1. Introduction

The development of mining dump trucks is hindered by high technical difficulty, the need for substantial capital investment, and a lengthy research and development cycle, resulting in a scarcity of relevant studies. Additionally, due to the wide dimensions, heavy payload, and harsh working conditions of mining dump trucks, significant vibrations are easily generated, affecting both handling stability and ride comfort [

1]. Suspension systems play a vital role as essential components in vehicles, primarily being tasked with dampening vibrations arising from road roughness. They are also responsible for transmitting forces to the vehicle body, thereby influencing ride comfort, handling, stability, and overall safety performance [

2,

3,

4].

Currently, mining dump trucks mainly utilize integral front axles as their front suspension. However, due to the integral front axle being a non-independent suspension, the front wheels interfere with each other during operation, resulting in relatively lower handling stability and smoothness of the entire vehicle. Moreover, as the overall vehicle weight of dump trucks continues to increase, there is an urgent need to adopt a new type of independent suspension to meet design goals. The candle-type front suspension is relatively mature in the field of medium and small mining dump trucks. The structure of mining vehicles equipped with candle-type independent front suspension is more compact, allowing the engine’s assembly components to be easily adjusted to a lower position, thus lowering the vehicle’s center of gravity. However, since the kingpin is fixed on the frame, the front wheel track may be affected by the up-and-down movement of the piston rod of the oil-gas suspension, resulting in lateral tire slip, further increasing tire wear. Additionally, the contact surface between the rod and cylinder of this suspension often generates significant lateral forces, greatly reducing the service life of the front suspension components due to the significant effects of lateral forces. The double-wishbone front suspension, on the other hand, does not have these drawbacks. These wishbones can absorb lateral forces, enhancing the vehicle’s resistance to tilting during steering; the kingpin only needs to bear the weight of the vehicle. Additionally, the structural design of the double-wishbone front suspension allows the vehicle to correct its camber angle during operation, to some extent reducing the lateral slip of the wheels and decreasing tire wear. Furthermore, it can adjust the position of the wishbones to adapt to the road surface, enabling the tires to have a larger contact area with the ground, thereby improving ground adhesion performance. Therefore, this paper proposes to transform the integral front axle into a double-wishbone independent front suspension and conduct research on it.

Amir Afkar [

5] utilized ADAMS software to model and optimize an off-road vehicle in 2012. By conducting simulation analyses on various subsystems of the entire vehicle, potential design issues were identified, leading to improvements in the overall handling stability and smoothness. The outcomes of this research not only serve as a reference for the design and optimization of off-road vehicles, but also offer valuable insights and experiences applicable to the design of other vehicle types. In 2014, Kang Yiting [

6] and other scholars conducted a study on the ride comfort of a 190-ton mining truck, employing various front suspension systems, including double-wishbone independent suspension and candlestick suspension. The researchers utilized Maple Sim to model and simulate the different front suspension systems under various road conditions. Through comparative analysis of the wheel alignment parameters with changing wheel bounce, they ultimately concluded that the double-wishbone independent suspension and multi-link independent suspension exhibited superior kinematic characteristics. Global mining truck manufacturers have also actively pursued technological innovations, exploring various approaches to innovate and enhance the structural design of mining trucks to improve overall performance. The Liebherr Group, in its 600-ton mining truck, employs a double-wishbone front suspension and a multi-link rear suspension, significantly reducing the lateral forces experienced by the wheels. Various configurations are implemented to minimize tire wear, maximizing the lifespan of the tires to the greatest extent possible [

7]. In recent years, scholars in the field have gradually shifted their research focus towards enhancing the handling stability and ride comfort of mining dump trucks. Wang et al. [

8,

9] applied the quasi-zero stiffness isolator to the vibration isolation of the car, established a vehicle-seat-human coupling dynamics model, and studied the impact excitation and random excitation of the model. The dynamic characteristics of the vehicle have effectively improved the vibration comfort of the vehicle. To meet the increasingly higher demands for vibration comfort, active vibration control [

10] technology has begun to be applied in vehicle damping, including both active and semi-active suspension technologies. Xiao et al. [

11] transformed the base between the cabin floor and the seat into a particle damper, establishing a discrete element model for the damper to analyze and determine the optimal solution. They successfully reduced the vibrations in the mining dump truck’s cabin, thereby improving vibration comfort. Zou et al. [

12] proposed a hydraulic interconnected suspension system based on energy regenerative shock absorbers to simultaneously enhance ride comfort, traction capability, and energy recovery potential. They established a seven-degree-of-freedom whole-vehicle suspension model for modeling and driving analysis. The results indicate that the new suspension system can attenuate vibrations, maintaining excellent ride comfort. Kihan Kwon [

13] improved vehicle ride comfort and stability by optimizing the parameters of the oil and gas suspension. Subsequently, they built a comprehensive vehicle model to analyze the vehicle’s performance. Proper suspension design is more crucial for heavy-duty vehicles than for passenger cars due to their different dynamic behaviors [

14,

15]. Due to the interdependencies among various performance parameters of suspension systems, to avoid situations where improving one performance aspect leads to a decline in others, multi-objective optimization should be conducted to determine design solutions that simultaneously optimize all performance indicators [

16,

17,

18]. Additionally, accurate analysis of heavy-duty vehicle behavior, considering pitch and roll effects, requires a comprehensive vehicle model to achieve optimal suspension design.

