Paper-Mill Wastes for Bioethanol Production in Relation to Circular Economy Concepts: A Review

Abstract

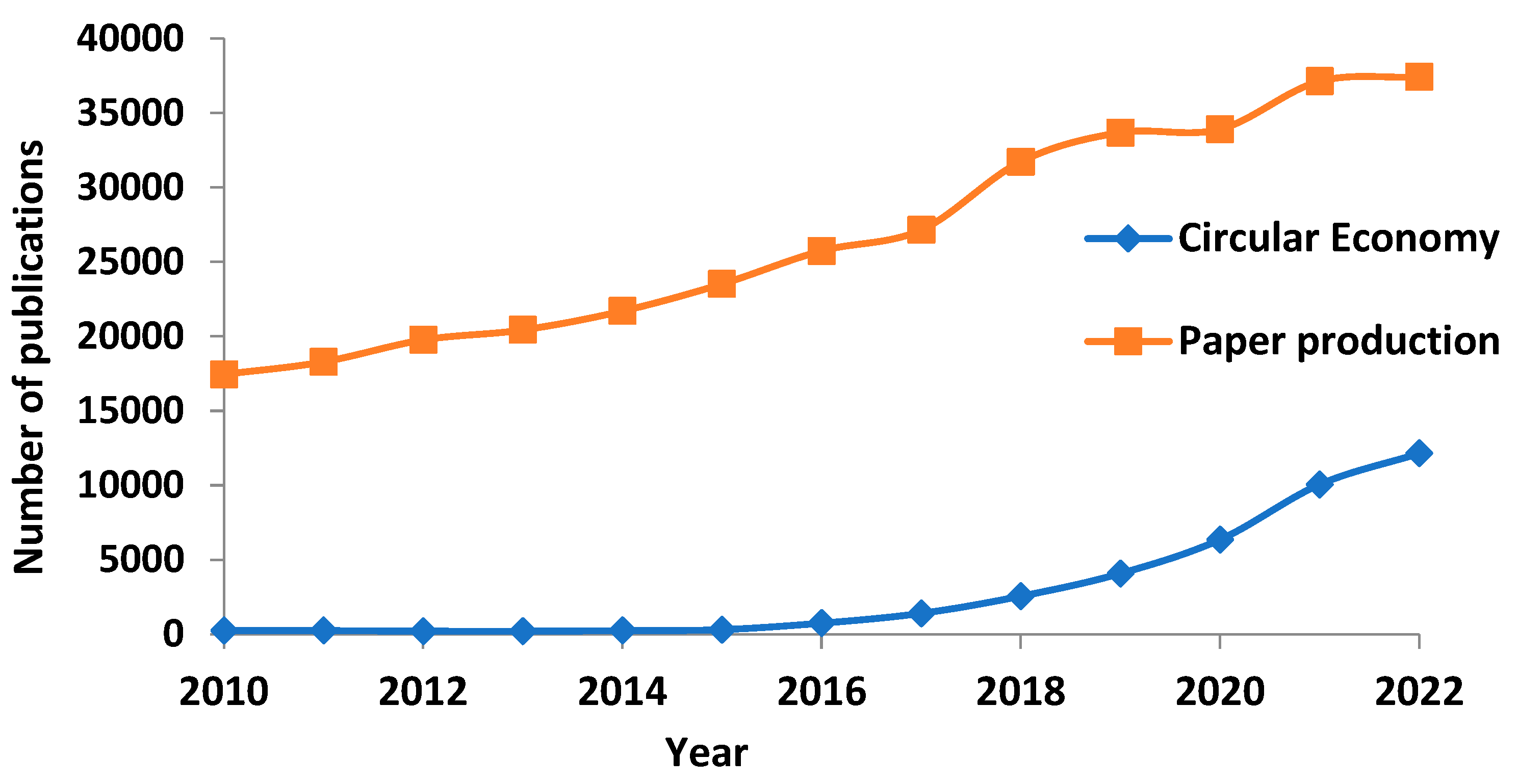

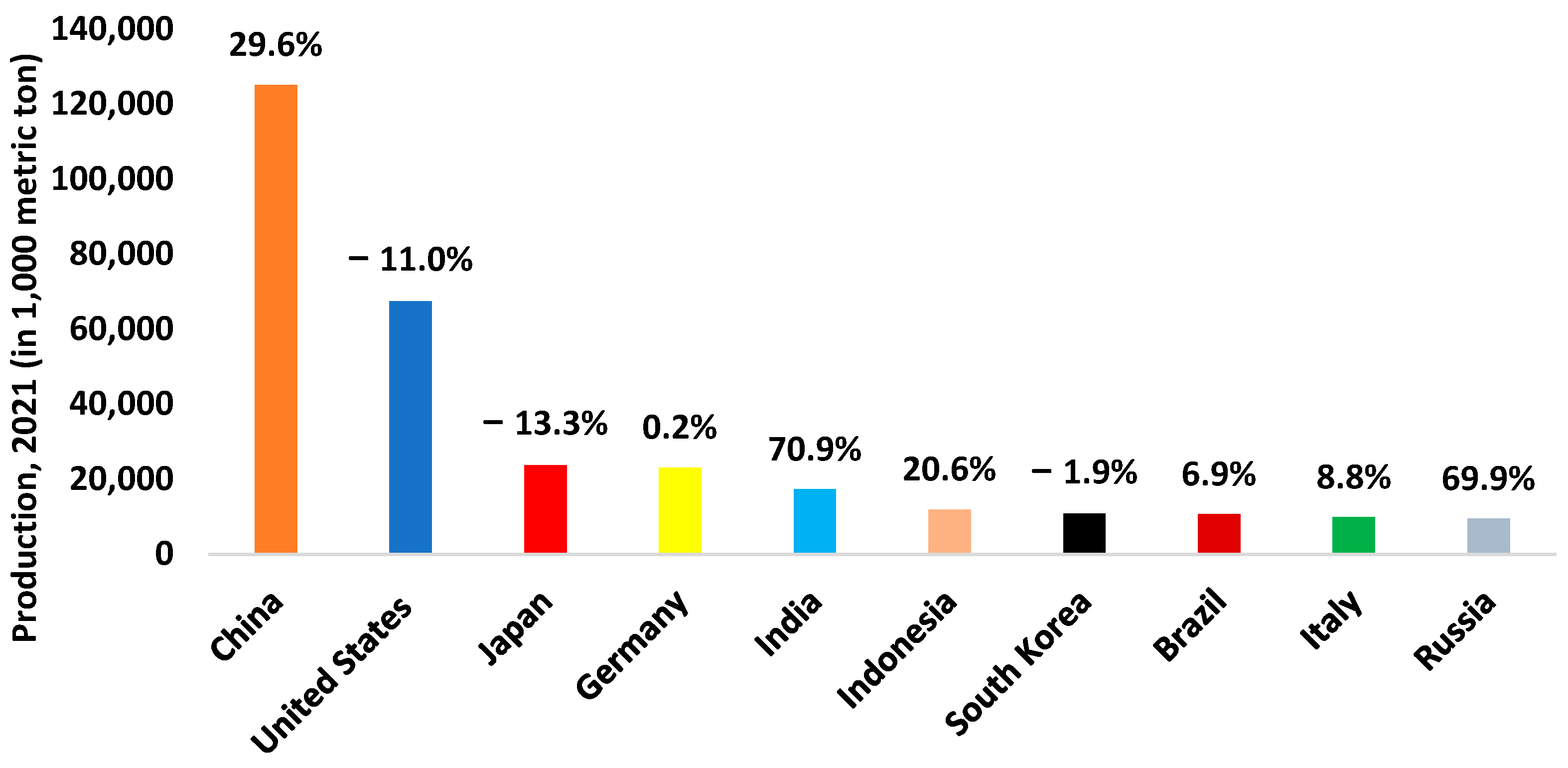

1. Introduction

2. Paper and Cardboard Manufacturing Process

2.1. Paper and Cardboard Feedstock Materials

2.2. Pulping Process

2.3. Bleaching

2.4. Papermaking

2.5. Paper Grades and Properties

2.6. Paper Recycling

| Grade | Quality | Examples |

|---|---|---|

| 1 | Low | Corrugates board, unsold magazines, mixed magazine and newspaper, mixed-paper, and paperboard |

| 2 | Medium | Newspaper, printed white shaving, sorted office paper, PE-coated paperboard, colored wood-free paper |

| 3 | High | Wood-free binders, white wood-free paper, SBS paperboard, coated mechanical pulp paper |

| 4 | Kraft | New shavings of corrugated board, used kraft paper |

| 5 | Special | Liquid packaging paperboard, wet-strength wood free paper, and labels |

