A Review of Industry 4.0 Assessment Instruments for Digital Transformation

Abstract

Featured Application

Abstract

1. Introduction

2. Methodology

2.1. Eligibility Criteria

- Keywords, titles, and abstract: The main words used in the eligibility criteria for keywords, titles, and abstract were questionnaire, roadmap, maturity model, framework, digital transformation, and Industry 4.0.

- Language: The language considered was English.

- Content type: All content types were considered. Some of these were articles, conference papers, review articles, and book chapters, among others.

- Year: All years up to mid-December 2023.

- Subject area: All subject areas were included.

- Publication title: All publication titles were included.

2.2. Information Sources

2.3. Search Strategy

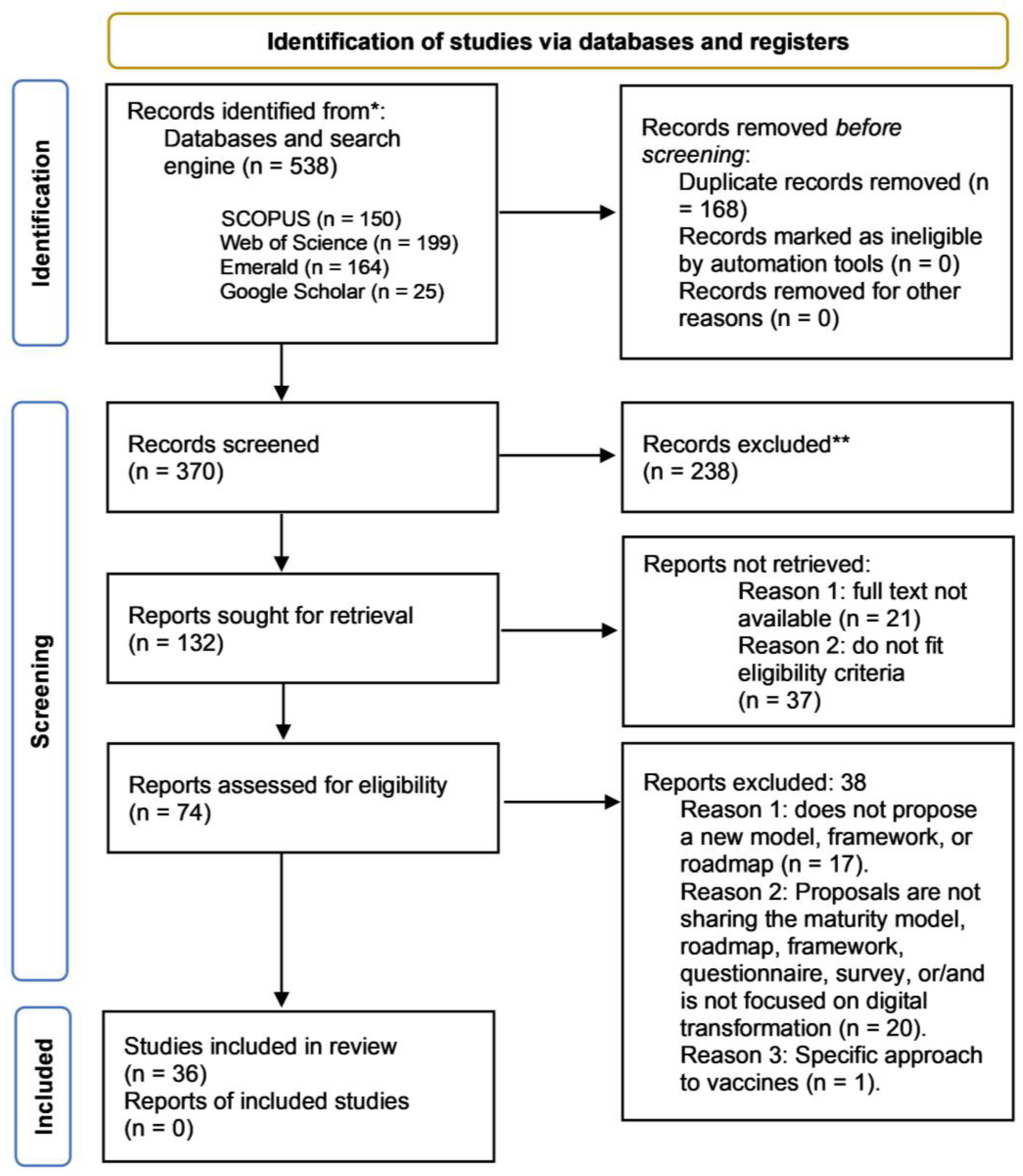

2.4. Selection Process

2.5. Data Items

- Definitions: Concepts such as maturity model, roadmap, framework, and readiness assessment are defined because some papers are not clear about what they are proposing, which makes it confusing for the reader to understand the outcome.

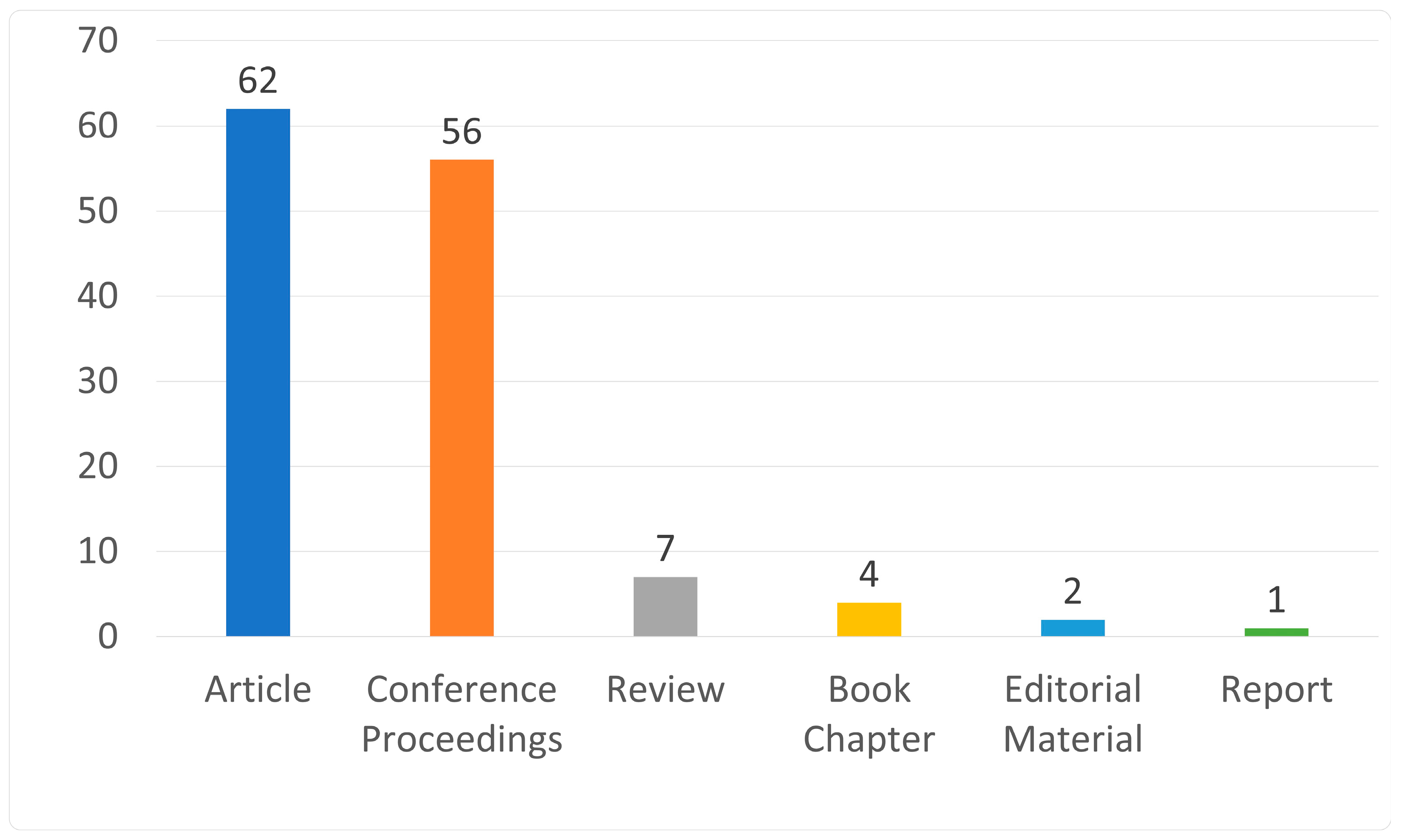

- Type of research: The types of papers are divided into these sections: article, book chapter, conference proceedings, editorial material, review, and report. A brief analysis of these papers is conducted about the number of papers each section has and the topics being covered.

