An Overview of Recent Developments and Understandings of Unconventionals in the Vaca Muerta Formation, Argentina

Abstract

1. Introduction

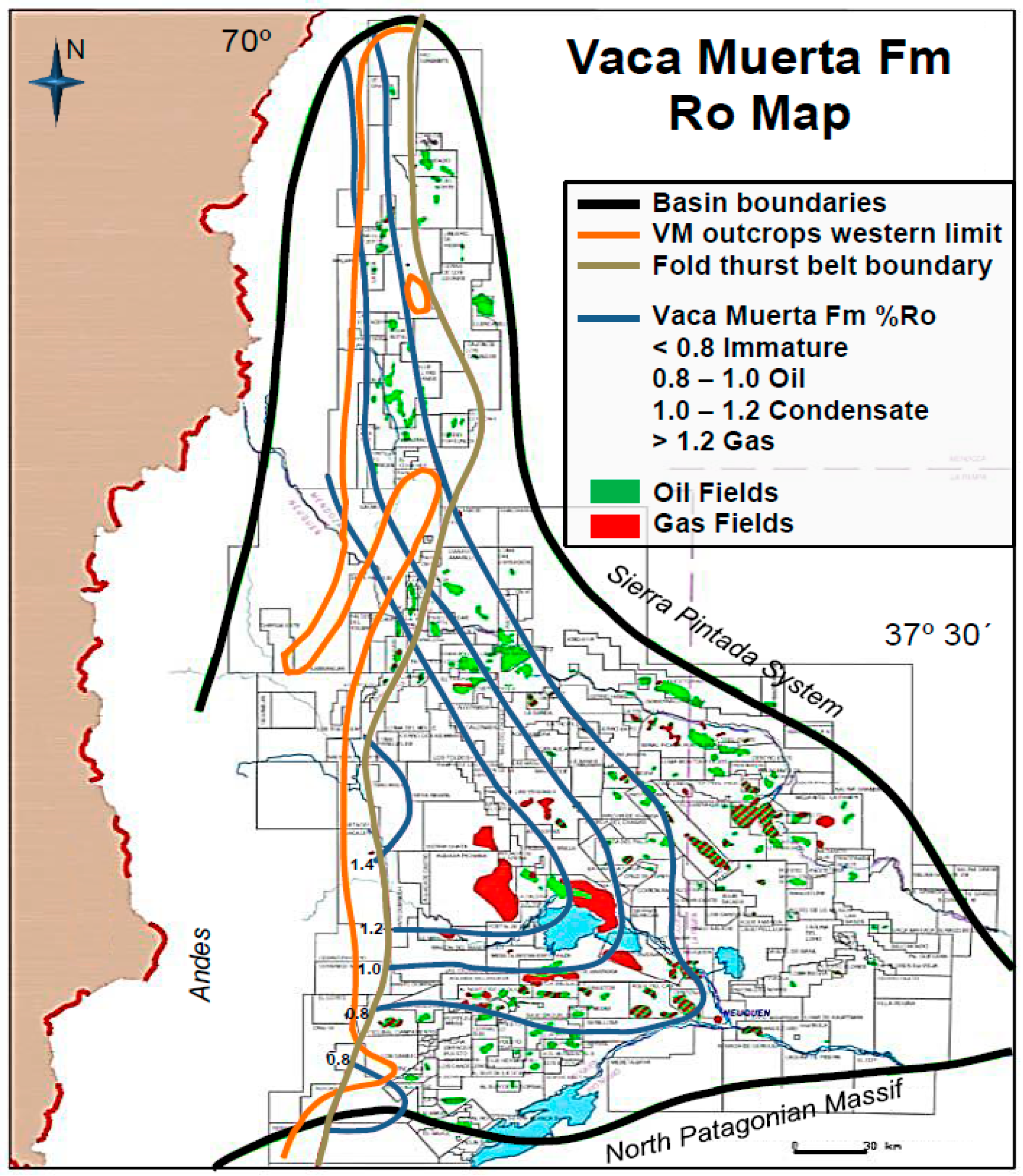

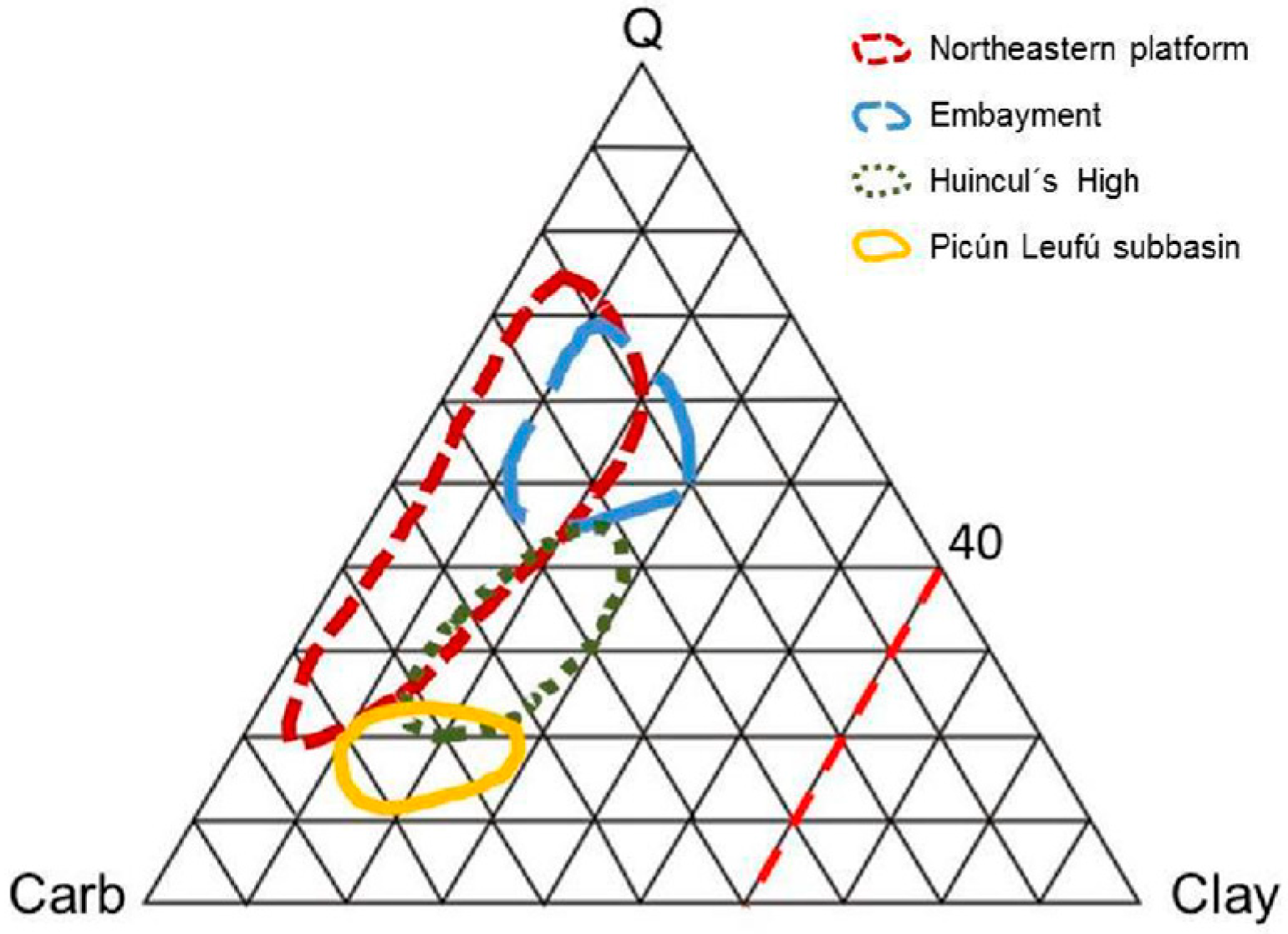

2. Geological Context and Current Production Base Status

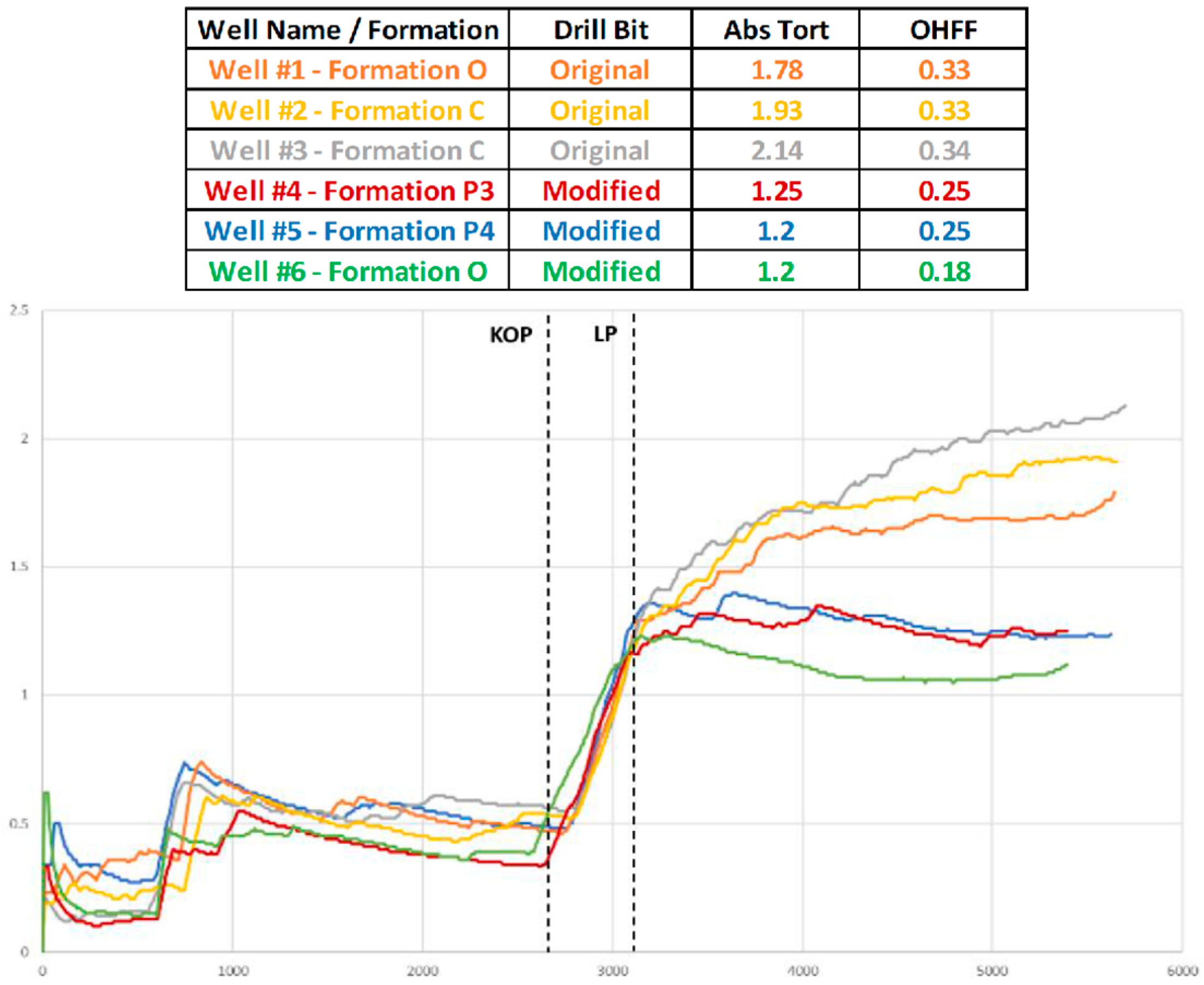

3. Drilling

3.1. Gas Kick

3.2. Extended Drilling

3.3. Azimuthal Hold Technology

4. Hydraulic Fracturing

4.1. Child and Parent Well Effect

4.2. Diagnostic Fracture Injection Test (DFIT) New Approach

4.3. Stimulated Reservoir Volume (SRV) Characterization

4.4. Fracturing Fluids

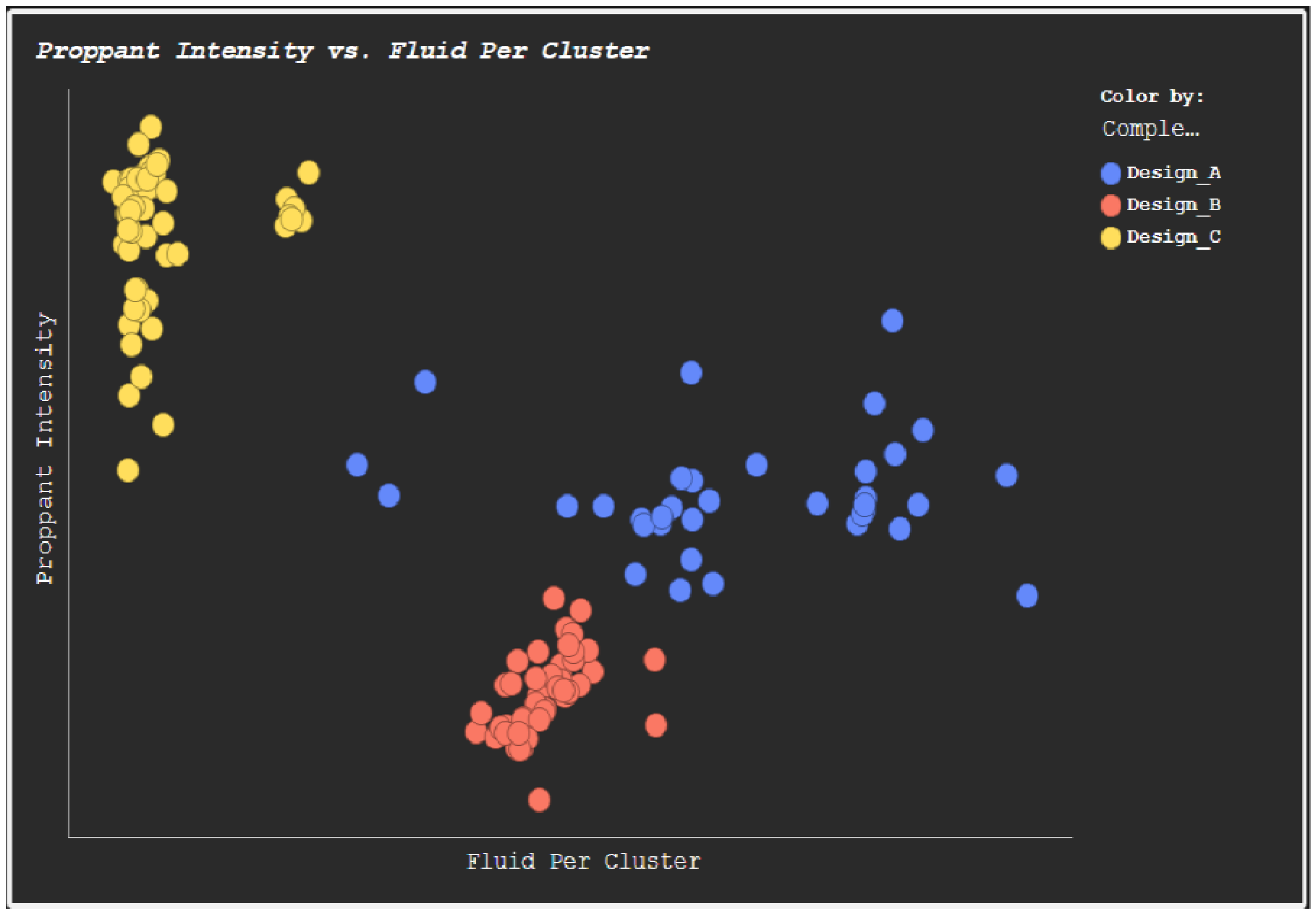

