1. Introduction

Higher education has faced a constant challenge since technological progress generates new applications that require greater knowledge in the handling, control, and even maintenance of equipment. This has generated the need to train highly trained and competent professionals who are able to meet the changing demands of society and industry. In this context, meaningful teaching emerges as a fundamental pedagogical approach that increases the potential to transform the way students acquire and apply knowledge in the workplace [

1,

2]. The application of meaningful teaching focuses on enabling a deep understanding of concepts and their applicability and not just on storing data, concepts, and facts. In engineering, professionals must be able to innovate with knowledge so that they can address the most pressing technical and technological challenges [

3]. For this reason, several studies focus on providing a comprehensive and updated view on meaningful teaching processes in higher education in engineering, highlighting their relevance in the training of engineers in the 21st century [

4,

5]. As industry and society evolve, it is imperative that higher engineering education adapts and embraces pedagogical approaches.

In this context, engineering education needs to adapt to the demands of an industry in constant transformation. The industrial revolution, driven by digitization and connectivity, demands the incorporation of advanced technologies to optimize production and management processes [

6,

7]. Among these, mention should be made of several research works focused on the implementation of virtual environments applying virtual reality, augmented reality, and even mixed reality [

8,

9,

10]. These allow for the simulation and visualization of the entire life cycle of a product or process, from design and connection to monitoring and control in real time. This enables more informed decision making, identification of inefficiencies, and risk reduction before implementation in the real world. In addition, virtual environments are critical for the education and training of workers in the new era of Industry 4.0, providing a safe space to acquire skills in technologies such as Artificial Intelligence (AI), the Internet of Things (IoT), and Advanced Automation (AA) [

11,

12,

13,

14]. Ultimately, virtual environments are a cornerstone in the successful adoption of Industry 4.0 by driving innovation, efficiency, and workforce readiness for the challenges of modern industry [

15,

16].

For this reason, the implementation of VR and AR environments is emerging as a pedagogical approach that promises to revolutionize the way students acquire and apply technical knowledge and practical skills [

17,

18,

19]. VR and AR have experienced significant advances in terms of hardware and software in recent years, enabling the creation of immersive and highly interactive learning environments [

15,

20]. These environments offer students the opportunity to experience and explore automation concepts in a virtual space that simulates real-world situations, providing a learning experience that transcends the limitations of traditional methods. The implementation of virtual environments has revolutionized the development of serious games for teaching industrial process automation, offering a highly interactive and immersive medium that significantly enhances the effectiveness of training [

21,

22]. These virtual environments allow students to immerse themselves in simulated environments that closely replicate industrial operations, giving them the opportunity to experience real-life situations hands-on without risk. In addition, gamification and real-time interaction through virtual environments motivate students and improve their participation and knowledge retention [

23,

24]. Likewise, the adaptability of these games allows learning to be personalized according to the needs of each student, which optimizes the teaching and learning process.

These strategies have become a key tool to enhance the teaching process in industry. By combining these technologies through the “Hardware in the Loop” (HIL) technique, a powerful synergy is achieved, which allows students to enter virtual environments that faithfully replicate real industrial scenarios [

18,

25]. By simulating and controlling physical systems in real time through HIL, students can experience practical situations, make decisions, and learn from their results safely and effectively. This strategy not only facilitates the acquisition of technical skills but also fosters a deeper and more practical approach to industrial education, preparing future professionals for real-world challenges [

26,

27]. The incorporation of HIL in the design phases of the industrial system represents a highly effective strategy to increase both the reliability and efficiency of the system, significantly increasing the value of the final product. This study addresses the structure and components of an HIL for the purpose of monitoring and controlling various processes in the industry, in addition to generating historical data and meaningful alarms [

28,

29].

In this context, the present work focuses on the conception and implementation of a Supervisory Control and Data Acquisition (SCADA) system with a Human–Machine Interface (HMI) that communicates effectively with a Programmable Logic Controller (PLC) to carry out operations in the industrial environment. In addition, the virtualization of an industrial environment will be developed, which complies with the real characteristics of its physical environment, using Unity 2023.1.0 software, which will allow interaction with the industrial devices of the SCADA system, effectively bringing students closer to the real environment and practical applications. This approach seeks to eliminate the existing barriers between the theoretical academic environments and the practical application in the industry. In this context, the processes are monitored and controlled using the OPC UA communication protocol. The SCADA data acquisition is stored in an Excel and Visual Basic template, allowing the customer to monitor and control all control modules simultaneously with the server. The communication will be performed in real time using the Ethernet protocol, a serial data transfer application widely used in several modern networks for its simplicity, reliability, and efficiency in data communication. This protocol, with its request–response approach implemented in a primary–secondary relationship, finds its application in industrial process manufacturing, where the human–machine interface (HMI) or SCADA system acts as primary, while the sensors play the role of secondaries or programmable logic controllers (PLC). All process software shares an identical processor module for connections, and a detailed description of how to establish the connection between the PLC, HMI, and Unity is given. In this work, the Ethernet module stands as an essential tool for efficient communication between devices and software.

2. Conceptualization

This section describes the methodology implemented to develop the teaching–learning process aimed at controlling industrial processes. For this purpose, a brewing process is considered, which combines innovation and effectiveness by integrating the HIL technique. With the purpose of combining theoretical knowledge in a controlled environment, improving the understanding of concepts of process control, manipulation and supervision. In addition, it facilitates the development of essential practical skills by simulating real industrial situations, effectively preparing students for the challenges of the working world. The work considers a brewing process that combines innovation and efficiency by integrating the HIL technique.

