Research on Kinematics and Efficiency Calculation of Binary Logic Planetary Gearbox Based on Graph Theory

Abstract

1. Introduction

2. Dual-State Logic Drive

3. Double-State Logic Drive–Double Internal Meshing Coplanar Gear Planetary Array Characteristic Analysis

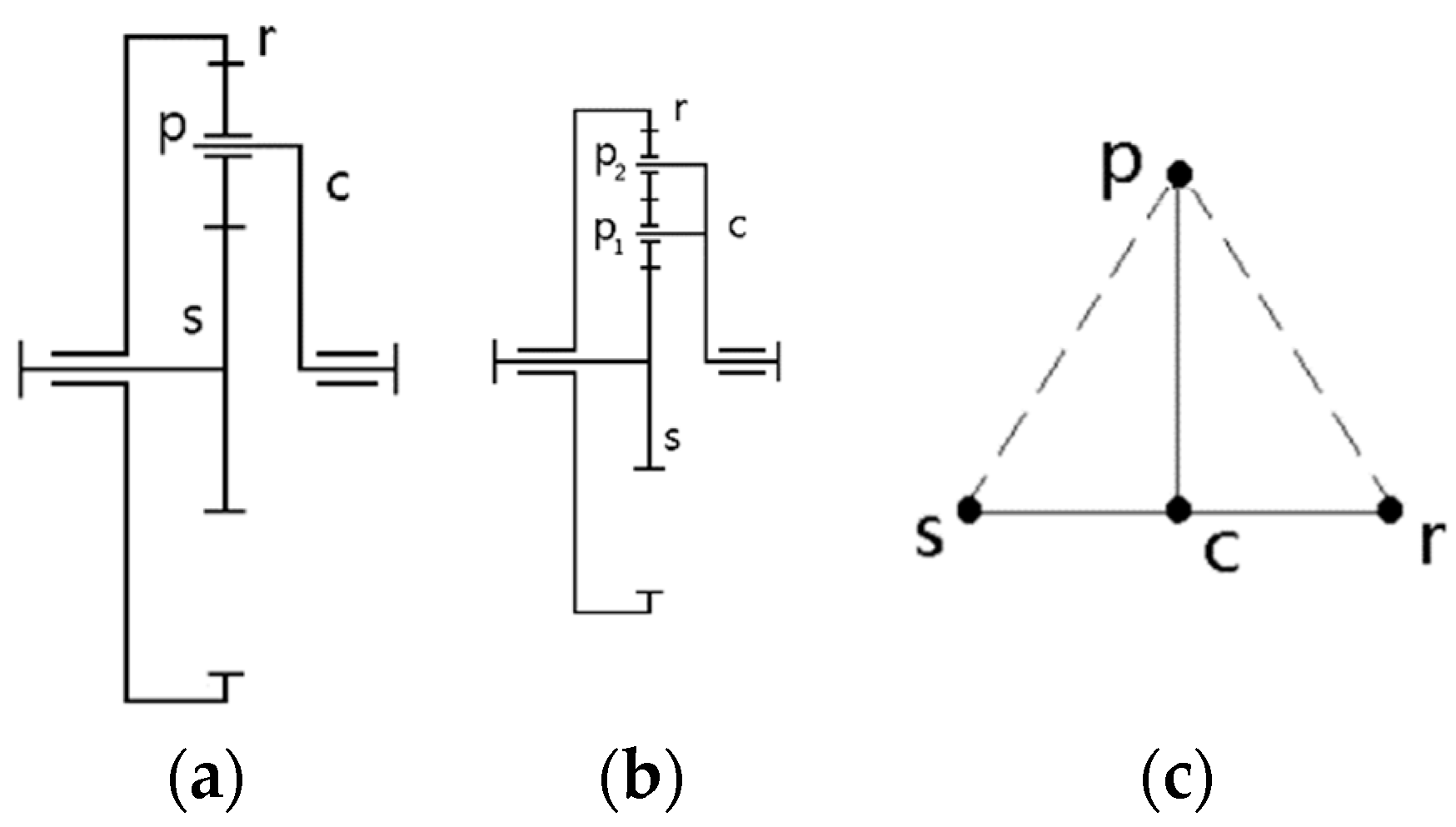

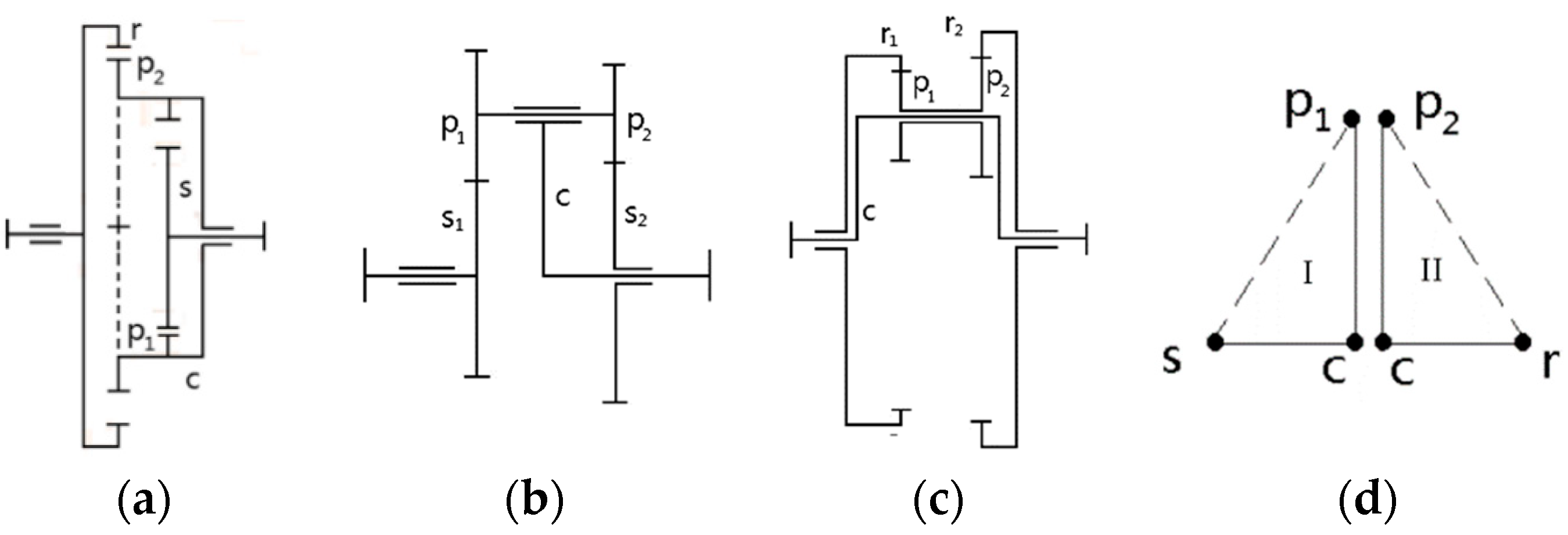

3.1. Graph Theory Model of Coplanar Gear Planetary Array

3.2. Analysis of Rotational Speed and Speed Ratio of Single-Row Coplanar Gear Planetary Array

3.3. Speed Matrix Analysis of a Coplanar Gear Planetary Gearbox

3.4. Analysis of Gear and Dual-State Logic Characteristics of Coplanar Gear Planetary Transmission

3.5. Transmission Control Logic Characteristic Matrix

3.6. The Velocity Characteristic Matrix of Each Gear of a Coplanar Gear Planetary Transmission

4. Analysis and Calculation of Speed and Speed Ratio of Two-State Logic Transmission Gearbox

5. Analysis and Calculation of Power Loss and Efficiency of a Two-State Logic Transmission

6. Conclusions

- Due to the particularity of the double internal meshing planetary row, this paper splits the k value of the planetary row, establishes its graph theory model and its corresponding speed equation, and uses the standard form of the equations to assemble the kinematics equation of the whole two-state logical planetary transmission to realize the calculation and analysis of the speed (speed ratio) expression of each gear. This provides strong support for further optimization and design of the transmission. Through in-depth understanding of the kinematic characteristics of the double inner meshing planetary rows, the corresponding transmission system can be better designed and improved, and its performance and efficiency can be improved.