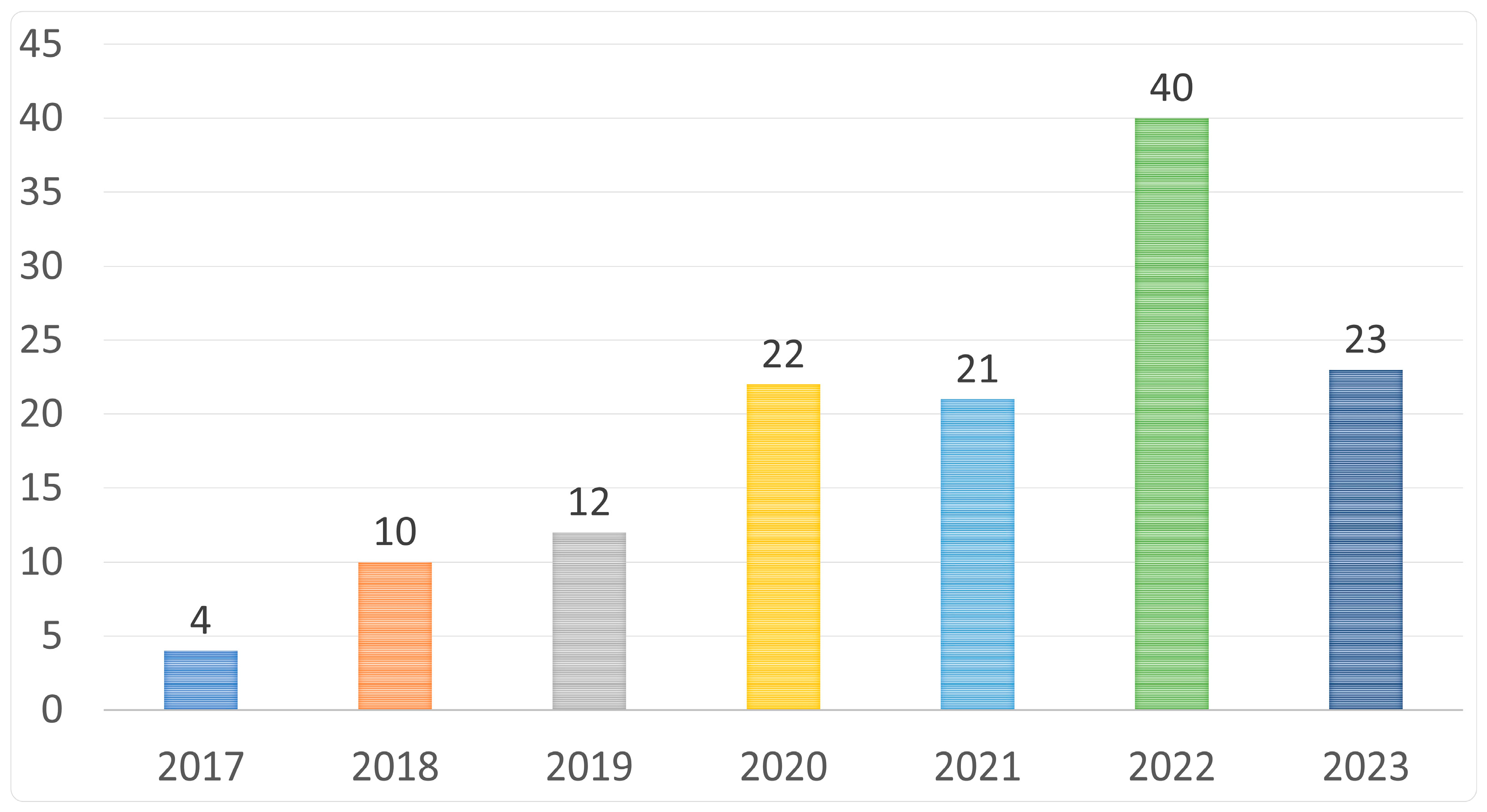

- Findings per year: All years to present were considered when searching in the databases. However, publication records for this topic (considering the eligibility criteria) started in 2017. Consequently, only papers from 2017 to 2023 were identified. The year 2022 is the year when most publications regarding the concepts studied are published.

- Publisher: 38 different publishers are mentioned due to the systematic review process. Section 3.4 shows the most relevant publishers.

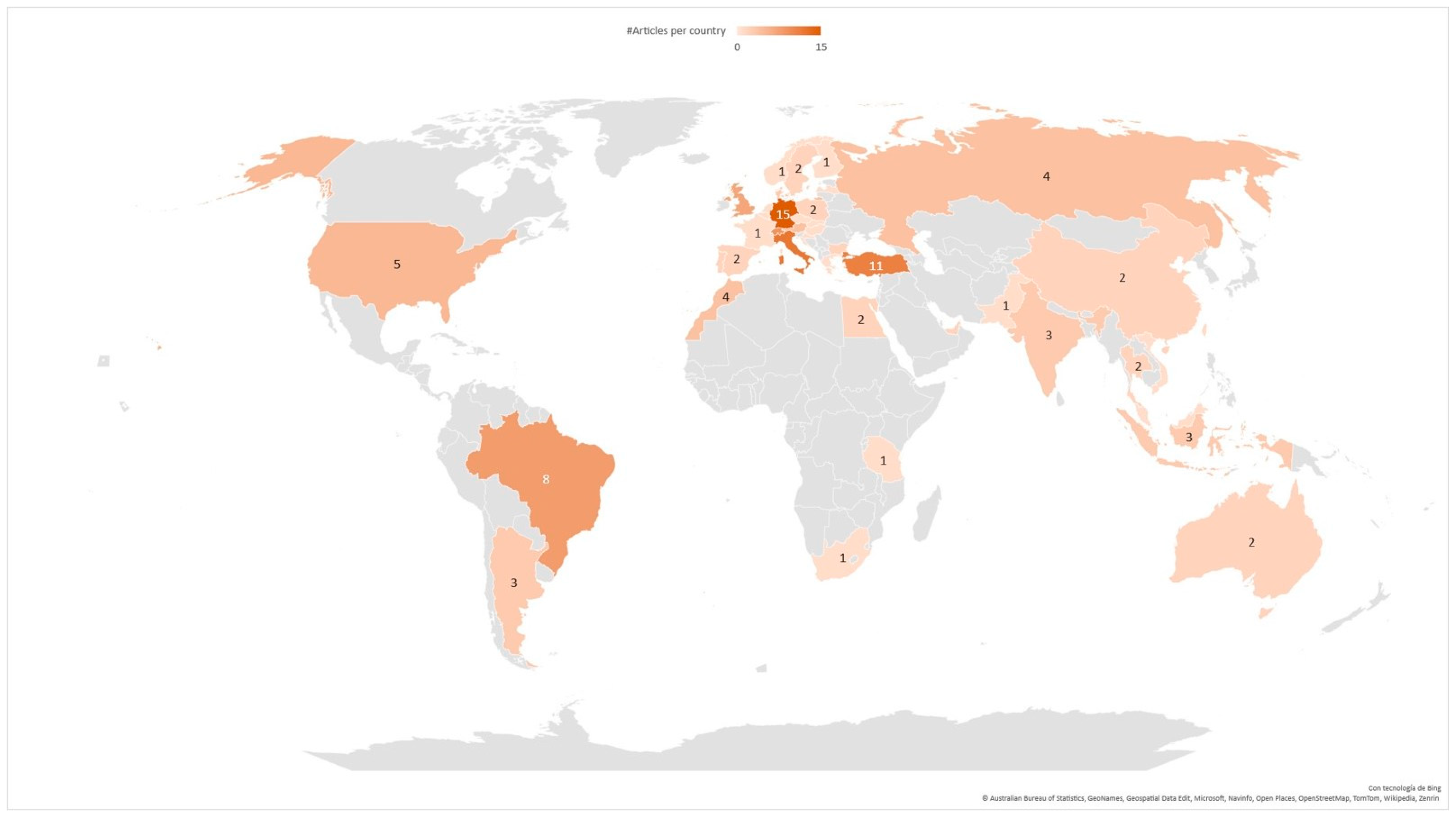

- Country: Papers are being published all around the world. However, Europe is the continent with the most publications, with Germany being the country most relevant.

- Case studies: Some of the papers included a case study. These papers were analyzed by the title, author, industry where the case study was applied, assessment instrument, and a brief description of the tool and application. Most of these studies were applied in the automotive and manufacturing industries.

- Frequent keywords: The most frequently used keywords are analyzed to determine the most used for new proposals in the assessment instrument for Industry 4.0 and digital transformation. Digital, industry, maturity, and model were the most popular keywords.

2.6. Study Risk of Bias Assessment

2.7. Effect Measures

2.8. Synthesis Methods

- The manuscript proposes a tool (maturity model, framework, roadmap, survey, questionnaire, form, assessment tool, evaluation, instrument) for Industry 4.0 and digital transformation.

- Application of technology, enablers, and drivers for the proposal.

- Some sort of validation method is included.

- The article is written in the English language.

2.9. Study Selection

2.10. Study Characteristics

3. Results

3.1. Definitions

- Maturity models are instruments that provide knowledge about the organization’s current capabilities to execute a particular task and the level of progress toward an objective. These models offer comprehensive guidance that supports an improvement in certain tasks—in this case, the implementation of Industry 4.0. These usually include qualitative dimensions and levels of progress that allow assessing the company through a set of guiding questions [11,12,14,22,23].

