Effect of Pouring Time on the Integrity of Pulverized Fuel Ash Concrete

Abstract

1. Introduction

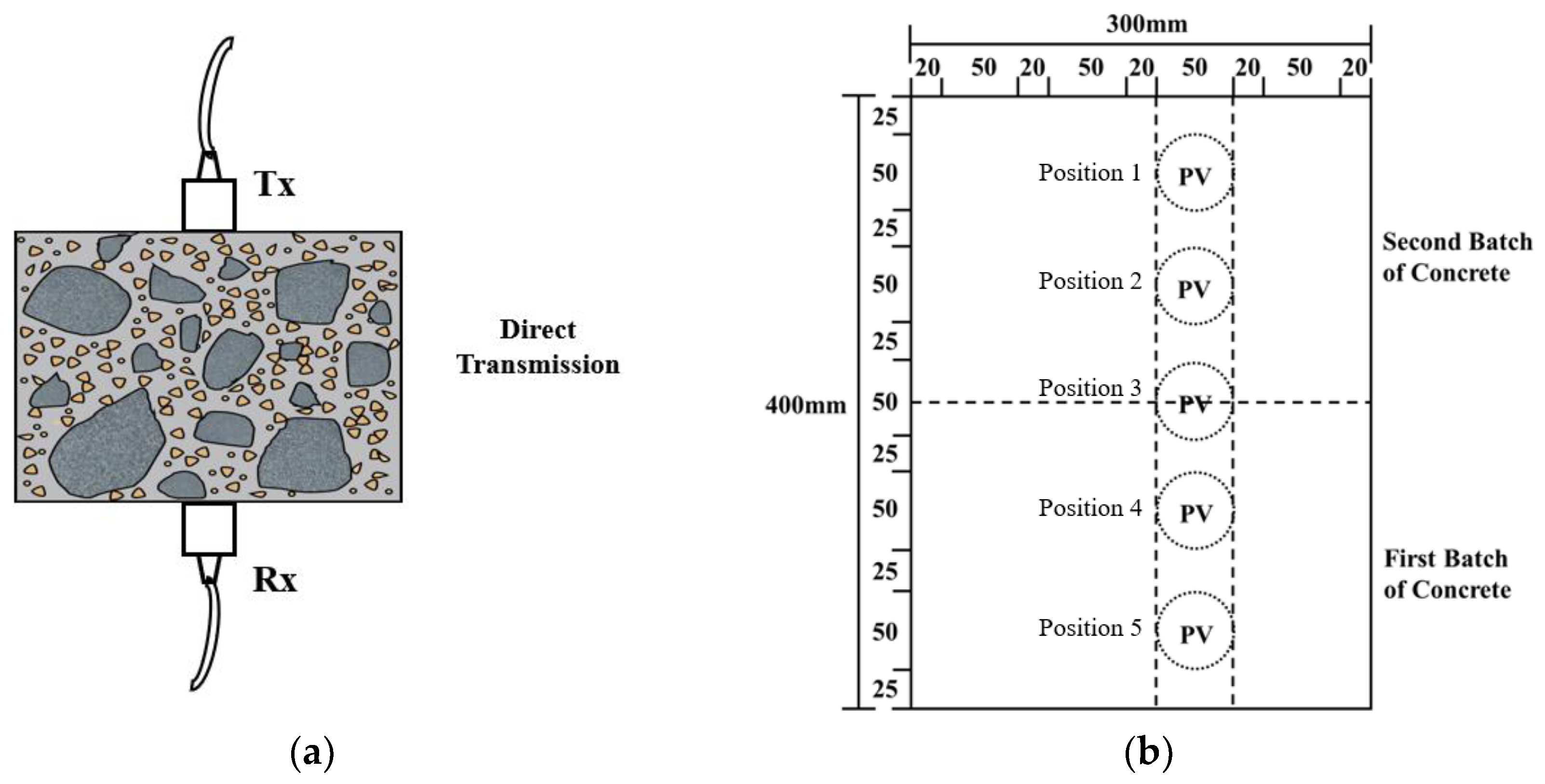

