A Review of Friction Dissipative Beam-to-Column Connections for the Seismic Design of MRFs

Abstract

1. Introduction

2. Research and Devices Categorization

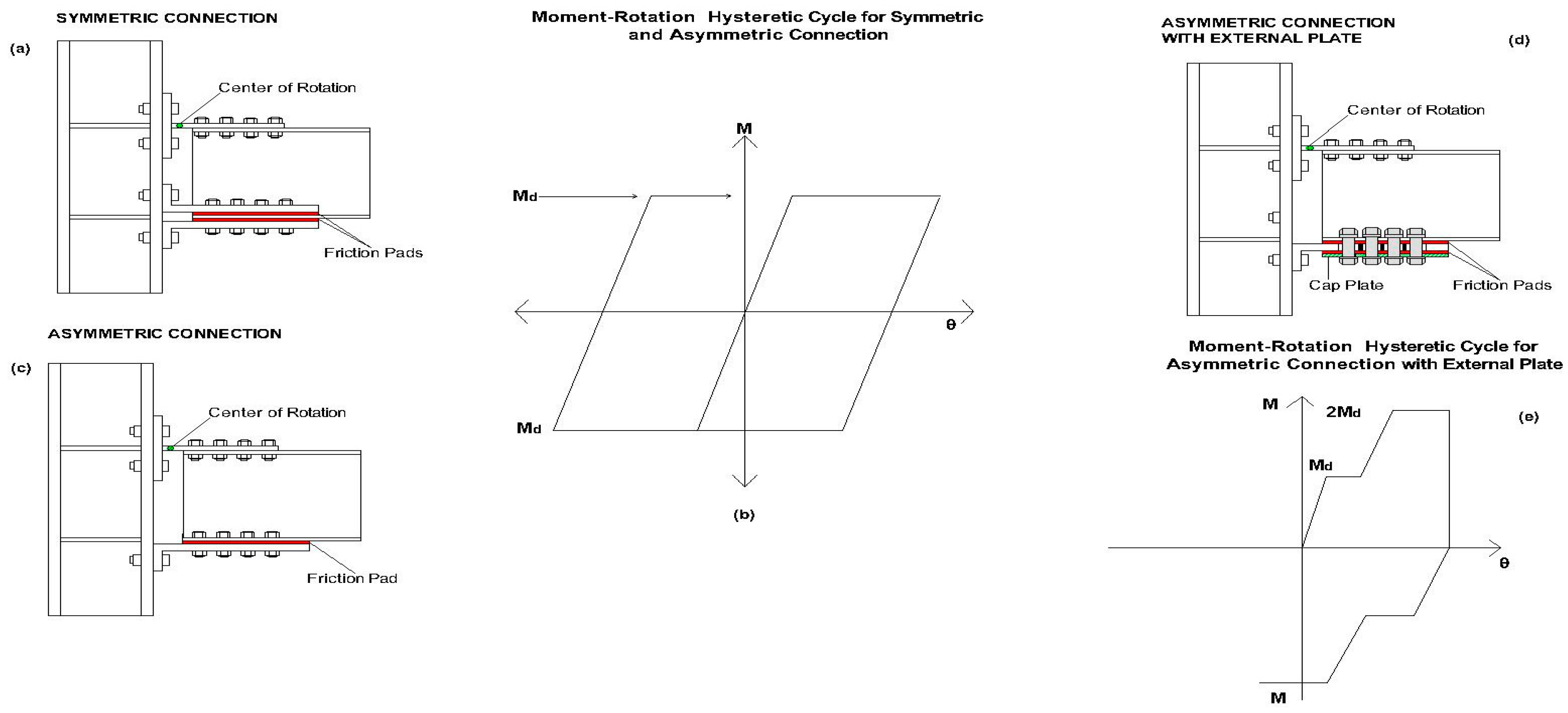

- Symmetric friction connections (SFC);

- Asymmetric friction connections (AFC);

- Asymmetric friction connections with cap plate (AFCCP);

- Rotational friction devices.