- A roadmap is a comprehensive plan that includes dimensions and drivers for digital transformation in an organized approach. It provides a look into the future of a particular area; it is a knowledge tool for businesses [24]. It provides orientation for decision making and helps foresee future technologies and strategies for obtaining a competitive advantage. For Industry 4.0, organizations can develop a roadmap to improve the implementation process and increase their maturity level [24]. Also, a roadmap includes a set of recommendations for guiding companies, in this case, for digital transformation [10].

- A framework provides a foundation for developing instruments and methodologies; it is a holistic approach that can help adopt digitalization [25]. Also, a framework may provide structure to the research. Additionally, according to Pirola et al. [22], they enable benchmarking and performance improvement.

- A readiness assessment is a systemic analysis of an organization’s ability to cope with and undertake a transformational process or change. Also, it is a measure and evaluation process to identify implementation facilitators and barriers, opportunities and potential challenges or risks. Thus, it provides an opportunity to address any gaps in the existing organization [26]. The main objective is to reduce the transformation process implementation failures effectively [27]. For that, it must effectively identify (a) the high-performance strategies for frontline responders [28]; (b) tools that are needed for the company’s core engagement, technological transformation, or skills [27]; and (c) the relationship between the actors and variables in the system; for instance: customer resources, operation/service processes, quality, among others [29].

- For this study, the authors proposed the following construct for an assessment instrument: englobes any of the previously defined instruments maturity model, roadmap, framework, readiness assessment as well as other tools identified in the SLR such as questionnaires, checklists, surveys, diagnostic tools, or leveling instruments. Each one of the assessment instruments defined aims for the continuous improvement of a system from a holistic or micro-point of view. It considers the variables, actors, stakeholders, processes, and worldview of the system in the context to which it belongs and impacts.

- Industry 4.0 is based on merging the cyber and physical dimensions, combining the physical and digital realms, fostering the integration of advanced technologies, such as augmented reality, automated manufacturing, Internet of Things, cloud computing, artificial intelligence (AI) and machine learning (ML), (industrial) big data, big data analytics, fog and edge computing, robotics, cybersecurity, semantic web technologies, and additive manufacturing [30].

3.2. Bibliometric Analysis and Findings

Type of Research

3.3. Findings per Year

3.4. Publisher

3.5. Country

3.6. Case Studies

3.7. Frequent Keywords

3.8. Analysis and Findings of the Key Research Studies

4. Discussion

- Second, another key discovery is the recognition of drivers and dimensions (refer to Table 3 and Table 4) as crucial constituents in crafting an assessment tool for Industry 4.0 digital transformation. Table 6 elaborates on each dimension identified, namely strategy, technology, product, culture, service, process, operation, organization, governance, and operation.

- Fourth, the SLR highlights the importance of data analytics and management to be implemented correctly and considered to create the best practices for an assessment instrument for digital transformation.

- Five, there are only three papers focused on the automotive industry, and only one contains a detailed questionnaire focused on assessing digital transformation in a company. This creates an opportunity to design a new tool that covers this gap.

- Six, this study takes a holistic view of assessment instruments and constructs defined as maturity models, roadmaps, frameworks, readiness assessments, questionnaires, checklists, and surveys by clarifying the diverse tools used when implementing Industry 4.0.

- Seven, there is a lack of studies in this area in some geographical regions such as Canada, Africa, and Central America.

Other Considerations When Elaborating an Assessment Instrument

5. Conclusions

- The application of the PRISMA methodology has yielded notable outcomes, providing a thorough and all-encompassing examination of critical evaluation tools, including maturity models, frameworks, roadmaps, and readiness assessments. As a result, supplementary instruments, such as questionnaires, surveys, and checklists, have been incorporated. Additionally, these findings have been scrutinized to discern essential observations about present research emphases and potential prospects for future exploration, all of which are interrelated with RQ1.

- While crafting an assessment tool for Industry 4.0 digital transformation, an important discovery was made regarding the significance of “drivers” and “dimensions” as crucial components, answering RQ2. These ten dimensions, along with their corresponding drivers, can be utilized as a foundational framework to design a survey that can assist businesses in assessing their progress in Industry 4.0.

- There is a wide range of assessment instruments that can guide the implementation of Industry 4.0 by identifying what the company needs to focus on and helping prioritize the areas of opportunities regarding Industry 4.0 digital transformation.

- Using these assessment instruments requires basic training on what Industry 4.0 is.

- Selecting a proper assessment instrument supports investing appropriately and allocating resources according to the objectives, improving key performance indicators, and overall, enhancing their performance, productivity, and sales.

- An extended SLR can include studies in other languages besides English.

- Developing an assessment instrument might fill the gap in the literature of current tools that evaluate the implementation of Industry 4.0 in companies.

- Qualitative studies, such as interviews and focus groups, can be used to formulate appropriate questions for each of the ten different dimensions: strategy, workforce, leadership, clients, smart factories, smart products and services, technology, operations, governance, and supply chain. The drivers associated with each dimension should also be considered.

- Validation of the instrument can be completed via interviews with experts or conducting a case study based on the use of the proposed instrument.

- The instrument may become more user-friendly and efficient by developing a digital interface that allows information and data to be stored in real time. Thus, results can be visually accessed from a platform (e.g., a dashboard).

- To implement a mixed-quantitative method to make this study more flexible and precise, aligned with the company´s goals, and easier to interpret. For example, depending on the company, some questions are more important or impactful than others. Suppose the organization assigns the questions a numerical value depending on its priority. In that case, they can identify what areas are the ones that they should focus on and develop a plan or roadmap depending on that.

- Include quantitative methods such as fuzzy logic, Spherical Fuzzy COPRAS, Analytical Hierarchy Process, and intra-class correlation to help integrate qualitative and quantitative data.

- Finally, the instrument can be further adapted beyond the manufacturing area, that is, the service industry, such as healthcare.

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Hamilton Ortiz, J. (Ed.) Industry 4.0—Current Status and Future Trends; IntechOpen: Rijeka, Croatia, 2020. [Google Scholar] [CrossRef]

- Ghobakhloo, M. Industry 4.0, Digitization, and Opportunities for Sustainability. J. Clean. Prod. 2020, 252, 119869. [Google Scholar] [CrossRef]

- Shahin, M.; Chen, F.F.; Bouzary, H.; Krishnaiyer, K. Integration of Lean Practices and Industry 4.0 Technologies: Smart Manufacturing for next-Generation Enterprises. Int. J. Adv. Manuf. Technol. 2020, 107, 2927–2936. [Google Scholar] [CrossRef]

- Braga Tadeu, H.F.; de Castro Moura Duarte, A.L.; Taurion, C.; Jamil, G.L. Digital Transformation: Digital Maturity Applied to Study Brazilian Perspective for Industry 4.0. Best Pract. Manuf. Process. 2018, 3–27. [Google Scholar] [CrossRef]

- Pereira, C.S.; Durão, N.; Moreira, F.; Veloso, B. The Importance of Digital Transformation in International Business. Sustainability 2022, 14, 834. [Google Scholar] [CrossRef]

- Hein-Pensel, F.; Winkler, H.; Brückner, A.; Wölke, M.; Jabs, I.; Mayan, I.J.; Kirschenbaum, A.; Friedrich, J.; Zinke-Wehlmann, C. Maturity Assessment for Industry 5.0: A Review of Existing Maturity Models. J. Manuf. Syst. 2023, 66, 200–210. [Google Scholar] [CrossRef]

- Vogelsang, K.; Kirsten, L.-N.; Packmohr, S.; Hoppe, U. Barriers to Digital Transformation in Manufacturing: Development of a Research Agenda. In ScholarSpace; University of Hawai’i at Mānoa: Honolulu, HI, USA, 2019; Available online: https://scholarspace.manoa.hawaii.edu/items/ac040d17-4195-4f33-8bd6-775dc56db7f3 (accessed on 29 May 2023).