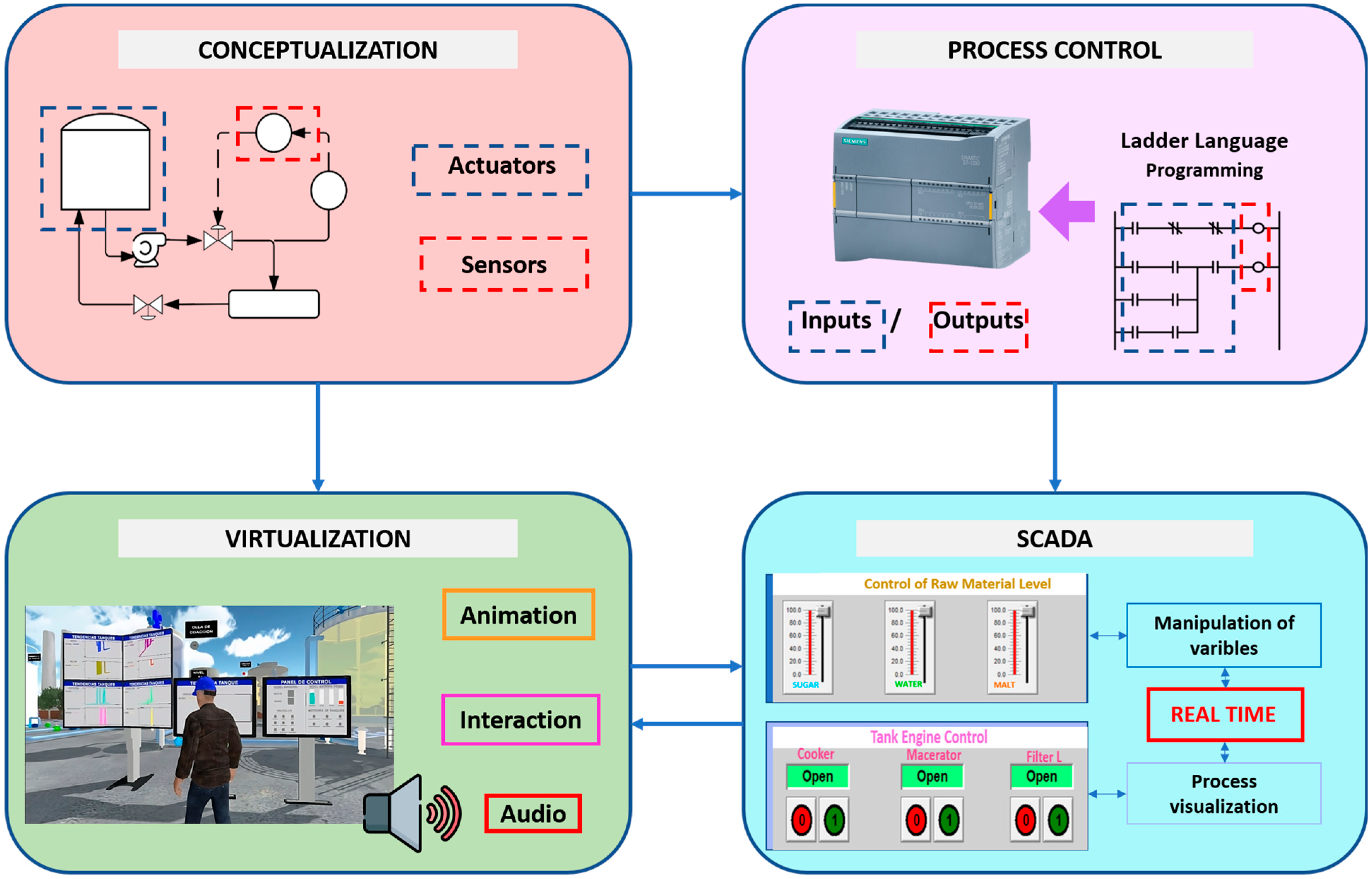

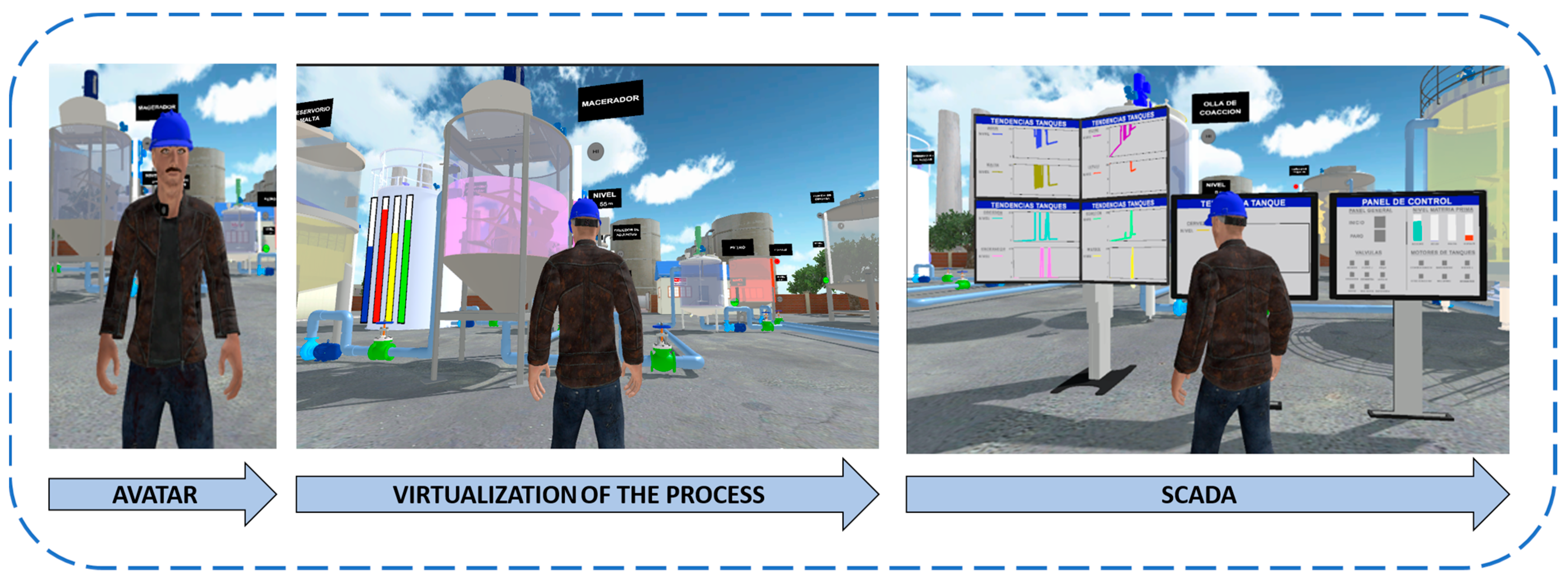

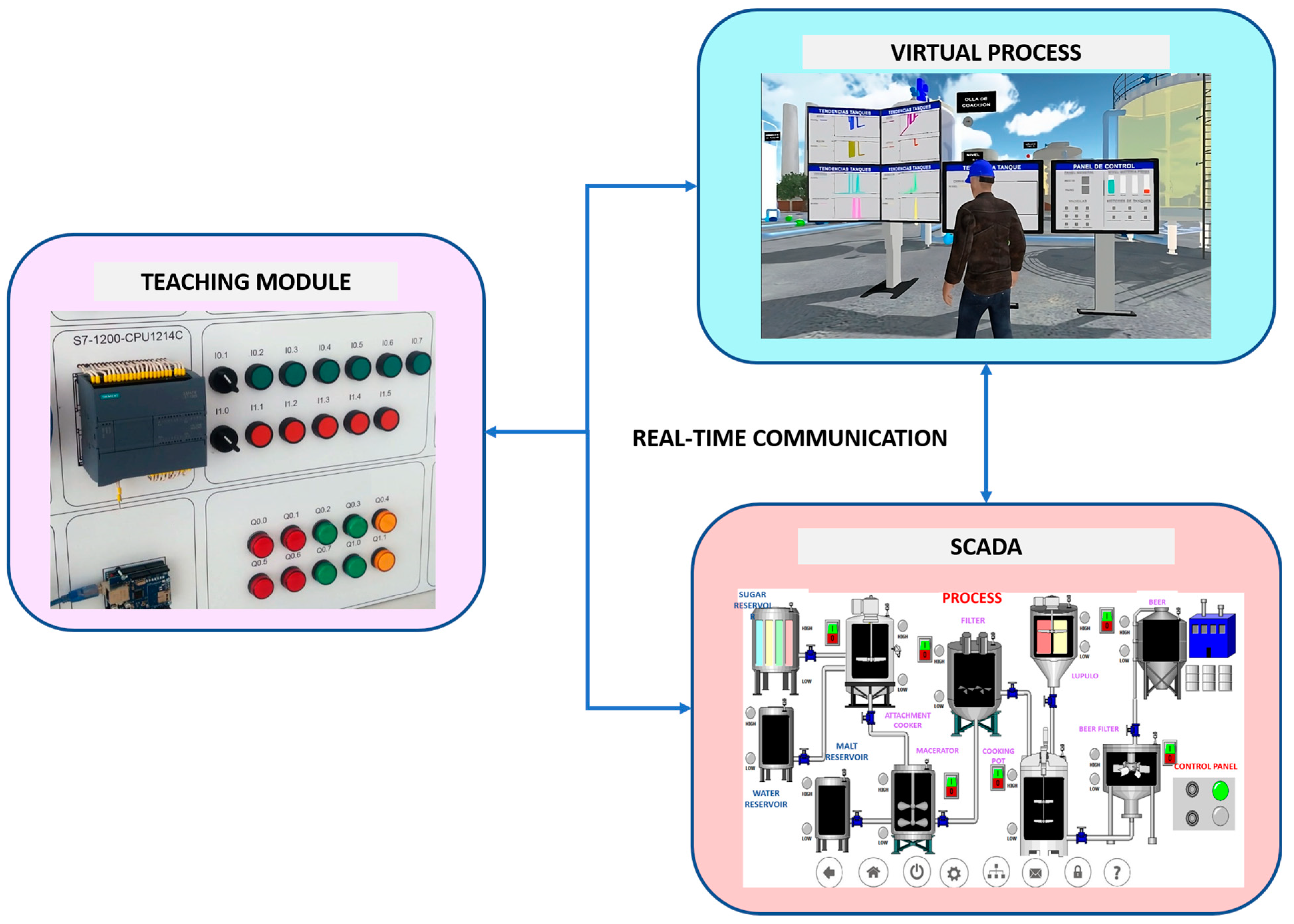

Figure 1 shows the stages of the implemented methodology, the purpose of which is to establish real-time communication between a didactic module, the SCADA system, and the virtualized process.

The stages developed are as follows: (i) Conceptualization of the process, a phase that allows the determination of the physical characteristics of the brewing. This considers the behavior of the actuators and sensors by means of the piping and instrumentation diagrams (PI&D). (ii) Process Control, based on the first phase, the automatic control of the process is programmed. This considers mixing times, brewing temperature, and amount of material for mixing. This phase is also implemented in (iii) Virtualization of the process, which considers the characteristics of the process elements in order to give realism to the system through the animation of the actuators and sensors. In addition, an avatar will be incorporated to allow interaction with the process, allowing the student to actively navigate with the virtual process, and finally (iv) SCADA system, which will provide students with a complete and real-time view of the industrial process. Because, it allows efficient monitoring of critical variables, real-time data analysis and identification of potential problems. This hands-on, visual approach enhances understanding of industrial control concepts and prepares students to address work-world situations more effectively. Fusion allows engineering students to navigate actively through a hands-on and stimulating learning environment. Students can apply theories and concepts in a realistic scenario, adjust parameters in real time, and evaluate the results, which enhances their understanding of control processes and their ability to troubleshoot real-world situations. The combination of the physical and virtual in this methodology provides students with an enriching learning experience geared toward the acquisition of essential practical skills in the field of control engineering. In addition, this interaction allows the development of new meaningful teaching strategies, where the student is allowed to see the behavior of a real process without generating failures in the system or suffering some kind of incident in the development of the work.

3. Structure of the Process

This section describes the stages considered for the development of a teaching–learning process that applies the HIL technique, which allows for the implementation of the control in the Tia Portal v16 software. The visualization and manipulation in InTouch are performed in order to communicate with the virtualized process and the didactic module formed by a PLC s7-1200. The development is based on the brewing process and is divided into three main sections: (i) Process control, which requires knowing the characteristics of the brewing process in order to determine the actuators and transducers required to manipulate, control, and visualize the industrial process and finally; (ii) Virtualization, which describes the methodology implemented to virtualize the industrial brewing process.