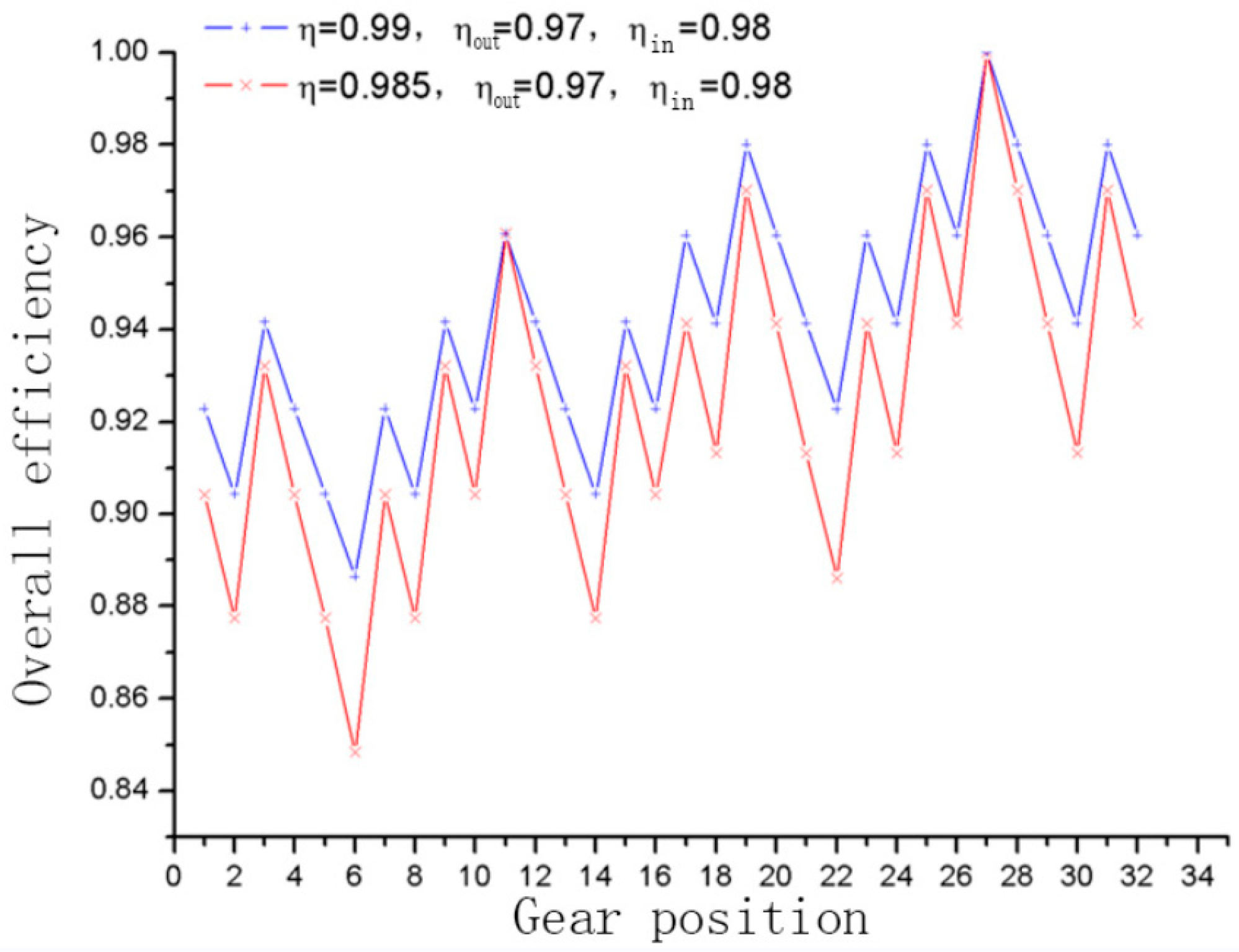

- The efficiency improvement in a planetary gearbox with dual internal meshing gears is evident compared to traditional conventional planetary gearboxes. As can be seen from the figure above, when the efficiency of the double inner meshing gear with a large contact degree changes from 0.985 to 0.99, the efficiency of the entire two-state logic double inner meshing planetary transmission is significantly improved. In the two-state logic planetary transmission, the efficiency gradually increases with the rise in gear, especially when the speed is close to the maximum, giving an efficiency roughly above 95%. The low efficiency of individual gears, such as sixth gear, is due to the large number of planetary rows involved in the working condition (four rows), so the meshing power loss is large. In the follow-up study, parameters such as module and meshing angle of the gear can be optimized, and the number of planetary rows can be adjusted in the design to reduce the meshing power loss.

- Based on the graph theory method, this paper establishes the speed and efficiency analysis and calculation model of 32 gears (this paper only studies the 32 gears in the forward gear) in full gear working conditions and establishes the corresponding program model to determine the efficiency calculation and power loss analysis of the whole planetary gearbox in all working conditions, laying a foundation for further research.

- In this paper, from the perspective of digital circuits, the corresponding logical relationship table is established between each gear control and each gear of two-state logic transmission, which provides a clear and feasible basis for the analysis and simulation of speed, torque, efficiency and automatic shift.