2. Materials and Methods

3. Results

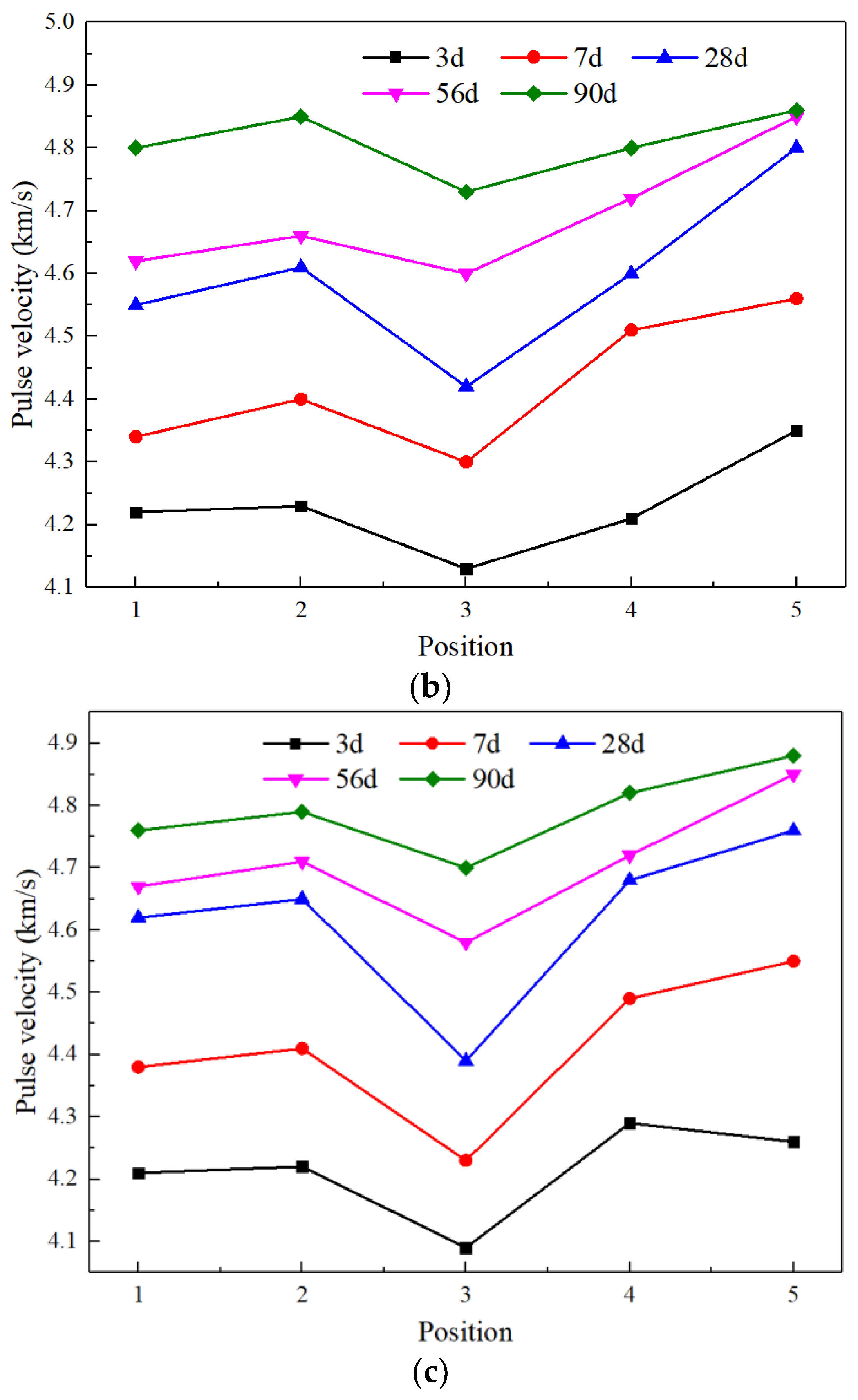

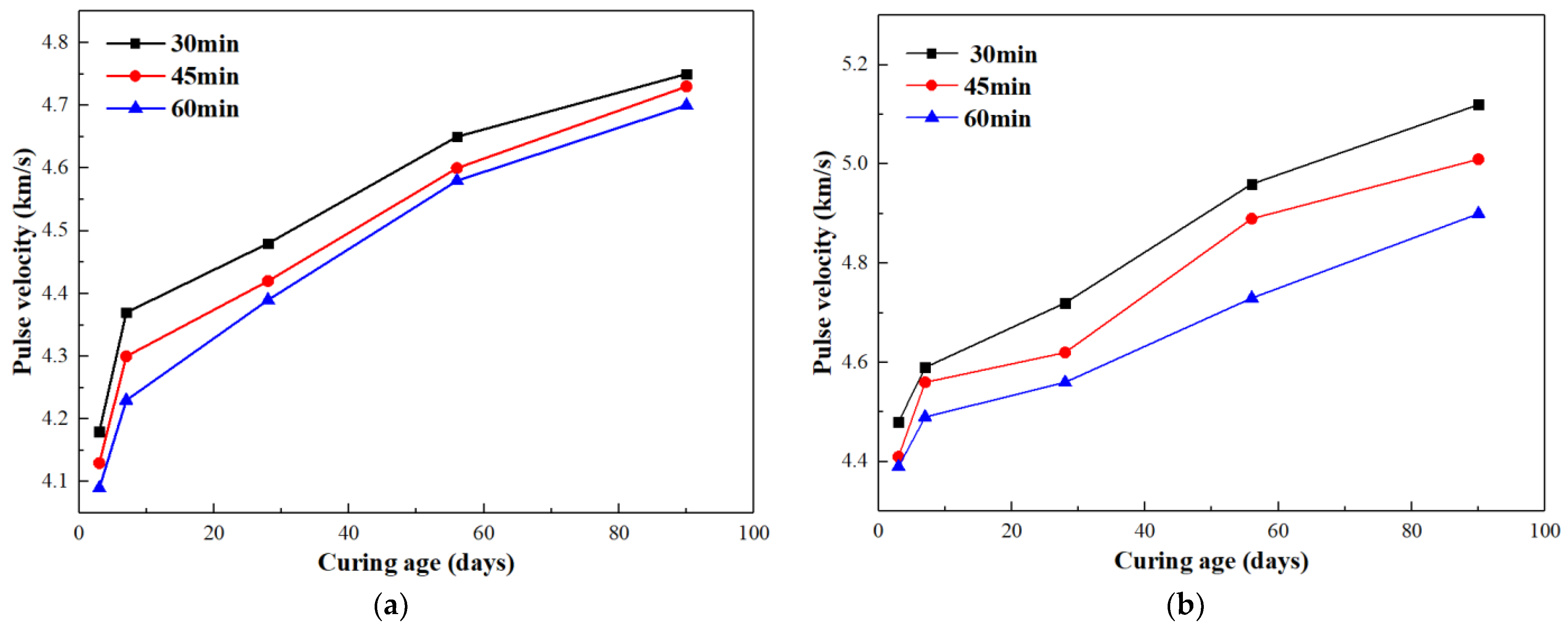

3.1. The Pundits Test