2.7. Manufacturing Process in Hadera Paper Mill, Israel: A Case Study

3. Paper Mill Wastes

3.1. Global Solid Waste and Paper Waste

3.2. Waste Cycle in Pulping and Bleaching Processes

3.3. Waste-Water Treatment and Paper Sludge

4. CE Aspects of Paper Manufacturing and Bioethanol Production

4.1. CE in Pulp and Paper Mills

4.2. CE Indicators

5. RPS for Energy Applications

5.1. Waste-to-Energy (WtE)

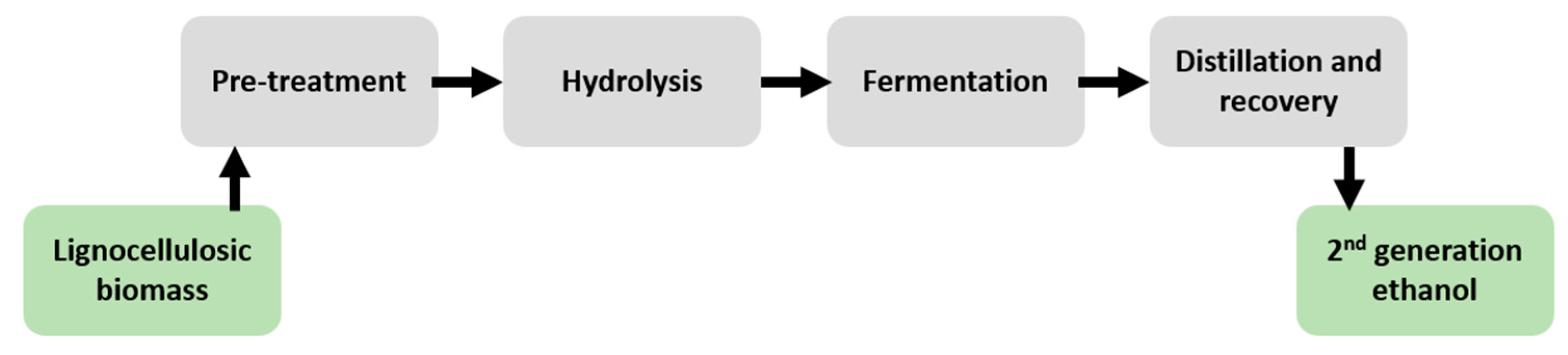

5.2. Bioethanol Production from Lignocellulosic Biomass

5.3. Paper Wastes as a Lignocellulosic Material

5.4. Paper Sludge as a Source of Ethanol

5.5. Economic Aspects of CE in the Paper Industry

6. Conclusions and Future Directions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Adamcová, D.; Vaverková, M.D.; Stejskal, B.; Břoušková, E. Household solid waste composition focusing on hazardous waste. Pol. J. Environ. Stud. 2016, 25, 487–493. [Google Scholar] [CrossRef] [PubMed]

- Kaza, S.; Yao, L.; Bhada-Tata, P.; van Woerden, F. What a Waste 2.0: A Global Snapshot of Solid Waste Management to 2050, World Bank Group. 2018. Available online: https://datatopics.worldbank.org/what-a-waste/ (accessed on 20 September 2018).

- Pour, N.; Webley, P.A.; Cook, P.J. Potential for using municipal solid waste as a resource for bioenergy with carbon capture and storage (BECCS). Int. J. Greenh. Gas Control 2018, 68, 1–15. [Google Scholar] [CrossRef]

- Sadasivan Nair, A.; Al-battashi, H.; Al-akzawi, A.; Annamalai, N.; Gujarathi, A. Waste office paper: A potential feedstock for cellulase production by a novel strain Bacillus velezensis ASN1. Waste Manag. 2018, 79, 491–500. [Google Scholar] [CrossRef]

- Peretz, R.; Mamane, H.; Wissotzky, E.; Sterenzon, E.; Gerchman, Y. Making cardboard and paper recycling more sustainable: Recycled paper sludge for energy production and water-treatment applications. Waste Biomass Valorization 2020, 12, 1599–1608. [Google Scholar] [CrossRef]

- Robus, C.L.L.; Gottumukkala, L.D.; Rensburg, V.; Johann, F.G. Feasible process development and techno-economic evaluation of paper sludge to bioethanol conversion: South African paper mills scenario. Renew. Energy 2016, 92, 333–345. [Google Scholar] [CrossRef]

- Monrroy, M.; García, J.R.; Mendonça, R.T.; Baeza, J.; Freer, J. Kraft pulping of Eucalyptus globulus as a pretreatment for bioethanol production by simultaneous saccharification and fermentation. J. Chil. Chem. Soc. 2012, 57, 1113–1117. [Google Scholar] [CrossRef]

- Adu, C.; Jolly, M.; Kumar Thakur, V. Exploring new horizons for paper recycling: A review of biomaterials and biorefinery feedstocks derived from wastepaper. Curr. Opin. Green Sustain. Chem. 2018, 13, 21–26. [Google Scholar] [CrossRef]

- U.S. Congress, Biomass Research and Development Act of 2000, Washington, DC. Available online: https://www.energy.gov/eere/bioenergy/articles/biomass-research-and-development-act-2000 (accessed on 22 June 2000).

- Peretz, R.; Gerchman, Y.; Mamane, H. Ozonation of tannic acid to model biomass pretreatment for bioethanol production. Bioresour. Technol. 2017, 241, 1060–1066. [Google Scholar] [CrossRef]

- Rosen, Y.; Mamane, H.; Gerchman, Y. Short ozonation of lignocellulosic waste as energetically favorable pretreatment. Bioenergy Res. 2019, 12, 292–301. [Google Scholar] [CrossRef]

- Cabrera, M.N. Pulp Mill Wastewater: Characteristics and Treatment, in Biological Wastewater Treatment and Resource Recovery; Farooq, R., Ahmad, Z., Eds.; InTech Open: London, UK, 2016; pp. 119–138. [Google Scholar]

- van Caneghem, J.; van Acker, K.; de Greef, J.; Wauters, G.; Vandecasteele, C. Waste-to-energy is compatible and complementary with recycling in the circular economy. Clean Technol. Environ. Policy 2019, 21, 925–939. [Google Scholar] [CrossRef]

- Acheampong, M.; Ertem, F.C.; Kappler, B.; Neubauer, P. In pursuit of Sustainable Development Goal (SDG) number 7: Will biofuels be reliable? Renew. Sustain. Energy Rev. 2017, 75, 927–937. [Google Scholar] [CrossRef]

- Rosales-Calderon, O.; Arantes, V. A review on commercial-scale high-value products that can be produced alongside cellulosic ethanol. Biotechnol. Biofuels 2019, 12, 240. [Google Scholar] [CrossRef]

- Singh, S.; Kumar, A.; Sivakumar, N.; Verma, J.P. Deconstruction of lignocellulosic biomass for bioethanol production: Recent advances and future prospects. Fuel 2022, 327, 125109. [Google Scholar] [CrossRef]

- Mandil, C.; Shihab-Eldin, A. Assessment of Biofuels Potential and Limitations, International Energy Forum. 2010. Available online: https://www.ief.org/_resources/files/events/biofuels-assessment-report/ief-biofuels-report.pdf (accessed on 10 March 2010).

- Suhr, M.; Klein, G.; Kourti, I.; Gonzalo, M.R.; Santonja, G.G.; Roudier, S.; Sancho, L.D. Best Available Techniques (BAT) Reference Document for the Production of Pulp, Paper and Board, Industrial Emissions Directive 2010/75/EU (Integrated Pollution Prevention and Control). JRC Science and Policy Reports. 2015. Available online: https://publications.jrc.ec.europa.eu/repository/handle/JRC95678 (accessed on 19 May 2015).

- Kong, L.; Hasanbeigi, A.; Price, L. Assessment of emerging energy-efficiency technologies for the pulp and paper industry: A technical review. J. Clean. Prod. 2016, 122, 5–28. [Google Scholar] [CrossRef]

- Statista Website, Distribution of Paper Imports Worldwide in 2021, by Country. 2023. Available online: https://www.statista.com/statistics/1073508/global-share-paper-imports-by-country/ (accessed on 24 March 2023).

- Statista Website, Production Volume of Paper and Paperboard in Selected Countries Worldwide in 2010 and 2022. 2024. Available online: https://www.statista.com/statistics/240598/production-of-paper-and-cardboard-in-selected-countries/ (accessed on 8 January 2024).

