Analysis of the Dynamic Mechanical Properties and Energy Dissipation of Water-Saturated Fissured Sandstone Specimens

Abstract

1. Introduction

2. Processing and Preparation of Water-Saturated Fissured Sandstone Specimens and SHPB Test Device

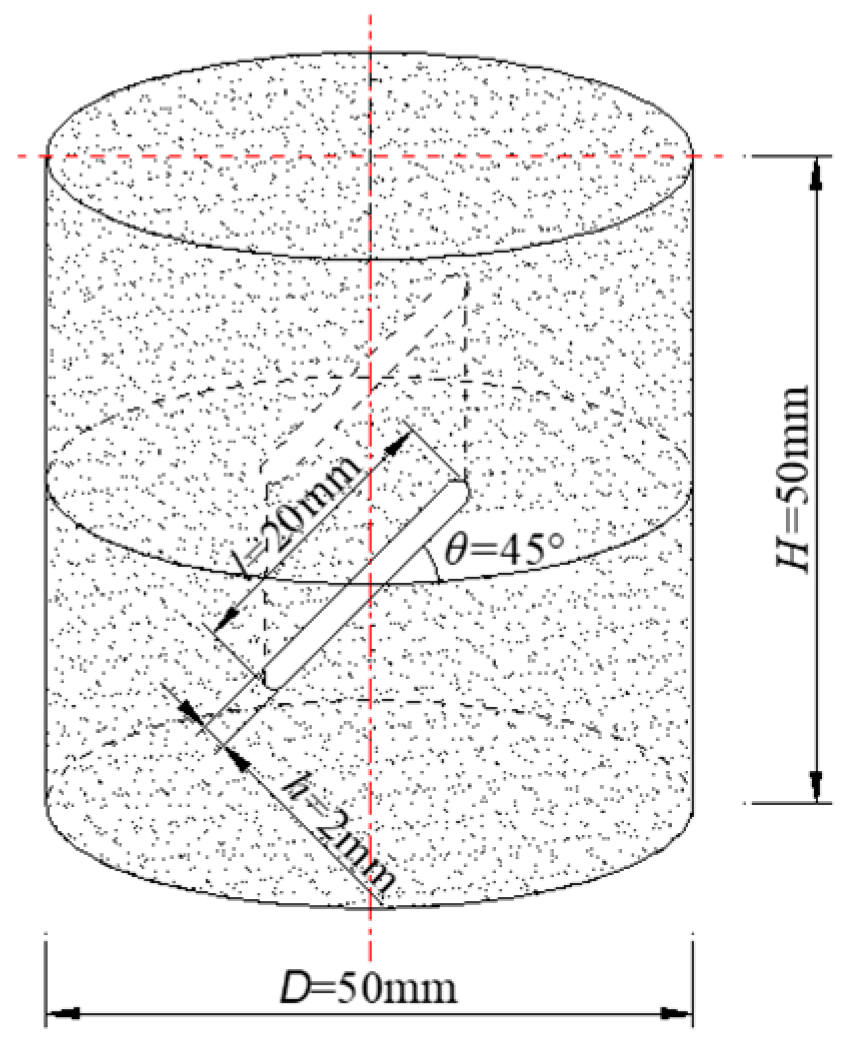

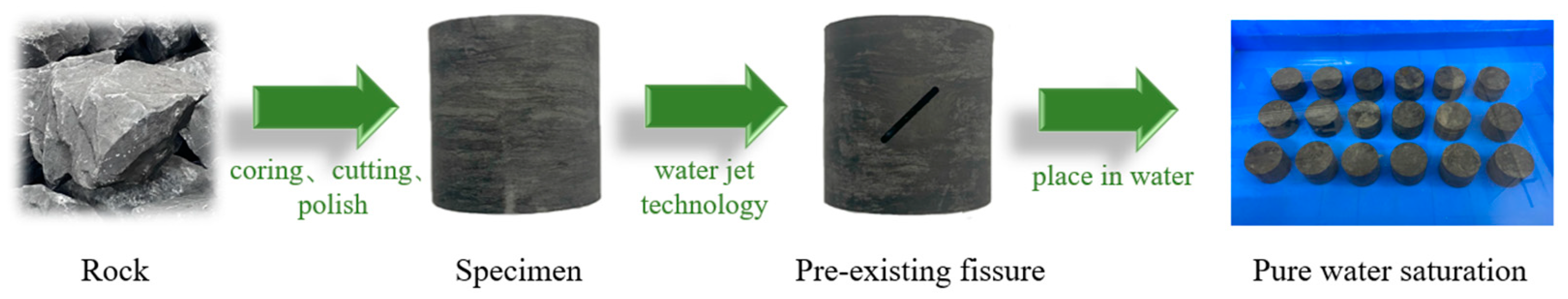

2.1. Processing of Water-Saturated Fissured Sandstone Specimens

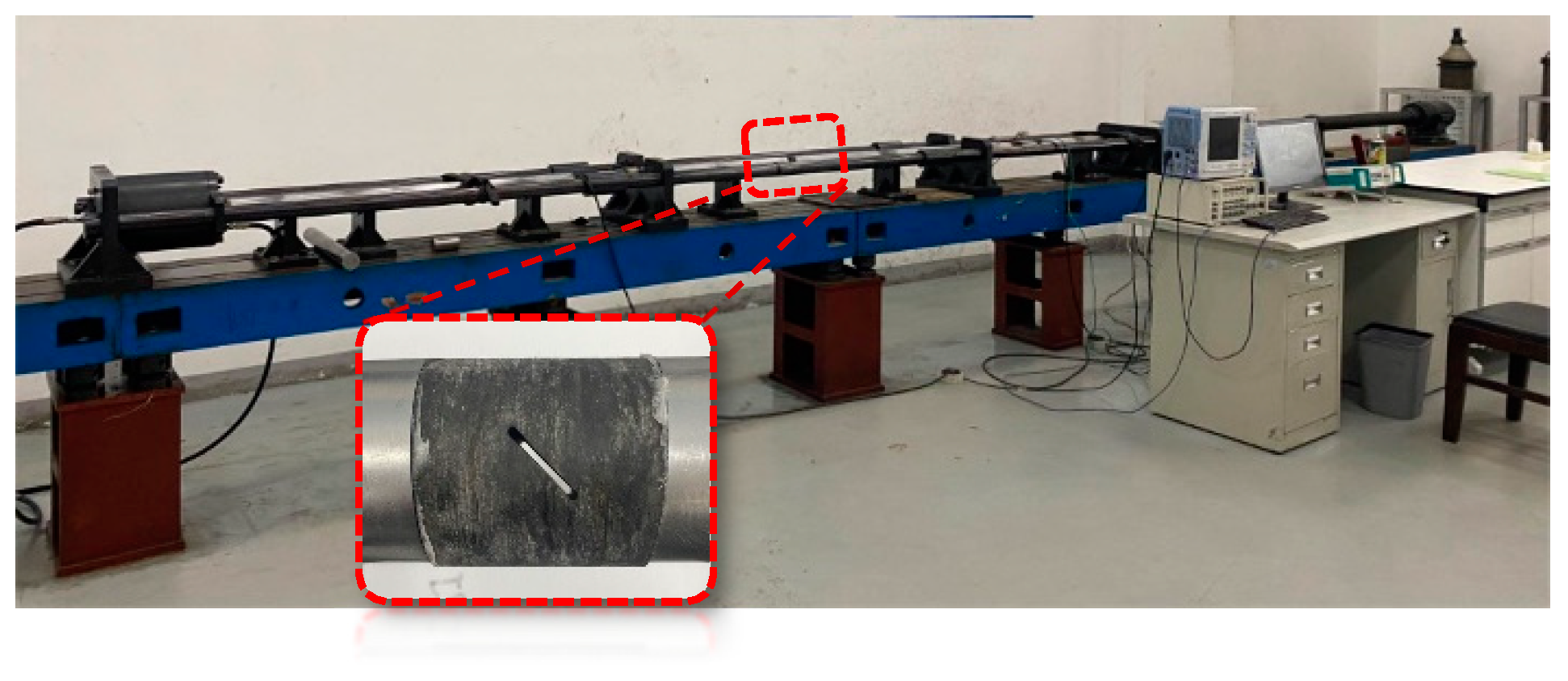

2.2. SHPB Test Device and Principle