4.5. Well Completion

5. Geomechanics

5.1. Geostress Status

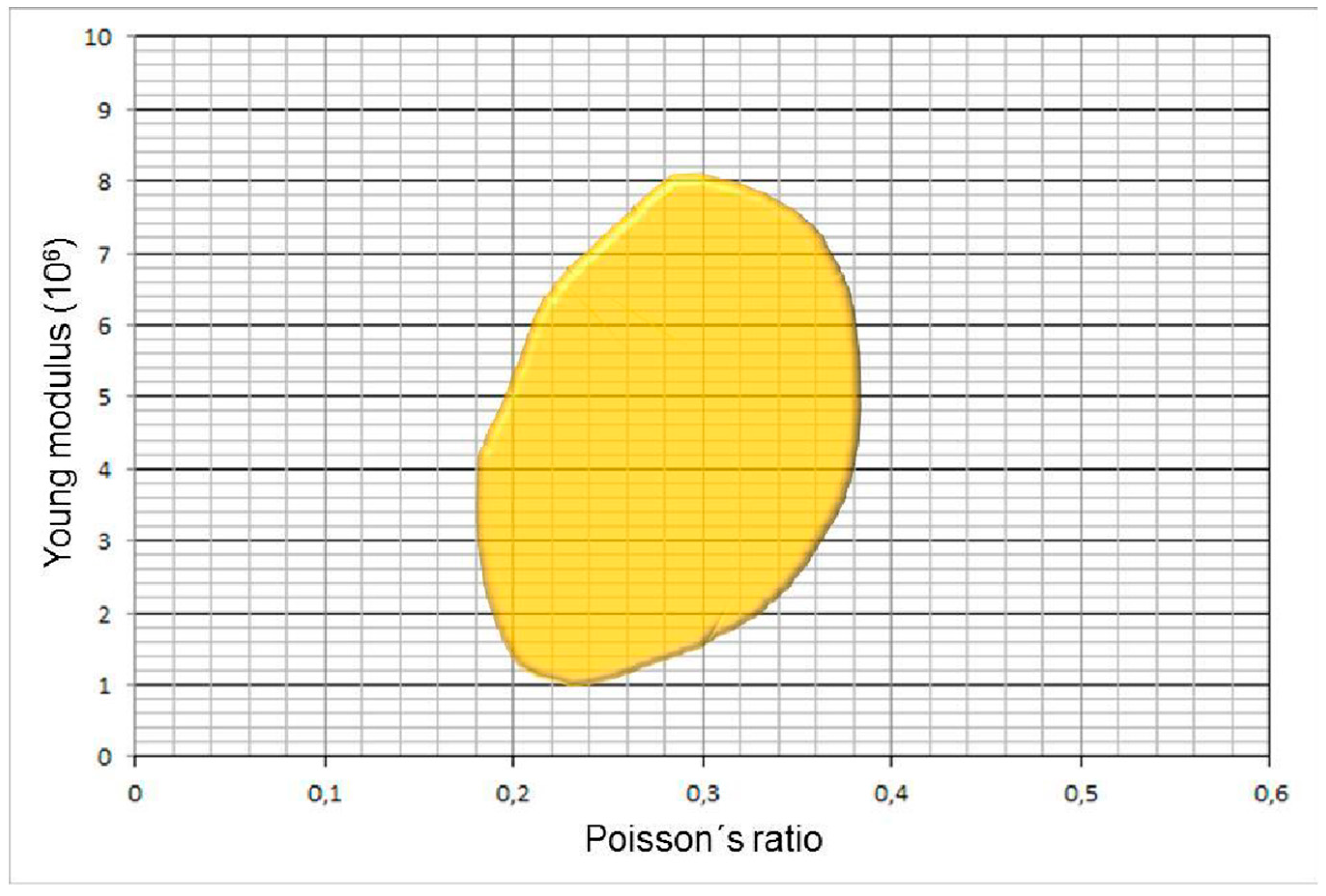

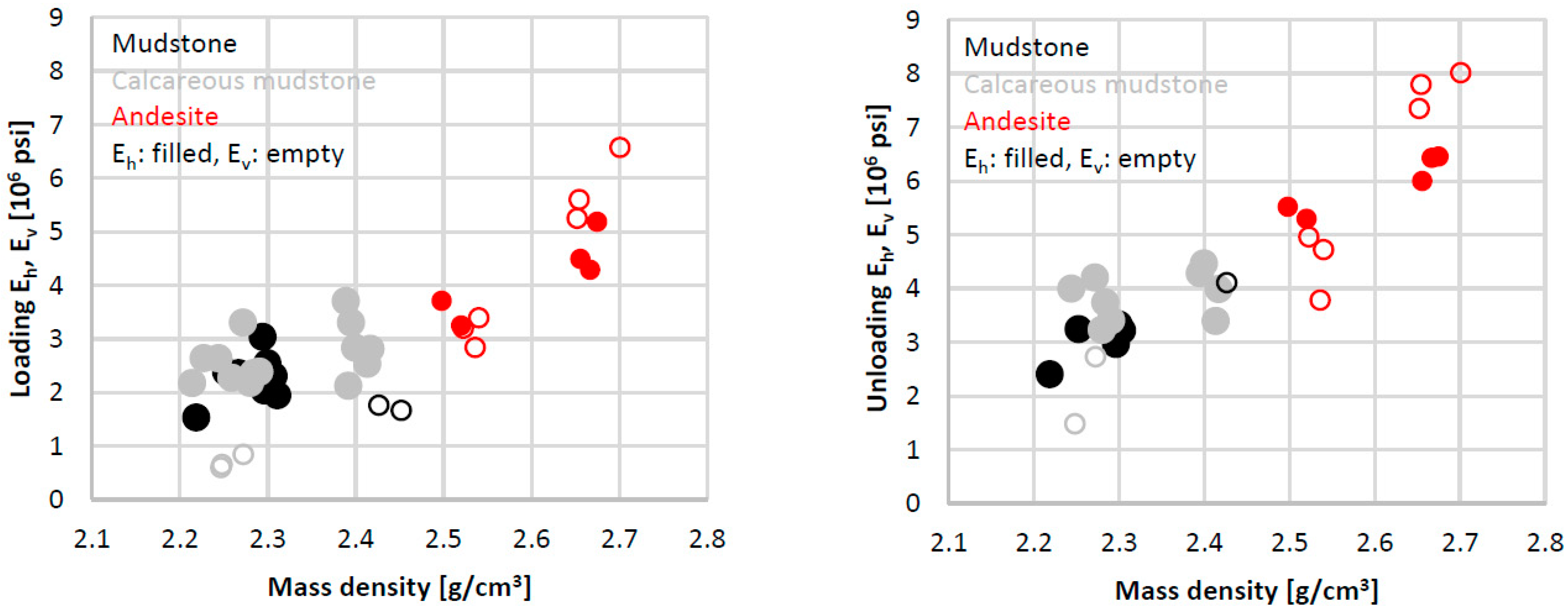

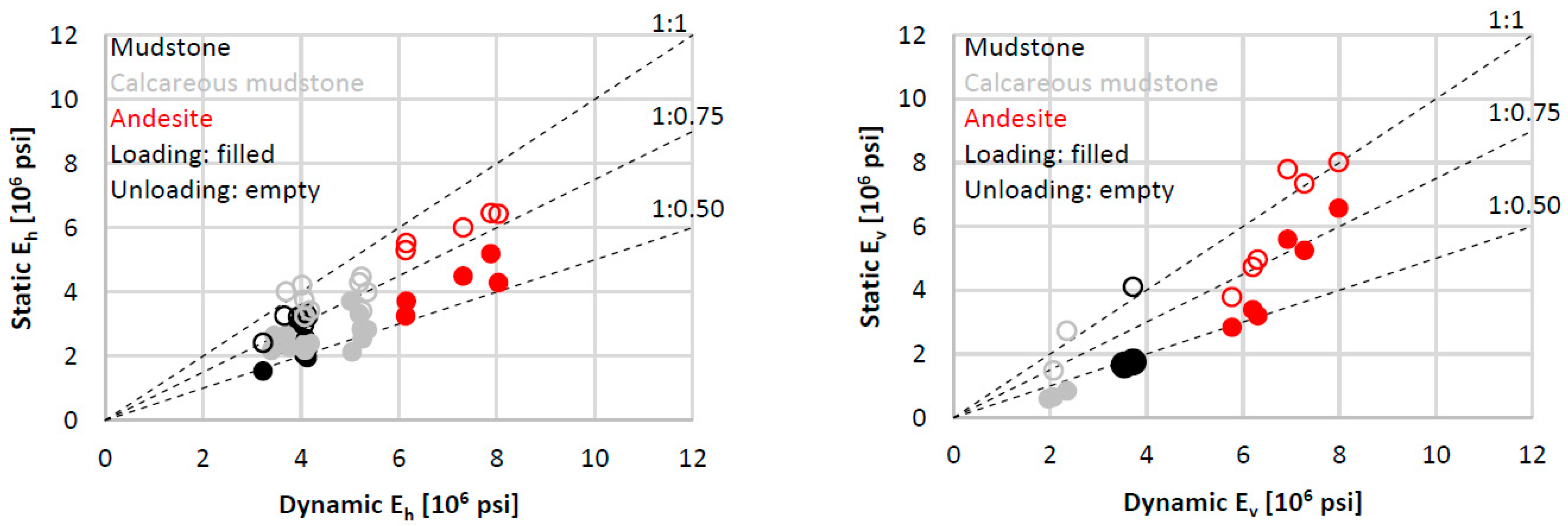

5.2. Static and Dynamic Geomechanics

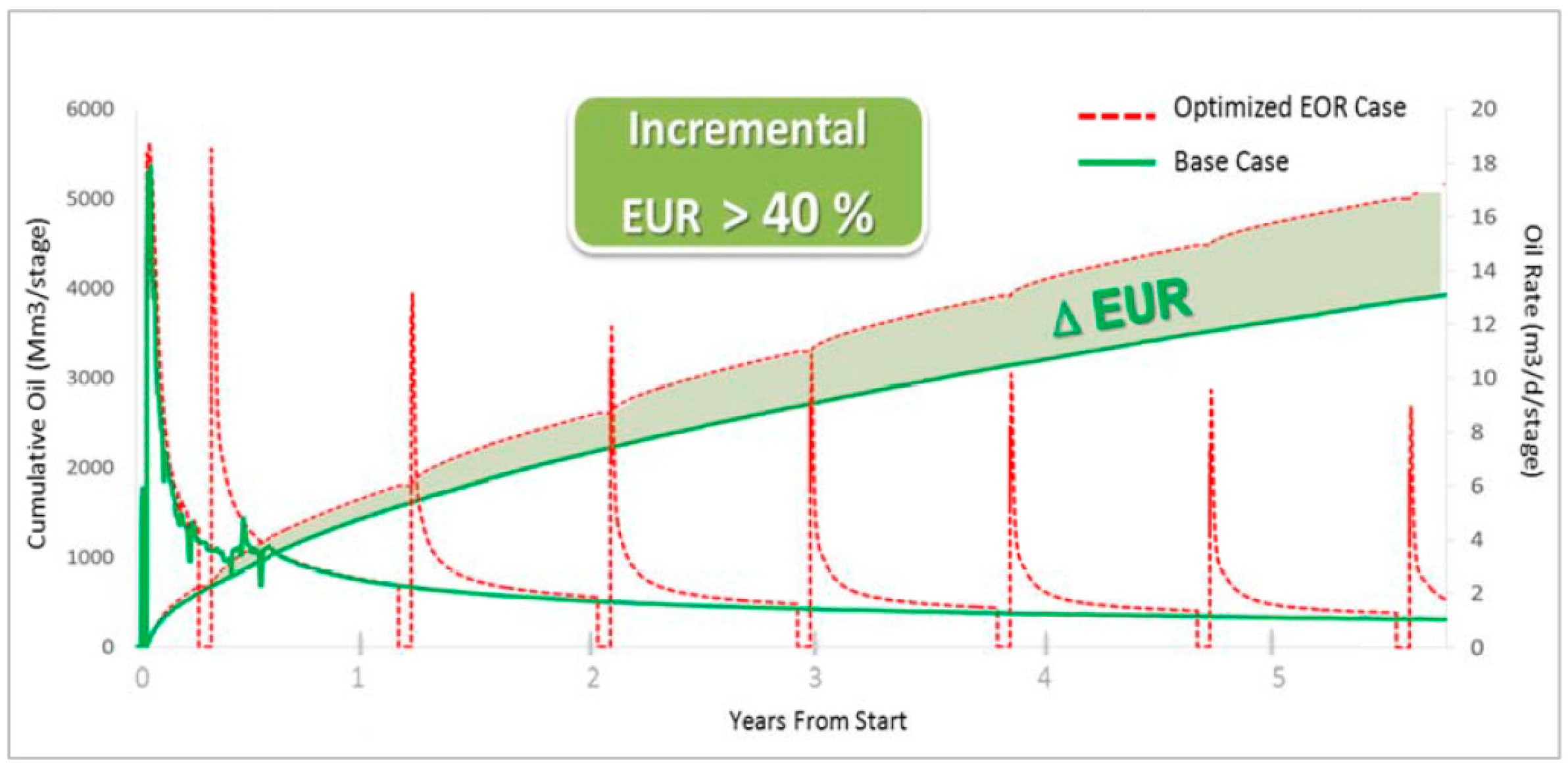

6. Enhanced Oil Recovery

6.1. Solvent Injection

6.2. Countercurrent Imbibition

7. Production

7.1. Gas Lift

7.2. Production Rate Calculation

8. Integrated Development in Vaca Muerta

9. Optimization

9.1. Geological Characterization and Sweet Spots

9.2. Reservoir Management and Production Optimization

9.3. Real-Time Optimization

9.4. Well Spacing Stimulation Design Optimization

9.5. Economics Consideration during Optimization

10. Potential Issues

11. Conclusions

- In terms of geological characterization, the Vaca Muerta formation’s geological analysis reveals significant hydrocarbon potential, with TOC values ranging from 3% to 8%, indicating rich organic content. The formation varies in thickness (60–520 m) and exhibits diverse porosity (4–14%), emphasizing its complexity.

- Technological advances in drilling has shown the shift to horizontal drilling, with laterals extending 2500–2800 m, and even up to 4000 m in some projects, marking a significant advancement. This approach, despite challenges in wellbore stability and tortuosity, has led to improved production efficiency.

- Hydraulic fracturing innovations include the application of tailored fracturing fluid compositions and injection protocols, based on reservoir conditions, has optimized fracturing processes. The use of polyacrylamide-based viscosifying friction reducers in some regions has reduced operational costs by 34%.

- Regarding economic considerations and investment, the formation continues to attract significant investment, despite high operational costs due to logistical constraints. The decrease in extraction costs and the introduction of efficient technologies have enhanced its global competitiveness.