- Branco, R.H.R.; Serafim, L.S.; Xavier, A.M.R.B. Second generation bioethanol production: On the use of pulp and paper industry wastes as feedstock. Fermentation 2019, 5, 4. [Google Scholar] [CrossRef]

- Berg, P.; Lingqvist, O. Pulp, Paper, and Packaging in the Next Decade: Transformational Change. McKinsey Co. 2019. Available online: https://www.mckinsey.com/industries/paper-forest-products-and-packaging/our-insights/pulp-paper-and-packaging-in-the-next-decade-transformational-change#/ (accessed on 7 August 2019).

- Risén, J.; Hultén, A.H.; Paulsson, M. Influence of fiber properties on the network strength of softwood and hardwood kraft pulp fibers from different stages of a bleaching sequence. J. Wood Chem. Technol. 2004, 24, 289–306. [Google Scholar] [CrossRef]

- Dong, Y.; Wang, B.; Ji, H.; Zhu, W.; Long, Z.; Dong, C. Effect of papermaking conditions on the ink absorption and overprint accuracy of paper. BioResources 2020, 15, 1397–1406. [Google Scholar] [CrossRef]

- Ververis, C.; Georghiou, K.; Christodoulakis, N.; Santas, P.; Santas, R. Fiber dimensions, lignin and cellulose content of various plant materials and their suitability for paper production. Ind. Crops Prod. 2004, 19, 245–254. [Google Scholar] [CrossRef]

- de Assis, T.; Pawlak, J.; Pal, L.; Jameel, H.; Venditti, R.; Reisinger, L.W.; Kavalew, D.; Gonzalez, R.W. Comparison of wood and non-wood market pulps for tissue paper application. BioResources 2019, 14, 6810–8781. [Google Scholar] [CrossRef]

- Liu, Z.; Wang, H.; Hui, L. Pulping and papermaking of non-wood fibers. In Pulp and Paper Processing; Kazi, S.N., Ed.; InTech Open: London, UK, 2018; pp. 3–31. [Google Scholar]

- Worku, L.A.; Bachheti, A.; Bachheti, R.K.; Rodrigues Reis, C.E.; Chandel, A.K. Agricultural residues as raw materials for pulp and paper production: Overview and applications on membrane fabrication. Membranes 2023, 13, 228. [Google Scholar] [CrossRef]

- Li, X.; Li, M.; Pu, Y.; Ragauskas, A.J.; Klett, A.S.; Thies, M.; Zheng, Y. Inhibitory effects of lignin on enzymatic hydrolysis: The role of lignin chemistry and molecular weight. Renew. Energy 2018, 123, 664–674. [Google Scholar] [CrossRef]

- Viikari, L.; Suurnäkki, A.; Grönqvist, S.; Raaska, L.; Ragauskas, A. Forest Products: Biotechnology in Pulp and Paper Processing, in Encyclopedia of Microbiology; Schaechter, M., Ed.; Elsevier: Amsterdam, The Netherlands, 2009; pp. 80–94. [Google Scholar]

- Sixta, H. Handbook of Pulp; Wiley: Hoboken, NJ, USA, 2006. [Google Scholar]

- Ahmad, E.; Pant, K.K. Lignin Conversion: A Key to the Concept of Lignocellulosic Biomass-Based Integrated Biorefinery. In Waste Biorefinery—Potential and Perspective; Elsevier: Amsterdam, The Netherlands, 2018; pp. 409–444. [Google Scholar]

- Bujanovic, B.; Ralph, S.; Reiner, R.; Hirth, K.; Atalla, R. Polyoxometalates in oxidative delignification of chemical pulps: Effect on lignin. Materials 2010, 3, 1888–1903. [Google Scholar] [CrossRef]

- CEPI. Pulp and Paper Industry: Definitions and Concepts. 2021. Available online: https://www.cepi.org/wp-content/uploads/2021/01/Cepi-Definitions-and-Concepts_2021-compressed.pdf (accessed on 1 January 2021).

- Bajpai, P. Pulp and Paper Production Processes and Energy Overview. In Pulp and Paper Industry—Energy Conservation; Elsevier: Amsterdam, The Netherlands, 2016; pp. 15–49. [Google Scholar]

- Shukla, S.K.; Kumar, V.; van Doan, T.; Yoo, K.; Kim, Y.; Park, J. Combining activated sludge process with membrane separation to obtain recyclable quality water from paper mill effluent. Clean Technol. Environ. Policy 2015, 17, 781–788. [Google Scholar] [CrossRef]

- Juričić, D. Estimation and Control of the Kappa Number in a Pulp Cooking Process. IFAC Proc. Vol. 1991, 24, 775–780. [Google Scholar] [CrossRef]

- Małachowska, E.; Dubowik, M.; Lipkiewicz, A.; Przybysz, K.; Przybysz, P. Analysis of cellulose pulp characteristics and processing parameters for efficient paper production. Sustainability 2020, 12, 7219. [Google Scholar] [CrossRef]

- Friebel, C.; Bischof, R.H.; Schild, G.; Fackler, K.; Gebauer, I. Effects of caustic extraction on properties of viscose grade dissolving pulp. Processes 2019, 7, 122. [Google Scholar] [CrossRef]

- Tripathi, S.K.; Bhardwaj, N.K.; Ghatak, H.R. Effect of introducing ozone prior to elemental chlorine free bleaching of wheat straw pulp on pulp, paper and effluent properties. Cellul. Chem. Technol. 2019, 53, 105–112. [Google Scholar] [CrossRef]

- Torres, A.L.; Roncero, M.B.; Colom, J.F.; Martínez, J.A.; Vidal, T. Application of an experimental design to modeling of ozone bleaching stage in TCF processes. Ozone Sci. Eng. 2004, 26, 443–451. [Google Scholar] [CrossRef]

- Suess, H.U. Pulp Bleaching Today; De Gruyter: Berlin, Germany, 2010. [Google Scholar]

- Kasmani, J.E.; Mahdavi, S.; Alizadeh, A.; Nemati, M.; Samariha, A. Physical properties and printability characteristics of mechanical printing paper with LWC. BioResources 2013, 8, 3646–3656. [Google Scholar]

- Smook, G.A. Handbook for Pulp and Paper Technologists; TAPPI Press: Atlanta, GA, USA, 1989. [Google Scholar]

- Howard, R.C.; Bichard, W. Basic effects of recycling on pulp properties. J. Pulp Pap. Sci. 1992, 266, 195–214. [Google Scholar] [CrossRef]

- Hubbe, M.A.; Gill, R.A. Fillers for Papermaking: A Review of their Properties, Usage Practices, and their Mechanistic Role. BioResources 2016, 11, 2886–2963. [Google Scholar] [CrossRef]

- Caulfield, D.; Gunderson, D. Paper Testing and Strength Characteristics. In Proceedings of the TAPPI Proceedings: 1988 Paper Preservation Symposium, Washington, DC, USA, 19–21 October 1988; pp. 31–40. [Google Scholar]

- Shen, J.; Song, Z.; Qian, X.; Liu, W. Modification of papermaking grade fillers: A brief review. BioResources 2009, 4, 1190–1209. [Google Scholar] [CrossRef]

- Pivnenko, K.; Olsson, M.E.; Götze, R.; Eriksson, E.; Astrup, T.F. Quantification of chemical contaminants in the paper and board fractions of municipal solid waste. Waste Manag. 2016, 51, 43–54. [Google Scholar] [CrossRef]

- CEPI. Key Statistics 2019: European Pulp & Paper Industry. 2020. Available online: https://www.cepi.org/key-statistics-2019/ (accessed on 23 July 2020).

- EPA. Pulping and Bleaching System NESHAP for the Pulp and Paper Industry: A Plain English Description. 2001. Available online: https://nepis.epa.gov/ (accessed on 1 September 2001).

- Ellen MacArthur Foundation. Growth within: A Circular Economy Vision for a Competitive Europe. 2015. Available online: https://ellenmacarthurfoundation.org/growth-within-a-circular-economy-vision-for-a-competitive-europe (accessed on 1 June 2015).

- Moe, S.T.; Roring, A. Theory and Practice of Flotation Deinking, in Research Forum on Recycling, Proceedings, 55–60, 6th Research Forum on Recycling, Magog, Que., Canada. 2001. Available online: https://iranarze.ir/wp-content/uploads/2016/07/4390-English.pdf (accessed on 4 October 2001).

- Beneventi, D.; Almeida, F.; Marlin, N.; Curtil, D.; Salgueiro, L.; Aurousseau, M. Hydrodynamics and recovered papers deinking in an ozone flotation column. Chem. Eng. Process. Process Intensif. 2009, 48, 1517–1526. [Google Scholar] [CrossRef]

- Da Silva, L.M.; Jardim, W.F. Trends and strategies of ozone application in environmental problems. Quim. Nova 2006, 29, 310–317. [Google Scholar] [CrossRef]

- Bajpai, P. Recycling and Deinking of Recovered Paper, Recycling and Deinking of Recovered Paper; Elsevier: Amsterdam, The Netherlands, 2014. [Google Scholar]

- CEPI. En 643 European List of Standard Grades of Paper and Board for Recycling. 2013. Available online: https://prn.nl/wp-content/uploads/2019/01/CEPI_EN-643_brochure_FINAL_0.pdf (accessed on 29 November 2013).