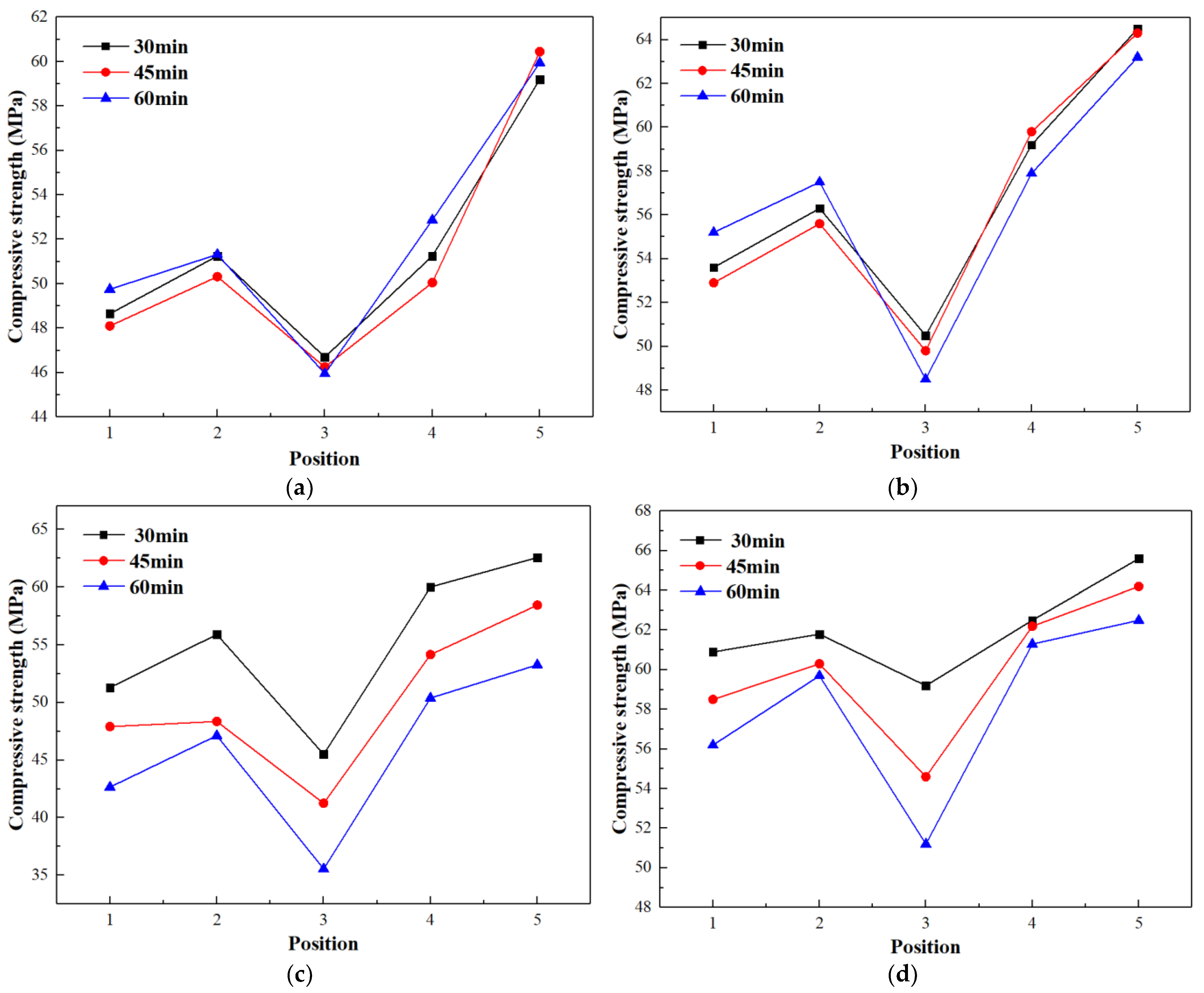

3.2. Compressive Strength

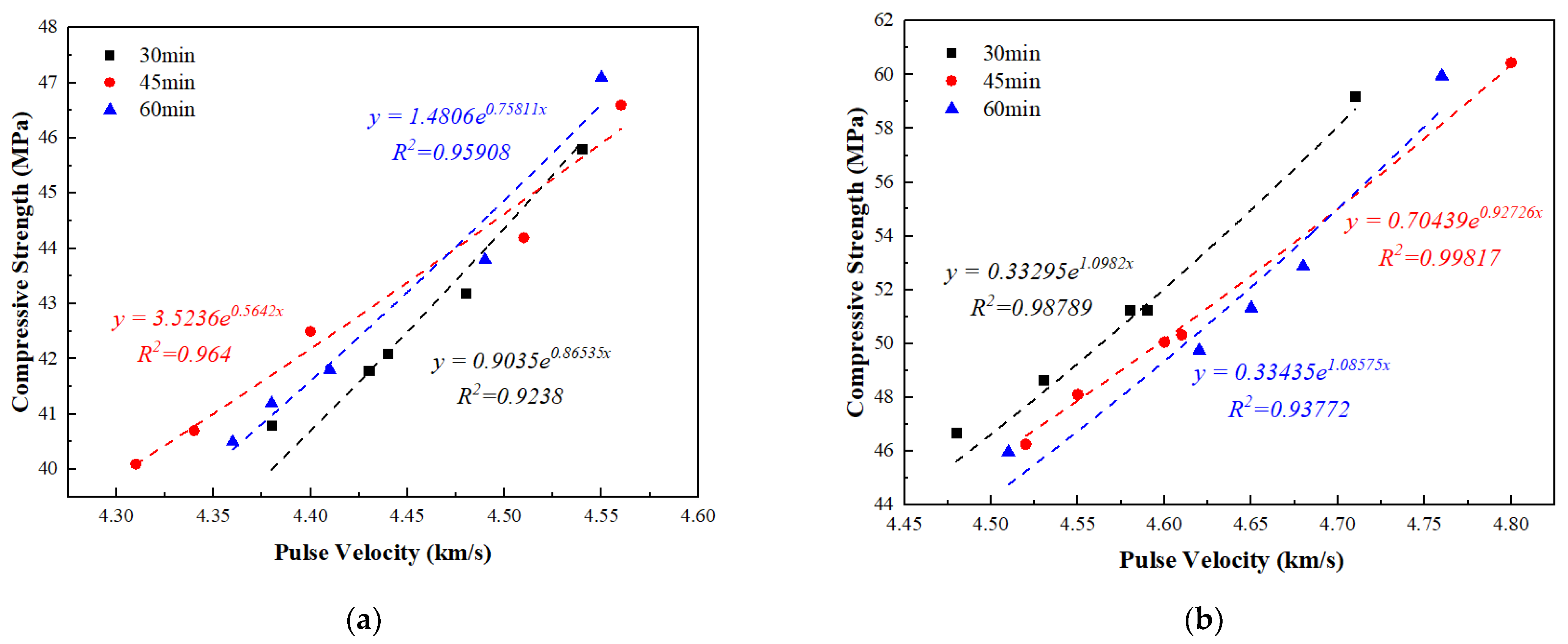

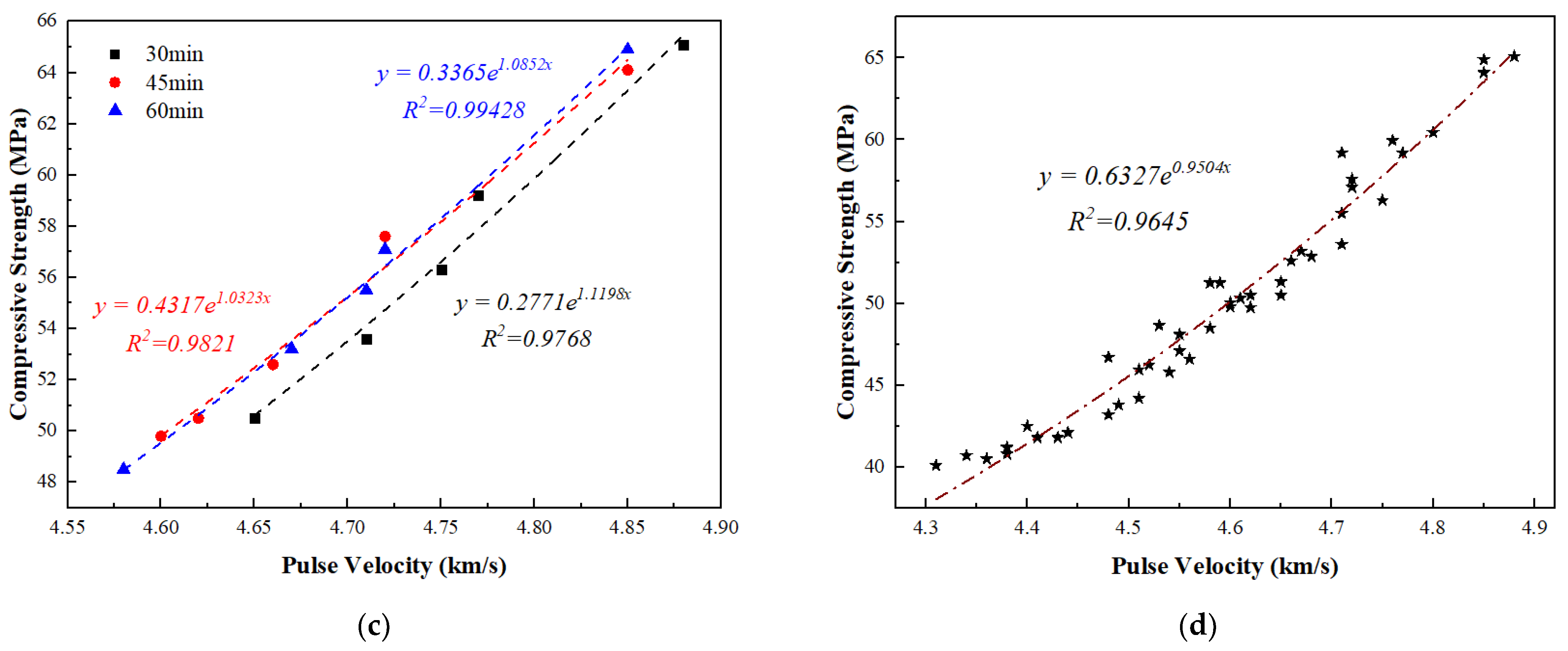

3.3. Relationship between Compressive Strength and Pulse Velocity

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Hemalatha, T.; Ramaswamy, A. A review on fly ash characteristics—Towards promoting high volume utilization in developing sustainable concrete. J. Clean. Prod. 2017, 147, 546–559. [Google Scholar] [CrossRef]

