A Study of the Bond Strength and Mechanism between Basalt Fibers and Asphalt Binders

Abstract

1. Introduction

2. Materials and Methods

2.1. Raw Materials

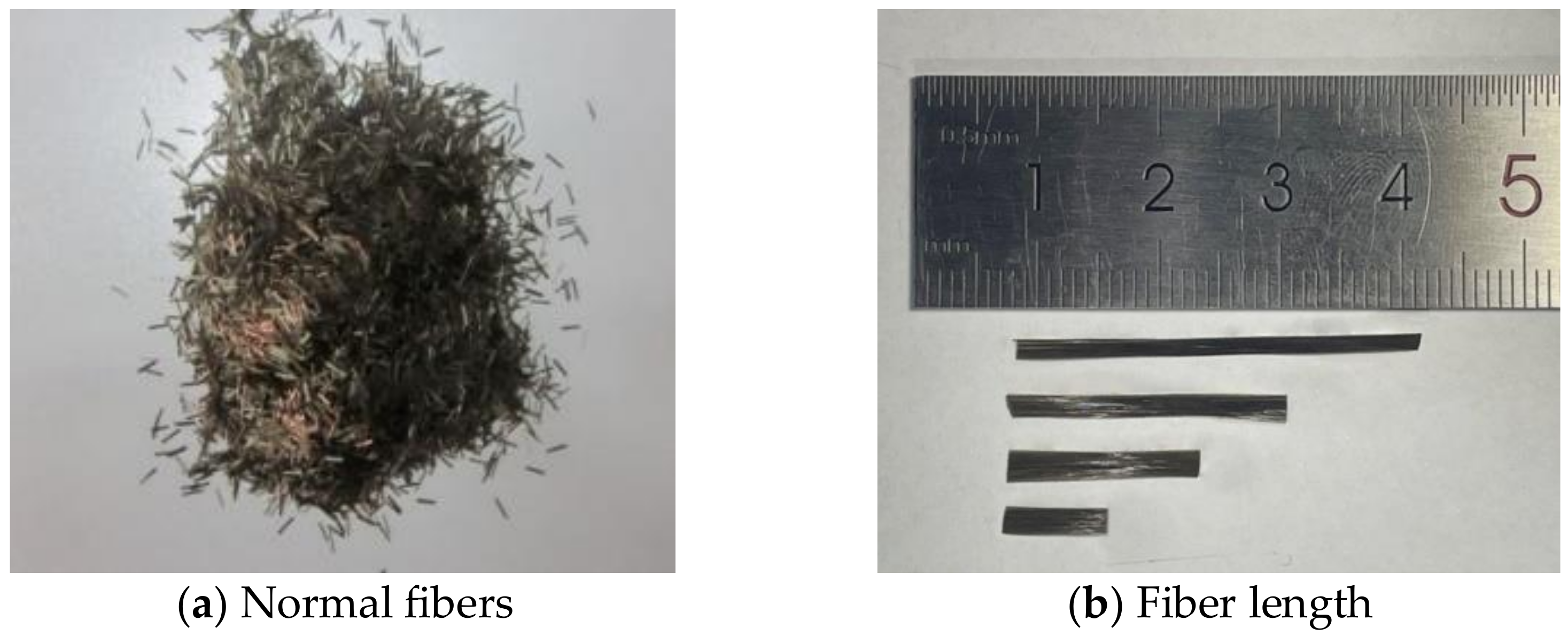

2.1.1. Fiber

2.1.2. Asphalt

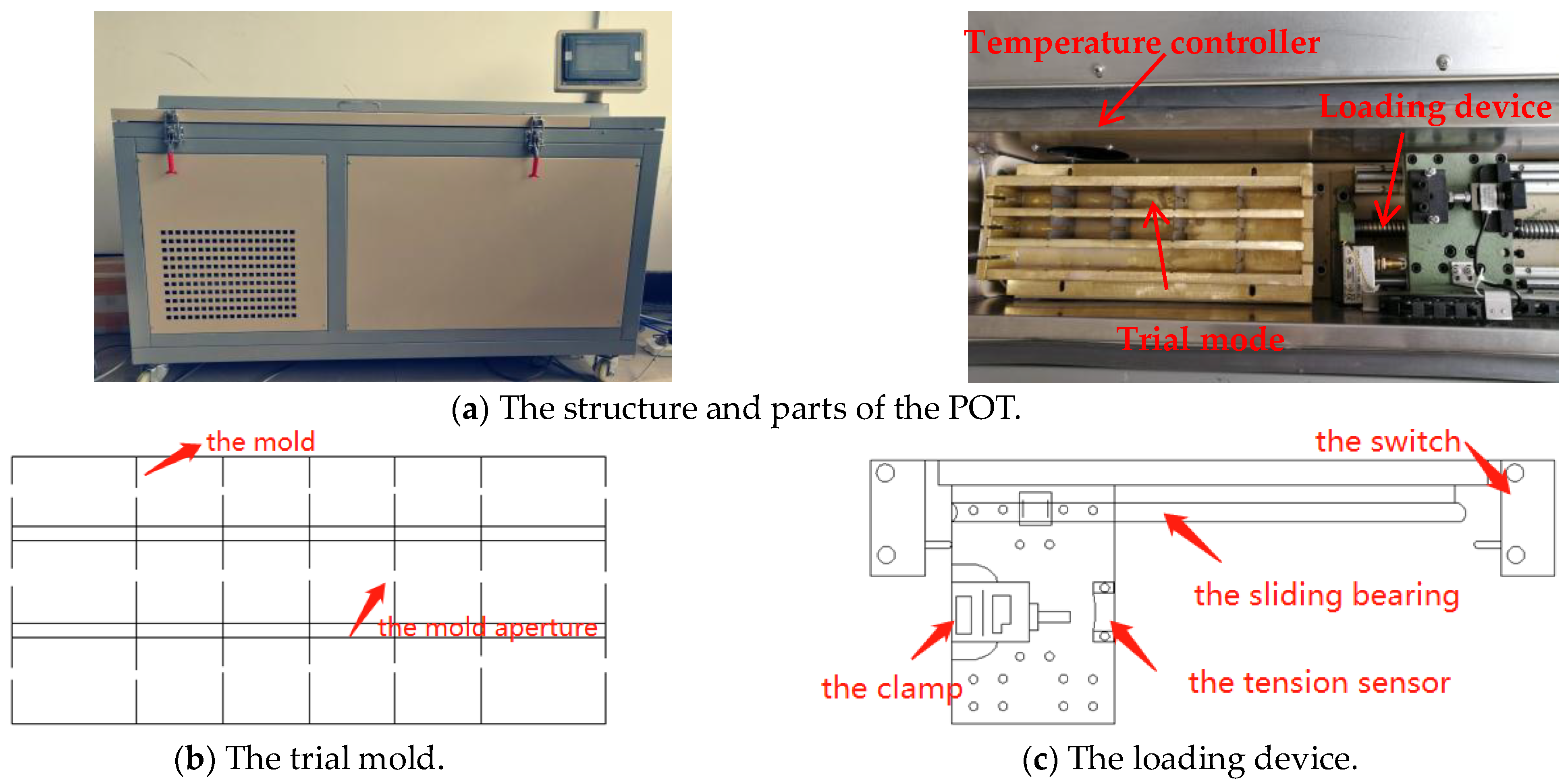

2.2. Pull-Out Test

2.2.1. Pull-Out Equipment

2.2.2. Testing Procedure

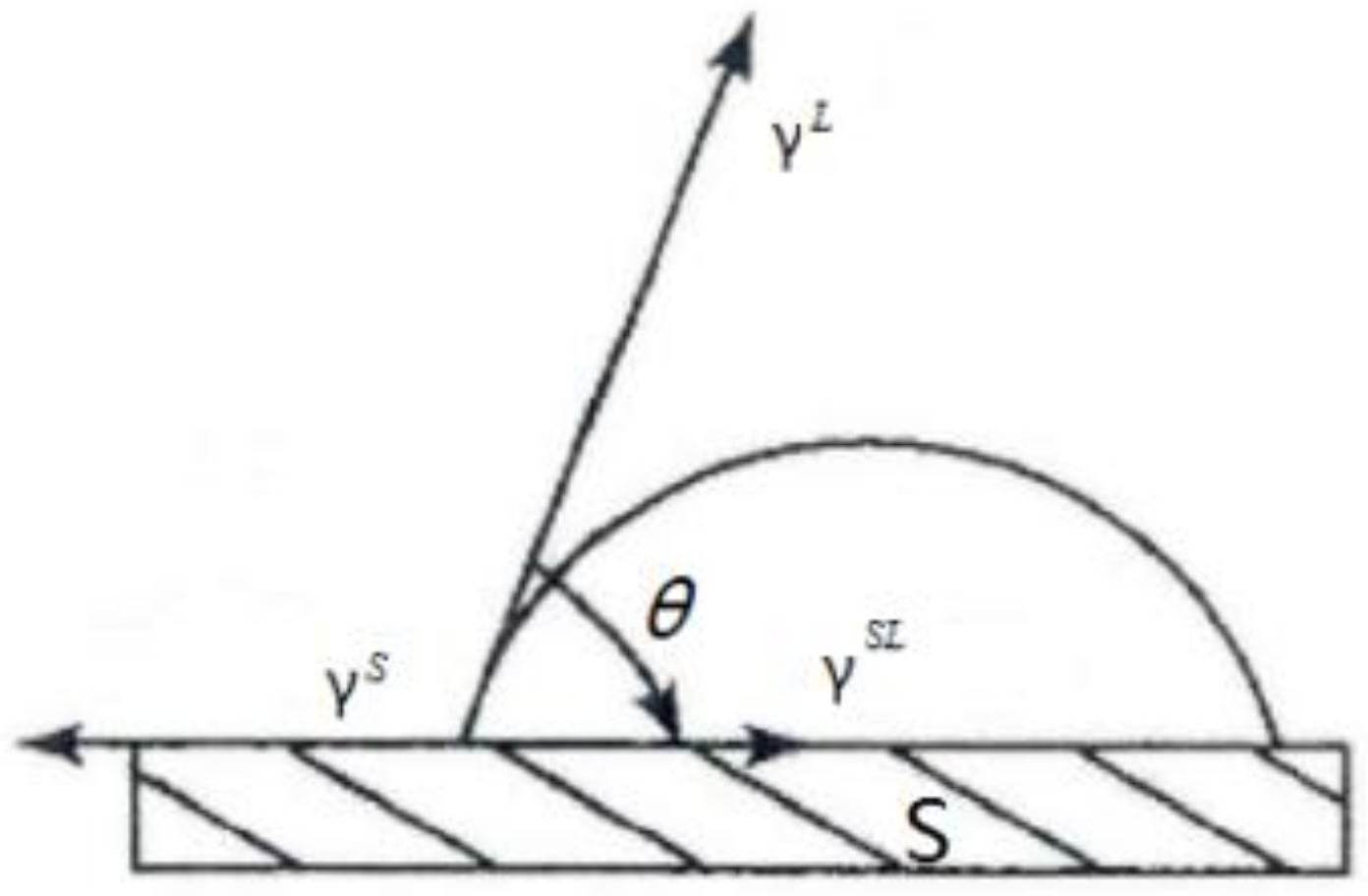

2.3. Contact Angle Test (CAT)

2.3.1. Surface Energy

