Simulation and Optimization of Available Local Feed Resources for Dairy Cattle in Burkina Faso

Abstract

1. Introduction

2. Materials and Methods

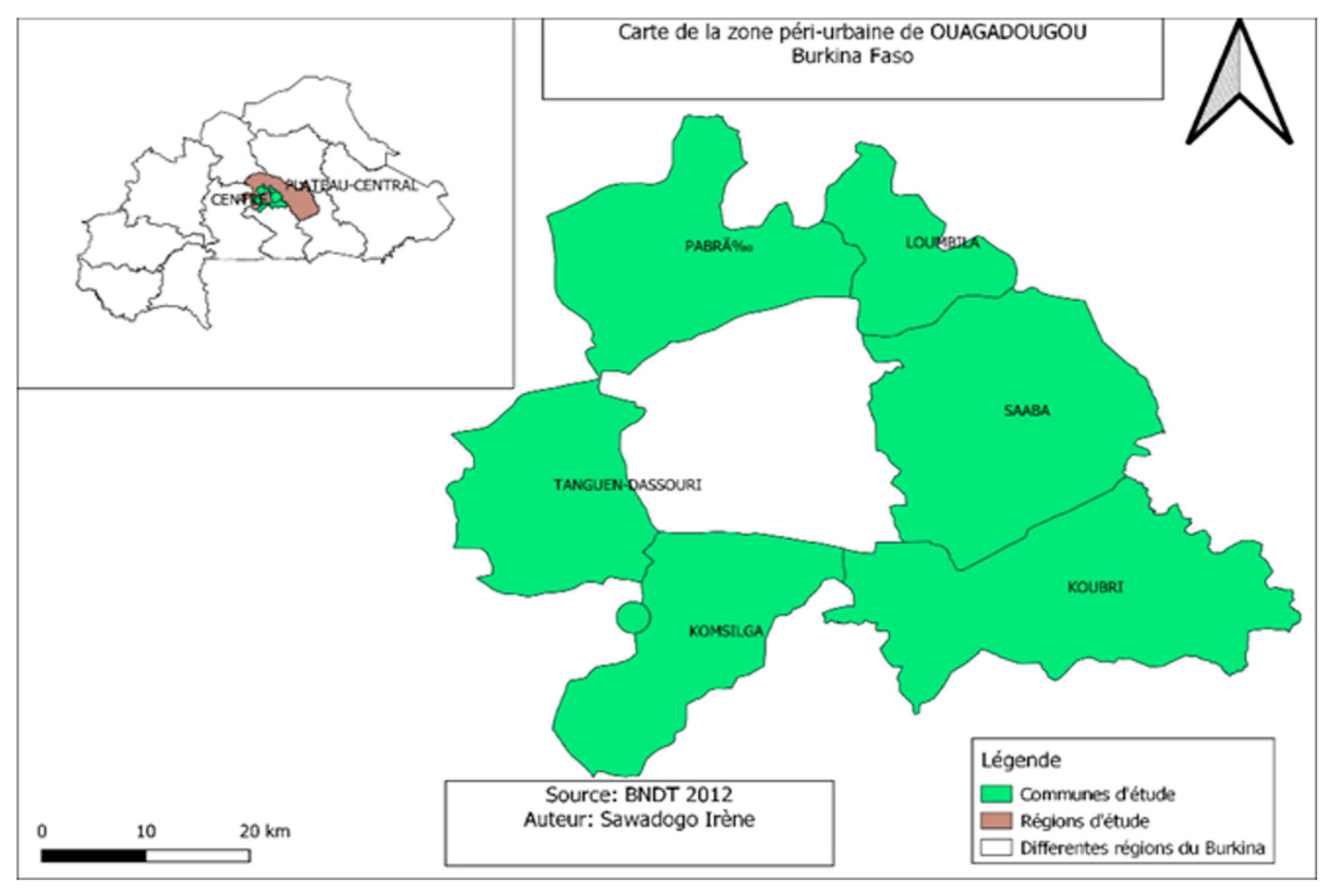

2.1. Farm Description

2.2. Questionnaire Design

2.3. Survey Procedure and Collection of Animal Feed Ingredients

2.4. Chemical Analysis of Various Animal Feed Ingredients

2.5. Statistical Analysis of Survey Data and Bromatological Analysis Data

2.6. Diet Formulation and Rationing Methodology Based on Survey Data

2.6.1. Diet Determination (Formulation or Calculation)

2.6.2. Pre-Setting

2.6.3. Dietary Assessment Methodology

2.6.4. Methods for Determining the Nutritional Value of Ingredients

2.6.5. Optimized Diets

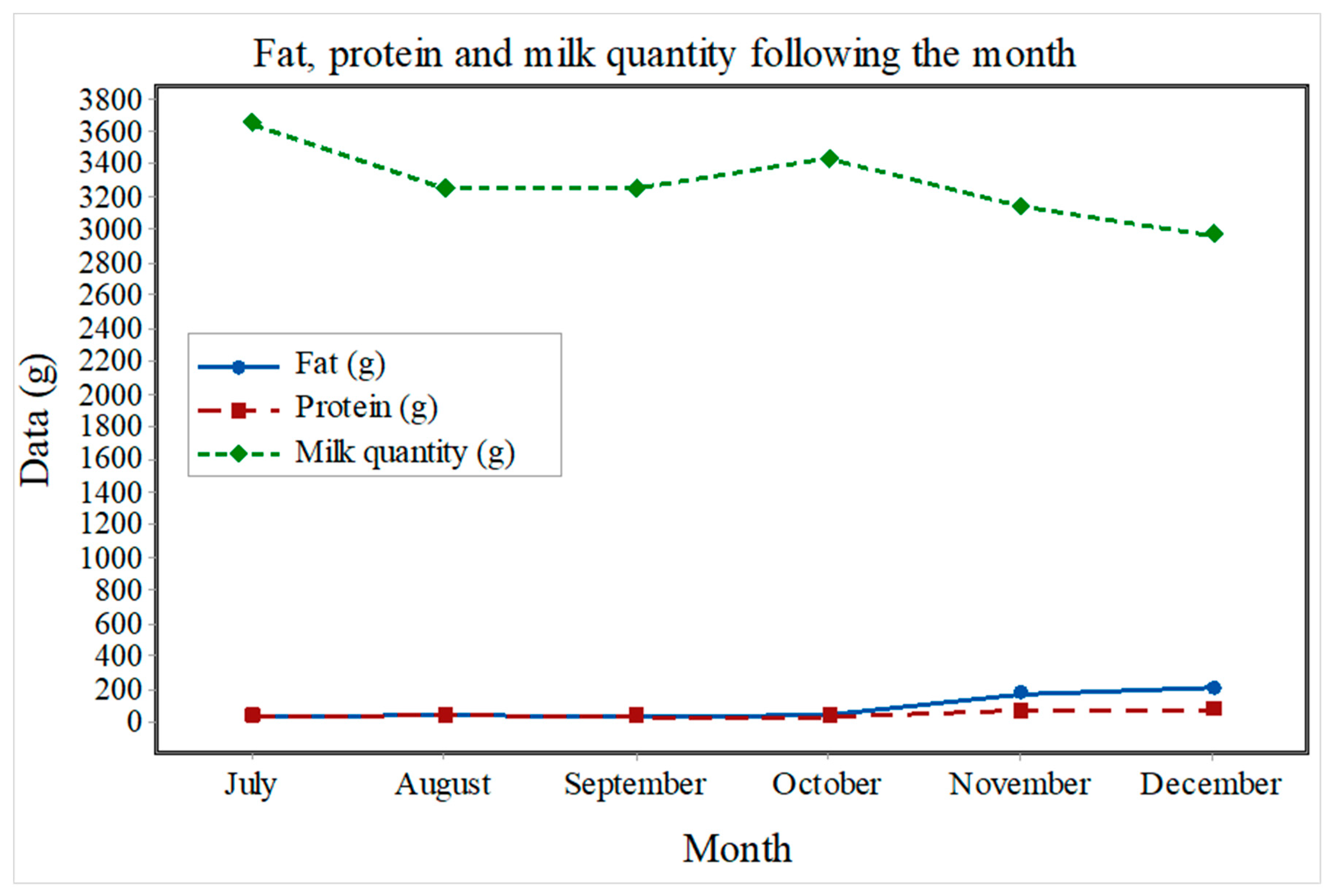

2.7. Monitoring of Milk Production on Farm

2.7.1. Milking Process

2.7.2. Milk Composition Chemical Analysis and Statistical Analysis of Milk’s Chemical Data

3. Results

3.1. Feed Ingredient Resources Used by Peri-Urban Farms of Ouagadougou

3.2. Feed Ingredients Chemical Composition

3.3. Nutritive Values of the Dominant Feed Ingredients

3.4. Comparison of Dairy Cattle Diets Requirements

3.5. Diet Suggestion for Dairy Cow of a Body Weight of 400 kg0.75

3.6. Amount of Ingredient Comparison Between On-Farm and Survey

3.7. Average Chemical Composition of Raw Milk from Dairy Farms

4. Discussion

4.1. Local Available Ingredient Nutritive Values

4.2. Simulation Diets and Suggestions

4.3. Raw Milk Yield and Chemical Composition Importance During Diet Calculation