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Shen, Z.; Qiao, B.; Yang, L.; Luo, W.; Yang, Z.; Chen, X. Fault mechanism and dynamic modeling of planetary gear with gear wear. Mech. Mach. Theory 2021, 155, 104098. [Google Scholar] [CrossRef]

- Yuksel, C.; Kahraman, A. Dynamic tooth loads of planetary gear sets having tooth profile wear. Mech. Mach. Theory 2004, 39, 695–715. [Google Scholar] [CrossRef]

- Kahraman, A.; Ding, H. A methodology to predict surface wear of planetary gears under dynamic conditions. Mech. Based Des. Struct. Mach. 2010, 38, 493–515. [Google Scholar] [CrossRef]

- Gao, M.; Shang, Z.; Li, W.; Liu, F.; Pang, H.; Liu, J. Analysis of Wear Mechanism and Fault Characteristics of Planet Gears with Multiple Wear Types in Planetary Gearbox. J. Vib. Eng. Technol. 2023, 11, 945–975. [Google Scholar] [CrossRef]

- Wang, J.; Zhang, J. Assessment of Residual Useful Life of Sun Gear in a Planetary Gearbox Based on Dynamic Wear Behaviors Analyses. Machines 2023, 11, 149. [Google Scholar] [CrossRef]

- Bodas, A.; Kahraman, A. Influence of carrier and gear manufacturing errors on the static load sharing behavior of planetary gear sets. JSME Int. J. Ser. C Mech. Syst. Mach. Elem. Manuf. 2004, 47, 908–915. [Google Scholar] [CrossRef]

- Lei, Y.; Liu, Z.; Wu, X.; Li, N.; Chen, W.; Lin, J. Health condition identification of multi-stage planetary gearboxes using a mRVM-based method. Mech. Syst. Signal Process. 2015, 60, 289–300. [Google Scholar] [CrossRef]

- Wei, J.; Sun, Q.; Sun, W.; Ding, X.; Tu, W.; Wang, Q. Load-sharing characteristic of multiple pinions driving in tunneling boring machine. Chin. J. Mech. Eng. 2013, 26, 532–540. [Google Scholar] [CrossRef]

