Numerical Study on the Dynamic Response of Gas Explosion in Uneven Coal Mine Tunnels Using CESE Reaction Dynamics Model

Abstract

Featured Application

Abstract

1. Introduction

2. Numerical Simulation Algorithm and Constitutive Model

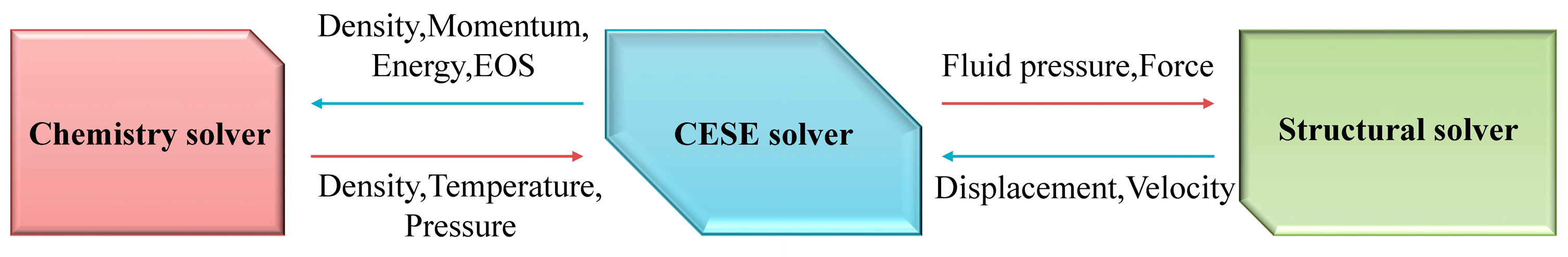

2.1. CESE-IBM Coupling Model

2.2. Finite-Rate Chemical Reaction Model

2.3. Material Failure Criterion

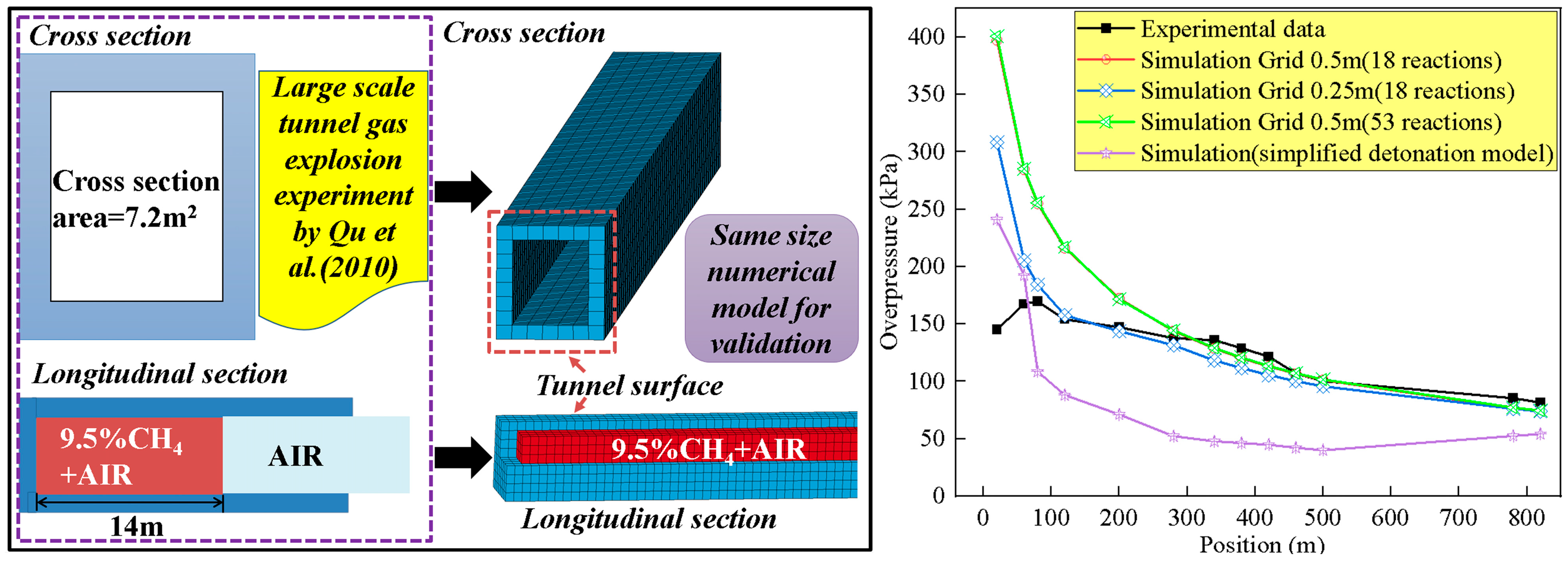

2.4. Chemical Model Validation

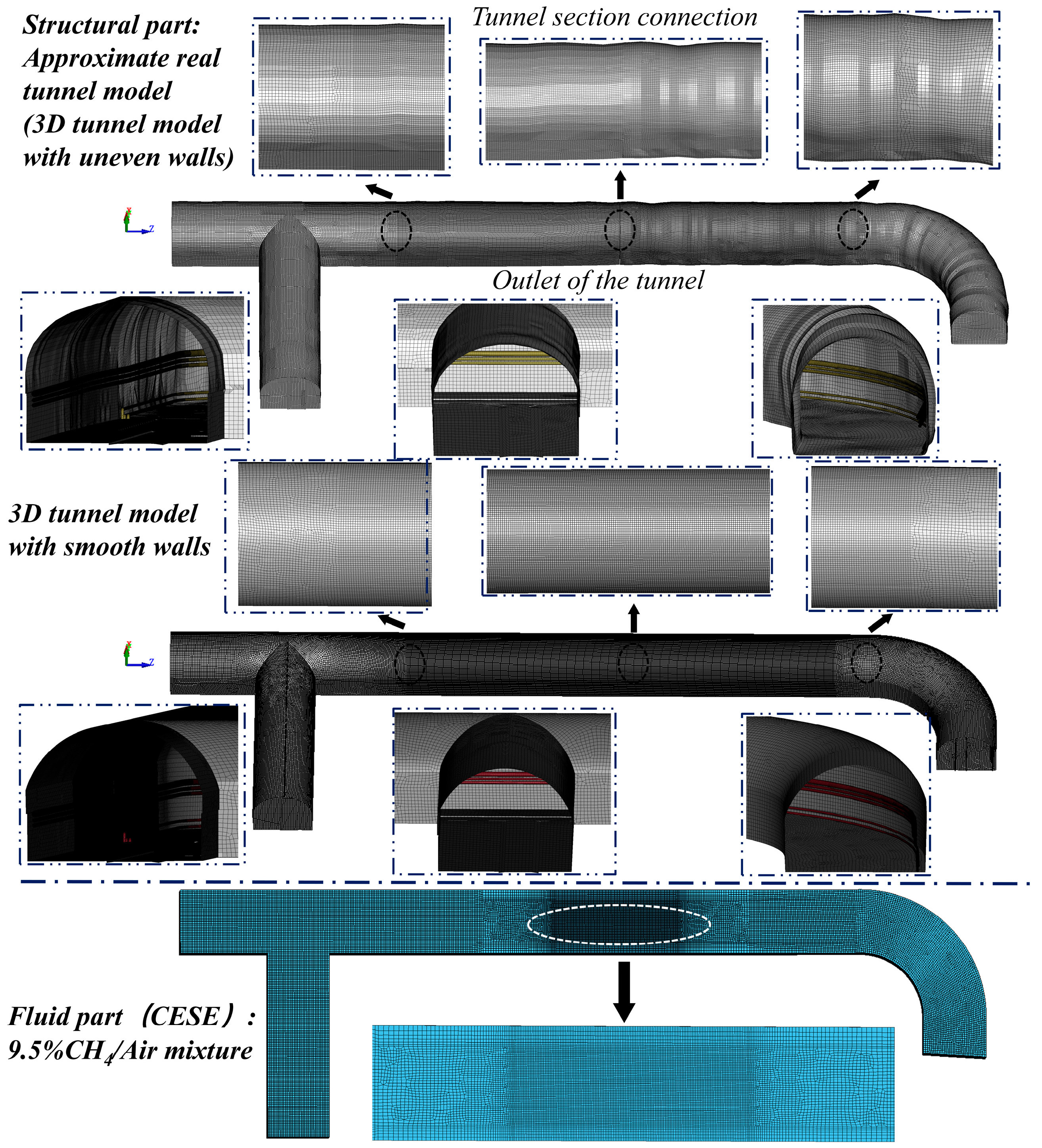

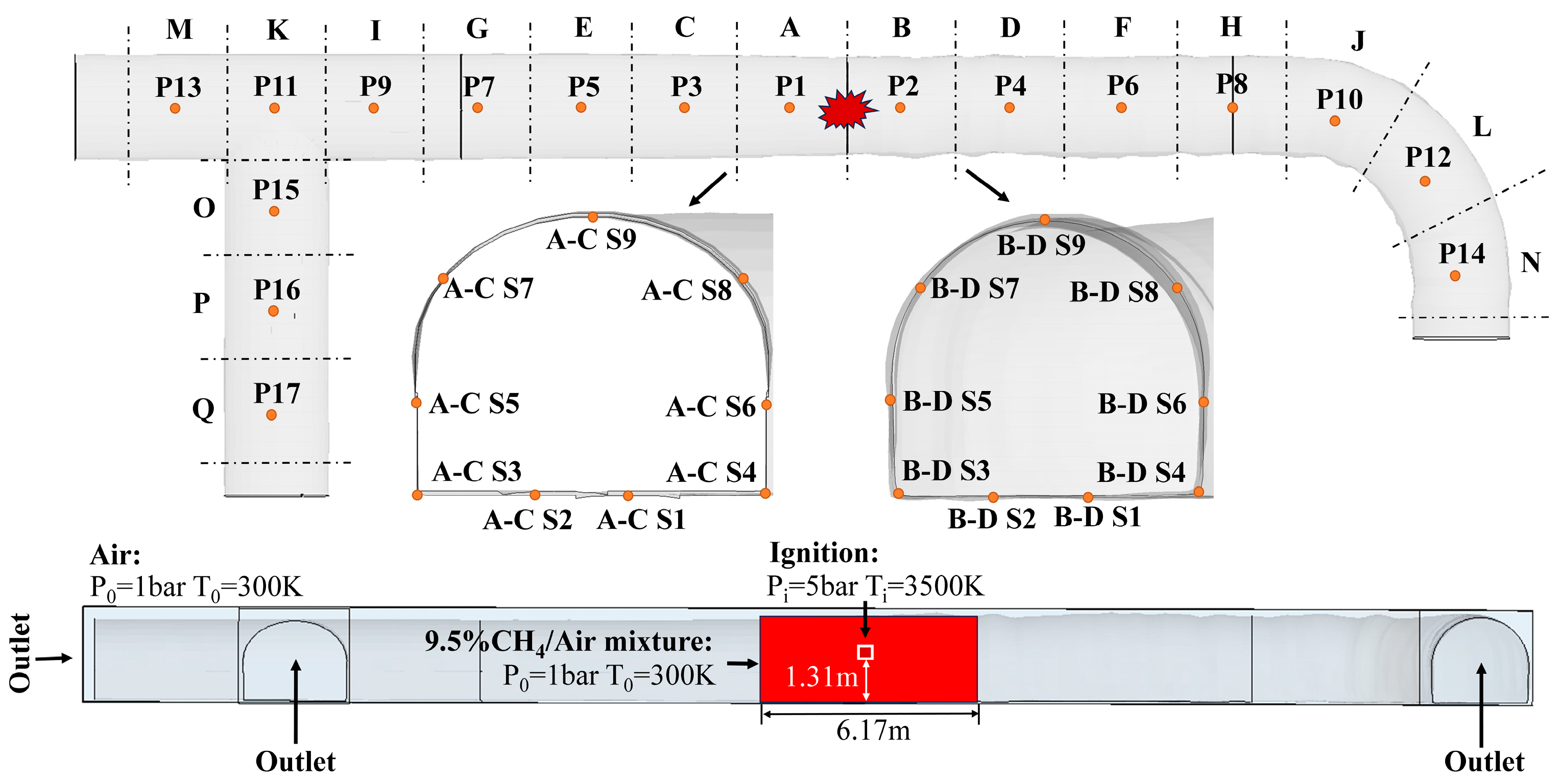

3. Numerical Model of Gas Deflagration in Tunnel

4. Results and Discussion

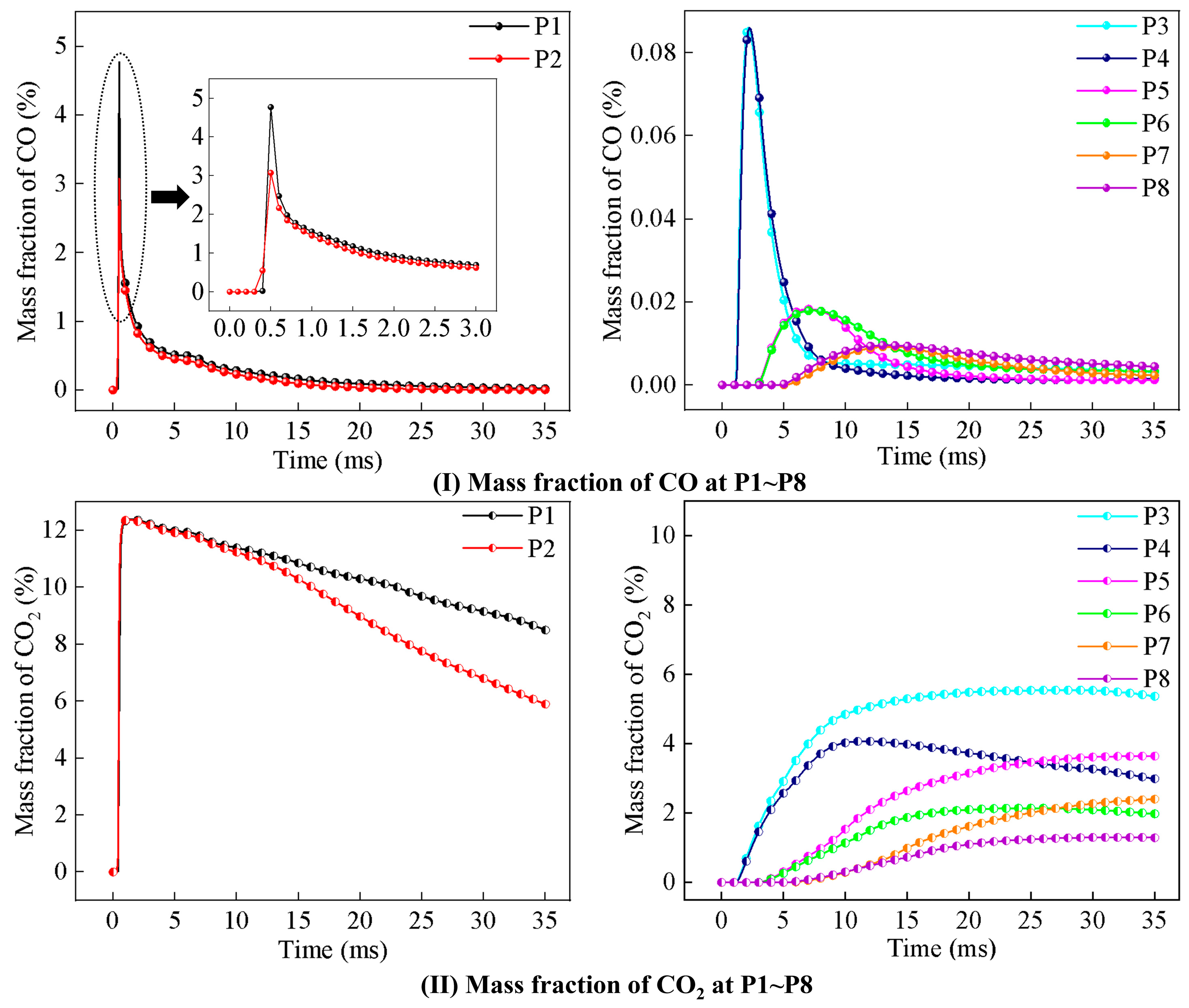

4.1. Formation and Dissipation of Reactants and Reaction Products

4.2. Propagation Characteristics of Shock Wave in Approximate Real Tunnel Model and Tunnel Model with Smooth Walls

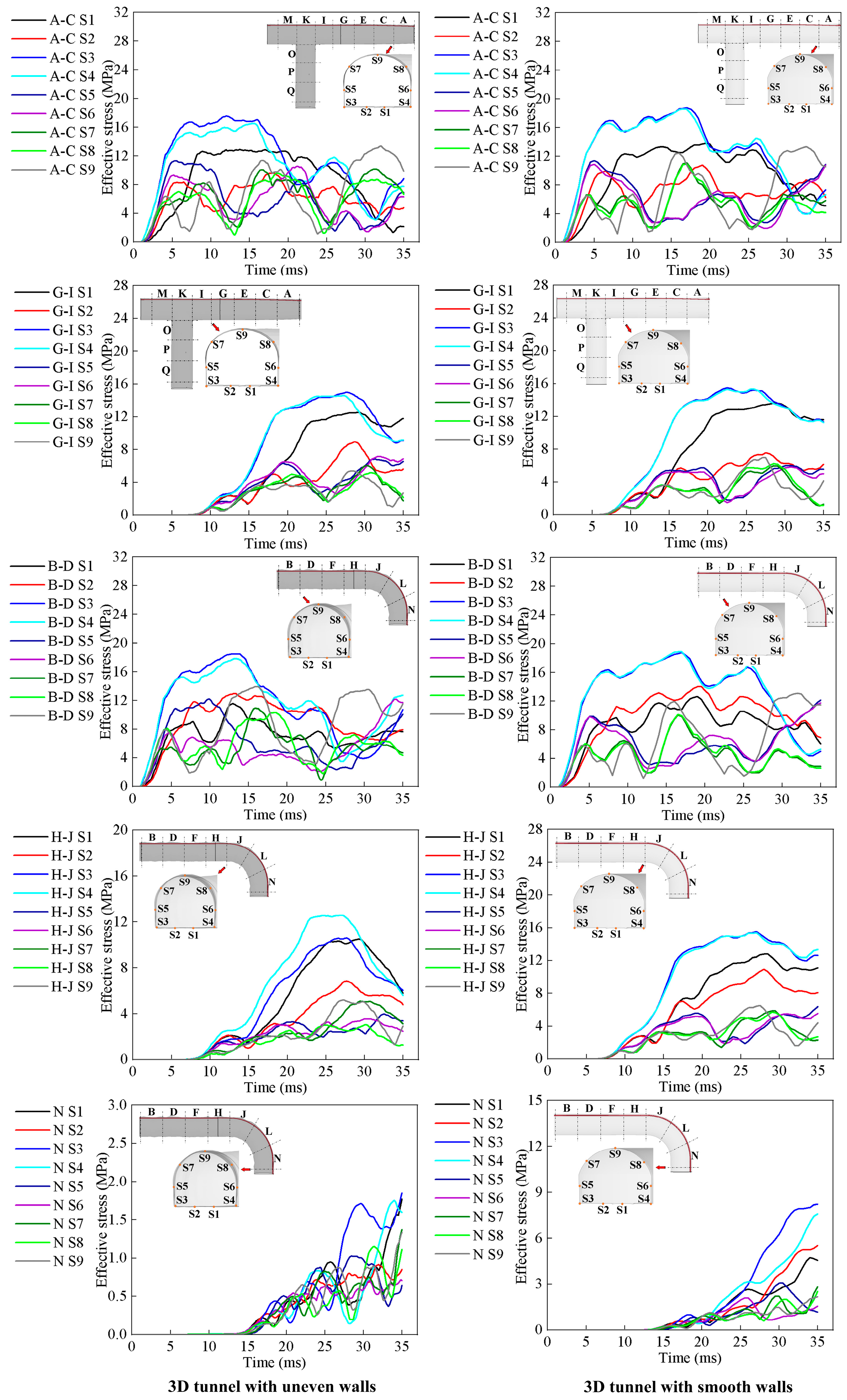

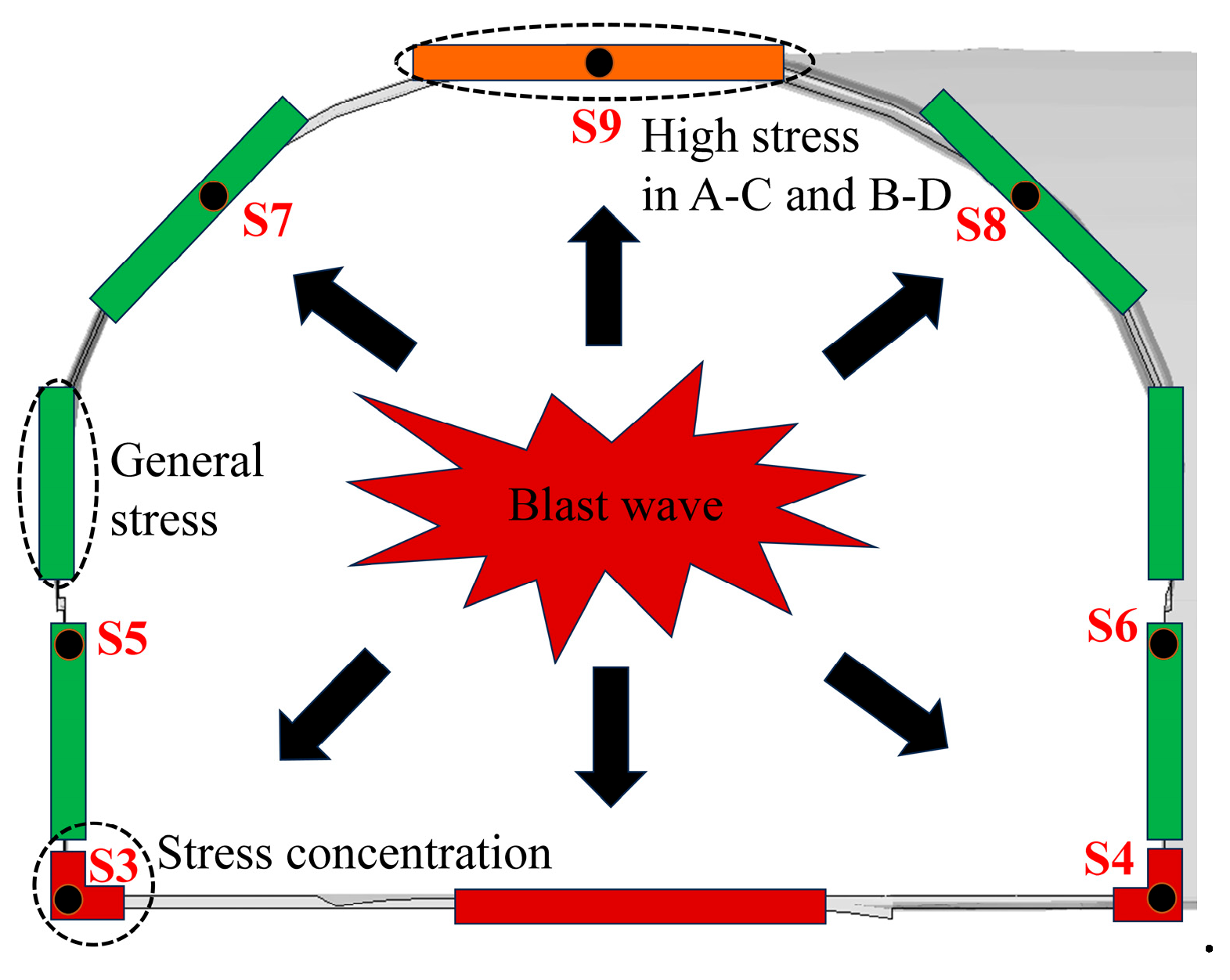