- Future prospects and challenges are revealed. Projected advancements in technology and favorable policy shifts could significantly increase the formation’s contribution to global hydrocarbon production. Continued research and development are essential to overcoming the operational and environmental challenges.

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Minisini, D.; Sanchez Ferrer, F. Chapter 7: Geology and Economy to DE-Risk the Unconventional Vaca Muerta Play, Argentina. In Memoir 125: Giant Fields of the Decade: 2010–2020; American Association of Petroleum Geologists (AAPG): Tulsa, OK, USA, 2021; pp. 189–212. [Google Scholar]

- Fernández González, R.; Arce Fariña, M.E.; Garza Gil, M.D. Resolving Conflict between Parties and Consequences for Foreign Direct Investment: The Repsol-YPF Case in Argentina. Sustain. Sci. Pract. Policy 2019, 11, 6012. [Google Scholar] [CrossRef]

- Primera, A.; Klie, H.; Klie, A.; Quesada, M. Leveraging US Unconventional Data Analytics Learnings in Vaca Muerta Shale Formation. In Proceedings of the SPE Europec Featured at 81st EAGE Conference and Exhibition, England, UK, 3–6 June 2019. [Google Scholar]

- Fleischer, R.L.; Naeser, C.W.; Price, P.B.; Walker, R.M.; Marvin, U.B. Fossil Particle Tracks and Uranium Distributions in Minerals of the Vaca Muerta Meteorite. Science 1965, 148, 629–632. [Google Scholar] [CrossRef]

- Stinco, L.; Barredo, S. Unconventional Shale and Tight Reservoirs of Argentina. Opportunities and Challenges. In Proceedings of the 22nd World Petroleum Congress, Istanbul, Turkey, 9–13 July 2017. D023S002R004. [Google Scholar]

- Codorniú, L.; Garrido, A. New Fossil Record of a Jurassic Pterosaur from Neuquen Basin, Vaca Muerta Formation, Argentina. J. S. Am. Earth Sci. 2013, 48, 315–321. [Google Scholar] [CrossRef]

- Gao, S.; Dong, D.; Tao, K.; Guo, W.; Li, X.; Zhang, S. Experiences and Lessons Learned from China’s Shale Gas Development: 2005–2019. J. Nat. Gas Sci. Eng. 2021, 85, 103648. [Google Scholar] [CrossRef]

- deLlano-Paz, F.; Calvo-Silvosa, A.; Iglesias Antelo, S.; Soares, I. The European Low-Carbon Mix for 2030: The Role of Renewable Energy Sources in an Environmentally and Socially Efficient Approach. Renew. Sustain. Energy Rev. 2015, 48, 49–61. [Google Scholar] [CrossRef]

- Litvinenko, V. The Role of Hydrocarbons in the Global Energy Agenda: The Focus on Liquefied Natural Gas. Resources 2020, 9, 59. [Google Scholar] [CrossRef]

- Hansen, S.; Mirkouei, A.; Diaz, L.A. A Comprehensive State-of-Technology Review for Upgrading Bio-Oil to Renewable or Blended Hydrocarbon Fuels. Renew. Sustain. Energy Rev. 2020, 118, 109548. [Google Scholar] [CrossRef]

- Wei, S.; Hu, M.; He, S.; Shu, Y.; Dong, T.; He, Q.; Yang, W.; Cai, Q. Effects of Quartz Precipitation on the Abundance and Preservation of Organic Matter Pores in Cambrian Marine Shale in South China. J. Mar. Sci. Eng. 2023, 11, 1267. [Google Scholar] [CrossRef]

- Bruno, P.P.G. Seismic Exploration Methods for Structural Studies and for Active Fault Characterization: A Review. Appl. Sci. 2023, 13, 9473. [Google Scholar] [CrossRef]

- Bellucci, L.G.; Giuliani, S. The Role of Sediment Records in Environmental Forensic Studies: Two Examples from Italy of Research Approaches Developed to Address Responsibilities and Management Options. Appl. Sci. 2023, 13, 6999. [Google Scholar] [CrossRef]

- Lellouch, A.; Biondi, B.L. Seismic Applications of Downhole DAS. Sensors 2021, 21, 2897. [Google Scholar] [CrossRef]

- Hendry, J.; Burgess, P.; Hunt, D.; Janson, X.; Zampetti, V. Seismic Characterization of Carbonate Platforms and Reservoirs: An Introduction and Review; The Geological Society of London: London, UK, 2021. [Google Scholar]

- Fais, S.; Casula, G.; Cuccuru, F.; Ligas, P.; Bianchi, M.G.; Plaisant, A.; Pettinau, A. A Contribution to the Geological Characterization of a Potential Caprock-Reservoir System in the Sulcis Coal Basin (South-Western Sardinia). Energies 2019, 12, 4524. [Google Scholar] [CrossRef]

- Donaldson, E.C.; Tiab, D. Petrophysics: Theory and Practice of Measuring Reservoir Rock and Fluid Transport Properties; Elsevier: Amsterdam, The Netherlands, 2004; ISBN 978-0-08-049765-5. [Google Scholar]

- Salih, M.; Reijmer, J.J.G.; El Husseiny, A.; Bashri, M.; Eltom, H.; Mukainah, H.A.; Kaminski, M.A. Controlling Factors on Petrophysical and Acoustic Properties of Bioturbated Carbonates: (Upper Jurassic, Central Saudi Arabia). Appl. Sci. 2021, 11, 5019. [Google Scholar] [CrossRef]

- Tran, L.; Gupta, I.; Devegowda, D.; Karami, H.; Rai, C.; Jayaram, V.; Sondergeld, C. Machine Learning Workflow to Identify Brittle, Fracable and Producible Rock in Horizontal Wells Using Surface Drilling Data. In Proceedings of the SPE Annual Technical Conference and Exhibition, Virtual, 27–29 October 2020. D031S033R007. [Google Scholar]

- Ibrahim, A.F.; Hiba, M.; Elkatatny, S.; Ali, A. Estimation of Tensile and Uniaxial Compressive Strength of Carbonate Rocks from Well-Logging Data: Artificial Intelligence Approach. J. Pet. Explor. Prod. Technol. 2023. [Google Scholar] [CrossRef]

- Hesselbrandt, M.; Erlström, M.; Sopher, D.; Acuna, J. Multidisciplinary Approaches for Assessing a High Temperature Borehole Thermal Energy Storage Facility at Linköping, Sweden. Energies 2021, 14, 4379. [Google Scholar] [CrossRef]

- Stadtműller, M.; Jarzyna, J.A. Estimation of Petrophysical Parameters of Carbonates Based on Well Logs and Laboratory Measurements, a Review. Energies 2023, 16, 4215. [Google Scholar] [CrossRef]

- Dada, M.A.; Mellal, M.; Makhloufi, A.; Belhouchet, H. A Field Development Strategy for the Joint Optimization of Flow Allocations, Well Placements and Well Trajectories. Energy Explor. Exploit. 2021, 39, 502–527. [Google Scholar] [CrossRef]

- Wiśniowski, R.; Łopata, P.; Orłowicz, G. Numerical Methods for Optimization of the Horizontal Directional Drilling (HDD) Well Path Trajectory. Energies 2020, 13, 3806. [Google Scholar] [CrossRef]

- Birkholzer, J.T.; Morris, J.; Bargar, J.R.; Brondolo, F.; Cihan, A.; Crandall, D.; Deng, H.; Fan, W.; Fu, W.; Fu, P.; et al. A New Modeling Framework for Multi-Scale Simulation of Hydraulic Fracturing and Production from Unconventional Reservoirs. Energies 2021, 14, 641. [Google Scholar] [CrossRef]

