Co-Design of Mechanical and Vibration Properties of a Star Polygon-Coupled Honeycomb Metamaterial

Abstract

1. Introduction

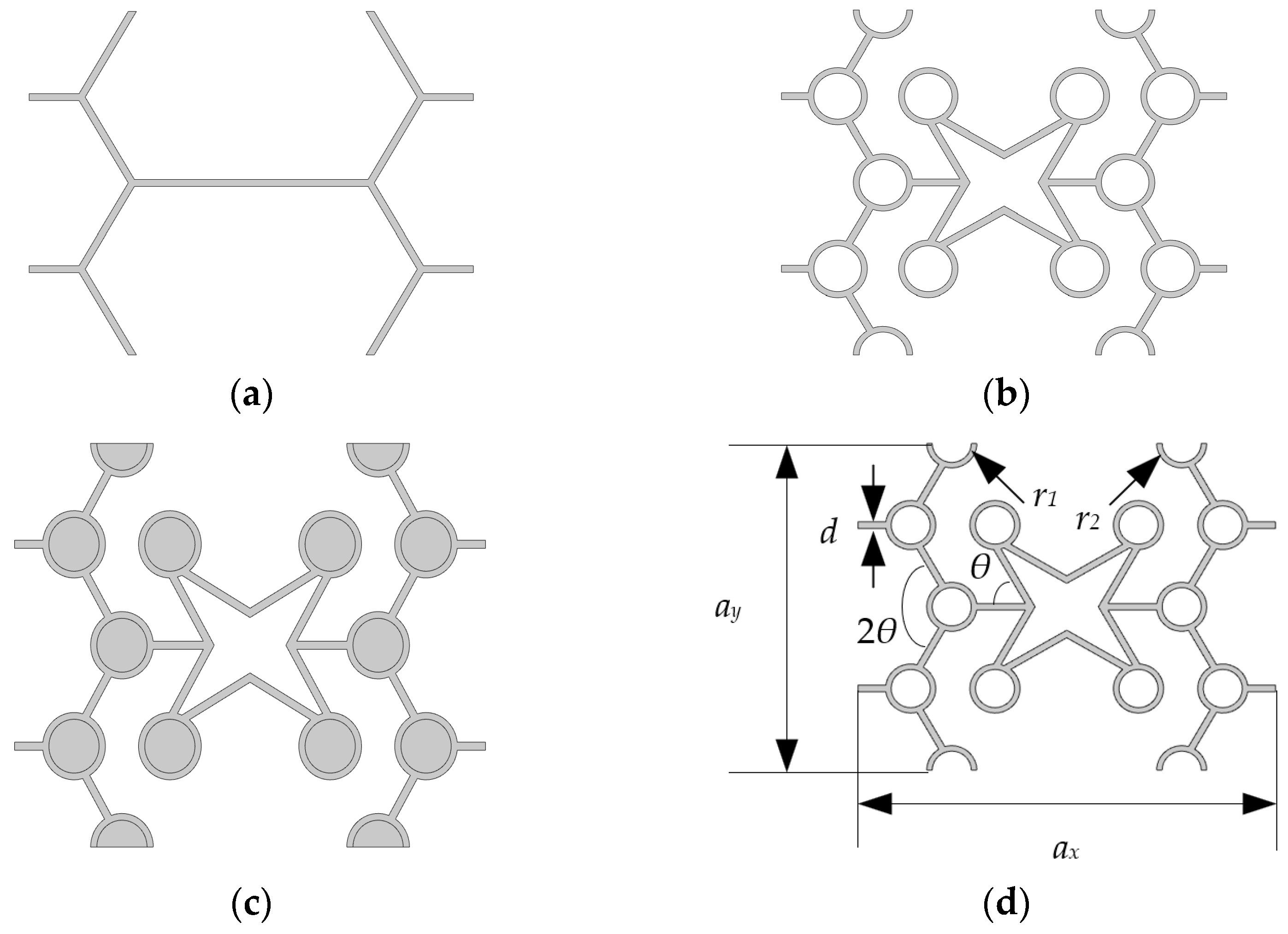

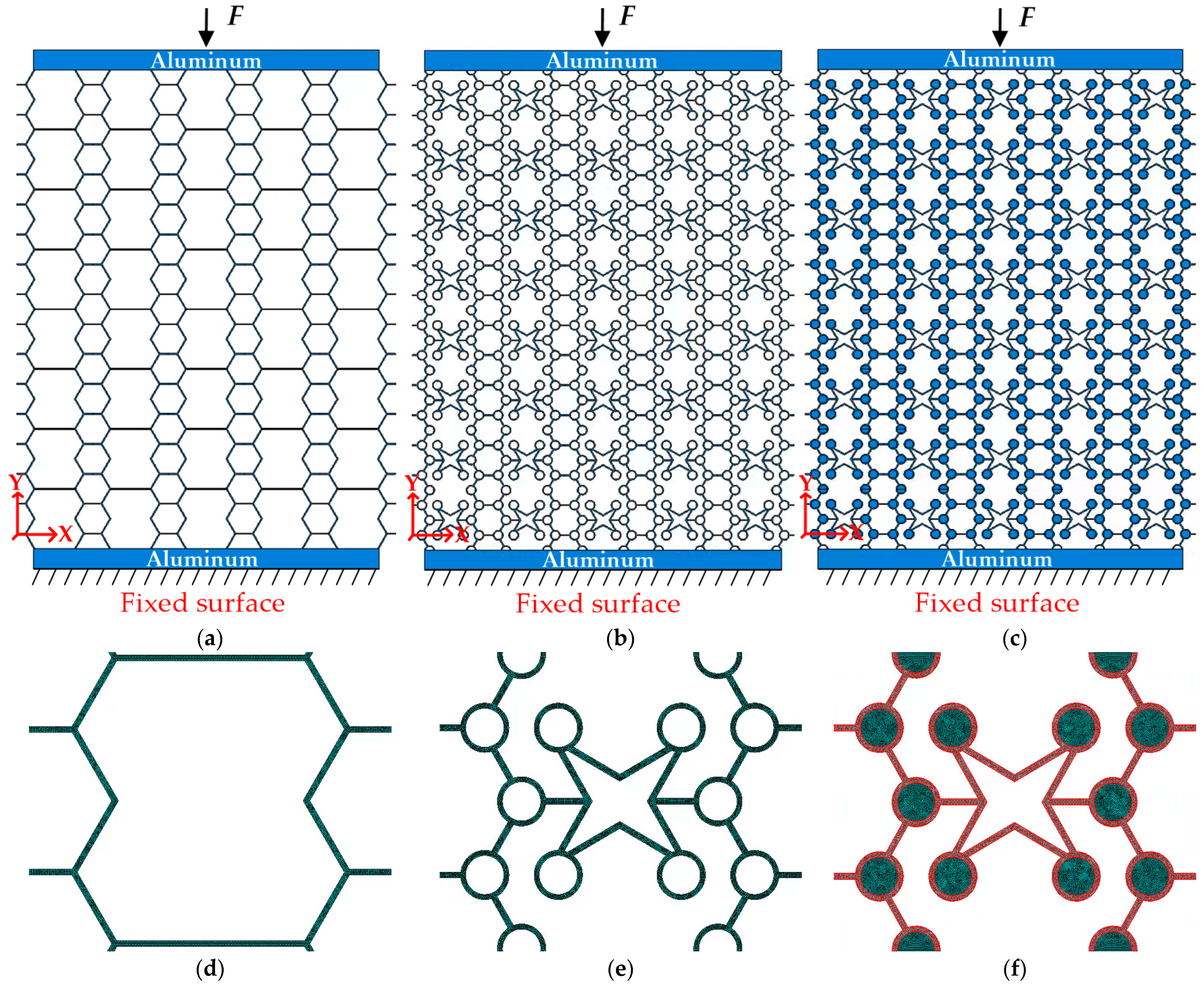

2. Structure Design of the Star Polygon-Coupled Honeycomb Metamaterial

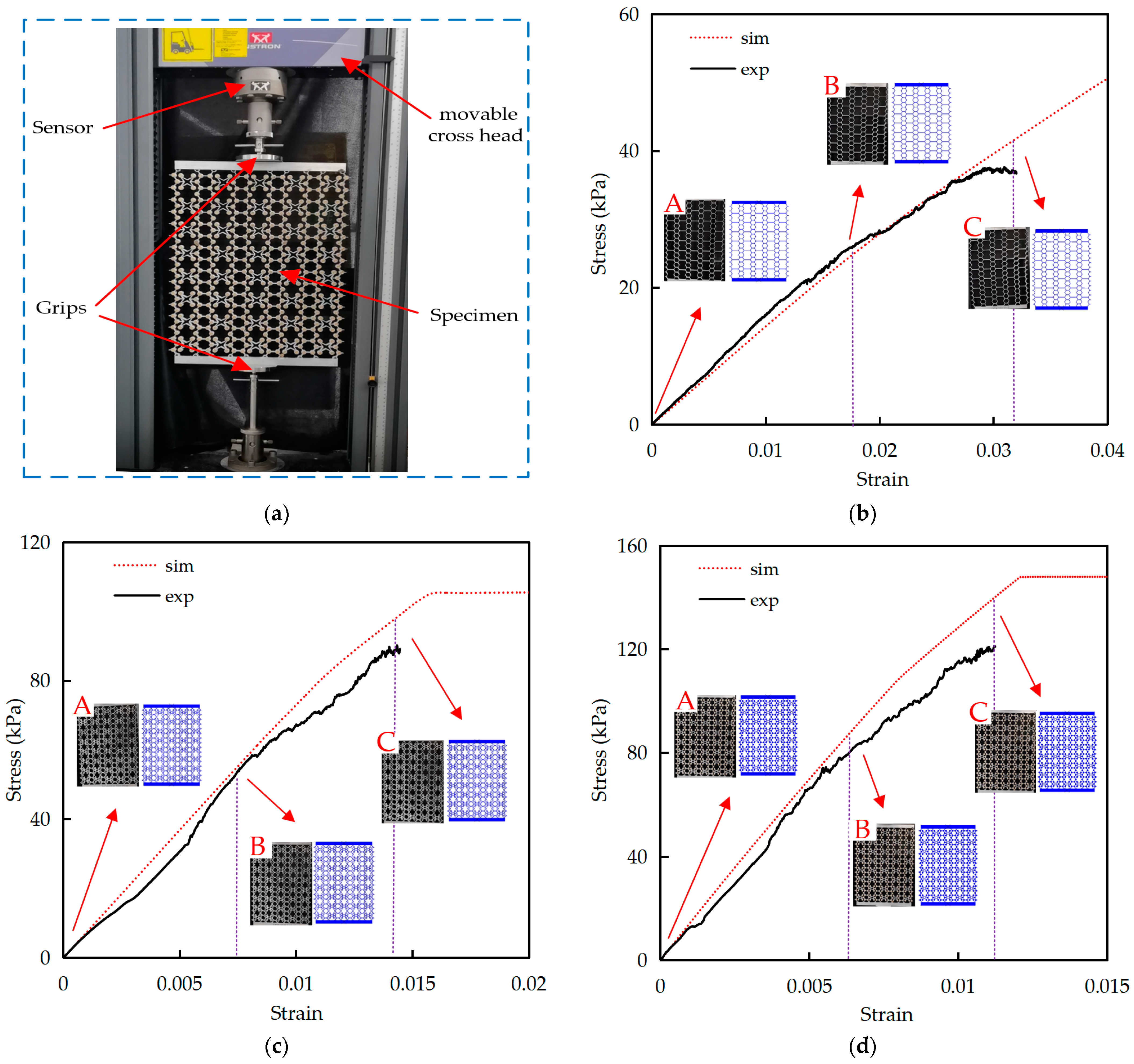