3. Results of SHPB Tests

3.1. Dynamic Mechanical Parameters of Water-Saturated Fissured Sandstone

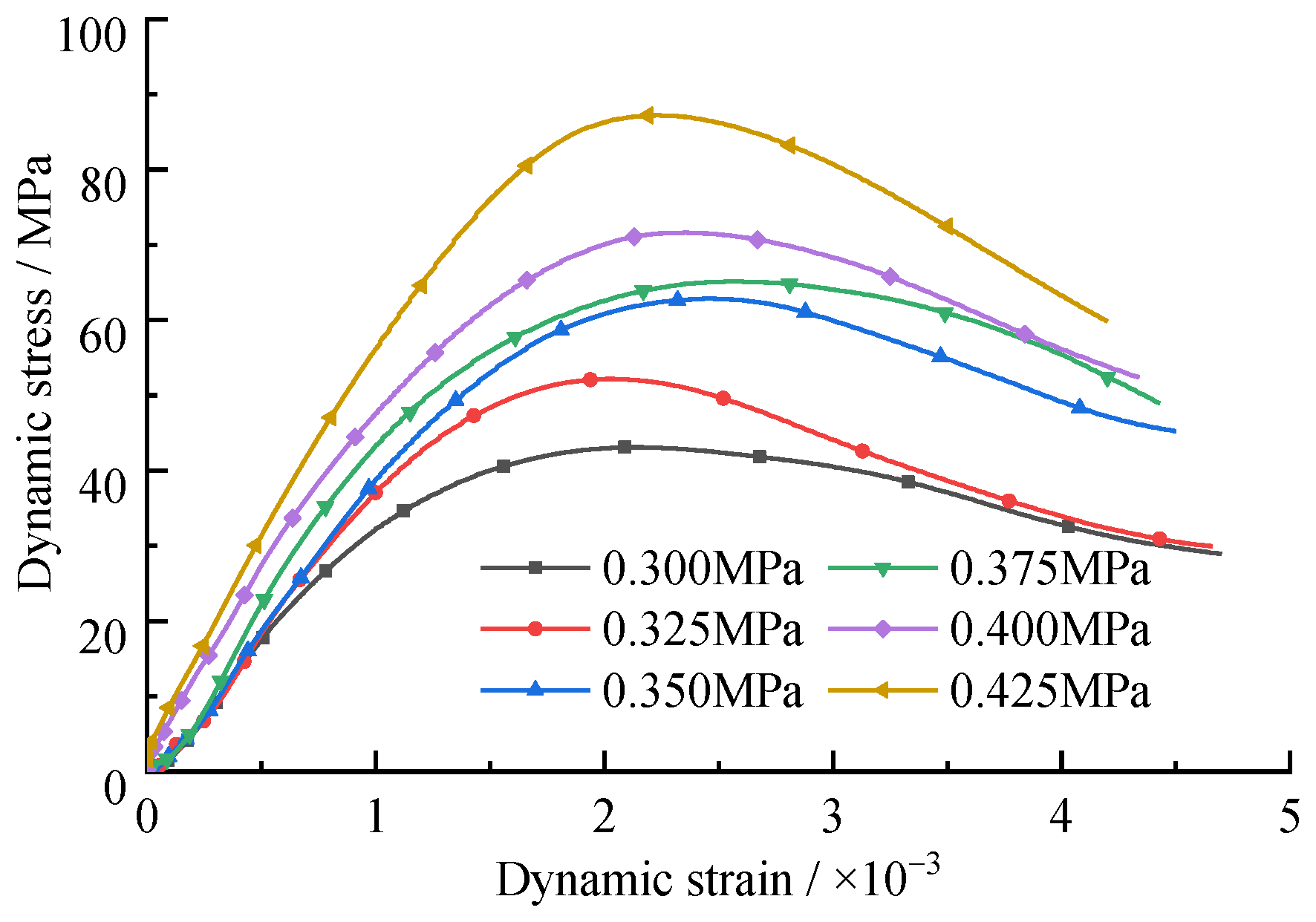

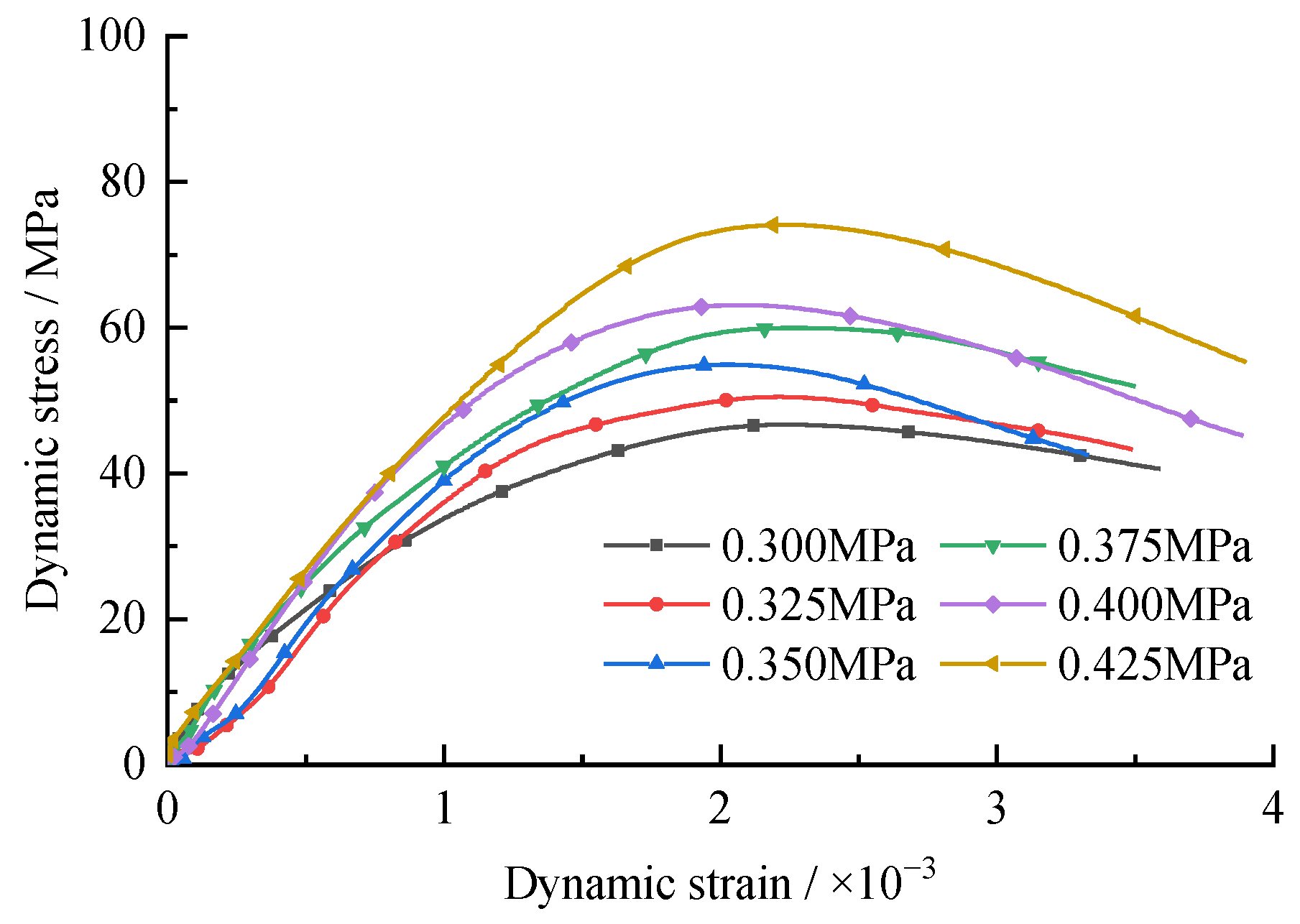

3.2. Dynamic Stress–Strain Curve Analysis

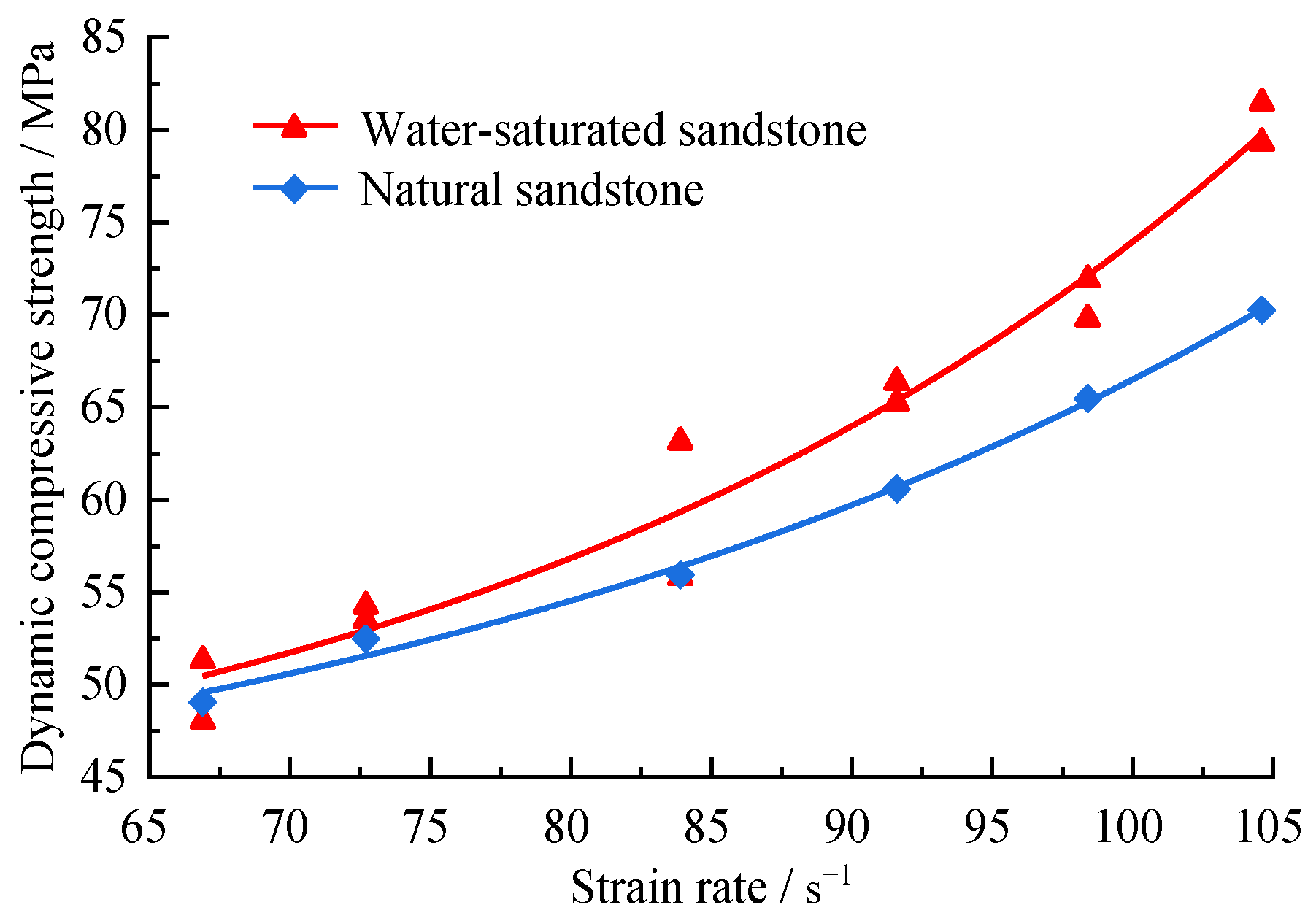

3.3. Dynamic Compressive Strength

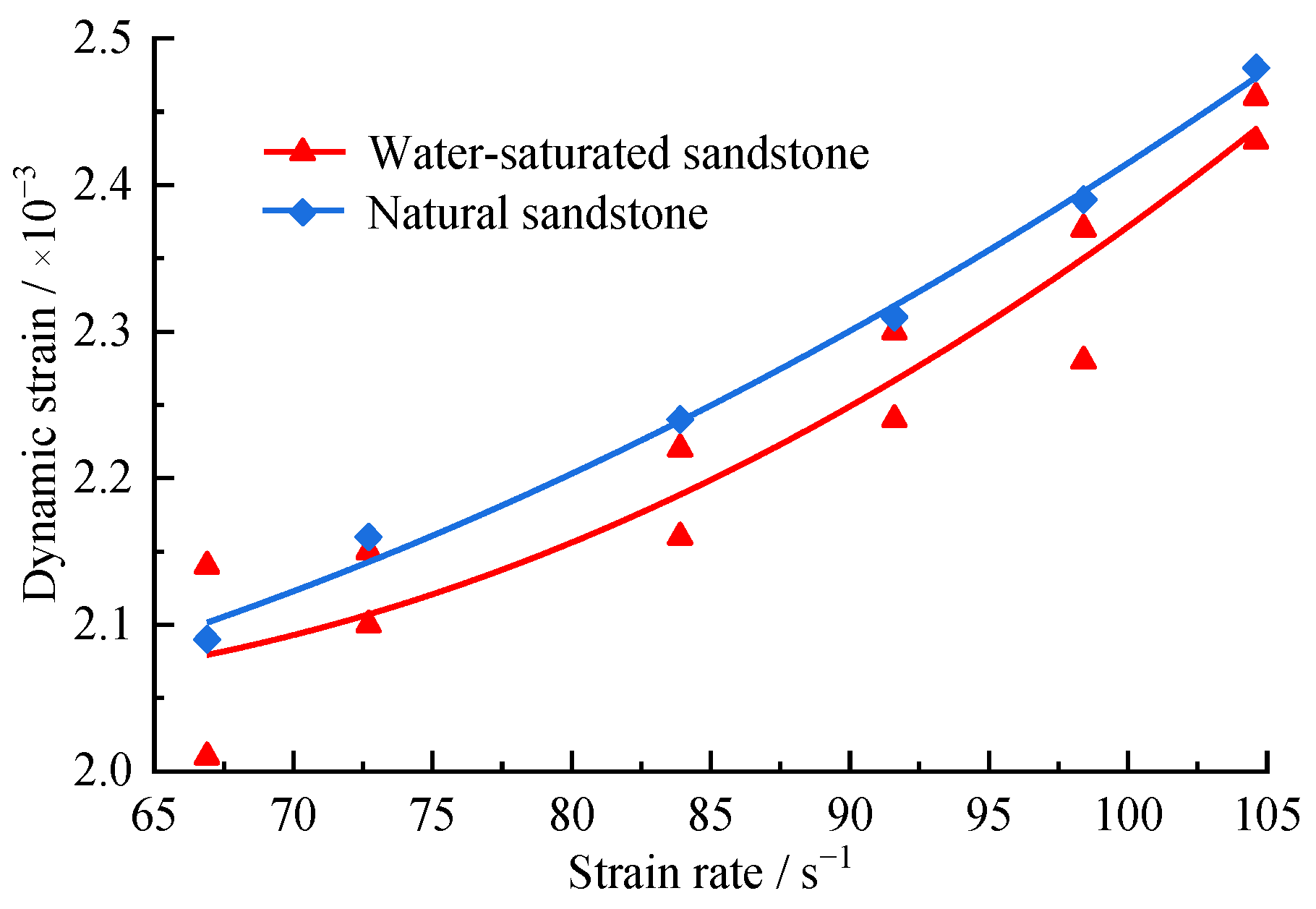

3.4. Dynamic Strain

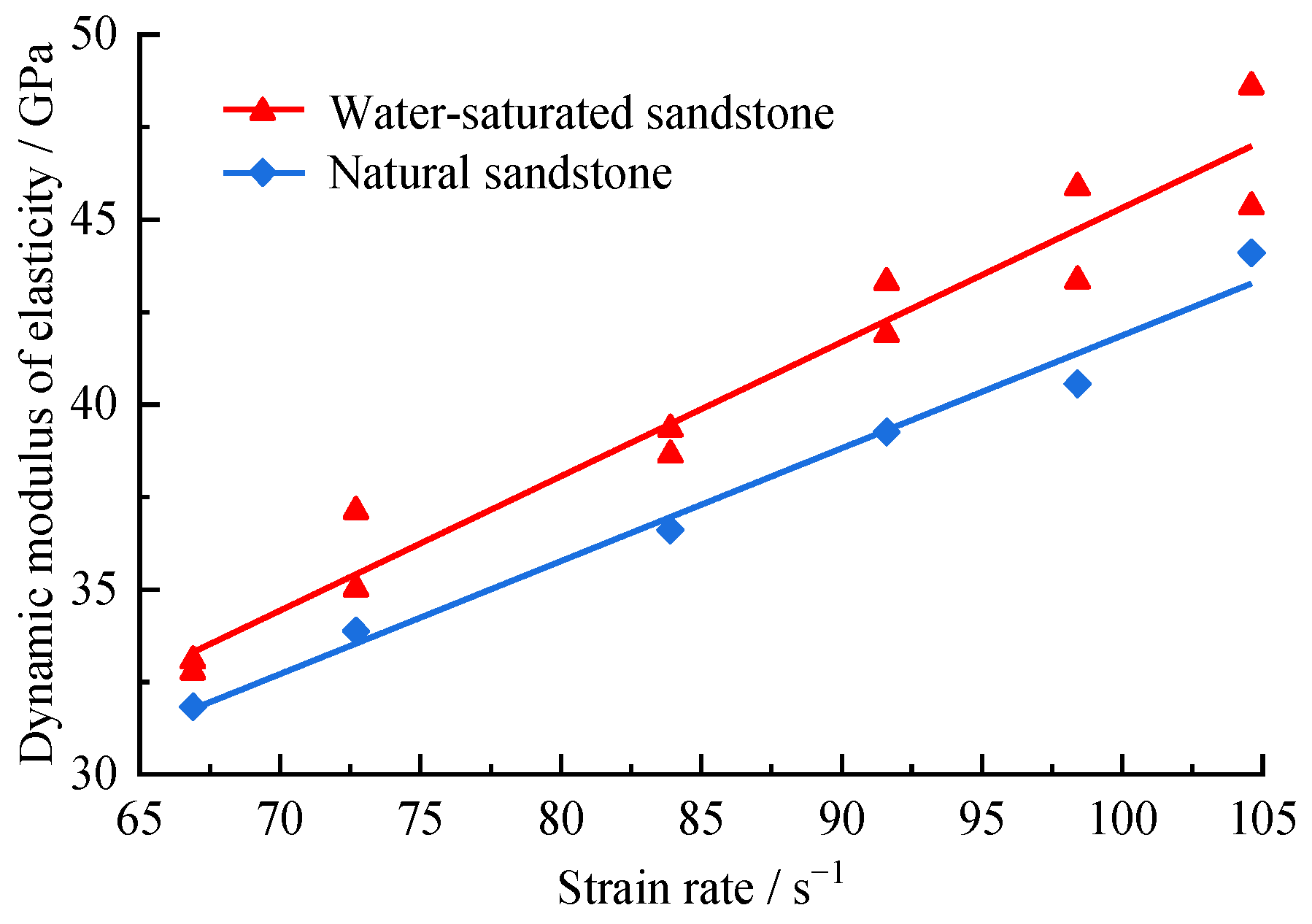

3.5. Dynamic Elastic Modulus