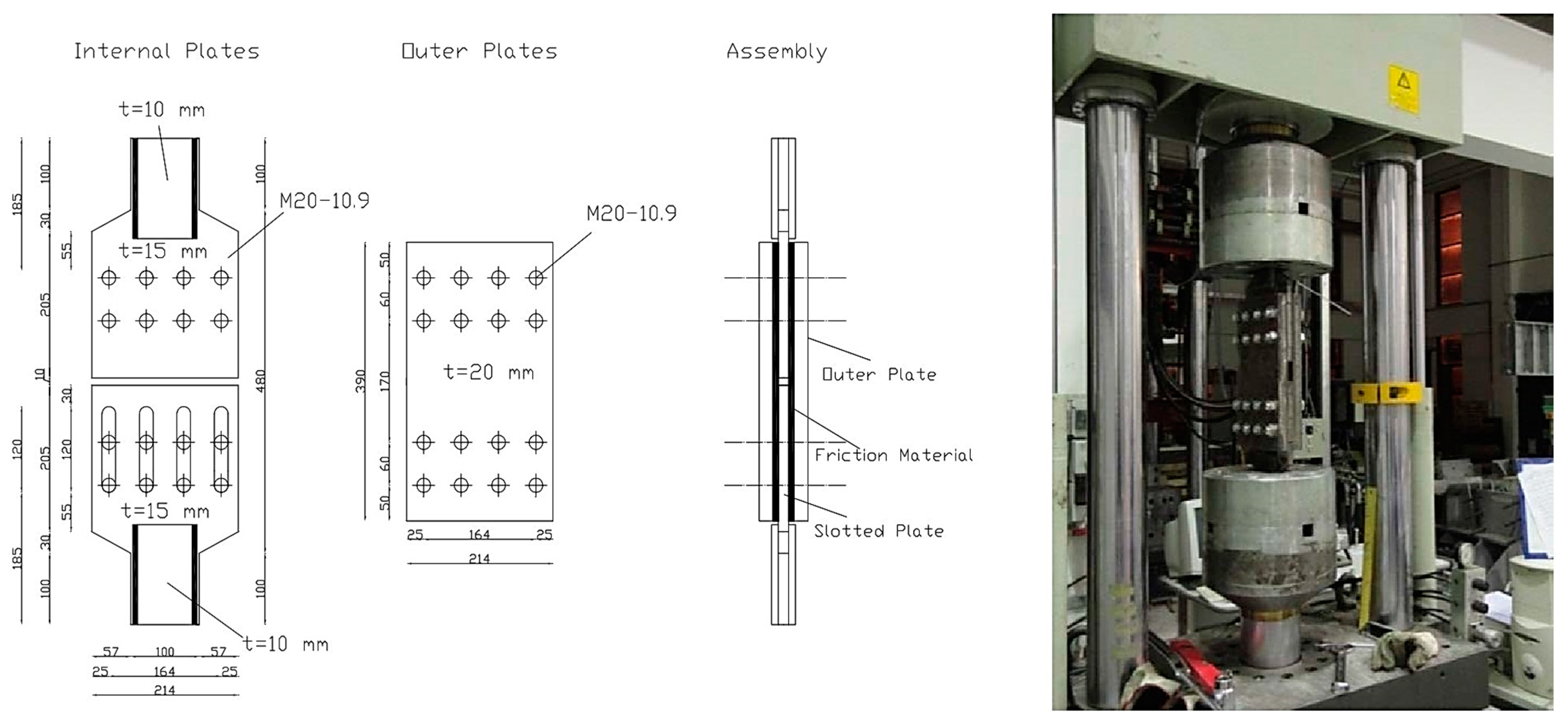

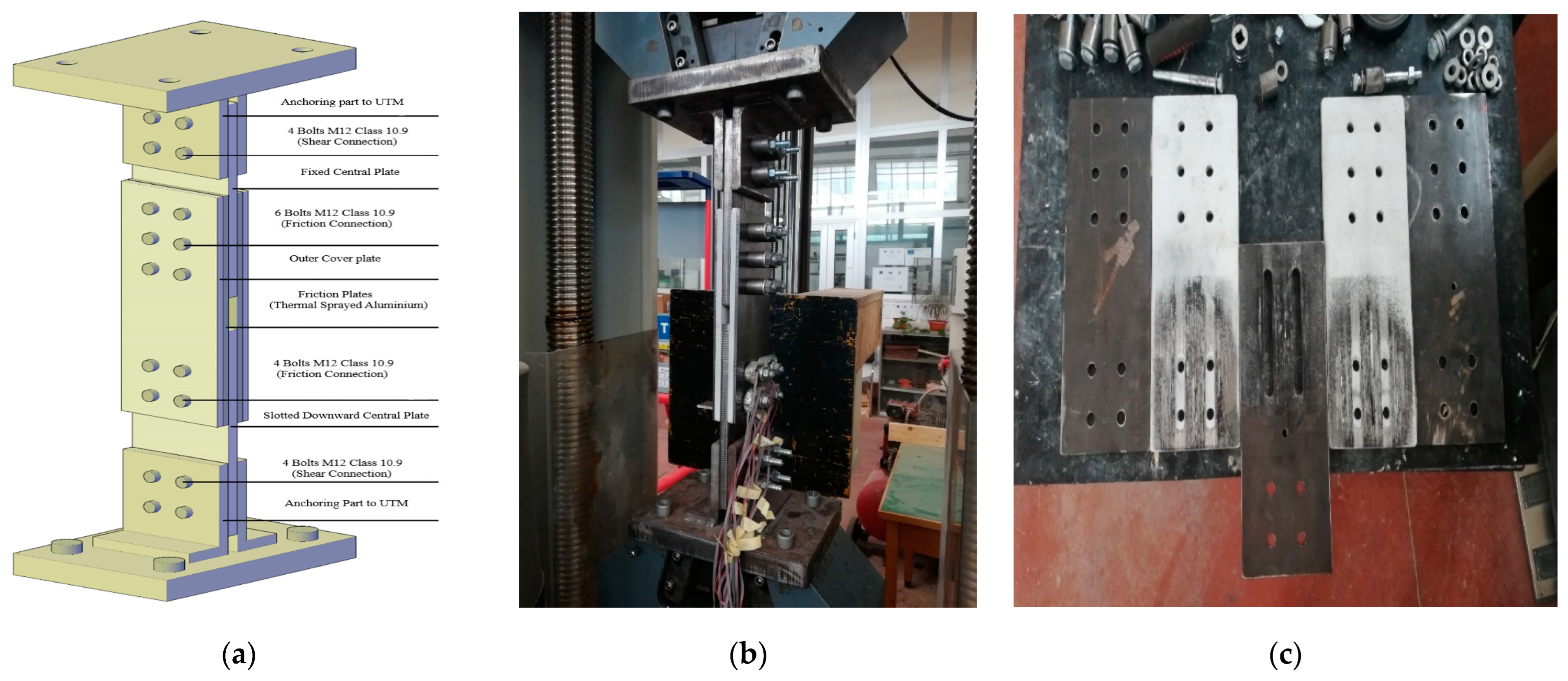

3. Symmetric Friction Connections (SFC)

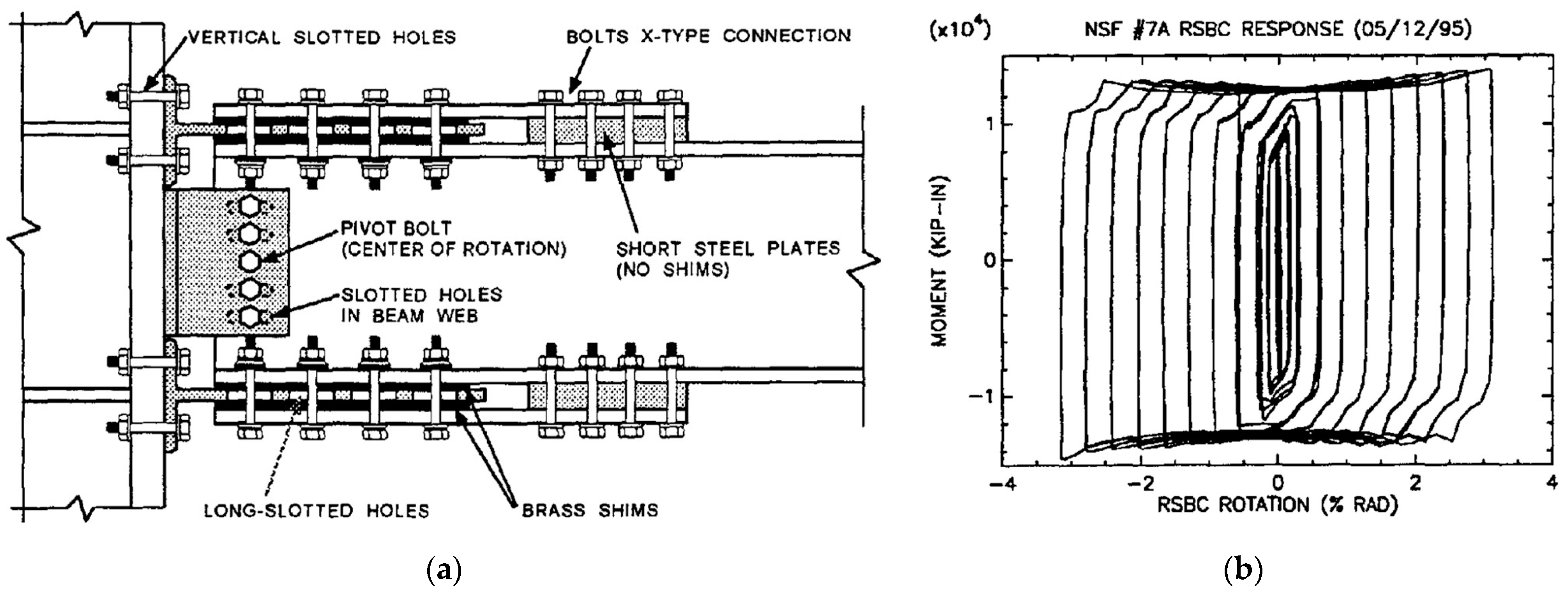

3.1. Rotational Slotted Bolted Connection

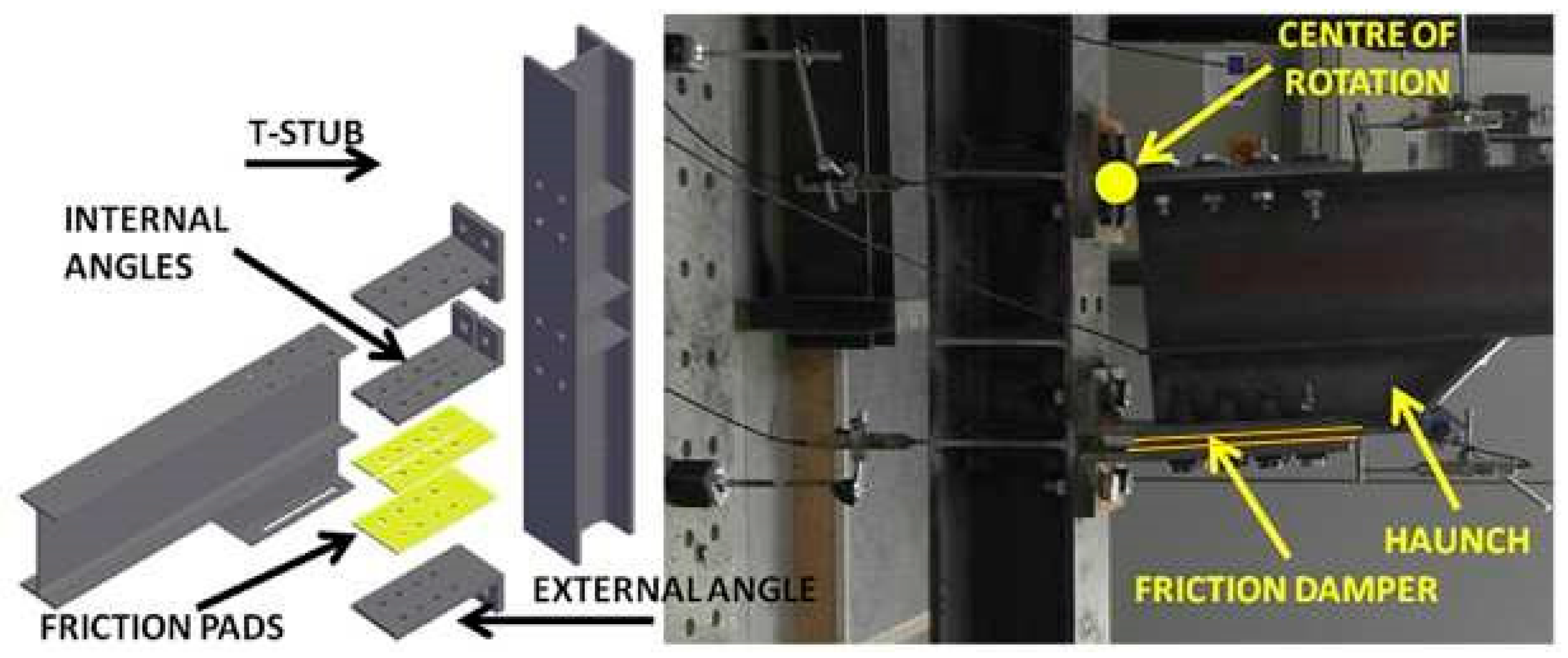

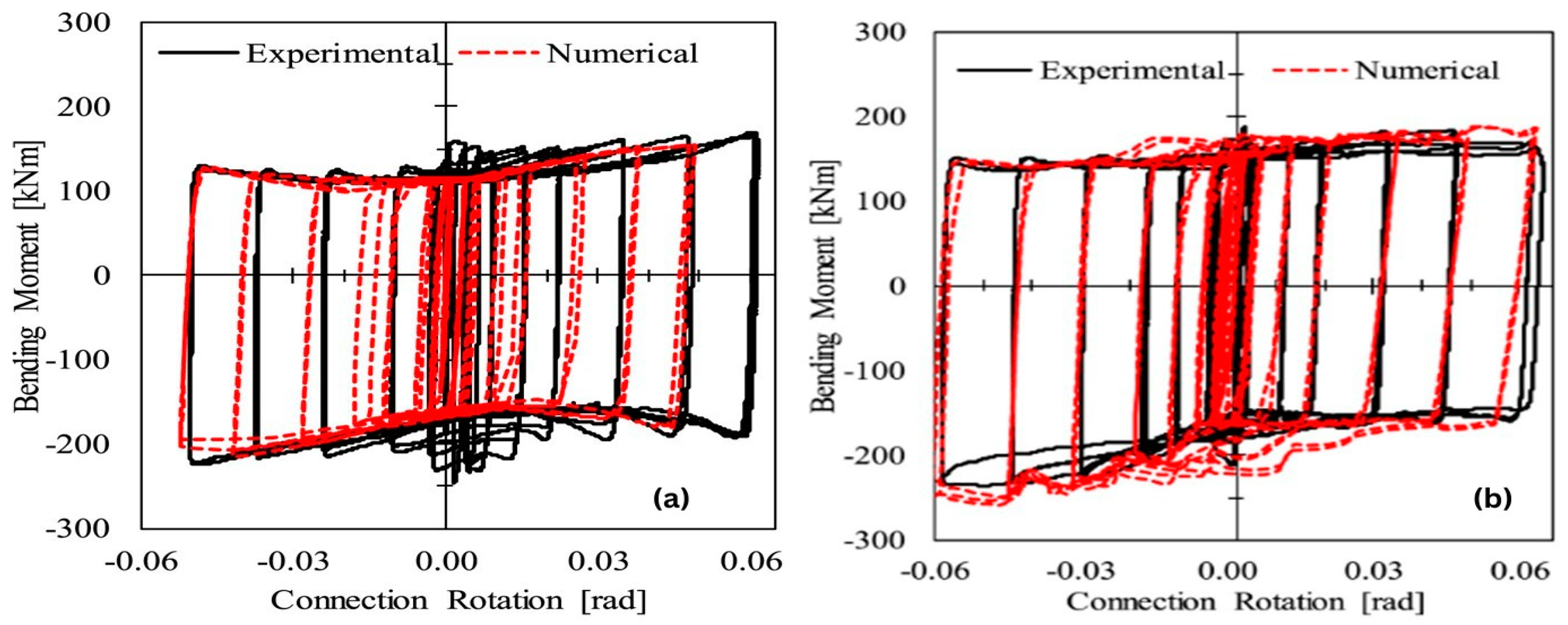

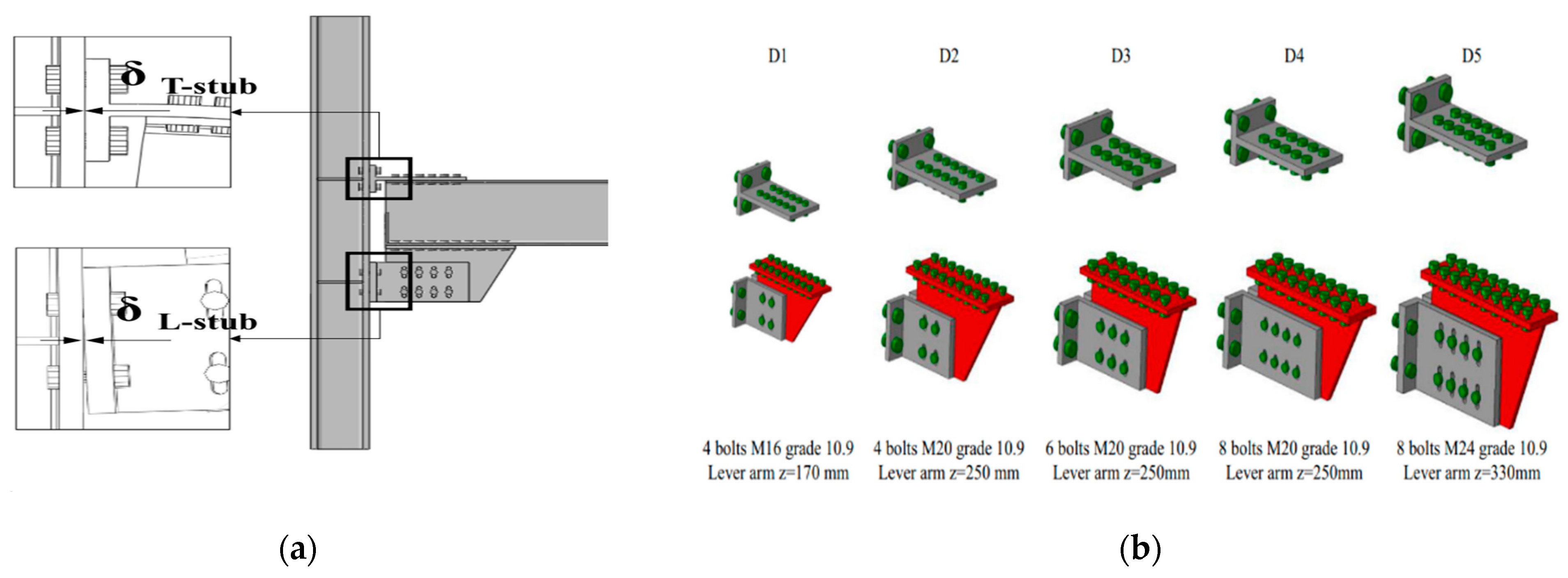

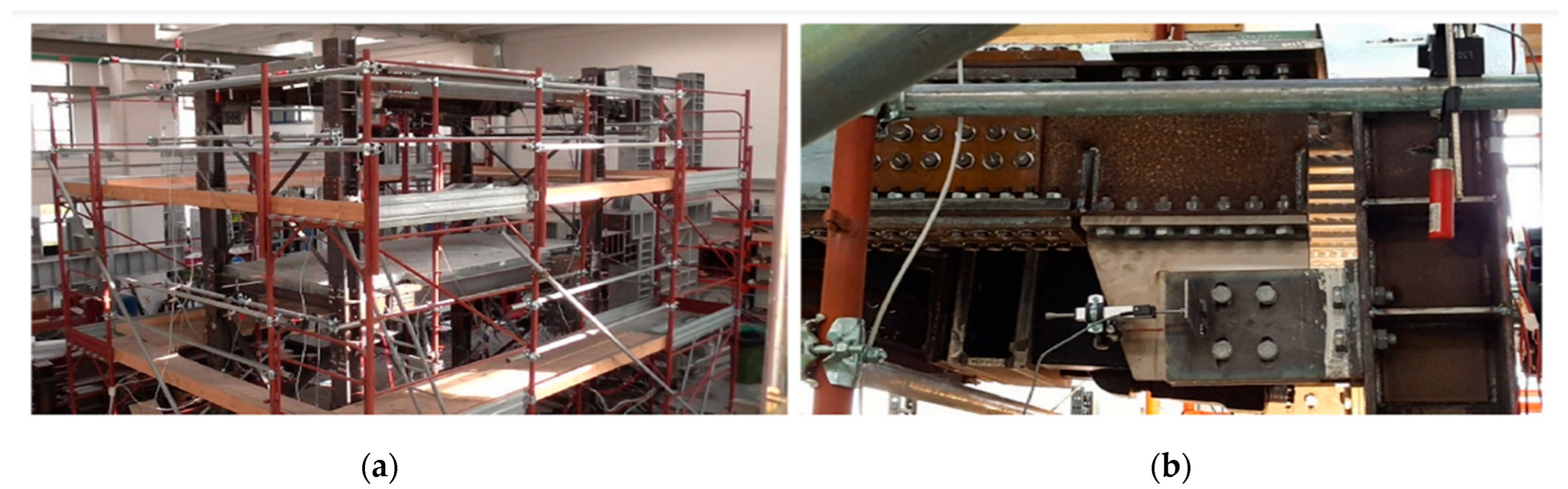

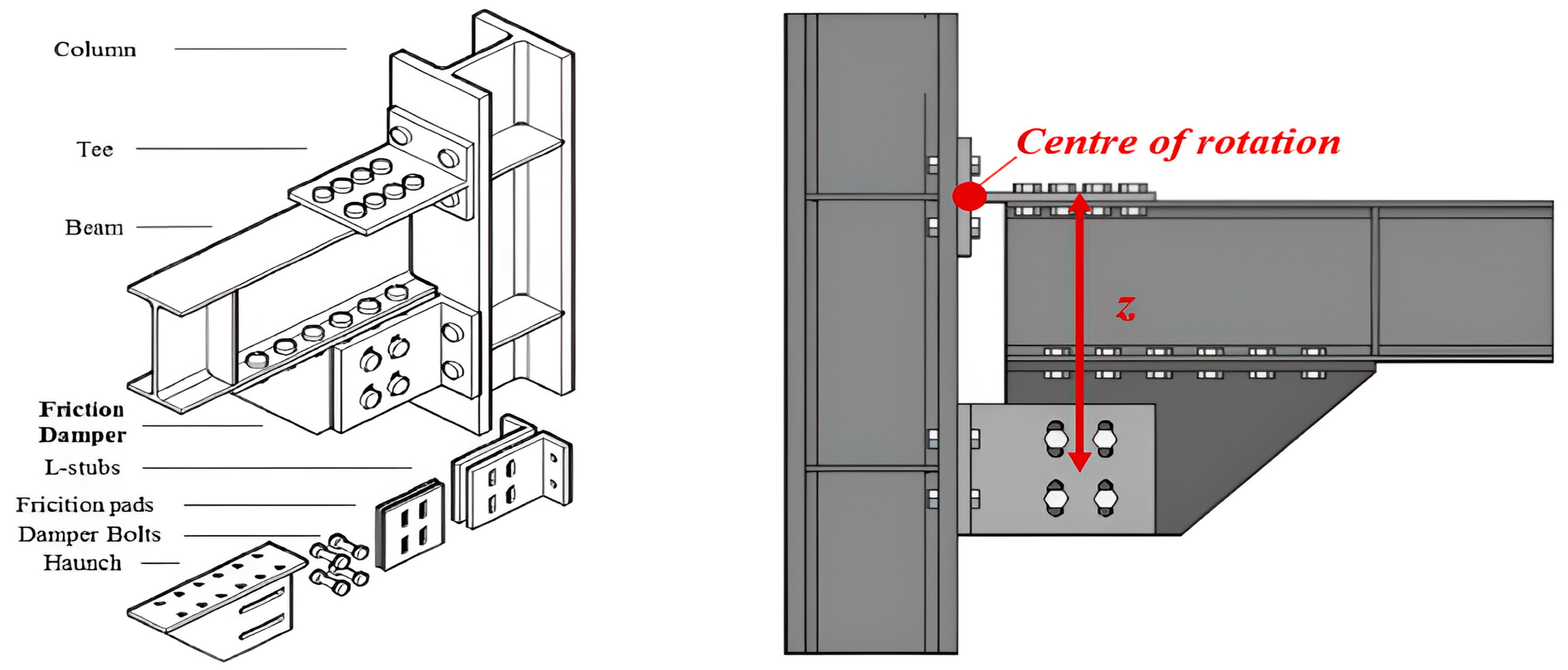

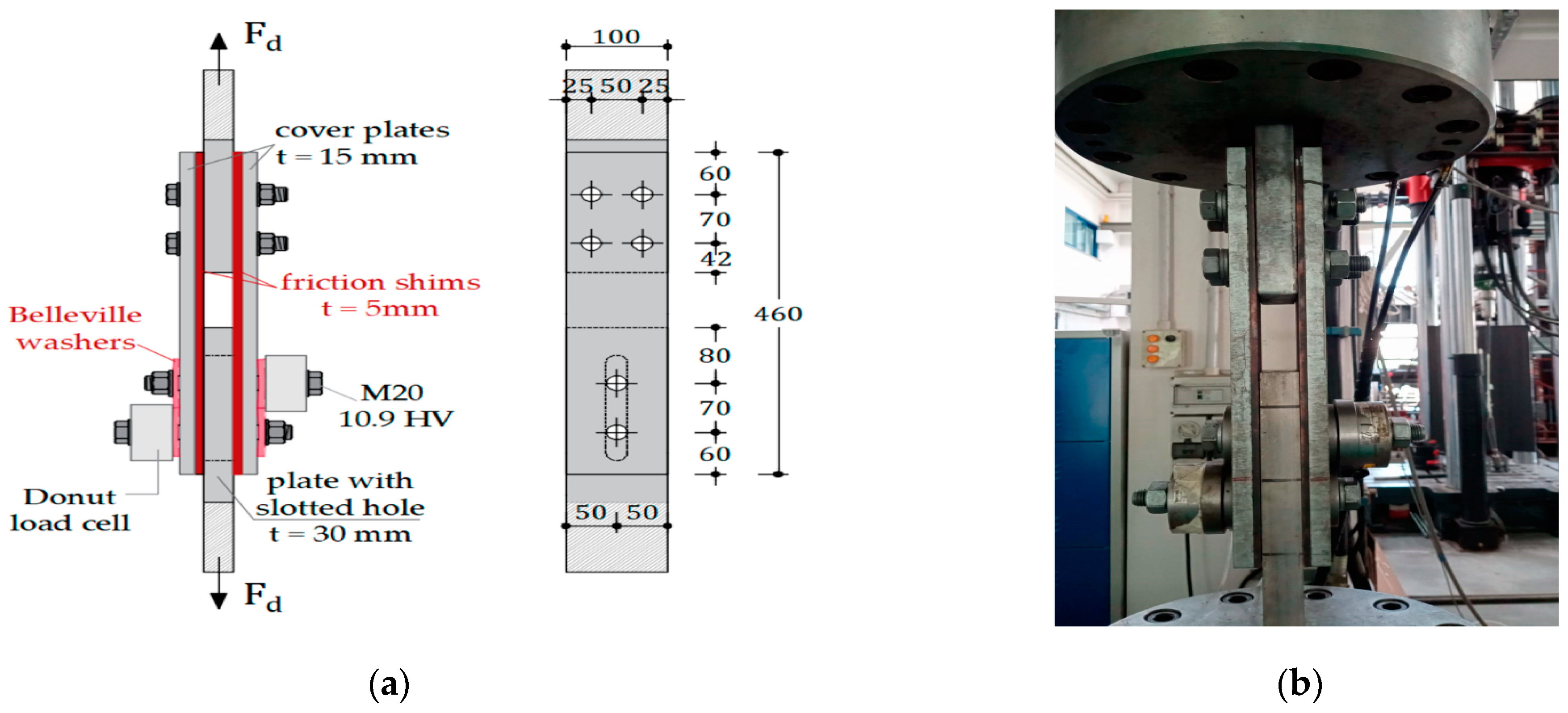

3.2. Removable Friction Dampers for Low-Damage Connections

- The rotational capacity and ductility of the friction connection is dependent on some of the factors like the lever arm of joint, the length of the slotted holes in the rib, and the gap between the beam’s tip and column flange, which restrains contact between the connected members under hogging flexure, while it permits plastic hinge formation at the base of the T-stub web;

- It was found that the effectiveness of friction joints is not dependent on the size of the connected members because the hysteretic and monotonic response of all joints was almost the same;

- The friction dampers and connections give a rotation capacity of about 0.07 rad, which fulfills the minimum rotation capacity criteria given in [99] for dissipative joints;

- The flexural response of the joints having the proposed dampers is not symmetric, and for the chord rotation of 0.04 rad the hogging resistance is about 25% greater than the sagging resistance. This is mainly due to the higher deformability of L-stubs under the sagging moment, which causes a higher loss of bolt preload as compared to the loss when the L-stubs are in compression.