- Klaes, M.; Zwartscholten, J.; Narayan, A.; Lehnhoff, S.; Rehtanz, C. Impact of ICT Latency, Data Loss and Data Corruption on Active Distribution Network Control. IEEE Access 2023, 11, 14693–14701. [Google Scholar] [CrossRef]

- Rauch, E.; Unterhofer, M.; Rojas, R.A.; Gualtieri, L.; Woschank, M.; Matt, D.T. A Maturity Level-Based Assessment Tool to Enhance the Implementation of Industry 4.0 in Small and Medium-Sized Enterprises. Sustainability 2020, 12, 3559. [Google Scholar] [CrossRef]

- Colli, M.; Berger, U.; Bockholt, M.; Madsen, O.; Møller, C.; Wæhrens, B.V. A Maturity Assessment Approach for Conceiving Context-Specific Roadmaps in the Industry 4.0 Era. Annu. Rev. Control 2019, 48, 165–177. [Google Scholar] [CrossRef]

- Akdil, K.Y.; Ustundag, A.; Cevikcan, E. Maturity and Readiness Model for Industry 4.0 Strategy. In Springer Series in Advanced Manufacturing; Springer: Berlin/Heidelberg, Germany, 2018; pp. 61–94. [Google Scholar] [CrossRef]

- Gollhardt, T.; Halsbenning, S.; Hermann, A.; Karsakova, A.; Becker, J. Development of a Digital Transformation Maturity Model for IT Companies. In Proceedings of the 2020 IEEE 22nd Conference on Business Informatics (CBI), Antwerp, Belgium, 22–24 June 2020. [Google Scholar] [CrossRef]

- Angreani, L.S.; Vijaya, A.; Wicaksono, H. Systematic Literature Review of Industry 4.0 Maturity Model for Manufacturing and Logistics Sectors. Procedia Manuf. 2020, 52, 337–343. [Google Scholar] [CrossRef]

- Santos, R.C.; Martinho, J.L. An Industry 4.0 Maturity Model Proposal. J. Manuf. Technol. Manag. 2019, 31, 1023–1043. [Google Scholar] [CrossRef]

- Ávila Bohórquez, J.H.; Gil Herrera, R.d.J. Proposal and Validation of an Industry 4.0 Maturity Model for SMEs. J. Ind. Eng. Manag. 2022, 15, 433. [Google Scholar] [CrossRef]

- Bellantuono, N.; Nuzzi, A.; Pontrandolfo, P.; Scozzi, B. Digital Transformation Models for the I4.0 Transition: Lessons from the Change Management Literature. Sustainability 2021, 13, 12941. [Google Scholar] [CrossRef]

- Zuluaga, J.A.F.; Escobar, J.F.; Martínez, G.A.G.; D’Aleman, J.C.; Vallejo, A.O. Model for Measuring Technological Maturity for Critical Sector Industries. J. Open Innov. Technol. Mark. Complex. 2024, 10, 100194. [Google Scholar] [CrossRef]

- Bastos, A.; De Andrade, M.L.S.C.; Yoshino, R.T.; Santos, M.M.D. Industry 4.0 Readiness Assessment Method Based on RAMI 4.0 Standards. IEEE Access 2021, 9, 119778–119799. [Google Scholar] [CrossRef]

- Page, M.J.; McKenzie, J.E.; Bossuyt, P.M.; Boutron, I.; Hoffmann, T.C.; Mulrow, C.D.; Shamseer, L.; Tetzlaff, J.M.; Akl, E.A.; Brennan, S.E.; et al. The PRISMA 2020 Statement: An Updated Guideline for Reporting Systematic Reviews. BMJ 2021, 88, 105906. [Google Scholar] [CrossRef]

- Cornell University Library. “Risk of Bias Assessment”. A Guide to Evidence Synthesis: 9. Risk of Bias Assessment. Cornell University. 2023. Available online: https://guides.library.cornell.edu/evidence-synthesis/bias (accessed on 1 June 2023).

- Critical Appraisal Skills Programme. CASP (Systematic Review) Checklist. Available online: https://casp-uk.net/casp-tools-checklists/ (accessed on 25 September 2022).

- Pirola, F.; Cimini, C.; Pinto, R. Digital Readiness Assessment of Italian SMEs: A Case-Study Research. J. Manuf. Technol. Manag. 2019, 31, 1045–1083. [Google Scholar] [CrossRef]

- Gökalp, E.; Şener, U.; Eren, P.E. Development of an Assessment Model for Industry 4.0: Industry 4.0-MM. In Software Process Improvement and Capability Determination, Proceedings of the SPICE 2017, Communications in Computer and Information Science, Palma de Mallorca, Spain, 4–5 October 2017; Mas, A., Mesquida, A., O’Connor, R., Rout, T., Dorling, A., Eds.; Springer: Cham, Switzerland, 2017; Volume 770. [Google Scholar] [CrossRef]

- Nachit, M.; Okar, C. Digital Transformation of Human Resources Management: A Roadmap. In Proceedings of the 2020 IEEE International Conference on Technology Management, Operations and Decisions (ICTMOD), Marrakech, Morocco, 25–27 November 2020. [Google Scholar] [CrossRef]

- Aripin, A.I.; Abimanyu, A.; Prabowo, F.S.; Priandika, B.; Sulivan, B.; Zahra, A. Mobile Cloud Computing Readiness Assessment Framework in Upstream Oil and Gas Using RAMI 4.0. In Proceedings of the 2020 International Conference on Information Management and Technology (ICIMTech), Jakarta, Indonesia, 13–14 August 2020. [Google Scholar] [CrossRef]

- Holt, D.T.; Armenakis, A.A.; Feild, H.S.; Harris, S.G. Readiness for Organizational Change. J. Appl. Behav. Sci. 2007, 43, 232–255. [Google Scholar] [CrossRef]

- Yusif, S.; Hafeez-Baig, A.; Soar, J. E-Health Readiness Assessment Factors and Measuring Tools: A Systematic Review. Int. J. Med. Inform. 2017, 107, 56–64. [Google Scholar] [CrossRef]

- Nobrega, S.; Morocho, C.; Robertson, M.M.; Kurowski, A.; Rice, S.; Henning, R.A.; Punnett, L. A Mixed-Method Approach to Tailor the Implementation of a Participatory Total Worker Health® Program. Int. J. Workplace Health Manag. 2021, 14, 409–425. [Google Scholar] [CrossRef]

- Grönroos, C. Relationship Marketing Readiness: Theoretical Background and Measurement Directions. J. Serv. Mark. 2017, 31, 218–225. [Google Scholar] [CrossRef]

- Duggal, A.S.; Malik, P.; Gehlot, A.; Singh, R.; Gaba, G.S.; Masud, M.; Al-Amri, J.F. A sequential roadmap to Industry 6.0: Exploring future manufacturing trends. IET Commun. 2021, 16, 521–531. [Google Scholar] [CrossRef]

- Agca, O.; Gibson, J.; Godsell, J.; Ignatius, J.; Davies, C.W.; Xu, O. An Industry 4 Readiness Assessment Tool. 2018. Available online: https://hdl.handle.net/2134/24114621.v1 (accessed on 29 May 2023).

- Chonsawat, N.; Sopandang, A. The Development of the Maturity Model to evaluate the Smart SMEs 4.0 Readiness. In Proceedings of the International Conference on Industrial Engineering and Operations Management, Bangkok, Thailand, 5–7 March 2019; pp. 354–363. Available online: http://ieomsociety.org/ieom2019/papers/97.pdf (accessed on 29 May 2023).

- Castro, H.F.; Carvalho, A.R.F.; Leal, F.; Gouveia, H. Assessing Industry 4.0 Readiness of Portuguese Companies. In Progress in Digital and Physical Manufacturing: Proceedings of ProDPM’19; Lecture Notes in Mechanical Engineering; Springer: Berlin/Heidelberg, Germany, 2019; pp. 57–64. [Google Scholar] [CrossRef]

- Dutta, G.; Kumar, R.; Sindhwani, R.; Singh, R.K. Digital Transformation Priorities of India’s Discrete Manufacturing SMEs—A Conceptual Study in Perspective of Industry 4.0. Compet. Rev. Int. Bus. J. 2020, 30, 289–314. [Google Scholar] [CrossRef]

- Vasconcellos, L.R.; Junior, P.G.; Rodrigues, F. An Industry 4.0 Maturity Model Applied to the automotive supply chain. Rev. Gestão Tecnol. 2021, 21, 255–268. [Google Scholar]

- Agostino, D.; Costantini, C. A Measurement Framework for Assessing the Digital Transformation of Cultural Institutions: The Italian Case. Meditari Account. Res. 2021, 30, 1141–1168. [Google Scholar] [CrossRef]

- Isaev, E.; Korovkina, N.; Tabakova, M. Evaluation of the Readiness of a Company’s IT Department for Digital Business Transformation. Bus. Inform. 2018, 2018, 55–64. [Google Scholar] [CrossRef]

- Brozzi, R.; D’Amico, R.D.; Pasetti Monizza, G.; Marcher, C.; Riedl, M.; Matt, D. Design of Self-Assessment Tools to Measure Industry 4.0 Readiness. A Methodological Approach for Craftsmanship SMEs. Product Lifecycle Management to Support Industry 4.0. In Proceedings of the 15th IFIP WG 5.1 International Conference, PLM 2018, Torino, Italy, 2–4 July 2018; pp. 566–578. [Google Scholar] [CrossRef]

- Scott, I.A.; Sullivan, C.; Staib, A. Going Digital: A Checklist in Preparing for Hospital-Wide Electronic Medical Record Implementation and Digital Transformation. Aust. Health Rev. 2019, 43, 302. [Google Scholar] [CrossRef] [PubMed]

- Schumacher, A.; Nemeth, T.; Sihn, W. Roadmapping towards Industrial Digitalization Based on an Industry 4.0 Maturity Model for Manufacturing Enterprises. Procedia CIRP 2019, 79, 409–414. [Google Scholar] [CrossRef]

- A Framework for BPM Software Selection in Relation to Digital Transformation Drivers. Teh. Vjesn. Tech. Gaz. 2020, 27, 1108–1114. [CrossRef]