3. Stress–Strain Characteristics of the Metamaterials by Simulation and Experiment

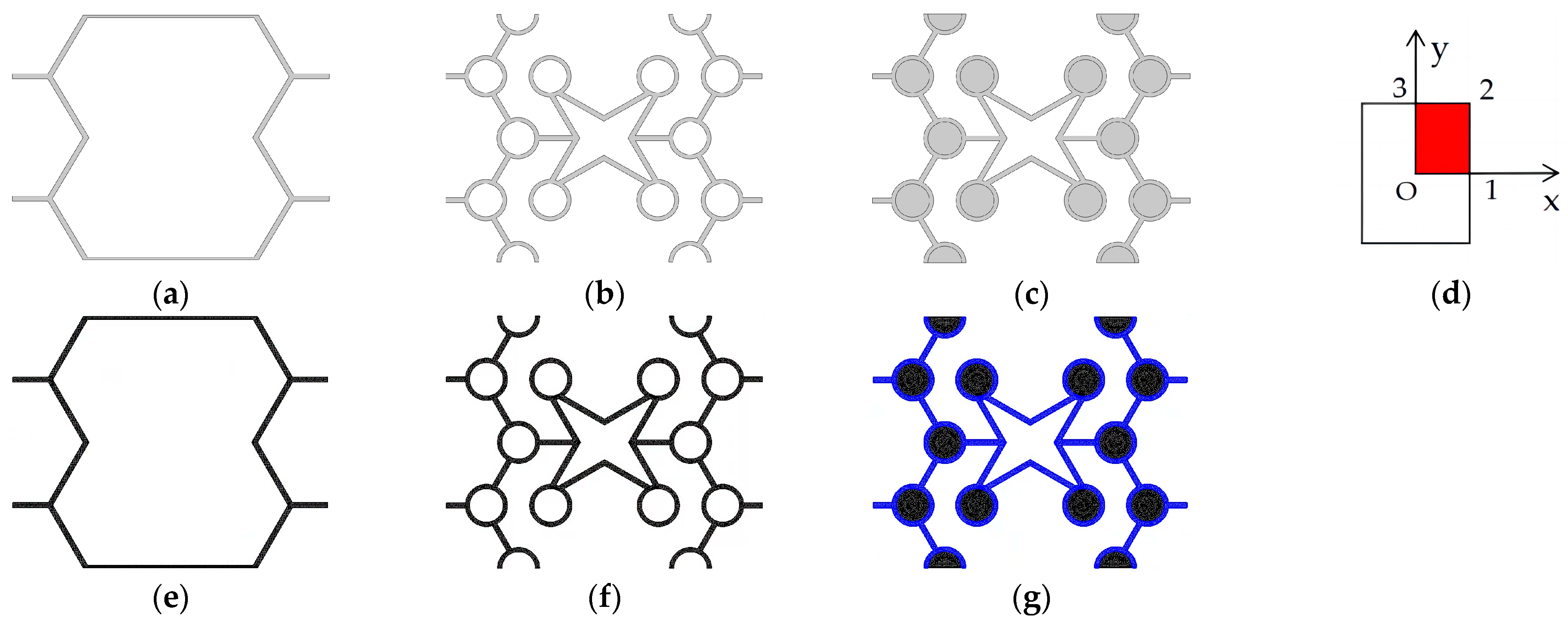

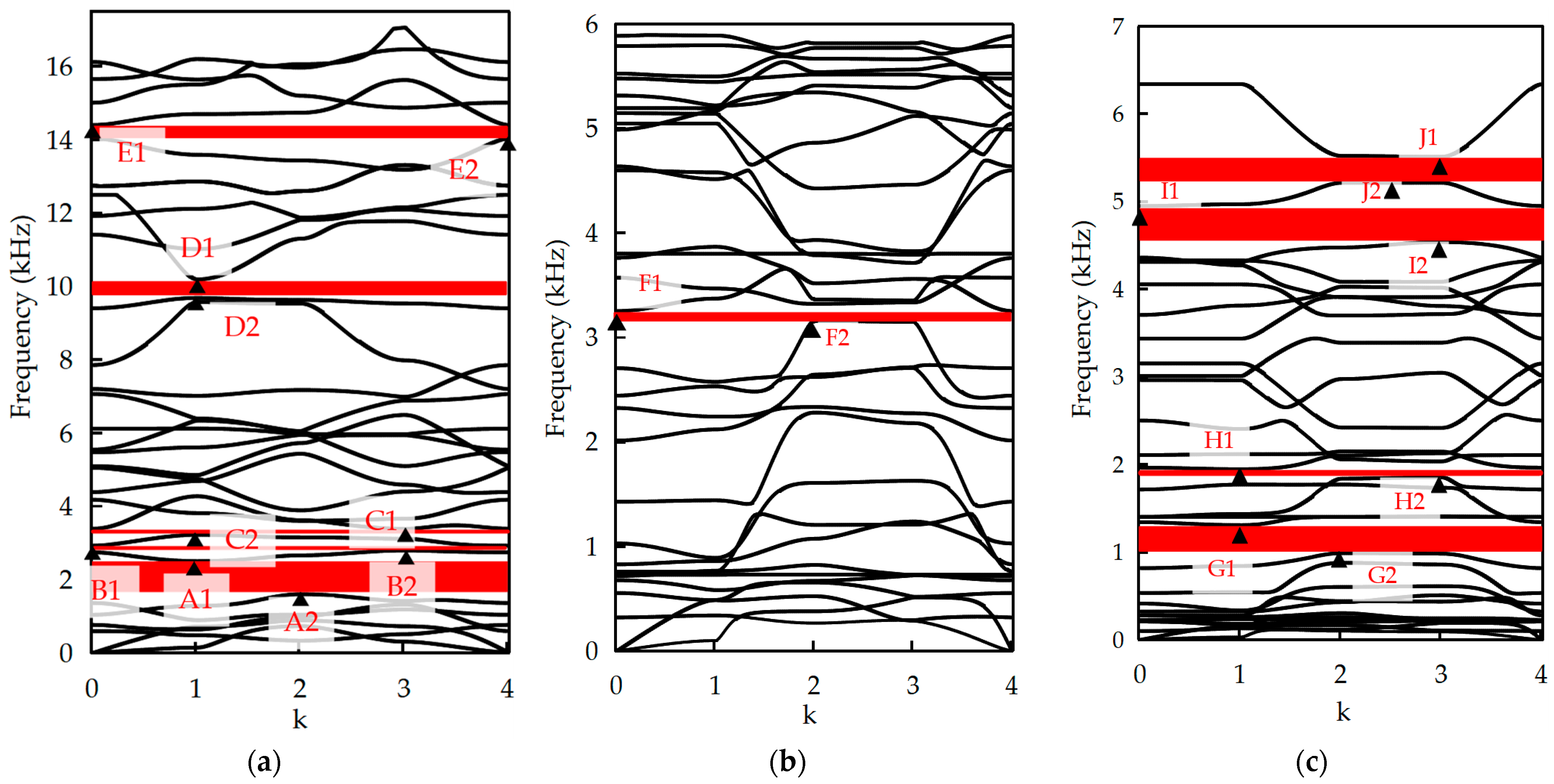

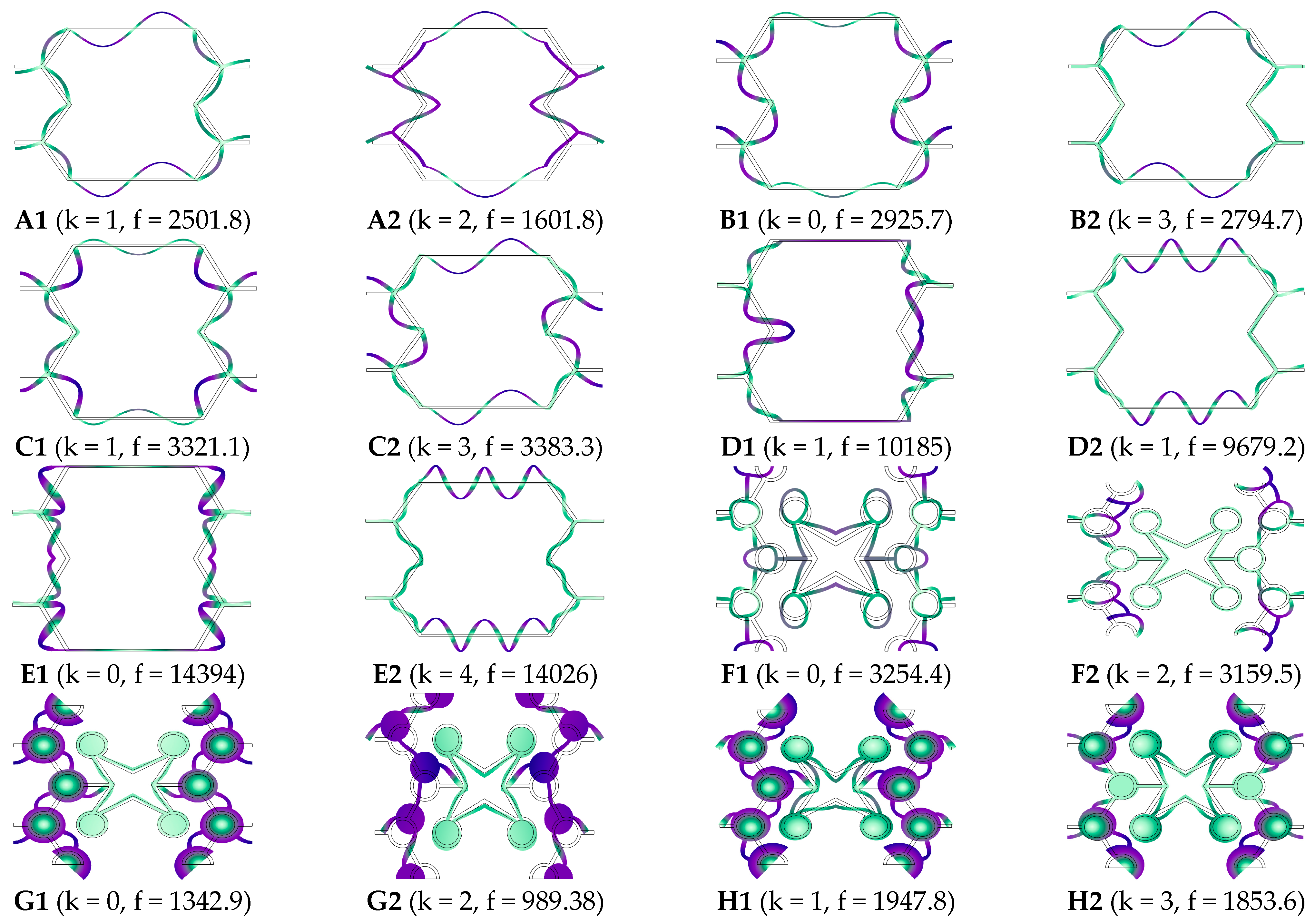

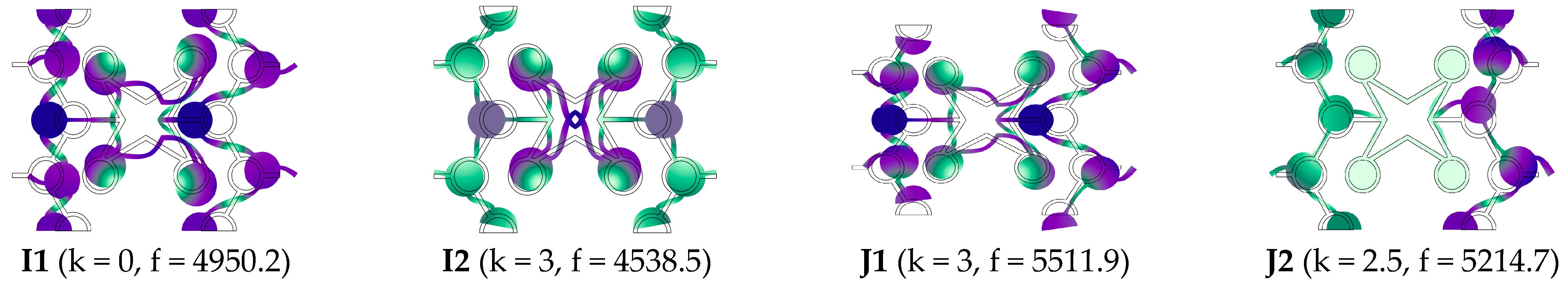

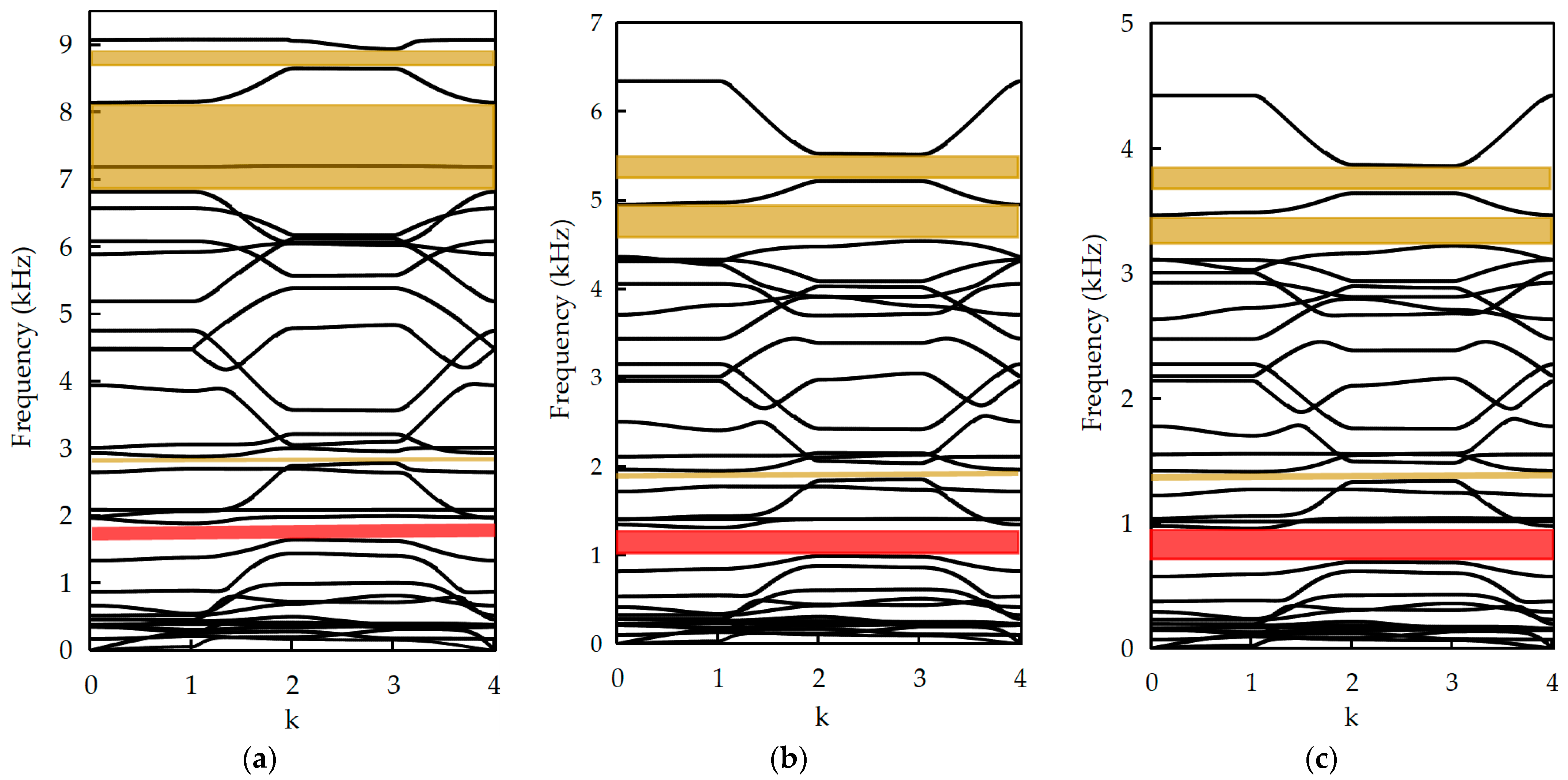