In recent years, scholars in the field have primarily focused on active vibration control technology, optimization of oil and gas springs, and cabin damping for the suspension system of mining dump trucks. This research aims to enhance the handling stability and ride comfort of dump trucks. However, there is relatively limited research on the application of double-wishbone suspension in mining dump trucks; therefore, it is essential to modify, validate, analyze, and optimize the front suspension of a 300-ton-class mining dump truck. Subsequently, conducting a comprehensive comparison with actual data for the entire vehicle becomes necessary. This paper focuses on optimizing specific spatial parameters of the double-wishbone front suspension to enhance suspension performance, with noticeable effects. The modified vehicle’s ride comfort is then compared with experimental data to validate the improvement in ride comfort. The main content is as follows:

Section 2 optimizes the parameters of the double-wishbone front suspension and conducts simulations;

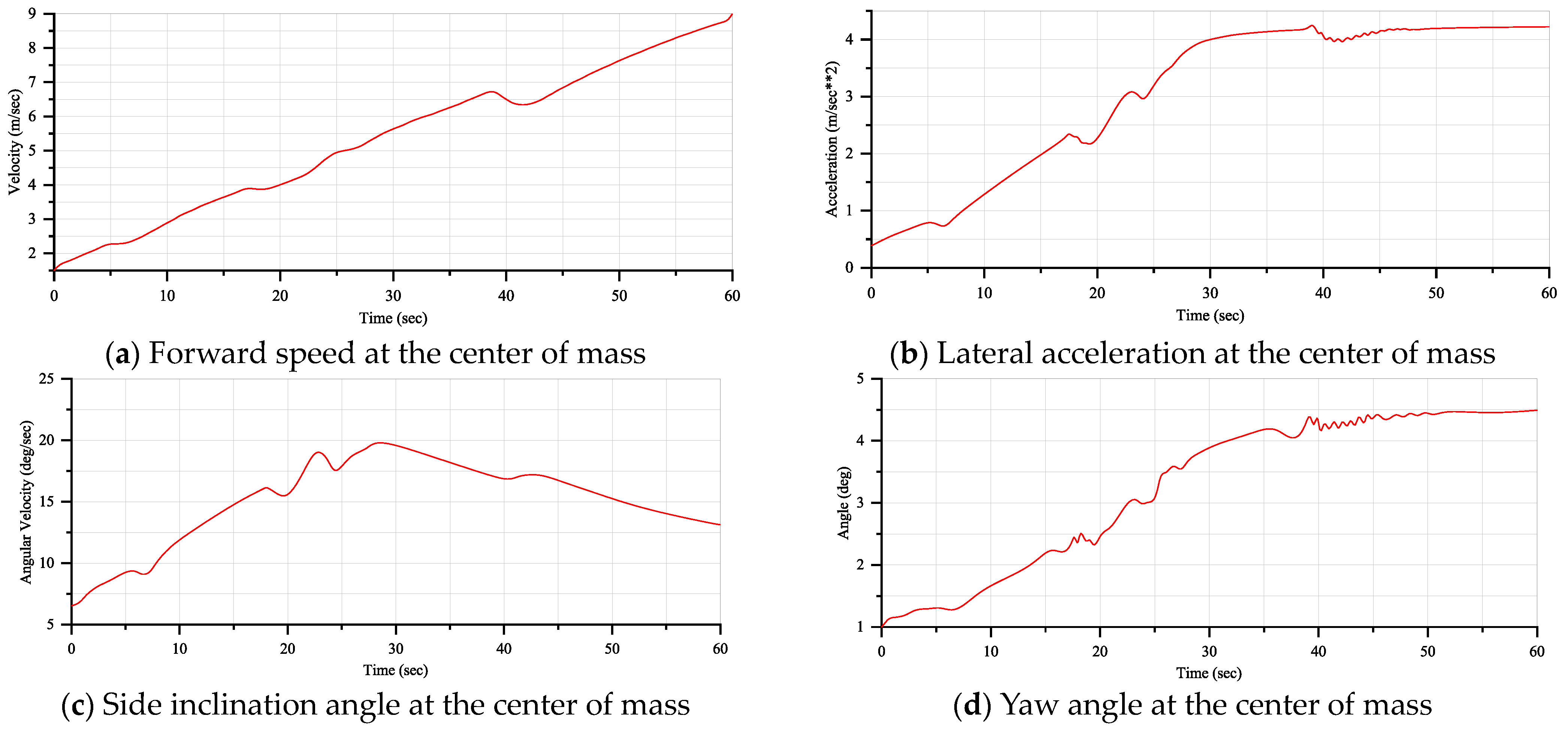

Section 3 establishes a whole vehicle model for verification of handling stability and ride comfort;

Section 4 analyzes and compares the optimized results with empirical results;

Section 5 provides a summary and discussion.