3.1. Development of the Supervision, Control and Data Adquisition System (SCADA)

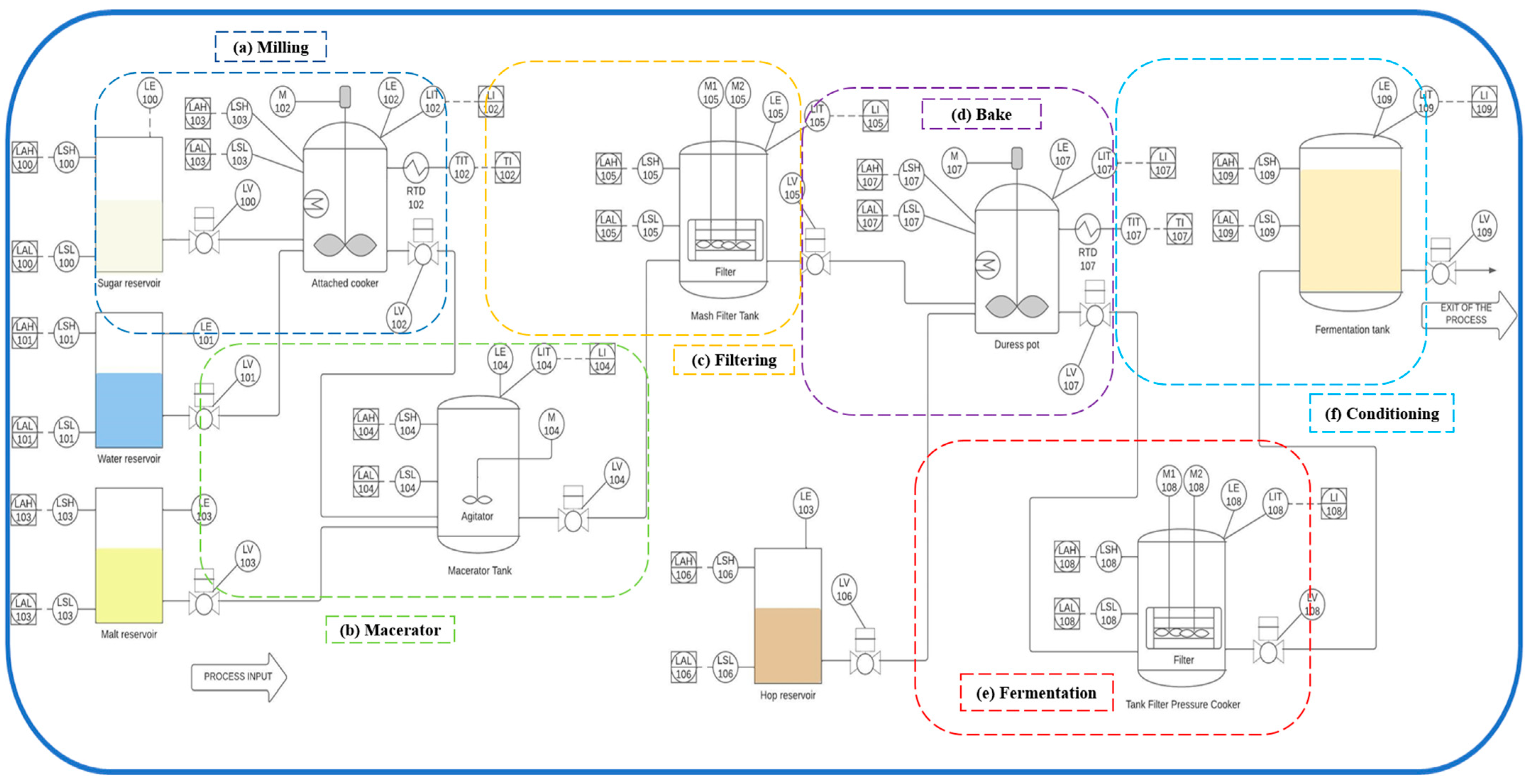

The implementation and development of the SCADA system are based on the P&ID diagram shown in

Figure 2.

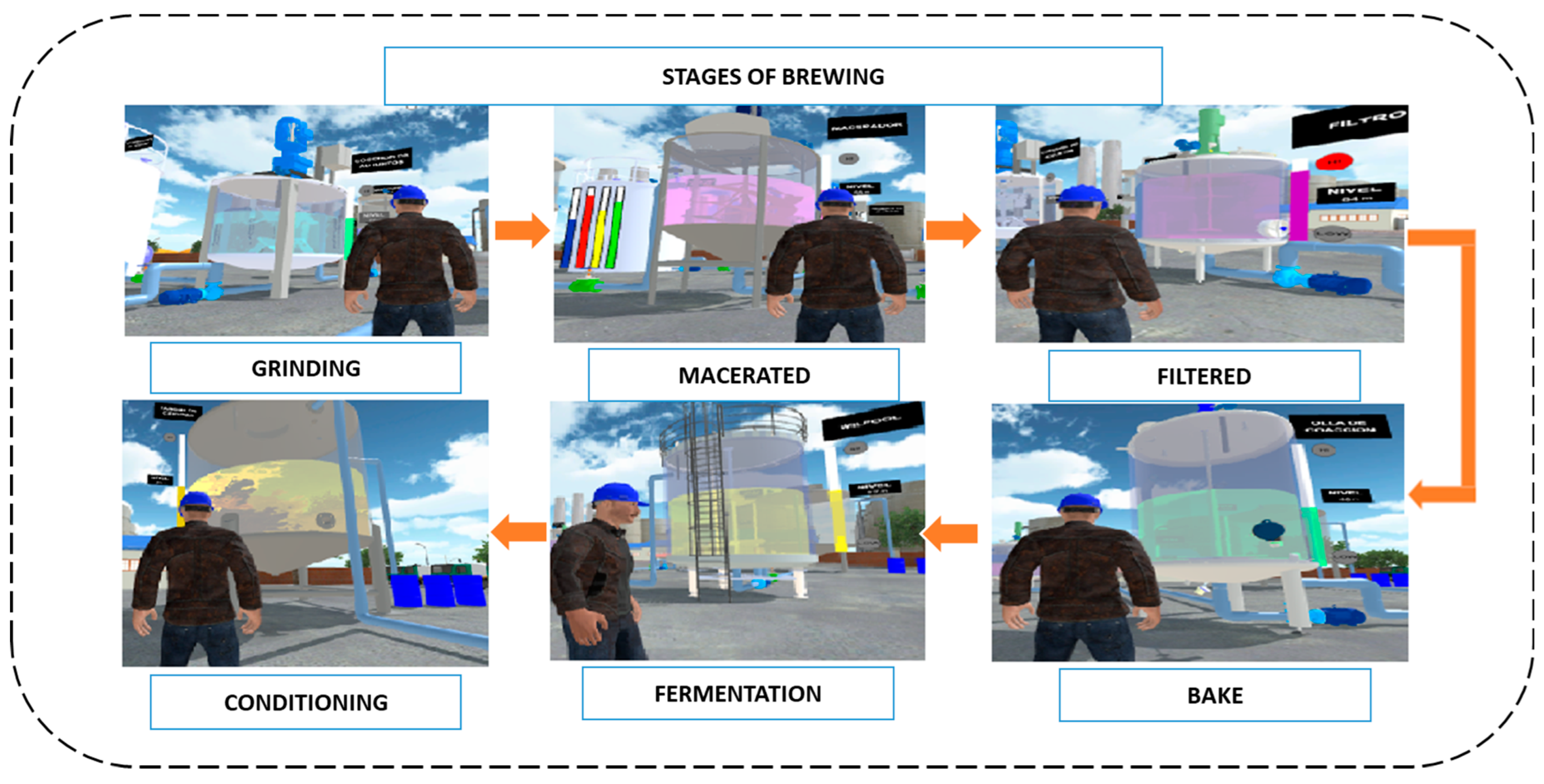

The process is divided into six stages: (i) Milling or boiling, which consists of incorporating the raw material, malted barley grains, water and adjuncts to generate a homogeneous liquid; (ii) Maceration, the malt is mixed with water at different times and temperatures, producing the necessary transformations to convert the starch into fermentable sugars; (iii) Filtering, responsible for separating the remains of malt from the liquid worth; (iv) Boiling, the liquid resulting from the filtrate is mixed with the hops at a temperature of 100 °C to provide the bitterness and aroma present in the hops, which will determine the alcohol content of the beer; (v) Fermentation, the yeast is added to the mixture to convert the sugar into alcohol and CO2, which must remain at a constant temperature for a period of two weeks to finally separate the remains of yeast; (vi) Conditioning, a carbonation process is carried out on the mixture resulting from fermentation and filtering at low temperatures, where we will obtain our final product.