- Maslennikov, A.; Peretz, R.; Vadivel, V.K.; Mamane, H. Recycled Paper Sludge (RPS)-Derived Nanocellulose: Production, Detection and Water Treatment Application. Appl. Sci. 2022, 12, 3077. [Google Scholar] [CrossRef]

- Peretz, R.; Sterenzon, E.; Gerchman, Y.; Vadivel, V.V.; Luxbacher, T.; Mamane, H. Nanocellulose production from recycled paper mill sludge using ozonation pretreatment followed by recyclable maleic acid hydrolysis. Carbohydr. Polym. 2019, 216, 343–351. [Google Scholar] [CrossRef]

- Annamalai, N.; Al Battashi, H.; Anu, S.N.; Al Azkawi, A.; Al Bahry, S.; Sivakumar, N. Enhanced bioethanol production from waste paper through separate hydrolysis and fermentation. Waste Biomass-Valorization 2020, 11, 121–131. [Google Scholar] [CrossRef]

- Marques, S.; Alves, L.; Roseiro, J.C.; Gırio, F.M. Conversion of recycled paper sludge to ethanol by SHF and SSF using Pichia stipitis. Biomass Bioenergy 2008, 32, 400–406. [Google Scholar] [CrossRef]

- Schroeder, B.G.; Zanoni, P.R.S.; Magalhaes, W.L.E.; Hansel, F.A.; Tavares, L.B.B. Evaluation of biotechnological processes to obtain ethanol from recycled paper sludge. J. Mater. Cycles Waste Manag. 2017, 19, 463–472. [Google Scholar] [CrossRef]

- Srivastava, V.; Ismail, S.A.; Singh, P.; Singh, R.P. Urban solid waste management in the developing world with emphasis on India: Challenges and opportunities. Rev. Environ. Sci. Biotechnol. 2015, 14, 317–337. [Google Scholar] [CrossRef]

- Joshi, R.; Ahmed, S. Status and challenges of municipal solid waste management in India: A review. Cogent Environ. Sci. 2016, 2, 1139434. [Google Scholar] [CrossRef]

- Kawai, K.; Tasaki, T. Revisiting estimates of municipal solid waste generation per capita and their reliability. J. Mater. Cycles Waste Manag. 2016, 18, 1–13. [Google Scholar] [CrossRef]

- Alfaia, R.G.D.S.M.; Costa, A.M.; Campos, J.C. Municipal solid waste in Brazil: A review. Waste Manag. Res. 2017, 35, 1195–1209. [Google Scholar] [CrossRef] [PubMed]

- Statista website. Production of Processed Paper and Cardboard in China from January 2020 to March 2023. Available online: https://www.statista.com/statistics/226467/production-of-paper-and-cardboard-in-china-by-month/ (accessed on 22 January 2024).

- Badran, M.F.; El-Haggar, S.M. Optimization of municipal solid waste management in Port Said—Egypt. Waste Manag. 2006, 26, 534–545. [Google Scholar] [CrossRef]

- Beylot, A.; Muller, S.; Descat, M.; Ménard, Y.; Villeneuve, J. Life cycle assessment of the French municipal solid waste incineration sector. Waste Manag. 2018, 80, 144–153. [Google Scholar] [CrossRef]

- Nelles, M.; Grünes, J.; Morscheck, G. Waste Management in Germany—Development to a Sustainable Circular Economy? Procedia Environ. Sci. 2016, 35, 6–14. [Google Scholar] [CrossRef]

- Erkut, E.; Karagiannidis, A.; Perkoulidis, G.; Tjandra, S.A. A multicriteria facility location model for municipal solid waste management in North Greece. Eur. J. Oper. Res. 2008, 187, 1402–1421. [Google Scholar] [CrossRef]

- Mahanti, J.C. Clean India (Swacha Bharat) through Reuse and Recycling of Wastes. J. Pollut. Eff. Control 2017, 5, 1–6. [Google Scholar] [CrossRef]

- Rajaeifar, M.A.; Tabatabaei, M.; Ghanavati, H.; Khoshnevisan, B.; Rafiee, S. Comparative life cycle assessment of different municipal solid waste management scenarios in Iran. Renew. Sustain. Energy Rev. 2015, 51, 886–898. [Google Scholar] [CrossRef]

- Daskal, S.; Ayalon, O.; Shechter, M. The state of municipal solid waste management in Israel. Waste Manag. Res. 2018, 36, 527–534. [Google Scholar] [CrossRef]

- Chifari, R.; Renner, A.; Lo Piano, S.; Ripa, M.; Bukkens, S.G.F.; Giampietro, M. Development of a municipal solid waste management decision support tool for Naples, Italy. J. Clean. Prod. 2017, 161, 1032–1043. [Google Scholar] [CrossRef]

- Durán Moreno, A.; Garcés Rodríguez, M.; Velasco, A.R.; Marín Enriquez, J.C.; Gutiérrez Lara, R.; Moreno Gutiérrez, A.; Delgadillo Hernández, N.A. Mexico city’s municipal solid waste characteristics and composition analysis. Rev. Int. Contam. Ambient. 2013, 29, 39–46. [Google Scholar]

- Masood, M.; Barlow, C.Y.; Wilson, D.C. An assessment of the current municipal solid waste management system in Lahore, Pakistan. Waste Manag. Res. 2014, 32, 834–847. [Google Scholar] [CrossRef] [PubMed]

- Magrinho, A.; Didelet, F.; Semiao, V. Municipal solid waste disposal in Portugal. Waste Manag. 2006, 26, 1477–1489. [Google Scholar] [CrossRef]

- Ouda, O.K.M.; Raza, S.A.; Al-Waked, R.; Al-Asad, J.F.; Nizami, A.S. Waste-to-energy potential in the western province of Saudi Arabia. J. King Saud Univ.—Eng. Sci. 2017, 29, 212–220. [Google Scholar] [CrossRef]

- Duc Luong, N.; Minh Giang, H.; Xuan Thanh, B.; The Hung, N. Challenges for municipal solid waste management practices in Vietnam. Waste Technol. 2013, 1, 17–21. [Google Scholar] [CrossRef]

- Zhang, D.; Keat, T.S.; Gersberg, R.M. A comparison of municipal solid waste management in Berlin and Singapore. Waste Manag. 2010, 30, 921–933. [Google Scholar] [CrossRef]

- Malinauskaite, J.; Jouhara, H.; Czajczyńska, D.; Stanchev, P.; Katsou, E.; Rostkowski, P.; Thorne, R.J.; Colón, J.; Ponsá, S.; Al-Mansour, F.; et al. Municipal solid waste management and waste-to-energy in the context of a circular economy and energy recycling in Europe. Energy 2017, 141, 2013–2044. [Google Scholar] [CrossRef]

- Friedrich, E.; Trois, C. Current and future greenhouse gas (GHG) emissions from the management of municipal solid waste in the eThekwini Municipality—South Africa. J. Clean. Prod. 2016, 112, 4071–4083. [Google Scholar] [CrossRef]

- Yildiz, S.; Yaman, C.; Demie, G.; Ozcan, H.K.; Coban, A.; Okten, H.E.; Sezer, K.; Goren, S. Characterization of Municipal Solid Waste in Istanbul, Turkey. Environ. Prog. Sustain. Energy 2013, 32, 676–680. [Google Scholar] [CrossRef]

- Arafat, H.A.; Jijakli, K. Modeling and comparative assessment of municipal solid waste gasification for energy production. Waste Manag. 2013, 33, 1704–1713. [Google Scholar] [CrossRef]

- Jeswani, H.K.; Azapagic, A. Assessing the environmental sustainability of energy recovery from municipal solid waste in the UK. Waste Manag. 2016, 50, 346–363. [Google Scholar] [CrossRef]

- EPA. Advancing Sustainable Materials Management: 2017 Facts Sheet. 2019. Available online: https://www.epa.gov/facts-and-figures-about-materials-waste-and-recycling/advancing-sustainable-materials-management (accessed on 1 November 2019).