2. The Optimization Design of Parameters and Parallel Wheel Travel Simulation

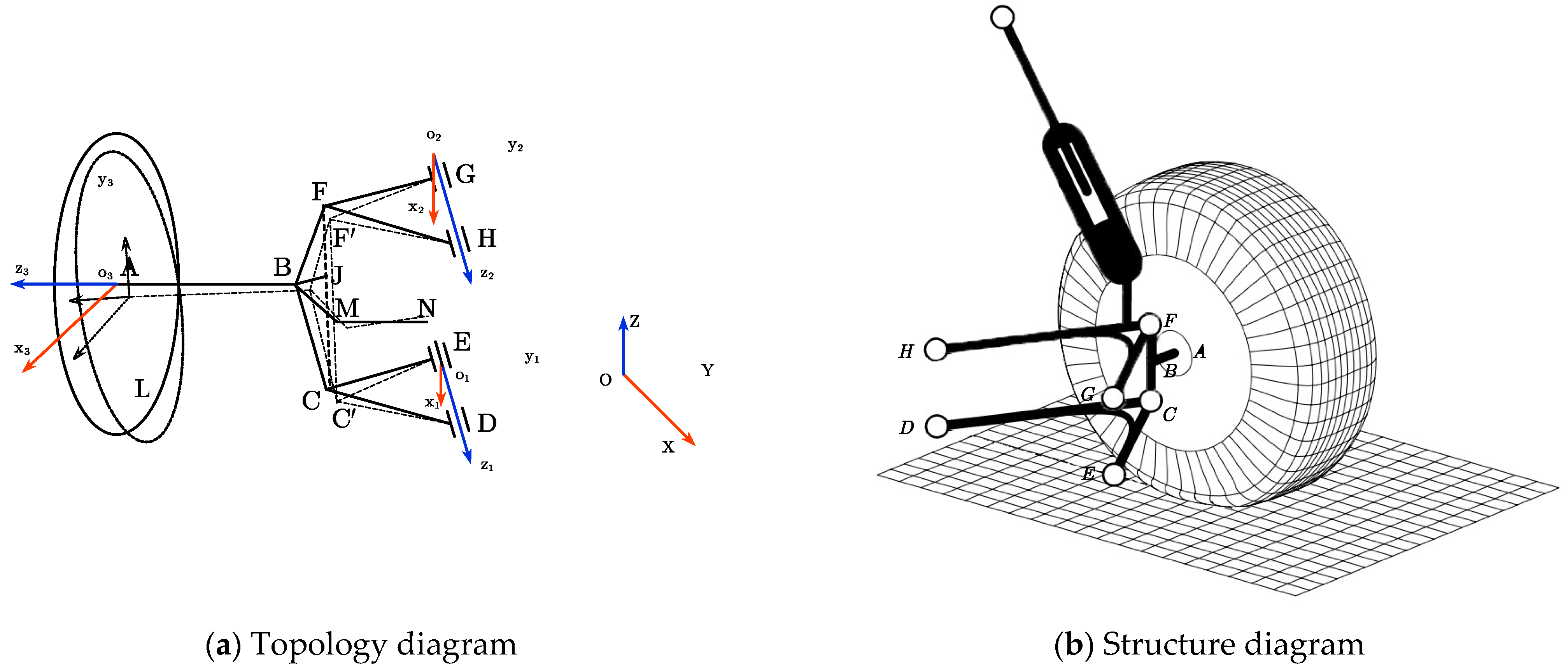

Figure 1a depicts the spatial topology diagram of a double-wishbone front suspension. In this diagram, CDE and FGH constitute the upper and lower control arms, respectively, rotating around the virtual axes Co1 and Fo2 at points o1 and o2. F and C are the connection points (outer points of the upper and lower arms) to the wheel-steering knuckle using ball joints. Point B represents the power input half-shaft end, MN denotes the steering tie rod, A is the center of the wheel, and L is the point of wheel contact with the ground. The origin o serves as the coordinate origin for the entire vehicle, and local coordinate systems are established at o1, o2, and the wheel center point A.

Figure 1b provides a schematic diagram of a double-wishbone front suspension structure.

The quality of the suspension guidance structural performance is determined by the ability of the wheel and suspension parameters to remain within reasonable limits during the normal vertical travel of the wheel. The wheel and suspension characteristics of the suspension system shown in the figure can be calculated using the following formula [

19,

20]:

Defining the kingpin inclination angle as positive when the kingpin is inclined inward. When the kingpin is inclined backward, the caster angle is defined as positive. When the wheel is tilted outward, the camber angle is defined as positive. When the front toe is inclined towards the vehicle’s neutral plane, the toe angle is defined as positive.

During the vertical travel of the suspension, it is required to minimize the wheel’s camber angle, while keeping the lateral slip and toe angle as constant or changing it as minimally as possible. Simultaneously, when determining the suspension hard points’ positions, it is essential to ensure other suspension characteristics, such as roll height.

The lateral slip at the wheel center

A :

Set and as the unit vectors along the Z axes in the coordinate system and . When the wheel undergoes vertical motion, the upper and lower arms rotate about the direction vectors and by angles and . As a result, points C and F rotate to C’ and F’.

Applying the finite rotation tensor, we get:

in which:

Solving the transcendental equation above reveals the relationship between the angles

and

:

in which:

In order to analyze the characteristics of the wheel and suspension during vertical oscillations, it is necessary to determine the coordinates of each hard point in the suspension guidance mechanism shown in

Figure 1a during the wheel’s vertical travel. During the wheel’s vertical travel, the suspension’s upper and lower swing arms are connected to the chassis via a sub-frame, allowing only rotation along the vectors

and

.

Therefore, the coordinates of each hard point are determined using the following method:

Point

C, during the vertical motion of the wheel, consistently moves within a plane with

as the center and

as the normal. Specifically, at the lower swing arm

:

Subsequently, to determine the

coordinate array E

1 and the coordinates of point

, we have:

in which:

Similarly, applying the method used to solve for point

C, we can solve for point F:

in which:

In the process of vertical oscillation of the wheel, the projection of the main axle point J along the main axle CF is at a fixed ratio. The coordinates of point J are calculated using the fixed ratio point division formula:

Set the fixed ratio as

, then the coordinates of point

J :

In the vertical oscillation process of the wheel, the longitudinal arm connecting point M constrains the spatial orientation of the wheel support ABCF concerning the pivoting arm. Point M, relative to the longitudinal arm pivot point N and the external points

C and F of the pivoting arm, maintains a constant scale. Set longitudinal arm

MN:

in which:

Solve the system of equations to obtain the coordinates of point

M, set:

in which:

In the process of vertical wheel travel, point B serves as the semi-axis power input point. However, its distance from the longitudinal arm endpoint

M, as well as the connecting points

C and

J of the wheel support, remains constant. Let the distance BM be denoted as Rm and the distances

BC and

BJ be denoted as

RBC and

RBJ. Similarly, applying the method used to solve for point M as described above, the coordinates of point B can be determined:

in which:

.