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| ADF | Acid detergent fiber |

| ADL | Acid detergent lignin |

| AIBP | Agro-industrial by-products |

| AOAC | Association of Official Analytical Chemists |

| ANOVA | Analysis of variance |

| BC | Gross Cellulose |

| BCS | Body conditions score |

| BNTD | Base Nationale Topographiques data |

| °C | Celcius degree |

| CF | Crude fiber |

| CP | Crude protein |

| CREAF | Recherches Environnementales, Agricoles et de Formation |

| DM | Dry matter |

| DT | Theoretical degradability |

| dr | Actual digestibility |

| E | Evening |

| EM | Metabolizable energy |

| ENEC II | Enquête nationale de l’effectif du cheptel tome II |

| ENEV | Net energy for maintenance and meat production |

| ENL | Net energy for lactation |

| FC | Fat content |

| F | Fat |

| g | Gram |

| kcal | Kilo calorie |

| Kl | Output of métabolisable energy in clear energy for the production of milk |

| Kg | Kilogram |

| Kmf | Output of métabolisable energy in clear energy for maintenance |

| L | Lactose |

| L | Liter |

| M | Morning |

| mL | Milliliter |

| MM | Mineral matter |

| N | Nitrogen |

| NDF | Neutral detergent fiber |

| PC | Protein content |

| TNM | Total Nitrogen Matter |

| OM | Organic matter |

| MAT | Total nitrogenous matter |

| MOD | Digestible organic matter |

| MOF | Fermentable organic matter |

| Pm | Panicum maximum |

| PDIA | Digestible protein in the small intestine from feed |