- Nausch, M.; Schumacher, A.; Sihn, W. Assessment of Organizational Capability for Data Utilization—A Readiness Model in the Context of Industry 4.0. In Proceedings of the International Symposium for Production Research 2019; Lecture Notes in Mechanical Engineering; Springer: Berlin/Heidelberg, Germany, 2019; pp. 243–252. [Google Scholar] [CrossRef]

- Beyaz, H.F.; Yıldırım, N. A Multi-Criteria Decision-Making Model for Digital Transformation in Manufacturing: A Case Study from Automotive Supplier Industry. In Proceedings of the International Symposium for Production Research 2019; Lecture Notes in Mechanical Engineering; Springer: Berlin/Heidelberg, Germany, 2019; pp. 217–232. [Google Scholar] [CrossRef]

- Nick, G.; Kovács, T.; Kő, A.; Kádár, B. Industry 4.0 Readiness in Manufacturing: Company Compass 2.0, a Renewed Framework and Solution for Industry 4.0 Maturity Assessment. Procedia Manuf. 2021, 54, 39–44. [Google Scholar] [CrossRef]

- Gökalp, E.; Martinez, V. Digital Transformation Capability Maturity Model Enabling the Assessment of Industrial Manufacturers. Comput. Ind. 2021, 132, 103522. [Google Scholar] [CrossRef]

- Von Solms, J.; Langerman, J. Digital Technology Adoption in a Bank Treasury and Performing a Digital Maturity Assessment. Afr. J. Sci. Technol. Innov. Dev. 2021, 14, 302–315. [Google Scholar] [CrossRef]

- Kruszyńska-Fischbach, A.; Sysko-Romańczuk, S.; Rafalik, M.; Walczak, R.; Kludacz-Alessandri, M. Organizational E-Readiness for the Digital Transformation of Primary Healthcare Providers during the COVID-19 Pandemic in Poland. J. Clin. Med. 2021, 11, 133. [Google Scholar] [CrossRef]

- Machado, C.G.; Winroth, M.; Almström, P.; Ericson Öberg, A.; Kurdve, M.; AlMashalah, S. Digital Organisational Readiness: Experiences from Manufacturing Companies. J. Manuf. Technol. Manag. 2021, 32, 167–182. [Google Scholar] [CrossRef]

- Caiado, R.G.G.; Scavarda, L.F.; Gavião, L.O.; Ivson, P.; Nascimento, D.L.d.M.; Garza-Reyes, J.A. A Fuzzy Rule-Based Industry 4.0 Maturity Model for Operations and Supply Chain Management. Int. J. Prod. Econ. 2021, 231, 107883. [Google Scholar] [CrossRef]

- Kusmiarto, K.; Aditya, T.; Djurdjani, D.; Subaryono, S. Digital Transformation of Land Services in Indonesia: A Readiness Assessment. Land 2021, 10, 120. [Google Scholar] [CrossRef]

- Amaral, A.; Peças, P. A Framework for Assessing Manufacturing SMEs Industry 4.0 Maturity. Appl. Sci. 2021, 11, 6127. [Google Scholar] [CrossRef]

- Metta, M.; Ciliberti, S.; Obi, C.; Bartolini, F.; Klerkx, L.; Brunori, G. An Integrated Socio-Cyber-Physical System Framework to Assess Responsible Digitalisation in Agriculture: A First Application with Living Labs in Europe. Agric. Syst. 2022, 203, 103533. [Google Scholar] [CrossRef]

- Han, X.; Zhang, M.; Hu, Y.; Huang, Y. Study on the Digital Transformation Capability of Cost Consultation Enterprises Based on Maturity Model. Sustainability 2022, 14, 10038. [Google Scholar] [CrossRef]

- Kırmızı, M.; Kocaoglu, B. Digital Transformation Maturity Model Development Framework Based on Design Science: Case Studies in Manufacturing Industry. J. Manuf. Technol. Manag. 2022, 33, 1319–1346. [Google Scholar] [CrossRef]

- Nenadál, J.; Vykydal, D.; Halfarová, P.; Tylečková, E. Quality 4.0 Maturity Assessment in Light of the Current Situation in the Czech Republic. Sustainability 2022, 14, 7519. [Google Scholar] [CrossRef]

- Szelągowski, M.; Berniak-Woźny, J. How to Improve the Assessment of BPM Maturity in the Era of Digital Transformation. Inf. Syst. e-Bus. Manag. 2021, 20, 171–198. [Google Scholar] [CrossRef]

- Kayikci, Y.; Kazancoglu, Y.; Gozacan-Chase, N.; Lafci, C.; Batista, L. Assessing Smart Circular Supply Chain Readiness and Maturity Level of Small and Medium-Sized Enterprises. J. Bus. Res. 2022, 149, 375–392. [Google Scholar] [CrossRef]

- Prashar, A. Towards Digitalisation of Quality Management: Conceptual Framework and Case Study of Auto-Component Manufacturer. TQM J. 2023, 35, 2436–2454. [Google Scholar] [CrossRef]

- Govindan, K.; Arampatzis, G. A Framework to Measure Readiness and Barriers for the Implementation of Industry 4.0: A Case Approach. Electron. Commer. Res. Appl. 2023, 59, 101249. [Google Scholar] [CrossRef]

| Concept | Abbreviation |

|---|---|

| Big Data | BD |

| Cloud Computing | CC |

| Cyber–Physical Systems | CPS |

| Sustainable Development Goals | SDGs |

| Industry 4.0 | I4.0 |

| Small and Medium-Sized Enterprises | SMEs |

| Internet of Things | IoT |

| Key Performance Indicators | KPIs |

| Case Study | CS |

| Literature Review | LR |

| Circular Economy | CE |

| Information Technology | IT |

| Business Process Management | BPM |

| Digital Transformation | DT |

| Not Available | NA |

| Digital Governance Assessment Framework | DGRA |

| Additive Manufacturing | AM |

| Augmented Reality | AR |

| Artificial Intelligence | AI |

| Automated Guided Vehicles | AGV |

| Human–Machine Interface | HMI |

| Radio-Frequency Identification | RFID |

| Real-Time Location Systems | RTLS |

| # Paper (See Supplementary Materials) | Outcome | Assessment Tool Included in the Article | Methodology | Validation Method | Drivers | Dimensions | Industry | Objective | Contribution |

|---|---|---|---|---|---|---|---|---|---|

| 1 | Framework | No | Qualitative and quantitative | LR, CS, Delphi method | Information and communication technology infrastructure, CPS, smart factory, SDGs, horizontal and vertical integration, leadership, employee willingness. | Economic, environmental, social, policy, process, product, strategy, technology. | Smart circular supply chain. | Evaluate the readiness and maturity level for I4.0 and CE in SMEs. | Readiness and maturity model that combines I4.0 and CE in a smart circular supply chain context. |

| 2 | Roadmap | Questionnaire | Qualitative and quantitative | LR, CS | CPS, embedded systems, horizontal and vertical integration, sensors, employee willingness. | Technology, products, customers and partners, value creation processes, data and information, corporate standards, employees, strategy, and leadership. | Manufacturing. | Present a new I4.0 guidance model. | Develop an integrated approach to lead from the first contact in I4.0 until the specific timelines, resources, and responsibilities are defined for the company. |

| 3 | Readiness assessment | Questionnaire and regression model | Qualitative and quantitative | CS | General technological drivers. | Strategy, organization, user interaction, partnership, operating activities, technology, innovation. | IT department. | Develop a model that quantifies the readiness of an IT department for its digital business transformation. | Better decision making when entering the digital market, comprehension of digital bottlenecks, better at identifying problems, increased competitive strategies, improved digital products and services. |

| 4 | Framework | No | Qualitative and quantitative | LR, CS | Willingness to change, innovation management, equipment infrastructure, leadership, KPIs, coordination. | Technology, production processes, people, product, change, organization. | Manufacturing in SMEs. | To propose a framework for a maturity model to assess the I4.0 maturity level of SMEs. | Help SMEs and companies with low maturity levels obtain the benefits of I4.0, evaluate their own maturity and help analyze their current strategies. |

| 5 | Framework | No | Conceptual | LR | Principles of process execution, modeling, design and improvement, IT tools, requirements for people working. | Asset management, data governance, application management, process transformation, organizational alignment. | BPM. | To develop a theoretical framework of the BPM maturity assessment process that includes the BPM implementation and one the includes the DT requirements. | Enables companies to perform a more reliable assessment of process maturity than current BPM maturity models. |

| 6 | Readiness assessment | Questionnaire | Qualitative and quantitative | CS | NA | Leadership and governance, user-centered design, public administration and change management, capabilities, culture and skills, technology infrastructure, data infrastructure, strategies and governance, cybersecurity, privacy and resilience, legislation and regulation and digital ecosystem. | Land services. | To develop an assessment tool for evaluating DT of land services in Indonesia based on the World Bank´s DGRA model. | Ensures that land services can be implemented digitally and helps develop a strategy for the progression of the land service business process. |

