, X.C.; Zhang, H.; Gerada, C.; Zhu, M.J.; Xia, L.Q.; Zhang, W.; Degano, M. Improved Thermal Modeling and Experimental Validation of Oil-Flooded High-Performance Machines with Slot-Channel Cooling. IEEE Trans. Transp. Electrif. 2022, 8, 312–324. [Google Scholar] [CrossRef]

- Feng, J.; Tan, D.; Yuan, M. Influence of road excitation on thermal field characteristics of the water-cooled IWM. Arch. Electr. Eng. 2021, 70, 689–704. [Google Scholar]

- Cui, L.; Wang, Q.S. IOP: Thermal Properties Analysis of Compact Motorized Spindle Considering Fluid-Solid Thermal Coupling. In Proceedings of the 2nd International Conference on Advanced Technologies in Manufacturing and Materials Engineering (ATMME), Harbin, China, 4–6 May 2018. [Google Scholar]

- Bae, J.C.; Cho, H.R.; Yadav, S.; Kim, S.C. Cooling Effect of Water Channel with Vortex Generators on In-Wheel Driving Motors in Electric Vehicles. Energies 2022, 15, 722. [Google Scholar] [CrossRef]

- Wu, S.; Hao, D.; Tong, W. Cooling System Design and Thermal Analysis of Modular Stator Hybrid Excitation Synchronous Motor. CES Trans. Electr. Mach. Syst. 2022, 6, 241–251. [Google Scholar] [CrossRef]

- Kong, W.; Huang, S.; Wu, W. Design and Development of High-Speed and High-Power Drive Motor for Heavy Commercial Vehicle. In Proceedings of the 2022 IEEE 5th International Electrical and Energy Conference (CIEEC) 2022, Nanjing, China, 27–29 May 2022; pp. 869–874. [Google Scholar]

- Zhang, L.X.; Li, J.P.; Wu, Y.H.; Zhang, K.; Wang, Y.W. Prediction model and experimental validation for the thermal deformation of motorized spindle. Heat Mass Transf. 2018, 54, 2691–2704. [Google Scholar] [CrossRef]

- Du, G.H.; Xu, W.; Zhu, J.G.; Huang, N. Power Loss and Thermal Analysis for High-Power High-Speed Permanent Magnet Machines. IEEE Trans. Ind. Electron. 2020, 67, 2722–2733. [Google Scholar] [CrossRef]

- Kepsu, D.; Jastrzebski, R.P.; Pyrhonen, O. Modeling of a 30,000 Rpm Bearingless SPM Drive with Loss and Thermal Analyses for a 0.5 MW High-Temperature Heat Pump. IEEE Trans. Ind. Appl. 2021, 57, 6965–6976. [Google Scholar] [CrossRef]

- Liu, Y.; Ma, Y.X.; Meng, Q.Y.; Xin, X.C.; Ming, S.S. Improved thermal resistance network model of motorized spindle system considering temperature variation of cooling system. Adv. Manuf. 2018, 6, 384–400. [Google Scholar] [CrossRef]

- Zhu, G.J.; Liu, X.M.; Li, L.N.; Chen, H.; Tong, W.M.; Zhu, J.G. Cooling System Design of a High-Speed PMSM Based on a Coupled Fluidic-Thermal Model. IEEE Trans. Appl. Supercond. 2019, 29, 0601405. [Google Scholar] [CrossRef]

- Li, Z.; Wang, P.J.; Liu, L.B.; Xu, Q.Q.; Che, S.; Zhang, L.C.; Du, S.H.; Zhang, H.J.; Sun, H.X. Loss calculation and thermal analysis of ultra-high speed permanent magnet motor. Heliyon 2022, 8, e11350. [Google Scholar] [CrossRef] [PubMed]

- Zhang, F.G.; Hao, Y.; Liu, G.W.; Qiu, F.Y. Ieee: Design and Analysis of 100 kW High Speed Permanent Magnet Synchronous Motor. In Proceedings of the IEEE Transportation Electrification Conference and Expo, Asia-Pacific (ITEC Asia-Pacific), Busan, Republic of Korea, 1–4 June 2016; pp. 843–847. [Google Scholar]

- Dong, B.T.; Wang, K.; Han, B.C.; Zheng, S.Q. Thermal Analysis and Experimental Validation of a 30 kW 60,000 r/min High-Speed Permanent Magnet Motor with Magnetic Bearings. IEEE Access 2019, 7, 92184–92192. [Google Scholar] [CrossRef]

- Kang, M.; Wang, H.M.; Guo, L.Y.; Shi, T.N.; Xia, C.L. Self-circulation cooling structure design of permanent magnet machines for electric vehicle. Appl. Therm. Eng. 2020, 165, 114593. [Google Scholar] [CrossRef]