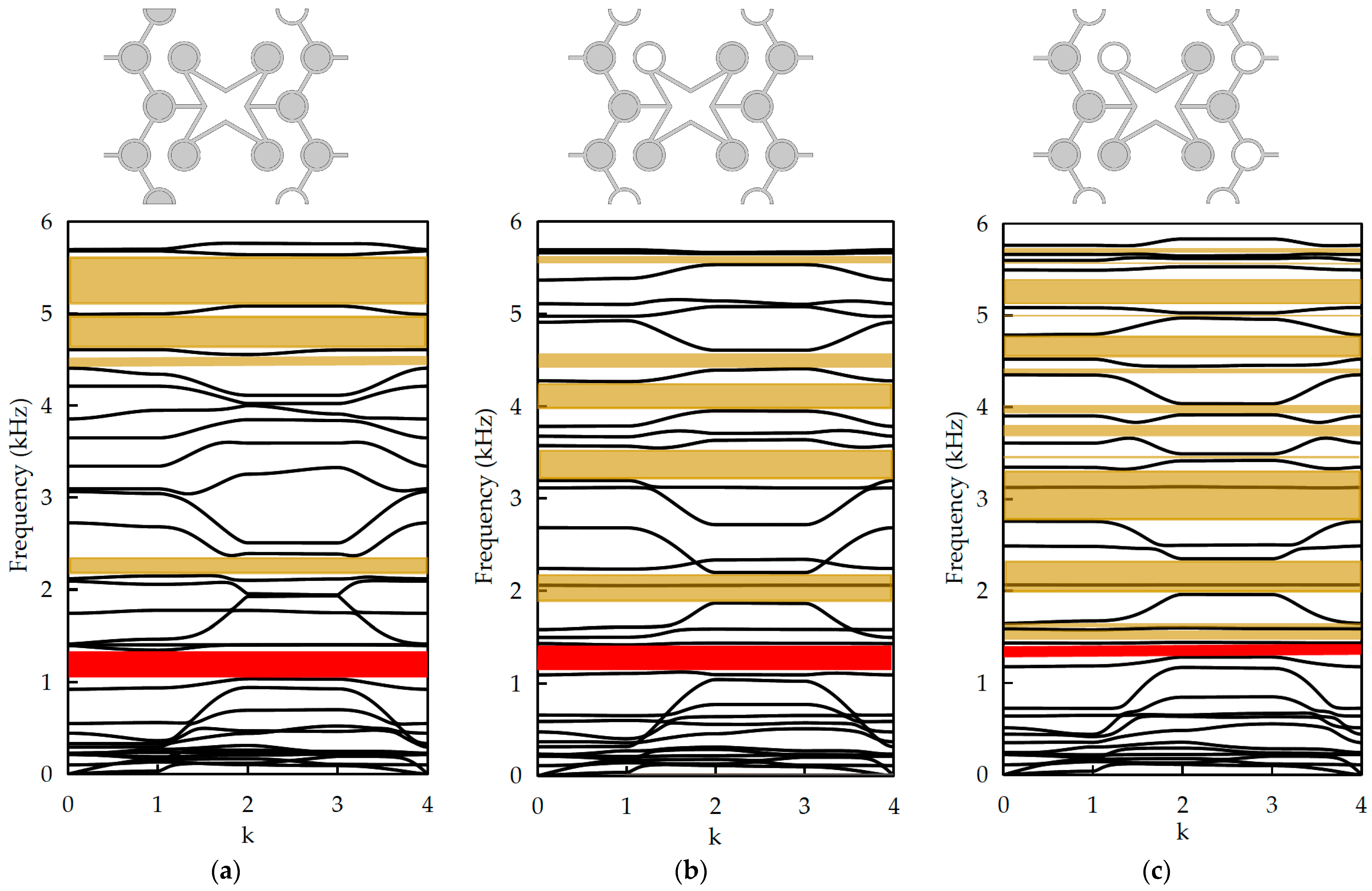

4. Comparison and Analysis of the Bandgap Properties

4.1. Calculation of Bandgap Properties

4.2. Comparison of Bandgap Properties between the IM and SPCHM

4.3. Effects of the Configuration Parameters

4.3.1. Materials of the Inserted Pins

4.3.2. Size of the Inserted Pins