4.3. Stress Response of Approximate Real Tunnel Model and Tunnel Model with Smooth Walls

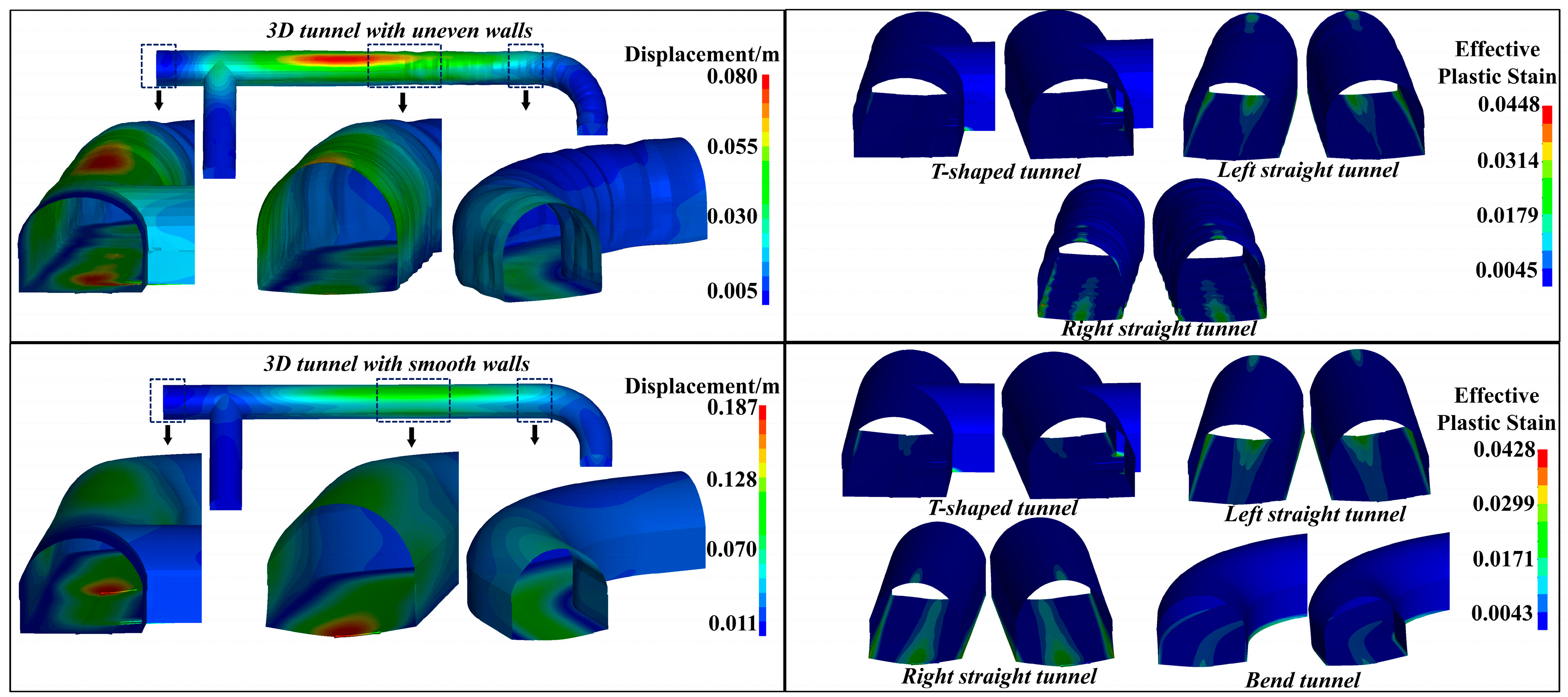

4.4. Displacement Response of Approximate Real Tunnel Model and Tunnel Model with Smooth Walls

5. Conclusions

- (1)

- The highest mass fraction of intermediates CH3 and CH2O produced by methane deflagration is much lower than the final product CO2, and they are almost simultaneously depleted after the complete consumption of methane. At a distance of 1.5 m from the ignition point, the maximum mass fraction of intermediate product CO reaches 4.77%, but CO gas is consumed in large quantities prior to diffusion. At a distance of 1.5–10.5 m from the ignition point, the CO2 mass fraction reaches 1.29–12.11%.

- (2)

- The uneven walls of a tunnel that are approximately real cause changes in the distribution of shock wave overpressure. On straight tunnels, the distribution of shock wave overpressure