Assessment of Engineering Behavior and Water Resistance of Stabilized Waste Soils Used as Subgrade Filling Materials

Abstract

1. Introduction

2. Materials and Methods

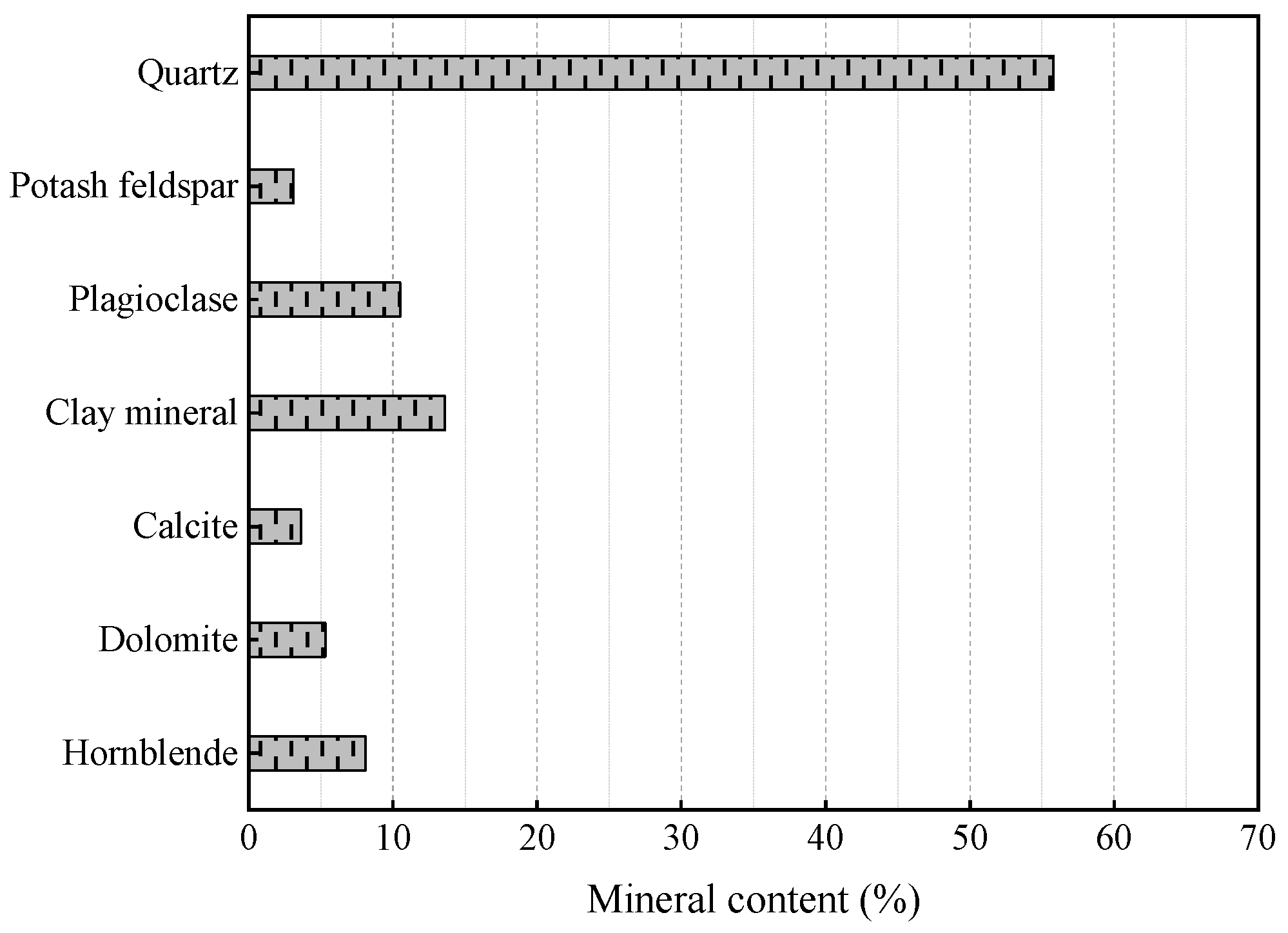

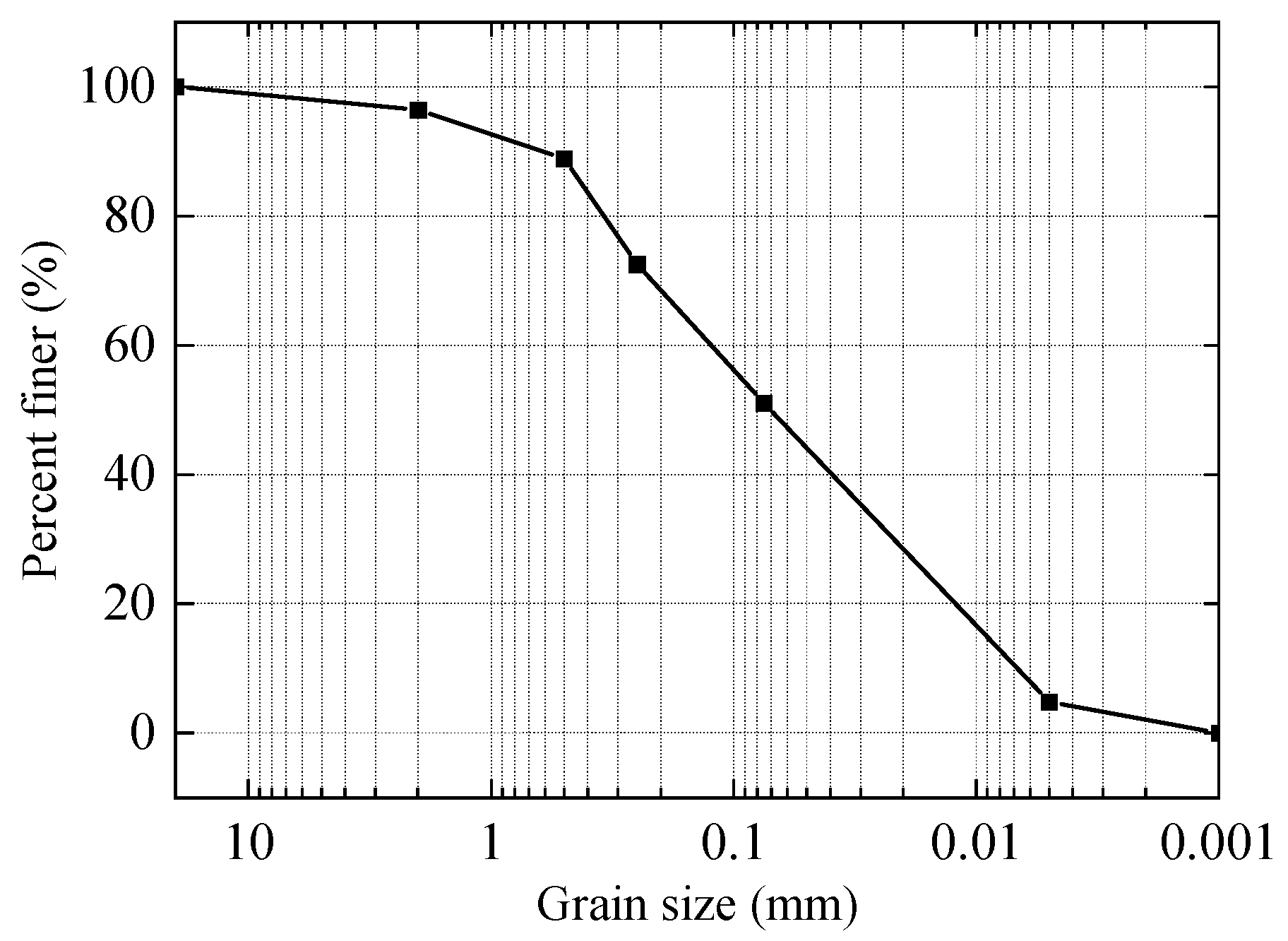

2.1. Physical and Mechanical Properties of Waste Soil

2.2. Modification Scheme and Test Arrangements