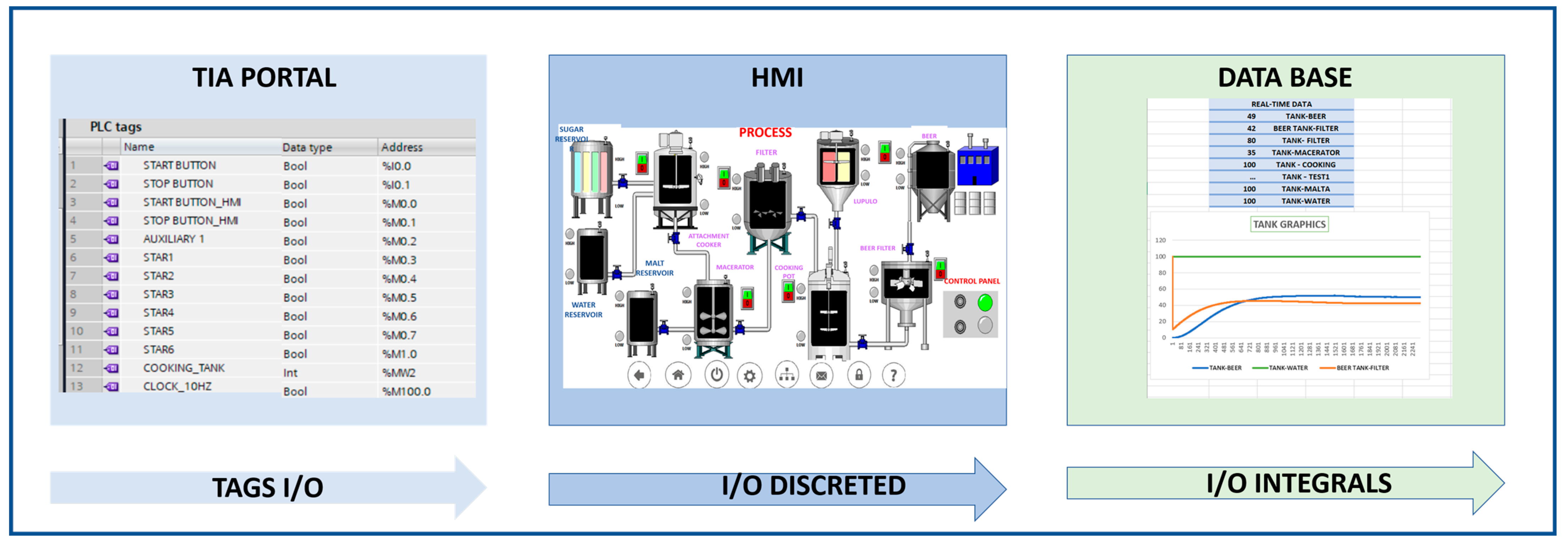

The SCADA system consists of six screens, illustrated in

Figure 3, which was developed in the InTouch 10.0.0.1 software and allows the manipulation and visualization of the process operation. The screens are as follows: (a) Welcome, allows access to all interface windows through a user and password, granting rights according to the type of user; (b) Process, this screen displays the stage of the process in real time, also allows graphic display of all system components and access to controls and indicators; (c) Control Panel, allows to control the behavior of all the valves and motors present in the interface; (d) Trends, there is also the general stop of the process; (e) History, shows the alarms and alarms of unusual events that may occur at any stage of the brewing process; (f) Help, which finally shows a total description of all the components and elements of the process.

In addition, the operating data of the beer brewing process are saved in order to maintain a record that allows for determining the type and frequency of maintenance required by the process. The data are sent through labels considering the inputs, outputs, and marks present in the programming; the program developed in InTouch can read all the labels assigned by the OPC as discrete input–output type variables sent by the TIA Portal. To store the data in Excel, it is required to assign a different type of data; the types of variables that are sent to the different software are shown in

Figure 4.

Excel can only read integral input–output type data. For this reason, it is through a script that the discrete I/O and integral I/O type variables are combined, and the sampling time in which it will be saved is defined information. Moreover, a file, xlsm, stores the data; it must be linked with all the variables of the InTouch script in order to acquire the process data. It is recommended to configure the cells to which the date and time, temperature, levels, and alarm status will be assigned, considering interaction with the process in real time. Finally, the information obtained can be used to generate trend graphs that allow the management level to define its quality and production level.

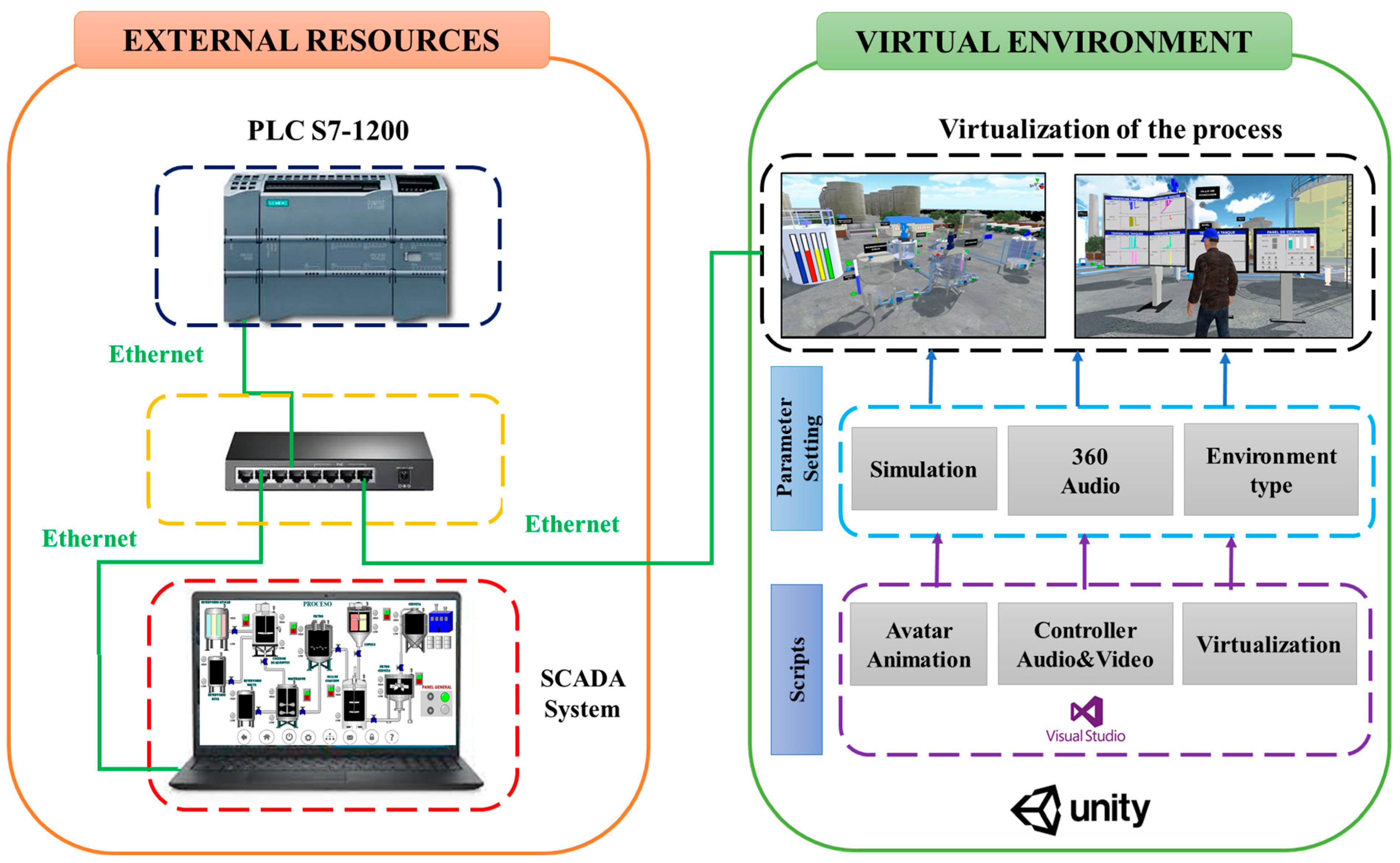

3.2. Process Virtualization

The virtualization of the beer production process is developed in order to create a teaching–learning environment that allows the student to have active navigation. That is, the student will be able to visualize the operation of the process and also have control of the variables of the process, allowing him to make decisions of the operation and production for which it is considered: (i) External resources, the same that performs the automatic control and visualization of the process. They have a PLC s7-1200, an ethernet module, and a SCADA system that allows the user to control the system physically and (ii) A virtual environment, which presents the stages of production of the beer virtually through the configuration of parameters and scripts in Visual Studio. Learning environments are developed in Unity 3D, and several tools and knowledge are necessary to create an environment that is as close to reality as possible so that the actual physical characteristics of the process are considered. That is to say, an Avatar is created that allows interaction with the process, which must have a similarity with a real process. For this purpose, texturization of the elements is used, as well as surround audio, the animation of the actuators, and the transducers of the process.

Figure 5 shows the communication between the external resources and the virtual environment through the Ethernet protocol.

The development of the virtual environment is carried out in the Unity 3D software, which allows working with virtual reality and augmented reality, among other applications. The virtualization of the development process consists of the following steps: (i) Creation of the avatar. It must be imported into Unity 3D as an FBX or COLLADA model file, which is the file of the humanoid. In this case, it is a character with the characteristics of an operator. For the animation of the avatar, the base must be structured by updating the rig of the imported model, which allows animation like this so that the avatar can perform the movements of the plant operator. (ii) Virtualization of the process. For the virtualization of the selected industrial process, the scenario is implemented, which is a factory where all the elements necessary for the implementation of the plant are incorporated, such as tanks, pipes, valves, motors, and indicators, among others, the same ones that have animation, sound with the purpose of generating realism in their operation. (iii) Implementation of SCADA, with the objective of presenting trends in the operation of the process. It also allows the student to know the variables with which the process is operating and finally allows the manipulation of the system.

