Deep Learning (Fast R-CNN)-Based Evaluation of Rail Surface Defects

Abstract

1. Introduction

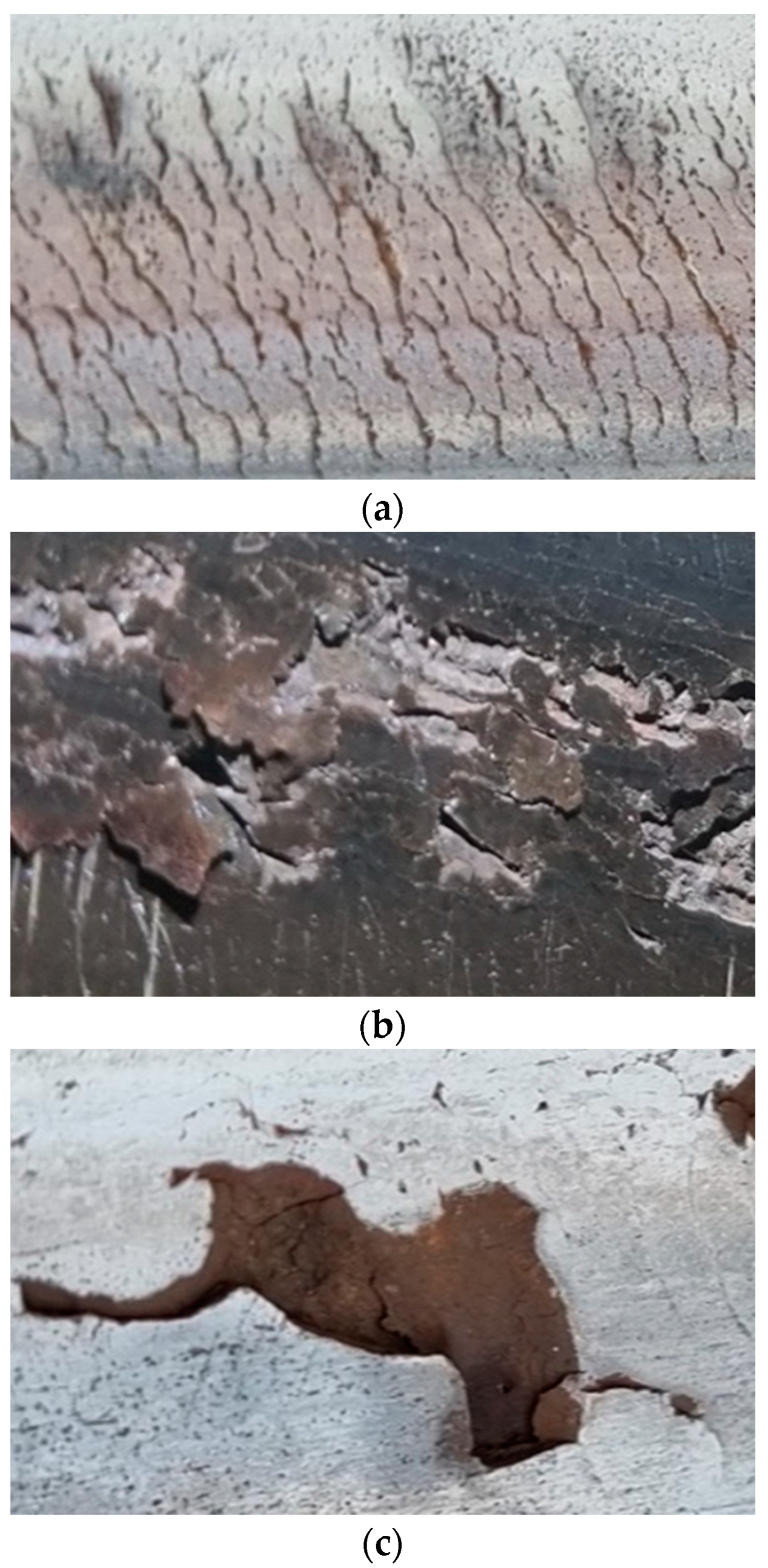

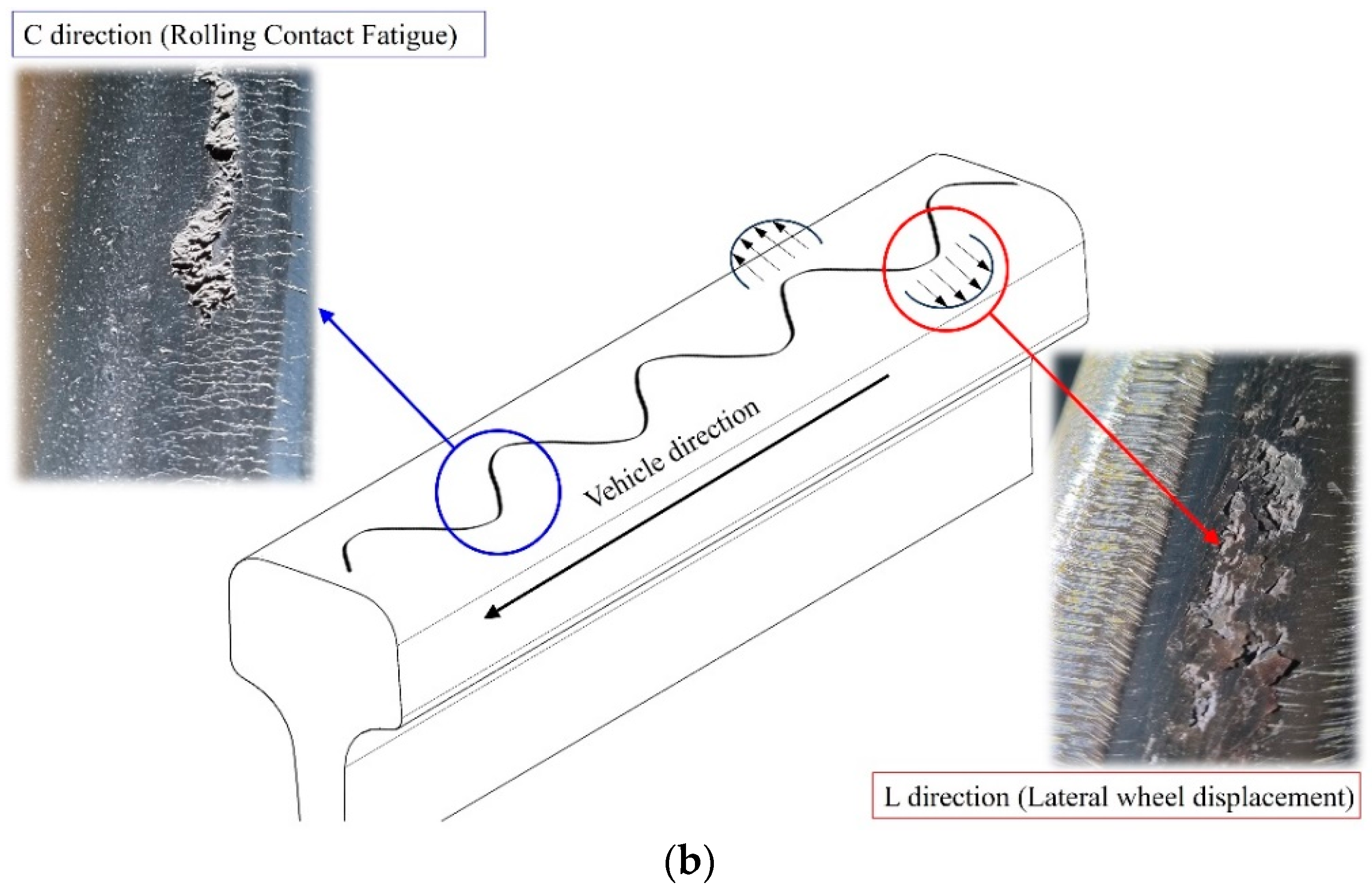

2. Rail Damage Inspection