| 7 | Maturity model | No | Empirical | LR, CS | CC, Web 2.0, digitally rooted corporate culture and interoperability. | Customer, logistics, suppliers, integration, production, planning and control, quality and maintenance | Operations and supply chain management in manufacturing. | To develop a I4.0 maturity model for operations and supply chain management based on an existing procedure model | Assess the operations and supply chain management digitalization in real-life conditions and provide organizations measurable results. |

| 8 | Framework | No | Qualitative and quantitative | LR, CS | Quality management principles, leadership, organizational culture, processes management, BD, smart sensors, IoT. | Strategic direction, people and culture, processes and methods and tools. | Quality management | Propose a framework and methodology that assesses and measures the maturity level for Quality 4.0. | Incorporates new technologies with traditional practices and optimize them for better performance and innovation. |

| 9 | Framework | No | Qualitative | LR, CS | Customer focus, fact- based decision making, employee involvement, process management, integrated systems, leadership commitment. | People and culture, I4.0 awareness, organizational strategy, value chain and processes, smart manufacturing technology, product and service- oriented technology, I4.0 base technology. | Quality management in automotive component industry. | To develop a Quality 4.0 framework and present its application in an automotive company during the DT. | Contributes with the growing amount of I4.0 and DT literature in the context of operations management and helps understand how to work toward the transformation of quality management processes. |

| 10 | Assessment tool | No | Qualitative | LR | Industrial IoT, BD, CC, AM, simulation, CPS, autonomous robots, KPIs. | Foundation, product design, production planning, production engineering, production execution, services, infrastructure. | Manufacturing in SMEs. | Define the I4.0 priorities for Indian small and medium discrete manufacturing establishments through a questionnaire assessment survey. | Guide organizations define their digital strategies and help plan and execute them efficiently. |

| 11 | Framework | Questionnaire | Qualitative and quantitative | LR, CS | Digital skills, technology adoption, digital strategy, data analytics, technology infrastructure, front office, back office. | People, technology, process, customer and strategy, and investment. | General. | Develop a framework for assessing the level of DT of an organization. | Provides a quantitative approach for digital readiness at the organizational level. Helps the understanding and evaluation of the DT of museums. |

| 12 | Assessment tool | No | Qualitative | CS | Assign clear responsibilities, collaborative organizational structure, digital skills, data flow integration, IT infrastructure. | Digital strategy, digital maturity models, digitalization, investments, data analysis and KPIs. | Manufacturing. | Identify and organize the circumstances of the readiness for DT through a questionnaire. | Understand how change processes management applies to DT. |

| 13 | Framework | No | Qualitative and quantitative | LR, CS | Investment planning, project management, horizontal and vertical integration, data analytics, IT cybersecurity. | Strategy and governance, organization and corporate culture, smartness, employees, processes, customer. | Manufacturing. | Propose a new maturity model development framework based on design theory and develops a DT maturity model using this framework. | Provides guidance to develop a maturity model regardless of the domain, extends the design science literature and demonstrates the applicability of the framework. |

| 14 | Maturity model | No | Qualitative | LR | CC, IoT, IT security, data analytics, BD tools, data flow, integration of manufacturing and automation technologies, IT personnel skill set and planning, acquisition, production and sale, and distribution. | Asset management, data governance, application management, process transformation, organizational alignment. | Manufacturing. | Propose a maturity model for I4.0 based on software process improvement and capability determination. | Standardize development, provide higher quality, more flexibility, continuous benchmarking, global competition, job creation. |

| 15 | Readiness assessment | Questionnaire | Triangulation | LR, CS | AR, AI, blockchain, cloud storage, coordination, collaboration. | Organizational, technological. | Healthcare. | Examine the technological and operational capabilities that impact the level of organizational e- readiness for DT in Polish primary healthcare providers. Develop a model for DT organizational e-readiness. | Provide guidance for healthcare staff when developing strategies and distributing medical resources. Help healthcare staff of primary healthcare providers assess the e-readiness for DT and overcome barriers. |

| 16 | Maturity model | No | Qualitative and quantitative | LR, CS | Organizational structure, horizontal and vertical integration, CC, digital cost, strategy design, efficiency measure, intelligent cost construction capability. | Top-level design, infrastructure, cost consultation business process, professional management, comprehensive integration and digital cost performance. | Cost consultation. | Develop a digital maturity model to evaluate the digital maturity level of cost consultation enterprises. | Measures the digital level of cost consultation from multiple dimensions. Provides a guiding tool for DT of cost consultation. Provides a theoretical reference for DT of the cost consultation industry. |

| 17 | Roadmap | Quantitative scorecard | Empirical, quantitative | LR | AI, machine learning, BD analytics, CC, robotic process automation, distributed ledger technology, natural language processing, and application program interface. | Digital leadership, technical knowledge, data and insights, technology infrastructure, automation of process. | Bank treasury. | To perform a digital maturity assessment to determine the maturity level of a treasury. | It ensures the right activities and digital technologies are identified for DT. |

| 18 | Maturity model | No | Qualitative | CS | Skills development, project management, agile software development, architecture integration, IT strategy management. | Strategic governance, information and technology, digital process. transformation, workforce management. | Manufacturing. | To analyze how DT capability maturity model identifies organizations ‘current DT maturity level. To provide roadmaps for DT maturity improvement. Apply the DT capability maturity model to verify its usability. | Provides guidance and promotes continuous improvement of the lifecycle for DT processes in an efficient and organized way. |

| 19 | Assessment tool | No | Empirical | CS | BD, AM, IoT, CPS, automation, robotics, cybersecurity, product and process simulation. | Strategy, people, processes, technology and integration. | General SMEs. | Propose an assessment tool (questionnaire) for evaluating SME’s digital readiness and apply it for a case study. | Provides support and understanding to SMEs in their DT journey. |

| 20 | Framework | Scorecard template | Qualitative and quantitative | CS | E-Kanban, control systems, AGV, tracking systems, laser welding. | Financial, organizational, and technological. | Automotive. | A multi-criteria decision-making model and framework. Explores criteria and methods that can be used in a feasibility analysis decision-making model for identifying the technologies for effective DT. | Includes business-related financial issues to the model. It serves strategy makers and the knowledge based on multi-criteria technology selection. |

| 21 | Readiness assessment | No | Qualitative | LR, CS | NA | Strategy, governance, operations, object. | Manufacturing. | Develop a readiness model that assesses the capability to use data in industrial enterprises. | Provides information about organizational and structural readiness for data utilization. It assesses the data utilization capability. |

| 22 | Maturity model | Questionnaire | Qualitative and quantitative | Delphi method, pilot testing | CPS, IoT, BD, VR, AR, simulation, smart manufacturing, HMI, robotization, manufacturing execution systems. | Service, operations, quality, products, documented information—big data, leadership and strategy, communication, culture and staff. | Manufacturing in SMEs. | Establish a I4.0 maturity model for manufacturing SMEs. | It can be applied in any industry. Determines the degree of implementation compliance of companies in the same sector. Presents the dimensions holistically, considering important criteria. The model is detailed for SMEs to self-assess themselves. |

| 23 | Framework | No | Qualitative | LR | Autonomous operation, IT infrastructure, digital twin, role of people and willingness, strong partnerships and connections, I4.0 strategy, financial resources, data Utilization. | Physical and virtual world, human, strategy and culture, products and services, value chain, and the broader environment. | Manufacturing. | Renews the Company Compass 2.0 model by developing a I4.0 conceptual framework and maturity assessment solution to support I4.0 progression. | It is a holistic approach. It determines the deficiencies and gaps of I4.0 organizations readiness level and provides guidelines for improvement. |

| 24 | Maturity model | Questionnaire | Qualitative and empirical | LR, pilot testing | Strategic management, skills acquisition, CC, autonomous equipment, AR, embedded software, real-time data analytics. | Organizational strategy, structure and culture, workforce, smart factories, smart processes, smart products and services. | Manufacturing. | Develops a maturity model 4.0 to support companies in their implementation strategies. | It provides support for initial diagnosis and establishes a roadmap for implementation. |

| 25 | Assessment tool | No | Qualitative | LR, CS | Customer orientation, leadership, training of employees, robots, flexible manufacturing, CPS, IoT, BD. | Strategy, structure and organizational culture, workforce, smart factories, smart processes, smart products and services, technology. | Automotive supply chain. | Present and apply questionnaires to analyze the companies’ results in I4.0 and the supply chain context. | Collaborates with business areas to help with the understanding and implementation of I4.0 technologies. |

| 26 | Readiness assessment | No | Qualitative | CS | Mass product customization, cloud solution, IT and data security, people capabilities, collaboration, inventory control, supply chain integration, flexibility and visibility, real-time data, intellectual property, contracting models. | Products and services, manufacturing and operations, strategy and organization, supply chain, business model, legal considerations. | Supply chain. | Present a readiness self-assessment templates tool to determine the I4.0 of a company while providing a benchmark of I4.0 readiness. | Helps verify companies that are using the opportunities of cyber–physical age present in a proactive and effective way. |