Figure 6 shows the interaction between the virtualized agents, which have a behavior similar to external resources.

4. Communication

System integration for process automation promoted the technologies of accessing functions and data from the field device, controller, and SCADA system. In addition, the archived device data can be applied to solve the diagnosis and preventive maintenance of the devices. This paper describes the practical technique to configure and implement the control and SCADA system that focuses on the integration of the field device, a PLC controller, and a SCADA system.

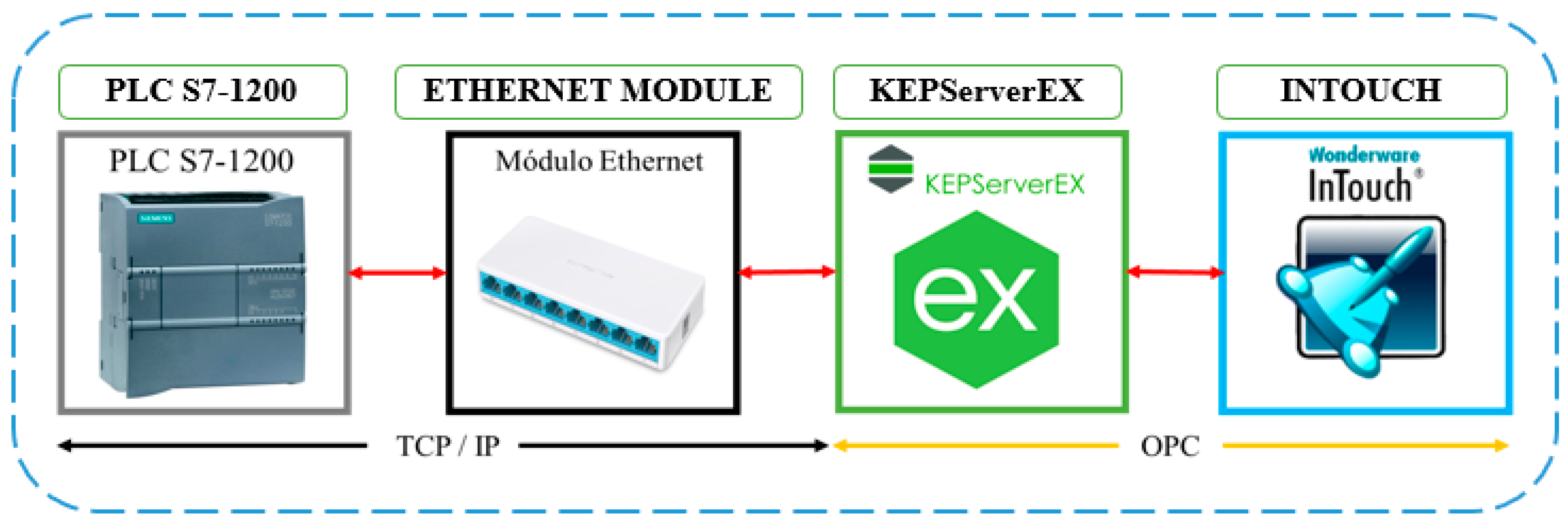

4.1. Communication between the PLC and SCADA

Process control communication requires two types of communication: (a) The Ethernet TCP/IP protocol, which is responsible for sending and receiving data from the PLC to the software that will process the information, and (b) the OPC protocol, which allows having a client-server dialogue, its function is to send or request data in real time, such as sensor readings, device states, or any other relevant information. As shown in

Figure 7, the communication consists of the following elements: (i) Siemens S7 1200 PLC, which executes the program previously written in its memory, transferred from the Tia Portal v16 software. (ii) Ethernet module, used to act as an interface between the PLC and InTouch. This device allows you to create a virtual communication interface to connect the simulation to the network. (iii) KEPServerEX facilitates project development using a server interface. This interface is independent of the type of system. Therefore, it allows communication between devices, facilitating the centralization of communication and realization for users. (iv) Wonderware software works as SCADA, which means it controls, monitors, stores, and accesses data.

On the other hand, for the KEPServerEX server configuration, devices were added to the communication protocol. The read and write variables are configured for each device; it should be mentioned that the types of variables are important. Due to the use of marked or unmarked addresses, care must be taken, and the defined variables must be selected from the addresses assigned to the PLC global variables. The KEPServerEX tool establishes the link between the physical interface network and the PLC instance. The Wonderware InTouch software via OPC connects to the S7-1200 PLC. To connect to the PLC from the development station, you only need to connect to the Alias assigned to the PLC from KEPServerEX.

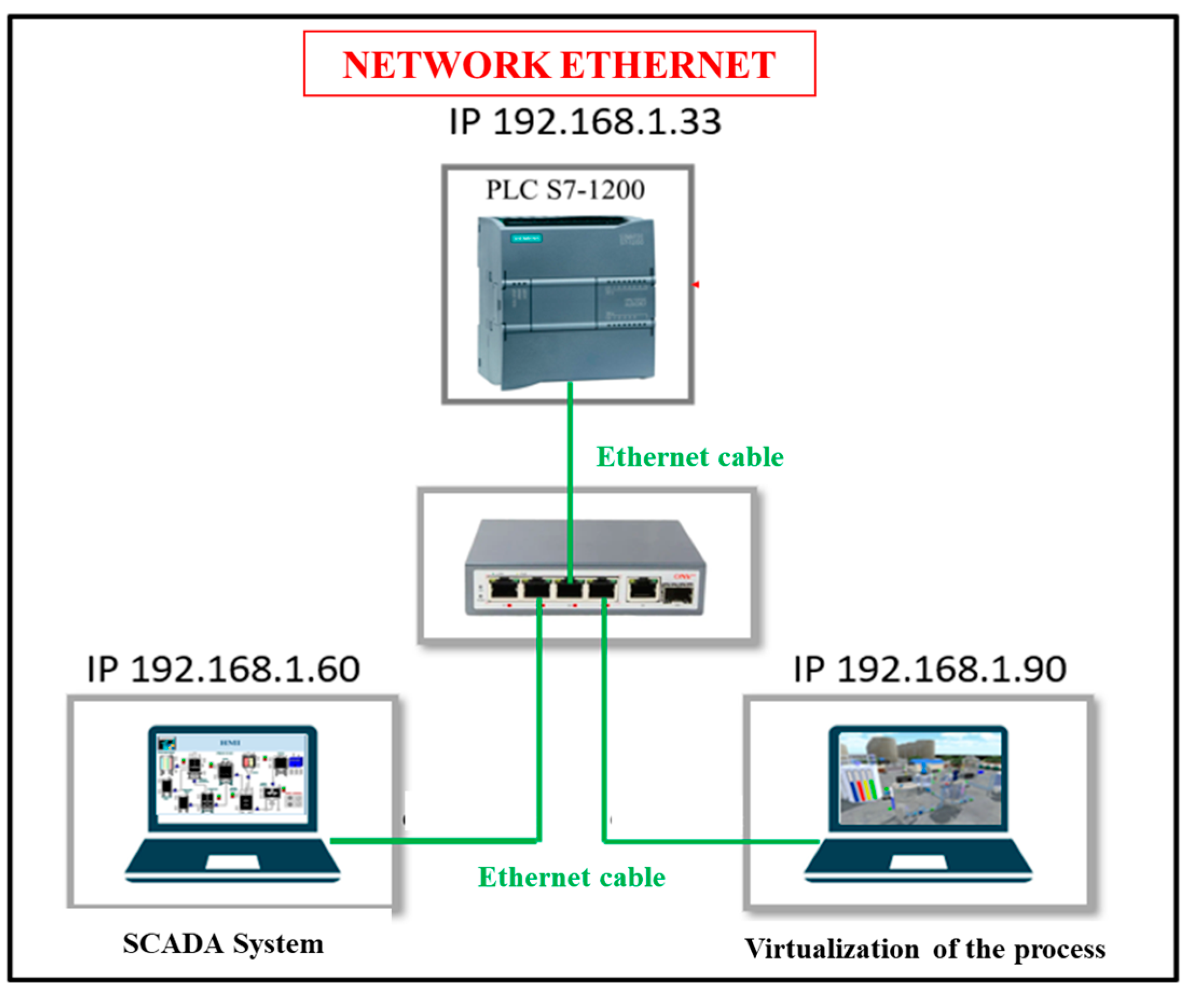

4.2. Ethernet Communication between PLC, SCADA, and Virtual Environment

The interconnection between the PLC, the SCADA, and the virtual environment of the brewing process in Unity is carried out through a LAN network. For this purpose, a SWITCH was used, which allows different devices to be connected to the network through the Ethernet cable. To carry out the communication, it was necessary to configure the IP addresses of the different devices within the same subnet. In

Figure 8, a LAN network is seen with an RJ45 physical medium cable using the Ethernet communication protocol.

5. Experimental Design

This section presents the experimental design considered to determine the functionality of the teaching–learning tool using the HIL technique for Automation Engineering students. The proposed tool is evaluated in order to determine the effectiveness and degree of active interaction of the student with the work environment during the learning process, where it is considered that the communication between the virtual environment and the control system interact in real time. It is essential to highlight that the transmission time of sending and receiving information becomes a relevant aspect of this dynamic. The validation of the virtualization of the brewing process is based on the successful implementation, efficiency, and functionality of this real-time communication.