| PDIE | Digestible protein in the intestine from available energy |

References

- Nallet, C. Identifier les Classes Moyennes Africaines: Diversité, Spécificités et Pratiques de Consommation Sous Contrainte; Ifri: Paris, France, 2015; 45p. [Google Scholar]

- Duteurtre, G.; Corniaux, C. Etude Relative à la Formulation du Programme D’actions Détaillé de Développement de la Filière Lait en Zone Uemoa; Uemoa/Cirad: Montpellier, France, 2013; 75p. [Google Scholar]

- MARAH/DGESS. Annuaire des Statistiques Agro-Sylvo-Pastorale; Ministère De L’agriculture des Ressources Animales et Halieutiques: Ouagadougou, Burkina Faso, 2022; 444p. [Google Scholar]

- Zoungrana, I. Recherches sur les Aires Pâturées du Burkina Faso. Ph.D. Thesis, Université de Bordeaux III, Pessac, France, 1991; 290p. [Google Scholar]

- Sanon, H.O.; Drabo, A.; Sangaré, M.; Kiendrebeogo, T.; Gomgnibou, A. Caractérisation des pratiques d’embouche bovine dans l’Ouest du Burkina Faso. J. Biol. Chem. Sci. 2014, 8, 536–550. [Google Scholar] [CrossRef]

- Kagoné, H. Gestion Durable des Écosystèmes Pâturés en Zone Nord-Soudanienne du Burkina Faso. Ph.D. Thesis, Faculté Universitaire des Sciences Agronomiques de Gembloux, Gembloux, Belgium, 2000; 113p. [Google Scholar]

- Coulibaly, D.; Moulin, C.H.; Poccard Chapuis, R.; Morin, G.; Sidibé, S.I.; Corniaux, C. Evolution des stratégies d’alimentation des élevages bovins dans le bassin d’approvisionnement en lait de la ville de Sikasso au Mali. Rev. D’élevage Méd. Vét. Pays Trop. 2007, 60, 103–111. [Google Scholar] [CrossRef]