3. Rail Internal Defects Specificity, Characteristic

3.1. Overview

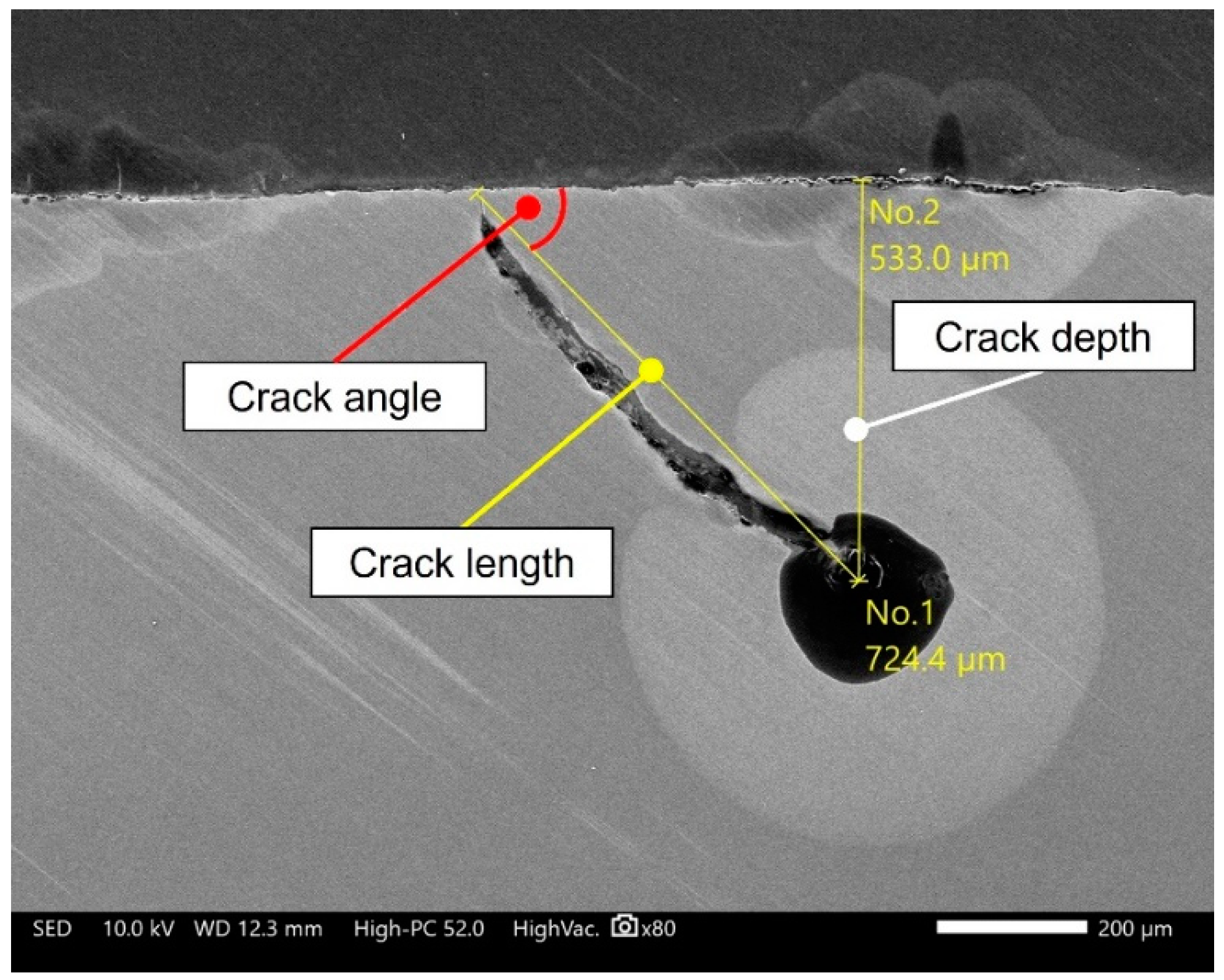

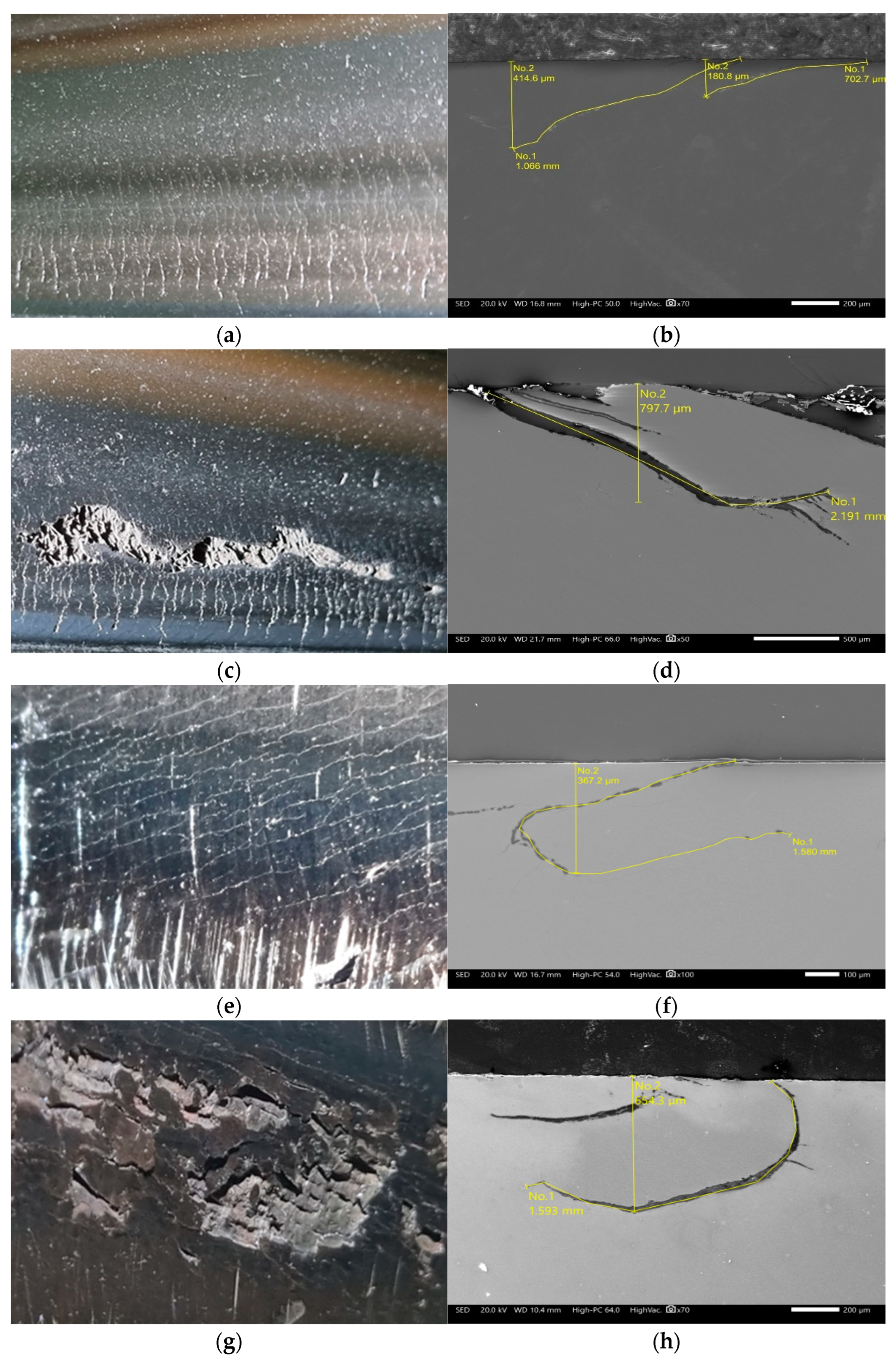

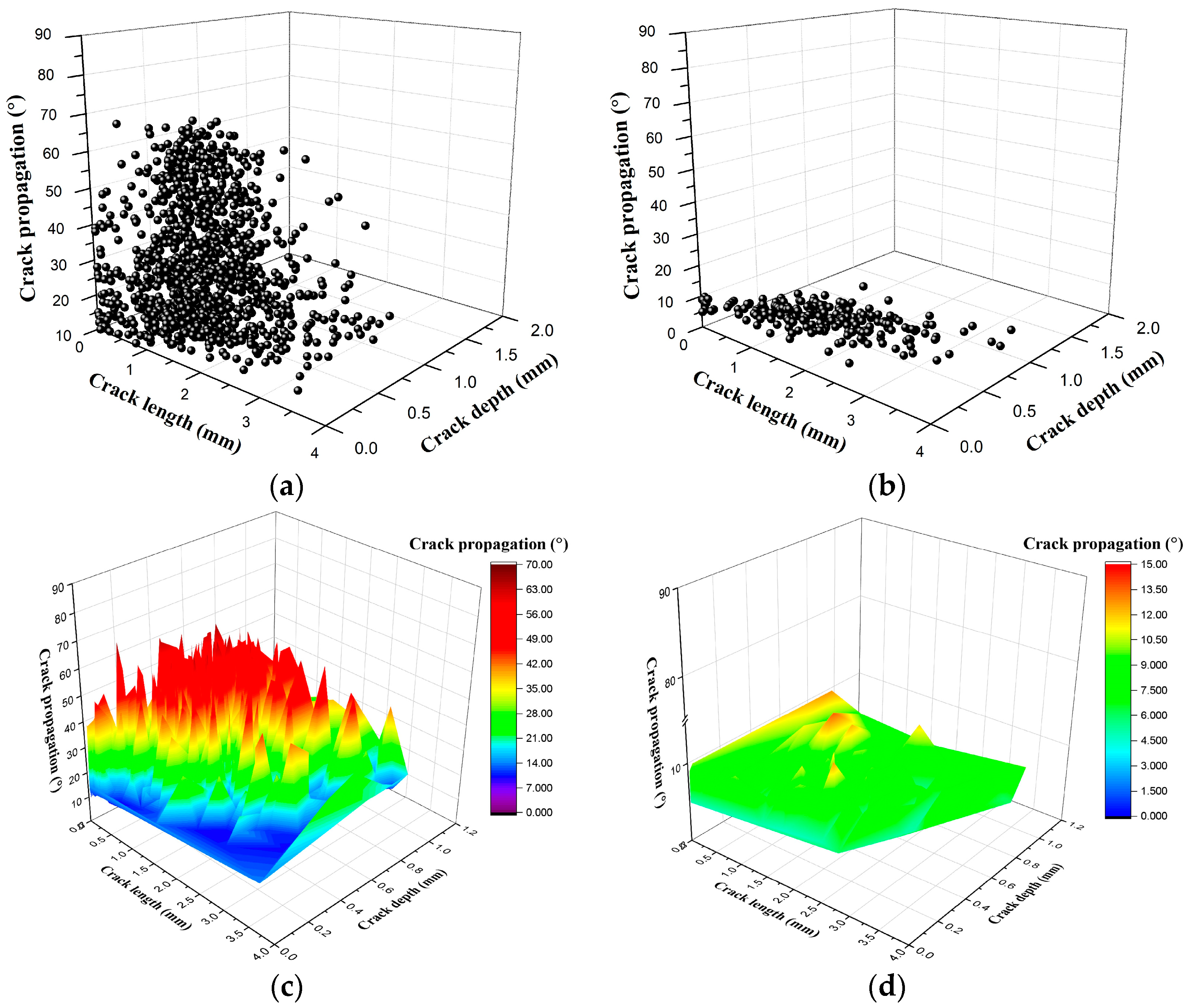

3.2. SEM Test Results