- Tran, H.; Jones, A.K.; Grace, T.M. Understanding recovery boiler smelt runoff phenomena. TAPPI J. 2015, 14, 41–50. [Google Scholar] [CrossRef]

- Bajpai, P. Pulp and Paper Chemicals. In Pulp and Paper Industry-Chemicals; Elsevier: Amsterdam, The Netherlands, 2016; pp. 25–273. [Google Scholar]

- Monte, M.C.; Fuente, E.; Blanco, A.; Negro, C. Waste management from pulp and paper production in the European Union. Waste Manag. 2009, 29, 293–308. [Google Scholar] [CrossRef] [PubMed]

- Gomes, D.; Domingues, L.; Gama, M. Valorizing recycled paper sludge by a bioethanol production process with cellulase recycling. Bioresour. Technol. 2016, 216, 637–644. [Google Scholar] [CrossRef] [PubMed]

- Likon, M.; Trebe, P. Recent Advances in Paper Mill Sludge Management, in Industrial Waste; Show, K.Y., Guo, X., Eds.; InTech Open: London, UK, 2012; pp. 73–90. [Google Scholar]

- Goel, G.; Kalamdhad, A.S. An investigation on use of paper mill sludge in brick manufacturing. Constr. Build. Mater. 2017, 148, 334–343. [Google Scholar] [CrossRef]

- Simão, L.; Hotza, D.; Raupp-Pereira, F.; Labrincha, J.A.; Montedo, O.R.K. Wastes from pulp and paper mills—A review of generation and recycling alternatives. Cerâmica 2018, 64, 443–453. [Google Scholar] [CrossRef]

- Oladejo, J.; Shi, K.; Luo, X.; Yang, G.; Wu, T. A review of sludge-to-energy recovery methods. Energies 2019, 12, 60. [Google Scholar] [CrossRef]

- Mänttäri, M.; Viitikko, K.; Nyström, M. Nanofiltration of biologically treated effluents from the pulp and paper industry. J. Memb. Sci. 2006, 272, 152–160. [Google Scholar] [CrossRef]

- Wei, Y.; van Houten, R.T.; Borger, A.R.; Eikelboom, D.H.; Fan, Y. Minimization of excess sludge production for biological wastewater treatment. Water Res. 2003, 37, 4453–4467. [Google Scholar] [CrossRef] [PubMed]

- Thompson, G.; Swain, J.; Kay, M.; Forster, C.F. The treatment of pulp and paper mill effluent: A review. Bioresour. Technol. 2001, 77, 275–286. [Google Scholar] [CrossRef]

- Migneault, S.; Koubaa, A.; Riedl, B.; Nadji, H.; Deng, J.; Zhang, S.Y. Binderless fiberboard made from primary and secondary pulp and paper sludge. Wood Fiber Sci. 2011, 43, 180–193. [Google Scholar]

- Faubert, P.; Barnabé, S.; Bouchard, S.; Côté, R.; Villeneuve, C. Pulp and paper mill sludge management practices: What are the challenges to assess the impacts on greenhouse gas emissions? Resour. Conserv. Recycl. 2016, 108, 107–133. [Google Scholar] [CrossRef]

- Mahmood, T.; Elliott, A. A review of secondary sludge reduction technologies for the pulp and paper industry. Water Res. 2006, 40, 2093–2112. [Google Scholar] [CrossRef] [PubMed]

- Stoica, A.; Sandberg, M.; Holby, O. Energy use and recovery strategies within wastewater treatment and sludge handling at pulp and paper mills. Bioresour. Technol. 2009, 100, 3497–3505. [Google Scholar] [CrossRef]

- Krigstin, S.; Sain, M. Characterization and potential utilization of recycled paper mill sludge. Pulp Pap. Can. 2006, 107, 201–204. [Google Scholar]

- Ozola, Z.U.; Vesere, R.; Kalnins, S.N.; Blumberga, D. Paper Waste Recycling. Circular Economy Aspects. Environ. Clim. Technol. 2019, 23, 260–273. [Google Scholar] [CrossRef]

- Ellen MacArthur Foundation. Think2030—A Low-Carbon and Circular Industry in Europe, Policy Paper. Available online: https://think2030.eu/a-low-carbon-and-circular-industry-for-europe/ (accessed on 3 March 2021).

- Li, Y.; Ma, C. Circular economy of a papermaking park in China: A case study. J. Clean. Prod. 2015, 92, 65–74. [Google Scholar] [CrossRef]

- Borrello, M.; Altomonte, E.; Cambalo, L.; D’Amico, V.; Lombardi, A. Circular bioeconomy and the forest-wood sector: Bridging the gap between policies and disadvantaged forest areas. Appl. Sci. 2023, 13, 1349. [Google Scholar] [CrossRef]

- Preisner, M.; Smol, M.; Horttanainen, M.; Deviatkin, I.; Havukainen, J.; Klavins, M.; Ozola-Davidane, R.; Kruopienė, J.; Szatkowska, B.; Appels, L.; et al. Indicators for resource recovery monitoring within the circular economy model implementation in the wastewater sector. Environ. Manag. 2022, 304, 114261. [Google Scholar] [CrossRef] [PubMed]

- Hamm, U.; Schabel, S. Effluent-free papermaking: Industrial experiences and latest developments in the German paper industry. Water Sci. Technol. 2007, 55, 205–211. [Google Scholar] [CrossRef] [PubMed]

- Bokhary, A.; Tikka, A.; Leitch, M.; Liao, B. Membrane fouling prevention and control strategies in pulp and paper industry applications: A review. J. Membr. Sci. Res. 2018, 4, 181–197. [Google Scholar]

- Mänttäri, M.; Kuosa, M.; Kallas, J.; Nyström, M. Membrane filtration and ozone treatment of biologically treated effluents from the pulp and paper industry. J. Memb. Sci. 2008, 309, 112–119. [Google Scholar] [CrossRef]

- Ngan, S.L.; How, B.S.; Teng, S.Y.; Promentilla, M.A.B.; Yatim, P.; Er, A.C.; Lam, H.L. Prioritization of sustainability indicators for promoting the circular economy: The case of developing countries. Renew. Sustain. Energy Rev. 2019, 111, 314–331. [Google Scholar] [CrossRef]

- Molina-Sánchez, E.; Leyva-Díaz, J.C.; Cortés-García, F.J.; Molina-Moreno, V. Proposal of sustainability indicators for the waste management from the paper industry within the circular economy model. Water 2018, 10, 1014. [Google Scholar] [CrossRef]

- Rigamonti, L.; Mancini, E. Life cycle assessment and circularity indicators. Int. J. Life Cycle Assess. 2021, 26, 1937–1942. [Google Scholar] [CrossRef]

- Sánchez-Ortiz, J.; Rodríguez-Cornejo, V.; Del Río-Sánchez, R.; García-Valderrama, T. Indicators to measure efficiency in circular economies. Sustainability 2020, 12, 4483. [Google Scholar] [CrossRef]

- Perey, R.; Benn, S.; Agarwal, R.; Edwards, M. The place of waste: Changing business value for the circular economy. Bus. Strategy Environ. 2018, 27, 631–642. [Google Scholar] [CrossRef]

- Strezov, V.; Evans, T.J. Thermal processing of paper sludge and characterisation of its pyrolysis products. Waste Manag. 2009, 29, 1644–1648. [Google Scholar] [CrossRef]

- Al-Hasan, M. Effect of ethanol-unleaded gasoline blends on engine performance and exhaust emission. Energy Convers. Manag. 2003, 44, 1547–1561. [Google Scholar] [CrossRef]

- Douvartzides, S.; Coutelieris, F.; Tsiakaras, P. Exergy analysis of a solid oxide fuel cell power plant fed by either ethanol or methane. J. Power Sources 2004, 131, 224–230. [Google Scholar] [CrossRef]

- Ruan, R.; Zhang, Y.; Chen, P.; Liu, S.; Fan, L.; Zhou, N.; Ding, K.; Peng, P.; Addy, M.; Cheng, Y.; et al. Biofuels: Introduction. In Biofuels: Alternative Feedstocks and Conversion Processes for the Production of Liquid and Gaseous Biofuels, 2nd ed.; Pandey, A., Larroche, C., Dussap, C.G., Gnansounou, E., Khanal, S.K., Ricke, S., Eds.; Elsevier Inc.: Amsterdam, The Netherlands, 2019; pp. 3–43. [Google Scholar]

- Halder, P.; Azad, K.; Shah, S.; Sarker, E. Prospects and technological advancement of cellulosic bioethanol ecofuel production. In Advances in Eco-Fuels for a Sustainable Environment; Azad, K., Ed.; Elsevier: Amsterdam, The Netherlands, 2019; pp. 211–236. [Google Scholar]

- Sebayang, A.H.; Masjuki, H.H.; Ong, H.C.; Dharma, S.; Silitonga, A.S.; Mahlia, T.M.I.; Aditiya, H.B. A perspective on bioethanol production from biomass as alternative fuel for spark ignition engine. RSC Adv. 2016, 6, 14964–14992. [Google Scholar] [CrossRef]