As the sought point represents an intersection point in the spatial sphere, employing different computational methods may yield solutions that satisfy the constraint equations but do not correspond to the desired point. Therefore, the coordinates of points B are determined using the method described in the reference.

In the process of vertical wheel travel, the center point of the wheel undergoes vertical movement in response to the angular displacement of the upper and lower pivoting arms, causing changes around the kingpin CF. Meanwhile, point A maintains a constant distance from the longitudinal arm endpoint M and the external endpoints C and F of the wheel support. Let the distance AM be denoted as RA, and the distances AC and AF be denoted as RAC and RAF.

Similarly, following the method used to solve for point B as described above, the coordinates of point A can be determined:

in which:

.

During the suspension motion, vector consistently remains perpendicular to the wheel plane , even as vector maintains orthogonality with vector . Given the fixed length of the wheel radius , it is possible to determine the coordinates of the wheel contact point I. A local rigid coordinate system is established at the center of the wheel, with the unit vector in the -direction oriented perpendicular to the wheel plane pointing outward. The -axis is directed upward, and the -axis direction is determined by the right-hand rule.

Based on this, the transformation matrix

expressing the relative transformation of the body coordinate system

concerning the global coordinate system

can be determined:

in which:

The coordinate matrix in the global coordinate system

after the wheel oscillation can be expressed as follows:

By substituting the obtained coordinates of the hard points during the wheel travel process into Equations (1)–(3), the lateral slip , camber angle , toe angle , and other suspension motion characteristics at the center of the wheel can be solved based on the aforementioned formulas.

According to the current technical specifications, the preliminary design coordinates of the hard points are presented in

Table 1.

Based on the preliminary design coordinates of the hard points, a physical model of the double-wishbone front suspension was created in SolidWorks 2023, as depicted in

Figure 2a. Subsequently, this model was imported into ADAMS/Car 2020, as illustrated in

Figure 2b.