| 27 | Maturity model | Questionnaire | Qualitative and quantitative | LR, CS | Adaptive robotics, data analytics, AI, simulation, embedded systems, communication and networking, cybersecurity, cloud, AM, virtualization, sensors and actuators, RFID and RTLS technologies, mobile technologies. | Smart products and services, smart business process, strategy and organization. | General. | Propose an I4.0 maturity model, discuss the problems with I4.0 implementation, explain reasons to implement and its benefits and to explain and compare existing maturity models. | Smart finance, smart marketing and human resources were proposed to differentiate the model and help organizations broad their perspective for I4.0 applications. |

| 28 | Roadmap | No | Qualitative | LR | Data security, digital devices, flexibility in producing products/services, internet connection, collect data, data usage, collaboration. | Production and operations, digitalization, and ecosystem. | SMEs in manufacturing and construction. | Present the approach used to develop a self-assessment tool that determines I4.0 readiness of craftmanship SMEs organizations. | Provide evidence on the design of assessment tools regarding I4.0 readiness in SMEs craftmanship organizations. |

| 29 | Roadmap | No | Qualitative | LR | Digital collaboration, digital skills training, business and IT synergy, process standardization, security and legal issues. | Culture, ecosystem, operations, governance, and strategy. | IT companies. | To develop dimensions and criteria for a DT maturity model for IT companies. | Provides understanding of critical areas that are impacted by DT. Provides new ways for a DT assessment specifically for the needs of IT companies. |

| 30 | Assessment tool | No | Qualitative | LR | Leadership, governance structure, IT team, collaboration, automated data, training program, communication, patient-focused plan and innovation plan. | Checklist for organizational, training, technical, cultural, management and further improvement. | Healthcare | To develop a checklist that defines the steps for electronical medical records implementation and DT for hospitals | Provides guidance in preparing hospitals for the implementation of electronic medical records. Separates the readiness for electronical medical records and for DT. |

| 31 | Assessment tool | Questionnaire and roadmap | Empirical | CS | I4.0 strategy, indicators, investment plan, IT infrastructure, data collection, autonomous control, ICT functions, data analytics, data-based services, personalization, ICT employee skills, continuous training. | Self-assessment platform for strategy and organization, smart factory, smart operations, smart products, data-driven services, and human resources. | General SMEs. | Present a self-assessment tool that evaluates I4.0 readiness level of a company. | The tool provides a report/roadmap that guides companies with an action plan and recommendations. |

| 32 | Framework | No | Qualitative and quantitative | CS | IoT, BD, cloud and mobile technologies, VR, AR, robotics, customer journey, organizational culture, resource management, innovation capacity, improvement goals, flexibility. | Technology, customer, governance, and capability. | Business process management. | Develop a framework for self-assessment regarding the evaluation of business process management software in the DT. | Describes how business process management dimensions are related to DT and demonstrates how analytic hierarchy process can serve for selecting a business process management software. |

| 33 | Framework | No | Qualitative | LR | Telecommunication technology, people, platform, process, device, station, work unit, enterprise and connected world. | Hierarchical and aspect. | Oil and gas industry. | To develop a readiness assessment framework of mobile CC in the upstream oil and gas industry. | Oil and gas industry are assessed accurately. Provides flexibility in the adoption stages. |

| 34 | Framework | No | Empirical | CS | E-governance, collaborative platforms, software, data protection, data sharing, digital infrastructure, cloud storing. | Entities, relationships, and activities. | Agriculture. | To outline a framework to operationalize the concept of socio-cyber–physical system with the research and innovation approach and SDGs. | Provides insights on the multifaceted impacts of digitalization. |

| 35 | Framework and Readiness Assessment | No | Review DEMATEL | CS | NA | Business models and products; market and sales; value chains and operations; it infrastructure; legal and security; organization and strategy. | Manufacturing and services. | To propose a framework to assist industries in promoting Industry 4.0 through two phases. | Combines an analysis of a firm’s readiness level with its corresponding barriers to Industry 4.0 implementation and proposes a series of sequential steps to be carried out for industries seeking to implement Industry 4.0 in their organization. |

| 36 | Framework | No | Review, conceptual paper | LR | RAMI 4.0, Standards I4.0 Ontology. | Hierarchy level, lifecycle and value stream, layers. | Manufacturing. | Calculate the readiness and maturity levels of the institution accordingly to RAMI 4.0 framework. | The questionnaire consists of the gathering of the definition of adherent or not adherent to each one of the RAMI and 142 standards. |

| Characteristic | Bastos et al. (2021) [18] | Agca et al. (2017) [31] | Gökalp et al. (2017) [23] | Isaev et al. (2018) [37] | Akdil et al. (2018) [11] | Brozzi et al. (2018) [38] | Scott et al. (2019) [39] | Pirola et al. (2019) [22] | Schumacher at al. (2019) [40] | Aripin et al. (2020) [25] | Brkić et al. (2020) [41] | Castro et al. (2020) [33] | Gollhardt et al. (2020) [12] | Santos and Martinho (2020) [14] | Nausch et al. (2020) [42] | Beyaz and Yıldırım (2020) [43] | |

| Dimensions | |||||||||||||||||

| Smart factory | x | x | x | ||||||||||||||

| Process | x | x | x | x | x | ||||||||||||

| Product | x | x | x | x | x | x | x | x | x | ||||||||

| Strategy | x | x | x | x | x | x | x | x | x | x | |||||||

| Technology | x | x | x | x | x | x | x | x | |||||||||

| Customers/Clients | x | x | x | ||||||||||||||

| Employees/Workforce | x | x | x | x | x | ||||||||||||

| Leadership | x | x | |||||||||||||||

| Governance/Policy | x | x | x | x | x | x | |||||||||||

| Organization | x | x | x | x | x | x | x | x | |||||||||

| Operation | x | x | x | x | x | x | x | ||||||||||

| Culture | x | x | x | ||||||||||||||

| Supply chain | x | ||||||||||||||||

| Services | x | x | x | x | |||||||||||||

| Others | x | x | |||||||||||||||

| Drivers | Bastos et al. (2021) [18] | Agca et al. (2017) [31] | Gökalp et al. (2017) [23] | Isaev et al. (2018) [37] | Akdil et al. (2018) [11] | Brozzi et al. (2018) [38] | Scott et al. (2019) [39] | Pirola et al. (2019) [22] | Schumacher at al. (2019) [40] | Aripin et al. (2020) [25] | Brkić et al. (2020) [41] | Castro et al. (2020) [33] | Gollhardt et al. (2020) [12] | Santos and Martinho (2020) [14] | Nausch et al. (2020) [42] | Beyaz and Yıldırım (2020) [43] | |

| General drivers | x | x | |||||||||||||||

| Cyber–physical systems | x | x | x | x | |||||||||||||

| Horizontal and vertical integration | x | x | |||||||||||||||

| Employee’s willingness, skills, roles, and Flexibility | x | x | x | x | x | x | x | x | x | x | |||||||

| Embedded systems | x | x | x | x | |||||||||||||

| ICT infrastructure | x | x | x | x | x | ||||||||||||

| Sensors and/or tracking devices | x | x | x | x | |||||||||||||

| Innovation | x | x | |||||||||||||||

| Key performance indicators | x | x | |||||||||||||||

| Coordination and collaboration | x | x | x | x | x | x | x | ||||||||||

| Cloud computing | x | x | x | x | x | x | |||||||||||

| Big data, data analytics, and/or data management and technology | x | x | x | x | x | x | x | x | x | x | |||||||

| Internet of Things | x | x | x | x | |||||||||||||

| Management | x | x | x | ||||||||||||||

| Simulation | x | x | |||||||||||||||

| Robots | x | x | x | x | |||||||||||||

| Strategy | |||||||||||||||||

| Cybersecurity | x | x | x | x | x | x | |||||||||||

| Automation | x | x | x | x | x | x | |||||||||||

| Augmented reality | x | x | |||||||||||||||

| Virtual reality | x | ||||||||||||||||

| Artificial Intelligence | x | x | |||||||||||||||

| Additive manufacturing | x | x | |||||||||||||||

| Mass customization | x | x | x | x | |||||||||||||

| Includes a questionnaire, survey or checklist | x | x | x | x | x | X | x | ||||||||||

| # of questions | - | - | - | 29 | 68 | - | 19 | 46 | 65 | - | - | - | - | 41 | - | - | |

| Characteristic | Dutta et al. (2020) [34] | Vasconcellos et al. (2021) [35] | Nick et al. (2021) [44] | Gökalp and Martinez (2021) [45] | Von Solms and Langerman (2021) [46] | Kruszyska-Fischbach et al. (2021) [47] | Machado et al. (2021) [48] | Agostino Costantini (2021) [36] | Caiado et al. (2021) [49] | Kusmiarto et al. (2021) [50] | Amaral and Peças (2021) [51] | Metta et al. (2022) [52] | Ávila-Bohórquez and Gil-Herrera (2022) [15] | Han et al. (2022) [53] | Kırmızı and Kocaoglu (2022) [54] | Nenadál et al. (2022) [55] | Szelągowski and Berniak-Woźny (2022) [56] | Kayikci et al. (2022) [57] | Prashar (2023) [58] | Govindan K. et al. (2023) [59] | |