4. Failure Pattern and Analysis of the Energy Consumption

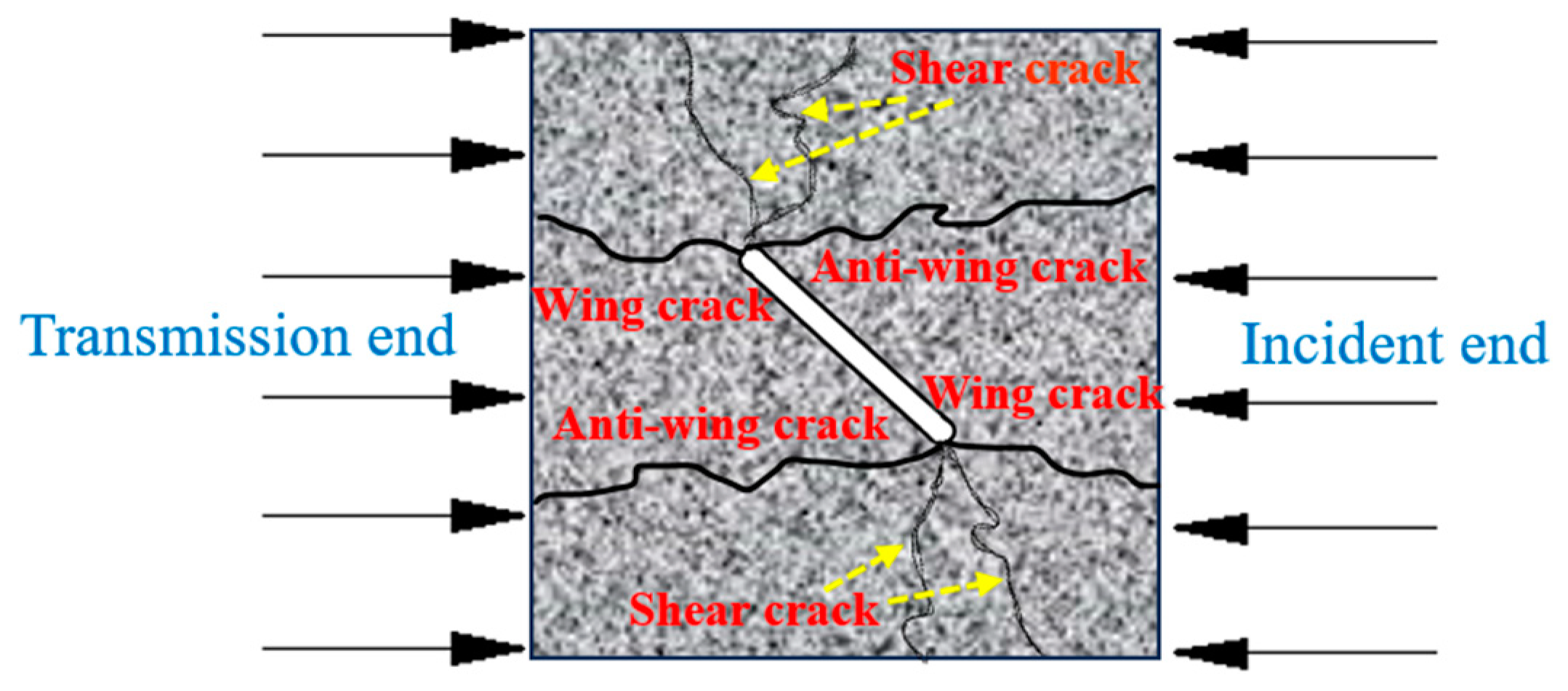

4.1. Failure Pattern of Specimen

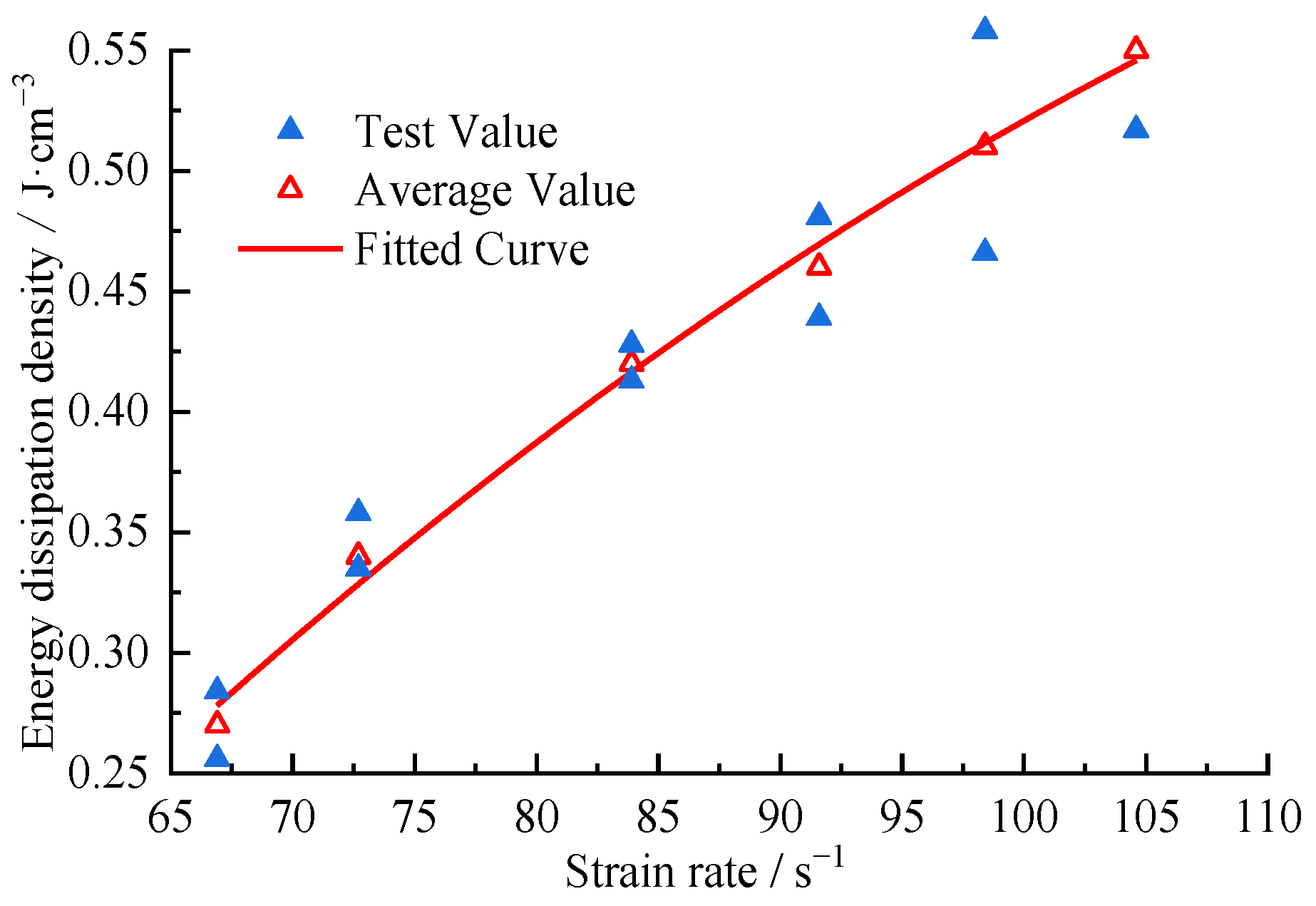

4.2. Analysis of the Energy Dissipation

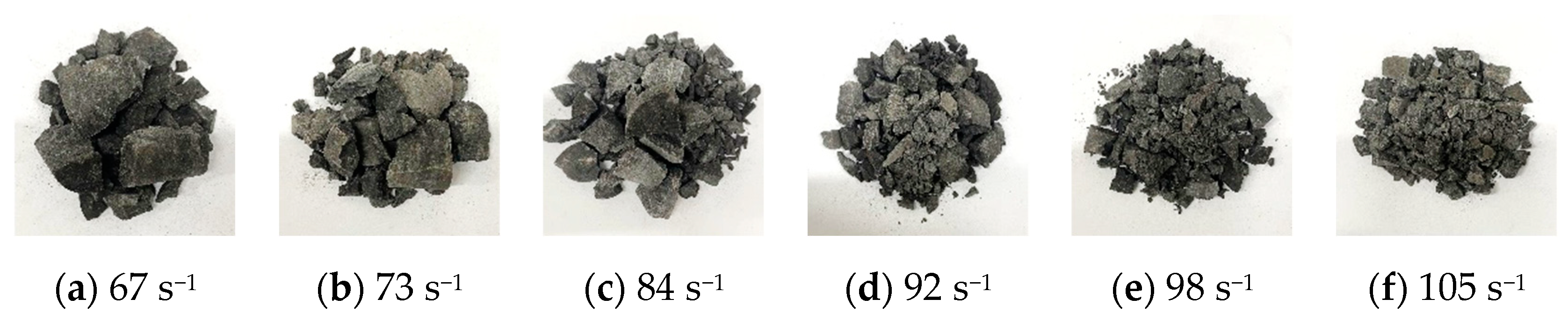

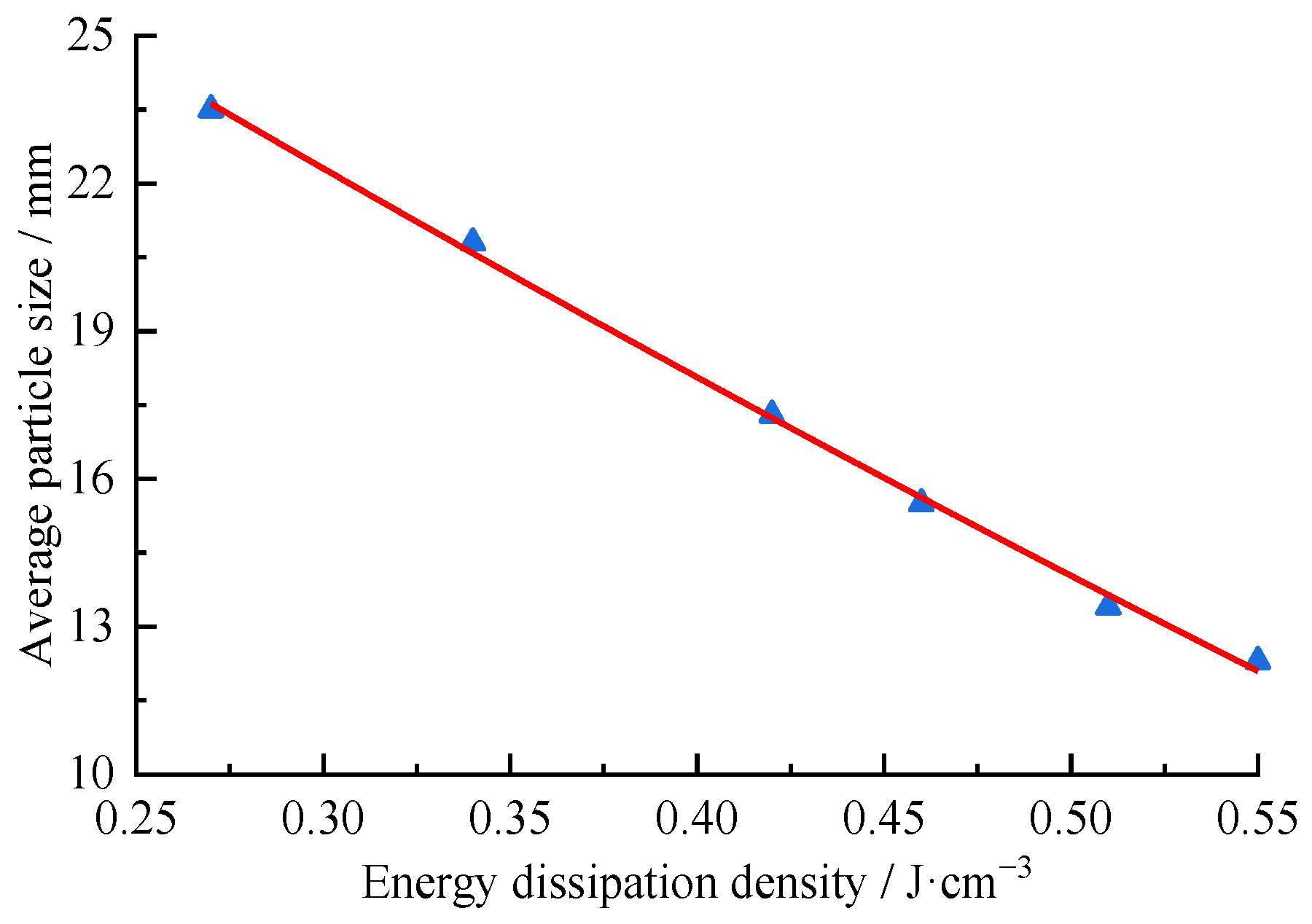

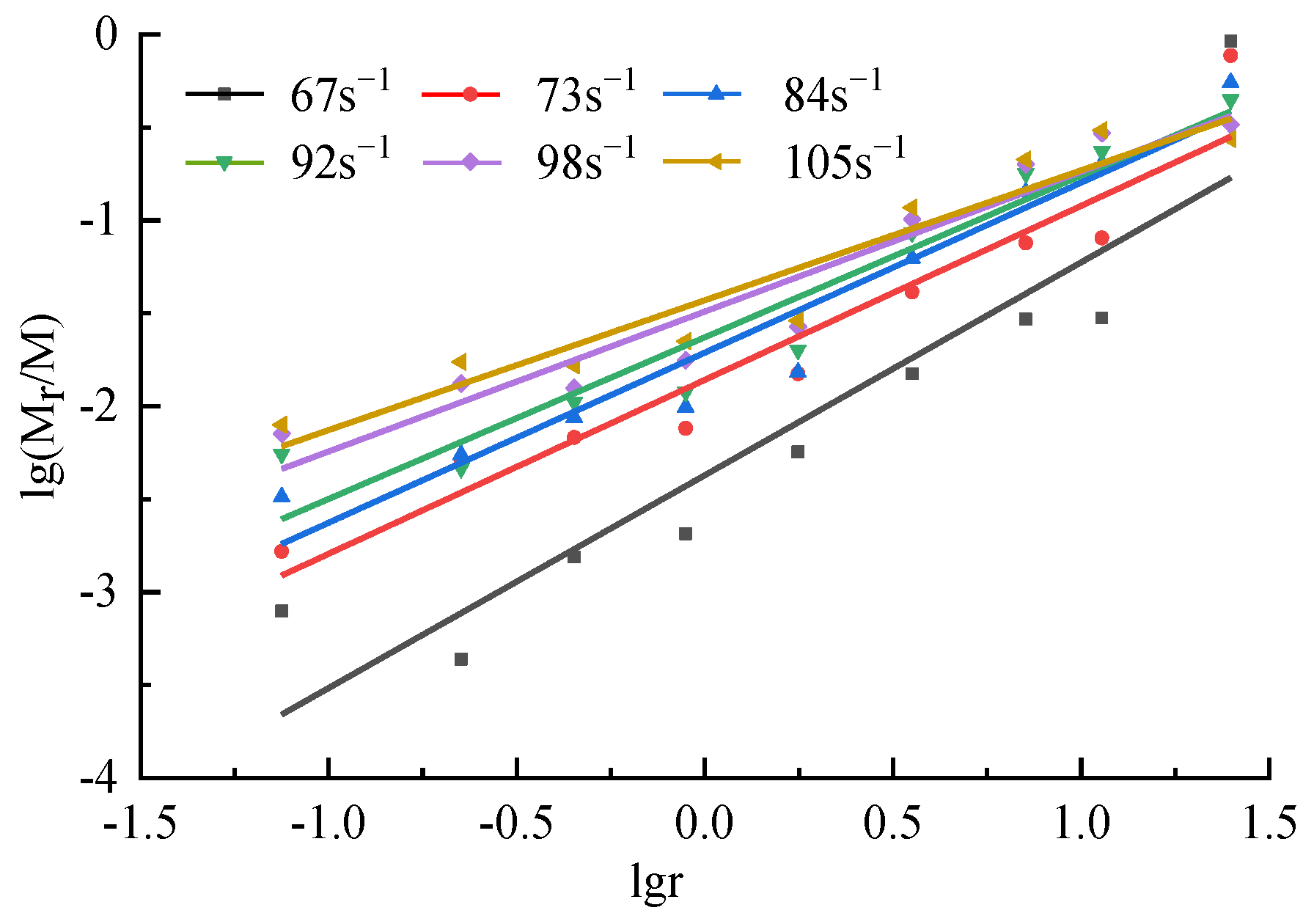

4.3. Fragment Size Distributions and Crushing Energy Dissipation of Specimens

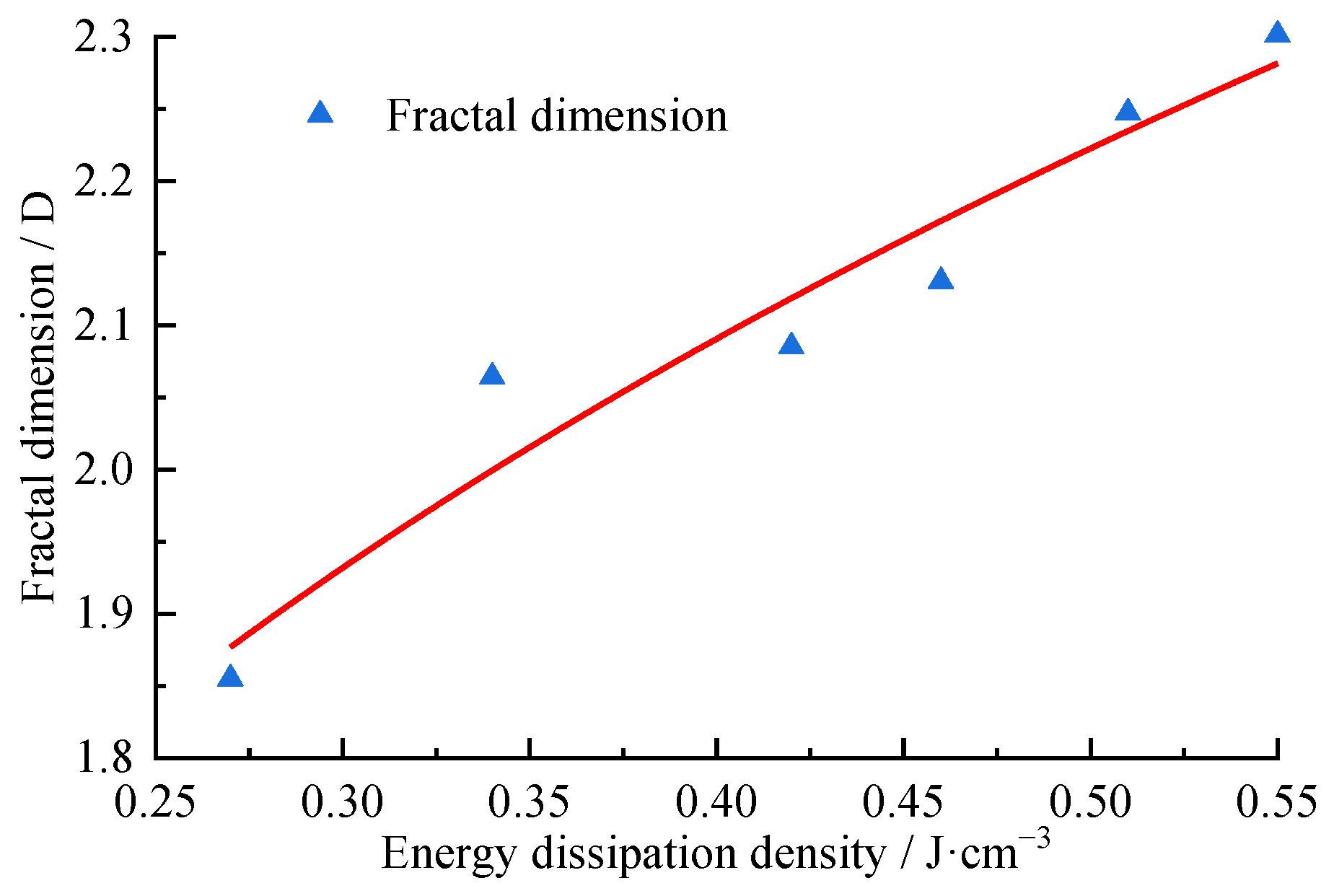

4.4. Fractal Dimension and Energy Dissipation Density of Fragments

5. Conclusions

- (1)

- The dynamic stress–strain curve clusters of water-saturated fissured sandstone and natural fissured sandstone specimens are basically similar, which can be approximately divided into four stages, including the elastic stage, the crack extension stage, the plastic yielding stage, and the damage stage.

- (2)

- The dynamic compressive strength of the water-saturated fractured sandstone specimens is higher than that of the natural sandstone specimens. This is mainly due to the surface tension generated by the free water at the fissure tip of the water-saturated specimen, which hinders the instantaneous expansion of cracks and generates the Stefan effect. The dynamic strain of the water-saturated fissured sandstone specimen is slightly lower than that of the natural sandstone specimen. Both of them have a strain rate effect.

- (3)

- In the case of increasing impact air pressure, the specimen undergoes tensile and shear composite damage, the number of cracks is dense, and the size of the broken block is obviously reduced.

- (4)

- The energy-consuming density of crushing a water-saturated fissured sandstone specimen tends to increase quadratically with strain rate, and more energy needs to be absorbed in the process for the germination, extension, and penetration of cracks within the specimen.