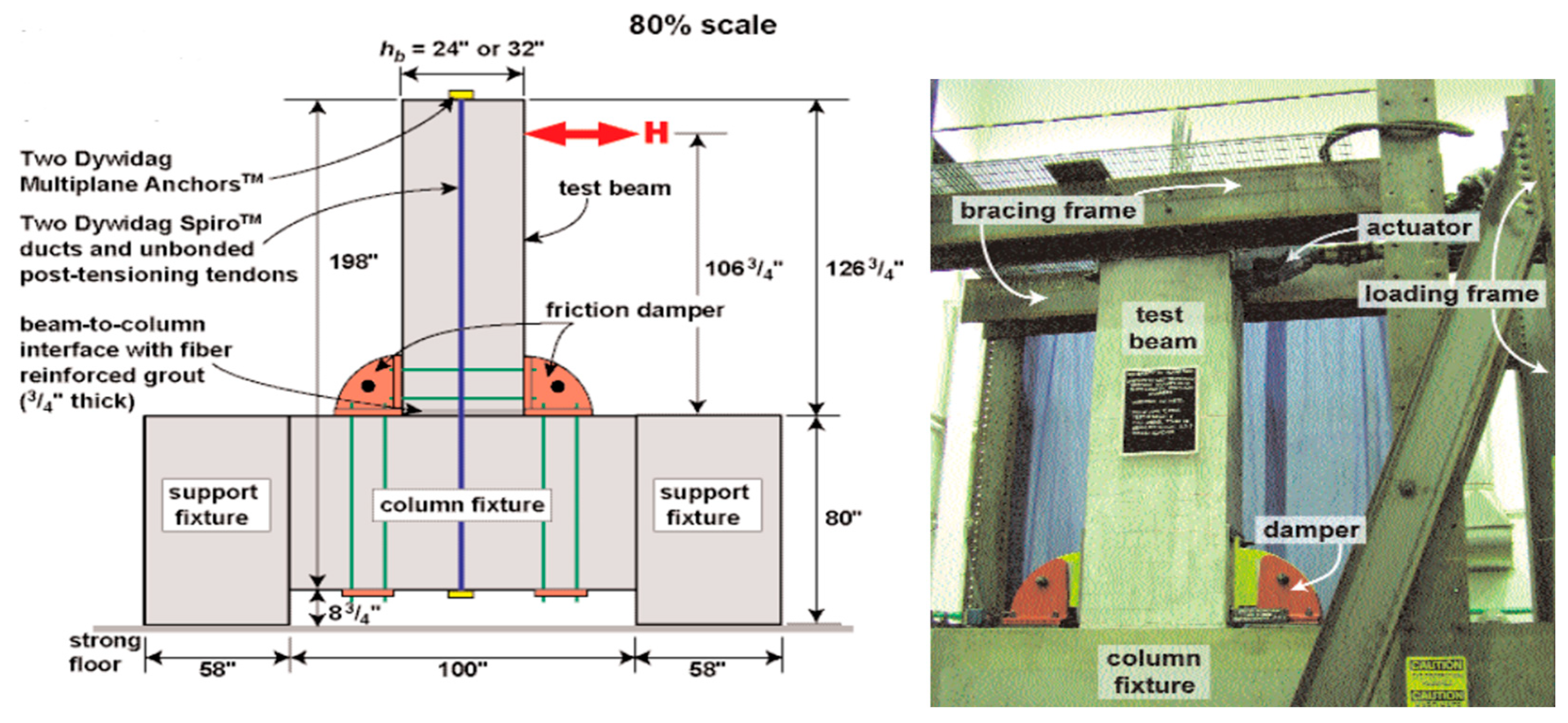

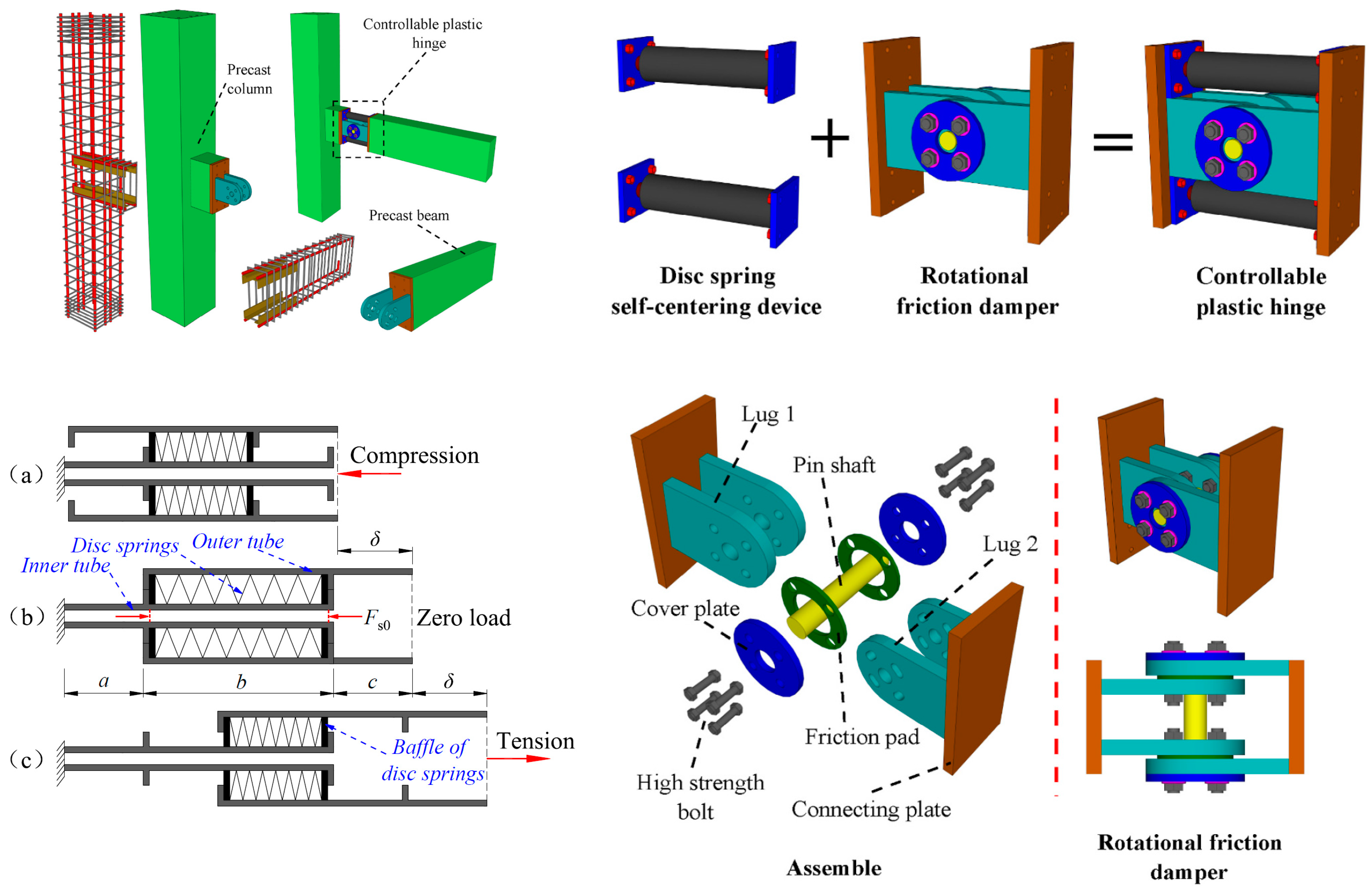

3.3. Self-Centering Friction Connection for PRC MRFs

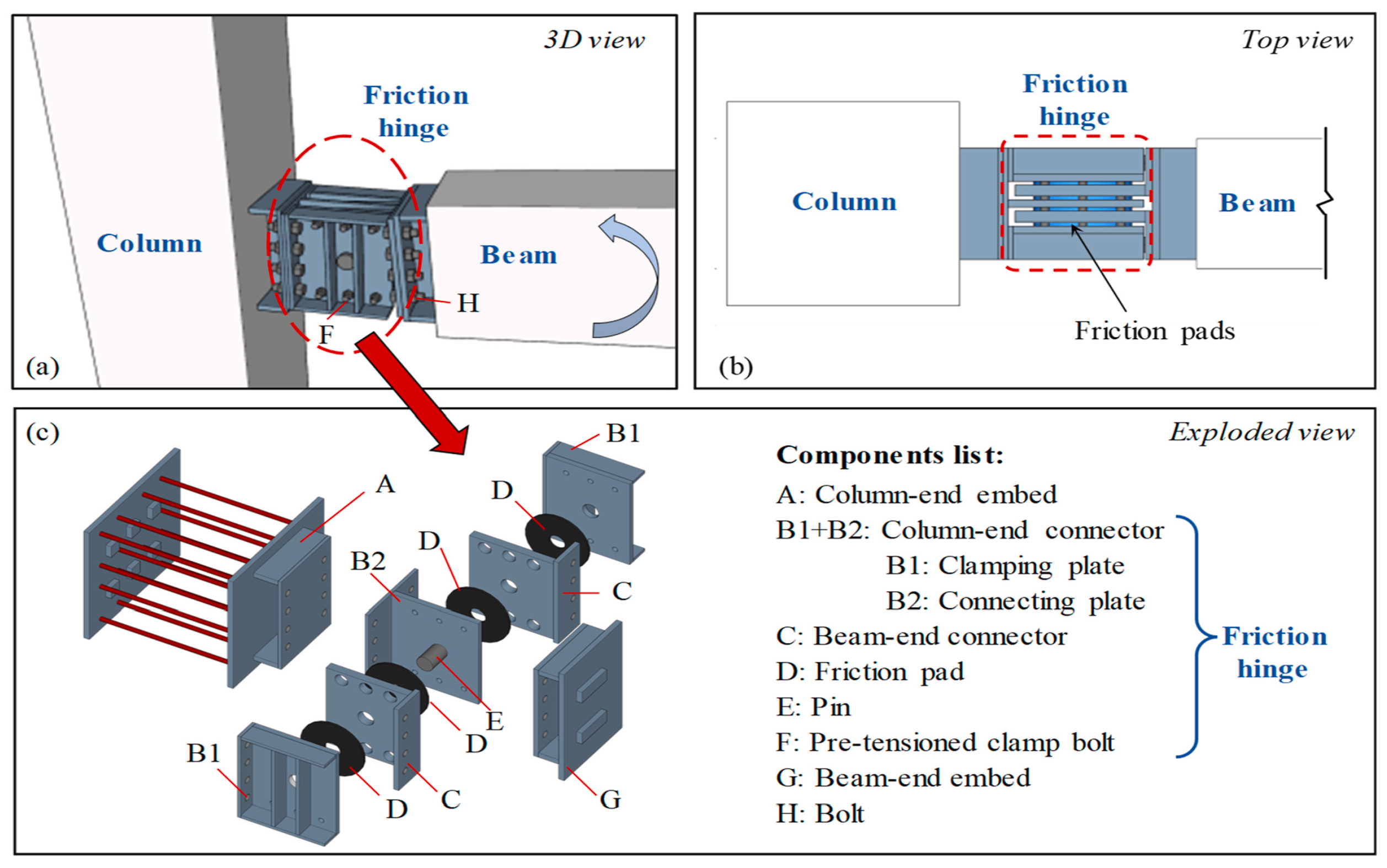

3.4. Symmetric Vertical Friction Connection for RC Columns and Hybrid Beams

4. Asymmetric Friction Connections (AFC)

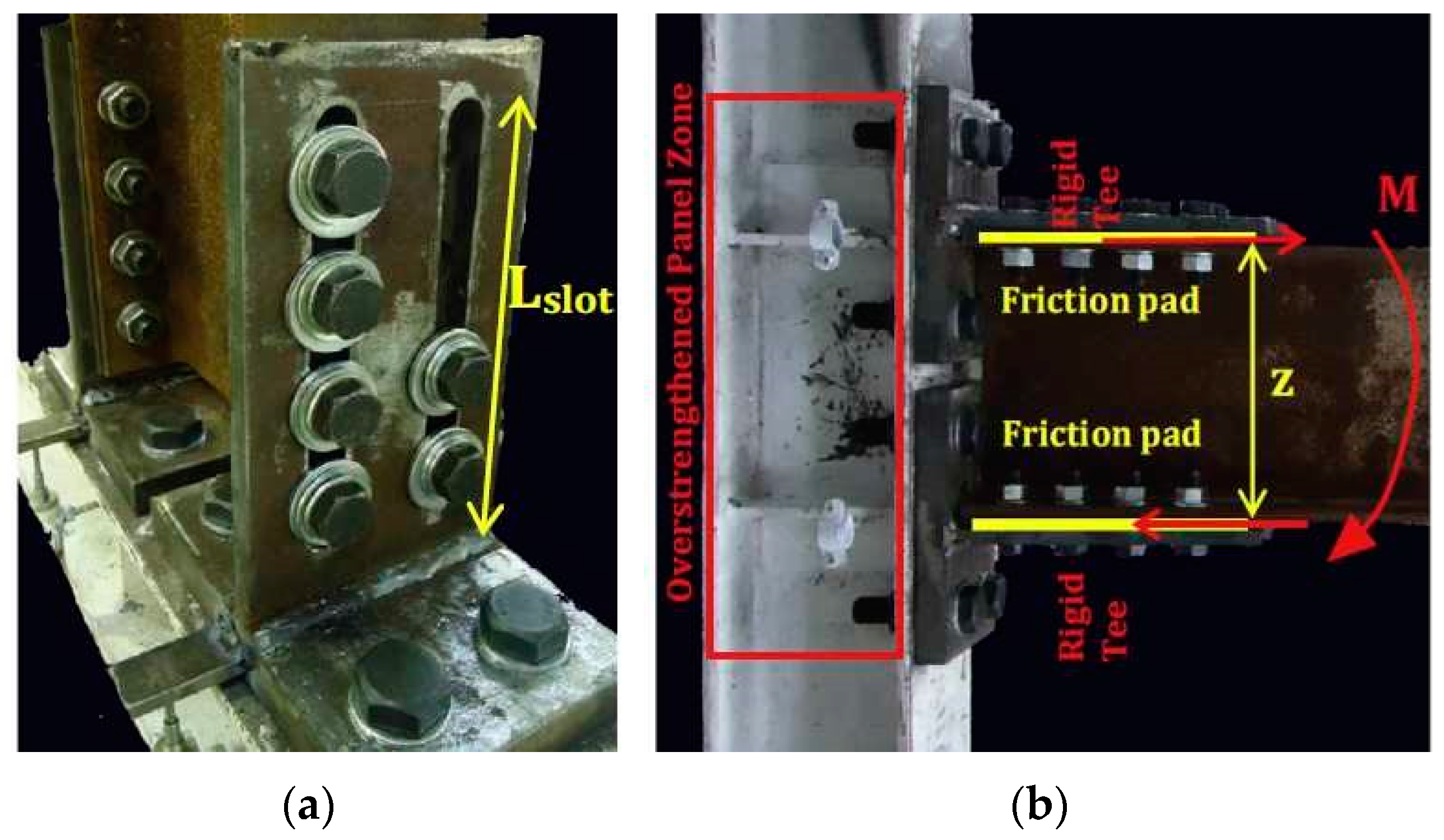

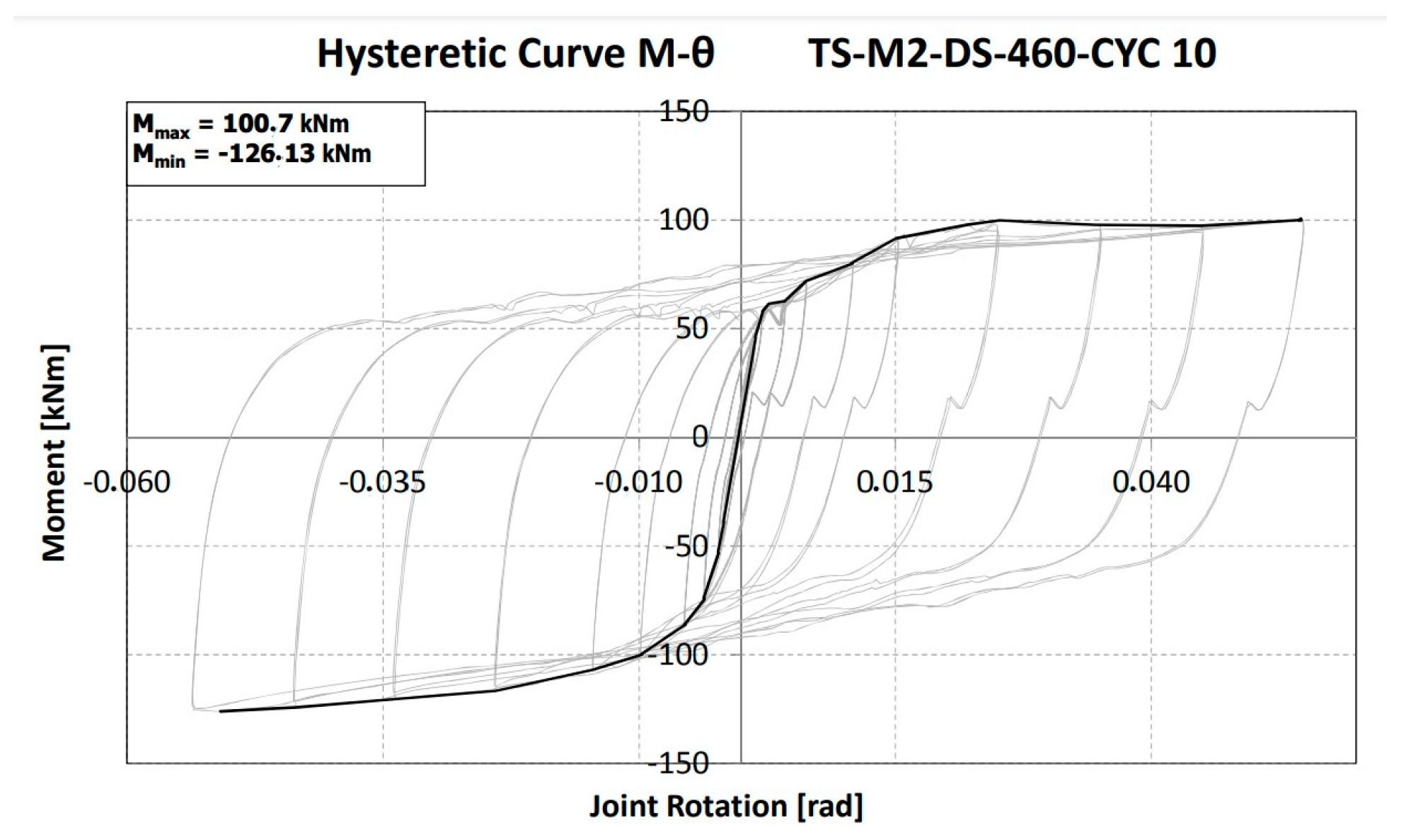

4.1. Dissipative Double Split Tee Connection

4.2. Two-Level Friction-Yielding System

5. Asymmetric Connections with Cap Plate

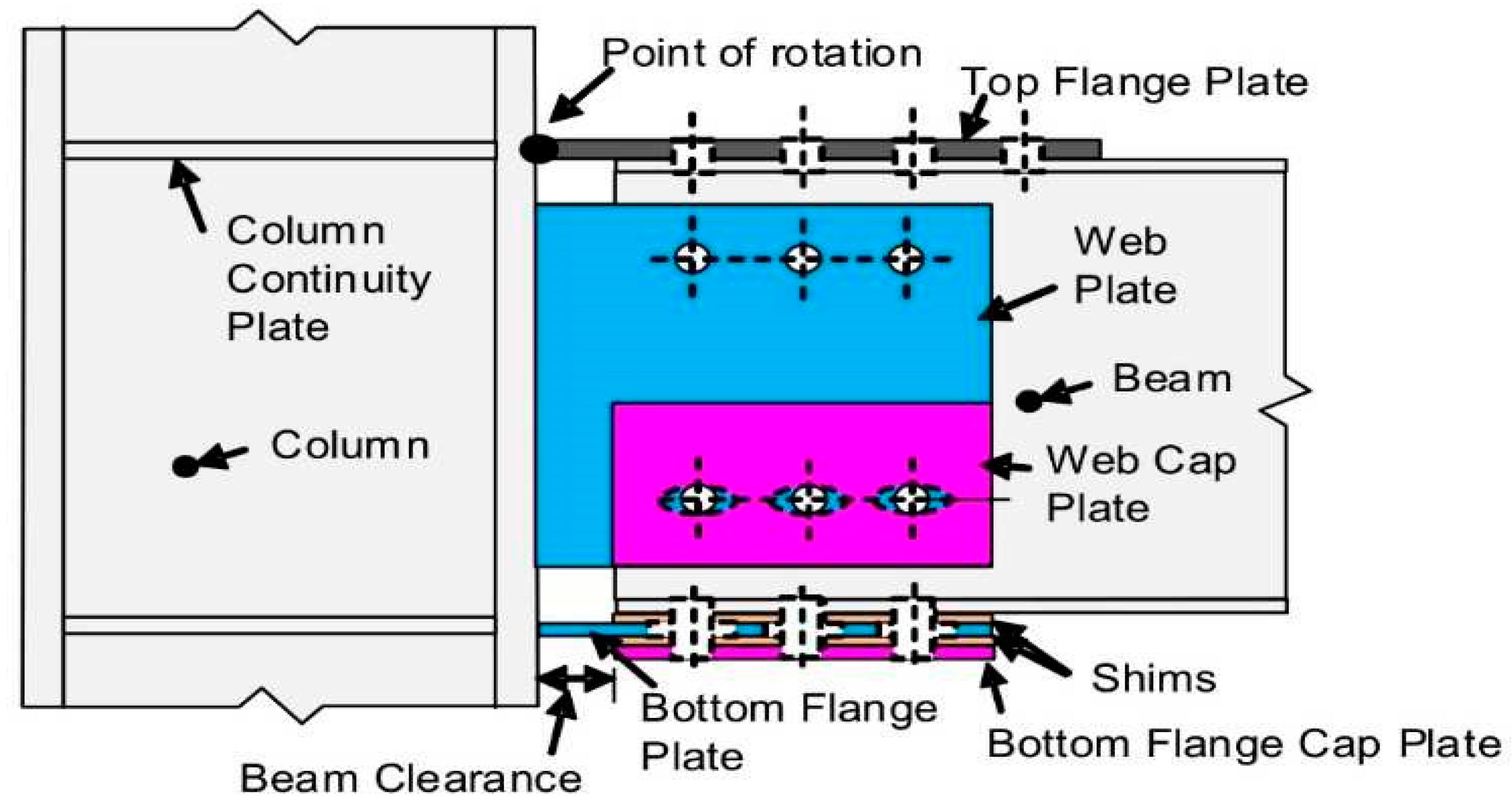

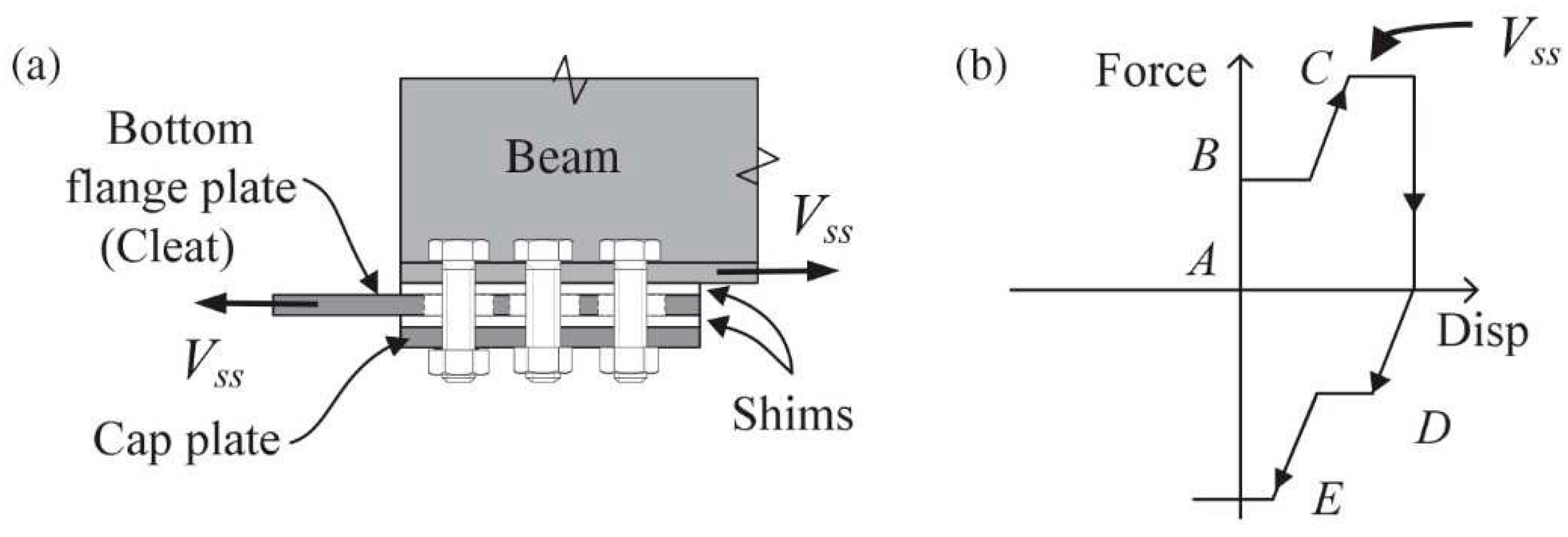

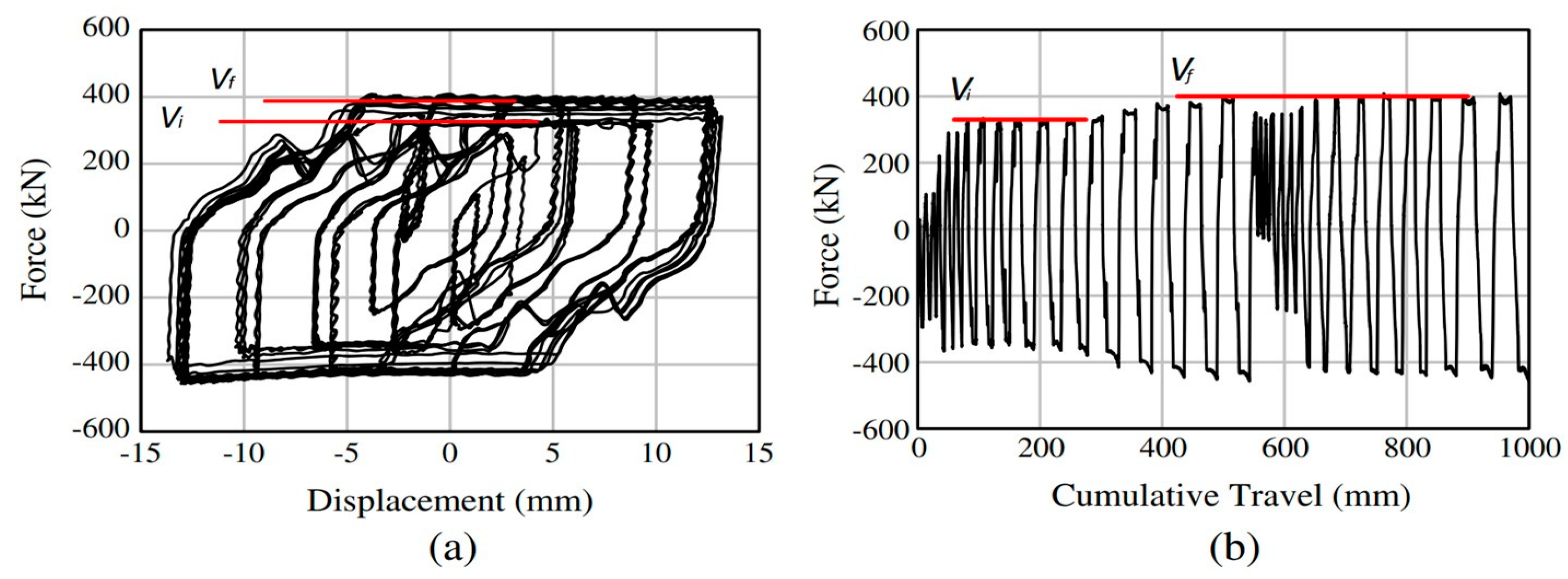

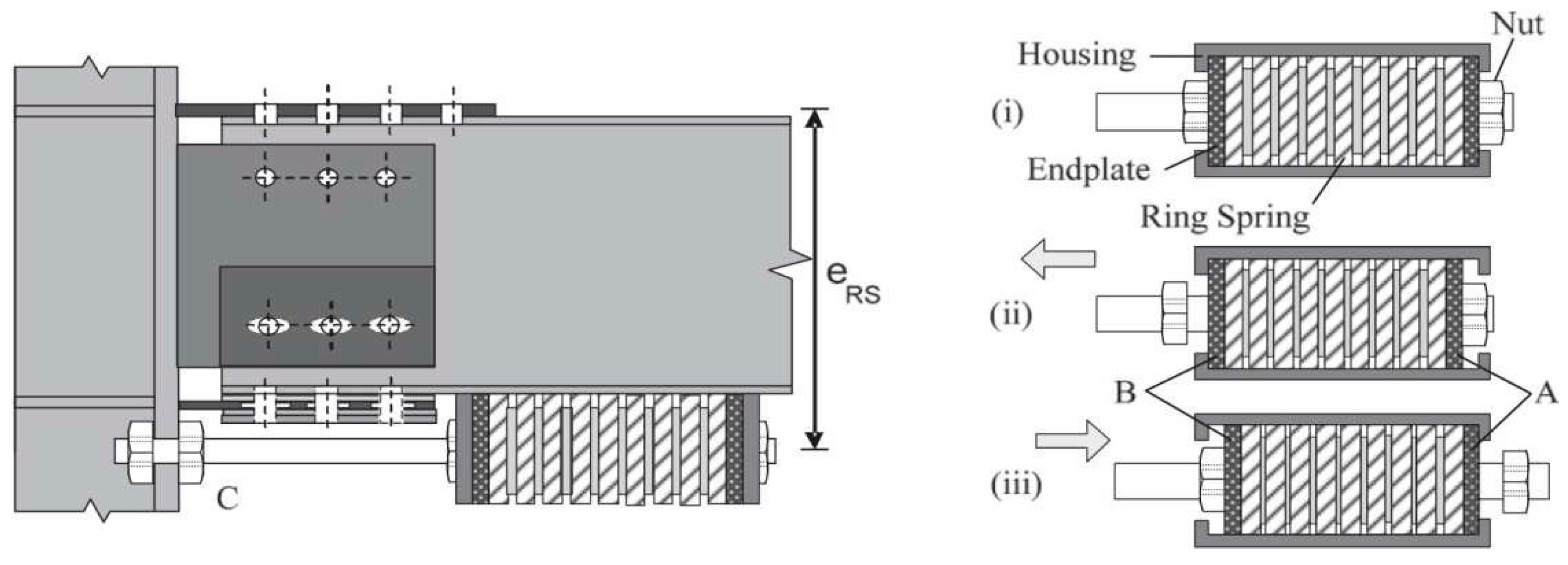

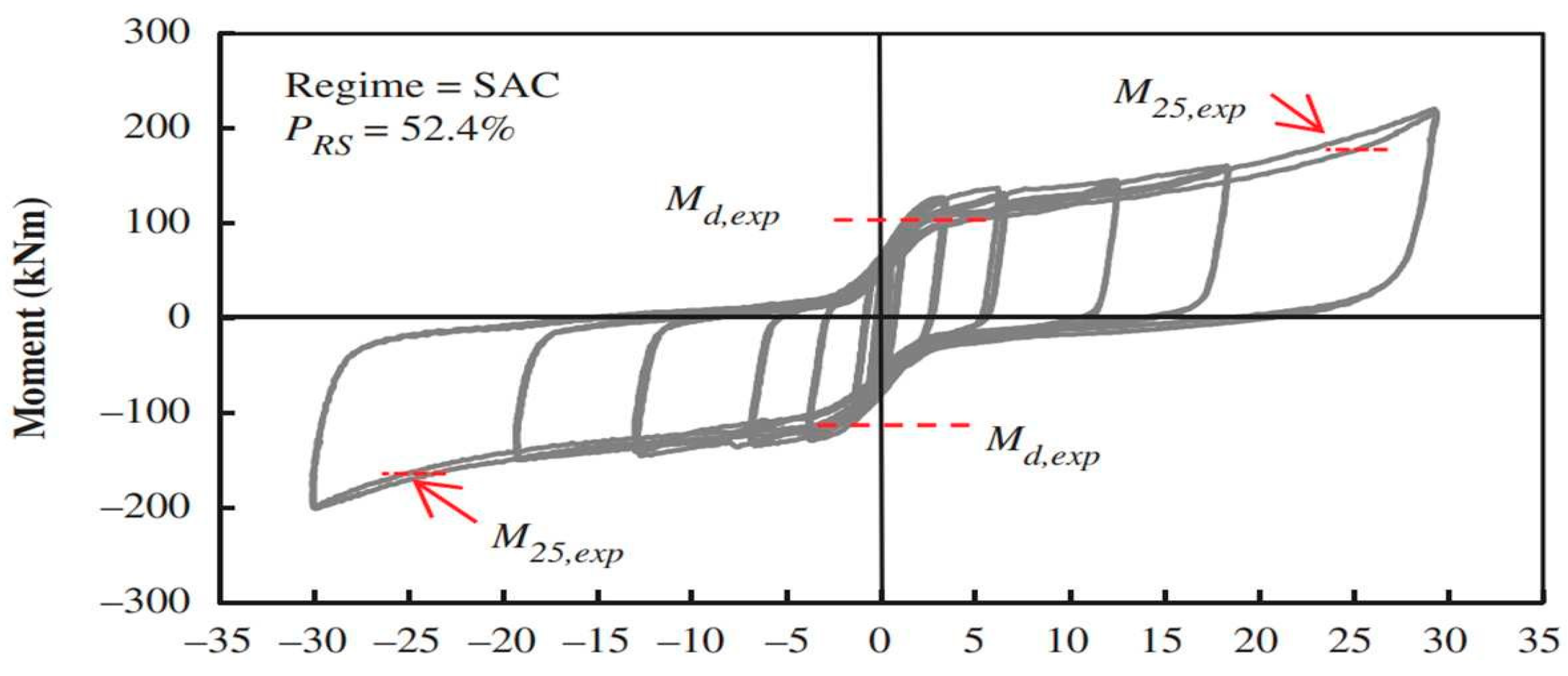

Sliding Hinge Joint with Asymmetric Friction Connection

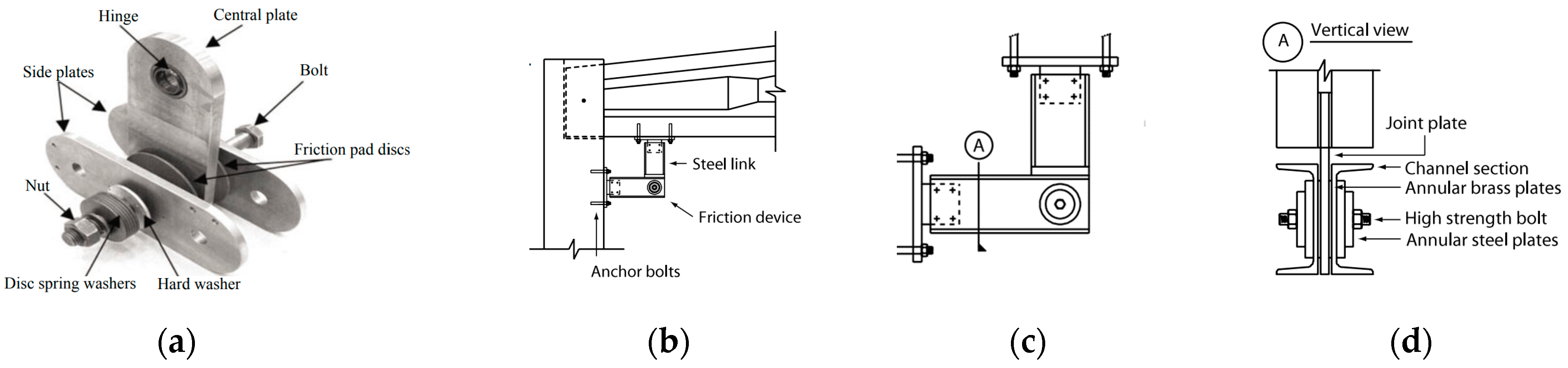

6. Rotational Friction Devices

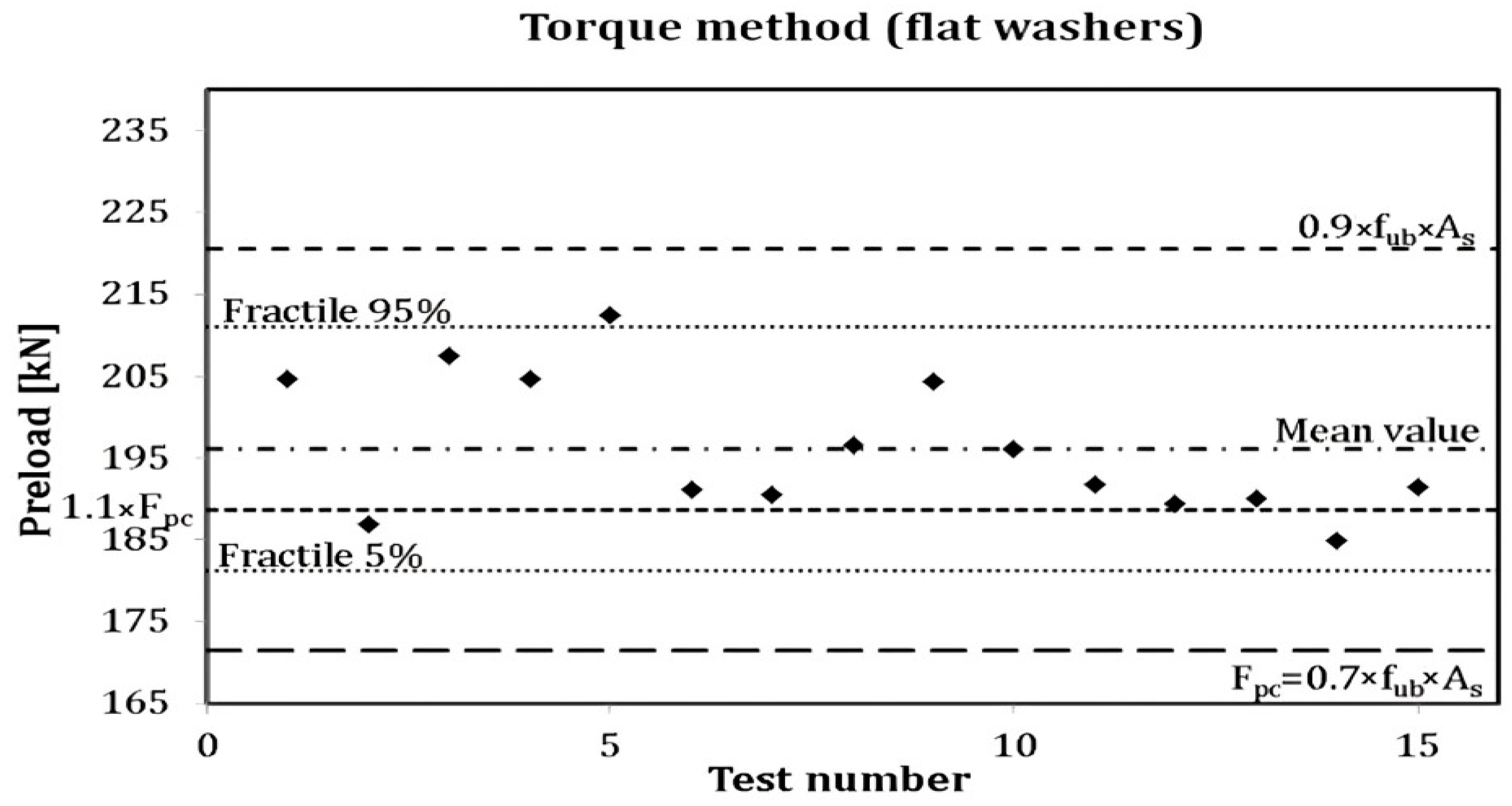

7. Common Issues Affecting Friction Connections

- Characteristics of the friction shim;

- Values and control of the bolt preload.

8. Conclusions

- Symmetric dissipative systems ensure a stable response in terms of bending moment capacity, at the same time reducing the stresses experienced by the bolts; by contrast, they have greater complexity and cost and are widespread mainly in Europe, where the relatively low seismicity makes the use of these solutions attractive for buildings of a certain importance, for which the higher costs for the device are justified;

- The introduction of a vertical web at the end of the beam, on which the friction forces are exerted, allows the arm of the internal couple to be enlarged, increasing the moment of resistance of the connection; this effective structural solution clashes with the need to reduce the overall dimensions of the device;

- The kinematic behavior of the beam-to-column connection is predictable only if it is known prior to the position of the center of rotation;

- The dissipative device used only at the lower part of the beam ensures identification of a fixed center of rotation, reducing variations in the strength of the connection; its location near the extrados of the beam reduces or avoids damage to the slab;

- The steel angles connected to the vertical dissipative device remain within the elastic range, simplifying the constructional system with respect to the horizontal dissipative device;

- T-stubs and/or L-stubs of horizontal dissipative device(s) provide a bending moment contribution during the sliding phase;

- The vertical dissipative device with two groups of slotted holes, one vertically oriented on the steel angles and the other one horizontally oriented on the friction shims, exhibits an undesired contribution as well, provided by the bolts of friction device which have to be dragged up and down during the sliding phase;

- Separating the beam end section and the column face prevents damage occurring at this interface.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Housner, G.W. Limit Design of Structures to Resist Earthquakes. In Proceedings of the World Conference on Earthquake Engineering, Berkeley, CA, USA, June 1956; pp. 5–13. [Google Scholar]