2.2.1. Compaction Test

2.2.2. CBR Test

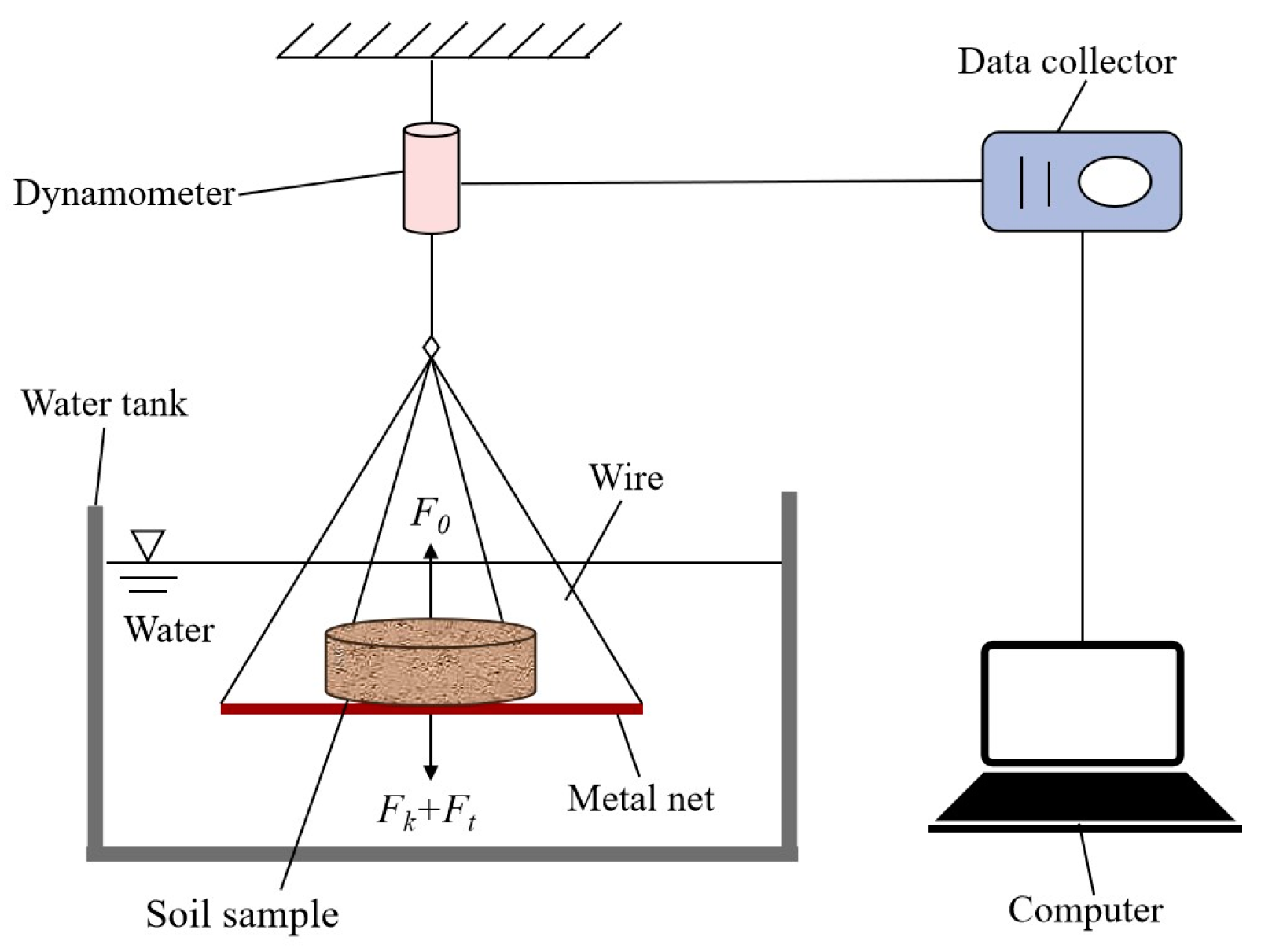

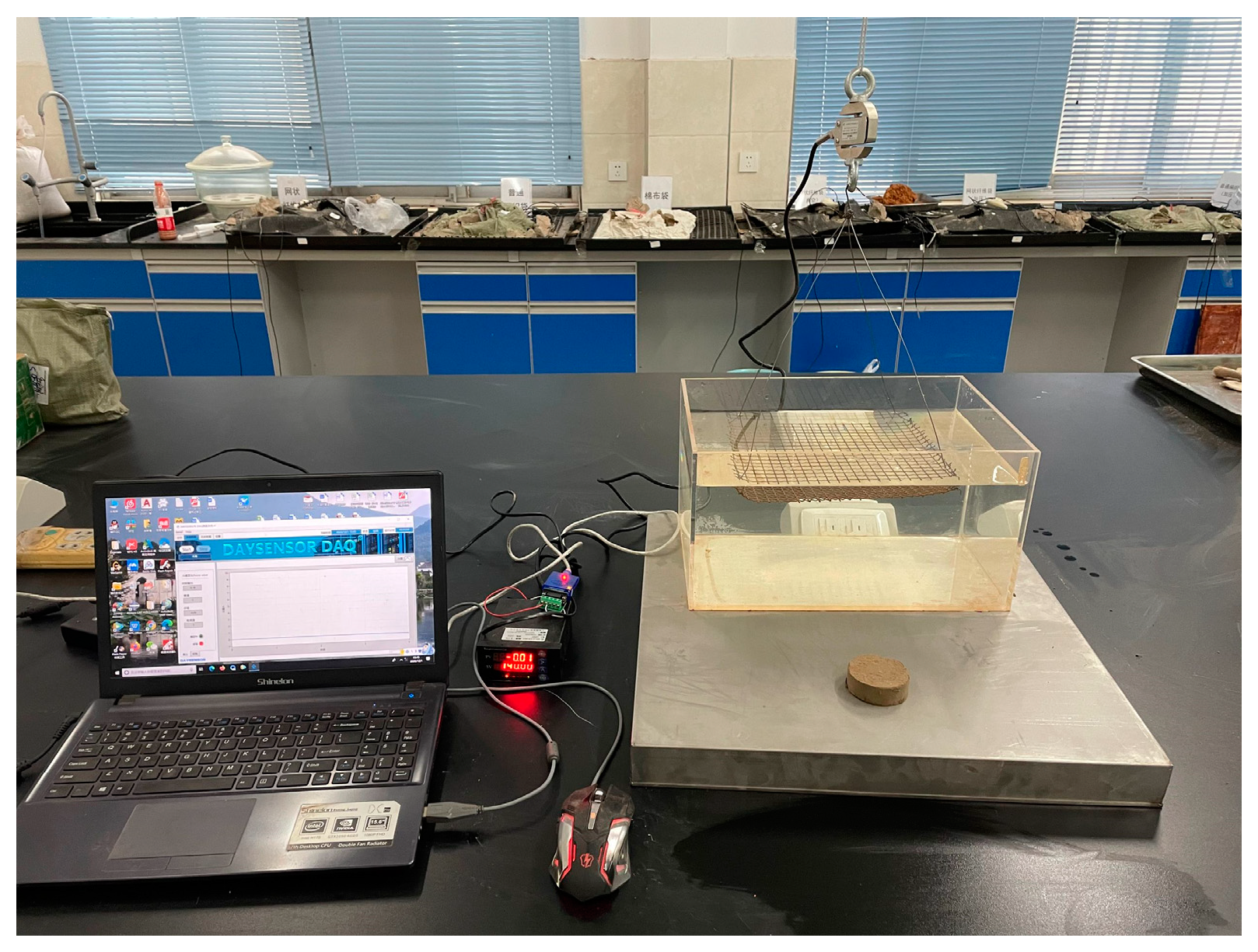

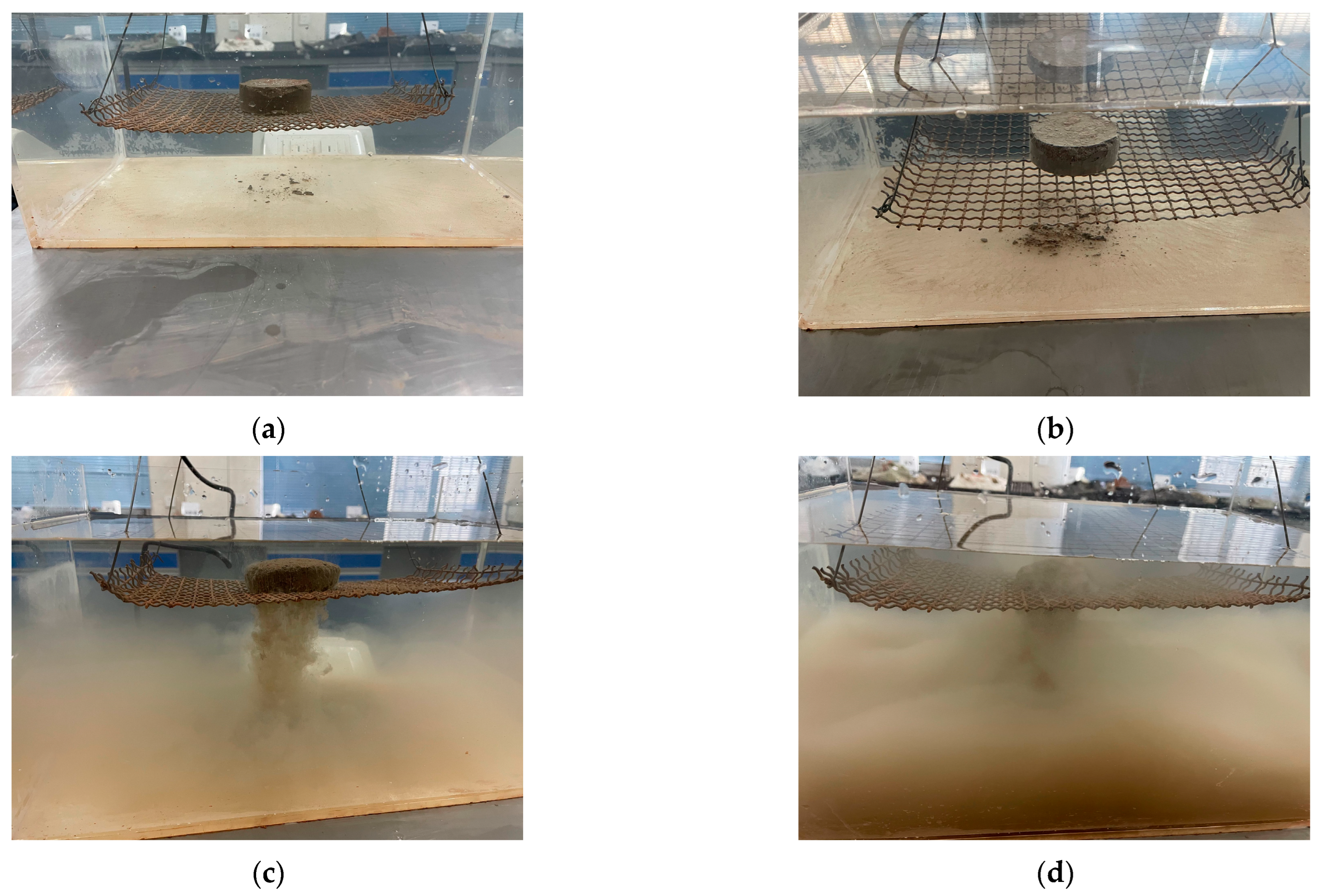

2.2.3. Disintegration Test

3. Results

3.1. Effect of Stabilizer Contents on Compaction Characteristics

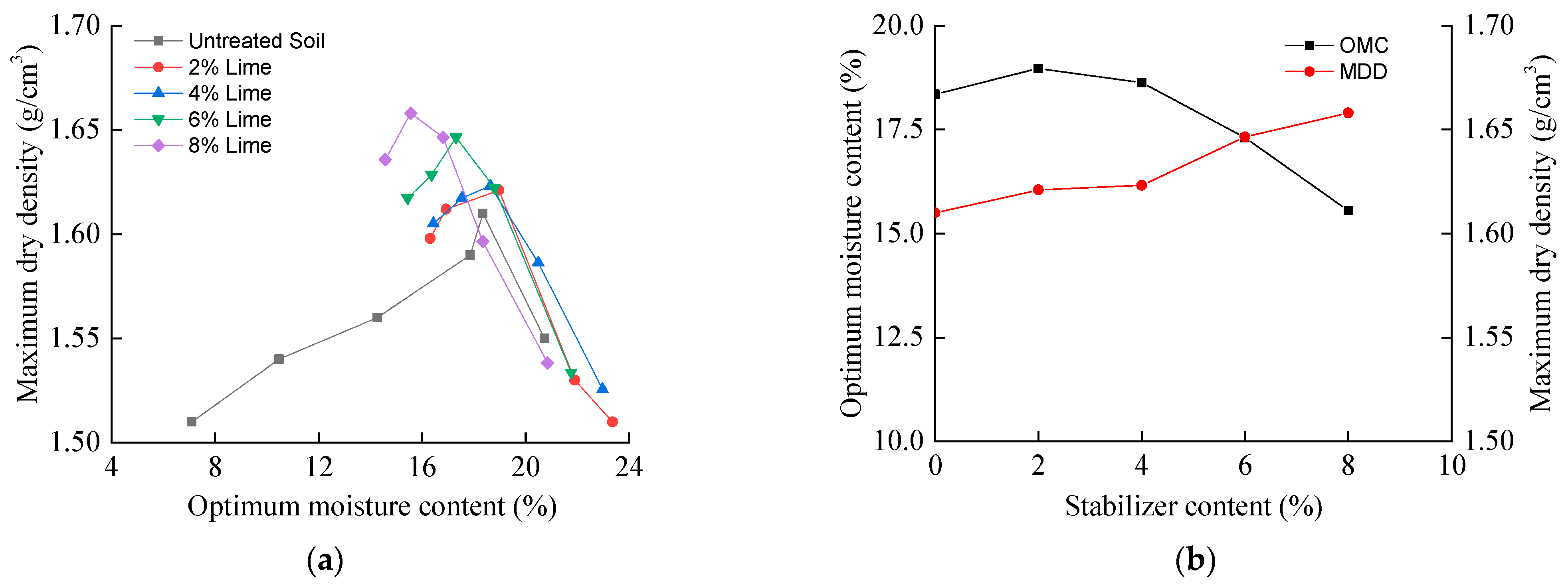

3.1.1. Influence of Lime Content