- (5)

- The average particle size of specimen crushing gradually decreases with the increase in crushing energy dissipation density; the higher the energy absorption of the rock specimen, the higher the energy dissipation in the deformation and destruction process of the specimen, which leads to the formation of more cracks, and the rock specimen will be crushed into small fragments or even powder form. As the crushing energy dissipation density increases, the fractal dimension of sandstone fragments also increases, which satisfies the multiplicative power function relationship. The fractal dimension is suitable as a quantitative index to characterize sandstone crushing.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Li, X.; Gong, F.; Tao, M.; Dong, L.; Du, K.; Ma, C.; Zhou, Z.; Yin, T. Failure mechanism and coupled static-dynamic loading theory in deep hard rock mining: A review. J. Rock Mech. Geotech. Eng. 2017, 9, 767–782. [Google Scholar] [CrossRef]

- Hokka, M.; Black, J.; Tkalich, D.; Fourmeau, M.; Kane, A.; Hoang, N.H.; Li, C.C.; Chen, W.W.; Kuokkala, V.T. Effects of strain rate and confining pressure on the compressive behavior of Kuru granite. Int. J. Impact Eng. 2016, 91, 183–193. [Google Scholar] [CrossRef]

- Feng, X.; Xiao, Y.; Feng, G.; Yao, Z.; Chen, B.; Yang, C.; Su, G. Study on the development process of rockbursts. Chin. J. Rock Mech. Eng. 2019, 38, 649–673. [Google Scholar] [CrossRef]

- Qian, Q. Challenges faced by underground projects construction safety and countermeasures. Chin. J. Rock Mech. Eng. 2012, 31, 1945–1956. [Google Scholar]

- Han, Z.; Li, D.; Li, X. Effects of axial pre-force and loading rate on Mode I fracture behavior of granite. Int. J. Rock Mech. Min. Sci. 2022, 157, 105172. [Google Scholar] [CrossRef]

- Ping, Q.; Wang, S.; Wu, Y.; Sun, S.; Shen, K.; Wang, C.; Gao, Q.; Fang, C.; Zhang, Y. Study on mechanical properties and energy consumption of fissured sandstone with different dip angles under impact load. Shock Vib. 2022, 2022, 5335357. [Google Scholar] [CrossRef]

- Yang, S.; Huang, Y.; Tian, W.; Yin, P.; Jing, H. Effect of high temperature on deformation failure behavior of granite specimen containing a single fissure under uniaxial compression. Rock Mech. Rock Eng. 2019, 52, 2087–2107. [Google Scholar] [CrossRef]

- Du, W.; Zhang, D.; Yu, B. Mechanical and fractal characteristics of sandstone with pre-existing fissures of different lengths under varying impact loads in SHPB tests. Theor. Appl. Fract. Mech. 2023, 125, 103884. [Google Scholar] [CrossRef]

- Feng, P.; Xu, Y.; Dai, F. Effects of dynamic strain rate on the energy dissipation and fragment characteristics of cross-fissured rocks. Int. J. Rock Mech. Min. Sci. 2021, 138, 104600. [Google Scholar] [CrossRef]

- Li, D.; Han, Z.; Sun, X.; Zhou, T.; Li, X. Dynamic mechanical properties and fracturing behavior of marble specimens containing single and double flaws in SHPB tests. Rock Mech. Rock Eng. 2018, 52, 1623–1643. [Google Scholar] [CrossRef]

- Wang, T.; Elsworth, D.; He, Y.; Zhao, X.; Wang, S.; Xu, D.; Lei, M. Impact of loading rate on the mechanical behavior of jointed rock. Geomech. Geophys. Geo-Energy Geo-Resour. 2023, 9, 127. [Google Scholar] [CrossRef]

- Feng, P.; Dai, F.; Liu, Y.; Xu, N.; Zhao, T. Effects of strain rate on the mechanical and fracturing behaviors of rock-like specimens containing two unparallel fissures under uniaxial compression. Soil Dyn. Earthq. Eng. 2018, 110, 195–211. [Google Scholar] [CrossRef]

- Li, X.; Zhou, T.; Li, D. Dynamic strength and fracturing behavior of single-flawed prismatic marble specimens under impact loading with a split hopkinson pressure bar. Rock Mech. Rock Eng. 2016, 50, 29–44. [Google Scholar] [CrossRef]

- Kim, E.; Changani, H. Effect of water saturation and loading rate on the mechanical properties of red and buff sandstones. Int. J. Rock Mech. Min. Sci. 2016, 88, 23–28. [Google Scholar] [CrossRef]

- Zhou, Z.; Cai, X.; Zhao, Y.; Chen, L.; Xiong, C.; Li, X. Strength characteristics of dry and saturated rock at different strain rates. Trans. Nonferr. Met. Soc. China 2016, 26, 1919–1925. [Google Scholar] [CrossRef]

- Zhu, J.; Deng, J.; Ma, Y.; Pak, R.Y.S.; Zhang, Z. Experimental study on the competing effects of strain rate and water weakening on compressive strength of saturated rocks. Eng. Geol. 2022, 310, 106873. [Google Scholar] [CrossRef]

- Feng, F.; Chen, S.; Han, Z.; Golsanami, N.; Liang, P.; Xie, Z. Influence of moisture content and intermediate principal stress on cracking behavior of sandstone subjected to true triaxial unloading conditions. Eng. Fract. Mech. 2023, 284, 109265. [Google Scholar] [CrossRef]

- Liu, X.; Li, Y.; Wang, W. Study on mechanical properties and energy characteristics of carbonaceous shale with different fissure angles under dry–wet cycles. Bull. Eng. Geol. Environ. 2022, 81, 319. [Google Scholar] [CrossRef]

- Padmanabha, V.; Schäfer, F.; Rae, A.S.P.; Kenkmann, T. Dynamic split tensile strength of basalt, granite, marble and sandstone: Strain rate dependency and fragmentation. Rock Mech. Rock Eng. 2022, 56, 109–128. [Google Scholar] [CrossRef]

- Zhao, Y.; Li, Q.; Zhang, K.; Yang, Y.; Gu, X. Effect of fissure angle on energy evolution and failure characteristics of fractured rock under uniaxial cyclic loading. Sci. Rep. 2023, 13, 2678. [Google Scholar] [CrossRef]

- You, W.; Dai, F.; Liu, Y.; Yan, Z. Effect of confining pressure and strain rate on mechanical behaviors and failure characteristics of sandstone containing a pre-existing flaw. Rock Mech. Rock Eng. 2022, 55, 2091–2109. [Google Scholar] [CrossRef]

- Malachi Ozoji, T.; Zhang, Z.; Emman Aladejare, A.; Zhang, N.; Paasovaara, N.; Rodriguez Arrieta, M. Effect of strain rate on specific fracture energy and micro-fracture surface properties of rock specimen under dynamic uniaxial compression. Eng. Fract. Mech. 2024, 295, 109763. [Google Scholar] [CrossRef]

- Yin, Q.; Liu, R.; Jing, H.; Su, H.; Yu, L.; He, L. Experimental study of nonlinear flow behaviors through fractured rock samples after high-temperature exposure. Rock Mech. Rock Eng. 2019, 52, 2963–2983. [Google Scholar] [CrossRef]

- Yan, Z.; Dai, F.; Liu, Y.; Du, H. Experimental investigations of the dynamic mechanical properties and fracturing behavior of cracked rocks under dynamic loading. Bull. Eng. Geol. Environ. 2020, 79, 5535–5552. [Google Scholar] [CrossRef]

- Yin, T.; Lu, J.; Guo, W.; Wu, Y.; Ma, J. Dynamic mechanical response and damage constitutive model of end-jointed rock bridge with different water content states under impact load. Theor. Appl. Fract. Mech. 2024, 130, 104255. [Google Scholar] [CrossRef]

- International Society of Rock Mechanics (ISRM). Chin. J. Rock Mech. Eng. 1982, 1, 141–142.

- T/CSRME 001-2019; Technical Specification for Testing Method of Rock Dynamic Properties. Chinese Society for Rock Mechanics & Engineering: Beijing, China, 2019.

- SL 264-2001; Specifications for Rock Tests in Water Conservancy and Hydroelectric Engineering. Yangtze River Science Institute of Water Resources Commission: Wuhan, China, 2001; 113p.