- Kelly, J.M. Aseismic Base Isolation: Review and Bibliography. Soil Dyn. Earthq. Eng. 1986, 5, 202–216. [Google Scholar] [CrossRef]

- Cacciola, P.; Tombari, A. Vibrating Barrier: A Novel Device for the Passive Control of Structures under Ground Motion. Proc. R. Soc. A 2015, 471, 20150075. [Google Scholar] [CrossRef] [PubMed]

- Colajanni, P.; Papia, M. Hysteretic Behavior Characterization of Friction-Damped Braced Frames. J. Struct. Eng. 1997, 123, 1020–1028. [Google Scholar] [CrossRef]

- Akiyama, H. Earthquake-Resistant Limit-State Design for Buildings; University of Tokyo Press: Tokyo, Japan, 1985; ISBN 4-13-068111-7. [Google Scholar]

- Martinez-Rueda, J.E.; Elnashai, A.S. A Novel Technique for the Retrofitting of Reinforced Concrete Structures. Eng. Struct. 1995, 17, 359–371. [Google Scholar] [CrossRef]

- Skinner, R.I.; Kelly, J.M.; Heine, A.J. Hysteretic Dampers for Earthquake-resistant Structures. Earthq. Eng. Struct. Dyn. 1974, 3, 287–296. [Google Scholar] [CrossRef]

- Cao, X.-Y.; Shen, D.; Feng, D.-C.; Wang, C.-L.; Qu, Z.; Wu, G. Seismic Retrofitting of Existing Frame Buildings through Externally Attached Sub-Structures: State of the Art Review and Future Perspectives. J. Build. Eng. 2022, 57, 104904. [Google Scholar] [CrossRef]

- Pall, A.S. Friction Devices for Aseismic Design of Buildings. In Proceedings of the Fourth Canadian Conference on Earthquake Engineering: Proceedings; University of British Columbia: Vancouver, BC, Canada, 1983; pp. 475–484. [Google Scholar]

- Pasquin, C.; Leboeuf, N.; Pall, R.T.; Pall, A. Friction Dampers for Seismic Rehabilitation of Eaton’s Building, Montreal. In Proceedings of the 13th World Conference on Earthquake Engineering, Vancouver, BC, Canada, 1–6 August 2004; pp. 1–2. [Google Scholar]

- Gledhill, S.; Sidwell, G.; Khoo, H.H.; Clifton, G.C. Steel Moment Frames with Sliding Hinge Joints—Lessons Learnt during Implementation. In Proceedings of the Steel Innovations Conference, Christchurch, New Zealand, 21–22 February 2013; pp. 21–22. [Google Scholar]

- Gledhill, S.M.; Sidwell, G.K.; Bell, D.K. The Damage Avoidance Design of Tall Steel Frame Buildings-Fairlie Terrace Student Accommodation Project, Victoria University of Wellington. In Proceedings of the New Zealand Society of Earthquake Engineering Annual Conference, Taupo, New Zealand, 11–13 April 2008; pp. 11–13. [Google Scholar]

- Ansal, A. (Ed.) Perspectives on European Earthquake Engineering and Seismology: Volume 2; Geotechnical, Geological and Earthquake Engineering; Springer International Publishing: Cham, Switzerland, 2015; Volume 39, ISBN 978-3-319-16963-7. [Google Scholar]

- Oxford Terrace Christchurch, New Zealand. Available online: https://www.Tectonus.Com/Projects/Oxford-Terrace (accessed on 6 February 2024).

- Benfratello, S.; Palizzolo, L.; Vazzano, S. A New Design Problem in the Formulation of a Special Moment Resisting Connection Device for Preventing Local Buckling. Appl. Sci. 2021, 12, 202. [Google Scholar] [CrossRef]