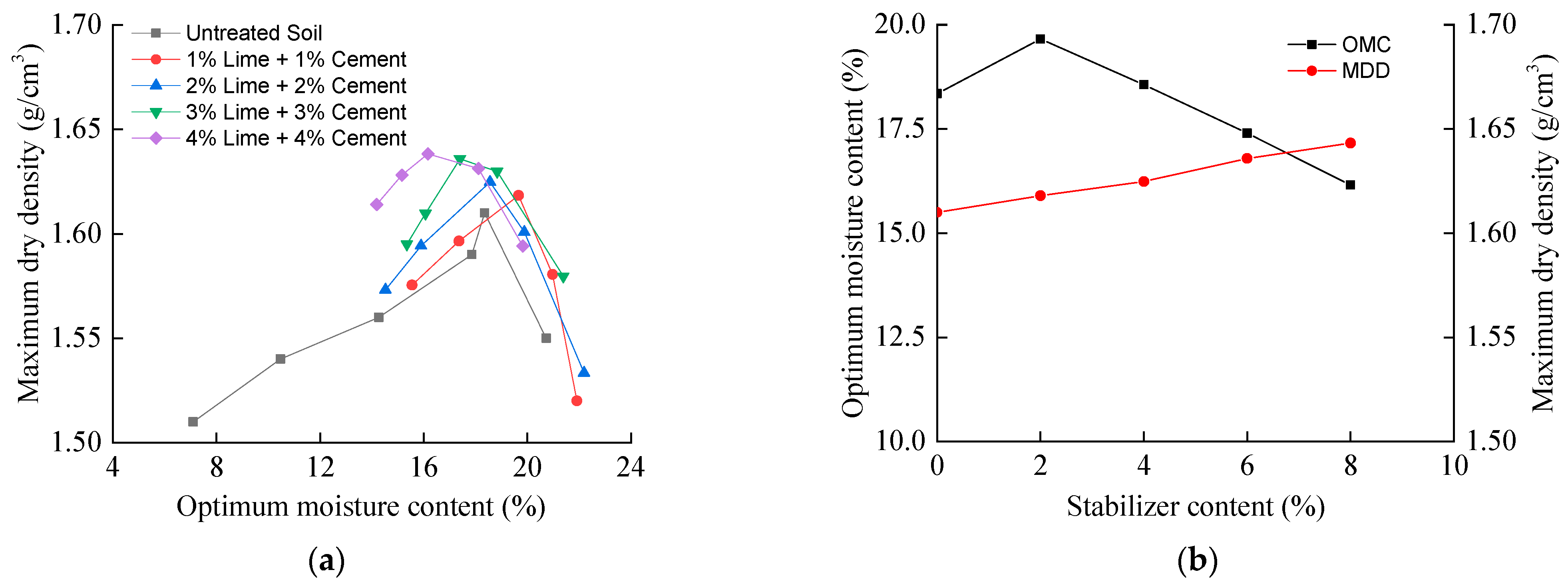

3.1.2. Influence of Lime and Cement Content

3.2. Effect of Stabilizer Contents on Bearing Capacity

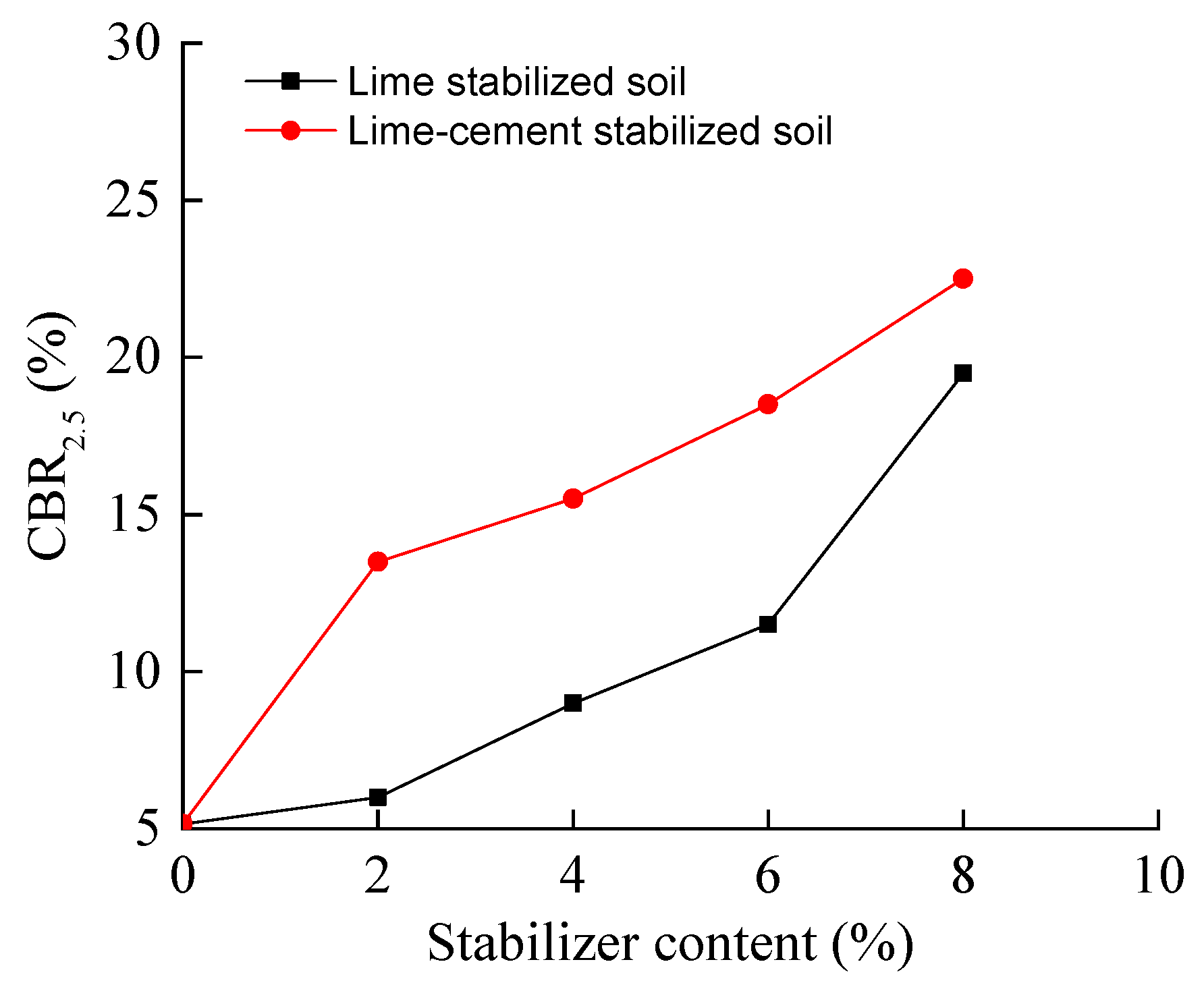

3.2.1. CBR2.5

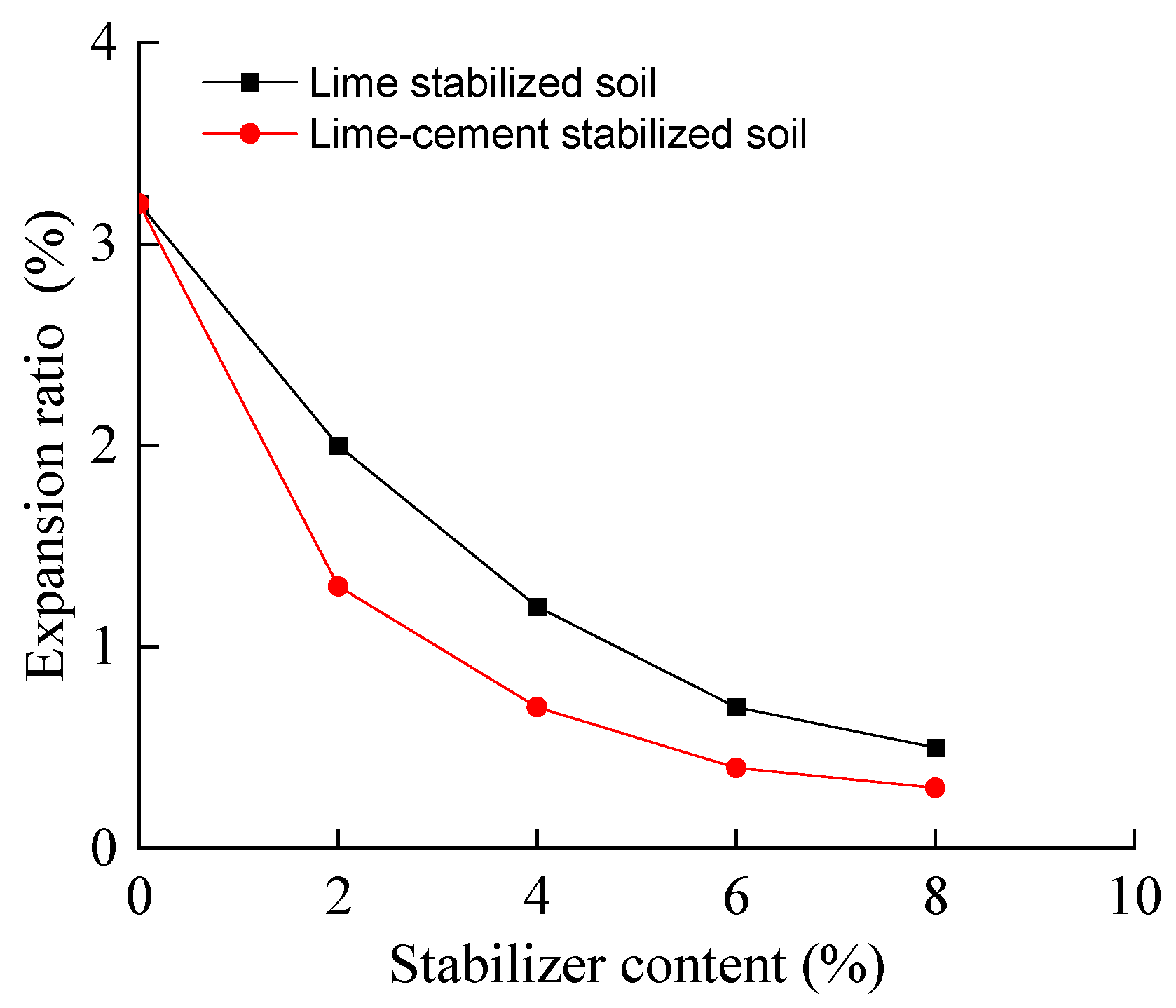

3.2.2. Expansion Ratio

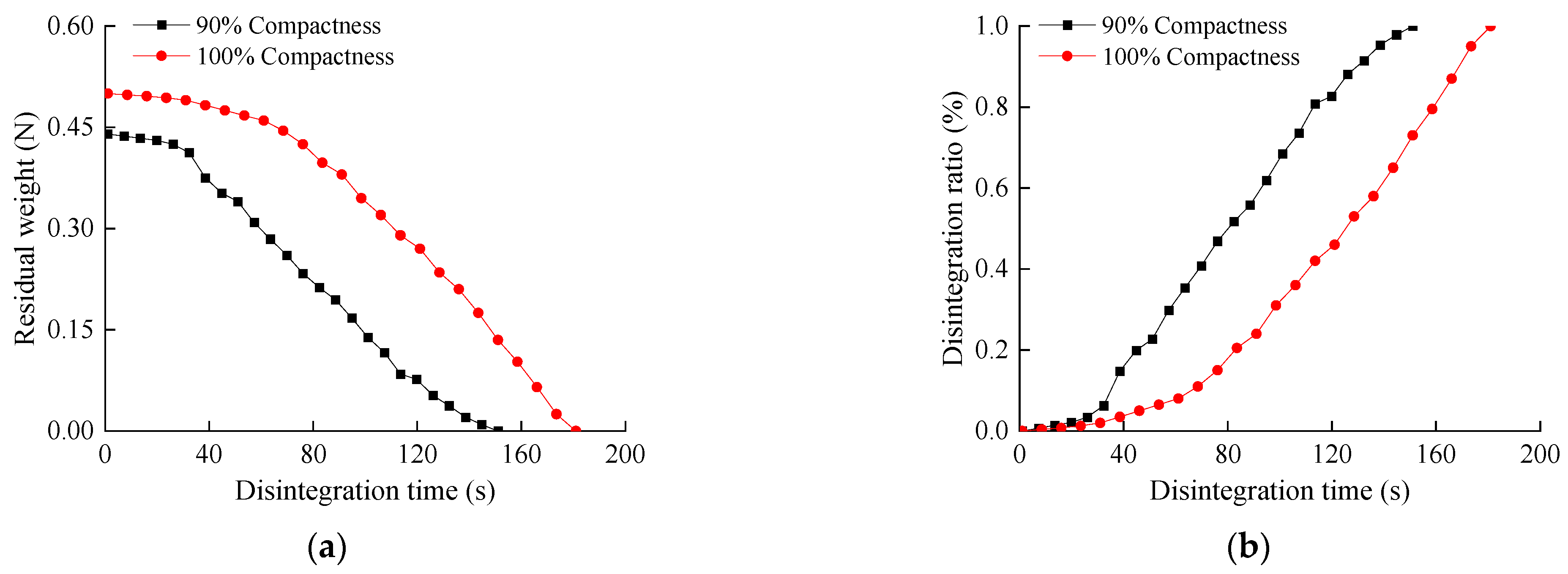

3.3. Effect of Compactness on Disintegration Characteristics