- Katende, A. The Impact of Rock Lithology and Microstructural Properties on Proppant Embedment and Fracture Conductivity: A Case Study of the Caney Shale, Southern Oklahoma, USA. Bachelor’s Thesis, Oklahoma State University, Stillwater, OK, USA, 2022. [Google Scholar]

- Qu, G.; Su, J.; Zhao, M.; Bai, X.; Yao, C.; Peng, J. Optimizing Composition of Fracturing Fluids for Energy Storage Hydraulic Fracturing Operations in Tight Oil Reservoirs. Energies 2022, 15, 4292. [Google Scholar] [CrossRef]

- McKenna, J.P.; Quezada, O.; Toohey, N.M.; Grealy, M.H. A Data-Driven Proppant-Filled Fracture Model: Comparing Sliding Sleeve and Plug and Perf Completion Styles. In Proceedings of the SEG Technical Program Expanded Abstracts, New Orleans, LA, USA, 18–23 October 2015; Society of Exploration Geophysicists: Tulsa, OK, USA, 2015. SEG-2015-5933284. [Google Scholar]

- Gandomkar, A.; Katz, D.; Gomez, R.; Gundersen, A.; Khan, P. Casing Deformation Mitigation Achieved through Ball Activated Sliding Fracturing Sleeves—An Alternative to Plug and Perf Fracturing Operations. In Proceedings of the SPE International Hydraulic Fracturing Technology Conference & Exhibition, Muscat, Oman, 11–13 January 2022. [Google Scholar]

- Tabatabaei, M.; Kazemzadeh, F.; Sabah, M.; Wood, D.A. Chapter Ten—Sustainability in Natural Gas Reservoir Drilling: A Review on Environmentally and Economically Friendly Fluids and Optimal Waste Management. In Sustainable Natural Gas Reservoir and Production Engineering; Wood, D.A., Cai, J., Eds.; Gulf Professional Publishing: Houston, TX, USA, 2022; Volume 1, pp. 269–304. ISBN 978-0-12-824495-1. [Google Scholar]

- Danso, D.K.; Negash, B.M.; Ahmed, T.Y.; Yekeen, N.; Omar Ganat, T.A. Recent Advances in Multifunctional Proppant Technology and Increased Well Output with Micro and Nano Proppants. J. Pet. Sci. Eng. 2021, 196, 108026. [Google Scholar] [CrossRef]

- Shibaev, A.V.; Osiptsov, A.A.; Philippova, O.E. Novel Trends in the Development of Surfactant-Based Hydraulic Fracturing Fluids: A Review. Gels 2021, 7, 258. [Google Scholar] [CrossRef] [PubMed]

- Jia, B.; Tsau, J.-S.; Barati, R. A Review of the Current Progress of CO2 Injection EOR and Carbon Storage in Shale Oil Reservoirs. Fuel 2019, 236, 404–427. [Google Scholar] [CrossRef]

- Shumakov, Y.; Hollaender, F.; Theuveny, B. Successful Well Test Operations in Complex Reservoir Fluids: Lessons Learned and Best Practices over 40 Years of Worldwide Operations. In Proceedings of the Abu Dhabi International Petroleum Exhibition & Conference, Abu Dhabi, United Arab Emirates, 12–15 November 2018. [Google Scholar]

- Yao, J.; Han, H.; Yang, Y.; Song, Y.; Li, G. A Review of Recent Progress of Carbon Capture, Utilization, and Storage (CCUS) in China. Appl. Sci. 2023, 13, 1169. [Google Scholar] [CrossRef]

- Junior, A.N.; Queiroz, G.N.; Godoy, M.G.; da Silva Cardoso, V.; Cedrola, S.M.L.; Mansoldo, F.R.P.; Firpo, R.M.; Gomes Paiva, L.M.; Sohrabi, M.; Vermelho, A.B. Assessing EOR Strategies for Application in Brazilian Pre-Salt Reservoirs. Geoenergy Sci. Eng. 2023, 223, 211508. [Google Scholar] [CrossRef]

- Lei, Q.; Xu, Y.; Cai, B.; Guan, B.; Wang, X.; Bi, G.; Li, H.; Li, S.; Ding, B.; Fu, H.; et al. Progress and Prospects of Horizontal Well Fracturing Technology for Shale Oil and Gas Reservoirs. Pet. Explor. Dev. 2022, 49, 191–199. [Google Scholar] [CrossRef]

- Schiozer, D.J.; dos Santos, A.A.d.S.; de Graça Santos, S.M.; von Hohendorff Filho, J.C. Model-Based Decision Analysis Applied to Petroleum Field Development and Management. Oil Gas Sci. Technol. Rev. d’IFP Energ. Nouv. 2019, 74, 46. [Google Scholar] [CrossRef]

- Syed, F.I.; Alnaqbi, S.; Muther, T.; Dahaghi, A.K.; Negahban, S. Smart Shale Gas Production Performance Analysis Using Machine Learning Applications. Pet. Res. 2022, 7, 21–31. [Google Scholar] [CrossRef]

- Pandey, R.K.; Dahiya, A.K.; Mandal, A. Identifying Applications of Machine Learning and Data Analytics Based Approaches for Optimization of Upstream Petroleum Operations. Energy Technol. 2021, 9, 2000749. [Google Scholar] [CrossRef]

- Danyaro, K.U.; Hussain, H.H.; Abdullahi, M.; Liew, M.S.; Shawn, L.E.; Abubakar, M.Y. Development and Integration of Metocean Data Interoperability for Intelligent Operations and Automation Using Machine Learning: A Review. Appl. Sci. 2022, 12, 5690. [Google Scholar] [CrossRef]

- Stinco, L.P.; Barredo, S.P. Vaca Muerta Formation: An Example of Shale Heterogeneities Controlling Hydrocarbon Accumulations. In Proceedings of the SPE/AAPG/SEG Unconventional Resources Technology Conference, Denver, CO, USA, 25–27 August 2014. [Google Scholar]

- Matesanz, M.; Bodini, S.A.; Quintero Ramirez, J.; Diz, R.; Forni, L.P.; Fumagalli, N.A. Design and Drilling Performance of Two Exploratory Wells in Argentinean Parva Negra Oeste Shale Gas Field from the Vaca Muerta Formation. Experiences and Lessons Learnt. In Proceedings of the SPE Argentina Exploration and Production of Unconventional Resources Symposium, Buenos Aires, Argentina, 20–22 March 2023. [Google Scholar]

- Fang, Q.; Meng, Y.; Wei, N.; Xu, C.; Li, G. A Hydraulic Model for Multiphase Flow Based on the Drift Flux Model in Managed Pressure Drilling. Energies 2019, 12, 3930. [Google Scholar] [CrossRef]

- Soric, T.; Marinescu, P.; Huelke, R. Silicate-Based Drilling Fluids Deliver Optimum Shale Inhibition and Wellbore Stability. In Proceedings of the IADC/SPE Drilling Conference, Dallas, TX, USA, 2–4 March 2004. [Google Scholar]

- Abramova, E.; Popova, N.; Artemiev, G.; Zharkova, V.; Zakharova, E.; Safonov, A. Characteristics and Rates of Microbial Processes in Clays of Different Mineral and Elemental Composition in Relation to Safety Prediction for ESB Clay Materials. Appl. Sci. 2022, 12, 1843. [Google Scholar] [CrossRef]

- Sánchez, F.; Al-Harthy, M.H. Risk Analysis: Casing-While-Drilling (CwD) and Modeling Approach. J. Pet. Sci. Eng. 2011, 78, 1–5. [Google Scholar] [CrossRef]

- Gaurina-Međimurec, N.; Pašić, B.; Mijić, P.; Medved, I. Drilling Fluid and Cement Slurry Design for Naturally Fractured Reservoirs. Appl. Sci. 2021, 11, 767. [Google Scholar] [CrossRef]