- Ximenes, E.; Kim, Y.; Mosier, N.; Dien, B.; Ladisch, M. Deactivation of cellulases by phenols. Enzym. Microb. Technol. 2011, 48, 54–60. [Google Scholar] [CrossRef] [PubMed]

- Zheng, Y.; Pan, Z.; Zhang, R. Overview of biomass pretreatment for cellulosic ethanol production. Int. J. Agric. Biol. Eng. 2009, 2, 51–68. [Google Scholar]

- Haghighi Mood, S.; Hossein Golfeshan, A.; Tabatabaei, M.; Salehi Jouzani, G.; Najafi, G.H.; Gholami, M.; Ardjmand, M. Lignocellulosic biomass to bioethanol, a comprehensive review with a focus on pretreatment. Renew. Sustain. Energy Rev. 2013, 27, 77–93. [Google Scholar] [CrossRef]

- Sun, Y.; Cheng, J. Hydrolysis of lignocellulosic materials for ethanol production: A review. Bioresour. Technol. 2002, 83, 1–11. [Google Scholar] [CrossRef] [PubMed]

- Bhutto, A.W.; Qureshi, K.; Harijan, K.; Abro, R.; Abbas, T.; Bazmi, A.A.; Karim, S.; Yu, G. Insight into progress in pre-treatment of lignocellulosic biomass. Energy 2017, 122, 724–745. [Google Scholar] [CrossRef]

- Banerjee, G.; Scott-Craig, J.S.; Walton, J.D. Improving enzymes for biomass conversion: A basic research perspective. Bioenergy Res. 2010, 3, 82–92. [Google Scholar] [CrossRef]

- Minami, E.; Saka, S. Comparison of the decomposition behaviors of hardwood and softwood in supercritical methanol. J. Wood Sci. 2003, 49, 73–78. [Google Scholar] [CrossRef]

- Rosen, Y.; Maskennikov, A.; Trabelcy, B.; Gerchman, Y.; Mamane, H. Short ozonation for effective removal and detoxification of fermentation inhibitors resulting from thermal pretreatment. Renew. Energy 2022, 189, 1407–1418. [Google Scholar] [CrossRef]

- Alvira, P.; Tomás-Pejó, E.; Ballesteros, M.; Negro, M.J. Pretreatment technologies for an efficient bioethanol production process based on enzymatic hydrolysis: A review. Bioresour. Technol. 2010, 101, 4851–4861. [Google Scholar] [CrossRef] [PubMed]

- Muller, C.; Scapini, T.; Rempel, A.; Abaide, E.R.; Camargo, A.F.; Nazari, M.T.; Tadioto, V.; Bonatto, C.; Tres, M.V.; Zabot, L.M.; et al. Challenges and opportunities for third-generation ethanol production: A critical review. Eng. Microbiol. 2023, 3, 100056. [Google Scholar] [CrossRef]

- Hawaguchi, H.; Hasunuma, T.; Ogino, C.; Kondo, A. Bioprocessing of bio-based chemicals produced from lignocellulosic feedstocks. Curr. Opin. Biotechnol. 2016, 42, 30–39. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Z.; Macquarrie, D.J.; de Bruyn, M.; Budarin, V.L.; Hunt, A.J.; Gronnow, M.J.; Fan, J.; Shuttleworth, P.S.; Clark, J.H.; Matharu, A.S. Low-temperature microwave-assisted pyrolysis of waste office paper and the application of bio-oil as an Al adhesive. Green Chem. 2015, 17, 260–270. [Google Scholar] [CrossRef]

- Kumar, V.; Pathak, P.; Bhardwaj, N.K. Waste paper: An underutilized but promising source for nanocellulose mining. Waste Manag. 2020, 102, 281–303. [Google Scholar] [CrossRef]

- Gonzalez-Estrella, J.; Asato, C.M.; Jerke, A.C.; Stone, J.J.; Gilcrease, P.C. Effect of structural carbohydrates and lignin content on the anaerobic digestion of paper and paper board materials by anaerobic granular sludge. Biotechnol. Bioeng. 2017, 114, 951–960. [Google Scholar] [CrossRef]

- Schmitt, E.; Bura, R.; Gustafson, R.; Cooper, J.; Vajzovic, A. Converting lignocellulosic solid waste into ethanol for the State of Washington: An investigation of treatment technologies and environmental impacts. Bioresour. Technol. 2012, 104, 400–409. [Google Scholar] [CrossRef]

- Singh, Y.D.; Satapathy, K.B. Conversion of lignocellulosic biomass to bioethanol: An overview with a focus on pretreatment. Int. J. Eng. Technol. 2018, 15, 17–43. [Google Scholar] [CrossRef]

- He, M.; Yang, G.; Chen, J.; Ji, X.; Wang, Q. Production and characterization of cellulose nanofibrils from different chemical and mechanical pulps. J. Wood Chem. Technol. 2018, 38, 149–158. [Google Scholar] [CrossRef]

- Lahtinen, P.; Liukkonen, S.; Pere, J.; Sneck, A.; Kangas, H. A Comparative study of fibrillated fibers from different mechanical and chemical pulps. BioResources 2014, 9, 2115–2127. [Google Scholar] [CrossRef]

- Borrega, M.; Sixta, H. Purification of cellulosic pulp by hot water extraction. Cellulose 2013, 20, 2803–2812. [Google Scholar] [CrossRef]

- Koshijima, T.; Watanabe, T. Association between Lignin and Carbohydrates in Wood and Other Plant Tissues; Springer: Berlin/Heidelberg, Germany, 2003. [Google Scholar]

- Faruk, O.; Sain, M. Lignin in Polymer Composites, Lignin in Polymer Composites; Elsevier: Amsterdam, The Netherlands, 2016. [Google Scholar]

- Malakahmad, A.; Ahmad Basri, N.E.; Md Zain, S. Production of renewable energy by transformation of kitchen waste to biogas, case study of Malaysia. In Proceedings of the IEEE Symposium on Business, Engineering and Industrial Applications (ISBEIA), Langkawi, Malaysia, 25–28 September 2011; pp. 219–223. [Google Scholar]

- Prasetyo, J.; Park, E.Y. Waste paper sludge as a potential biomass for bio-ethanol production. Korean J. Chem. Eng. 2013, 30, 253–261. [Google Scholar] [CrossRef]

- Nishimura, H.; Tan, L.; Sun, Z.; Tang, Y.; Kida, K.; Morimura, S. Efficient production of ethanol from waste paper and the biochemical methane potential of stillage eluted from ethanol fermentation. Waste Manag. 2016, 48, 644–651. [Google Scholar] [CrossRef] [PubMed]

- Farghaly, A.; Elsamadony, M.; Ookawara, S.; Tawfik, A. Bioethanol production from paperboard mill sludge using acid-catalyzed bio-derived choline acetate ionic liquid pretreatment followed by fermentation process. Energy Convers. Manag. 2017, 145, 255–264. [Google Scholar] [CrossRef]

- Lin, Y.; Wang, D.; Wang, T. Ethanol production from pulp & paper sludge and monosodium glutamate waste liquor by simultaneous saccharification and fermentation in batch condition. Chem. Eng. J. 2012, 191, 31–37. [Google Scholar]

- Mussatto, S.I. Biomass Fractionation Technologies for a Lignocellulosic Feedstock Based Biorefinery; Elsevier: Amsterdam, The Netherlands, 2016. [Google Scholar]

- Elliston, A.; Collins, S.R.A.; Wilson, D.R.; Roberts, I.N.; Waldron, K.W. High concentrations of cellulosic ethanol achieved by fed batch semi simultaneous saccharification and fermentation of waste-paper. Bioresour. Technol. 2013, 134, 117–126. [Google Scholar] [CrossRef]

- Boshoff, S.; Gottumukkala, L.D.; van Rensburg, E.; Görgens, J. Paper sludge (PS) to bioethanol: Evaluation of virgin and recycle mill sludge for low enzyme, high-solids fermentation. Bioresour. Technol. 2016, 203, 103–111. [Google Scholar] [CrossRef] [PubMed]

- Wang, L.; Sharifzadeh, M.; Templer, R.; Murphy, R.J. Bioethanol production from various waste papers: Economic feasibility and sensitivity analysis. Appl. Energy. 2013, 111, 1172–1182. [Google Scholar] [CrossRef]

- TAPPI, Forming Handsheets for Physical Tests of Pulp (Reaffirmation of T 205 sp-02). 2006. Available online: https://www.tappi.org/content/sarg/t205.pdf (accessed on 11 July 2006).