4.3.3. Distribution of the Inserted Pins

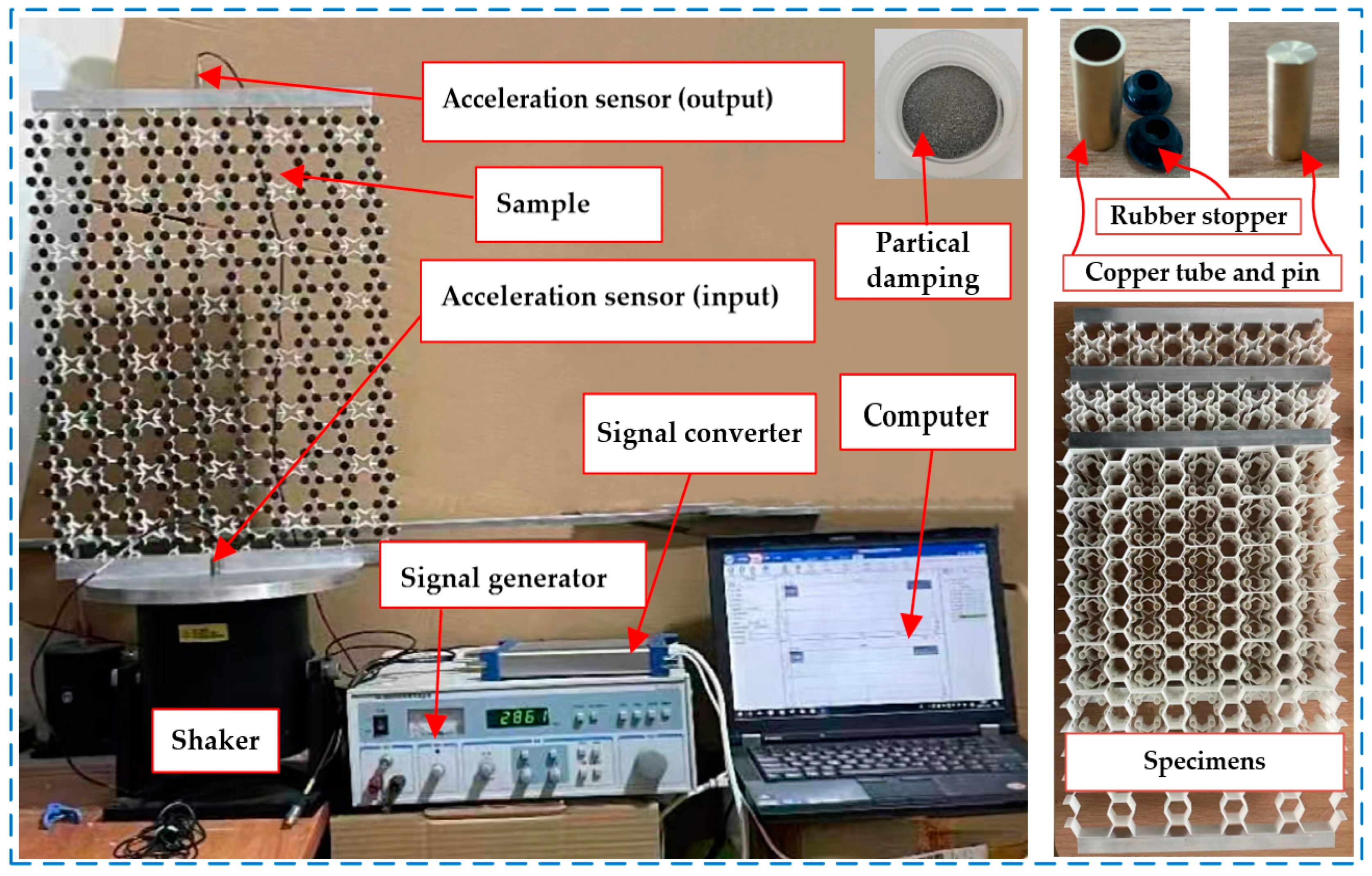

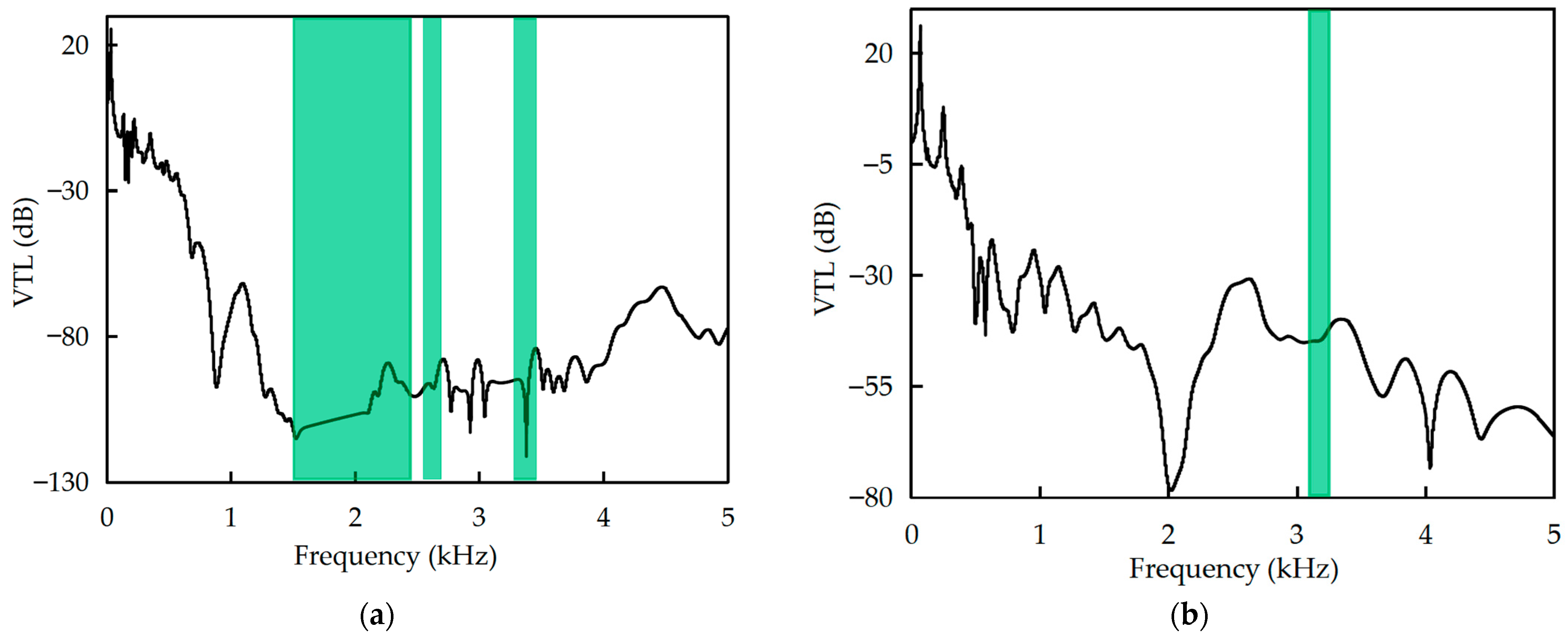

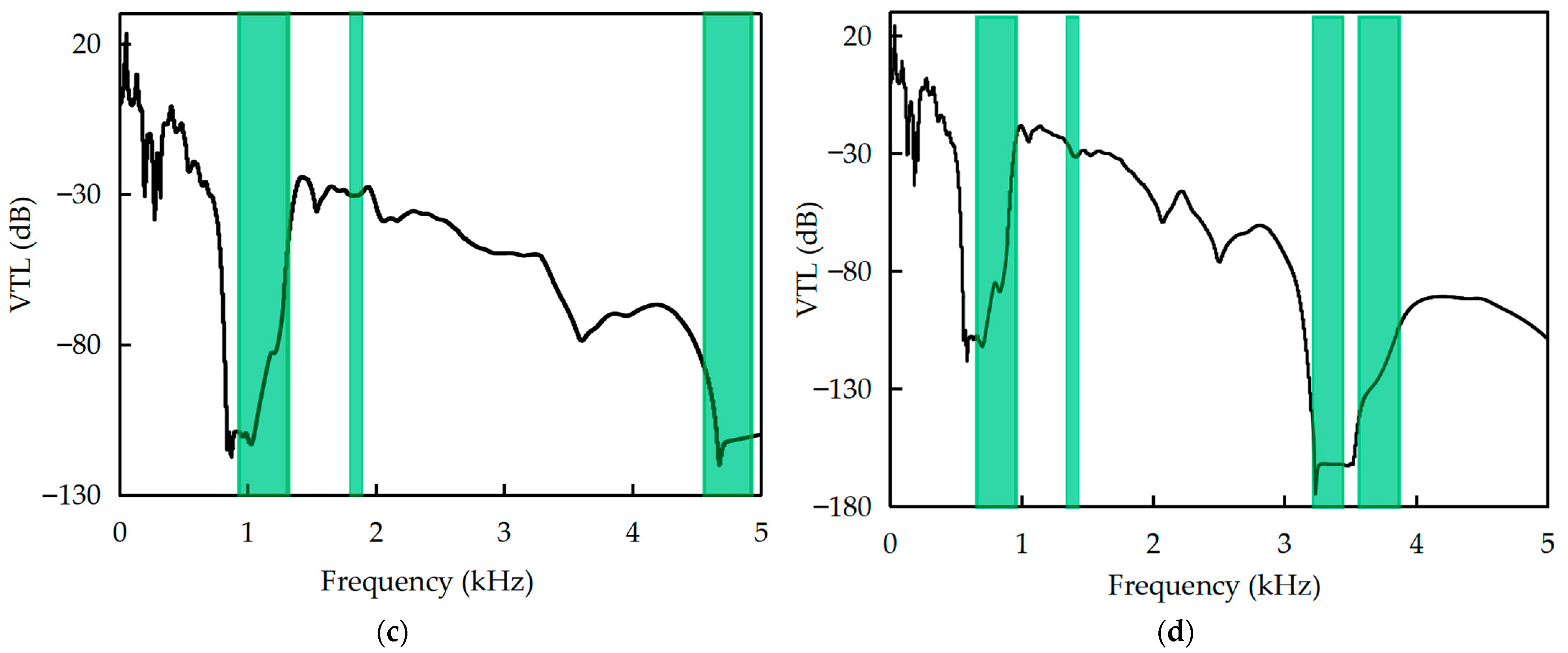

5. Evaluation of Vibration Suppression Performance by Simulation and Experiment

6. Conclusions

- (1)

- With the design of rings, the stiffness of the SPCHM has increased by 325% compared to that of the IM, while the mass of the SPCHM is only 23.8% heavier than that of the IM. Moreover, the stiffness of the SPCHM with copper pins has further increased by 62% on the basis of the SPCHM, and the mass of the SPCHM with copper pins is 335% heavier than that of the SPCHM. These features indicate a notable improvement in load-bearing capacity.

- (2)

- The bandgap properties could be effectively regulated by inserting different sizes and materials of pins, thereby improving the vibration suppression performance. Furthermore, more bandgaps will be generated by changing the number and position of pins.