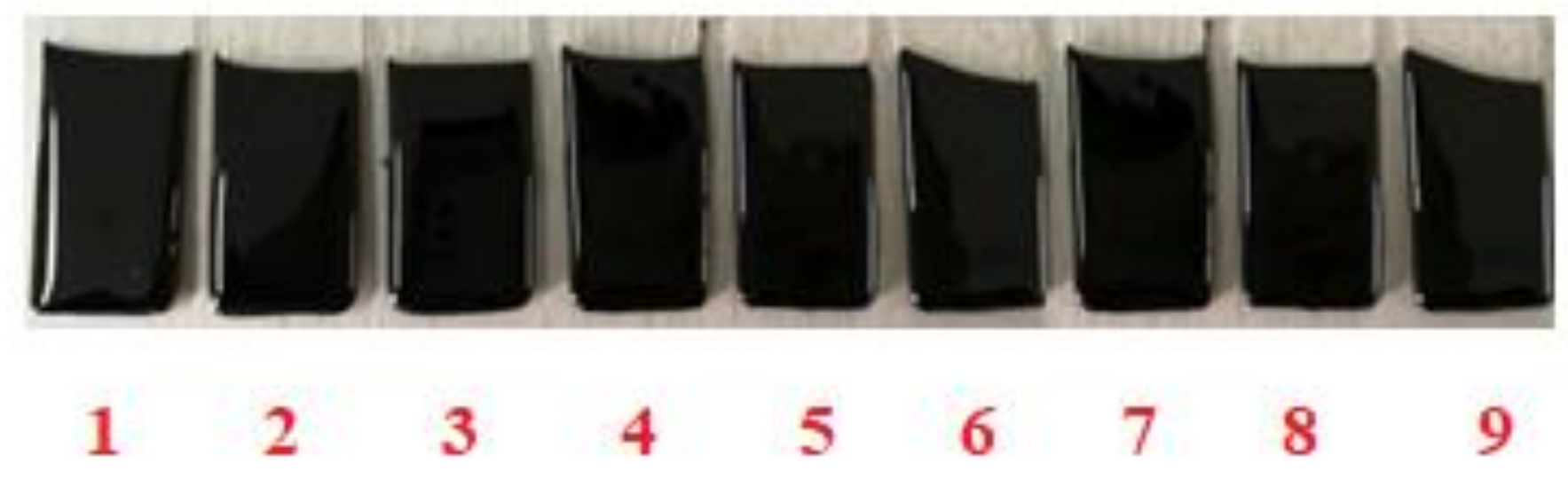

2.3.2. Specimen Preparation for CAT

2.4. Scanning Electron Microscopy

3. Results and Analysis

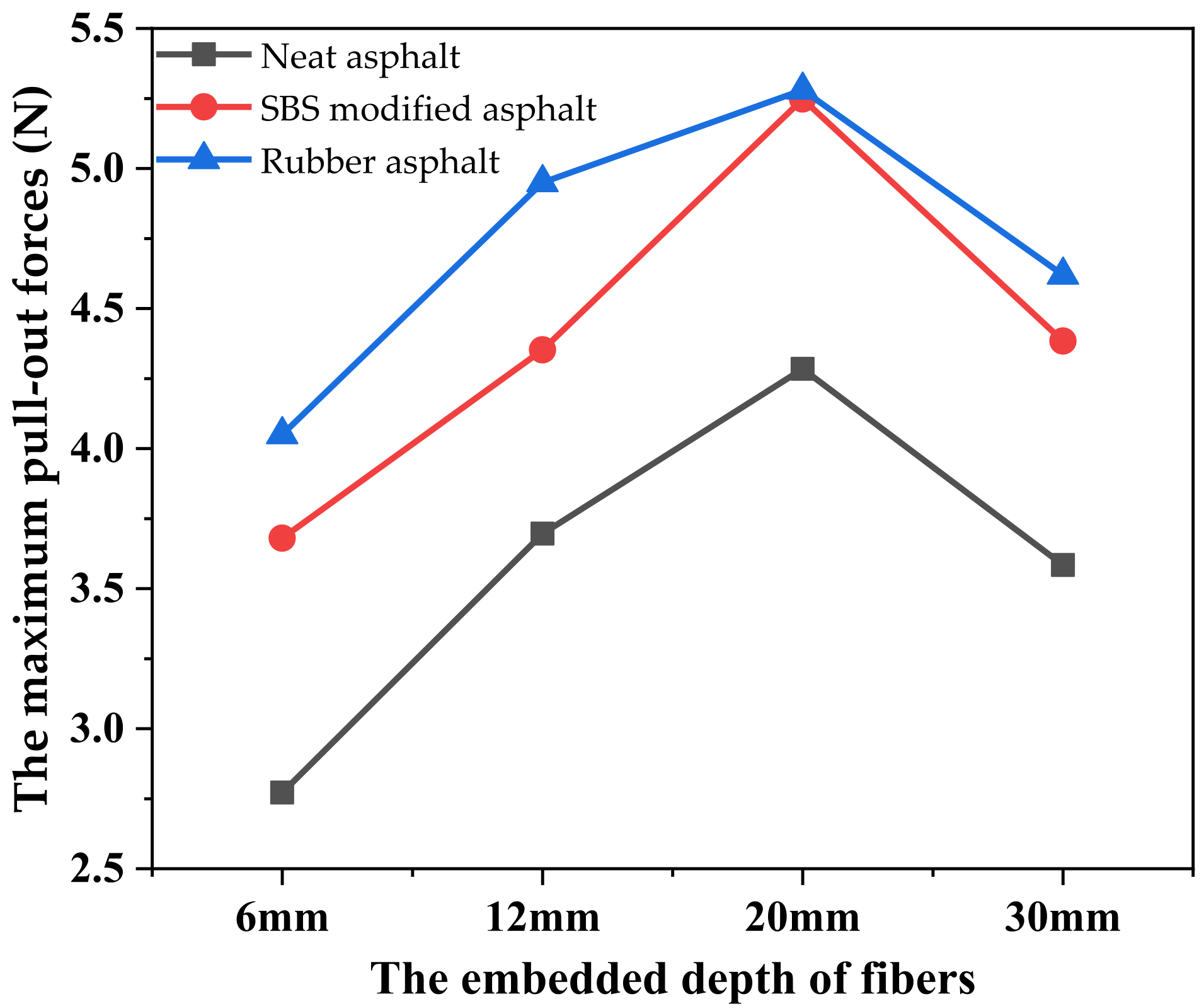

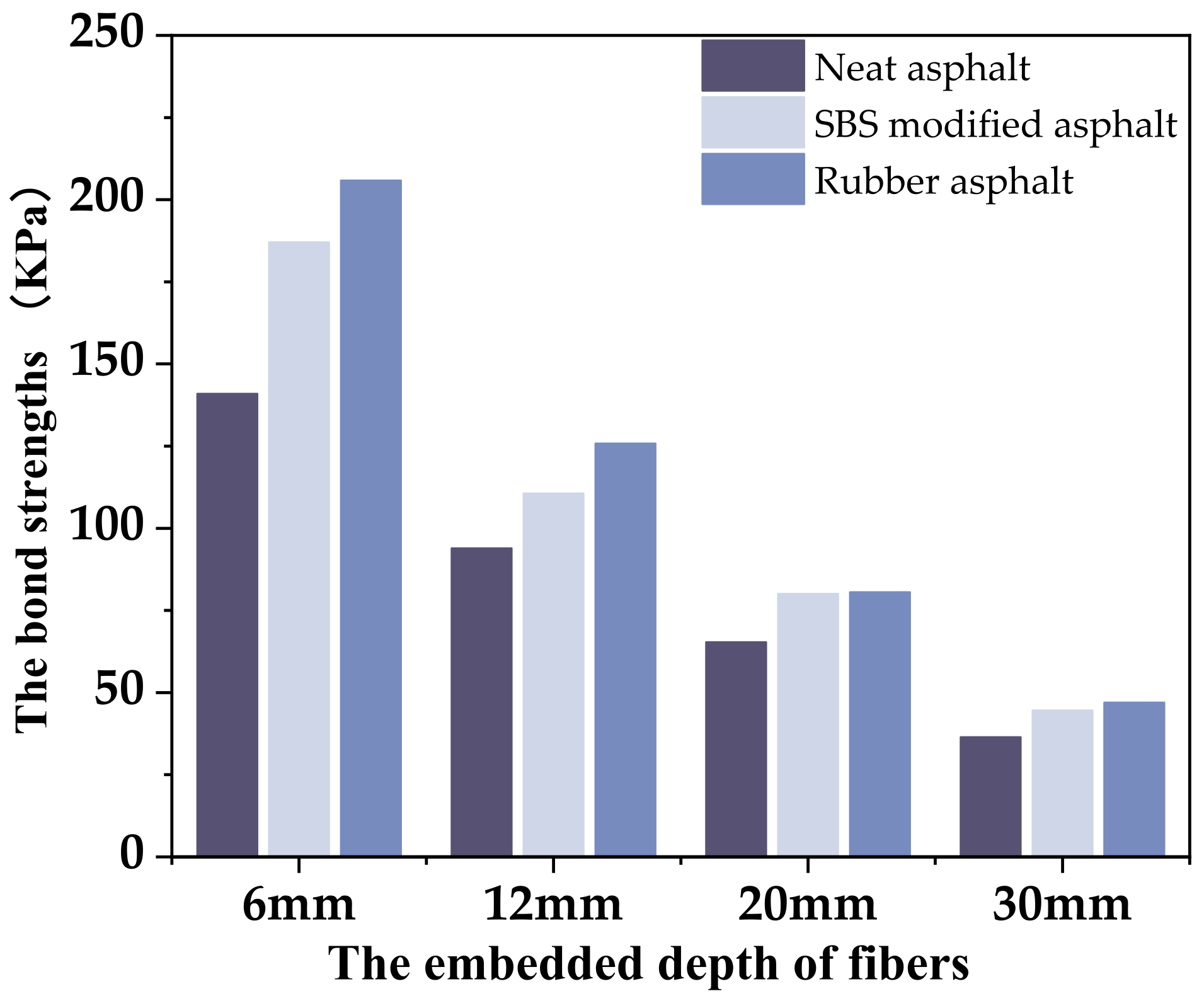

3.1. Influence of Fiber Embedment Depths and Asphalt Binders on POT Results

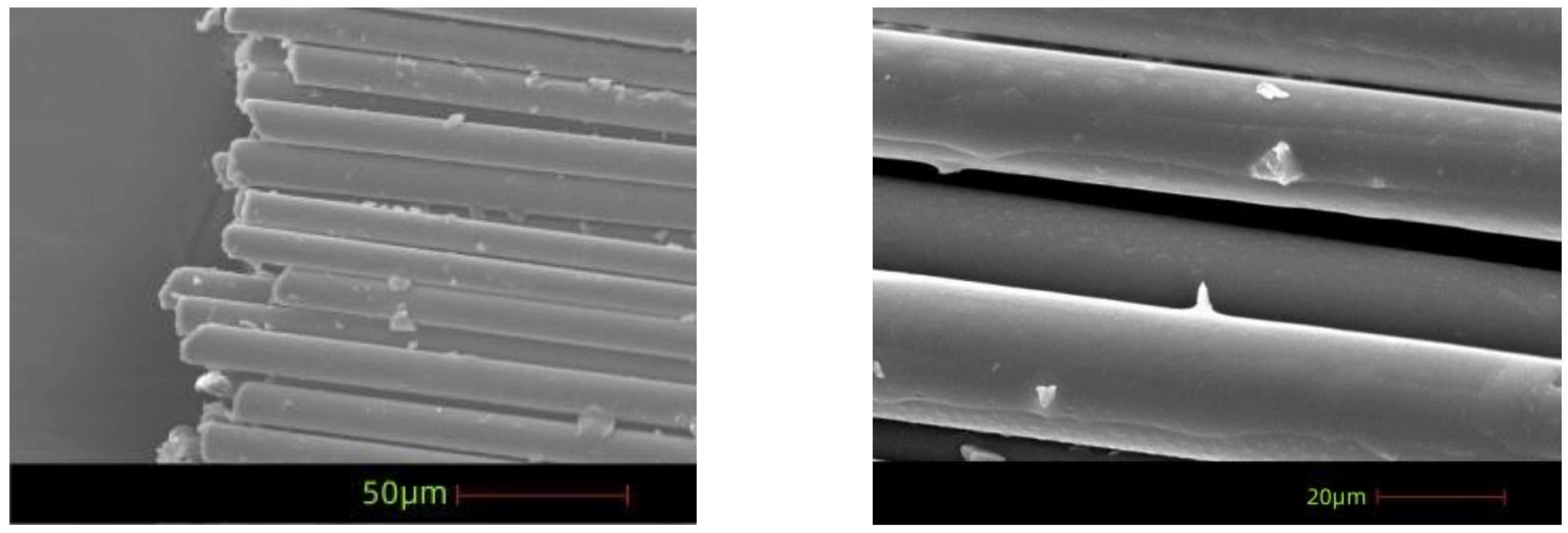

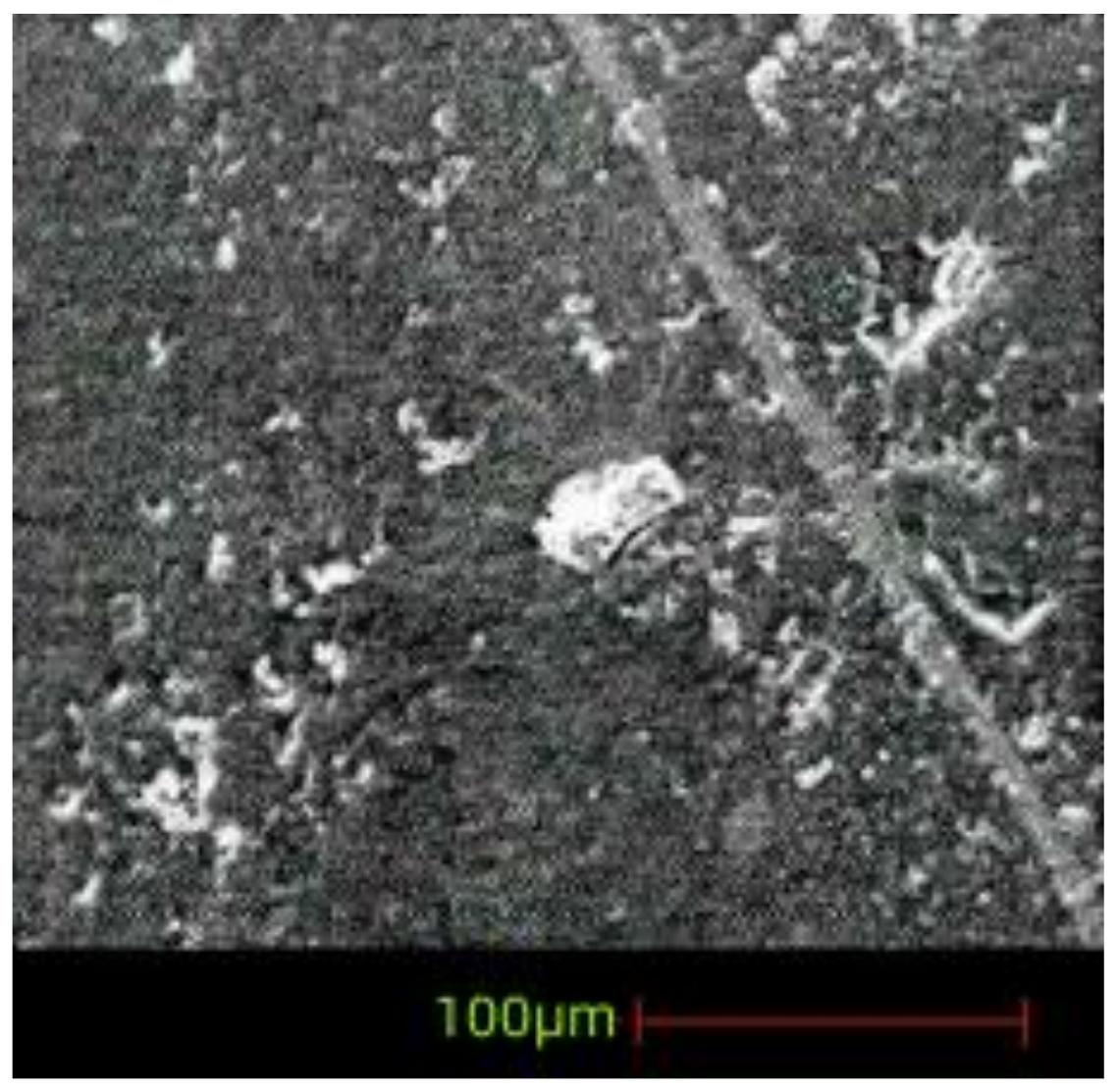

3.2. Scanning Electron Micrograph

3.3. Surface Energy and Contact Angle

3.3.1. Surface Energy Calculation of Asphalt

3.3.2. Surface Energy Calculation for BFs

3.3.3. Adhesion Work of Asphalt Binders and Basalt Fibers

3.4. Comprehensive Analysis of Bond Strength Based on the Grey Relational Method

4. Conclusions

- Appropriate embedment depths of BFs are beneficial to the bonding strength between basalt fibers and asphalt binders, which can further guide the selection of basalt fiber length. In addition, rubber asphalt has a higher bond strength with basalt fibers than the other two asphalts.

- The types of asphalt binders suitable for basalt fibers and the appropriate fiber embedding depths for different types of asphalt binders guiding the selection of fiber length were recommended based on the influence of the fiber embedding depth and asphalt binders on fiber–asphalt bonding strength. The recommended fiber length is 20 mm. The recommended asphalt type is rubber asphalt.

- SEM images revealed the uniform distribution of fibers in the asphalt binders and the spatial networks of basalt fibers in the asphalt binders.

- The surface energy of the asphalt binders and basalt fibers showed that rubber asphalt with BFs had good adhesivity and high homogeneity.

- The results obtained using the gray correlation method showed that bond strength correlates more closely with the type of asphalt binder than embedment depth.