4. Analysis and Discussion

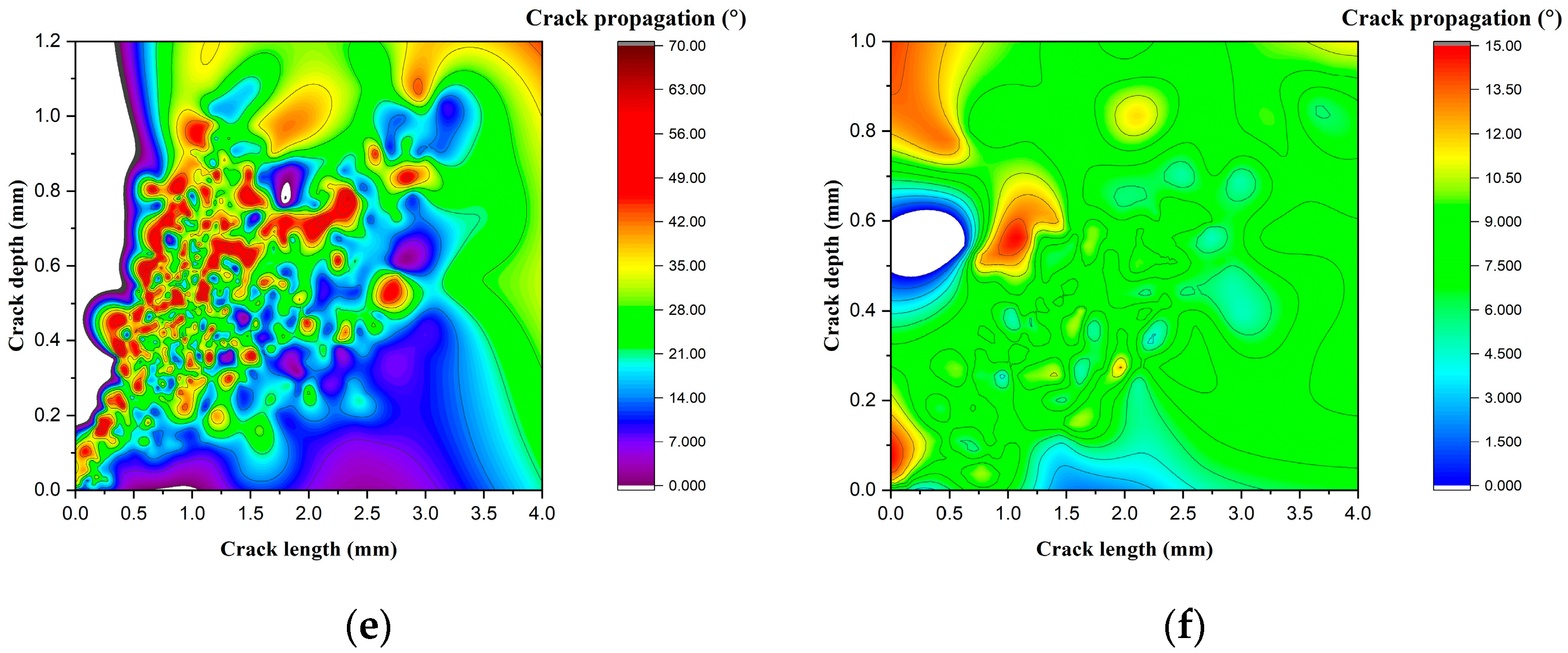

4.1. Gaussian Probability Density Analysis of Rail Internal Defects

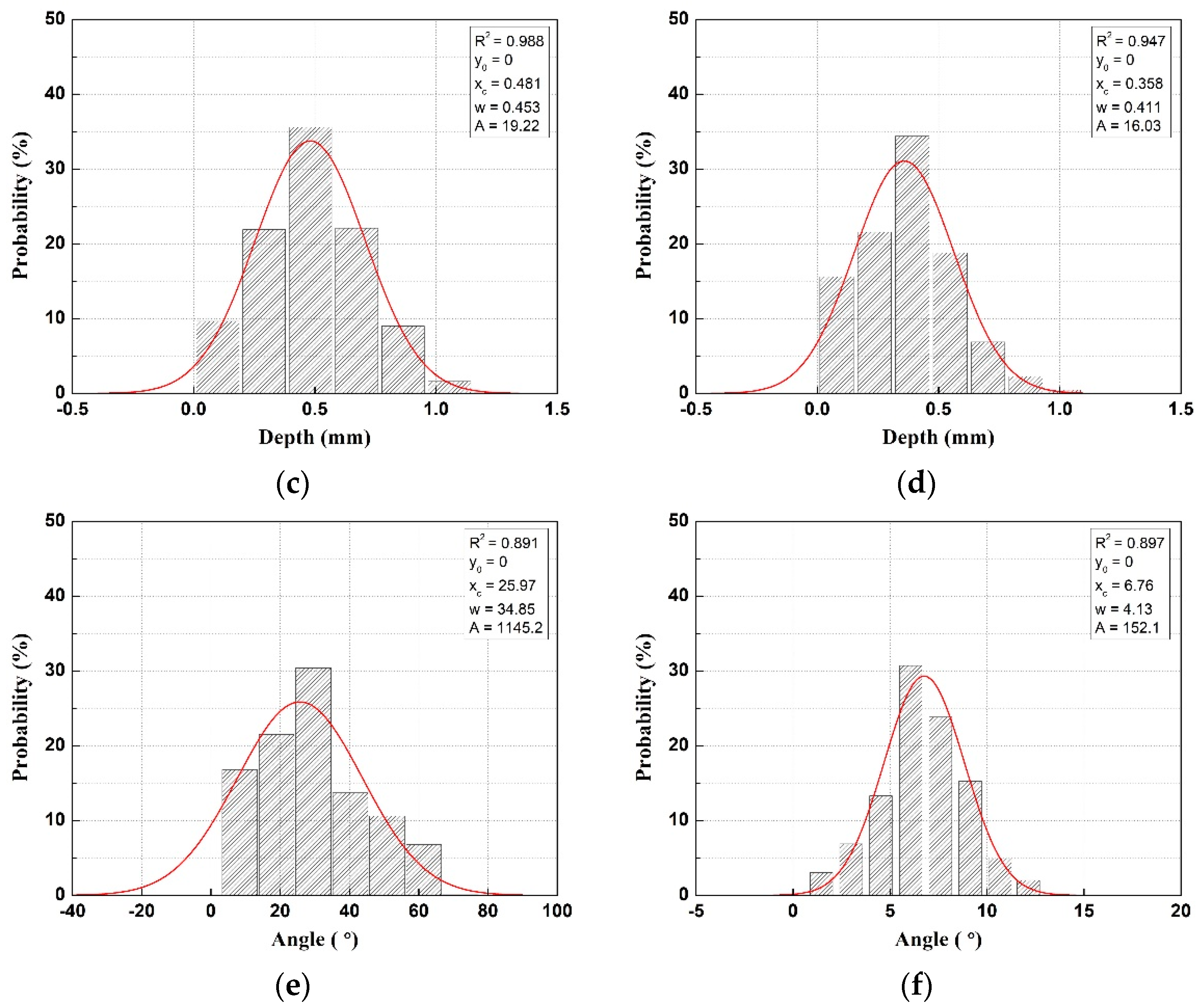