is asymmetric, with the red high-pressure zone leaning to the right. Meanwhile, the severely uneven tunnel walls decrease the propagation speed and overpressure of the shock wave. Compared with the tunnels with smooth walls, the peak overpressure reduction value of the shock wave reaches 81.91 kPa, and the time when the shock wave overpressure reaches its peak is extended by a maximum of 7.4 ms.

- (3)

- The development and diffusion processes of stress loads are close to synchronization with the propagation of shock waves. The propagation speed of stress waves in the bend of the approximate real tunnel is slower than that in the smooth wall tunnel model. Except in the bend tunnel, the positions and ranges of the green stress zone and the red stress concentration zone in the two tunnel models are the same. Compared with smooth-walled tunnels, the stress distribution in the approximate real tunnel is discontinuous, and the transition zone between the green stress zone and the blue unloading zone is serrated, with a shorter duration of high loads.

- (4)

- The approximate real tunnel will not lose stability as a result of gas explosion. The displacement of the approximate real tunnel after gas explosion is lower than that in tunnels with smooth walls, and the area of plastic deformation zone is small. The wall displacement of the left tunnel is, at most, 26.9% lower than that of the smooth tunnel. The displacement values of most monitoring points on the right tunnel section are less than half of those in the tunnel with smooth walls.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Wang, G.; Wang, R.; Wu, M.M.; Fan, C.; Song, X. Strength criterion effect of the translator and destabilization model of gas-bearing coal seam. Int. J. Min. Sci. Technol. 2019, 29, 327–333. [Google Scholar] [CrossRef]