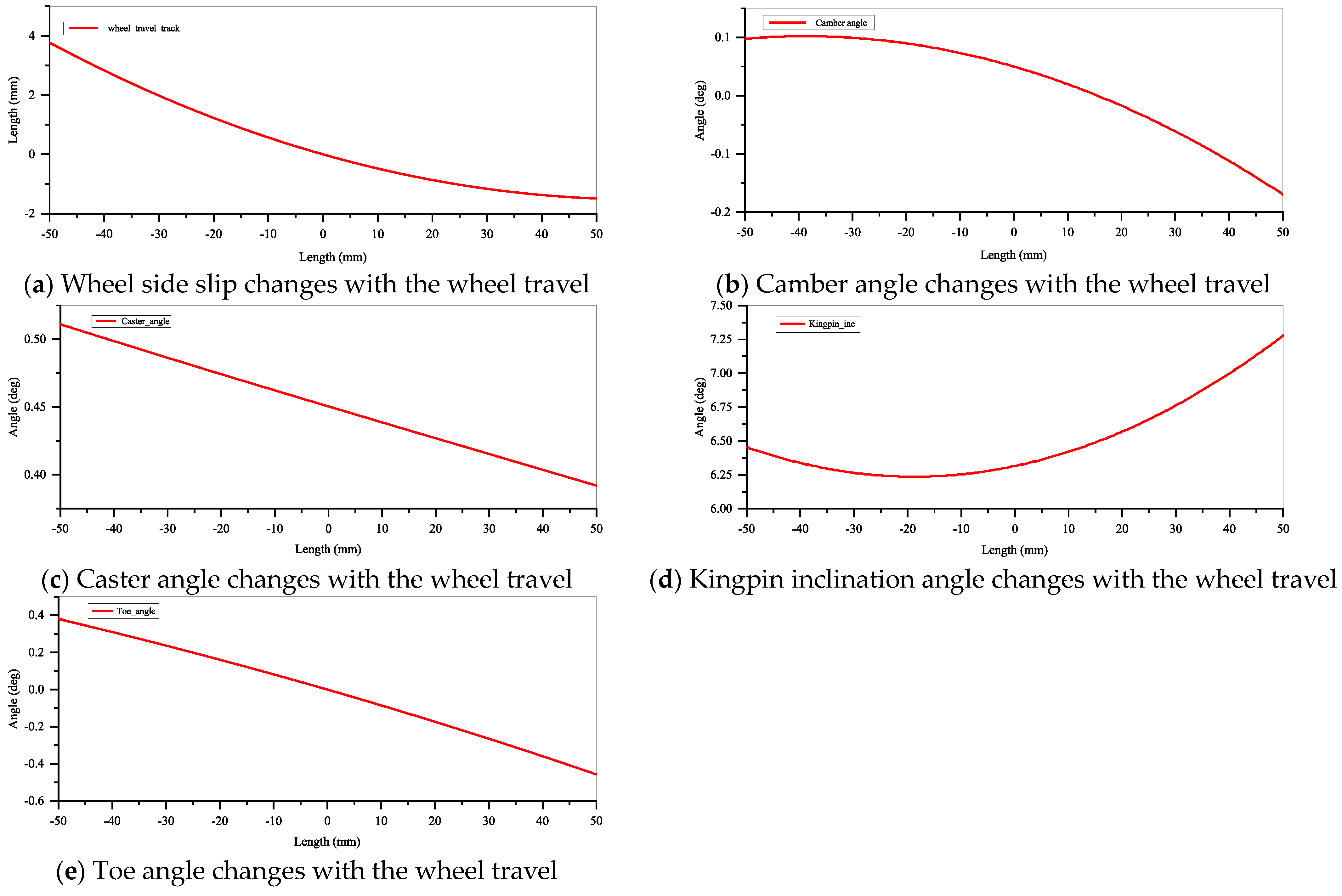

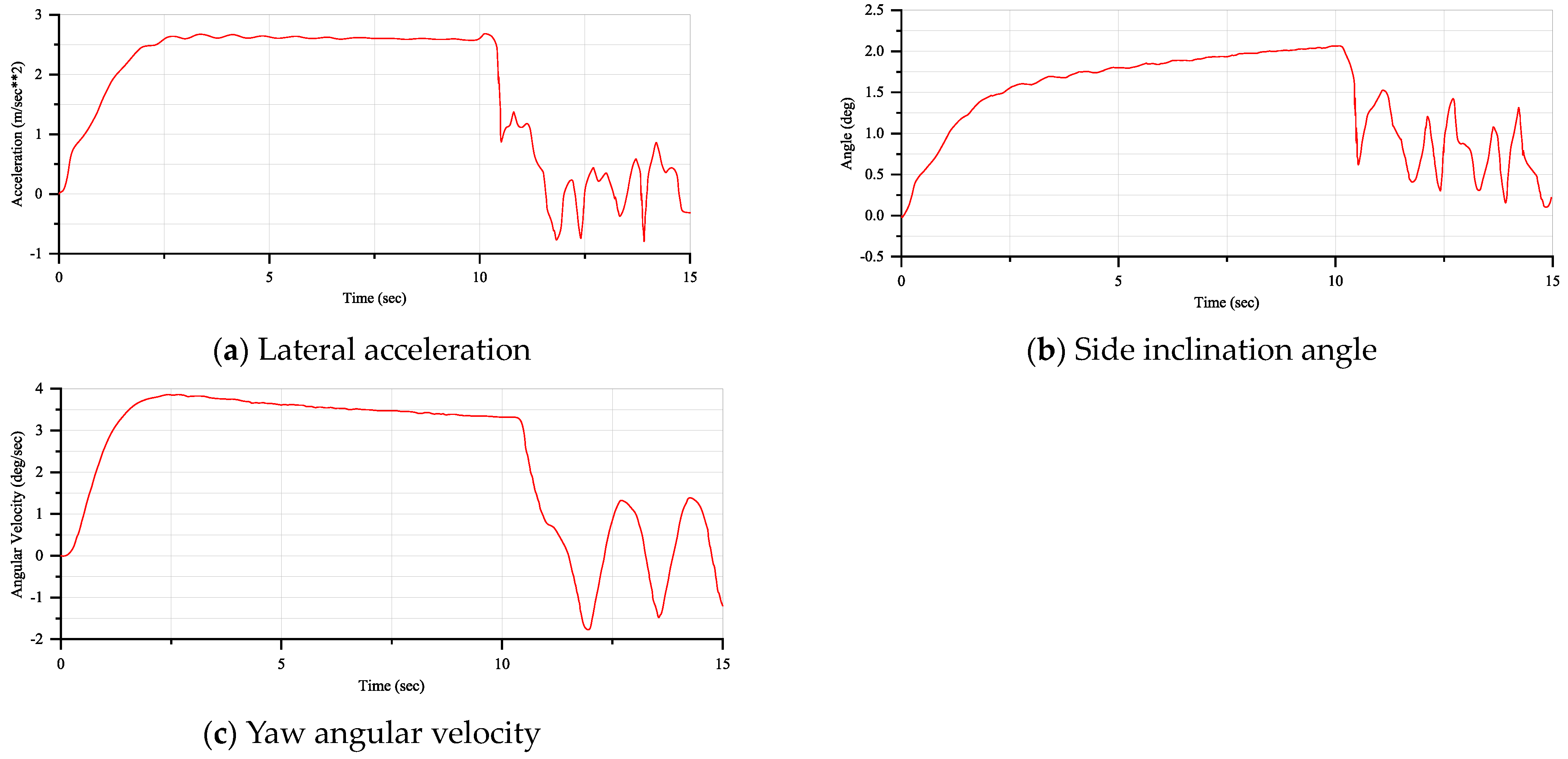

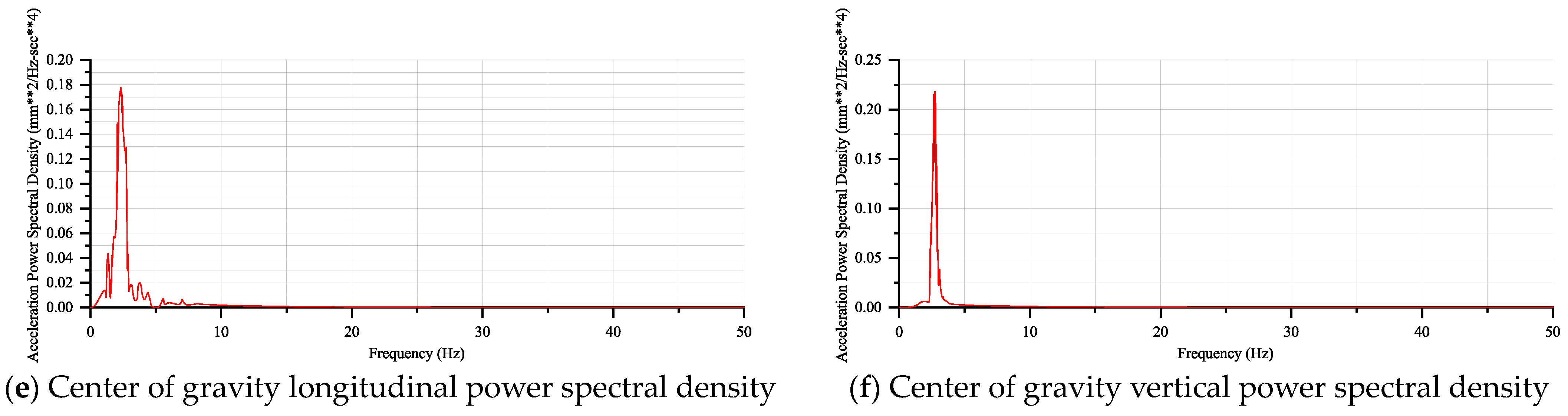

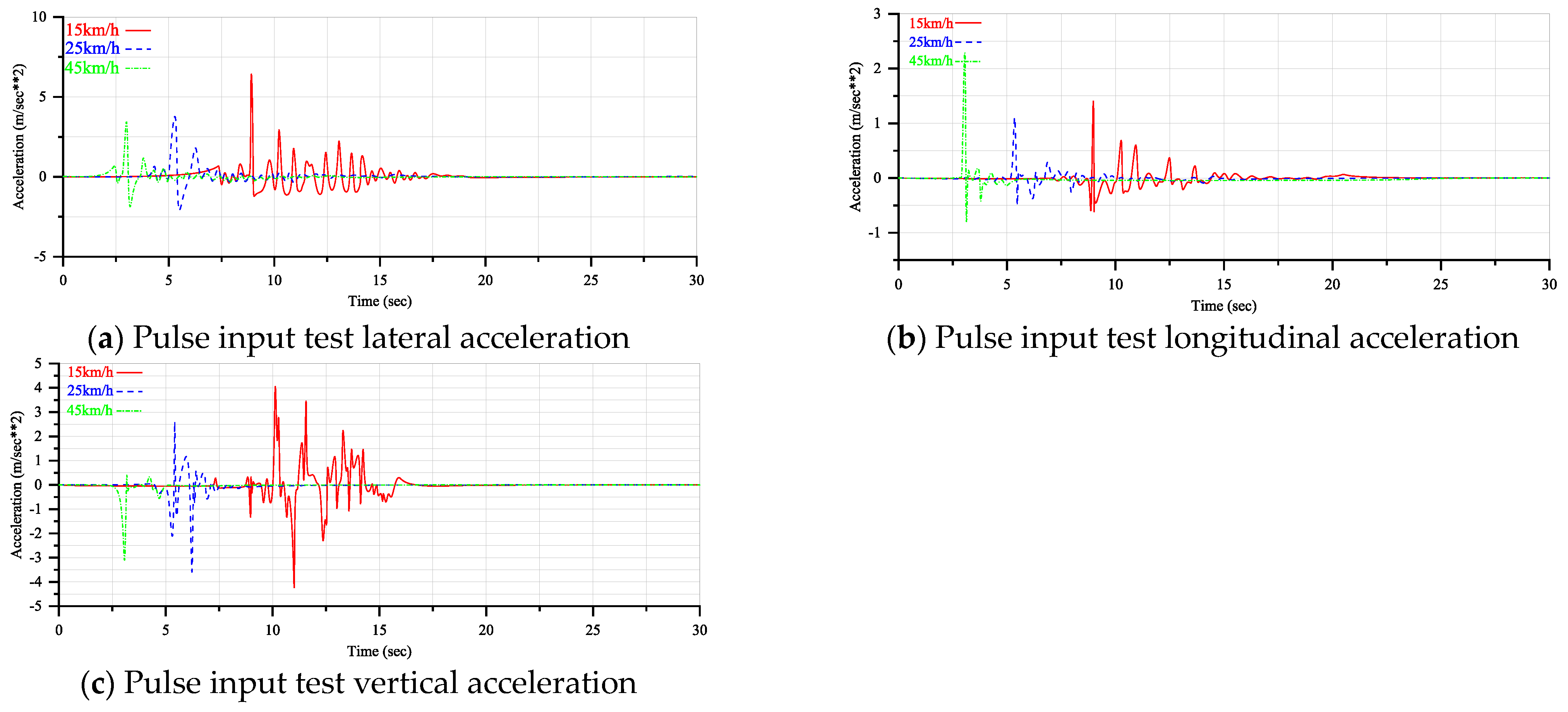

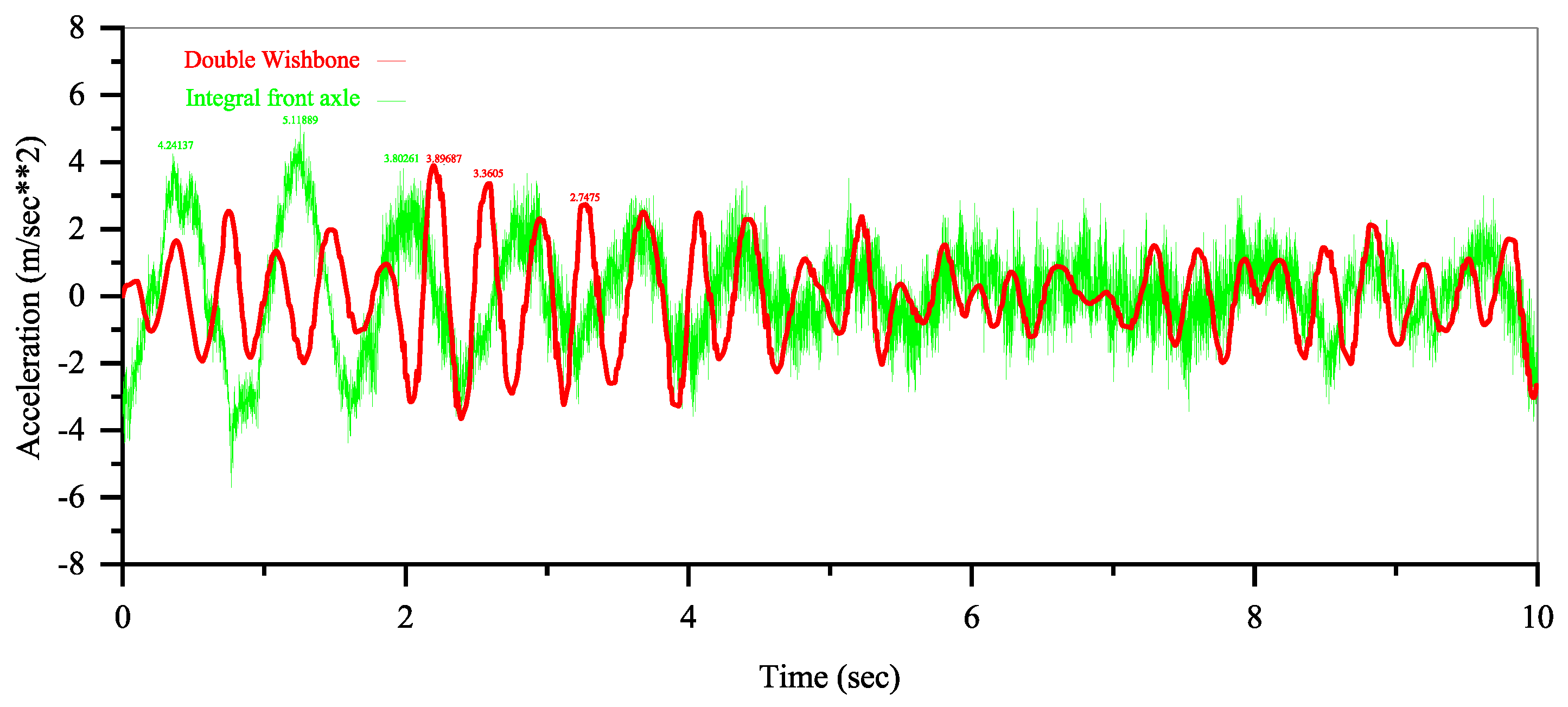

Performing a parallel-wheel travel simulation on the suspension model simulates the actual conditions of suspension motion when the wheel encounters obstacles or other situations that cause the tire to bounce during its operation. Based on the simulation results, a comprehensive analysis of the suspension characteristics under these conditions is conducted. Setting the simulation wheel bounce from −50 mm to 50 mm, the variation in major parameters with wheel travel range is depicted in

Figure 3 after the simulation. Utilizing the double-wishbone suspension kinematic model developed in this paper for motion analysis, the comparison in the figure shows a close match between the simulation results and the model’s predictions, thus validating the correctness of the virtual prototype model of the double-wishbone suspension presented in this study.

In simulated experiments conducted in ADAMS, the curve of the wheel’s lateral slip with wheel bounce is illustrated in