- Sib, O.; Bougouma-Yameogo, V.M.C.; Blanchard, M.; Gonzalez-Garcia, E.; Vall, E. Production laitière à l’Ouest du Burkina Faso dans un contexte d’émergence de laiteries: Diversité des pratiques d’élevage et propositions d’amélioration. Rev. D’élevage Médecine Vétérinaire Pays Trop. 2017, 70, 81–91. [Google Scholar] [CrossRef]

- Gnanda, B.I. Importance Socio-Économique de la Chèvre du Sahel Burkinabé et Amélioration de sa Productivité par L’alimentation. Ph.D. Thesis, Institut du Développement Rural, Université Polytechnique de Bobo-Dioulasso, Dindéresso, Burkina Faso, 2008; 188p. [Google Scholar]

- CIRAD-GRET. Le Memento de L’agronome; Ministère Français des Affaires Etrangères: Paris, France, 1991; 1692p. [Google Scholar]

- Deuxième Enquête Nationale sur les Effectifs du Cheptel (ENEC II); Rapport Méthodologique de l’ENEC II; 2003, 27p. Available online: https://nada.insd.bf/index.php/catalog/33 (accessed on 27 October 2024).

- Association of Analytical Chemists. Official Methods of Analysis, 13th ed.; Hoerwitz, W., Ed.; Association of Analytical Chemists: Washington, DC, USA, 1990. [Google Scholar]

- Van Soest, P.J.; Robertson, J.B.; Lewis, B.A. Methods for dietary fiber, neutral detergent fiber, and nonstarch polysaccharides in relation to animal nutrition. J. Dairy Sci. 1991, 74, 3583–3597. [Google Scholar] [CrossRef] [PubMed]

- Millogo, V.; Kéré, M.; Amoussou, T.O.; Nikiema, R.; Barro, A.; Harrigan, T.; Burdick, R.; Ouedraogo, G.A. Évaluation de la force et de la vitesse de travail des bœufs de trait à l’aide d’un dynamomètre numérique en début de campagne agricole au Burkina Faso. Tropicultura 2020, 38, 2295–8010. [Google Scholar]

- INRA. Alimentation des Bovins, Ovins et Caprins; Éditions Quæ: Versailles, France, 2010; 315p. [Google Scholar]

- Gardarin, A.; Garnier, E.; Carrere, P.; Cruz, P.; Andueza, D.; Bonis, A.; Colace, M.P.; Dumont, B.; Duru, M.; Farruggia, A.; et al. Plant trait-digestibility relationships across management and climate gradients in permanent grasslands. J. Appl. Ecol. 2014, 51, 1207–1217. [Google Scholar] [CrossRef]

- Grant, K.; Kreyling, J.; Dienstbach, L.F.H.; Beierkuhnlein, C.; Jentsch, A. Water stress due to increased intra-annual precipitation variability reduced forage yield but raised forage quality of a temperate grassland. Agric. Ecosyst. Environ. 2014, 186, 11–22. [Google Scholar] [CrossRef]

- Ray, D.K.; Gerber, J.S.; MacDonald, G.K.; West, P.C. Climate variation explains a third of global crop yield variability. Nat. Commun. 2015, 6, 1–9. [Google Scholar] [CrossRef]

- Akakpoa, D.B.; Boer, I.M.; Adjei-Nsiahc, S.; Duncand, A.J.; Giller, K.E.; Oosting, S.J. Evaluating the effects of storage conditions on dry matter loss and nutritional quality of grain legume fodders in West Africa. Anim. Feed. Sci. Technol. 2020, 262, 114419. [Google Scholar] [CrossRef]

- Shinners, K.J.; Boettcher, G.C.; Muck, R.E.; Weimer, P.J.; Casler, M.D. Harvest and storage of two perennial grasses as biomass feedstocks. Trans. Asabe J. 2010, 53, 359–370. [Google Scholar] [CrossRef]

- Feyissa, F.; Prasad, S.; Assefa, G.; Bediye, S.; Kitaw, G.; Kehaliew, A.; Kebede, G. Dynamics in nutritional characteristics of natural pasture hay as affected by harvesting stage, storage method and storage duration in the cooler tropical highlands. Afr. J. Agric. Res. 2014, 9, 3233–3244. [Google Scholar]