- Ban, C.C.; Yaw, C.K.; Ramli, M.; Keat, L.G. The engineering properties and microstructure development of cement mortar containing high volume of inter-grinded GGBS and PFA cured at ambient temperature. Constr. Build. Mater. 2016, 122, 683–693. [Google Scholar] [CrossRef]

- Man, C.K.; Yeung, H.S. The effects of using pulverized fuel ash as partial substitute for cement in concrete. Sci. Total Environ. 1997, 196, 171–176. [Google Scholar] [CrossRef]

- De Weerdt, K.; Haha, M.B.; Le Saout, G.; Kjellsen, K.O.; Justnes, H.; Lothenbach, B. Hydration mechanisms of ternary Portland cements containing limestone powder and fly ash. Cem. Concr. Res. 2011, 41, 279–291. [Google Scholar] [CrossRef]

- Ismail, I.; Bernal, S.A.; Provis, J.L.; San Nicolas, R.; Hamdan, S.; van Deventer, J.S.J. Modification of phase evolution in alkali-activated blast furnace slag by the incorporation of fly ash. Cem. Concr. Compos. 2014, 45, 125–135. [Google Scholar] [CrossRef]

- Samad, S.; Shah, A.; Lambachiya, M.C.; Desai, S.B. Strength development of binary cement concrete, using Pulverized Fly Ash (PFA) under various curing conditions. Sci. Iran. 2019, 26, 615–624. [Google Scholar] [CrossRef]

- Bai, J.; Wild, S.; Sabir, B.B.; Kinuthia, J.M. Workability of concrete incorporating pulverized fuel ash and metakaolin. Mag. Concr. Res. 1999, 51, 207–216. [Google Scholar] [CrossRef]

- Zhou, X.M.; Slater, J.R.; Wavell, S.E.; Oladiran, O. Effects of PFA and GGBS on Early-Ages Engineering Properties of Portland Cement Systems. J. Adv. Concr. Technol. 2012, 10, 74–85. [Google Scholar] [CrossRef]

- Ukwattage, N.L.; Ranjith, P.G.; Yellishetty, M.; Bui, H.H.; Xu, T. A laboratory-scale study of the aqueous mineral carbonation of coal fly ash for CO2 sequestration. J. Clean. Prod. 2015, 103, 665–674. [Google Scholar] [CrossRef]

- Şahmaran, M.; Li, V.C. Durability properties of micro-cracked ECC containing high volumes fly ash. Cem. Concr. Res. 2009, 39, 1033–1043. [Google Scholar] [CrossRef]

- Yang, H.-M.; Lee, H.-S.; Yang, K.-H.; Ismail, M.A.; Kwon, S.-J. Time and cold joint effect on chloride diffusion in concrete containing GGBFS under various loading conditions. Constr. Build. Mater. 2018, 167, 739–748. [Google Scholar] [CrossRef]

- Kwon, S.-J.; Na, U.-J. Prediction of Durability for RC Columns with Crack and Joint under Carbonation Based on Probabilistic Approach. Int. J. Concr. Struct. Mater. 2011, 5, 11–18. [Google Scholar] [CrossRef]

- Xiao, J.; Sun, C.; Lange, D.A. Effect of joint interface conditions on shear transfer behavior of recycled aggregate concrete. Constr. Build. Mater. 2016, 105, 343–355. [Google Scholar] [CrossRef]

- Yoo, S.-W.; Kwon, S.-J. Effects of cold joint and loading conditions on chloride diffusion in concrete containing GGBFS. Constr. Build. Mater. 2016, 115, 247–255. [Google Scholar] [CrossRef]

- Banthia, N.; Biparva, A.; Mindess, S. Permeability of concrete under stress. Cem. Concr. Res. 2005, 35, 1651–1655. [Google Scholar] [CrossRef]

- Roy, B.; Laskar, A.I. Cyclic behavior of in-situ exterior beam-column subassemblies with cold joint in column. Eng. Struct. 2017, 132, 822–833. [Google Scholar] [CrossRef]