- Finally, further research is required to investigate the distribution of basalt fibers in asphalt binders. In this study, a preliminary analysis of the microscopic mechanism of BFs in asphalt binders was carried out. The microscopic mechanisms of basalt fibers–asphalt binders also need to be further analyzed.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Li, Z.; Li, K.; Chen, W.; Liu, W.; Yin, Y.; Cong, P. Investigation on the characteristics and effect of plant fibers on the properties of asphalt binders. Constr. Build. Mater. 2022, 338, 127652. [Google Scholar] [CrossRef]

- Zhang, X.; Chen, E.; Li, N.; Wang, L.; Si, C.; Wang, C. Micromechanical analysis of the rutting evolution of asphalt pavement under temperature–stress coupling based on the discrete element method. Constr. Build. Mater. 2022, 325, 126800. [Google Scholar] [CrossRef]

- Li, D.; Leng, Z.; Zhang, S.; Jiang, J.; Yu, H.; Wellner, F.; Leischner, S. Blending efficiency of reclaimed asphalt rubber pavement mixture and its correlation with cracking resistance. Resour. Conserv. Recycl. 2022, 185, 106506. [Google Scholar] [CrossRef]

- Xu, O.; Li, Y.; Xu, R.; Liu, Y.; Dong, Y. Performance evaluation of waterborne epoxy resin modified emulsified asphalt mixtures for asphalt pavement pothole repair. Constr. Build. Mater. 2022, 325, 126709. [Google Scholar] [CrossRef]

- Wang, S.; Sui, X.; Leng, Z.; Jiang, J.; Lu, G. Asphalt pavement density measurement using non-destructive testing methods: Current practices, challenges, and future vision. Constr. Build. Mater. 2022, 344, 128154. [Google Scholar] [CrossRef]

- Ghuzlan, K.A.; Bara, W.A.M.; Al-Momani, A.S. Rutting performance of asphalt mixtures with gradations designed using Bailey and conventional Superpave methods. Constr. Build. Mater. 2020, 261, 119941. [Google Scholar] [CrossRef]

- Zhou, X.; Zhao, G.; Tighe, S.; Chen, M.; Wu, S.; Adhikari, S.; Gao, Y. Quantitative comparison of surface and interface adhesive properties of fine aggregate asphalt mixtures composed of basalt, steel slag, and andesite. Constr. Build. Mater. 2020, 246, 118507. [Google Scholar] [CrossRef]

- Cui, S.; Sheng, Y.; Wang, Z.; Jia, H.; Qiu, W.; Temitope, A.A.; Xu, Z. Effect of the fiber surface treatment on the mechanical performance of bamboo fiber modified asphalt binder. Constr. Build. Mater. 2022, 347, 128453. [Google Scholar] [CrossRef]

- Chu, H.H.; Almohana, A.I.; QasMarrogy, G.A.; Almojil, S.F.; Alali, A.F.; Almoalimi, K.T.; Raise, A. Experimental investigation of performance properties of asphalt binder and stone matrix asphalt mixture using waste material and warm mix additive. Constr. Build. Mater. 2023, 368, 130397. [Google Scholar] [CrossRef]

- Slebi-Acevedo, C.J.; Lastra-González, P.; Pascual-Muñoz, P.; Castro-Fresno, D. Mechanical performance of fibers in hot mix asphalt: A review. Constr. Build. Mater. 2019, 200, 756–769. [Google Scholar] [CrossRef]

- Li, Z.; Shen, A.; Wang, H.; Guo, Y.; Wu, H. Effect of basalt fiber on the low-temperature performance of an asphalt mixture in a heavily frozen area. Constr. Build. Mater. 2020, 253, 119080. [Google Scholar] [CrossRef]

- Davar, A.; Tanzadeh, J.; Fadaee, O. Experimental evaluation of the basalt fibers and diatomite powder compound on enhanced fatigue life and tensile strength of hot mix asphalt at low temperatures. Constr. Build. Mater. 2017, 153, 238–246. [Google Scholar] [CrossRef]

- Katkhuda, H.; Shatarat, N. Improving the mechanical properties of recycled concrete aggregate using chopped basalt fibers and acid treatment. Constr. Build. Mater. 2017, 140, 328–335. [Google Scholar] [CrossRef]

- Alnahhal, W.; Aljidda, O. Flexural behavior of basalt fiber reinforced concrete beams with recycled concrete coarse aggregates. Constr. Build. Mater. 2018, 169, 165–178. [Google Scholar] [CrossRef]

- Xie, T.; Wang, L. Optimize the design by evaluating the performance of asphalt mastic reinforced with different basalt fiber lengths and contents. Constr. Build. Mater. 2023, 363, 129698. [Google Scholar] [CrossRef]

- Gu, Q.; Kang, A.; Li, B.; Xiao, P.; Ding, H. Effect of fiber characteristic parameters on the high and low temperature rheological properties of basalt fiber modified asphalt mortar. Case Stud. Constr. Mater. 2022, 17, e01247. [Google Scholar] [CrossRef]

- Lou, K.; Xiao, P.; Kang, A.; Wu, Z.; Li, B.; Lu, P. Performance evaluation and adaptability optimization of hot mix asphalt reinforced by mixed lengths basalt fibers. Constr. Build. Mater. 2021, 292, 123373. [Google Scholar] [CrossRef]

- Qin, X.; Shen, A.; Guo, Y.; Li, Z.; Lv, Z. Characterization of asphalt mastics reinforced with basalt fibers. Constr. Build. Mater. 2018, 159, 508–516. [Google Scholar] [CrossRef]

- Khan, M.; Cao, M.; Ali, M. Effect of basalt fibers on mechanical properties of calcium carbonate whisker-steel fiber reinforced concrete. Constr. Build. Mater. 2018, 192, 742–753. [Google Scholar] [CrossRef]

- Kathari, P.M.; Sandra, A.K.; Sravana, P. Experimental investigation on the performance of asphalt binders reinforced with basalt fibers. Innov. Infrastruct. Solut. 2018, 3, 76. [Google Scholar] [CrossRef]