- Wang, L. Foundation of Stress Waves, 2nd ed.; National Defense Industry Press: Beijing, China, 2005. [Google Scholar]

- Ping, Q.; Wu, M.; Ma, Q.; Yuan, P.; Zhang, H. Comparison and analysis of reasonable loading waveforms in SHPB tests. J. Undergr. Space Eng. 2017, 13, 1499–1505. [Google Scholar]

- Rossi, P.; Mier, J.; Boulay, C.; Maou, F.L. The dynamic behaviour of concrete: Influence of free water. Mater. Struct. 1992, 25, 509–514. [Google Scholar] [CrossRef]

- Zou, C.; Wong, L.N.Y.; Loo, J.J.; Gan, B.S. Different mechanical and cracking behaviors of single-flawed brittle gypsum specimens under dynamic and quasi-static loadings. Eng. Geol. 2016, 201, 71–84. [Google Scholar] [CrossRef]

- Ping, Q.; Luo, X.; Ma, Q.; Yuan, P. Broken energy dissipation characteristics of sandstone specimens under impact loads. Chin. J. Rock Mech. Eng. 2015, 34, 4197–4203. [Google Scholar] [CrossRef]

- Cheng, T.; Wang, L.; Xiao, Y.; He, M.; Wang, T.; Peng, M.; Li, H. Correlational fractal characteristics and damage progression of granite with different grain sizes based on acoustic emission monitoring. Eng. Geol. 2023, 327, 107358. [Google Scholar] [CrossRef]

- He, W.; Hayatdavoudi, A.; Shi, H.; Sawant, K.; Huang, P. A preliminary fractal interpretation of effects of grain size and grain shape on rock strength. Rock Mech. Rock Eng. 2018, 52, 1745–1765. [Google Scholar] [CrossRef]

- Deng, Y.; Chen, M.; Jin, Y.; Zou, D. Theoretical analysis and experimental research on the energy dissipation of rock crushing based on fractal theory. J. Nat. Gas Sci. Eng. 2016, 33, 231–239. [Google Scholar] [CrossRef]

| Specimen Number | Dynamic Compressive Strength /MPa | Dynamic Modulus of Elasticity /GPa | Dynamic Strain /×10−3 | Strain Rate /s−1 |

|---|---|---|---|---|

| PJ42-01 PJ42-02 | 48.04 51.32 | 32.78 33.08 | 2.01 2.14 | 67 |

| PJ42-04 PJ42-05 | 53.50 54.25 | 35.02 37.12 | 2.15 2.10 | 73 |

| PJ42-07 PJ42-08 | 55.81 63.15 | 38.64 39.34 | 2.22 2.16 | 84 |

| PJ42-10 PJ42-11 | 65.26 66.36 | 41.90 43.30 | 2.24 2.30 | 92 |

| PJ42-13 PJ42-14 | 69.80 71.90 | 43.35 45.87 | 2.37 2.28 | 98 |

| PJ42-16 PJ42-17 | 79.30 81.46 | 45.35 48.60 | 2.46 2.43 | 105 |

| Specimen Number | Dynamic Compressive Strength /MPa | Dynamic Modulus of Elasticity /GPa | Dynamic Strain /×10−3 | Strain Rate /s−1 |

|---|---|---|---|---|

| PJ42-03 | 49.06 | 31.83 | 2.09 | 67 |

| PJ42-06 | 52.49 | 34.88 | 2.16 | 73 |

| PJ42-09 | 54.96 | 36.61 | 2.24 | 84 |

| PJ42-12 | 60.61 | 39.26 | 2.31 | 92 |

| PJ42-15 | 65.48 | 40.56 | 2.39 | 98 |

| PJ42-18 | 70.27 | 44.10 | 2.48 | 105 |

| Impact Air Pressure /MPa | Specimen Number | Incident Energy EI/J | Reflected Energy ER/J | Transmitted Energy ET/J | Absorbed Energy ED/J | Effective Volume of Specimen VS/cm3 |

|---|---|---|---|---|---|---|

| 0.300 | PJ42-01 | 76.74 | 42.77 | 9.28 | 24.68 | 96.23 |

| PJ42-02 | 71.99 | 34.98 | 9.66 | 27.36 | 96.18 | |

| 0.325 | PJ42-04 | 90.95 | 47.56 | 10.02 | 32.37 | 96.40 |

| PJ42-05 | 87.74 | 42.74 | 10.47 | 34.54 | 96.38 | |

| 0.350 | PJ42-07 | 100.75 | 47.85 | 11.61 | 41.29 | 96.27 |

| PJ42-08 | 106.34 | 55.71 | 10.85 | 39.78 | 96.22 | |

| 0.375 | PJ42-10 | 120.05 | 65.97 | 11.74 | 42.34 | 96.34 |

| PJ42-11 | 118.11 | 60.71 | 11.11 | 46.29 | 96.19 | |

| 0.400 | PJ42-13 | 133.97 | 76.33 | 12.74 | 44.91 | 96.33 |

| PJ42-14 | 134.43 | 68.33 | 12.29 | 53.80 | 96.31 | |

| 0.425 | PJ42-16 | 139.34 | 76.93 | 12.65 | 49.76 | 96.21 |

| PJ42-17 | 139.91 | 69.40 | 14.30 | 56.21 | 96.30 |

| Impact Air Pressure/MPa | Size of Screen Mesh/mm | Gross Mass /g | Average Particle Size of Fragments/mm | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 0 | 0.15 | 0.30 | 0.60 | 1.18 | 2.36 | 4.75 | 9.50 | 13.20 | |||

| 0.300 | 0.20 | 0.11 | 0.39 | 0.52 | 1.43 | 3.77 | 7.42 | 7.52 | 230.80 | 252.16 | 23.49 |

| 0.325 | 0.42 | 1.27 | 1.72 | 1.93 | 3.80 | 10.46 | 19.14 | 20.41 | 194.62 | 253.77 | 20.80 |

| 0.350 | 0.83 | 1.40 | 2.22 | 2.53 | 3.89 | 16.00 | 36.30 | 51.59 | 140.75 | 255.51 | 17.33 |

| 0.375 | 1.42 | 1.19 | 2.70 | 3.06 | 5.15 | 22.01 | 45.88 | 60.45 | 114.62 | 256.48 | 15.47 |

| 0.400 | 1.83 | 3.40 | 3.22 | 4.53 | 6.89 | 26.10 | 51.30 | 75.59 | 83.83 | 256.69 | 13.36 |

| 0.425 | 2.03 | 4.42 | 4.23 | 5.72 | 7.39 | 30.00 | 54.27 | 77.90 | 69.73 | 255.69 | 12.28 |

| Specimen Number | Slope | Correlation Coefficient | Fractal Dimension |

|---|---|---|---|

| PJ42-01 | 1.1448 | 0.8627 | 1.8552 |

| PJ42-04 | 0.9357 | 0.9286 | 2.0643 |

| PJ42-08 | 0.9147 | 0.9437 | 2.0853 |

| PJ42-10 | 0.8694 | 0.9281 | 2.1306 |

| PJ42-13 | 0.7526 | 0.9266 | 2.2474 |

| PJ42-17 | 0.6986 | 0.9199 | 2.3014 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ping, Q.; Sun, S.; Li, X.; Wu, S.; Xu, Y.; Hu, J.; Hu, W. Analysis of the Dynamic Mechanical Properties and Energy Dissipation of Water-Saturated Fissured Sandstone Specimens. Appl. Sci. 2024, 14, 1368. https://doi.org/10.3390/app14041368

Ping Q, Sun S, Li X, Wu S, Xu Y, Hu J, Hu W. Analysis of the Dynamic Mechanical Properties and Energy Dissipation of Water-Saturated Fissured Sandstone Specimens. Applied Sciences. 2024; 14(4):1368. https://doi.org/10.3390/app14041368

Chicago/Turabian StylePing, Qi, Shijia Sun, Xiangyang Li, Shiwei Wu, Yijie Xu, Jing Hu, and Wei Hu. 2024. "Analysis of the Dynamic Mechanical Properties and Energy Dissipation of Water-Saturated Fissured Sandstone Specimens" Applied Sciences 14, no. 4: 1368. https://doi.org/10.3390/app14041368

APA StylePing, Q., Sun, S., Li, X., Wu, S., Xu, Y., Hu, J., & Hu, W. (2024). Analysis of the Dynamic Mechanical Properties and Energy Dissipation of Water-Saturated Fissured Sandstone Specimens. Applied Sciences, 14(4), 1368. https://doi.org/10.3390/app14041368