- Choinska, M.; Khelidj, A.; Chatzigeorgiou, G.; Pijaudier-Cabot, G. Effects and interactions of temperature and stress-level related damage on permeability of concrete. Cem. Concr. Res. 2007, 37, 79–88. [Google Scholar] [CrossRef]

- Kewalramani, M.A.; Gupta, R. Concrete compressive strength prediction using ultrasonic pulse velocity through artificial neural networks. Autom. Constr. 2006, 15, 374–379. [Google Scholar] [CrossRef]

- Berriman, J.; Purnell, P.; Hutchins, D.A.; Neild, A. Humidity and aggregate content correction factors for air-coupled ultrasonic evaluation of concrete. Ultrasonics 2005, 43, 211–217. [Google Scholar] [CrossRef] [PubMed]

- Ohdaira, E.; Masuzawa, N. Water content and its effect on ultrasound propagation in concrete—The possibility of NDE. Ultrasonics 2000, 38, 546–552. [Google Scholar] [CrossRef]

- BS EN 12390-2; Testing of Hardened Concrete. British Standards Institution: London, UK, 2019.

- BS 1881-203:1986; Testing Concrete—Part 203: Recommendations for Measurement of Velocity of Ultrasonic Pulses in Concrete. British Standards Institution: London, UK, 1986.

- BS EN 12390-3; Testing of Hardened Concrete—Part 3: Testing Hardened Concrete. Compressive Strength of Test Specimens. British Standards Institution: London, UK, 2019.

- Rathi, V.R.; Kolase, P.K. Effect of Cold Joint on Strength of Concrete. Int. J. Innov. Res. Sci. Eng. Technol. 2013, 2, 4671–4679. [Google Scholar]

- Kırca, Ö.; Turanlı, L.; Erdoğan, T.Y. Effects of retempering on consistency and compressive strength of concrete subjected to prolonged mixing. Cem. Concr. Res. 2002, 32, 441–445. [Google Scholar] [CrossRef]

- Gül, R.; Demirboğa, R.; Güvercin, T. Compressive strength and ultrasound pulse velocity of mineral admixtured mortars. Indian J. Eng. Mater. Sci. 2006, 13, 18–24. [Google Scholar]

- del Rio, L.M.; Jimenez, A.; Lopez, F.; Rosa, F.J.; Rufo, M.M.; Paniagua, J.M. Characterization and hardening of concrete with ultrasonic testing. Ultrasonics 2004, 42, 527–530. [Google Scholar] [CrossRef]

- Lin, Y.; Shih-Fang, K.; Hsiao, C.; Chao-Peng, L. Investigation of pulse velocity-strength relationship of hardened concrete. ACI Mater. J. 2007, 104, 344–350. [Google Scholar]

- Yılmaz, T.; Ercikdi, B. Predicting the uniaxial compressive strength of cemented paste backfill from ultrasonic pulse velocity test. Nondestruct. Test. Eval. 2015, 31, 247–266. [Google Scholar] [CrossRef]

| w/c | Cement | 20 mm Gravel | 10 mm Gravel | Fine Aggregate | PFA | Water | |

|---|---|---|---|---|---|---|---|

| Mix 1 | 0.55 | 360 | 680 | 290 | 800 | 40 | 220 |

| Mix 2 | 0.45 | 360 | 680 | 290 | 800 | 40 | 180 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ni, L.; Zheng, D.; Yang, H.; Ding, X. Effect of Pouring Time on the Integrity of Pulverized Fuel Ash Concrete. Appl. Sci. 2024, 14, 1332. https://doi.org/10.3390/app14041332

Ni L, Zheng D, Yang H, Ding X. Effect of Pouring Time on the Integrity of Pulverized Fuel Ash Concrete. Applied Sciences. 2024; 14(4):1332. https://doi.org/10.3390/app14041332

Chicago/Turabian StyleNi, Longyue, Dapeng Zheng, Haibin Yang, and Xiaobo Ding. 2024. "Effect of Pouring Time on the Integrity of Pulverized Fuel Ash Concrete" Applied Sciences 14, no. 4: 1332. https://doi.org/10.3390/app14041332

APA StyleNi, L., Zheng, D., Yang, H., & Ding, X. (2024). Effect of Pouring Time on the Integrity of Pulverized Fuel Ash Concrete. Applied Sciences, 14(4), 1332. https://doi.org/10.3390/app14041332