- Chen, J.; Cheng, W.; Wang, G.; Li, H.; Li, Y. New method of monitoring the transmission range of coal seam water injection and correcting the monitoring results. Measurement 2021, 177, 109334. [Google Scholar] [CrossRef]

- Wang, G.; Qin, X.; Zhou, J.; Han, F.; Cai, J. Simulation of coal microstructure characteristics under temperature-pressure coupling based on micro-computer tomography. J. Nat. Gas. Sci. Eng. 2021, 91, 103906. [Google Scholar] [CrossRef]

- Wang, Y.; Fu, G.; Lyu, Q.; Li, X.; Chen, Y.; Wu, Y.; Xie, X. Modelling and analysis of unsafe acts in coal mine gas explosion accidents based on network theory. Process Saf. Environ. Prot. 2023, 170, 28–44. [Google Scholar] [CrossRef]

- Xiao, G.Q.; Wang, S.; Mi, H.F.; Khan, F.; Yu, M.G. Analysis of obstacle shape on gas explosion characteristics. Process Saf. Environ. Prot. 2022, 161, 78–87. [Google Scholar] [CrossRef]

- Hou, Z.H.; Wang, D.M.; Zhang, W.; Luo, S.Y.; Lu, Y.S.; Tian, S.Y.; Zhou, Q.; Xu, Z.M. Study on the influence of ignition position on the explosion characteristics of methane-air premix in a semi-closed pipeline. Process Saf. Environ. Prot. 2023, 172, 642–651. [Google Scholar] [CrossRef]

- Meng, Q.; Wu, C.; Li, J.; Wu, P.; Xu, S.; Wang, Z. A study of pressure characteristics of methane explosion in a 20 m buried tunnel and influence on structural behaviour of concrete elements. Eng. Fail. Anal. 2021, 122, 105273. [Google Scholar] [CrossRef]

- Zhu, Y.; Wang, D.; Shao, Z.; Zhu, X.; Xu, C.; Zhang, Y. Investigation on the overpressure of methane-air mixture gas explosions in straight large-scale tunnels. Process Saf. Environ. Prot. 2020, 135, 101–112. [Google Scholar] [CrossRef]

- Zhang, X.B.; Shen, S.S.; Yang, M.; Wang, H.; Ren, J.Z.; Lu, F.C. Influence of length and angle of bifurcated tunnel on shock wave propagation. J. Loss Prev. Process Ind. 2022, 78, 104802. [Google Scholar] [CrossRef]