- Lou, K.; Xiao, P.; Tang, Q.; Wu, Y.; Wu, Z.; Pan, X. Research on the micro-nano characteristic of basalt fiber and its impact on the performance of relevant asphalt mastic. Constr. Build. Mater. 2022, 318, 126048. [Google Scholar] [CrossRef]

- Wu, B.; Pei, Z.; Luo, C.; Xia, J.; Chen, C.; Kang, A. Effect of different basalt fibers on the rheological behavior of asphalt mastic. Constr. Build. Mater. 2022, 318, 125718. [Google Scholar] [CrossRef]

- Wang, D.; Wang, L.; Gu, X.; Zhou, G. Effect of basalt fiber on the asphalt binder and mastic at low temperature. J. Mater. Civ. Eng. 2013, 25, 355–364. [Google Scholar] [CrossRef]

- Fu, Z.; Tang, Y.; Ma, F.; Wang, Y.; Shi, K.; Dai, J.; Hou, Y.; Li, J. Rheological properties of asphalt binder modified by nano-TiO2/ZnO and basalt fiber. Constr. Build. Mater. 2022, 320, 126323. [Google Scholar] [CrossRef]

- Cheng, X.; Liu, J.; Han, C.; Zhang, X.; Wu, Z. Silane coupling agent impact on surface features of modification of basalt fibers and the rheological properties of basalt fiber reinforced asphalt. Constr. Build. Mater. 2023, 366, 130182. [Google Scholar] [CrossRef]

- Mohammed, M.; Parry, T.; Thom, N.; Grenfell, J. Investigation into the bond strength of bitumen-fibre mastic. Constr. Build. Mater. 2018, 190, 382–391. [Google Scholar] [CrossRef]

- Rahim, A.; Thom, N.; Airey, G. Development of compression pull-off test (CPOT) to assess bond strength of bitumen. Constr. Build. Mater. 2019, 207, 412–421. [Google Scholar] [CrossRef]

- Zhang, X.; Gu, X.; Lv, J.; Zhu, Z.; Ni, F. Mechanism and behavior of fiber-reinforced asphalt mastic at high temperature. Int. J. Pavement Eng. 2018, 19, 407–415. [Google Scholar] [CrossRef]

- Zhang, X.; Gu, X.; Lv, J.; Zhu, Z.; Zou, X. Numerical analysis of the rheological behaviors of basalt fiber reinforced asphalt mortar using ABAQUS. Constr. Build. Mater. 2017, 157, 392–401. [Google Scholar] [CrossRef]

- Kou, C.; Chen, Z.; Kang, A.; Zhang, M.; Wang, R. Rheological behaviors of asphalt binders reinforced by various fibers. Constr. Build. Mater. 2022, 323, 126626. [Google Scholar] [CrossRef]

- Cui, B.; Wang, H.; Gu, X.; Hu, D. Study of the inter-diffusion characteristics and cracking resistance of virgin-aged asphalt binders using molecular dynamics simulation. Constr. Build. Mater. 2022, 351, 128968. [Google Scholar] [CrossRef]

- Gajewski, M.; Bańkowski, W.; Gajewska, B.; Sybilski, D.; Horodecka, R. Estimation of asphalt binders’ resistance to permanent deformation with application of the MSCR and multiple shear creep long recovery (MSCLR) tests. Constr. Build. Mater. 2021, 284, 122808. [Google Scholar] [CrossRef]

- Guo, F.; Li, R.; Lu, S.; Bi, Y.; He, H. Evaluation of the effect of fiber type, length, and content on asphalt properties and asphalt mixture performance. Materials 2020, 13, 1556. [Google Scholar] [CrossRef] [PubMed]

- JTG E20-2011; Standard Test Methods of Bitumen and Bituminous Mixtures for Highway Engineering. Occupation Standard of the People’s Republic of China: Beijing, China, 2011.

- Espinal, M.; Kane, S.; Ryan, C.; Phillips, A.; Heveran, C. Evaluation of the bonding properties between low-value plastic fibers treated with microbially-induced calcium carbonate precipitation and cement mortar. Constr. Build. Mater. 2022, 357, 129331. [Google Scholar] [CrossRef]

- Moraes, R.; Velasquez, R.; Bahia, H. Using bond strength and surface energy to estimate moisture resistance of asphalt-aggregate systems. Constr. Build. Mater. 2017, 130, 156–170. [Google Scholar] [CrossRef]

- Liu, Y.; Zhang, Z.; Tan, L.; Xu, Y.; Wang, C.; Liu, P.; Yu, H.; Oeser, M. Laboratory evaluation of emulsified asphalt reinforced with glass fiber treated with different methods. J. Clean. Prod. 2020, 274, 123116. [Google Scholar] [CrossRef]

- Park, P.; El-Tawil, S.; Naaman, A.E. Pull-out behavior of straight steel fibers from asphalt binder. Constr. Build. Mater. 2017, 144, 125–137. [Google Scholar] [CrossRef]

- Noorvand, H.; Mobasher, B.; Underwood, S.; Kaloush, K. Development of an analytical framework for evaluation of critical fiber length in asphalt concrete with a fiber pullout test. Constr. Build. Mater. 2022, 360, 129561. [Google Scholar] [CrossRef]

- Teklal, F.; Djebbar, A.; Allaoui, S.; Hivet, G.; Joliff, Y.; Kacimi, B. A review of analytical models to describe pull-out behavior–Fiber/matrix adhesion. Compos. Struct. 2018, 201, 791–815. [Google Scholar] [CrossRef]