- Benfratello, S.; Caddemi, S.; Palizzolo, L.; Pantò, B.; Rapicavoli, D.; Vazzano, S. Targeted Steel Frames by Means of Innovative Moment Resisting Connections. J. Constr. Steel Res. 2021, 183, 106695. [Google Scholar] [CrossRef]

- Benfratello, S.; Cucchiara, C.; Palizzolo, L.; Tabbuso, P. Fixed Strength and Stiffness Hinges for Steel Frames. In Proceedings of the 23rd Conference of the Italian Association of Theoretical and Applied Mechanics (AIMETA 2017), Salerno, Italy, 4–7 September 2017; Volume 1, pp. 1287–1296. [Google Scholar]

- Jaisee, S.; Yue, F.; Chen, L.; Yin, W.; Gong, H.; Wang, C. Shaking Table Investigations on the Seismic Performance of a Steel Frame with Optimized Passive Energy Dissipation Devices. IOP Conf. Ser. Earth Environ. Sci. 2019, 330, 022081. [Google Scholar] [CrossRef]

- Jaisee, S.; Yue, F.; Ooi, Y.H. A State-of-the-Art Review on Passive Friction Dampers and Their Applications. Eng. Struct. 2021, 235, 112022. [Google Scholar] [CrossRef]

- Roh, J.-E.; Hur, M.-W.; Choi, H.-H.; Lee, S.-H. Development of a Multiaction Hybrid Damper for Passive Energy Dissipation. Shock Vib. 2018, 2018, 5630746. [Google Scholar] [CrossRef]

- Kim, J.; Shin, H. Seismic Loss Assessment of a Structure Retrofitted with Slit-Friction Hybrid Dampers. Eng. Struct. 2017, 130, 336–350. [Google Scholar] [CrossRef]

- Asgari, H.; Zahrai, S.M.; Vajdian, M.; Mirhosseini, S.M. Cyclic Testing of Two-Level Control System Using Friction-Yielding Top Plates in Beam-to-Column Rigid Connections. Structures 2024, 59, 105696. [Google Scholar] [CrossRef]

- Janke, L.; Czaderski, C.; Motavalli, M.; Ruth, J. Applications of Shape Memory Alloys in Civil Engineering Structures—Overview, Limits and New Ideas. Mater. Struct. 2005, 38, 578–592. [Google Scholar]

- Higazey, M.M.; Alshannag, M.J.; Alqarni, A.S. Numerical Investigation on the Performance of Exterior Beam–Column Joints Reinforced with Shape Memory Alloys. Buildings 2023, 13, 1801. [Google Scholar] [CrossRef]

- Pall, A.S.; Marsh, C.; Fazio, P. Friction Joints for Seismic Control of Large Panel Structures. J. Prestress. Concr. Inst. 1980, 25, 38–61. [Google Scholar] [CrossRef]

- Pall, A.S.; Marsh, C. Response of Friction Damped Braced Frames. J. Struct. Div. 1982, 108, 1313–1323. [Google Scholar] [CrossRef]

- Chen, W.-F.; Lui, E.M. Handbook of Structural Engineering; CRC Press: Boca Raton, FL, USA, 2005; ISBN 1-4200-3993-8. [Google Scholar]

- Soong, T.T.; Dargush, G.F. Passive Energy Dissipation Systems in Structural Engineering; Wiley: Chichester, UK; New York, NY, USA, 1997; ISBN 978-0-471-96821-4. [Google Scholar]

- Symans, M.D.; Charney, F.A.; Whittaker, A.S.; Constantinou, M.C.; Kircher, C.A.; Johnson, M.W.; McNamara, R.J. Energy Dissipation Systems for Seismic Applications: Current Practice and Recent Developments. J. Struct. Eng. 2008, 134, 3–21. [Google Scholar] [CrossRef]

- Perkowski, W. Dry friction damper for supercritical drive shaft. J. KONES Powertrain Transp. 2016, 23, 389–396. [Google Scholar] [CrossRef]