Figure 3a. Based on the analysis of the lateral slip results in the figure, it is observed that the lateral slip of the wheel varies within the range of −1.8 mm–3.8 mm, with a total variation of 5.6 mm. It is generally recommended to control the lateral slip of the wheel within a range of 5 mm for optimal performance during wheel travel. Consequently, optimization measures are required to meet this criterion.

The ideal range for camber angle variation is typically 0°–1°. In

Figure 3b, the variation range of the camber angle during the wheel bounce travel is −0.17° to 0.1°, and its variation falls within the ideal range, meeting the design requirements.

In

Figure 3c, within the wheel bounce travel range of −50 mm–50 mm, the caster angle varies within the range of 0.35°–0.52°, which is generally under the design requirements.

The reasonable variation range of kingpin inclination angle is typically between 5° and 15°, with 5° being considered optimal for many off-road vehicles. From

Figure 3d, it is observed that the caster camber varies within the range of 6.25°–7.3°. Although the variation falls within the requirements, there is still room for optimization.

In

Figure 3e, it is observed that the variation range of the front toe angle is between 0.38° and −0.42°, indicating a relatively small and acceptable range, and the variation trend aligns with the design requirements.

Through the analysis results, the absolute value of the lateral slip at the wheel contact point reached 5.6 mm. Such a large lateral slip increased tire wear. To control the lateral slip of the double-wishbone front suspension of the mining dump truck, if the slip amount is within a reasonable range, parameterization and optimization analysis of key suspension points are required.

Due to the mutual influence between various suspension performance parameters, to avoid the situation where one performance is improved and other properties have deteriorated, this paper selects the changes in camber angle

ψ, toe angle

θ, caster angle

, the change in the kingpin inclination angle

α and the standard deviation of the change in the side slip amount

of the front suspension tire contact point. These five performance parameters are used as optimization targets, and their respective objective functions are as follows:

According to the unified objective method, the above sub-objectives are combined into a unified objective function as shown in Formula (20):

According to the characteristics of the suspension and the technical indicators of the car body, the z-coordinates of the front, rear, and outer points of the upper and lower wishbones of the front suspension are parameterized, and design variables are created accordingly.