The inclusion of HIL technology in this context not only ensures effective interaction between software and hardware but also significantly enriches the teaching process. By allowing students to experiment with real systems in a controlled and safe environment, HIL provides invaluable hands-on experience that complements the theory taught in the classroom. This not only strengthens the understanding of theoretical concepts but also prepares students to face real-world challenges in the field of Automation Engineering. In this context, the experimentation of the behavior of the teaching–learning tool was developed. Furthermore, an evaluation of the system that considers the usability of the system and the level of user satisfaction is presented.

In this context, it is considered to evaluate the effectiveness and usability of the proposed teaching–learning tool through the participation of a group of 20 students of Electronic Engineering and Automation, all belonging to the seventh semester of their studies. These students have successfully completed the Industrial Automation course, acquiring specialized knowledge in the programming of industrial processes using PLCs.

Table 1 details the demographic diversity of this specific population, highlighting aspects such as experience in PLC programming and level of technical skills, crucial elements for the detailed evaluation of the tool.

5.1. System Interaction Assessment

When the student interacts with the beer brewing process, he will do so with active navigation. That is, the student will visualize the operation in real time, and it also allows him to make decisions about the behavior of the process. That is, in the event of abnormal events, the student will be able to stop and modify the process variables so that the work is carried out appropriately.

The interaction with the process is presented in a friendly and understandable way, allowing the user to interact with the process and the system trends. The student’s active navigation in the virtual environment is associated with static and dynamic elements that exist in this environment. Static elements, as their name indicates, appear in the simulation, representing a specific object, but do not offer any movement in their simulation. They appear throughout the duration of the simulation. The dynamic elements associated with a Boolean variable produce movement during the simulation. The dynamism will depend on the object. That is, they will produce a more real dynamism in the process, creating an immersed virtual environment, as shown in

Figure 9.

Two elements are considered to start the virtualized beer brewing process. The first is an avatar, which was developed with the purpose of emulating the physical action of the operator and providing realism to the process. The second is a virtualized HMI, whose objective is to monitor, visualize, and control the variables of interest as if it were a real graphical interface. From this central screen, you can start and stop the virtualized process.

The bilateral operation test is carried out through the start and stop buttons of the SCADA system while verifying that there is communication between the HMI of the virtual environment and the teaching module. That is, when the start and stop lights of the teaching module are turned on, the process replicates the information in the SCADA system or vice versa. Furthermore, in the event of an emergency situation or failure in the process, the process can be stopped, as can be seen in

Figure 10. Bilateral communication is due to the fact that there is a connection link between the variables of our process both in the SCADA system and in the virtualized environment.

After starting the process, the simulation and visualization of the six stages corresponding to the production process for brewing beer immediately begins, as illustrated in

Figure 11. In the figure, an industrialized virtual environment is evident, with large-scale tanks, valves and realistic pipes, industrial sensors, and actuators, filling sound in the tanks, and colors in the liquids for a visualization of the behavior at each stage, among other things that can be observed, heard and analyzed by the user interacting with the virtualized environment.

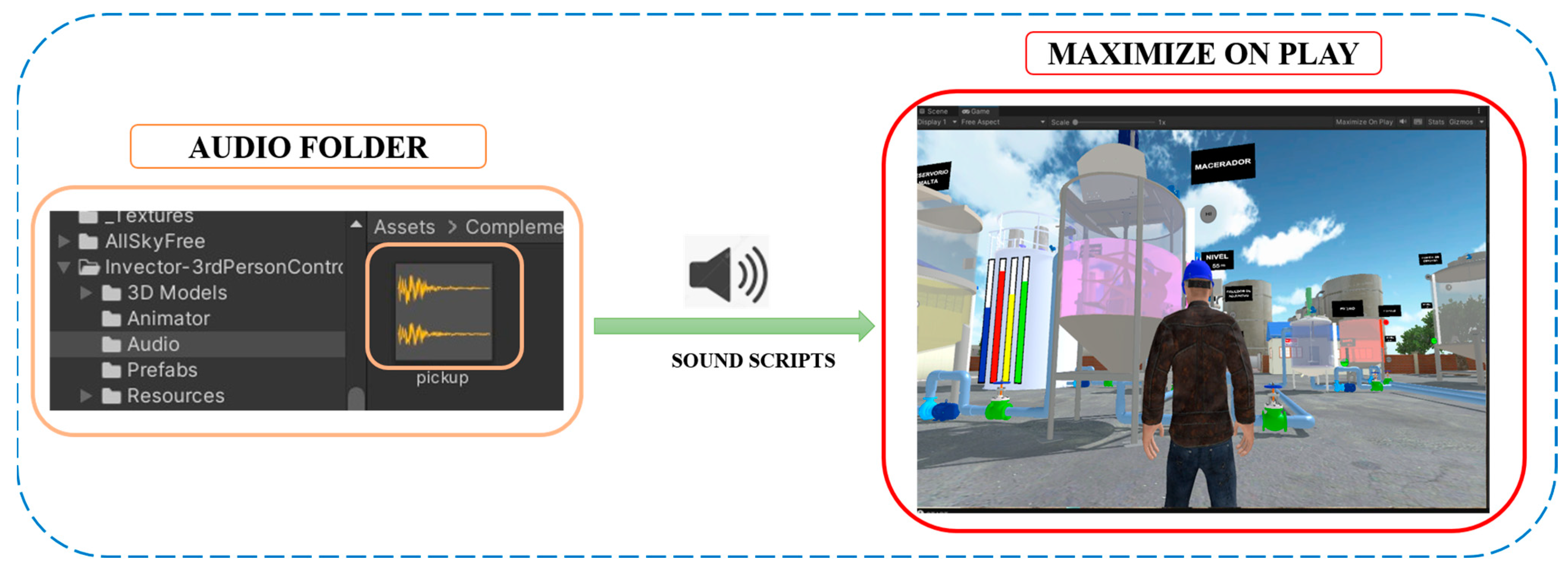

In order to improve the student’s interaction with the virtualized process, a sound immersion is implemented. The same will be found in the different stages of the process, e.g., the sound of a tank being filled or emptied, the activation of pumps, and the flow of liquid, among others. The sound interaction shown in

Figure 12 is performed by adding a specific folder for audio, where the previously saved sounds are played. These files must be in mp3 format with a collection name. When entering the sound into the folder, scripts are made in Visual Studio, and a sound variable is created to have a sound interaction in the process. You can see if there is sound in any element when the sound symbol or the Maximize in Playback ID appears.

The results of this study highlight the observations and conclusions derived from the implementation of real-time communication between the process controller, an S7-1200 PLC, and the virtual environment of the brewing process, together with the SCADA system as illustrated in

Figure 13. In the field of developing teaching-learning systems for industrial process control, the implementation of the SCADA system based on the OPC protocol, linked with an S7-1200 PLC, has proven to be essential. The use of InTouch as a SCADA interface provides an interactive and visual platform to monitor and control key variables in real time. In addition, the integration of scripts and programming logic allows efficient data acquisition from the PLC, facilitating the transmission of real-time information. For subsequent analysis, direct connection to Microsoft Excel is established through specialized tools or data export to CSV files (Comma-Separated Values), offering a comprehensive and effective solution for data collection and management in the teaching-learning process. In this context, the efficiency of the system is accentuated by the optimized communication time provided by the OPC protocol, which enables fast and reliable data transfer between the SCADA and the S7-1200 PLC. The use of this protocol contributes significantly to real-time response, crucial for accurately simulating industrial operations. In addition, the system efficiently handles various types of data, including analog and digital variables, by structuring and transmitting complex information. This versatile approach adapts to the diversity of data present in industrial processes, providing students with a comprehensive and realistic experience that addresses the complexity inherent in modern industrial environments.

The experimentation demonstrated successful and synchronized interaction between the controller and the virtual environment, which allowed data generated by sensors and actuators to be accurately reflected in real time. This two-way communication allowed the engineering students not only to observe the industrial process but also to intervene in it. Through the programs developed, students were able to control and manipulate the system, providing them with the opportunity to apply control theories and concepts in a practical environment. This approach proved valuable in improving students’ understanding of industrial processes and provided them with hands-on experience that fostered the development of engineering skills. In summary, the results indicate that the successful implementation of this real-time teaching–learning methodology holds promise for the training of future engineers in the field of industrial process control.

5.2. System Usability Testing

The evaluation of the usability of the proposed teaching–learning tool makes it possible to determine the effectiveness and usefulness of the system. The innovative integration between the virtual environment and the physical plant using HIL provides students of Electronics and Automation Engineering with hands-on experience in industrial process control and automation. In order to determine the usability of the system, the SUS (System Usability Scale) test is used to measure the user experience in terms of clarity and logic of the system, for which questions related to the interaction of the work environment detailed in

Table A1. are considered [

30]. This method obtained a very acceptable response, with an acceptance rate of 85% among the participants. The positive user acceptance, reflected in a high degree of satisfaction, underlines the positive impact of this approach on practical and meaningful learning. In terms of usability, the results indicate that the real-time connection has been valuable for understanding theoretical concepts. The intuitive interface and control capabilities have facilitated the adoption of the system, contributing to the learning objectives.