3.3.1. Initial Observations

3.3.2. Untreated Waste Soil

3.3.3. Lime-Stabilized Waste Soil

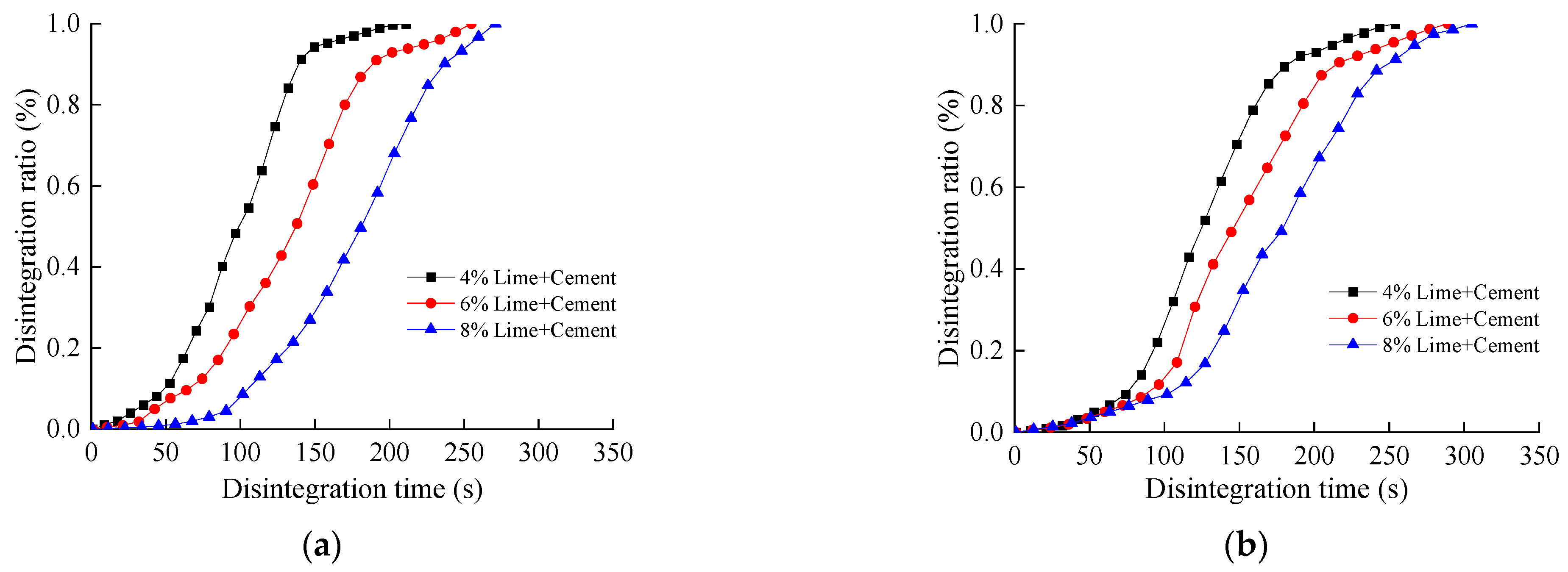

3.3.4. Lime–Cement–Stabilized Waste Soil

4. Discussion

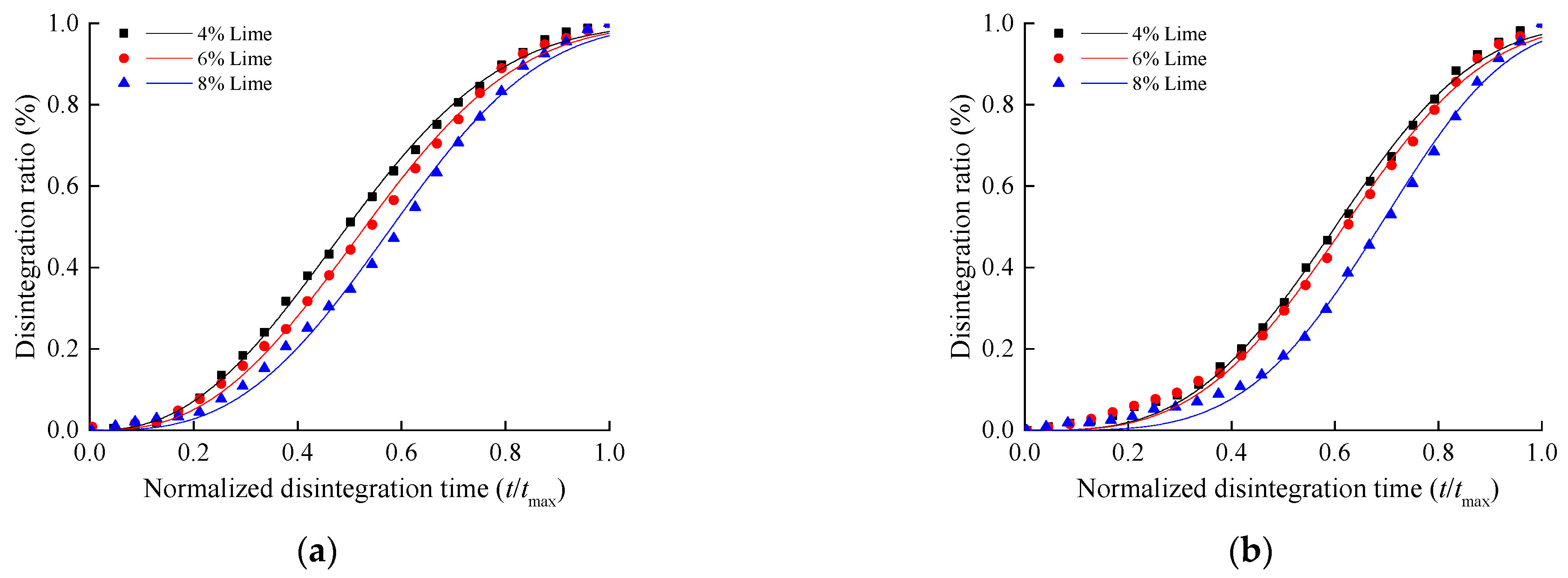

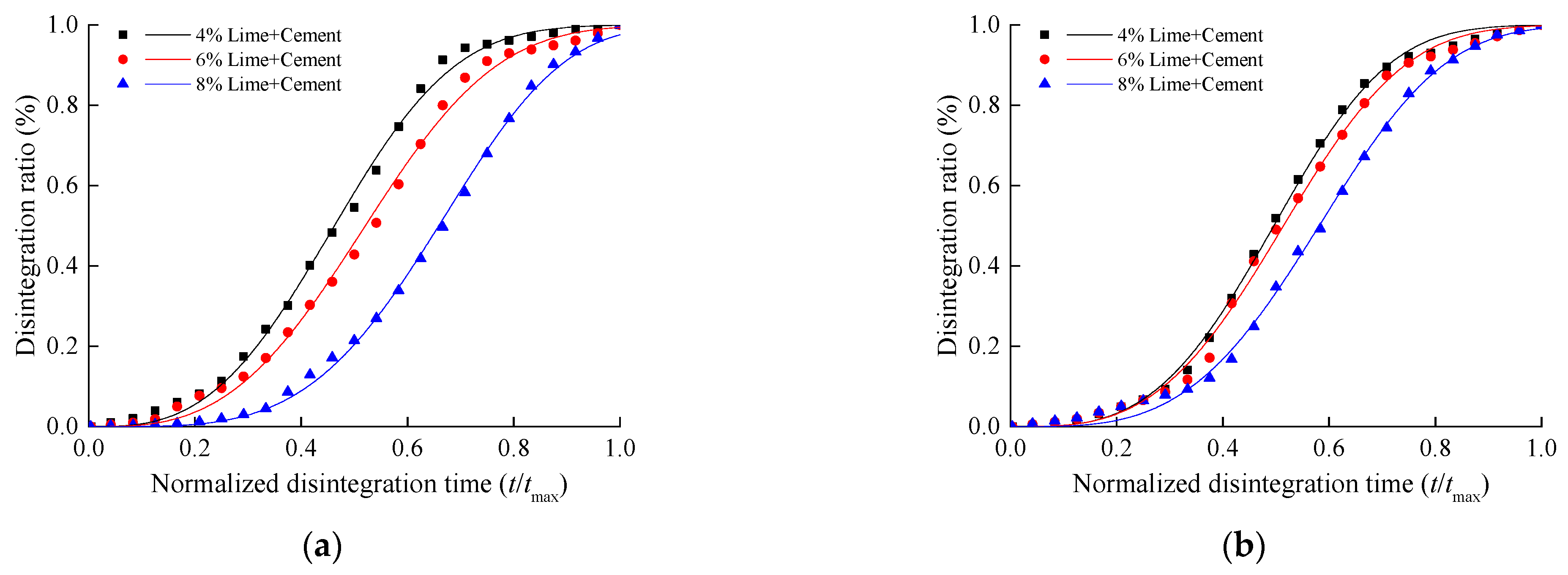

4.1. Development of Disintegration Model

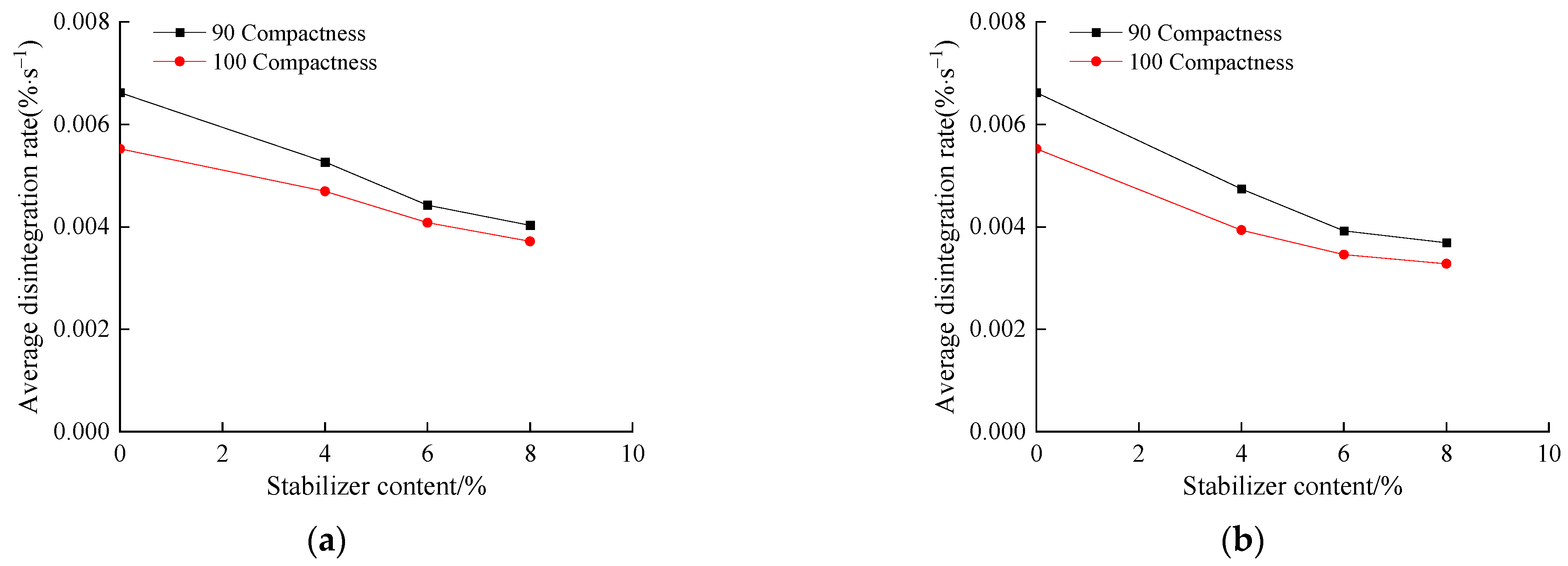