- Ismagilov, F.R.; Uzhegov, N.; Vavilov, V.E.; Bekuzin, V.I.; Ayguzina, V.V. Multidisciplinary Design of Ultra-High-Speed Electrical Machines. IEEE Trans. Energy Convers. 2018, 33, 1203–1212. [Google Scholar] [CrossRef]

- Sim, K.; Lee, Y.B.; Jang, S.M.; Kim, T.H. Thermal analysis of high-speed permanent magnet motor with cooling flows supported on gas foil bearings: Part I—Coupled thermal and loss modeling. J. Mech. Sci. Technol. 2015, 29, 5469–5476. [Google Scholar] [CrossRef]

- Avusula, V.; Khamari, S.S.; Rani, G.S.; Behera, R.K. Design of 15 kW, 440 V Three Phase Induction Motor for Electrical Vehicle Applications with Improved Efficiency and Wide Speed Range. In Proceedings of the 2023 International Conference on Power Electronics and Energy (ICPEE) 2023, Bhubaneswar, India, 3–5 January 2023; pp. 1–6. [Google Scholar]

- Enokizono, M.; Wakabayashi, D.; Soda, N.; Tsuchida, Y.; Ueno, S.; Oka, M. IEEE: High Power Density and High Efficiency of High-Speed Motor. In Proceedings of the International Conference on Electrical Machines (ICEM), Gothenburg, Sweden, 23–26 August 2020; pp. 170–176. [Google Scholar]

| Reference | Rotor Diameter (mm) | Power (kW) | Rotational Speed (rpm) | Cooling Method |

|---|---|---|---|---|

| [57] | 2660 | 630 | 37.5 | Air |

| [58] | 110 | 20 | 15,000 | Air |

| [19] | / | 10 | 5000 | Air |

| [37] | 92 | 225 | 35,000 | Air |

| [12] | 380 | 520 | 4700 | Air |

| [18] | 92 | 225 | 34,500 | Air |

| [59] | 54 | 0.264 | 12,600 | Air |

| [14] | 1960 | 480 | 6000 | Air |

| [60] | 330 | 600 | 4636 | Air |

| [61] | 65 | 105 | 36,000 | Air |

| [62] | 220 | 70 | 4000 | Air |

| [63] | 228.6 | 110 | 1500 | Liquid |

| [64] | 350 | 350 | 15,000 | Liquid |

| [65] | 38 | 8 | 100,000 | Liquid |

| [66] | 38.9 | 9.6 | 8700 | Liquid |

| [67] | 200 | 15 | 1000 | Liquid |

| [68] | / | 30 | 12,000 | Liquid |

| [69] | / | 25 | 5000 | Liquid |

| [70] | 300 | 100 | 3000 | Liquid |

| [71] | 185 | 305 | 10,000 | Liquid |

| [72] | / | 7.5 | 24,000 | Liquid |

| [73] | 204 | 800 | 15,000 | Liquid |

| [74] | 100 | 80 | 30,000 | Liquid |

| [75] | 60 | 11 | 12,000 | Liquid |

| [76] | 70 | 15 | 30,000 | Air and liquid |

| [77] | 36.3 | 22 | 90,000 | Air and liquid |

| [78] | 200 | 100 | 50,000 | Air and liquid |

| [79] | 55 | 30 | 60,000 | Air and liquid |

| [80] | 50.2 | 40 | 14,000 | Air and liquid |

| [81] | 5 | 0.138 | 1,200,000 | Air and liquid |

| [21] | 42 | 30 | 30,000 | Air and liquid |

| [82] | 69.5 | 223 | 60,000 | Air and liquid |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yan, S.; Qiang, M.; Zhao, Q.; Hou, Y.; Lai, T. Research Progress of Enhanced Thermal Evacuation and Cooling Technology for High-Speed Motors. Appl. Sci. 2024, 14, 2617. https://doi.org/10.3390/app14062617

Yan S, Qiang M, Zhao Q, Hou Y, Lai T. Research Progress of Enhanced Thermal Evacuation and Cooling Technology for High-Speed Motors. Applied Sciences. 2024; 14(6):2617. https://doi.org/10.3390/app14062617

Chicago/Turabian StyleYan, Shaohang, Mingchen Qiang, Qi Zhao, Yu Hou, and Tianwei Lai. 2024. "Research Progress of Enhanced Thermal Evacuation and Cooling Technology for High-Speed Motors" Applied Sciences 14, no. 6: 2617. https://doi.org/10.3390/app14062617

APA StyleYan, S., Qiang, M., Zhao, Q., Hou, Y., & Lai, T. (2024). Research Progress of Enhanced Thermal Evacuation and Cooling Technology for High-Speed Motors. Applied Sciences, 14(6), 2617. https://doi.org/10.3390/app14062617