- (3)

- The particle damping method has the advantage of replacing existing materials by designing an equal equivalent density, and it could even be used as a substitute for specific materials that exist in reality. Moreover, this feature makes it possible to adjust the bandgaps continuously, and the good adaptability of particles provides the potential to be applied in engineering applications with high precision requirements.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Li, K.; Zhang, Y.; Hou, Y.; Su, L.; Zeng, G.; Xu, X. Mechanical properties of re-entrant anti-chiral auxetic metamaterial under the in-plane compression. Thin-Walled Struct. 2023, 184, 110465. [Google Scholar] [CrossRef]

- Zhu, Y.; Jiang, S.; Zhang, Q.; Li, J.; Yu, C.; Zhang, C. A novel monoclinic auxetic metamaterial with tunable mechanical properties. Int. J. Mech. Sci. 2022, 236, 107750. [Google Scholar] [CrossRef]

- Tan, X.; Chen, S.; Wang, B.; Tang, J.; Wang, L.; Zhu, S.; Yao, K.; Xu, P. Real-time tunable negative stiffness mechanical metamaterial. Extreme Mech. Lett. 2020, 41, 100990. [Google Scholar] [CrossRef]

- Yang, H.; Ma, L. 1D to 3D multi-stable architected materials with zero Poisson’s ratio and controllable thermal expansion. Mater. Des. 2020, 188, 108430. [Google Scholar] [CrossRef]

- Tian, Z.; Shen, C.; Li, J.; Reit, E. Programmable Acoustic Metasurfaces. Adv. Funct. Mater. 2019, 29, 1808489. [Google Scholar] [CrossRef] [PubMed]

- Xie, Y.; Fu, Y.; Jia, Z.; Li, J.; Shen, C.; Xu, Y. Acoustic imaging with metamaterial luneburg lenses. Sci. Rep. 2018, 8, 16188. [Google Scholar] [CrossRef]

- Zhang, Z.; Wang, J.; Li, Z.; Zhang, X. Broadband Sound Insulation and Dual Equivalent Negative Properties of Acoustic Metamaterial with Distributed Piezoelectric Resonators. Materials 2022, 15, 4907. [Google Scholar] [CrossRef] [PubMed]

- Rupin, M.; Lerosey, G.; de Rosny, J.; Lemoult, F. Mimicking the cochlea with an active acoustic metamaterial. New J. Phys. 2019, 21, 093012. [Google Scholar] [CrossRef]

- Li, X.; Zhang, H.; Tian, H.; Huang, Y.; Wang, L. Frequency-tunable sound insulation via a reconfigurable and ventilated acoustic metamaterial. J. Phys. D 2022, 55, 495108. [Google Scholar] [CrossRef]

- Lv, J.; Zhou, M.; Gu, Q.; Jiang, X.; Ying, Y.; Si, G. Metamaterial Lensing Devices. Molecules 2019, 24, 2460. [Google Scholar] [CrossRef]

- Jafar-Zanjani, S.; Inampudi, S.; Mosallaei, H. Adaptive genetic algorithm for optical metasurfaces design. Sci. Rep. 2018, 8, 11040. [Google Scholar] [CrossRef]

- Pitchappa, P.; Kumar, A.; Prakash, S.; Jani, H.; Venkatesan, T.; Singh, R. Chalcogenide phase change material for active terahertz photonics. Adv. Mater. 2019, 31, 1808157. [Google Scholar] [CrossRef]

- Thabet, R.; Barkat, O. Transmission Spectra in One-dimensional Defective Photonic Crystal Integrating Metamaterial and Superconductor. J. Supercond. Nov. Magn. 2022, 35, 1473–1482. [Google Scholar] [CrossRef]

- Donnelly, E.; Durant, A.; Lacoste, C.; La Spada, L. Metamaterials for electromagnetic and thermal waves. In Proceedings of the 14th European Conference on Antennas and Propagation (EuCAP), Copenhagen, Denmark, 15–20 March 2020. [Google Scholar]

- Balbastre, J.; Nuño, L. Modelling the propagation of electromagnetic waves across complex metamaterials in closed structures. J. Comput. Appl. Math. 2019, 352, 40–49. [Google Scholar] [CrossRef]

- Cong, L.; Savinov, V.; Srivastava, Y.; Han, S.; Singh, R. A metamaterial analog of the Ising model. Adv. Mater. 2018, 30, 1804210. [Google Scholar] [CrossRef]

- Pak, M.; Kim, K.; Pak, H.; Hong, K. Influence of Geometric Structure, Convection, and Eddy on Sound Propagation in Acoustic Metamaterials with Turbulent Flow. Arch. Acoust. 2021, 46, 637–647. [Google Scholar]

- Zhang, Q. Unidirectional electromagnetic wave transmission in hyperbolic-gyroelectric metamaterials. In Proceedings of the Twelfth International Conference on Information Optics and Photonics, Xi’an, China, 1 November 2021. [Google Scholar]

- Liao, Y.; Huang, H.; Chang, G.; Luo, D.; Xu, C.; Wu, Y.; Tang, J. Research on Low-Frequency Noise Control of Automobiles Based on Acoustic Metamaterial. Materials 2022, 15, 3261. [Google Scholar] [CrossRef] [PubMed]

- Jung, J.; Kim, H.; Goo, S.; Chang, K.; Wang, S. Realisation of a locally resonant metamaterial on the automobile panel structure to reduce noise radiation. Mech. Syst. Signal Process. 2019, 122, 206–231. [Google Scholar] [CrossRef]

- Li, Y.; Huang, Z.; Xu, Y.; Zhang, H.; Wang, Q.; Qian, H.; Shang, W.; Deng, T.; Cui, K. Scalable-Manufactured Plasmonic Metamaterial with Omnidirectional Absorption Bandwidth across Visible to Far-Infrared. Adv. Funct. Mater. 2022, 32, 2207239. [Google Scholar] [CrossRef]

- Kumar, R.; Kumar, M.; Chohan, J.; Kumar, S. Overview on metamaterial: History, types and applications. Mater. Today Proc. 2022, 56, 3016–3024. [Google Scholar] [CrossRef]

- Zhang, X.; Li, Y.; Wang, Y.; Luo, Y. Ultra-wide low-frequency bandgap design of acoustic metamaterial via multi-material topology optimization. Compos. Struct. 2023, 306, 116584. [Google Scholar] [CrossRef]

- Liu, Y.; Yang, J.; Yi, X.; Guo, W.; Feng, Q. Dimitrios Chronopoulos, Enhanced vibration suppression using diatomic acoustic metamaterial with negative stiffness mechanism. Eng. Struct. 2022, 271, 114939. [Google Scholar] [CrossRef]

- Wang, X.; Wang, L.; Shu, H. Research on dual-functional properties of an improved piezoelectric metamaterial beam for simultaneous vibration suppression and energy harvesting. Appl. Phys. 2022, 128, 906. [Google Scholar] [CrossRef]

- Ye, M.; Gao, L.; Wang, F.; Li, H. A Novel Design Method for Energy Absorption Property of Chiral Mechanical Metamaterials. Materials 2021, 14, 5386. [Google Scholar] [CrossRef]

- Chen, S.; Tan, X.; Hu, J.; Wang, B.; Wang, L.; Zou, Y.; Wu, L. Continuous carbon fiber reinforced composite negative stiffness mechanical metamaterial for recoverable energy absorption. Compos. Struct. 2022, 288, 115411. [Google Scholar] [CrossRef]