- Pesaresi, L.; Stender, M.; Ruffini, V.; Schwingshackl, C.W. DIC Measurement of the Kinematics of a Friction Damper for Turbine Applications. In Dynamics of Coupled Structures, Volume 4: Proceedings of the 35th IMAC, A Conference and Exposition on Structural Dynamics 2017; Springer: Berlin/Heidelberg, Germany, 2017; pp. 93–101. [Google Scholar]

- Csaba, G. Modelling of a Microslip Friction Damper Subjected to Translation and Rotation. In Turbo Expo: Power for Land, Sea, and Air; American Society of Mechanical Engineers: New York, NY, USA, 1999; Volume 78613, p. V004T03A012. [Google Scholar]

- Sanati, M.; Khadem, S.E.; Mirzabagheri, S.; Sanati, H.; Khosravieh, M.Y. Performance Evaluation of a Novel Rotational Damper for Structural Reinforcement Steel Frames Subjected to Lateral Excitations. Earthq. Eng. Eng. Vib. 2014, 13, 75–84. [Google Scholar] [CrossRef]

- Lee, C.-H.; Kim, J.; Kim, D.-H.; Ryu, J.; Ju, Y.K. Numerical and Experimental Analysis of Combined Behavior of Shear-Type Friction Damper and Non-Uniform Strip Damper for Multi-Level Seismic Protection. Eng. Struct. 2016, 114, 75–92. [Google Scholar] [CrossRef]

- Titirla, M.D.; Papadopoulos, P.K.; Doudoumis, I.N.; Katakalos, K.V. Cyclic Response of an Antisesmic Steel Device for Building–an Experimental and Numerical Study. In Proceedings of the 16th World Conference on Earthquake Engineering, Chilean Association on Seismology and Earthquake Engineering (ACHISINA), Santiago, Chile, 9–13 January 2017; pp. 1–11. [Google Scholar]

- Titirla, M.D.; Papadopoulos, P.K.; Doudoumis, I.N. Finite Element Modelling of an Innovative Passive Energy Dissipation Device for Seismic Hazard Mitigation. Eng. Struct. 2018, 168, 218–228. [Google Scholar] [CrossRef]

- Bagheri, S.; Barghian, M.; Saieri, F.; Farzinfar, A. U-Shaped Metallic-Yielding Damper in Building Structures: Seismic Behavior and Comparison with a Friction Damper. Structures 2015, 3, 163–171. [Google Scholar] [CrossRef]

- Gagnon, L.; Morandini, M.; Ghiringhelli, G.L. A Review of Friction Damping Modeling and Testing. Arch. Appl. Mech. 2020, 90, 107–126. [Google Scholar] [CrossRef]

- Titirla, M.D. A State-of-the-Art Review of Passive Energy Dissipation Systems in Steel Braces. Buildings 2023, 13, 851. [Google Scholar] [CrossRef]

- Lai, Z.; Fischer, E.C.; Varma, A.H. Database and Review of Beam-to-Column Connections for Seismic Design of Composite Special Moment Frames. J. Struct. Eng. 2019, 145, 04019023. [Google Scholar] [CrossRef]

- Ugalde, D.; Almazán, J.L.; Santa María, H.; Guindos, P. Seismic Protection Technologies for Timber Structures: A Review. Eur. J. Wood Prod. 2019, 77, 173–194. [Google Scholar] [CrossRef]

- Rebouças, A.S.; Mehdipour, Z.; Branco, J.M.; Lourenço, P.B. Ductile Moment-Resisting Timber Connections: A Review. Buildings 2022, 12, 240. [Google Scholar] [CrossRef]

- Wakashima, Y.; Ishikawa, K.; Shimizu, H.; Kitamori, A.; Matsubara, D.; Tesfamariam, S. Dynamic and Long-Term Performance of Wood Friction Connectors for Timber Shear Walls. Eng. Struct. 2021, 241, 112351. [Google Scholar] [CrossRef]

- Morgen, B.G.; Kurama, Y.C. A Friction Damper for Post-Tensioned Precast Concrete Moment Frames. PCI J. 2004, 49, 112–133. [Google Scholar] [CrossRef]

- Morgen, B.G.; Kurama, Y.C. Seismic Design of Friction-Damped Precast Concrete Frame Structures. J. Struct. Eng. 2007, 133, 1501–1511. [Google Scholar] [CrossRef]

- Morgen, B.G.; Kurama, Y.C. Seismic Response Evaluation of Posttensioned Precast Concrete Frames with Friction Dampers. J. Struct. Eng. 2008, 134, 132–145. [Google Scholar] [CrossRef]

- Huang, L.; Zhou, Z.; Clayton, P.M.; Zeng, B.; Qiu, J. Experimental Investigation of Friction-Damped Self-Centering Prestressed Concrete Beam-Column Connections with Hidden Corbels. J. Struct. Eng. 2020, 146, 04019228. [Google Scholar] [CrossRef]

- Huang, L.; Clayton, P.M.; Zhou, Z. Seismic Design and Performance of Self-Centering Precast Concrete Frames with Variable Friction Dampers. Eng. Struct. 2021, 245, 112863. [Google Scholar] [CrossRef]

- Pagnotta, S.; Monaco, A.; Colajanni, P.; La Mendola, L. Experimental Characterization of Friction Properties of Materials for Innovative Beam-to-Column Dissipative Connection for Low-Damage RC Structures. Procedia Struct. Integr. 2023, 44, 1909–1916. [Google Scholar] [CrossRef]

- Colajanni, P.; La Mendola, L.; Monaco, A.; Pagnotta, S. Design of RC Joints Equipped with Hybrid Trussed Beams and Friction Dampers. Eng. Struct. 2021, 227, 111442. [Google Scholar] [CrossRef]

- Di Benedetto, S.; Francavilla, A.B.; Latour, M.; Piluso, V.; Rizzano, G. Experimental Response of a Large-Scale Two-Storey Steel Building Equipped with Low-Yielding Friction Joints. Soil Dyn. Earthq. Eng. 2022, 152, 107022. [Google Scholar] [CrossRef]

- Francavilla, A.B.; Latour, M.; Piluso, V.; Rizzano, G. Design Criteria for Beam-to-Column Connections Equipped with Friction Devices. J. Constr. Steel Res. 2020, 172, 106240. [Google Scholar] [CrossRef]

- Guo, T.; Wang, L.; Xu, Z.; Hao, Y. Experimental and Numerical Investigation of Jointed Self-Centering Concrete Walls with Friction Connectors. Eng. Struct. 2018, 161, 192–206. [Google Scholar] [CrossRef]

- Cho, C.; Kwon, M. Development and Modeling of a Frictional Wall Damper and Its Applications in Reinforced Concrete Frame Structures. Earthq. Engng. Struct. Dyn. 2004, 33, 821–838. [Google Scholar] [CrossRef]

- Ramirez, J.M.; Tirca, L. Numerical Simulation and Design of Friction-Damped Damped Steel Frame Structures. In Proceedings of the 15th World Conference on Earthquake Engineering 2012 (15WCEE), Lisbon, Portugal, 24–28 September 2012; p. 15052, ISBN 978-1-63439-651-6. [Google Scholar]

- Colajanni, P.; La Mendola, L.; Monaco, A.; Pagnotta, S. Seismic Performance of Earthquake-Resilient RC Frames Made with HSTC Beams and Friction Damper Devices. J. Earthq. Eng. 2022, 26, 7787–7813. [Google Scholar] [CrossRef]

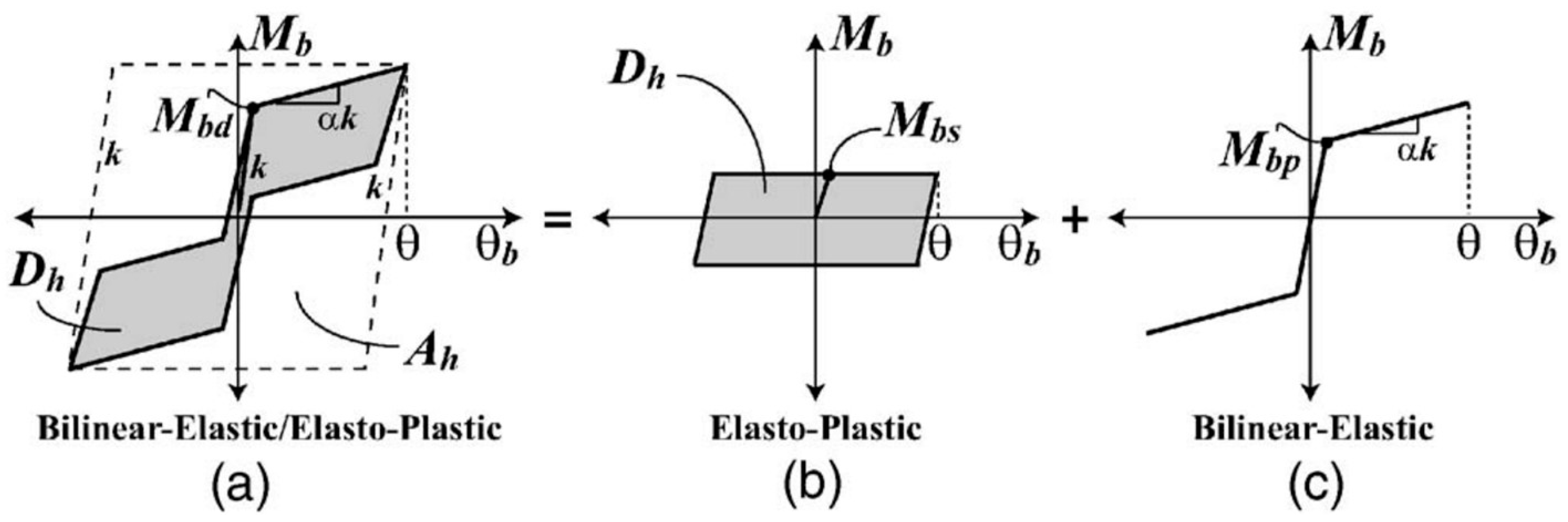

- Sivaselvan, M.V.; Reinhorn, A.M. Hysteretic Models for Deteriorating Inelastic Structures. J. Eng. Mech. 2000, 126, 633–640. [Google Scholar] [CrossRef]

- Ma, L.; Shi, Q.; Wang, B.; Tao, Y.; Wang, P. Research on Design and Numerical Simulation of Self-Centering Prefabricated RC Beam-Column Joint with Pre-Pressed Disc Spring Devices. Soil Dyn. Earthq. Eng. 2023, 166, 107762. [Google Scholar] [CrossRef]

- McKenna, F. OpenSees: A Framework for Earthquake Engineering Simulation. Comput. Sci. Eng. 2011, 13, 58–66. [Google Scholar] [CrossRef]

- Huang, L.; Qian, Z.; Meng, Y.; Jiang, K.; Zhang, J.; Sang, C. Parametric Investigation of Self-Centering Prestressed Concrete Frame Structures with Variable Friction Dampers. Buildings 2023, 13, 3029. [Google Scholar] [CrossRef]

- Colajanni, P.; La Mendola, L.; Monaco, A.; Pagnotta, S. Dissipative Connections of Rc Frames with Prefabricated Steel-Trussed-Concrete Beams. Ing. Sismica 2020, 37, 51–63. [Google Scholar]

- Liu, R.; Wu, J.; Yan, G.; Lai, Q.; Wang, H. Seismic Performance of Earthquake-Resilient Beam-to-Column Connection Considering Friction-Slip Mechanism. J. Build. Eng. 2023, 75, 107055. [Google Scholar] [CrossRef]

- Latour, M.; Piluso, V.; Rizzano, G. Experimental Analysis on Friction Materials for Supplemental Damping Devices. Constr. Build. Mater. 2014, 65, 159–176. [Google Scholar] [CrossRef]

- Francavilla, A.B.; Latour, M.; Rizzano, G. Prototype Test of Resilient Friction Materials for Seismic Dampers. Materials 2023, 16, 7336. [Google Scholar] [CrossRef]

- Chan, D.; Stachowiak, G.W. Review of Automotive Brake Friction Materials. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2004, 218, 953–966. [Google Scholar] [CrossRef]

- Golondrino, J.C.; MacRae, G.; Clifton, C. Behaviour of Asymmetrical Friction Connections Using Different Shim Materials. In Proceedings of the New Zealand Society for Earthquake Engineering Conference, Christchurch, New Zealand, 13–15 April 2012. [Google Scholar]

- Chanchi Golondrino, J.C.; MacRae, G.A.; Chase, J.G.; Rodgers, G.W.; Clifton, G.C. Hysteretic Behaviour of Asymmetrical Friction Connections Using Brake Pads of D3923. Structures 2018, 16, 164–175. [Google Scholar] [CrossRef]

- Chan, R.W.K.; Tang, W. Serviceability Conditions of Friction Dampers for Seismic Risk Mitigations. Structures 2022, 35, 500–510. [Google Scholar] [CrossRef]