- Sanchez, O.; Mela, F.J.; Martin, R. Azimuthal Hold Technology Implementation in Vaca Muerta. In Proceedings of the Asia Pacific Unconventional Resources Technology Conference, Tulsa, OK, USA, 16–18 November 2021. [Google Scholar]

- Zang, C.; Lu, Z.; Ye, S.; Xu, X.; Xi, C.; Song, X.; Guo, Y.; Pan, T. Drilling Parameters Optimization for Horizontal Wells Based on a Multiobjective Genetic Algorithm to Improve the Rate of Penetration and Reduce Drill String Drag. Appl. Sci. 2022, 12, 11704. [Google Scholar] [CrossRef]

- Yan, X.; Mou, J.; Tang, C.; Xin, H.; Zhang, S.; Ma, X.; Duan, G. Numerical Investigation of Major Impact Factors Influencing Fracture-Driven Interactions in Tight Oil Reservoirs: A Case Study of Mahu Sug, Xinjiang, China. Energies 2021, 14, 4881. [Google Scholar] [CrossRef]

- Sarhan, C.E.; Gavilan, J.M.; Pitz, J.M. First Operator’s Tested Strategies in Vaca Muerta to Prevent EUR Degradation by Parent Child Effects. In Proceedings of the 11th Unconventional Resources Technology Conference, Denver, CO, USA, 13–15 June 2023; American Association of Petroleum Geologists: Tulsa, OK, USA, 2023. [Google Scholar]

- Zanganeh, B.; Clarkson, C.R.; Hawkes, R.V. Reinterpretation of Fracture Closure Dynamics during Diagnostic Fracture Injection Tests. In Proceedings of the SPE Western Regional Meeting, Bakersfield, CA, USA, 23–27 April 2017. [Google Scholar]

- Xu, H.; Jiang, H.; Wang, J.; Wang, T.; Zhao, K.; Zhang, L. Frac-Hit Prevention Countermeasures in Shale Gas Reservoirs with Natural Fractures. Processes 2023, 11, 2509. [Google Scholar] [CrossRef]

- Mahmoud, A.; Gowida, A.; Aljawad, M.S.; Al-Ramadan, M.; Ibrahim, A.F. Advancement of Hydraulic Fracture Diagnostics in Unconventional Formations. Geofluids 2021, 2021, 4223858. [Google Scholar] [CrossRef]

- Zhang, S.; Feng, Y.; Li, B.; Deng, J.; Geng, T.; Zhang, J. Fracture Development during Disposal of Hazardous Drilling Cuttings by Deep Underground Injection: A Review. J. Rock Mech. Geotech. Eng. 2022, 14, 1652–1670. [Google Scholar] [CrossRef]

- Sousa, A.M.; Ribeiro, T.P.; Pereira, M.J.; Matos, H.A. Review of the Economic and Environmental Impacts of Producing Waxy Crude Oils. Energies 2022, 16, 120. [Google Scholar] [CrossRef]

- Ogbesejana, A.B.; Liu, B.; Gao, S.; Akinyemi, S.A.; Bello, O.M.; Song, Y. Applying Biomarkers as Paleoenvironmental Indicators to Reveal the Organic Matter Enrichment of Shale during Deep Energy Exploration: A Review. RSC Adv. 2023, 13, 25635–25659. [Google Scholar] [CrossRef]

- González, C.F.; Arhancet, I. Improvement in the Characterization of Vaca Muerta with DFIT Type Curves Analysis. In Proceedings of the 10th Unconventional Resources Technology Conference, Houston, TX, USA, 20–22 June 2022; American Association of Petroleum Geologists: Tulsa, OK, USA, 2022. [Google Scholar]

- Suliman, B.; Meek, R.; Hull, R.; Bello, H.; Portis, D.; Richmond, P. Variable Stimulated Reservoir Volume (SRV) Simulation: Eagle Ford Shale Case Study. In Proceedings of the SPE Unconventional Resources Conference, The Woodlands, TX, USA, 10–12 April 2013. SPE-164546-MS. [Google Scholar]

- Han, D.; Jung, J.; Kwon, S. Comparative Study on Supervised Learning Models for Productivity Forecasting of Shale Reservoirs Based on a Data-Driven Approach. Appl. Sci. 2020, 10, 1267. [Google Scholar] [CrossRef]

- Cugnart, R.; Rasoanaivo, S.; Clarkson, C.; Williams-Kovacs, J. Early Time SRV Characterization Through Flowback Analysis: Application of Clarkson/Williams-Kovacs Technique to Vaca Muerta. In Proceedings of the 5th Unconventional Resources Technology Conference, Austin, TX, USA, 24–26 July 2017; American Association of Petroleum Geologists: Tulsa, OK, USA, 2017. [Google Scholar]

- Valle-Falcones, L.M.; Grima-Olmedo, C.; Rodríguez-Pons Esparver, R.; Zamarro-Toves, E. Evaluation and Economics of Shale Gas Reserves in the Flysch-Eocene Formation of the Jaca Basin. Appl. Sci. 2023, 13, 1732. [Google Scholar] [CrossRef]

- Alkouh, A.; McKetta, S.; Wattenbarger, R.A. Estimation of Effective-Fracture Volume Using Water-Flowback and Production Data for Shale-Gas Wells. J. Can. Pet. Technol. 2014, 53, 290–303. [Google Scholar] [CrossRef]

- Bonapace, J.C. Water Management for Tight and Shale Reservoir: A Review of What Has Been Learned and What Should Be Considered for Development in Argentina. In Proceedings of the SPE Latin American and Caribbean Health, Safety, Environment, and Sustainability Symposium, Bogota, Columbia, 7–8 July 2015. [Google Scholar]

- Sentinelli, R.; Moreno, L.; Pellicer, M.; Domelen, M. Early Applications of Viscosifying Friction Reducers for Hydraulic Fracturing Operations in the Vaca Muerta Formation, Argentina. In Proceedings of the 2020 Latin America Unconventional Resources Technology Conference, Virtual, 16–18 November 2020; Unconventional Resources Technology Conference: Tulsa, OK, USA, 2020. [Google Scholar]

- Bonapace, J.C.; Riolfo, L.A.; Borgogno, F.G.; Zrain, R.; Santander, J.N.; Moussi, M.L. Tailoring the Frac Fluid’s Paradigm in Vaca Muerta. A Complete Review from Traditional Guar to New High Viscosity Friction Reducer Systems–Case History. In Proceedings of the SPE Argentina Exploration and Production of Unconventional Resources Symposium, Buenos Aires, Argentina, 20–22 March 2023. [Google Scholar]

- Crespo, P.A.; Pellicer, M.; Jacot, H. Applying State-of-the-Art Completion Techniques in Vaca Muerta Formation. In Proceedings of the 9th Unconventional Resources Technology Conference, Houston, TX, USA, 26–28 July 2021; American Association of Petroleum Geologists: Tulsa, OK, USA, 2021. [Google Scholar]

- Lerza, A.; Mamani, M.; Puidengolas, M.; Nuñez, S.; Acuna, J.A. Well Completion Performance Analysis in the Vaca Muerta Formation by Leveraging Fractional Dimension RTA—Case of Study. In Proceedings of the 10th Unconventional Resources Technology Conference, Houston, TX, USA, 20–22 June 2022; American Association of Petroleum Geologists: Tulsa, OK, USA, 2022. [Google Scholar]

- Pichon, S.; Varela, R.; Manière, J.; Hasbani, J. Flowback-Based Minimum Stress Estimate in Low-Permeability Environment: Procedure, Interpretation, and Application in the Vaca Muerta Shale. In Proceedings of the SPE Hydraulic Fracturing Technology Conference and Exhibition, The Woodlands, TX, USA, 23–25 January 2018. [Google Scholar]