- Sun, W.; Li, X.; Wei, J.; Zhang, A.; Ding, X.; Hu, X. A study on load-sharing structure of multi-stage planetary transmission system. J. Mech. Sci. Technol. 2015, 29, 1501–1511. [Google Scholar] [CrossRef]

- Kahraman, A.; Kharazi, A.A.; Umrani, M. A deformable body dynamic analysis of planetary gears with thin rims. J. Sound Vib. 2003, 262, 752–768. [Google Scholar] [CrossRef]

- Ambarisha, V.K.; Parker, R.G. Nonlinear dynamics of planetary gears using analytical and finite element models. J. Sound Vib. 2007, 302, 577–595. [Google Scholar] [CrossRef]

- Wei, J.; Zhang, A.; Qin, D.; Lim, T.C.; Shu, R.; Lin, X.; Meng, F. A coupling dynamics analysis method for a multistage planetary gear system. Mech. Mach. Theory 2017, 110, 27–49. [Google Scholar] [CrossRef]

- Karaivanov, D.P.; Troha, S. Optimal Selection of the Structural Scheme of Compound Two-Carrier Planetary Gear Trains and their Parameters. In Recent Advances in Gearing: Scientific Theory and Applications; Springer: Cham, Switzerland, 2022; pp. 339–403. [Google Scholar]

- Qiu, W.; Yang, F.; Wang, D.; Jiang, X. Design and free vibration characteristics of linkage planetary gear trains. J. Braz. Soc. Mech. Sci. Eng. 2022, 44, 58. [Google Scholar] [CrossRef]

- Shahabi, A.; Kazemian, A.H. Dynamic and Vibration Analysis for Geometrical Structures of Planetary Gears. J. Solid Mech. 2021, 13, 384–398. [Google Scholar]

- Fan, Y. Design of a planetary gear mechanism of a seven-speed automatic transmission based on the lever method. J. Phys. Conf. Ser. 2020, 1449, 012098. [Google Scholar] [CrossRef]

- Xue, H.; Li, L. Motion, Static Force, and Efficiency Analysis of Planetary Gear Transmission Based on Graph Theory. Appl. Sci. 2023, 13, 10983. [Google Scholar] [CrossRef]

- Esmail, E.L.; Juber, A.H. An application of graph theory for the detection of degenerate structures in planetary gear trains. In Proceedings of the International Design Engineering Technical Conferences and Computers and Information in Engineering Conference, Virtual, 17–21 August 2021; Volume 85444, p. V08AT08A025. [Google Scholar]

- Shanmukhasundaram, V.R.; Rao, Y.V.D.; Regalla, S.P. Algorithms for detection of degenerate structure in epicyclic gear trains using graph theory. J. Braz. Soc. Mech. Sci. Eng. 2019, 41, 496. [Google Scholar] [CrossRef]

- Fan, Y. Research on Transmission Performance of A Seven-gear Three-degree-of-freedom Planetary Gear Automatic Transmission Based on Graph Theory and Matrix Equation. J. Phys. Conf. Ser. 2020, 1601, 062031. [Google Scholar] [CrossRef]

- Fu, S.; Wang, L.; Du, Y.; Mao, E.; Zhu, Z.; Li, Z. Graph theory based scheme design synthesis for tractor fixed shaft gearbox. In Proceedings of the 2019 IEEE International Conference on Unmanned Systems and Artificial Intelligence (ICUSAI), Xi’an, China, 22–24 November 2019; pp. 232–237. [Google Scholar]

- Mustafa, J.; Hasan, A. Some application of graph theory to isomorphic analysis of epicyclic geared mechanisms. J. Inst. Eng. (India) Ser. C 2021, 102, 1051–1057. [Google Scholar] [CrossRef]