- Boudet, G. Manuel sur les Pâturages Tropicaux et les Cultures Fourragères; Ministère de la Cooperation: Paris, France, 1991; 265p. [Google Scholar]

- Magnani, S. Le Lait Local au Sénégal: Intensifier Pour Développer? Dynamiques Socio-Techniques et Anthropologie des Pratiques. Ph.D. Thesis, École des Hautes Études en Sciences Sociales, Marseille, France, 2016; p. 392. [Google Scholar]

- Sib, O. Co-Conception d’un Système Fourrager Innovant: Introduction des Banques Fourragères Arbustives dans les Élevages Laitiers de L’ouest du Burkina Faso. Ph.D. Thesis, Université Nazi Boni, Bobo-Dioulasso, Burkina Faso, 2018. [Google Scholar]

- Rufino, M.C.; Herrero, M.; Van Wijk, M.T.; Hemerink, L.; de Ridder, N.; Giller, K.E. Lifetime productivity of dairy cows in smallholder farming systems of the Central Highlands of Kenya. Animal 2009, 3, 1044–1056. [Google Scholar] [CrossRef]

- Beaumont, R.P.; Champciaux, J.; Agabriel, J.; Andrieu, J.; Aufrere, J.; Michal-Doreau, B.; Demarquilly, C. Une démarche intégrée pour prévoir la valeur des aliments pour les ruminants: PrévAlim pour INRAtion. INRAE Prod. Anim. 1999, 12, 183–194. [Google Scholar] [CrossRef]

- Rémond, B.; Pomiès, D.; Julien, C.; Pradel, P. Effets de faibles écarts de temps entre les deux traites de la journée sur la quantité de lait produite et sa composition, chez la vache laitière. Renc. Rech. Rumin. 2006, 13, 365–368. [Google Scholar]

- Sissao, M.; Millogo, V.; Ouedraogo, G.A. Effet de la fréquence de traite sur la production laitière de la vache Zébu Peulh. Int. J. Biol. Chem. Sci. 2016, 10, 2555–2567. [Google Scholar] [CrossRef][Green Version]

- Gilbert, G.R.; Hargrove, G.L.; Kroger, M. Diurnal variations in milk yield, fat yield, milk fat percentage, and milk protein percentage of Holstein-friesian cows Journal. Dairy Sci. 1973, 56, 409–410. [Google Scholar] [CrossRef]

- Syrstad, O. Day-to-day variation in milk yield, fat content and protein content. Livest. Prod. Sci. 1977, 4, 141–151. [Google Scholar] [CrossRef]

- Quist, M.A.; Leblanc, S.J.L.; Hand, K.J.; Lazenby, D.; Miglior, F.; Kelton, D.F. Milking-to-milking variability for milk yield, fat and protein percentage, and somatic cell count Journal. Dairy Sci. 2008, 91, 3412–3423. [Google Scholar] [CrossRef]

- Millogo, V.; Ouédraogo, G.A.; Agenäs, S.; Svennersten-Sjaunja, K. Day-to-day variation in yield, composition and somatic cells count of saleable milk in hand-milked zebu dairy cattle. Afr. J. Agric. Res. 2009, 4, 151–155. [Google Scholar]

- Forsbäck, L.; Lindmark-Månsson, H.; Andrén, A.; Åkersdert, M.; Andrée, L.; Svennersten-Sjauja, K. Day-to-day variation in milk yield and milk composition at the udder-quarter level Joutnal. Dairy Sci. 2010, 93, 3569–3577. [Google Scholar] [CrossRef]

- Raboisson, D.; Schelcher, F. Critères diagnostiques des maladies métaboliques. Point Vétérinaire 2009, 40, 109–115. [Google Scholar]

| Forage Types | %DM | %MM | %CP | %CF | %NDF | %ADF | %ADL |

|---|---|---|---|---|---|---|---|

| Maize stem | 97.45 ± 0.07 | 10.01 ± 0.06 | 3.84 ± 0.5 | 24.55 ± 0.11 | 63.78 ± 0.36 | 34.77 ± 0.69 | 8.51 ± 0.56 |

| Sorghum stem | 96.85 ± 0.14 | 6.12 ± 0.11 | 2.78 ± 0.5 | 27.59 ± 0.33 | 66.6 ± 0.16 | 35.84 ± 0.03 | 10.25 ± 0.7 |