Due to the technical specifications and structural space of the vehicle itself, this variable of the suspension structure’s hard point parameters cannot be too large. The constraints are in the form of percentage relative values, which are −10.0 and +10.0, respectively.

Considering the numerous hard-point coordinates present in a suspension design, comprehensively addressing all of them will significantly impact optimization speed. Therefore, ADAMS/Insight was used for sensitivity analysis of hard point coordinates, and key influencing factors were selected according to the size of the influence to optimize them. Through DOE (Design of Experiments) screening of linear partial factorial design, 128 iterations were performed to complete the optimization analysis. Evaluation of fit indices, such as R2 = 0.998 and R2adj = 0.998, approaching unity indicates a high reliability of the model.

Ultimately, through optimization analysis, the numerical values of hardpoint coordinates changed. Specific values of the hardpoint coordinates before and after optimization can be found in

Table 2.

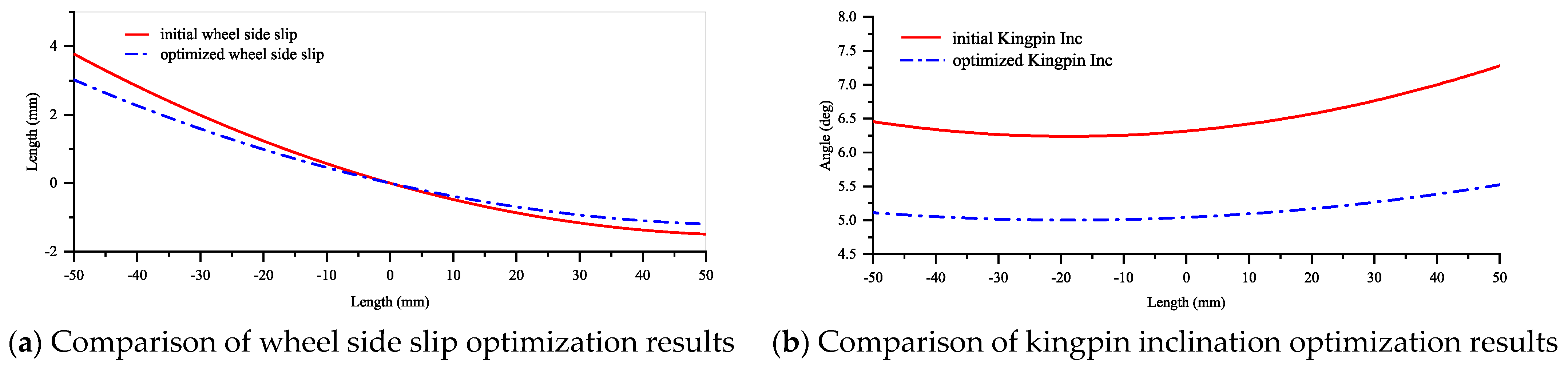

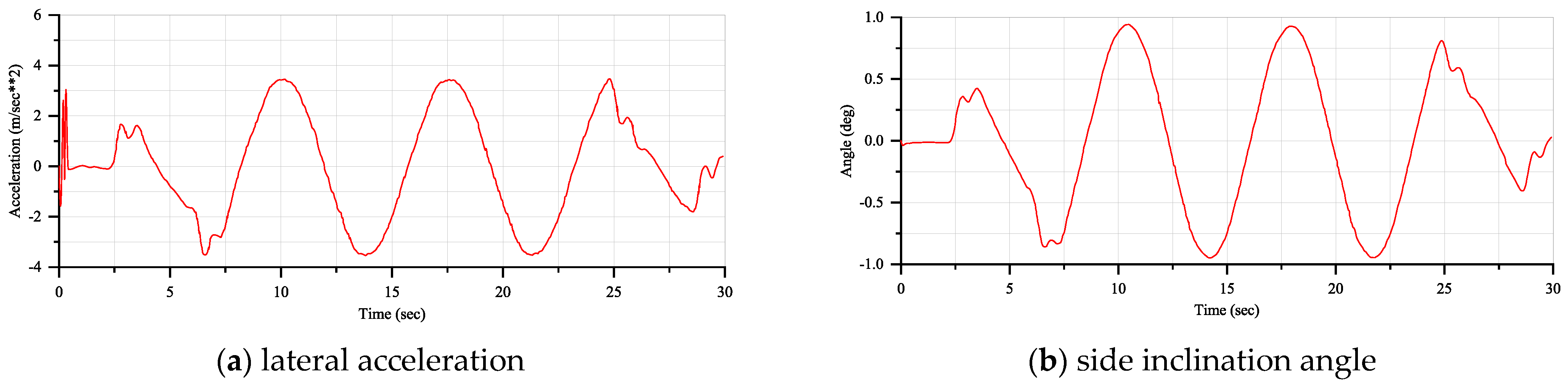

After optimizing the hardpoint coordinates, modifications were made to the original model. Subsequently, a parallel-wheel bounce simulation for the front suspension was conducted again. The results obtained after optimization were then compared and analyzed against the pre-optimized results. The lateral shift variation with wheel travel after optimization is illustrated in

Figure 4a, while the caster camber variation with wheel travel after optimization is depicted in

Figure 4b.

From the above figures, it can be observed that the lateral slip of the wheel during the optimized wheel travel process is controlled within 3.5 mm (−1~2.5), representing a 37.5% improvement. This meets the design requirements and significantly reduces tire wear. The optimized kingpin inclination angle (5.1–5.6°) not only approximates the optimal angle of 5° more closely, but also exhibits a reduced variation of 0.65° compared to before optimization, achieving a 61% improvement. This meets the design requirements, and the reduction in the kingpin inclination angle contributes to easier steering, achieving the optimization objective.