- Lin, C.; Xia, X.; Li, P. Geometric design and kinematics analysis of coplanar double internal meshing non-circular planetary gear train. Adv. Mech. Eng. 2018, 10, 1687814018818910. [Google Scholar] [CrossRef]

| C | B | B⨁C | State |

|---|---|---|---|

| 0 | 0 | 0 | × |

| 0 | 1 | 1 | √ |

| 1 | 0 | 1 | √ |

| 1 | 1 | 0 | × |

| Gear | 1 | 2 | 3 | 4 | 5 | |

|---|---|---|---|---|---|---|

| Array of Planets | ||||||

| 1 | Sun | 1 | k11k12 | 1 | k11k12 | 1 |

| Planet | 1 | k12 | 1 | k12 | 1 | |

| Ring | 1 | 1 | 1 | 1 | 1 | |

| Carrier | 1 | 0 | 1 | 0 | 0 | |

| 2 | Sun | 1 | k11k12 | 1 | k11k12 | 1 |

| Planet | 1/k21 | k11k12/k21 | 1 | k11k12 | 1/k21 | |

| Ring | 1/k21k22 | k11k12/k21k22 | 1 | k11k12 | 1/k21k22 | |

| Carrier | 0 | 0 | 1 | k11k12 | k11k12 | |

| 3 | Sun | 1/k21k22 | k11k12/k21k22 | 1 | k11k12 | K31k32/k21k22 |

| Planet | 1/k21k22 | k11k12/k21k22 | 1 | k11k12 | k32/k21k22 | |

| Ring | 1/k21k22 | k11k12/k21k22 | 1 | k11k12 | 1/k21k22 | |

| Carrier | 1/k21k22 | k11k12/k21k22 | 1 | k11k12 | 0 |

| Gear | Transmission Ratio Expression | Efficiency Expression | Efficiency | |

|---|---|---|---|---|

| η = 0.985, ηout = 0.98 ηin = 0.97 | η = 0.99, ηout = 0.98 ηin = 0.97 | |||

| 1 | k2 k4 (1 + k5) | η4(1 + k5ηinηout)/(1 + k5) | 0.9043 | 0.9228 |

| 2 | k2 k4 (1 + k5)/k1 | η6(1 + k5ηinηout)/(1 + k5) | 0.8774 | 0.9044 |

| 3 | k4 (1 + k5) | η2(1 + k5ηinηout)/(1 + k5) | 0.9321 | 0.9416 |

| 4 | k4 (1 + k5)/k1 | η4(1 + k5ηinηout)/(1 + k5) | 0.9043 | 0.9228 |

| 5 | k2 k4 (1 + k5)/k3 | η6(1 + k5ηinηout)/(1 + k5) | 0.8774 | 0.9044 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Q.; Wu, Z.; Shen, J.; Cui, S.; Cui, Y. Research on Kinematics and Efficiency Calculation of Binary Logic Planetary Gearbox Based on Graph Theory. Appl. Sci. 2024, 14, 1773. https://doi.org/10.3390/app14051773

Zhang Q, Wu Z, Shen J, Cui S, Cui Y. Research on Kinematics and Efficiency Calculation of Binary Logic Planetary Gearbox Based on Graph Theory. Applied Sciences. 2024; 14(5):1773. https://doi.org/10.3390/app14051773

Chicago/Turabian StyleZhang, Qiang, Zhe Wu, Jingtao Shen, Suxiao Cui, and Yanping Cui. 2024. "Research on Kinematics and Efficiency Calculation of Binary Logic Planetary Gearbox Based on Graph Theory" Applied Sciences 14, no. 5: 1773. https://doi.org/10.3390/app14051773

APA StyleZhang, Q., Wu, Z., Shen, J., Cui, S., & Cui, Y. (2024). Research on Kinematics and Efficiency Calculation of Binary Logic Planetary Gearbox Based on Graph Theory. Applied Sciences, 14(5), 1773. https://doi.org/10.3390/app14051773