| Sorghum leaves | 96.06 ± 0.04 | 8.66 ± 0.06 | 1.93 ± 0.74 | 21.66 ± 0.29 | 52.95 ± 0.04 | 27.12 ± 0.07 | 5.14 ± 0.39 |

| Soybean pod | 96.28 ± 0.02 | 5.46 ± 0.2 | 5.55 ± 0.97 | 33.45 ± 0.58 | 49.3 ± 00 | 26.46 ± 0.16 | 7.27 ± 0.01 |

| P. pedicellatum Straw | 98.7 ± 0.42 | 5.29 ± 0.04 | 1.57 ± 0.24 | 33.56 ± 0.13 | 75.55 ± 0.5 | 45.93 ± 0.4 | 10.62 ± 0.35 |

| Maize silage | 96.9 ± 0.28 | 5.59 ± 0.11 | 5.74 ± 0.77 | 11.13 ± 0.33 | 43.6 ± 0.04 | 16.05 ± 0.04 | 2.05 ± 0.04 |

| Sorghum seed head | 96.81 ± 0.05 | 4.58 ± 0.13 | 7.13 ± 0.19 | 18.9 ± 0.08 | 64.2 ± 0.1 | 29.2 ± 0.08 | 9.31 ± 0.22 |

| Maralfalfa | 97.29 ± 0.0 | 11.42 ± 0.02 | 3.66 ± 0.17 | 24.76 ± 0.08 | 65.43 ± 0.11 | 30.46 ± 0.27 | 8.14 ± 1.03 |

| Sorghum silage | 96.39 ± 0.05 | 10.18 ± 0.14 | 10.65 ± 0.16 | 25.08 ± 0.08 | 63.9 ± 0.19 | 33.91 ± 0.27 | 5.5 ± 0.24 |

| Soybean hay | 95.59 ± 0.01 | 6.85 ± 0.11 | 6.44 ± 0.52 | 29.44 ± 0.79 | 57.26 ± 0.04 | 38.62 ± 0.02 | 10.56 ± 0.24 |

| T. dolonepfolius hay | 96.75 ± 0.06 | 10.08 ± 0.0 | 9.25 ± 0.25 | 14.2 ± 0.13 | 39.12 ± 1.05 | 26.93 ± 0.04 | 4.82 ± 0.16 |

| A. gayanus hay | 97.44 ± 0.1 | 6.11± 0.1 | 2.44 ± 0.5 | 28.75 ± 0.19 | 72.83 ± 0.28 | 37.55 ± 0.57 | 10.23 ± 0.35 |

| Piliostigma pod | 96.64 ± 0.02 | 5.73 ± 0.05 | 7.68 ± 0.01 | 13.04 ± 0.06 | 53.49 ± 0.04 | 42.53 ± 0.35 | 22.17 ± 0.08 |

| P. pedicellatum hay | 96.43 ± 0.1 | 10.78 ± 0.67 | 5.73 ± 0.21 | 29.47 ± 0.53 | 69.53 ± 1.15 | 36.27 ± 0.26 | 7.165 ± 0.37 |

| Types of Concentrates | %DM | %MM | %CP | %CF | %NDF | %ADF | %ADL |

|---|---|---|---|---|---|---|---|

| Sogobalo | 93.15 ± 0.0 | 7.13 ± 0.05 | 16.04 ± 0.03 | 4.97 ± 0. 08 | 34.81 ± 0.06 | 38.62 ± 0.02 | 10.56 ± 0.24 |

| SOFAB milk diet | 97.95 ± 0.05 | 10.84 ±0.11 | 17.75 ± 0.4 | 6.46 ± 0.05 | 44.41 ± 0.54 | 13.85 ± 0.15 | 9.15 ± 0.01 |

| Cottonseed cake | 97.01 ± 0.05 | 4.54 ± 0.08 | 24.33 ± 0.42 | 19.23 ± 0.11 | 56.63 ±1.06 | 34.87 ± 0.7 | 2.59 ± 0.14 |

| Maize spent grain | 95.07 ± 0.06 | 4.79 ± 0.01 | 25.74 ± 0.45 | 12.75 ± 0.16 | 57.33 ± 1.34 | 20.35 ± 0.0 | 0.02 ± 0.007 |