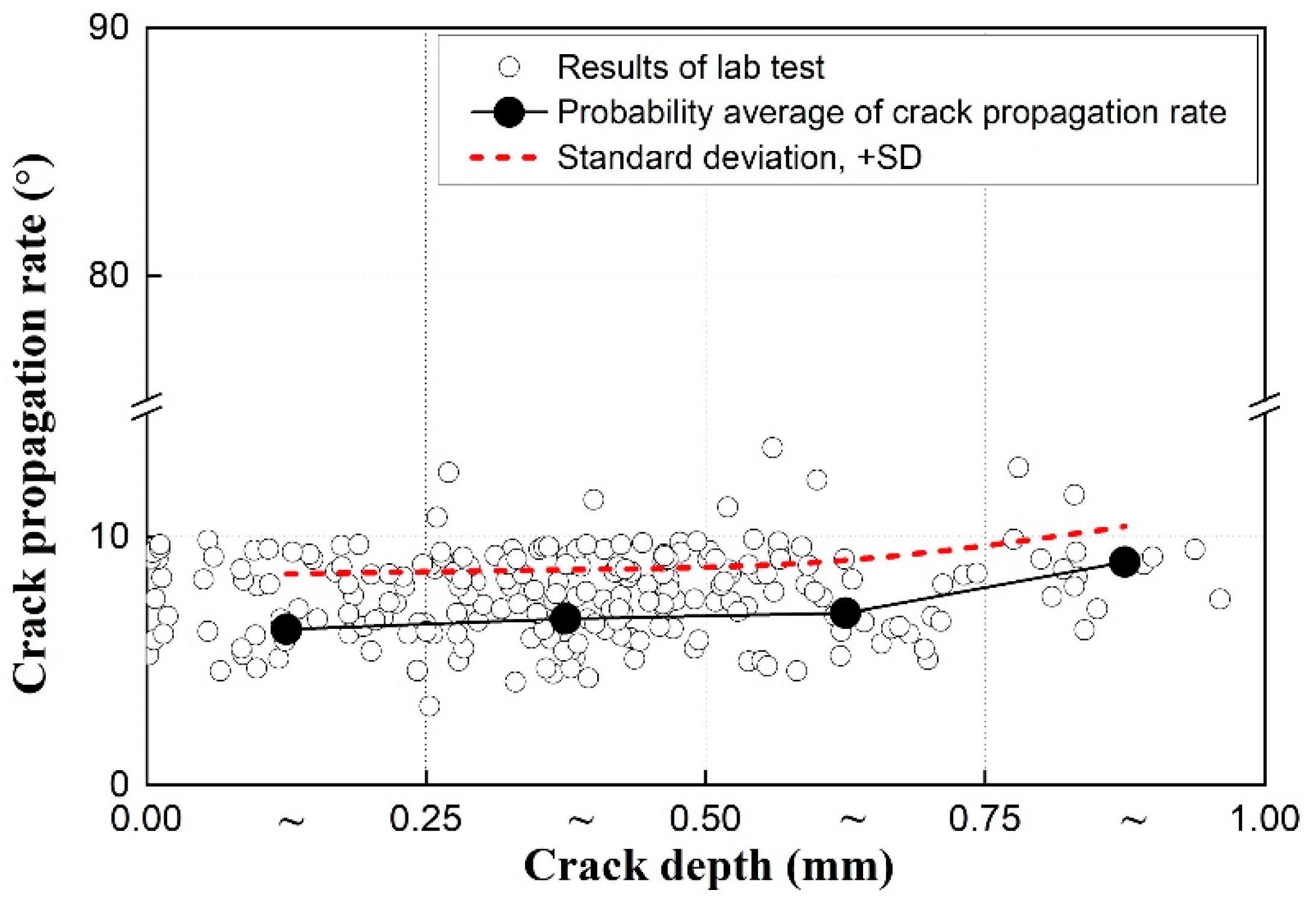

4.2. Gaussian Probability Density Function Analysis According to Crack Depth

5. Rail Surface Damage Deep Learning Model

5.1. Introduction

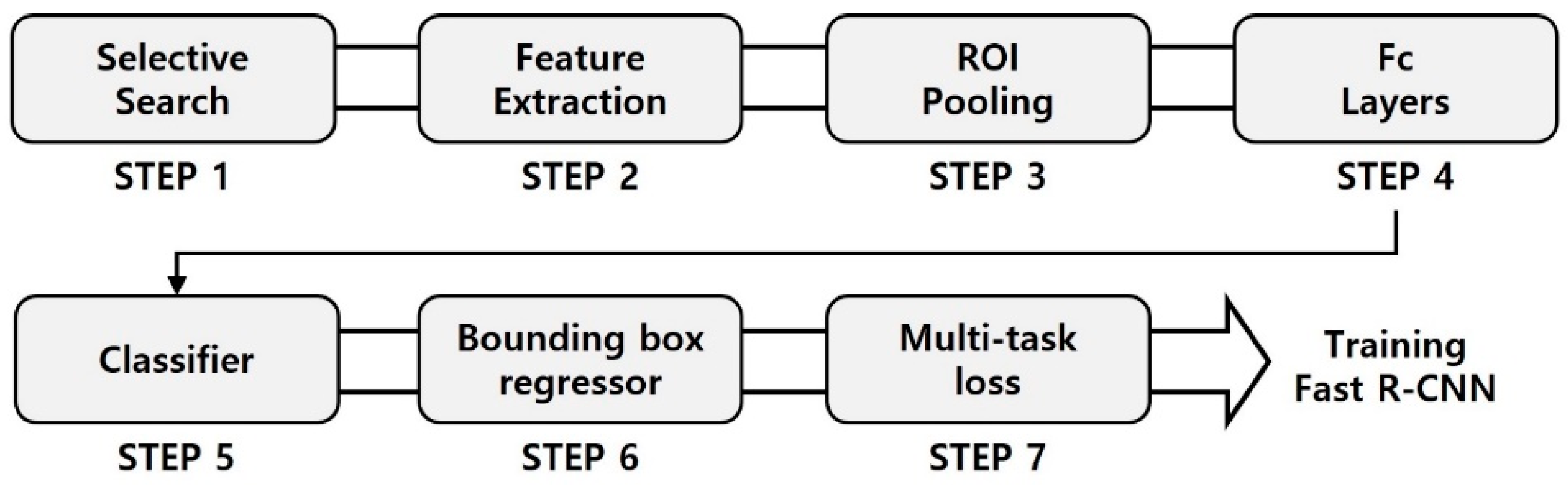