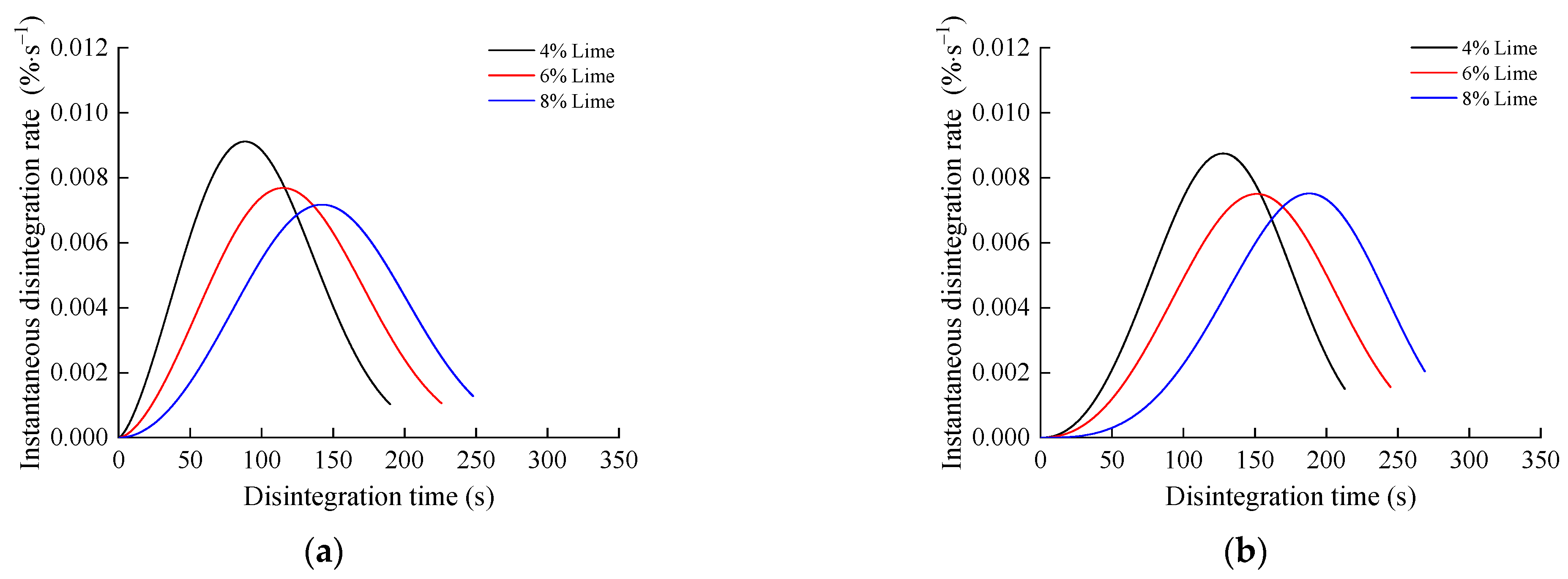

4.2. Evaluation of Disintegration Rate

5. Conclusions

- (1)

- With lime content increasing, the lime-stabilized soils presented an increase in the maximum dry density while the optimum moisture content decreased. The lime—cement–stabilized soils exhibited similar behavior but less maximum dry density.

- (2)

- Compared with the single stabilizer of lime, the CBR value of soils increased more significantly, and the expansion ratio was smaller using the addition of cement at the same stabilizer content. The stabilized waste soil with 4% lime or 1% lime + 1% cement could satisfy the requirements of subgrade materials, according to JTG D30-2015.