| Sorghum brewers | 93.82 ± 0.01 | 4.09 ± 0.02 | 25.46 ± 0.02 | 13.14 ± 0.11 | 60.15 ± 0.26 | 21.06 ± 0.01 | 1.89 ± 0.2 |

| Maize flour | 93.55 ± 0.04 | 3.61 ± 0.08 | 10.12 ± 1.01 | 1.77 ± 0.33 | 31.19 ± 0.04 | 5.04 ± 0.14 | 0.72 ± 0.04 |

| Soybean flour | 95.03 ± 0.06 | 5.46 ± 0.06 | 6.75 ± 0.29 | 8.1 ± 0.15 | 23.14 ± 1.2 | 9.94 ± 0.08 | 1.11 ± 0.11 |

| Lacto, Kossodo | 97.54 ± 0.04 | 9.69 ± 0.07 | 15.52 ± 1.58 | 10.44 ± 0.08 | 53.36 ± 0.25 | 17.11 ± 0.3 | 4.76 ± 0.75 |

| Maize seed | 91.26 ± 0.06 | 1.125 ± 0.01 | 7.15 ± 0.25 | 0.38 ± 0.02 | 20.79 ± 0.22 | 2.44 ± 0.18 | 1.65 ± 0.38 |

| Soybean Pougmbiga | 95.53 ± 0.11 | 8.42 ± 0.1 | 9.95 ± 0.23 | 25.72 ± 0.37 | 49.9 ± 1.15 | 33.45 ± 0.02 | 7.92 ± 0.35 |

| Maize bran | 93.06 ± 0.14 | 4.99 ± 0.05 | 9.42 ± 0.48 | 1.97 ± 1.87 | 35.88 ± 0.96 | 7.93 ± 0.52 | 8.51 ± 0.48 |

| Ingredients | Using Percentage | %DM | %CP | %CF | PDIE (g/kg) | PDIN (g/kg) | PDIA (g/kg) | UEL (kg) |

|---|---|---|---|---|---|---|---|---|

| Sorghum straw | 84.85 | 96.85 | 2.78 | 27.59 | 9.67 | 17.54 | 8.64 | 1.21 |

| P. pedicellatum straw | 90.91 | 98.70 | 1.57 | 33.56 | 5.46 | 9.91 | 4.87 | 1.28 |

| Cottonseed cake | 87.88 | 97.03 | 24.33 | 19.22 | 175.78 | 177.41 | 121.48 | --- |

| Maize bran | 69.70 | 93.06 | 9.42 | 1.97 | 102.50 | 64.82 | 38.75 | --- |

| Data Source | Forage Quantity/Cow/Day | Concentrate Quantity/Cow/Day | Milk Yield/Cow/Day |

|---|---|---|---|

| From survey | 10.75 ± 2.97 kg DM a | 4.18 ± 2.29 kg DM a | 6.75 ± 4.37 b kg of milk |

| From measurement | 11.58 ± 2.27 kg DM a | 9.53 ± 1.84 kg DM b | 7.6 ± 3.91 b kg of milk |

| Lactation Stages | DM (kg) | % DM Intake | Excepted Milk (kg/Day) | Gap Body Conditions Score (pt) | PDIN/UFL | PDIE/UFL |

|---|---|---|---|---|---|---|

| Early lactation | 13.3 | 100 | 13.5 | −0.46 | 123.6 | 123.6 |

| Mid lactation | 14.5 | 100 | 15.5 | −0.22 | 113.3 | 113.3 |

| End lactation and Dry Pregnant cows | 9.5 | 100 | +0.45 |

| Lactation Stages | Forages DM (kg) | Concentrates DM (kg) | Expected Milk Yield (L) |

|---|---|---|---|

| Early | 6.73 | 6.59 | 13.5 |

| Mid | 8.0 | 6.5 | 15.5 |

| End | 5.7 | 3.8 | 0.0 |

| Data Origin | Forage DM/Cow/Day (kg) | Concentrate DM/Cow/Day (kg) | Milk Yield/Day (L) |

|---|---|---|---|

| Survey | 10.75 ± 2.97 a | 4.18 ± 2.29 a | 6.75 ± 4.37 a |

| Measurements | 11.58 ± 2.27 a | 9.53 ± 1.84 b | 7.6 ± 3.91 a |

| Op-Ration | 6.81 ± 1.15 b | 5.63 ± 1.58 a | 14.5 ± 1.41 b |

| Cow ID | Milking Time | Milk Yield (L) | %Fat | %Protein | %Lactose | %Dry Matter | Density |