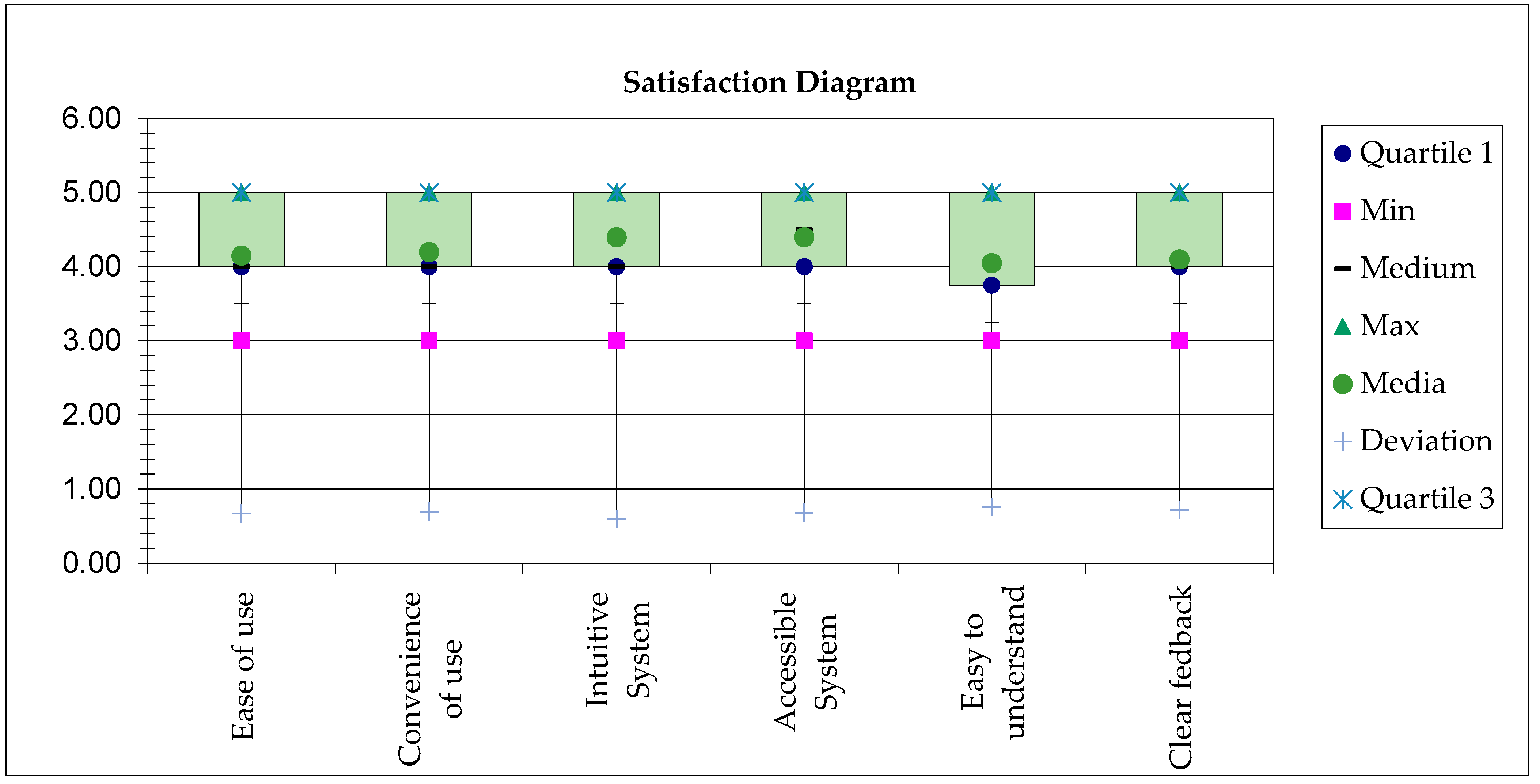

5.3. System Satisfaction Testing

Figure 14 shows in detail the results derived from the evaluation of the satisfaction of the proposed teaching–learning process for what is considered the interactive brewing system [

31]. This comprehensive analysis focused on six key aspects—ease of use, comfort of use, intuitive system, accessible system, ease of understanding the information, and clarity of information—evaluated by a group of 20 students. The results reveal an overall positive perception, where ease of use scored a mean of 4.15 (standard deviation of 0.67), indicating a friendly interaction. Comfort of use achieved a mean score of 4.20 (deviation of 0.7), reflecting a comfortable and satisfactory experience. System intuitiveness received a rating of 4.40 (deviation of 0.60), highlighting its easy comprehension. Accessibility, with a mean of 4.40 (deviation of 0.68), demonstrated a smooth user experience. Ease of understanding the information scored 4.05 (deviation of 0.76), indicating a clear and understandable presentation. Although slightly lower, clarity of information maintained an acceptable score of 4.10 (deviation of 0.72). These consolidated findings provide a comprehensive assessment of student satisfaction, highlighting strengths and pointing out areas for possible improvement, thus contributing to the ongoing optimization of the interactive brewing system.

6. Discussion and Conclusions

The teaching-learning tool proposed to address the control, manipulation and supervision of an industrial process for students of Electronic and Automatic Engineering has generated promising responses. Due to the active interaction of the students with the work environment, the effectiveness and usefulness of the proposed tool has been demonstrated, which establishes an innovative connection between the virtual work environment, the SCADA supervision system and the didactic module that represents the physical part of the industrial process through the HIL technique. Bi-lateral communication between the hardware and the software that controls the system significantly benefits the teaching-learning process by providing students with practical and applied experience in the field of industrial control and automation.

The work environment offers a significant teaching method, due to the incorporation of the SCADA System, which allows real-time supervision and direct control of key variables. The real-time connection between the virtual environment and the physical plant becomes a valuable tool for a deep understanding of theoretical concepts, offering students the opportunity to directly experience in control principles in a simulated industrial environment. In terms of working time, the SCADA system stands out for its efficiency in data management and transmission. The implementation of the OPC protocol ensures fast and reliable communication between the SCADA and the S7-1200 PLC, optimizing synchronization and information exchange. This protocol, recognized for its robustness in industrial environments, contributes to the fluidity of the system, allowing real-time interaction that is crucial for the accurate simulation of industrial operations. Furthermore, the successful convergence between the virtual world and the physical plant in real time is presented as a significant and contextualized approach for learning complex industrial processes.

On the other hand, the feedback obtained in terms of satisfaction and usability has yielded encouraging conclusions. The wide acceptance by users, reflected in a considerable degree of satisfaction, demonstrates the effectiveness of the implemented methodology. The usability of the system, evaluated through navigation, interactivity and feedback, has been rated as acceptable by users. The intuitive interface and control capabilities provided have facilitated the adoption of the system, contributing significantly to the achievement of the proposed learning objectives. Taking into account the inherent advantages of working in virtual environments, such as flexibility, security and the possibility of simulating different scenarios, this work lays the foundation for the continued development of teaching methodologies in the field of engineering.

However, it is important to complement this significant teaching process with practical activities at an industrial level, which allow students to interact with equipment for their respective control and manipulation. Given these encouraging results, future work will focus on continued usability optimization by incorporating user feedback for specific adjustments. In addition, new functionalities and interface improvements will be explored with the aim of offering an even more enriching experience. Two-way communication between the virtual world and the physical plant in real time lays the foundation for the continued development of teaching methodologies in the field of engineering, providing an innovative and effective approach to training students in this constantly evolving field.

Author Contributions

Conceptualization, J.S.O., R.S.P., J.A.Y. and M.M.R.; methodology, J.S.O.; software, R.S.P. and J.A.Y.; validation, J.S.O., R.S.P. and J.A.Y.; formal analysis, J.S.O.; investigation, J.S.O., R.S.P. and J.A.Y.; resources, J.S.O.; data curation, R.S.P. and J.A.Y.; writing—original draft preparation, J.S.O., R.S.P., J.A.Y. and M.M.R.; writing—review and editing, J.S.O. and M.M.R.; visualization, J.S.O., R.S.P. and J.A.Y.; supervision, J.S.O.; project administration, J.S.O. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data presented in this study can be consulted by mailing to the author.

Acknowledgments

The authors would like to thank the Universidad de las Fuerzas Armadas ESPE and the ARSI Research Group for their support in developing this work.

Conflicts of Interest

The authors declare no conflict of interest.

Appendix A

Table A1.

Usability testing of interaction with the brewing process.

Table A1.