- Gao, K.; Li, S.N.; Han, R.; Li, R.Z.; Liu, Z.M.; Qi, Z.P.; Liu, Z.Y. Study on the propagation law of gas explosion in the space based on the goaf characteristic of coal mine. Saf. Sci. 2020, 127, 104693. [Google Scholar] [CrossRef]

- Liu, W.; Mu, C.; Li, Z. Influence of cavity structure on gas explosion characteristics in coal mine. Powder Technol. 2022, 398, 117084. [Google Scholar] [CrossRef]

- Ma, Q.J.; Guo, Y.H.; Zhong, M.Y.; Ya, H.; You, J.F.; Chen, J.H.; Zhang, Z.K. Numerical simulation of hydrogen explosion characteristics and disaster effects of hydrogen fueling station. Int. J. Hydrogen Energy 2023, 51, 861–879. [Google Scholar] [CrossRef]

- Du, Y.; Ma, L.; Zheng, J.; Zhang, F.; Zhang, A. Coupled simulation of explosion-driven fracture of cylindrical shell using SPH-FEM method. Int. J. Press. Vessel. Pip. 2016, 139–140, 28–35. [Google Scholar] [CrossRef]

- Valsamos, G.; Casadei, F.; Solomos, G.; Larcher, M. Risk assessment of blast events in a transport infrastructure by fluid-structure interaction analysis. Saf. Sci. 2019, 118, 887–897. [Google Scholar] [CrossRef]

- Gu, Y.; Wang, J.; Li, H.; Tang, K.; Liu, L. Formation characteristics and penetration performance of an underwater shaped charge jet. Ocean Eng. 2022, 258, 111695. [Google Scholar] [CrossRef]

- Jiang, X.; Xue, Y.; Kong, F.; Gong, H.; Fu, Y.; Zhang, W. Dynamic responses and damage mechanism of rock with discontinuity subjected to confining stresses and blasting loads. Int. J. Impact Eng. 2023, 172, 104404. [Google Scholar] [CrossRef]

- Guo, Y.; He, L.; Wang, D.; Liu, S. Numerical investigation of surface conduit parallel gas pipeline explosive based on the TNT equivalent weight method. J. Loss Prev. Process Ind. 2016, 44, 360–368. [Google Scholar] [CrossRef]

- Xue, Y.; Chen, G.; Zhang, Q.; Xie, M.; Ma, J. Simulation of the dynamic response of an urban utility tunnel under a natural gas explosion. Tunn. Undergr. Space Technol. 2020, 108, 103713. [Google Scholar] [CrossRef]

- Zhu, L.Q.; Du, J.Q.; Chen, J.; Guo, L.W.; Wang, F.S. Dust raising law of gas explosion in a 3D reconstruction real tunnel: Based on ALE-DEM model. Powder Technol. 2024, 434, 119224. [Google Scholar] [CrossRef]

- Sochet, I.; Sauvan, P.E.; Boulanger, R.; Nozeres, F. External explosion in an industrial site. J. Loss Prev. Process Ind. 2014, 29, 56–64. [Google Scholar] [CrossRef]

- Jiang, H.; Chi, M.; Hou, D.; Ding, H.; Xie, Z.; Zeng, X. Numerical investigation and analysis of indoor gas explosion: A case study of “6·13” major gas explosion accident in Hubei Province, China. J. Loss Prev. Process Ind. 2023, 83, 105045. [Google Scholar] [CrossRef]

- Du, Y.; Zhou, F.; Ma, L.; Zheng, J.; Xu, C.; Chen, G. Consequence analysis of premixed flammable gas explosion occurring in pipe using a coupled fluid-structure-fracture approach. J. Loss Prev. Process Ind. 2019, 57, 81–93. [Google Scholar] [CrossRef]

- Yang, S.; Sun, W.; Fang, Q.; Yang, Y.; Xia, C.; Bao, Q. Investigation of practical load model for a natural gas explosion in an unconfined space. J. Saf. Sci. Resil. 2022, 3, 209–221. [Google Scholar] [CrossRef]

- Zhu, Y.; Wang, D.; Shao, Z.; Xu, C.; Li, M.; Zhang, Y. Characteristics of methane-air explosions in large-scale tunnels with different structures. Tunn. Undergr. Space Technol. 2021, 109, 103767. [Google Scholar] [CrossRef]

- Pang, L.; Zhang, Q.; Wang, T.; Lin, D.C.; Cheng, L. Influence of laneway support spacing on methane/air explosion shock wave. Saf. Sci. 2012, 50, 83–89. [Google Scholar] [CrossRef]

- Gao, K.; Liu, Z.; Wu, C.; Li, J.; Liu, K.; Liu, Y.; Li, S. Effect of low gas concentration in underground return tunnels on characteristics of gas explosions. Process Saf. Environ. Prot. 2021, 152, 679–691. [Google Scholar] [CrossRef]

- Zhang, B.; Zhao, W.; Wan, W.; Zhang, X. Pressure characteristics and dynamic response of coal mine refuge chamber with underground gas explosion. J. Loss Prev. Process Ind. 2014, 30, 37–46. [Google Scholar] [CrossRef]

- Chang, S.-C. The method of space-time conservation element and solution element—A new approach for solving the Navier-Stokes and Euler equations. J. Comput. Phys. 1995, 119, 295–324. [Google Scholar] [CrossRef]

- Rokhy, H.; Soury, H. Fluid structure interaction with a finite rate chemistry model for simulation of gaseous detonation metal-forming. Int. J. Hydrogen Energy 2019, 44, 23289–23302. [Google Scholar] [CrossRef]