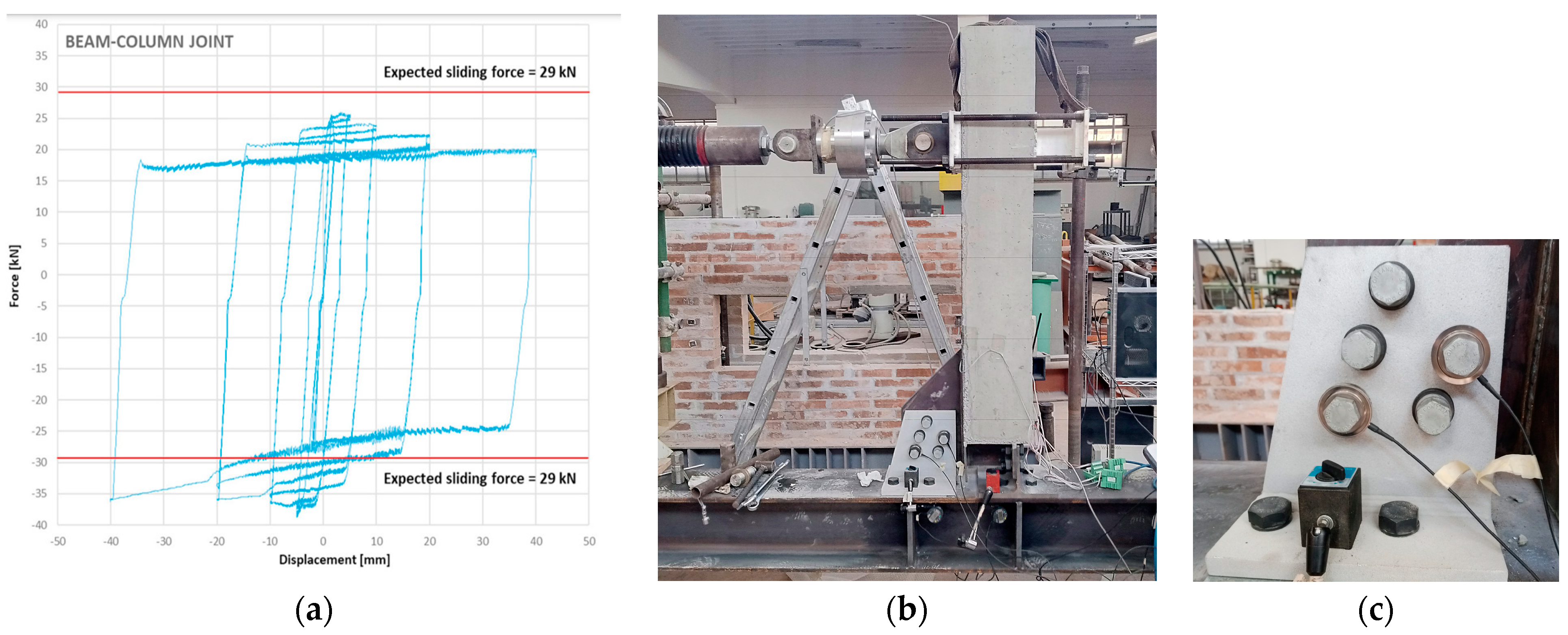

- Pagnotta, S.; Ahmed, M.; Colajanni, P. Experimental and finite element analysis of the cyclic behaviour of linear dissipative devices. In COMPDYN Proceedings; Eccomas Proceedia 2023; National Technical University of Athens: Athens, Greece, 2023; pp. 3077–3090. ISSN 2623-3347. [Google Scholar]

- Ferrante Cavallaro, G.; Francavilla, A.; Latour, M.; Piluso, V.; Rizzano, G. Experimental Behaviour of Innovative Thermal Spray Coating Materials for FREEDAM Joints. Compos. Part B Eng. 2017, 115, 289–299. [Google Scholar] [CrossRef]

- Ferrante Cavallaro, G.; Latour, M.; Francavilla, A.B.; Piluso, V.; Rizzano, G. Standardised Friction Damper Bolt Assemblies Time-Related Relaxation and Installed Tension Variability. J. Constr. Steel Res. 2018, 141, 145–155. [Google Scholar] [CrossRef]

- D’Antimo, M.; Latour, M.; Cavallaro, G.F.; Jaspart, J.-P.; Ramhormozian, S.; Demonceau, J.-F. Short- and Long- Term Loss of Preloading in Slotted Bolted Connections. J. Constr. Steel Res. 2020, 167, 105956. [Google Scholar] [CrossRef]

- Belleri, A.; Marini, A.; Riva, P.; Nascimbene, R. Dissipating and Re-Centring Devices for Portal-Frame Precast Structures. Eng. Struct. 2017, 150, 736–745. [Google Scholar] [CrossRef]

- Khoo, H.-H.; Clifton, C.; Butterworth, J.; MacRae, G.; Gledhill, S.; Sidwell, G. Development of the Self-Centering Sliding Hinge Joint with Friction Ring Springs. J. Constr. Steel Res. 2012, 78, 201–211. [Google Scholar] [CrossRef]

- Khoo, H.-H.; Clifton, C.; Butterworth, J.; MacRae, G. Experimental Study of Full-Scale Self-Centering Sliding Hinge Joint Connections with Friction Ring Springs. J. Earthq. Eng. 2013, 17, 972–997. [Google Scholar] [CrossRef]

- Iyama, J.; Seo, C.-Y.; Ricles, J.M.; Sause, R. Self-Centering MRFs with Bottom Flange Friction Devices under Earthquake Loading. J. Constr. Steel Res. 2009, 65, 314–325. [Google Scholar] [CrossRef]

- Tsai, K.-C.; Chou, C.-C.; Lin, C.-L.; Chen, P.-C.; Jhang, S.-J. Seismic Self-centering Steel Beam-to-column Moment Connections Using Bolted Friction Devices. Earthq. Eng. Struct. Dyn. 2008, 37, 627–645. [Google Scholar] [CrossRef]

- Campione, G.; Cannella, F. Overstrength Requirements to Avoid Brittle Shear Failure in RC Slender Beams with Stirrups. Eng. Fail. Anal. 2020, 118, 104815. [Google Scholar] [CrossRef]

- FitzGerald, T.F.; Anagnos, T.; Goodson, M.; Zsutty, T. Slotted Bolted Connections in Aseismic Design for Concentrically Braced Connections. Earthq. Spectra 1989, 5, 383–391. [Google Scholar] [CrossRef]

- Yang, T.-S. Experimental and Analytical Studies of Steel Connections and Energy Dissipators; University of California: Berkeley, CA, USA; U.S. Department of Commerce, National Technical Information Service: Alexandria, VA, USA, 1995; PB 97-186803.

- Khoo, H.; Clifton, C.; MacRae, G.; Zhou, H.; Ramhormozian, S. Proposed Design Models for the Asymmetric Friction Connection. Earthq. Engng. Struct. Dyn. 2015, 44, 1309–1324. [Google Scholar] [CrossRef]

- Mualla, I.H.; Belev, B. Performance of Steel Frames with a New Friction Damper Device under Earthquake Excitation. Eng. Struct. 2002, 24, 365–371. [Google Scholar] [CrossRef]

- Mirtaheri, M.; Zandi, A.P.; Samadi, S.S.; Samani, H.R. Numerical and Experimental Study of Hysteretic Behavior of Cylindrical Friction Dampers. Eng. Struct. 2011, 33, 3647–3656. [Google Scholar] [CrossRef]

- Latour, M.; Piluso, V.; Rizzano, G. Free from Damage Beam-to-Column Joints: Testing and Design of DST Connections with Friction Pads. Eng. Struct. 2015, 85, 219–233. [Google Scholar] [CrossRef]

- Yang, C.; Xie, L.; Li, A.; Wang, X. A Dry-Connected Rotational Friction Dissipative Beam-to-Column Joint for Precast Concrete Frame: Full-Scale Experimental and Numerical Investigations. J. Build. Eng. 2022, 54, 104685. [Google Scholar] [CrossRef]

- Grigorian, C.E. Energy Dissipation with Slotted Bolted Connections; University of California: Berkeley, CA, USA, 1994; ISBN 9798208467978. [Google Scholar]

- Latour, M.; Piluso, V.; Rizzano, G. Experimental Analysis of Beam-to-Column Joints Equipped with Sprayed Aluminium Friction Dampers. J. Constr. Steel Res. 2018, 146, 33–48. [Google Scholar] [CrossRef]

- Latour, M.; D’Aniello, M.; Zimbru, M.; Rizzano, G.; Piluso, V.; Landolfo, R. Removable Friction Dampers for Low-Damage Steel Beam-to-Column Joints. Soil Dyn. Earthq. Eng. 2018, 115, 66–81. [Google Scholar] [CrossRef]

- Tartaglia, R.; D’Aniello, M.; Campiche, A.; Latour, M. Symmetric Friction Dampers in Beam-to-Column Joints for Low-Damage Steel MRFs. J. Constr. Steel Res. 2021, 184, 106791. [Google Scholar] [CrossRef]

- Colajanni, P.; Pagnotta, S. Friction-Based Beam-to-Column Connection for Low-Damage RC Frames with Hybrid Trussed Beams. Steel Compos. Struct. 2022, 45, 231–248. [Google Scholar] [CrossRef]

- Colajanni, P.; La Mendola, L.; Monaco, A.; Pagnotta, S. Low-Damage Friction Connections in Hybrid Joints of Frames of Reinforced-Concrete Buildings. Appl. Sci. 2023, 13, 7876. [Google Scholar] [CrossRef]

- Chanchi Golondrino, J.C.; MacRae, G.A.; Chase, J.G.; Rodgers, G.W.; Clifton, G.C. Asymmetric Friction Connection (AFC) Design for Seismic Energy Dissipation. J. Constr. Steel Res. 2019, 157, 70–81. [Google Scholar] [CrossRef]

- Ramhormozian, S.; Clifton, G.C.; MacRae, G.A.; Khoo, H.H. The Sliding Hinge Joint: Final Steps towards an Optimum Low Damage Seismic-Resistant Steel System. KEM 2018, 763, 751–760. [Google Scholar]

- Ramhormozian, S.; Clifton, G.C.; MacRae, G.A.; Davet, G.P. Stiffness-Based Approach for Belleville Springs Use in Friction Sliding Structural Connections. J. Constr. Steel Res. 2017, 138, 340–356. [Google Scholar] [CrossRef]

- Latour, M.; Santos, A.F.; Santiago, A.; Ferrante Cavallaro, G.; Piluso, V. Component Modelling of Low-Damage Beam-to-Column Joints Equipped with Friction Dampers. Structures 2022, 46, 1561–1580. [Google Scholar] [CrossRef]

- CEN EN1993:1–8; Eurocode 3: Design of Steel Structures: Part 1.8: Design of Joints, 2005. European Committee for Standardization: Bruxelas, Belgium, 1993.

- Zimbru, M.; D’Aniello, M.; Martino, A.D.; Latour, M.; Rizzano, G.; Piluso, V. Investigation on Friction Features of Dissipative Lap Shear Connections by Means of Experimental and Numerical Tests. Open Constr. Build. Technol. J. 2018, 12, 154–169. [Google Scholar] [CrossRef]

- ANSI/AISC 341-16; Seismic Provisions for Structural Steel Buildings. Seismic Provisions for Structural Steel Buildings. American Insititute of Steel Construction: Chicago, IL, USA, 2016; p. 60601.

- CEN EN 1998-1; Design of Structures for Earthquake Resistance-Part 1: General Rules, Seismic Actions and Rules for Buildings. European Committee for Standardization: Brussels, Belgium, 2004.

- Monaco, A. Numerical Prediction of the Shear Response of Semi-Prefabricated Steel-Concrete Trussed Beams. Constr. Build. Mater. 2016, 124, 462–474. [Google Scholar] [CrossRef]

- Colajanni, P.; La Mendola, L.; Monaco, A.; Spinella, N. Cyclic Behavior of Composite Truss Beam-to-RC Column Joints in MRFS. KEM 2016, 711, 681–689. [Google Scholar]

- Colajanni, P.; La Mendola, L.; Monaco, A. Stiffness and Strength of Composite Truss Beam to R.C. Column Connection in MRFs. J. Constr. Steel Res. 2015, 113, 86–100. [Google Scholar] [CrossRef]

- Colajanni, P.; Pagnotta, S.; Recupero, A.; Spinella, N. Shear Resistance Analytical Evaluation for RC Beams with Transverse Reinforcement with Two Different Inclinations. Mater. Struct. 2020, 53, 18. [Google Scholar] [CrossRef]

- Colajanni, P.; Recupero, A.; Spinella, N. Shear Strength Degradation Due to Flexural Ductility Demand in Circular RC Columns. Bull. Earthq. Eng. 2015, 13, 1795–1807. [Google Scholar] [CrossRef]

- ACI374.2R-13; Guide for Testing Reinforced Concrete Structural Elements under Slowly Applied Simulated Seismic Loads; American Concrete Institute Committee 374. ACI: Farmington Hills, MI, USA, 2013.

- Martinelli, P.; Mulas, M.G. An Innovative Passive Control Technique for Industrial Precast Frames. Eng. Struct. 2010, 32, 1123–1132. [Google Scholar] [CrossRef]

- Huang, L.; Zhou, Z.; Huang, X.; Wang, Y. Variable Friction Damped Self-Centering Precast Concrete Beam–Column Connections with Hidden Corbels: Experimental Investigation and Theoretical Analysis. Eng. Struct. 2020, 206, 110150. [Google Scholar] [CrossRef]

- CEN 15129; Anti-Seismic Devices. European Committee for Standardization: Brussels, Belgium, 2009.

- EN 1993-1-1; Eurocode 3: Design of Steel Structures: Part 1-1: General Rules and Rules for Buildings. European Committee for Standardization: Brussels, Belgium, 2005.

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Colajanni, P.; Ahmed, M.; Pagnotta, S.; Orlando, P. A Review of Friction Dissipative Beam-to-Column Connections for the Seismic Design of MRFs. Appl. Sci. 2024, 14, 2291. https://doi.org/10.3390/app14062291

Colajanni P, Ahmed M, Pagnotta S, Orlando P. A Review of Friction Dissipative Beam-to-Column Connections for the Seismic Design of MRFs. Applied Sciences. 2024; 14(6):2291. https://doi.org/10.3390/app14062291

Chicago/Turabian StyleColajanni, Piero, Muhammad Ahmed, Salvatore Pagnotta, and Pietro Orlando. 2024. "A Review of Friction Dissipative Beam-to-Column Connections for the Seismic Design of MRFs" Applied Sciences 14, no. 6: 2291. https://doi.org/10.3390/app14062291

APA StyleColajanni, P., Ahmed, M., Pagnotta, S., & Orlando, P. (2024). A Review of Friction Dissipative Beam-to-Column Connections for the Seismic Design of MRFs. Applied Sciences, 14(6), 2291. https://doi.org/10.3390/app14062291