- Rocha, J.M.T.S.; Alencar, B.R.A.; Mota, H.G.; Gouveia, E.R. Enzymatic hydrolysis of waste office paper for ethanol production by spathaspora passalidarum. Cellul. Chem. Technol. 2016, 50, 243–246. [Google Scholar]

- Marques, S.; Matos, C.T.; Girio, F.M.; Roseiro, J.C.; Santos, J.A.L. Lactic acid production from recycled paper sludge: Process intensification by running fed-batch into a membrane-recycle bioreactor. Biochem. Eng. J. 2017, 120, 63–72. [Google Scholar] [CrossRef]

- Duncan, S.M.; Alkasrawi, M.; Gurram, R.; Almomani, F.; Wiberley-Bradford, A.E.; Singsaas, E. Paper mill sludge as a source of sugars for use in the production of bioethanol and isoprene. Energies 2020, 13, 4662. [Google Scholar] [CrossRef]

- Annamalai, N.; Sivakumar, N.; Oleskowicz-popiel, P. Enhanced production of microbial lipids from waste office paper by the oleaginous yeast Cryptococcus curvatus. Fuel 2018, 217, 420–426. [Google Scholar] [CrossRef]

- Frias, M.; Vegas, I.; Virgil de la Villa, R.; Gimenez, R.G. Recycling of waste paper sludge in cements: Characterization and behavior of new eco-efficient matrices. In Integrated Waste Management; InTech Open: London, UK, 2011; pp. 302–318. [Google Scholar]

- Namdarimonfared, M.; Zilouei, H.; Tondro, H. Biological hydrogen production from paper mill effluent via dark fermentation in a packed bed biofilm reactor. Fuel 2023, 338, 127231. [Google Scholar] [CrossRef]

- Kolbl, S.; Forte-Tavcer, P.; Stres, B. Potential for valorization of dehydrated paper pulp sludge for biogas production: Addition of selected hydrolytic enzymes in semi-continuous anaerobic digestion assays. Energy 2017, 126, 326–334. [Google Scholar] [CrossRef]

- Gogoi, H.; Nirosha, V.; Jayakumar, A.; Prabhu, K.; Maitra, M.; Panjanathan, R. Paper mill sludge as a renewable substrate for the production of acetone-butanol-ethanol using Clostridium sporogenes NCIM 2337. Energy Sources Part A Recover. Util. Environ. Eff. 2018, 40, 39–44. [Google Scholar]

- Reckamp, J.M.; Garrido, R.A.; Satrio, J.A. Selective pyrolysis of paper mill sludge by using pretreatment processes to enhance the quality of bio-oil and biochar products. Biomass.-Bioenergy 2014, 71, 235–244. [Google Scholar] [CrossRef]

- Shi, T.; Liu, Y.; Yang, A.; Sun, S.; Shen, W.; Ren, J. Developing a novel gasification-based sludge-to-methanol utilization process and exergy-economic-environmental (3E) analysis. Energy Convers. Manag. 2022, 260, 115600. [Google Scholar] [CrossRef]

- Gurram, R.N.; Al-Shannag, M.; Lecher, N.J.; Duncan, S.M.; Singsaas, E.L.; Alkasrawi, M. Bioconversion of paper mill sludge to bioethanol in the presence of accelerants or hydrogen peroxide pretreatment. Bioresour. Technol. 2015, 192, 529–539. [Google Scholar] [CrossRef] [PubMed]

- Romani, A.; Del-Rio, P.G.; Rubira, A.; Jose Perez, M.; Garrote, G. Co-valorization of discarded wood pinchips and sludge from the pulp and paper industry for production of advanced biofuels. Ind. Crops Prod. 2024, 209, 117992. [Google Scholar] [CrossRef]

- Prasetyo, J.; Naruse, K.; Kato, T.; Boonchird, C.; Harashima, S.; Park, E.Y. Bioconversion of paper sludge to biofuel by simultaneous saccharification and fermentation using a cellulase of paper sludge origin and thermotolerant Saccharomyces cerevisiae TJ14. Biotechnol. Biofuels Bioprod. 2011, 4, 35. [Google Scholar] [CrossRef] [PubMed]

- Ko, C.-H.; Wang, Y.-N.; Chang, F.-C.; Chen, J.-J.; Chen, W.-H.; Hwang, W.-S. Potentials of lignocellulosic bioethanols produced from hardwood in Taiwan. Energy 2012, 44, 329–334. [Google Scholar] [CrossRef]

- Buzała, K.P.; Kalinowska, H.; Małachowska, E.; Przybysz, P. The utility of selected kraft hardwood and softwood pulps for fuel ethanol production. Ind. Crop. Prod. 2017, 108, 824–830. [Google Scholar] [CrossRef]

- Xavier, A.M.R.B.; Correia, M.F.; Pereira, S.R.; Evtuguin, D.V. Second-generation bioethanol from eucalypt sulphite spent liquor. Bioresour. Technol. 2010, 101, 2755–2761. [Google Scholar] [CrossRef] [PubMed]

- Johansson, E.; Xiros, C.; Larsson, C. Fermentation performance and physiology of two strains of Saccharomyces cerevisiae during growth in high gravity spruce hydrolysate and spent sulphite liquor. BMC Biotechnol. 2014, 14, 47. [Google Scholar] [CrossRef] [PubMed]

- Wang, W.; Kang, L.; Lee, Y.Y. Production of cellulase from Kraft paper mill sludge by Trichoderma Reesei Rut C-30. Appl. Biochem. Biotechnol. 2010, 161, 382–394. [Google Scholar] [CrossRef]

- EURACTIVE. EU Paper Recyclers ‘in Crisis’ as China Waste Import Ban Bites. 2019. Available online: https://www.euractiv.com/section/circular-economy/news/eu-paper-recyclers-in-crisis-as-china-waste-import-ban-bites/ (accessed on 27 August 2019).

- Rendon, M.; Espluga-Trenc, J.; Verd, J.M. Assessing the functional relationship between the formal and informal waste systems: A case-study in Catalonia (Spain). Waste Manag. 2021, 131, 483–490. [Google Scholar] [CrossRef]

- The Wall Street Journal. What Cardboard Prices Tell Us about the State of the Economy. 2023. Available online: https://www.wsj.com/business/the-rising-price-of-cardboard-a-positive-sign-for-the-economy-08908d0f (accessed on 13 December 2023).

- Sahin, B.; Yilmaz, H.; Ust, Y.; Guneri, A.F.; Gulsun, B. An approach for analysing transportation costs and a case study. Eur. J. Oper. Res. 2009, 193, 1–11. [Google Scholar] [CrossRef]

- Wu, W.; Hasagawa, T.; Fujimori, S.; Takahashi, K.; Oshiro, K. Assessment of bioenergy potential and associated costs in Japan for the 21st century. Renew. Energy 2020, 162, 308–321. [Google Scholar] [CrossRef]

- Simoes, F.; Rios-Devila, F.J.; Paiva, H.; Maljaee, H.; Morais, M.; Ferreira, V.M. Sustainability evaluation using a life cycle and circular economy approach in precast concrete with waste incorporation. Appl. Sci. 2021, 11, 11617. [Google Scholar] [CrossRef]

- Liuzzi, S.; Rubino, C.; Martellotta, F.; Stefanizzi, P. Sustainable materials from waste paper: Thermal and acoustical characterization. Appl. Sci. 2023, 13, 4710. [Google Scholar] [CrossRef]

- Donkor, K.O.; Gottumukkala, L.D.; Diedericks, D.; Gorgens, J.F. An advanced approach towards sustainable paper industries through simultaneous recovery of energy and trapped water from paper sludge. J. Environ. Chem. Eng. 2021, 9, 105471. [Google Scholar] [CrossRef]

- Haites, E. Carbon taxes and greenhouse gas emissions trading systems: What have we learned? Clim. Policy 2018, 18, 955–966. [Google Scholar] [CrossRef]

- Phillips, R.B.; Jameel, H.; Chang, H.M. Integration of pulp and paper technology with bioethanol production. Biotechnol. Biofuels 2013, 6, 13. [Google Scholar] [CrossRef]

- Wu, S.; Jameel, H.; Chang, H.M.; Phillips, R. Techno-economic analysis of the optimum softwood lignin content for the production of bioethanol in a repurposed kraft mill. BioResources 2014, 9, 6817–6830. [Google Scholar] [CrossRef]

- Rueda, C.; Marinova, M.; Paris, J.; Ruiz, G.; Coz, A. Technoeconomic assessment of different biorefinery approaches for a spent sulfite liquor. J. Chem. Technol. Biotechnol. 2016, 91, 2646–2653. [Google Scholar] [CrossRef]