- Haghgoo, M.; Babaei, H.; Mostofi, T.M. 3D numerical investigation of the detonation wave propagation influence on the triangular plate deformation using finite rate chemistry model of LS-DYNA CESE method. Int. J. Impact Eng. 2022, 161, 104108. [Google Scholar] [CrossRef]

- Haghgoo, M.; Babaei, H.; Mostofi, T.M. Numerical simulation of the influence of confined multi-point ignited H2–O2 mixture on the propagation of shock waves towards a deformable plate. Int. J. Hydrogen Energy 2022, 47, 27080–27095. [Google Scholar] [CrossRef]

- Rokhy, H.; Mostofi, T.M. Tracking the explosion characteristics of the hydrogen-air mixture near a concrete barrier wall using CESE IBM FSI solver in LS-DYNA incorporating the reduced chemical kinetic model. Int. J. Impact Eng. 2023, 172, 104401. [Google Scholar] [CrossRef]

- Im, K.-S.; Joh, S.-T.; Kim, C.-K.; Chang, S.-C.; Jorgenson, C. Application of the CESE method to detonation with realistic finite-rate chemistry. In Proceedings of the 40th AIAA Aerospace Sciences Meeting & Exhibit, Reno, NV, USA, 14–17 January 2002; p. 1020. [Google Scholar] [CrossRef]

- Kee, R.J.; Rupley, F.M.; Miller, J.A. Chemkin-II: A Fortran Chemical Kinetics Package for the Analysis of Gas-Phase Chemical Kinetics; Sandia National Laboratories: Livermore, CA, USA, 1989. [Google Scholar] [CrossRef]

- Miller, J.A.; Kee, R.J.; Westbrook, C.K. Chemical Kinetics and Combustion Modeling. Annu. Rev. Phys. Chem. 1993, 41, 345–387. [Google Scholar] [CrossRef]

- Liu, H.; Chen, F.; Liu, H.; Zheng, Z.H.; Yang, S.H. 18-Step Reduced Mechanism for Methane/Air Premixed Supersonic Combustion. J. Combust. Sci. Technol. 2012, 18, 467–472. [Google Scholar]

- Wei, Y.; Li, X.; Che, X. Study on the effect of combustion efficiency of variable thrust rocket engines. J. Phys. Conf. Ser. 2023, 2551, 012025. [Google Scholar] [CrossRef]

- Lu, H.; Liu, F.; Wang, Y.; Fan, X.; Yang, J.; Liu, C.; Xu, G. Mechanism reduction and bunsen burner flame verification of methane. Energies 2018, 12, 97. [Google Scholar] [CrossRef]

- Gan, L.; Zong, Z.; Lin, J.; Chen, Y.; Xia, M.; Chen, L. Influence of U-shaped stiffeners on the blast-resistance performance of steel plates. J. Constr. Steel Res. 2022, 188, 107046. [Google Scholar] [CrossRef]

- Liu, F.; Silva, J.; Yang, S.; Lv, H.; Zhang, J. Influence of explosives distribution on coal fragmentation in top-coal caving mining. Geomech. Eng. 2019, 18, 111. [Google Scholar] [CrossRef]

- Qu, Z. Numerical study on shock wave propagation with obstacles during methane explosion. Appl. Mech. Mater. 2010, 33, 114–118. [Google Scholar] [CrossRef]

- Wang, S.; Li, Z.; Fang, Q.; Yan, H.; Liu, Y. Numerical simulation of overpressure loads generated by gas explosions in utility tunnels. Process Saf. Environ. Prot. 2022, 161, 100–117. [Google Scholar] [CrossRef]

| Material | ρ/kg·m−3 | E/GPa | μ | σy/MPa | Etan/GPa | C/s−1 | P | Β | Fs |

|---|---|---|---|---|---|---|---|---|---|

| Tunnel surface | 1860 | 2.61 | 0.30 | 12.3 | 0.25 | - | - | 0.5 | 0.8 |

| Steel pipe | 7850 | 200 | 0.33 | 473 | 75.19 | 6844 | 3.91 | 1 | 0.25 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Du, J.; Chen, J.; Zhu, L.; Guo, L.; Wang, F.; Hu, X. Numerical Study on the Dynamic Response of Gas Explosion in Uneven Coal Mine Tunnels Using CESE Reaction Dynamics Model. Appl. Sci. 2024, 14, 2372. https://doi.org/10.3390/app14062372

Du J, Chen J, Zhu L, Guo L, Wang F, Hu X. Numerical Study on the Dynamic Response of Gas Explosion in Uneven Coal Mine Tunnels Using CESE Reaction Dynamics Model. Applied Sciences. 2024; 14(6):2372. https://doi.org/10.3390/app14062372

Chicago/Turabian StyleDu, Jiaqi, Jian Chen, Lingqi Zhu, Liwen Guo, Fusheng Wang, and Xiangming Hu. 2024. "Numerical Study on the Dynamic Response of Gas Explosion in Uneven Coal Mine Tunnels Using CESE Reaction Dynamics Model" Applied Sciences 14, no. 6: 2372. https://doi.org/10.3390/app14062372

APA StyleDu, J., Chen, J., Zhu, L., Guo, L., Wang, F., & Hu, X. (2024). Numerical Study on the Dynamic Response of Gas Explosion in Uneven Coal Mine Tunnels Using CESE Reaction Dynamics Model. Applied Sciences, 14(6), 2372. https://doi.org/10.3390/app14062372