- Espinoza, D.N.; Massaro, A.S.; Gallardo-Giozza, G. Anisotropic and Nonlinear Properties of Rock Samples in the Vaca Muerta Formation: Experimental Measurements and Implications on Reservoir Geomechanics. In Proceedings of the 8th Unconventional Resources Technology Conference, Virtual, 20–22 July 2020; American Association of Petroleum Geologists: Tulsa, OK, USA, 2020. [Google Scholar]

- Tuero, F.R.; Crotti, M.; Labayen, I. Unconventional EOR: A Capillary Based Improved Oil Recovery Case Study for Shale Oil Scenarios in the Vaca Muerta Resource Play. In Proceedings of the 5th Unconventional Resources Technology Conference, Austin, TX, USA, 24–26 July 2017; American Association of Petroleum Geologists: Tulsa, OK, USA, 2017. [Google Scholar]

- Masud, L.; Cortez, V.L.; Ottulich, M.A.; Valderrama, M.P.; Ghilardi, J.; Sanchez Graff, L.A.; Biondi, J.; Sapag, F. Gas Lift Optimization in Unconventional Wells–Vaca Muerta Case Study. In Proceedings of the SPE Argentina Exploration and Production of Unconventional Resources Symposium, Buenos Aires, Argentina, 20–22 March 2023. [Google Scholar]

- Bellini Aragon, N.G.; Villagra, F.M.; Serrano, G.D. Production Rate Calculation Using Choke Correlation, Improving Matching Field Data on Vaca Muerta Formation. In Proceedings of the SPE Latin American and Caribbean Petroleum Engineering Conference, Port of Spain, Trinidad and Tobago, 14–15 June 2023. [Google Scholar]

- Rodríguez, L.G.; Moreno Cardenas, J.P.; Mónaco, A.; María, S.; Osorio Gallego, J.G.; Alvarez, J.B.A. Reducing Uncertainty in the Pore Pressure Profile of the Most Important Unconventional Argentinian Play: Vaca Muerta. In Proceedings of the International Geomechanics Symposium, Abu Dhabi, United Arab Emirates, 7–10 November 2022. [Google Scholar]

- Buijs, H.; Ponce, J. An Engineered Approach to Hydraulically Fracture the Vaca Muerta Shale. In Proceedings of the SPE Hydraulic Fracturing Technology Conference and Exhibition, The Woodlands, TX, USA, 23–25 January 2018. D021S005R002. [Google Scholar]

- Romero Quishpe, A.; Silva Alonso, K.; Alvarez Claramunt, J.I.; Barros, J.L.; Bizzotto, P.; Ferrigno, E.; Martinez, G. Innovative Artificial Intelligence Approach in Vaca Muerta Shale Oil Wells for Real Time Optimization. In Proceedings of the SPE Annual Technical Conference and Exhibition, Calgary, AB, Canada, 30 September–2 October 2019. [Google Scholar]

- Malhotra, S.; Lerza, A.; Cuervo, S. Well Spacing and Stimulation Design Optimization in the Vaca Muerta Shale: Hydraulic Fracture Simulations on the Cloud. In Proceedings of the SPE Hydraulic Fracturing Technology Conference and Exhibition, Virtual, 25–27 May 2021. [Google Scholar]

- The Vaca Muerta Play: Gaining Competitive Economics through Operational Efficiencies. Available online: https://www.spglobal.com/commodityinsights/en/ci/research-analysis/the-vaca-muerta-play.html#:~:text=The%20cost%20of%20drilling%20an,down%20%241.5%20million%20on%20average (accessed on 3 February 2024).

- Gawantka da Silva, L.A.; Toro Padilla, R.; Molina, M.S.; Benedetto, C.F.; Olivo, P.; Mazzina, R. Vaca Muerta Corrosiveness and Its Impact in Production Strategy. In Proceedings of the SPE Argentina Exploration and Production of Unconventional Resources Symposium, Buenos Aires, Argentina, 20–22 March 2023. [Google Scholar]

- Giraldo, M.; Garcia, M.B.; Pasini, M.; Sosa, J.I.; Muñoz, A.; Siviero, F.; Mazo, A. Agile Approach to Mitigate Corrosion and Scaling Issues in Unconventional Vaca Muerta Wells. In Proceedings of the SPE Argentina Exploration and Production of Unconventional Resources Symposium, Buenos Aires, Argentina, 20–22 March 2023. [Google Scholar]

- Khan, H.J.; Spielman-Sun, E.; Jew, A.D.; Bargar, J.; Kovscek, A.; Druhan, J.L. A Critical Review of the Physicochemical Impacts of Water Chemistry on Shale in Hydraulic Fracturing Systems. Environ. Sci. Technol. 2021, 55, 1377–1394. [Google Scholar] [CrossRef]

- Liu, Y.; Zhang, P. Review of Phosphorus-Based Polymers for Mineral Scale and Corrosion Control in Oilfield. Polymers 2022, 14, 2673. [Google Scholar] [CrossRef]

- Jingyuan, M.; Boru, X.; Yuxiu, A. Advanced Developments in Low-Toxic and Environmentally Friendly Shale Inhibitor: A Review. J. Pet. Sci. Eng. 2022, 208, 109578. [Google Scholar] [CrossRef]

- Davoodi, S.; Al-Shargabi, M.; Wood, D.A.; Rukavishnikov, V.S.; Minaev, K.M. Synthetic Polymers: A Review of Applications in Drilling Fluids. Pet. Sci. 2023. [Google Scholar] [CrossRef]

- Spicka, K.; Ruiz, D.; Holding Eagle, L.; Hudson, R. From the Bakken to Vaca Muerta–Chemical Program Lessons Learned in North America Can Provide Insight for Argentina’s Unconventional Production Future. In Proceedings of the 2020 Latin America Unconventional Resources Technology Conference, Virtual, 16–18 November 2020; Unconventional Resources Technology Conference: Tulsa, OK, USA, 2020. [Google Scholar]

- Available online: https://www.mckinsey.com/industries/oil-and-gas/our-insights/vaca-muerta-an-opportunity-to-respond-to-the-global-energy-crisis (accessed on 3 February 2024).

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lu, X.; Li, S.; Han, R.; Jia, B.; Xian, C.; Ding, F.; Zhang, Y.; Zhong, S.; Xu, Q.; Zuo, X. An Overview of Recent Developments and Understandings of Unconventionals in the Vaca Muerta Formation, Argentina. Appl. Sci. 2024, 14, 1366. https://doi.org/10.3390/app14041366

Lu X, Li S, Han R, Jia B, Xian C, Ding F, Zhang Y, Zhong S, Xu Q, Zuo X. An Overview of Recent Developments and Understandings of Unconventionals in the Vaca Muerta Formation, Argentina. Applied Sciences. 2024; 14(4):1366. https://doi.org/10.3390/app14041366

Chicago/Turabian StyleLu, Xinqian, Siyuan Li, Ruijing Han, Bao Jia, Chenggang Xian, Fei Ding, Yu Zhang, Shibo Zhong, Qi Xu, and Xuan Zuo. 2024. "An Overview of Recent Developments and Understandings of Unconventionals in the Vaca Muerta Formation, Argentina" Applied Sciences 14, no. 4: 1366. https://doi.org/10.3390/app14041366

APA StyleLu, X., Li, S., Han, R., Jia, B., Xian, C., Ding, F., Zhang, Y., Zhong, S., Xu, Q., & Zuo, X. (2024). An Overview of Recent Developments and Understandings of Unconventionals in the Vaca Muerta Formation, Argentina. Applied Sciences, 14(4), 1366. https://doi.org/10.3390/app14041366