5.2. Fast R-CNN (Regional Convolutional Neural Network)

5.3. Fast R-CNN Model Training and Prediction

5.4. Experiment Environment

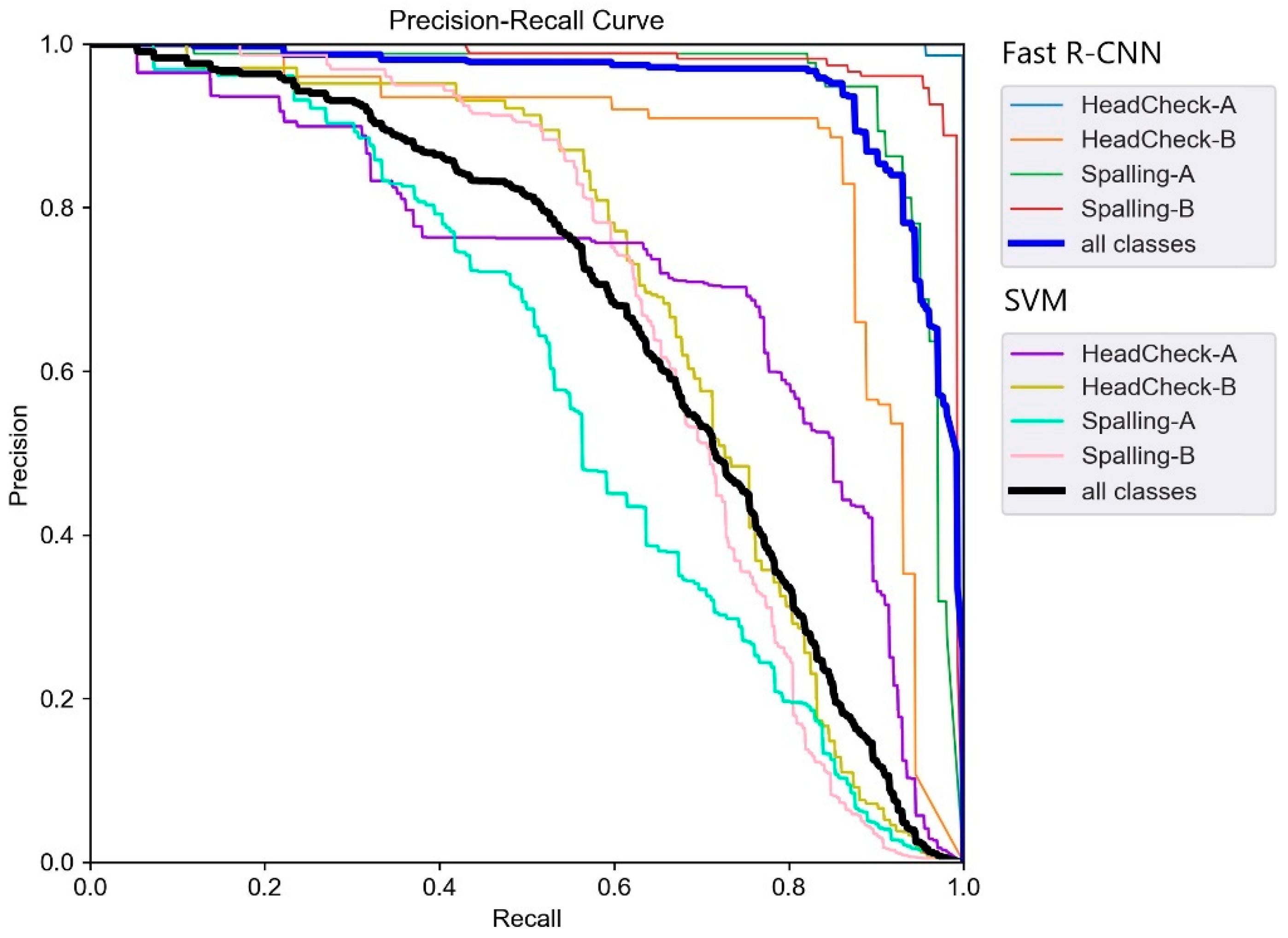

5.5. Experimental Result

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Choi, J.Y. Qualitative Analysis for Dynamic Behavior of Railway Ballasted Track. Ph.D. Thesis, Technical University of Berlin, Berlin, Germany, 2014. [Google Scholar]