- (3)

- The disintegration time of all the mixed soil with lime increased by 8%, corresponding to the addition of 1% in lime content. The lime and cement soil showed better resistance to disintegration, with an increase in disintegration time of approximately 110% and 115% at the compactness of 90% and 100%, respectively. The stabilizer of lime combined with cement for waste soil should be given priority in areas under high groundwater.

- (4)

- An evolution model describing the disintegration ratio in the stabilized soil using the Weibull distribution has been developed. The model parameters, namely d and k, were found to be associated with alterations in the disintegration curve, where d represents the intercept, and k signifies the gradient. Both parameters demonstrate gradual increments with increased stabilizer content.

- (5)

- Disintegration rate equations were formulated by using the developed evolution model. The disintegration rate curve demonstrates a parabolic pattern, with the peak disintegration rate being exactly twice the average disintegration rate. Higher levels of compactness and stabilizer contents reduce the peak disintegration rate and delay the occurrence of peak disintegration time.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Jin, R.; Li, B.; Zhou, T.; Wanatowski, D.; Piroozfar, P. An Empirical Study of Perceptions towards Construction and Demolition Waste Recycling and Reuse in China. Resour. Conserv. Recycl. 2017, 126, 86–98. [Google Scholar] [CrossRef]

- Wang, H.; Xia, S.; Zhang, Q.; Zhang, P. Has China’s Construction Waste Change Been Decoupled from Economic Growth? Buildings 2022, 12, 147. [Google Scholar] [CrossRef]

- Yang, H.; Xia, J.; Thompson, J.R.; Flower, R.J. Urban Construction and Demolition Waste and Landfill Failure in Shenzhen, China. Waste Manag. 2017, 63, 393–396. [Google Scholar] [CrossRef]

- Yang, X.; Chen, Q. Mining Violations, Rent-Seeking, and Resource Governance in China: Evidence from Central Environmental Protection Inspection. Extr. Ind. Soc. 2023, 13, 101218. [Google Scholar] [CrossRef]

- Wu, H.; Duan, H.; Zheng, L.; Wang, J.; Niu, Y.; Zhang, G. Demolition Waste Generation and Recycling Potentials in a Rapidly Developing Flagship Megacity of South China: Prospective Scenarios and Implications. Constr. Build. Mater. 2016, 113, 1007–1016. [Google Scholar] [CrossRef]

- Huang, J.; Kogbara, R.B.; Hariharan, N.; Masad, E.A.; Little, D.N. A State-of-the-Art Review of Polymers Used in Soil Stabilization. Constr. Build. Mater. 2021, 305, 124685. [Google Scholar] [CrossRef]

- Firoozi, A.A.; Guney Olgun, C.; Firoozi, A.A.; Baghini, M.S. Fundamentals of Soil Stabilization. Int. J. Geo-Eng. 2017, 8, 26. [Google Scholar] [CrossRef]

- Deneele, D.; Le Runigo, B.; Cui, Y.J.; Cuisinier, O.; Ferber, V. Experimental Assessment Regarding Leaching of Lime-Treated Silt. Constr. Build. Mater. 2016, 112, 1032–1040. [Google Scholar] [CrossRef]

- Guney, Y.; Sari, D.; Cetin, M.; Tuncan, M. Impact of Cyclic Wetting-Drying on Swelling Behavior of Lime-Stabilized Soil. Handb. Environ. 2007, 42, 681–688. [Google Scholar] [CrossRef]

- Al-Rawas, A.A.; Hago, A.W.; Al-Sarmi, H. Effect of Lime, Cement and Sarooj (Artificial Pozzolan) on the Swelling Potential of an Expansive Soil from Oman. Build. Environ. 2005, 40, 681–687. [Google Scholar] [CrossRef]

- Shen, Y.S.; Tang, Y.; Yin, J.; Li, M.P.; Wen, T. An Experimental Investigation on Strength Characteristics of Fiber-Reinforced Clayey Soil Treated with Lime or Cement. Constr. Build. Mater. 2021, 294, 123537. [Google Scholar] [CrossRef]

- Barbero-Barrera, M.M.; Jové-Sandoval, F.; González Iglesias, S. Assessment of the Effect of Natural Hydraulic Lime on the Stabilisation of Compressed Earth Blocks. Constr. Build. Mater. 2020, 260, 119877. [Google Scholar] [CrossRef]

- Khodaparast, M.; Rajabi, A.M.; Mohammadi, M. Mechanical Properties of Silty Clay Soil Treated with a Mixture of Lime and Zinc Oxide Nanoparticles. Constr. Build. Mater. 2021, 281, 122548. [Google Scholar] [CrossRef]

- Cheng, Y.; Wang, S.; Li, J.; Huang, X.; Li, C.; Wu, J. Engineering and Mineralogical Properties of Stabilized Expansive Soil Compositing Lime and Natural Pozzolans. Constr. Build. Mater. 2018, 187, 1031–1038. [Google Scholar] [CrossRef]

- Wang, D.X.; Abriak, N.E.; Zentar, R.; Xu, W. Solidification/Stabilization of Dredged Marine Sediments for Road Construction. Environ. Technol. 2012, 33, 95–101. [Google Scholar] [CrossRef] [PubMed]

- Wang, Q.; Kong, L.; Tseng, M.L.; Song, Y.; Wang, H. Solid Waste Material Reuse Analysis: Filling the Road Subgrade with Riverway Silt and Sediment. Environ. Sci. Pollut. Res. 2022, 29, 35096–35109. [Google Scholar] [CrossRef]

- Hossain, K.M.A.; Lachemi, M.; Easa, S. Characteristics of Volcanic Ash and Natural Lime Based Stabilized Clayey Soils. Can. J. Civ. Eng. 2006, 33, 1455–1458. [Google Scholar] [CrossRef]

- Federico, A.; Vitone, C.; Murianni, A. On the Mechanical Behaviour of Dredged Submarine Clayey Sediments Stabilized with Lime or Cement. Can. Geotech. J. 2015, 52, 2030–2040. [Google Scholar] [CrossRef]

- Locat, J.; Trembaly, H.; Leroueil, S. Mechanical and Hydraulic Behaviour of a Soft Inorganic Clay Treated with Lime. Can. Geotech. J. 1996, 33, 654–669. [Google Scholar] [CrossRef]

- Bell, F.G. Lime Stabilization of Clay Minerals and Soils. Eng. Geol. 1996, 42, 223–237. [Google Scholar] [CrossRef]

- Ouhadi, V.R.; Yong, R.N.; Amiri, M.; Ouhadi, M.H. Pozzolanic Consolidation of Stabilized Soft Clays. Appl. Clay Sci. 2014, 95, 111–118. [Google Scholar] [CrossRef]

- Zhao, X.; Rao, J.; Yang, Q.; Rong, Y.; Fu, Z.; Wang, Z.; Chen, Z. Experimental Study on Improvement Effects of Completely Weathered Phyllite Using Red Clay and Cement for High-Speed Railway Embankments. J. Renew. Mater. 2022, 10, 1287–1305. [Google Scholar] [CrossRef]

- Aziz, M.; Sheikh, F.N.; Qureshi, M.U.; Rasool, A.M.; Irfan, M. Experimental Study on Endurance Performance of Lime and Cement-Treated Cohesive Soil. KSCE J. Civ. Eng. 2021, 25, 3306–3318. [Google Scholar] [CrossRef]

- Bouras, F.; Al-Mukhtar, M.; Tapsoba, N.; Belayachi, N.; Sabio, S.; Beck, K.; Martin, M. Geotechnical Behavior and Physico-Chemical Changes of Lime-Treated and Cement-Treated Silty Soil. Geotech. Geol. Eng. 2022, 40, 2033–2049. [Google Scholar] [CrossRef]

- Graybeal, B.; Tanesi, J. A Cementitious Long-Life Wearing Course to Reduce Frequency of Maintenance Works on High-Traffic Roads. Transp. Res. Arena Eur. 2008, 1561, 454–461. [Google Scholar] [CrossRef]

- Elandaloussi, R.; Bennabi, A.; Dupla, J.C.; Canou, J.; Benamar, A.; Gotteland, P. Effectiveness of Lime Treatment of Coarse Soils against Internal Erosion. Geotech. Geol. Eng. 2019, 37, 139–154. [Google Scholar] [CrossRef]

- Zhang, X.W.; Kong, L.W.; Li, J.J. Influence of Dry and Wet Seasons on Disintegration Characteristics of Basalt Residual Soil from the Leizhou Peninsula, China. Q. J. Eng. Geol. Hydrogeol. 2018, 51, 450–460. [Google Scholar] [CrossRef]