|---|---|---|---|---|---|---|---|

| VA | M | 4.02 ± 0.17 b | 7.41 ± 2.52 b | 3.94 ± 0.61 b | 4.09 ± 0.87 b | 15.59 ± 3.21 b | 1.03 ± 0.004 b |

| E | 2.72 ± 0.13 b | 8.56 ± 2.38 b | 4.29 ± 0.57 b | 3.55 ± 0.71 b | 16.91 ± 3.16 b | 1.03 ± 0.004 b | |

| VB | M | 2.10 ± 0.24 cd | 9.80 ± 3.65 cd | 4.66 ± 1 cd | 4.08 ± 1.1 cd | 13.57 ± 2.1 cd | 1.03 ± 0.004 cd |

| E | 1.49 ± 0.21 c | 7.59 ± 2.41 c | 4.51 ± 0.60 c | 3.98 ± 1.09 c | 15.5 ± 3.78 c | 1.03 ± 0.004 c | |

| VC | M | 3.79 ± 0.43 b | 7.96 ± 3.05 b | 4.36 ± 0.64 b | 4.51 ± 0.90 b | 17.38 ± 3.8 b | 1.03 ± 0.004 b |

| E | 2.51 ± 0.26 b | 8.22 ± 2.81 b | 4.74 ± 0.60 b | 4.29 ± 0.89 b | 17.93 ± 3.66 b | 1.03 ± 0.004 b | |

| VD | M | 1.25 ± 0.1 d | 6.50 ± 2.22 d | 4.36 ± 0.64 d | 4.03 ± 0.89 d | 16.30 ± 2.82 d | 1.03 ± 0.003 d |

| E | 0.65 ± 0.80 d | 8.72 ± 3.05 d | 4.11 ± 0.75 d | 4.10 ± 0.86 d | 18.06 ± 3.67 d | 1.03 ± 0.004 d | |

| VE | M | 2.57 ± 0.38 c | 10.19 ± 4.39 c | 5.34 ± 1.11 c | 3.97 ± 1 c | 16.79 ± 4.81 c | 1.03 ± 0.004 c |

| E | 1.81 ± 0.26 c | 12.26 ± 4.7 c | 5.75 ± 1.02 c | 3.94 ± 0.95 c | 22.68 ± 5.81 c | 1.03 ± 0.004 c | |

| VF | M | 7.05 ± 0.36 a | 5.83 ± 2.29 a | 3.97 ± 0.57 a | 4.11 ± 0.88 a | 16.79 ± 4.81 a | 1.03 ± 0.004 a |

| E | 4.68 ± 0.31 a | 7.46 ± 2.83 a | 4.21 ± 0.69 a | 3.99 ± 0.85 a | 17.09 ± 3.61 a | 1.03 ± 0.003 a |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sawadogo, R.I.; Millogo, V.; Sissao, M.; Kere, M.; Sawadogo, W.A.; Séré, M. Simulation and Optimization of Available Local Feed Resources for Dairy Cattle in Burkina Faso. Appl. Sci. 2024, 14, 11891. https://doi.org/10.3390/app142411891

Sawadogo RI, Millogo V, Sissao M, Kere M, Sawadogo WA, Séré M. Simulation and Optimization of Available Local Feed Resources for Dairy Cattle in Burkina Faso. Applied Sciences. 2024; 14(24):11891. https://doi.org/10.3390/app142411891

Chicago/Turabian StyleSawadogo, Rayinwendé Irène, Vinsoun Millogo, Mariétou Sissao, Michel Kere, Wendpayanguedé Alain Sawadogo, and Modou Séré. 2024. "Simulation and Optimization of Available Local Feed Resources for Dairy Cattle in Burkina Faso" Applied Sciences 14, no. 24: 11891. https://doi.org/10.3390/app142411891

APA StyleSawadogo, R. I., Millogo, V., Sissao, M., Kere, M., Sawadogo, W. A., & Séré, M. (2024). Simulation and Optimization of Available Local Feed Resources for Dairy Cattle in Burkina Faso. Applied Sciences, 14(24), 11891. https://doi.org/10.3390/app142411891