- Zhang, Y.; Wang, Y.; Kang, A.; Wu, Z.; Li, B.; Zhang, C.; Wu, Z. Analysis of Rejuvenating Fiber Asphalt Mixtures’ Performance and Economic Aspects in High-Temperature Moisture Susceptibility. Materials 2022, 15, 7728. [Google Scholar] [CrossRef] [PubMed]

| Property | Diameter, μm | Length, mm | Destiny, g·cm−3 | Tensile Strength, MPa | Melting Point, °C | Water Absorption, % | pH |

|---|---|---|---|---|---|---|---|

| Value | 16 | 6/12/20/30 | 2.715 | ≥2000 | 1600 | 1.65 | 7.1 |

| Property | Acceptance Limits | Value | Test Method (JTG E20-2011) [34] | |

|---|---|---|---|---|

| Penetration (25 °C), 0.1 mm | 60~80 | 74 | T0604 | |

| Softening point, °C | Min. 46 | 48.3 | T0606 | |

| Ductility (15 °C 5 cm/min), cm | Min. 100 | >100 | T0605 | |

| PI | −1.5~1.0 | −0.13 | T0604 | |

| Wax content, % | Max. 2.2 | 1.8 | T0615 | |

| Density (15 °C), g/cm3 | Measured | 1.020 | T0603 | |

| * RTFOT | Quality, % | Max. ±0.8 | −0.05 | T0610 |

| Penetration ratio (25 °C), % | Min. 61 | 74.0 | T0604 | |

| Ductility (15 °C), cm | Min. 15 | 23.9 | T0605 | |

| Property | Acceptance Limits | Value | Test Method (JTG E20-2011) [34] | |

|---|---|---|---|---|

| Penetration (25 °C), 0.1 mm | 60~80 | 69 | T0604 | |

| Softening point, °C | Min. 55 | 64 | T0606 | |

| Ductility (15 °C 5 cm/min), cm | Min. 30 | 48 | T0605 | |

| PI | −0.4~1.0 | 0.5 | T0604 | |

| Solubility (Trichloroethylene), % | Min. 99 | 99.8 | T0607 | |

| Flash point, °C | Min. 230 | 329 | T0611 | |

| Kinematic viscosity (235 °C), Pa·s | Max. 3 | 1.8 | T0625 | |

| Elastic recovery (25 °C), % | Min. 65 | 76 | T0662 | |

| Softening point difference, °C | Max. 2.5 | 1.4 | T0661 | |

| * RTFOT | Quality, % | Max. ±1.0 | −0.08 | T0610 |

| Penetration ratio (25 °C), % | Min. 60 | 86 | T0604 | |

| Ductility (15 °C), cm | Min. 20 | 37 | T0605 | |

| Property | Acceptance Limits | Value | Test Method (JTG E20-2011) [34] |

|---|---|---|---|

| Penetration (25 °C), 0.1 mm | 30~60 | 53.7 | T0604 |

| Softening point, °C | Min. 60 | 64.0 | T0606 |

| Rotational viscosity (180 °C), Pa·s | 2.0~5.0 | 2.510 | T0625 |

| Elastic recovery (25 °C), % | Min. 60 | 68 | T0662 |

| Ductility (5 °C), cm | Min. 5 | 7.1 | T0605 |

| Test Liquid Type | Surface Energy and Its Component (mJ/m2) | ||

|---|---|---|---|

| Distilled water | 72.8 | 21.8 | 51 |

| Ethylene glycol | 48 | 29 | 19 |

| Formamide | 58 | 39 | 19 |

| Asphalt Type | Distilled Water | Ethylene Glycol | Formamide | |||

|---|---|---|---|---|---|---|

| Contact Angle (°) | SD | Contact Angle (°) | SD | Contact Angle (°) | SD | |

| Neat asphalt | 101.6 | 0.28 | 93.3 | 0.56 | 84.9 | 0.35 |

| SBS-modified asphalt | 96.2 | 0.37 | 87.7 | 0.52 | 76.9 | 0.41 |

| Rubber asphalt | 89.4 | 0.31 | 76.7 | 0.51 | 68.9 | 0.38 |

| Asphalt Binders | |||

|---|---|---|---|

| Neat asphalt | 18.58 | 16.59 | 1.99 |

| SBS-modified asphalt | 23.82 | 21.53 | 2.29 |

| Rubber asphalt | 28.57 | 25.04 | 3.53 |

| Type | Contact Angle with Liquid (°) | Surface Energy and Its Component (mJ/m2) | |||

|---|---|---|---|---|---|

| Distilled Water | Ethylene Glycol | ||||

| BFs | 71.103 ± 8.305 | 39.594 ± 5.074 | 37.98 | 11.39 | 26.61 |

| Bond Strengths/kPa | Embedment Depth/mm | Softening Point |

|---|---|---|

| 140.8869 | 6 | 74 |

| 93.92458 | 12 | 74 |

| 65.32027 | 20 | 74 |

| 36.43135 | 30 | 74 |

| 187.036 | 6 | 69 |

| 110.5952 | 12 | 69 |

| 80.01886 | 20 | 69 |

| 44.56335 | 30 | 69 |

| 205.8412 | 6 | 53.7 |

| 125.7918 | 12 | 53.7 |

| 80.50678 | 20 | 53.7 |

| 46.96229 | 30 | 53.7 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sun, Z.; Kou, C.; Lu, Y.; Wu, Z.; Kang, A.; Xiao, P. A Study of the Bond Strength and Mechanism between Basalt Fibers and Asphalt Binders. Appl. Sci. 2024, 14, 2471. https://doi.org/10.3390/app14062471

Sun Z, Kou C, Lu Y, Wu Z, Kang A, Xiao P. A Study of the Bond Strength and Mechanism between Basalt Fibers and Asphalt Binders. Applied Sciences. 2024; 14(6):2471. https://doi.org/10.3390/app14062471

Chicago/Turabian StyleSun, Zhiwei, Changjiang Kou, Yu Lu, Zhengguang Wu, Aihong Kang, and Peng Xiao. 2024. "A Study of the Bond Strength and Mechanism between Basalt Fibers and Asphalt Binders" Applied Sciences 14, no. 6: 2471. https://doi.org/10.3390/app14062471

APA StyleSun, Z., Kou, C., Lu, Y., Wu, Z., Kang, A., & Xiao, P. (2024). A Study of the Bond Strength and Mechanism between Basalt Fibers and Asphalt Binders. Applied Sciences, 14(6), 2471. https://doi.org/10.3390/app14062471