Usability testing of interaction with the brewing process.

| No. | Questions | Score |

|---|

| 1 | Do I think I would like to use this system frequently? | 4 |

| 2 | I found the system unnecessarily complex. | 2 |

| 3 | I think the system is easy to use. | 5 |

| 4 | I think I would need the help of a knowledgeable person to be able to use this system. | 1 |

| 5 | I found the functions of the system to be very well integrated. | 4 |

| 6 | I think the system was difficult to use. | 2 |

| 7 | I imagine that most people would learn to use this system very quickly. | 4 |

| 8 | I found the system very complicated. | 1 |

| 9 | I felt confident using the system. | 5 |

| 10 | I would need to learn a lot of things before I could use this system. | 2 |

References

- Mentzer, N.; Lee, W.; Jackson, A.; Bartholomew, S. Learning by Evaluating (LbE): Promoting Meaningful Reasoning in the Context of Engineering Design Thinking Using Adaptive Comparative Judgment (ACJ). Int. J. Technol. Des. Educ. 2023, 2023, 1–25. [Google Scholar] [CrossRef]

- Wankat, P.C.; Felder, R.M.; Smith, K.A.; Oreovicz, F.S. The Scholarship of Teaching and Learning in Engineering. In Disciplinary Styles in the Scholarship of Teaching and Learning; Routledge: London, UK, 2002; ISBN 978-1-00-344426-8. [Google Scholar]

- Lutz, B.; Paretti, M.C. Exploring the Social and Cultural Dimensions of Learning for Recent Engineering Graduates during the School-to-Work Transition. Eng. Stud. 2021, 13, 132–157. [Google Scholar] [CrossRef]

- Abad-Segura, E.; González-Zamar, M.-D.; Luque-de la Rosa, A.; Morales Cevallos, M.B. Sustainability of Educational Technologies: An Approach to Augmented Reality Research. Sustainability 2020, 12, 4091. [Google Scholar] [CrossRef]

- Duarte, M.L.; Santos, L.R.; Guimarães Júnior, J.B.; Peccin, M.S. Learning Anatomy by Virtual Reality and Augmented Reality. A Scope Review. Morphologie 2020, 104, 254–266. [Google Scholar] [CrossRef] [PubMed]

- Fuertes, J.J.; Prada, M.Á.; Rodríguez-Ossorio, J.R.; González-Herbón, R.; Pérez, D.; Domínguez, M. Environment for Education on Industry 4.0. IEEE Access 2021, 9, 144395–144405. [Google Scholar] [CrossRef]

- Oztemel, E.; Gursev, S. Literature Review of Industry 4.0 and Related Technologies. J. Intell. Manuf. 2020, 31, 127–182. [Google Scholar] [CrossRef]

- Sharma, A.; Mehtab, R.; Mohan, S.; Mohd Shah, M.K. Augmented Reality—An Important Aspect of Industry 4.0. Ind. Robot Int. J. Robot. Res. Appl. 2021, 49, 428–441. [Google Scholar] [CrossRef]

- Reljić, V.; Milenković, I.; Dudić, S.; Šulc, J.; Bajči, B. Augmented Reality Applications in Industry 4.0 Environment. Appl. Sci. 2021, 11, 5592. [Google Scholar] [CrossRef]

- Salah, B.; Abidi, M.H.; Mian, S.H.; Krid, M.; Alkhalefah, H.; Abdo, A. Virtual Reality-Based Engineering Education to Enhance Manufacturing Sustainability in Industry 4.0. Sustainability 2019, 11, 1477. [Google Scholar] [CrossRef]

- Roldán, J.J.; Crespo, E.; Martín-Barrio, A.; Peña-Tapia, E.; Barrientos, A. A Training System for Industry 4.0 Operators in Complex Assemblies Based on Virtual Reality and Process Mining. Robot. Comput. Integr. Manuf. 2019, 59, 305–316. [Google Scholar] [CrossRef]

- Damiani, L.; Demartini, M.; Guizzi, G.; Revetria, R.; Tonelli, F. Augmented and Virtual Reality Applications in Industrial Systems: A Qualitative Review towards the Industry 4.0 Era. IFAC-Papers 2018, 51, 624–630. [Google Scholar] [CrossRef]

- Morgan, J.; Halton, M.; Qiao, Y.; Breslin, J.G. Industry 4.0 Smart Reconfigurable Manufacturing Machines. J. Manuf. Syst. 2021, 59, 481–506. [Google Scholar] [CrossRef]

- Vrontis, D.; Christofi, M.; Pereira, V.; Tarba, S.; Makrides, A.; Trichina, E. Artificial Intelligence, Robotics, Advanced Technologies and Human Resource Management: A Systematic Review. Int. J. Hum. Resour. Manag. 2022, 33, 1237–1266. [Google Scholar] [CrossRef]

- Tapia, D.; Illescas, D.; Santamaría, W.; Ortiz, J.S. Wine Production through Virtual Environments with a Focus on the Teaching–Learning Process. Appl. Sci. 2023, 13, 10823. [Google Scholar] [CrossRef]

- Pogo, S.I.; Arias, J.F.; Andaluz, V.H. Control of the Malt Mashing and Boiling Process in Craft Beer Production: Hardware-in-The-Loop-Technique. In Proceedings of the Augmented Reality, Virtual Reality, and Computer Graphics; De Paolis, L.T., Arpaia, P., Bourdot, P., Eds.; Springer International Publishing: Cham, Switzerland, 2021; pp. 701–716. [Google Scholar]

- Ipiales, J.S.; Araque, E.J.; Andaluz, V.H.; Naranjo, C.A. Virtual Training System for the Teaching-Learning Process in the Area of Industrial Robotics. Electronics 2023, 12, 974. [Google Scholar] [CrossRef]

- Villarroel, A.; Toapanta, D.; Naranjo, S.; Ortiz, J.S. Hardware in the Loop Simulation for Bottle Sealing Process Virtualized on Unity 3D. Electronics 2023, 12, 2799. [Google Scholar] [CrossRef]

- Peres, R.S.; Jia, X.; Lee, J.; Sun, K.; Colombo, A.W.; Barata, J. Industrial Artificial Intelligence in Industry 4.0—Systematic Review, Challenges and Outlook. IEEE Access 2020, 8, 220121–220139. [Google Scholar] [CrossRef]

- Ortiz, J.S.; Palacios-Navarro, G.; Andaluz, V.H.; Guevara, B.S. Virtual Reality-Based Framework to Simulate Control Algorithms for Robotic Assistance and Rehabilitation Tasks through a Standing Wheelchair. Sensors 2021, 21, 5083. [Google Scholar] [CrossRef]

- Larson, K. Serious Games and Gamification in the Corporate Training Environment: A Literature Review. TechTrends 2020, 64, 319–328. [Google Scholar] [CrossRef]

- Teichmann, M.; Ullrich, A.; Knost, D.; Gronau, N. Serious Games in Learning Factories: Perpetuating Knowledge in Learning Loops by Game-Based Learning. Procedia Manuf. 2020, 45, 259–264. [Google Scholar] [CrossRef]

- Sochor, R.; Schenk, J.; Fink, K.; Berger, J. Gamification in Industrial Shopfloor—Development of a Method for Classification and Selection of Suitable Game Elements in Diverse Production and Logistics Environments. Procedia CIRP 2021, 100, 157–162. [Google Scholar] [CrossRef]

- Oliveira, R.P.; Santos, I.L.; de Souza, C.G.; da Cunha Reis, A.; de Souza, W.M. A Study on the Relation between Industry 4.0 Technologies and Gamification in e-Learning. Interact. Technol. Smart Educ. 2022, 20, 449–474. [Google Scholar] [CrossRef]

- Nissimagoudar, P.C.; Mane, V.; Gireesha, H.M.; Iyer, N.C. Hardware-in-the-Loop (HIL) Simulation Technique for an Automotive Electronics Course. Procedia Comput. Sci. 2020, 172, 1047–1052. [Google Scholar] [CrossRef]

- Dreyfus, P.-A.; Psarommatis, F.; May, G.; Kiritsis, D. Virtual Metrology as an Approach for Product Quality Estimation in Industry 4.0: A Systematic Review and Integrative Conceptual Framework. Int. J. Prod. Res. 2022, 60, 742–765. [Google Scholar] [CrossRef]

- Mihalič, F.; Truntič, M.; Hren, A. Hardware-in-the-Loop Simulations: A Historical Overview of Engineering Challenges. Electronics 2022, 11, 2462. [Google Scholar] [CrossRef]

- Cadena, M.S.; Novillo, K.; Ruiz, B.; Ortiz, J.S.; Rodríguez, D.; Varela-Aldás, J. Hardware in the Loop Simulation for Soda Can Palletizing Process Applying Ethernet TCP/IP Communication Protocols Based on Unity 3D. In Proceedings of the Advances in Information and Communication; Arai, K., Ed.; Springer Nature: Cham, Switzerland, 2023; pp. 558–569. [Google Scholar]

- Kohen, H.; Dori, D. Incorporating Hardware-in-the-Loop Simulation into Object-Process Methodology. In Proceedings of the 2020 IEEE International Systems Conference (SysCon), Montreal, QC, Canada, 24–27 August 2020; pp. 1–8. [Google Scholar]

- Lewis, J.R.; Sauro, J. Usability and User Experience: Design and Evaluation. In Handbook of Human Factors and Ergonomics; John Wiley & Sons, Ltd.: Hoboken, NJ, USA, 2021; pp. 972–1015. ISBN 978-1-119-63611-3. [Google Scholar]

- Keebler, J.; Shelstad, W.; Smith, D.; Chaparro, B.; Phan, M. Validation of the GUESS-18: A Short Version of the Game User Experience Satisfaction Scale (GUESS). J. Usability Stud. 2020, 16, 49–62. [Google Scholar]

| Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).