- Petersen, A.M.; Daful, A.G.; Görgens, J.F. Technical, economic, and greenhouse gas reduction potential of combined ethanol fermentation and biofuel gasification-synthesis at sulphite pulping mills. Energy Fuels 2016, 30, 7387–7399. [Google Scholar] [CrossRef]

- Fan, Z.; Lynd, L.R. Conversion of paper sludge to ethanol, II: Process design and economic analysis. Bioprocess. Biosyst. Eng. 2007, 30, 35–45. [Google Scholar] [CrossRef]

| Compound | Chemical Composition (%) | |

|---|---|---|

| Softwoods | Hardwoods | |

| Cellulose | 40–44 | 45–50 |

| Hemicellulose | 25–29 | 25–35 |

| Lignin | 26–31 | 18–24 |

| Moisture (%) | 40–45 |

| Insoluble lignin (%) | 8.22 ± 0.22 |

| Soluble lignin (%) | 10.71 ± 2.21 |

| Crystalline cellulose (%) | 75.30 ± 20.20 |

| Ash (%) | 16.64 ± 2.21 |

| Country | Paper Production (MTons) | Paper Consumption (Million Metric Tons) | MSW (kg Capita−1 Day−1) | % Paper within MSW (% wt.) | Paper Recycling Rate (%) | References |

|---|---|---|---|---|---|---|

| Argentina | 1.3 | 1.9 | 1.2 | N/A | N/A | [66] |

| Australia | 3.4 | 3.5 | 1.8 | 6.7 | 53 | [3,66] |

| Belgium | 2.1 | 2.8 | 1.3 | N/A | 60 | [66] |

| Brazil | 14 | 9 | 1.1 | 13.1 | 63.4 | [67] |

| China | 125 | 109 | 1 | 8 | 35 | [66,68] |

| Egypt | 0.7 | 1.7 | 1.4 | 10 | N/A | [66,69] |

| France | 8 | 8.7 | 1.5 | 16.2 | 54 | [66,70] |

| Germany | 22.6 | 20.5 | 1.7 | 8.1 | 83 | [66,71] |

| Greece | 0.4 | 1 | 1.4 | 20 | 37 | [66,72] |

| India | 17 | 17 | 0.4 | 6 | 29 | [66,73] |

| Iran | 0.8 | 1.8 | 0.2 | 7.8 * | N/A | [66,74] |

| Israel | 0.4 | 0.9 | 1.7 | 24 | 39 | [75] |

| Italy | 8.9 | 10.5 | 1.4 | 19 | 46 | [66,76] |

| Japan | 26.1 | 26 | 0.9 | N/A | 72 | [66] |

| Korea | 11.6 | 9.5 | 1 | 35 | 85 | [66] |

| Malaysia | 1.8 | 3.1 | 0.9 | 17.8 | N/A | [64,66] |

| Mexico | 5.7 | 8.9 | 1 | 5.89 * | 7 | [66,77] |

| Pakistan | 0.9 | 1.4 | 0.7 | 2.4 | N/A | [64,66,78] |

| Portugal | 2.2 | 1.2 | 1.2 | 27 | 50 | [66,79] |

| Poland | 4.6 | 6.4 | 0.9 | 19.1 * | 34 | [66,78] |

| Russia | 8.5 | 6.9 | 0.9 | N/A | N/A | [66] |

| Saudi Arabia | 1.2 | 2.1 | 1.3 | 28.5 | N/A | [66,80] |

| Singapore | 0.1 | 0.5 | 0.9 | 21.2 | 40.3 | [64,66,81,82] |

| Spain | 6.2 | 6.7 | 1.3 | 27 | 59 | [66,83] |

| South Africa | 2.2 | 2.3 | 2 | 18.2 | 59 | [66,84] |

| Turkey | 3 | 4.9 | 1.1 | 15 | 38 | [66,85] |

| United Arab Emirates | 0.2 | 0.9 | 1.7 | 22 | N/A | [66,86] |

| UK | 3.7 | 8.9 | 1.3 | 10.5 | 56 | [66,87] |

| USA | 73 | 70 | 2 | 26 | 50 | [88] |

| Pre-Treatment Method | Advantages | Disadvantages |

|---|---|---|

| Steam explosion |

|

|

| Ozonolysis |

|

|

| Ammonia fiber Explosion |

|

|

| Organosolv |

|

|

| Concentrated acid |

|

|

| Diluted acid |

|

|

| Source | Cellulose | Hemicellulose | Lignin | References |

|---|---|---|---|---|

| Newspaper | 40–69 | 25–40 | 18–30 | [137,138,139] |

| Kraft paper | 57.3 | 9.9 | 20.8 | [134] |

| Corrugated cardboard | 53–57 | 10–13 | 21–22 | [137] |

| Office and copy paper | 57–63 | 16–21 | 0–6.5 | [137,139] |

| Paper towel | 53 | 13 | 18 | [137] |

| Paperboard SBB a | 64 | 20 | 5 | [137] |

| Paperboard SUB b | 43 | 12.5 | 24.3 | [137] |

| Bleached softwood kraft pulp | 82 | 16 | 0.6 | [140,141] |

| Bleached hardwood kraft pulp | 70–81 | 17–27 | 0.8–3 | [140,141] |

| Unbleached kraft pulp | 72 | 20 | 3–7 | [142,143] |

| Chemi-thermomechanical pulp (CTM) | 54 | 25 | 19–21 | [140,141] |

| Municipal solid waste (MSW) | 15 | 10 | 8.5–15 | [144,145] |

| Waste paper | 40–80 | 5–20 | 1–10 | [138,146,147] |

| Paperboard mill sludge (PMS) | 23.4–37 | 8.6–33 | 16.5–24.5 | [141,148,149] |

| Lignocellulosic Source | Pre-Treatment | Ethanol Yield (L/Dry Ton Feedstock) | References |

|---|---|---|---|

| Recycled paper sludge (RPS) | Ozonation | 120 | [5] |

| Recycled paper sludge (RPS) | Sterilization (autoclaving with Sodium Azide) | 93–112 | [63] |

| Copy paper | None | 287 | [147] |

| Copier paper | None | 198 | [150] |

| Virgin pulp PS | None | 241 | [151] |

| Corrugated recycle PS | None | 214 | [151] |

| Newspaper | Oxidative lime: 1.875% w/w Ca(OH), 7.1 bar (absolute) O2, 140 °C, 3 h | 290 | [152] |

| Office paper | Diluted acid: 0.5% w/w H2SO4, 220 °C | 419 | [153] |

| Recycled paper sludge (RPS) | Ash removal (TAPPI, 1995) | 289–332 | [6,154] |

| Waste office paper | Diluted acid: 1% v/v H2SO4, 50 °C, 3 h | 206 | [155] |

| Raw Material | Ethanol Production (g/L) | Yield (%) | References |

|---|---|---|---|

| Recycled paper sludge | 14.9 | 9.44 | [5] |

| Recycled paper sludge | 5.6–6.3 | 67.9–76.8 | [63] |

| Virgin pulp sludge | 34.2 | 66.9 | [152] |

| Primary sludge | 25–30 | 94.5–95.7 | [165] |

| Primary sludge | 30.7–58.8 | 90 | [166] |

| Primary sludge | 37.2 | 23.5 | [167] |

| Kraft pulp | 30–38 | 16.8–20.2 | [7] |

| Kraft pulp | 5.88 | 4.5 | [168] |

| Kraft pulp | N/A | 12–20 | [169] |

| Spent sulfite liquor | 8.1 | 49 | [170] |

| Spent sulfite liquor | 9 | 25 | [171] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Or-Chen, D.; Gerchman, Y.; Mamane, H.; Peretz, R. Paper-Mill Wastes for Bioethanol Production in Relation to Circular Economy Concepts: A Review. Appl. Sci. 2024, 14, 1081. https://doi.org/10.3390/app14031081

Or-Chen D, Gerchman Y, Mamane H, Peretz R. Paper-Mill Wastes for Bioethanol Production in Relation to Circular Economy Concepts: A Review. Applied Sciences. 2024; 14(3):1081. https://doi.org/10.3390/app14031081

Chicago/Turabian StyleOr-Chen, Dafna, Yoram Gerchman, Hadas Mamane, and Roi Peretz. 2024. "Paper-Mill Wastes for Bioethanol Production in Relation to Circular Economy Concepts: A Review" Applied Sciences 14, no. 3: 1081. https://doi.org/10.3390/app14031081

APA StyleOr-Chen, D., Gerchman, Y., Mamane, H., & Peretz, R. (2024). Paper-Mill Wastes for Bioethanol Production in Relation to Circular Economy Concepts: A Review. Applied Sciences, 14(3), 1081. https://doi.org/10.3390/app14031081