- Czerewko, M.A.; Cripps, J.C. Assessing the Durability of Mudrocks Using the Modified Jar Slake Index Test. Q. J. Eng. Geol. Hydrogeol. 2001, 34, 153–163. [Google Scholar] [CrossRef]

- Admassu, Y.; Hamdan, H.; Gautam, T. Multivariate Statistical Approach to Re-Evaluate the Slake Durability Index Test (ASTM 4644-08). Eng. Geol. 2016, 209, 12–20. [Google Scholar] [CrossRef]

- Ze, Z.; Vadim, P.; Svetlana, N.; Zhongqiong, Z.; Junjie, W. Disintegration Characteristics of a Cryolithogenic Clay Loam with Different Water Content: Moscow Covering Loam (PrQIII), Case Study. Eng. Geol. 2019, 258, 105159. [Google Scholar] [CrossRef]

- Yan, L.; Liu, P.; Peng, H.; Kašanin-Grubin, M.; Lin, K. Laboratory Study of the Effect of Temperature Difference on the Disintegration of Redbed Softrock. Phys. Geogr. 2019, 40, 149–163. [Google Scholar] [CrossRef]

- Li, X.A.; Wang, L.; Yan, Y.L.; Hong, B.; Li, L.C. Experimental Study on the Disintegration of Loess in the Loess Plateau of China. Bull. Eng. Geol. Environ. 2019, 78, 4907–4918. [Google Scholar] [CrossRef]

- Zhang, X.; Liu, X.; Chen, C.; Kong, L.; Wang, G. Engineering Geology of Residual Soil Derived from Mudstone in Zimbabwe. Eng. Geol. 2020, 277, 105785. [Google Scholar] [CrossRef]

- Wang, J.; Gu, T.; Zhang, M.; Xu, Y.; Kong, J. Experimental Study of Loess Disintegration Characteristics. Earth Surf. Process. Landf. 2019, 44, 1317–1329. [Google Scholar] [CrossRef]

- Zhang, Z.; Liu, W.; Cui, Q.; Han, L.; Yao, H. Disintegration Characteristics of Moderately Weathered Mudstone in Drawdown Area of Three Gorges Reservoir, China. Arab. J. Geosci. 2018, 11, 405. [Google Scholar] [CrossRef]

- Zhang, X.; Liu, X.; Chen, C.; Xu, Y.; Liu, H. Evolution of Disintegration Properties of Granite Residual Soil with Microstructure Alteration Due to Wetting and Drying Cycles. Bull. Eng. Geol. Environ. 2022, 81, 93. [Google Scholar] [CrossRef]

- Sahoo, S.; Prasad Singh, S. Strength and Durability Properties of Expansive Soil Treated with Geopolymer and Conventional Stabilizers. Constr. Build. Mater. 2022, 328, 127078. [Google Scholar] [CrossRef]

- Mahedi, M.; Cetin, B.; Dayioglu, A.Y. Effect of Cement Incorporation on the Leaching Characteristics of Elements from Fly Ash and Slag Treated Soils. J. Environ. Manag. 2020, 253, 109720. [Google Scholar] [CrossRef] [PubMed]

- Hou, T.S.; Yuan, X.H.; Zeng, X.; Wang, X.; Ceng, Y.D.; Zhang, Z.Z.; Hou, M.L. Water Resistance Properties of Lime Soil Ground under Long-Term Soaking Environment. Indian Geotech. J. 2021, 51, 1299–1309. [Google Scholar] [CrossRef]

- Chinese Standard JTG E40-2007; Test Methods of Soils for Highway Engineering. China Communications Press: Beijing, China, 2007.

- Chinese Standard JTG D30-2015; Specifications for Design of Highway Subgrades. China Communications Press: Beijing, China, 2015.

- Khemissa, M.; Mahamedi, A. Cement and Lime Mixture Stabilization of an Expansive Overconsolidated Clay. Appl. Clay Sci. 2014, 95, 104–110. [Google Scholar] [CrossRef]

- Carde, C.; François, R. Effect of ITZ leaching on durability of cement-based materials. Cem. Concr. Res. 1997, 27, 971–978. [Google Scholar] [CrossRef]

- Nakagawa, T.; Osaki, S. The Discrete Weibull Distribution. IEEE Trans. Reliab. 1975, R-24, 300–301. [Google Scholar] [CrossRef]

- Lu, C.; Danzer, R.; Fischer, F.D. Fracture Statistics of Brittle Materials: Weibull or Normal Distribution. Phys. Rev. E 2002, 65, 67102. [Google Scholar] [CrossRef]

- Wong, T.; Wong, R.H.C.; Chau, K.T.; Tang, C.A. Microcrack Statistics, Weibull Distribution and Micromechanical Modeling of Compressive Failure in Rock. Mech. Mater. 2006, 38, 664–681. [Google Scholar] [CrossRef]

- Carrasco, J.M.F.; Ortega, E.M.M.; Cordeiro, G.M. A Generalized Modified Weibull Distribution for Lifetime Modeling. Comput. Stat. Data Anal. 2008, 53, 450–462. [Google Scholar] [CrossRef]

- Lobo-Guerrero, S.; Vallejo, L.E. Application of Weibull Statistics to the Tensile Strength of Rock Aggregates. J. Geotech. Geoenvironment. Eng. 2006, 132, 786–790. [Google Scholar] [CrossRef]

- Erami, F.E.; Firoozjaee, A.R. Numerical Solution of Bed Load Transport Equations Using Discrete Least Squares Meshless (DLSM) Method. Appl. Math. Model. 2020, 77, 1095–1109. [Google Scholar] [CrossRef]

| Properties | Test Values |

|---|---|

| Specific gravity, Gs | 2.60 |

| Coefficient of uniformity, Cu | 25.7 |

| Coefficient of curvature, Cc | 0.317 |

| d10 (mm) | 0.007 |

| d30 (mm) | 0.02 |

| d60 (mm) | 0.12 |

| Liquid limit, wL (%) | 35.3 |

| Plastic limit, wP (%) | 21.1 |

| Plasticity index, IP (%) | 14.2 |

| Friction angle, φ (°) | 26 |

| Cohesion, c (kPa) | 13 |

| Type of Stabilized Soil | Combinations |

|---|---|

| Lime-stabilized soil | 2% lime |

| 4% lime | |

| 6% lime | |

| 8% lime | |

| Lime- and cement-stabilized soil | 1% lime + 1% cement |

| 2% lime + 2% cement | |

| 3% lime + 3% cement | |

| 4% lime + 4% cement |

| Stabilizer Content | 90% Compactness | 100% Compactness | ||||

|---|---|---|---|---|---|---|

| d | k | R2 | d | k | R2 | |

| 4% lime | 0.5752 | 2.4582 | 0.9989 | 0.6726 | 3.2293 | 0.9975 |

| 6% lime | 0.6086 | 2.6464 | 0.9978 | 0.6902 | 3.2729 | 0.9959 |

| 8% lime | 0.6575 | 2.9838 | 0.9963 | 0.7516 | 3.9917 | 0.9956 |

| 2% lime + 2% cement | 0.5229 | 2.9825 | 0.9977 | 0.5535 | 3.3292 | 0.9985 |

| 3% lime + 3% cement | 0.5866 | 3.0707 | 0.9971 | 0.5753 | 3.2568 | 0.9976 |

| 4% lime + 4% cement | 0.7217 | 4.0194 | 0.9987 | 0.6445 | 3.5454 | 0.9983 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

He, F.; Liu, Z.; Yan, W. Assessment of Engineering Behavior and Water Resistance of Stabilized Waste Soils Used as Subgrade Filling Materials. Appl. Sci. 2024, 14, 1901. https://doi.org/10.3390/app14051901

He F, Liu Z, Yan W. Assessment of Engineering Behavior and Water Resistance of Stabilized Waste Soils Used as Subgrade Filling Materials. Applied Sciences. 2024; 14(5):1901. https://doi.org/10.3390/app14051901

Chicago/Turabian StyleHe, Fan, Ze Liu, and Wenqin Yan. 2024. "Assessment of Engineering Behavior and Water Resistance of Stabilized Waste Soils Used as Subgrade Filling Materials" Applied Sciences 14, no. 5: 1901. https://doi.org/10.3390/app14051901

APA StyleHe, F., Liu, Z., & Yan, W. (2024). Assessment of Engineering Behavior and Water Resistance of Stabilized Waste Soils Used as Subgrade Filling Materials. Applied Sciences, 14(5), 1901. https://doi.org/10.3390/app14051901