- Choi, J.Y.; Park, D.R.; Chung, J.S.; Kim, S.H. Dynamic wheel-rail force-based track-irregularity evaluation for ballasted track on serviced railway by adjacent excavation. Appl. Sci. 2022, 12, 375. [Google Scholar] [CrossRef]

- Gren, D.; Ahlstrom, J. Fatigue Crack Propagation on Uniaxial Loading of Biaxially Predeformed Pearlitic Rail Steel. Metals 2023, 13, 1726. [Google Scholar] [CrossRef]

- Constantin-Ioan, B.; Corneliu, M.; George-Radu, P.; Lorenz, P.; Daniela-Lucia, C.; Cătălina, A.; Andreea-Carmen, B. Determining the causes that led to a railway rail breaking. In Railway infrastructure development for an efficient & green transport; Railway PRO: Edinburgh, UK, 2011; pp. 5–9. [Google Scholar]

- Grassie, S.L. Rail Corrugation: Characteristics, Cause and Treatments. Proc. Inst. Mech. Eng. Pt. F J. Rail Rapid Transit 2009, 223, 581–596. [Google Scholar] [CrossRef]

- Damme, S.; Nackenhorst, U.; Wetzel, A.; Zastrau, B.W. On the Numerical Analysis of the Wheel-Rail System in Rolling Contact. In System Dynamics and Long-Term Behaviour of Railway Vehicles, Track and Subgrade; Springer: Berlin/Heidelberg, Germany, 2003; Volume 6, pp. 155–174. [Google Scholar]

- Baeza, L.; Thompson, D.J.; Squicciarini, G.; Denia, F.D. Method for Obtaining the Wheel–Rail Contact Location and Its Application to the Normal Problem Calculation through ‘CONTACT’. Veh. Syst. Dyn. 2018, 56, 1734–1746. [Google Scholar] [CrossRef]

- Franklin, F.J.; Weeda, G.-J.; Kapoor, A.; Hiensch, E.J.M. Rolling Contact Fatigue and Wear Behaviour of the Infrastar Two-Material Rail. Wear 2005, 258, 1048–1054. [Google Scholar] [CrossRef]

- Conner, B.P. Contact Fatigue: Life Prediction and Palliatives. Ph.D. Thesis, Massachusetts Institute of Technology, Cambridge, MA, USA, 2016. [Google Scholar]

- Donzella, G.; Mazzù, A.; Petrogalli, C. Competition between Wear and Rolling Contact Fatigue at the Wheel—Rail Interface: Some Experimental Evidence on Rail Steel. Proc. Inst. Mech. Eng. Pt. F J. Rail Rapid Transit 2009, 223, 31–44. [Google Scholar] [CrossRef]

- Steyn, E. Rail Surface Treatment Grinding and Milling—Competing or Complementary Technologies. Master’s Thesis, Chalmers University of Technology, Gothenburg, Sweden, 2019. [Google Scholar]

- Mihai, D.M. Efficient Solutions for Diminuting the Rolling Noise of Trains. In Railway infrastructure development for an efficient & green transport; Railway PRO: Edinburgh, UK, 2011; pp. 50–52. [Google Scholar]

- Popović, Z.; Lazarević, L.; Mićić, M.; Brajović, L. Critical analysis of RCF rail defects classification. Transp. Res. Procedia 2022, 63, 2550–2561. [Google Scholar] [CrossRef]

- Zerbst, U.; Lundén, R.; Edel, K.-O.; Smith, R.A. Introduction to the Damage Tolerance Behaviour of Railway Rails—A Review. Eng. Fract. Mech. 2009, 76, 2563–2601. [Google Scholar] [CrossRef]

- Ndao, B. Generation et Detection sans Contact des ondes de Rayleigh par Methodes Ultrasons-Laser et EMAT Mode Statique et Dynamic Application to the Detection of Surface Defects in the Rail Head. Ph.D. Thesis, University of Valenciennes and Hainaut-Cambresis, Valenciennes, France, 2016. [Google Scholar]

- Nielsen, J.C.O.; Johansson, A. Out-of-round railway wheels-a literature survey. Proc. Inst. Mech. Eng. Pt. F J. Rail Rapid Transit 2000, 214, 79–91. [Google Scholar] [CrossRef]

- Ishida, M.; Ban, T.; Iida, K.; Ishida, H.; Aoki, F. Effect of moderating friction of wheel/rail interface on vehicle/track dynamic behaviour. Wear 2008, 265, 1497–1503. [Google Scholar] [CrossRef]

- Kaewunruen, S. Monitoring structural deterioration of railway turnout systems via dynamic wheel/rail interaction. Case Stud. Nondestruct. Test. Eval. 2014, 1, 19–24. [Google Scholar] [CrossRef]

- Sresakoolchai, J.; Kaewunruen, S. Detection and severity evaluation of combined rail defects using deep learning. Vibration 2021, 4, 341–356. [Google Scholar] [CrossRef]

- Yang, Z.; Li, Z. Rail Infrastructure Resilience—Part 7 Wheel-Rail Dynamic Interaction; Elsevier: Amsterdam, The Netherlands, 2022; pp. 111–135. [Google Scholar] [CrossRef]

- Ministry of Land, Infrastructure and Transport. Guidelines for regular inspection of railway facilities, etc.; Ministry of Land, Infrastructure and Transport: Sejong-si, Republic of Korea.