| Dimensions | |||||||||||||||||||||

| Smart factory | x | ||||||||||||||||||||

| Process | x | x | x | x | x | x | x | x | x | x | x | ||||||||||

| Product | x | x | x | x | x | x | x | x | |||||||||||||

| Strategy | x | x | x | x | x | x | x | x | x | x | x | x | |||||||||

| Technology | x | x | x | x | x | x | x | x | x | x | x | x | x | x | |||||||

| Customers /Clients | x | x | x | ||||||||||||||||||

| Employees/Workforce | x | x | x | x | x | x | x | x | x | x | |||||||||||

| Leadership | x | x | x | ||||||||||||||||||

| Governance/Policy | x | x | x | x | x | ||||||||||||||||

| Organization | x | x | x | x | x | x | |||||||||||||||

| Culture | x | x | x | x | x | x | |||||||||||||||

| Operation | x | x | |||||||||||||||||||

| Supply chain | |||||||||||||||||||||

| Services | x | x | x | x | x | ||||||||||||||||

| Others | x | ||||||||||||||||||||

| Drivers | Dutta et al. (2020) [34] | Vasconcellos et al. (2021) [35] | Nick et al. (2021) [44] | Gökalp and Martinez (2021) [45] | Von Solms and Langerman (2021) [46] | Kruszyska-Fischbach et al. (2021) [47] | Machado et al. (2021) [48] | Agostino Costantini (2021) [36] | Caiado et al. (2021) [49] | Kusmiarto et al. (2021) [50] | Amaral and Peças (2021) [51] | Metta et al. (2022) [52] | Ávila-Bohórquez and Gil-Herrera (2022) [15] | Han et al. (2022) [53] | Kırmızı and Kocaoglu (2022) [54] | Nenadál et al. (2022) [55] | Szelągowski and Berniak-Woźny (2022) [56] | Kayikci et al. (2022) [57] | Prashar (2023) [58] | Govindan et al. (2023) [59] | |

| General drivers | x | ||||||||||||||||||||

| Cyber–physical systems | x | x | x | x | |||||||||||||||||

| Horizontal and vertical integration | x | x | x | ||||||||||||||||||

| Employee’ s willingness, skills, roles, and flexibility | x | x | x | x | x | x | x | x | x | ||||||||||||

| Embedded systems | x | ||||||||||||||||||||

| ICT infrastructure | x | x | x | x | x | x | x | x | |||||||||||||

| Sensors and/or tracking devices | x | ||||||||||||||||||||

| Innovation | x | ||||||||||||||||||||

| Key performance indicators | x | x | |||||||||||||||||||

| Coordination and collaboration | x | x | x | x | x | ||||||||||||||||

| Cloud computing | x | x | x | x | x | x | |||||||||||||||

| Big data, data analytics, and/or data management and technology | x | x | x | x | x | x | x | x | x | x | |||||||||||

| Internet of Things | x | x | x | x | |||||||||||||||||

| Management | x | x | x | x | |||||||||||||||||

| Simulation | x | x | |||||||||||||||||||

| Robots | x | x | x | x | |||||||||||||||||

| Strategy | |||||||||||||||||||||

| Cybersecurity | x | x | |||||||||||||||||||

| Automation | x | x | |||||||||||||||||||

| Augmented reality | x | x | x | ||||||||||||||||||

| Virtual reality | x | ||||||||||||||||||||

| Artificial Intelligence | x | x | |||||||||||||||||||

| Additive manufacturing | x | ||||||||||||||||||||

| Customization | x | ||||||||||||||||||||

| Includes a questionnaire, survey or checklist | x | x | x | x | x | x | x | ||||||||||||||

| # of questions | - | 66 | - | - | - | 32 | 70 | 19 | - | 67 | - | - | 49 | - | - | - | - | - | - | 36 | |

| Category | Key Insights |

|---|---|

| Assessment Tools | -Combine Industry 4.0 and circular economy for sustainable practices. |

| -Guide companies through digital transformation. | |

| -Help SMEs and low-maturity companies assess themselves. | |

| -Provide more reliable process maturity assessment than traditional models. | |

| -Develop questionnaires and frameworks for practical assessment. | |

| -Analyze data utilization and support technology selection. | |

| -Demonstrate tool effectiveness through case studies. | |

| Industry-Specific Applications | -Adapt models services, operations/supply chain, and Quality 4.0. |

| -Identify Industry 4.0 priorities for Indian manufacturing SMEs. | |

| -Develop e-readiness models for healthcare and cost consultation. | |

| -Assess data utilization capabilities in industrial enterprises. | |

| -Create maturity models for specific sectors like manufacturing and IT. | |

| Other Research-Related Areas | -Propose design theory-based framework for new maturity models. |

| -Examine e-readiness factors in healthcare and develop implementation checklists. | |

| -Offer self-assessment tools for Industry 4.0 readiness and BPM software evaluation. | |

| -Explore mobile cloud computing readiness in oil and gas and operationalize socio-cyber–physical systems. |

| # | Dimension | Description | Industry 4.0 Drivers |

|---|---|---|---|

| 1 | Strategy | To improve an organization through innovation culture, continuous improvement, implementation of new information and technologies, efficient organizational structure, and client satisfaction. It is considered the “input” for the transformation of Industry 4.0. Development of new smart products, services, and business operations and promote collaboration between stakeholders that fosters progress, structure, and leadership. | Business models Strategic partnerships and collaborations Technology investment Leadership Focus on organizational tasks, employee autonomy, motivation, and team skills. Customer orientation Adaptation to technological changes |

| 2 | Workforce | Implementing and developing suitable technical and management skills is necessary for digital transformation. Also, the willingness, autonomy, openness of the workforce, and flexibility are fundamental aspects of rapid Industry 4.0 changes. | New and better qualifications Learning platforms Appropriate training using technological tools. Digital thinking |

| 3 | Leadership | Implementing a vision or strategy for encouraging digital technology and drivers is necessary for this dimension. Organizational alignment to adopt Industry 4.0 concepts. | Communication of Industry 4.0 plans Willingness to realize Industry 4.0 Critical thinking Management of employees |

| 4 | Clients | Enhancing a client’s relationship with the company and their satisfaction are essential parts of this dimension. The ability to engage with clients and maintain effective communication. | Information technology-enhanced collaboration Digital contacts of clients Openness to new technology Client integration into product/service development Data utilization |

| 5 | Smart factories Smart services | To include technologies that promote real-time communication between machines, products, people, and infrastructure. Smart factories are composed of smart sensors and actuators, embedded systems, and connectivity. Smart services present wide digitalization and real-time connectivity and information. | Man–machine interaction. Robots Integration and operation Simulation, digital twins Cyber–physical systems, Industrial Internet of Things, Service Internet of Things |

| 6 | Smart products and services | Implementing products with embedded systems are the foundation for real-time data collection, promoting communication between customers, factories, and value chain processes. It measures the characteristics of the products and services that are driven by data. | Products and servers enabled by IT systems. Customer orientation Mass product customization Data-driven services. Digital product features Product data usage Share of revenue |

| 7 | Technology | To implement smart factories and processes, it is necessary to use interconnected technologies (cyber–physical systems, Internet of Things, big data, big data analytics, and cloud manufacturing) | Self-managed traceability systems Simultaneous communication between machines, products, and processes Communication between factories and supply chain Manufacturing optimization |

| 8 | Governance | To follow and comply with regulations and rules. It creates suitable structures to manage the organization’s operation. | Corporate social responsibility Data management Data utilization engagement Analytical abilities |

| 9 | Operations | To manage, measure, and control the processes and services of the company. It includes the technologies that enhance their productivity. | Technology integration Automation Data utilization Resource capability |

| 10 | Supply chain | To promote visibility and connection between several business functions by implementing advanced technology across the supply chain. An integrated supply chain connects suppliers and customers. It is required to develop processes, capabilities, and systems to support digital collaboration. | Inventory control Real-time data management Supply chain integration, flexibility, and visibility Lead times |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zamora Iribarren, M.; Garay-Rondero, C.L.; Lemus-Aguilar, I.; Peimbert-García, R.E. A Review of Industry 4.0 Assessment Instruments for Digital Transformation. Appl. Sci. 2024, 14, 1693. https://doi.org/10.3390/app14051693

Zamora Iribarren M, Garay-Rondero CL, Lemus-Aguilar I, Peimbert-García RE. A Review of Industry 4.0 Assessment Instruments for Digital Transformation. Applied Sciences. 2024; 14(5):1693. https://doi.org/10.3390/app14051693

Chicago/Turabian StyleZamora Iribarren, Miranda, Claudia Lizette Garay-Rondero, Isaac Lemus-Aguilar, and Rodrigo E. Peimbert-García. 2024. "A Review of Industry 4.0 Assessment Instruments for Digital Transformation" Applied Sciences 14, no. 5: 1693. https://doi.org/10.3390/app14051693

APA StyleZamora Iribarren, M., Garay-Rondero, C. L., Lemus-Aguilar, I., & Peimbert-García, R. E. (2024). A Review of Industry 4.0 Assessment Instruments for Digital Transformation. Applied Sciences, 14(5), 1693. https://doi.org/10.3390/app14051693