- Alomarah, A.; Yuan, Y.; Ruan, D. A bio-inspired auxetic metamaterial with two plateau regimes: Compressive properties and energy absorption. Thin-Walled Struct. 2023, 192, 111175. [Google Scholar] [CrossRef]

- Zhang, Y.; Wang, Y.; Chen, C. Ordered deformation localization in cellular mechanical metamaterials. J. Mech. Phys. Solids 2019, 123, 28–40. [Google Scholar] [CrossRef]

- Dong, P.; Hou, R.; Hu, J.; Lin, C.; Liu, Y.; Qin, L. Novel self-similar re-entrant auxetic metamaterials (SREAM): Design, mechanical property, and geometric optimization. Polym. Test. 2023, 122, 108015. [Google Scholar] [CrossRef]

- Zhang, L.; Pan, F.; Ma, Y.; Yang, K.; Guo, S.; Chen, Y. Bistable reconfigurable origami metamaterials with high load-bearing and low state-switching forces. Extreme Mech. Lett. 2023, 63, 102064. [Google Scholar] [CrossRef]

- Zhang, X.; Ren, X.; Zhang, Y.; Xie, Y. A novel auxetic metamaterial with enhanced mechanical properties and tunable auxeticity. Thin-Walled Struct. 2022, 174, 109162. [Google Scholar] [CrossRef]

- He, H.; Li, Y.; Liu, Y.; Shi, D.Y.; Fan, H.L. Vibration suppression and impact mitigation of locally resonant composite metamaterial columns. Compos. Struct. 2023, 307, 116631. [Google Scholar] [CrossRef]

- Kim, H.-G.; Jeon, O.; Wang, S. A Numerical and Experimental Study on an Interconnected Metamaterial for Flexural Vibration Control Based on Modal Strain Energy. Appl. Sci. 2021, 11, 4530. [Google Scholar] [CrossRef]

- Bai, Y.; Li, X.; Zhou, X.; Li, P.; Beer, M. Soil-expended seismic metamaterial with ultralow and wide bandgap. Mech. Mater. 2023, 180, 104601. [Google Scholar] [CrossRef]

- Das, S.; Dwivedi, K.; Geetha Rajasekharan, S.; Daseswara Rao, Y.V. Vibration attenuation and bandgap characteristics in plates with periodic cavities. J. Vib. Control 2021, 27, 827–838. [Google Scholar] [CrossRef]

- Bae, M.; Oh, J. Nonlinear elastic metamaterial for tunable bandgap at quasi-static frequency. Mech. Syst. Signal Process. 2022, 170, 108832. [Google Scholar] [CrossRef]

- Yang, L.; Wang, L. An ultrawide-zero-frequency bandgap metamaterial with negative moment of inertia and stiffness. New J. Phys. 2021, 23, 043003. [Google Scholar] [CrossRef]

- Bera, K.; Banerjee, A. Ultra-wide bandgap in active metamaterial from feedback control. J. Vib. Control 2022, 28, 3598–3607. [Google Scholar] [CrossRef]

- Muhammad, S.; Wang, S.; Li, F.; Zhang, C. Bandgap enhancement of periodic nonuniform metamaterial beams with inertial amplification mechanisms. J. Vib. Control 2020, 26, 1309–1318. [Google Scholar] [CrossRef]

- Gerard, N.; Oudich, M.; Xu, Z.; Yao, D.; Cui, H.; Naify, C.; Ikei, A.; Rohde, C.; Zheng, X.; Jing, X. Three-Dimensional Trampolinelike Behavior in an Ultralight Elastic Metamaterial. Phys. Rev. Appl. 2021, 16, 024015. [Google Scholar] [CrossRef]

- Zhao, P.; Zhang, K.; Qi, L.; Deng, Z. 3D chiral mechanical metamaterial for tailored band gap and manipulation of vibration isolation. Mech. Syst. Signal Process. 2022, 180, 109430. [Google Scholar] [CrossRef]

- De Ponti, J.; Riva, E.; Ardito, R.; Braghin, F.; Corigliano, A. Wide low frequency bandgap in imperfect 3D modular structures based on modes separation. Mech. Res. Commun. 2020, 105, 103512. [Google Scholar] [CrossRef]

- Ma, N.; Han, Q.; Han, S.; Li, C. Hierarchical re-entrant honeycomb metamaterial for energy absorption and vibration insulation. Int. J. Mech. Sci. 2023, 250, 108307. [Google Scholar] [CrossRef]

- Zheng, X.; Luo, X.; Qiu, Y.; Hao, Z. Modeling and NVH Analysis of a Full Engine Dynamic Model with Valve Train System. Appl. Sci. 2020, 10, 5145. [Google Scholar] [CrossRef]

- Ghosh, A.; Chatterjee, S. An overview on various sources of vibration in electric vehicle and their identification techniques. J. Braz. Soc. Mech. Sci. Eng. 2023, 45, 401. [Google Scholar] [CrossRef]

- Liu, Z.; Yuan, S.; Xiao, S.; Du, S.; Zhang, Y.; Lu, C. Full Vehicle Vibration and Noise Analysis Based on Substructure Power Flow. Shock. Vib. 2017, 2017, 8725346. [Google Scholar] [CrossRef]

- Pizzo, L.; Bianco, F.; Moro, A.; Schiaffino, G.; Licitra, G. Relationship between tyre cavity noise and road surface characteristics on low-noise pavements. Transp. Res. Part D Transp. Environ. 2021, 98, 102971. [Google Scholar] [CrossRef]

| ax (mm) | ay (mm) | d (mm) | θ (°) | r1 (mm) | r2 (mm) |

|---|---|---|---|---|---|

| 75 | 60 | 1.2 | 60 | 4 | 5 |

| Material | Density (kg/m³) | Elastic Modulus (GPa) |

|---|---|---|

| WL8000 | 1120 | 2.65 |

| Aluminum | 2700 | 71 |

| Copper | 8960 | 117 |

| Tungsten | 19,350 | 411 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yong, J.; Li, W.; Hu, X.; Wan, Z.; Dong, Y.; Feng, N. Co-Design of Mechanical and Vibration Properties of a Star Polygon-Coupled Honeycomb Metamaterial. Appl. Sci. 2024, 14, 1028. https://doi.org/10.3390/app14031028

Yong J, Li W, Hu X, Wan Z, Dong Y, Feng N. Co-Design of Mechanical and Vibration Properties of a Star Polygon-Coupled Honeycomb Metamaterial. Applied Sciences. 2024; 14(3):1028. https://doi.org/10.3390/app14031028

Chicago/Turabian StyleYong, Jiawang, Wanting Li, Xiaojun Hu, Zhishuai Wan, Yiyao Dong, and Nenglian Feng. 2024. "Co-Design of Mechanical and Vibration Properties of a Star Polygon-Coupled Honeycomb Metamaterial" Applied Sciences 14, no. 3: 1028. https://doi.org/10.3390/app14031028

APA StyleYong, J., Li, W., Hu, X., Wan, Z., Dong, Y., & Feng, N. (2024). Co-Design of Mechanical and Vibration Properties of a Star Polygon-Coupled Honeycomb Metamaterial. Applied Sciences, 14(3), 1028. https://doi.org/10.3390/app14031028