- Korea National Railway. Detailed Guidelines on Performance Evaluation of Track Facilities; Korea National Railway: Daejeon, Republic of Korea, 2021. [Google Scholar]

- Babu, S.R.; Jaskari, M.; Järvenpää, A.; Porter, D. The Effect of Hot-Mounting on the Microstructure of an as-Quenched Auto-Tempered Low-Carbon Martensitic Steel. Metals 2019, 9, 550. [Google Scholar] [CrossRef]

- Dasgupta, A.; Wahed, A. Clinical Chemistry, Immunology and Laboratory Quality Control; Elsevier: Amsterdam, The Netherlands, 2014; pp. 47–66. [Google Scholar]

- Perez, L.; Wang, J. The Effectiveness of Data Augmentation in Image Classification using Deep Learning. arXiv 2017, arXiv:1712.04621. [Google Scholar]

- Ross, G. Fast R-CNN. IEEE International Conference on Computer Vision (ICCV). arXiv 2015, arXiv:1504.08083. [Google Scholar]

- Jog, G.M.; Koch, C.; Golparvar-Fard, M.; Brilakis, I. Pothole properties measurement through visual 2D recognition and 3D reconstruction. In Proceedings of the International Conference on Computing in Civil Engineering, Clearwater Beach, FL, USA, 17–20 June 2012; pp. 553–560. [Google Scholar] [CrossRef]

- Buza, E.; Omanovic, S.; Huseinovic, A. A Pothole Detection with Image Processing and Spectral Clustering. In Proceedings of the 2nd International Conference on Information Technology and Computer Networks, Konya, Turkey, 8–10 October 2013; pp. 48–53. [Google Scholar]

- Mednis, A.; Strazdins, G.; Zviedris, R.; Kanonirs, G.; Selavo, L. Real Time Pothole Detection using Android Smartphones with Accelerometers. In Proceedings of the IEEE International Conference on Distributed Computing in Sensor Systems and Workshops, Barcelona, Spain, 27–29 June 2011. [Google Scholar] [CrossRef]

- Yin, T.; Yang, J. Detection of Steel Surface Defect Based on Faster R-CNN and FPN. In Proceedings of the International Conference on Computing and Artificial Intelligence (ICCAI), Tianjin, China, 23–26 April 2021; pp. 15–20. [Google Scholar] [CrossRef]

- Wang, H.; Li, M.; Wan, Z. Rail Surface Defect Detection Based on Improved Mask R-CNN. Comput. Electr. Eng. 2022, 102, 108269. [Google Scholar] [CrossRef]

- Munawar, H.S.; Hammad, A.W.; Haddad, A.; Soares, C.A.P.; Waller, S.T. Image-based crack detection methods: A review. Infrastructures 2021, 6, 115. [Google Scholar] [CrossRef]

- Guo, Z.; Wang, C.; Yang, G.; Huang, Z.; Li, G. MSFT-YOLO: Improved YOLOv5 Based on Transformer for Detecting Defects of Steel Surface. Sensors 2022, 22, 3467. [Google Scholar] [CrossRef] [PubMed]

- Yu, R.; Wei, X.; Liu, Y.; Yang, F.; Shen, W.; Gu, Z. Research on Automatic Recognition of Dairy Cow Daily Behaviors Based on Deep Learning. Animals 2024, 14, 458. [Google Scholar] [CrossRef] [PubMed]

| Division | Crack Depth (mm) | Crack Length (mm) | Crack Propagation Angle (°) |

|---|---|---|---|

| C direction | 0.481 (±0.227) 0.254–0.708 | 0.902 (±0.436) 0.466–1.338 | 25.97 (±17.43) 8.54–43.4 |

| L direction | 0.358 (±0.206) 0.152–0.564 | 1.504 (±0.835) 0.669–2.339 | 6.76 (±2.07) 4.69–8.83 |

| Crack Depth Range | Crack Propagation Probability Average Value (Xc, mm) | Standard Deviation (SD, mm) | Crack Propagation Angle (°) |

|---|---|---|---|

| 0.00–0.25 mm | 18.2 | ±9.43 | 8.77–27.63 |

| 0.25–0.50 mm | 21.34 | ±14.10 | 7.24–35.44 |

| 0.50–0.75 mm | 30.46 | ±19.9 | 10.56–50.36 |

| 0.75 mm< | 25.12 | ±12.27 | 12.85–37.39 |

| Crack Depth Range | Crack Propagation Probability Average Value (Xc, mm) | Standard Deviation (SD, mm) | Crack Propagation Angle (°) |

|---|---|---|---|

| 0.00–0.25 mm | 6.28 | ±2.23 | 4.05–8.51 |

| 0.25–0.50 mm | 6.71 | ±1.98 | 4.73–8.69 |

| 0.50–0.75 mm | 6.93 | ±1.89 | 5.04–8.82 |

| 0.75 mm< | 9.01 | ±1.42 | 7.59–10.43 |

| Division | Environment |

|---|---|

| OS | Windows 11 Professional |

| CPU | Intel(R) Core (TM) i5-13600K CPU @ 3.5GHz |

| RAM | DDR5 32G(PC5-44800) * 4 = 128G |

| GPU | GeForce RTX 4060Ti |

| SSD | Gold P31 M.2 2TB |

| Correct Answer | |||

|---|---|---|---|

| True | False | ||

| Classification result | True | True Positive | False Positive |

| False | False Negative | True Negative | |

| Learning Data | Model (mAP (IoU@0.5)) | |

|---|---|---|

| Fast R-CNN | SVM | |

| Headchek_A | 99.4 | 72.0 |

| Headchek_B | 86.8 | 70.1 |

| Spalling_A | 95.3 | 58.4 |

| Spalling_B | 98.2 | 68.2 |

| All classes | 94.9 | 67.2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Choi, J.-Y.; Han, J.-M. Deep Learning (Fast R-CNN)-Based Evaluation of Rail Surface Defects. Appl. Sci. 2024, 14, 1874. https://doi.org/10.3390/app14051874

Choi J-Y, Han J-M. Deep Learning (Fast R-CNN)-Based Evaluation of Rail Surface Defects. Applied Sciences. 2024; 14(5):1874. https://doi.org/10.3390/app14051874

Chicago/Turabian StyleChoi, Jung-Youl, and Jae-Min Han. 2024. "Deep Learning (Fast R-CNN)-Based Evaluation of Rail Surface Defects" Applied Sciences 14, no. 5: 1874. https://doi.org/10.3390/app14051874

APA StyleChoi, J.-Y., & Han, J.-M. (2024). Deep Learning (Fast R-CNN)-Based Evaluation of Rail Surface Defects. Applied Sciences, 14(5), 1874. https://doi.org/10.3390/app14051874