Studying Radiation-Induced Degradation of Reinforced Concrete Structures: Review and Numerical Analysis of Reinforcement Corrosion Processes in Concrete

Abstract

1. Introduction

2. Materials and Methods

3. Research Results and Discussion

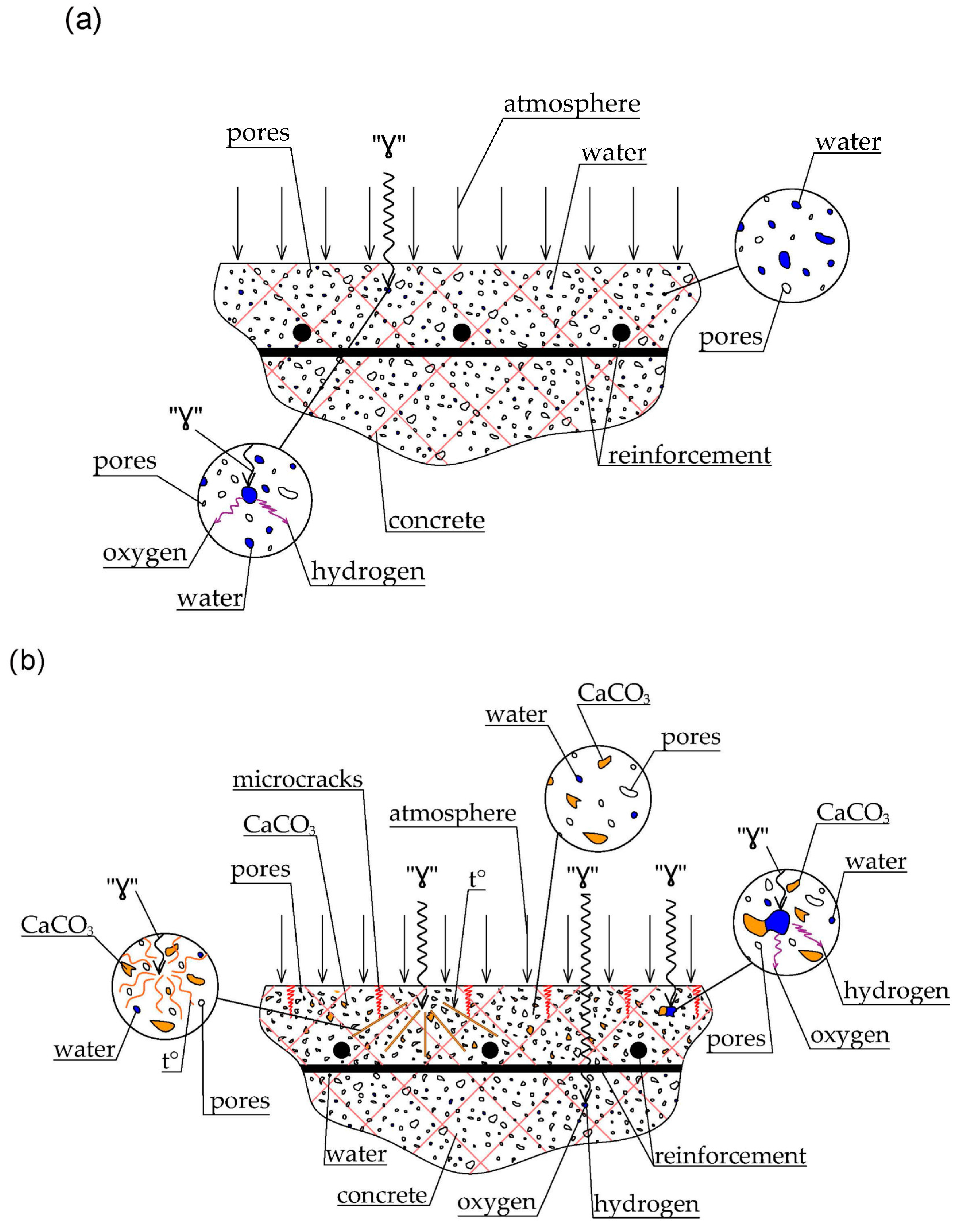

3.1. Analysis of Degradation of Reinforced Concrete Structures Exposed to Gamma Radiation from the Standpoint of Reinforcement Corrosion

3.1.1. Concrete Degradation Due to Exposure to Ionizing Radiation, Contributing to Corrosion of Reinforcement Bars

Radiation-Related Structural Changes in Concrete

Radiogenic Heating

Radiolysis

Carbonization

3.1.2. Corrosion of Reinforcement in Reinforced Concrete Structures Under the Effect of Gamma Radiation

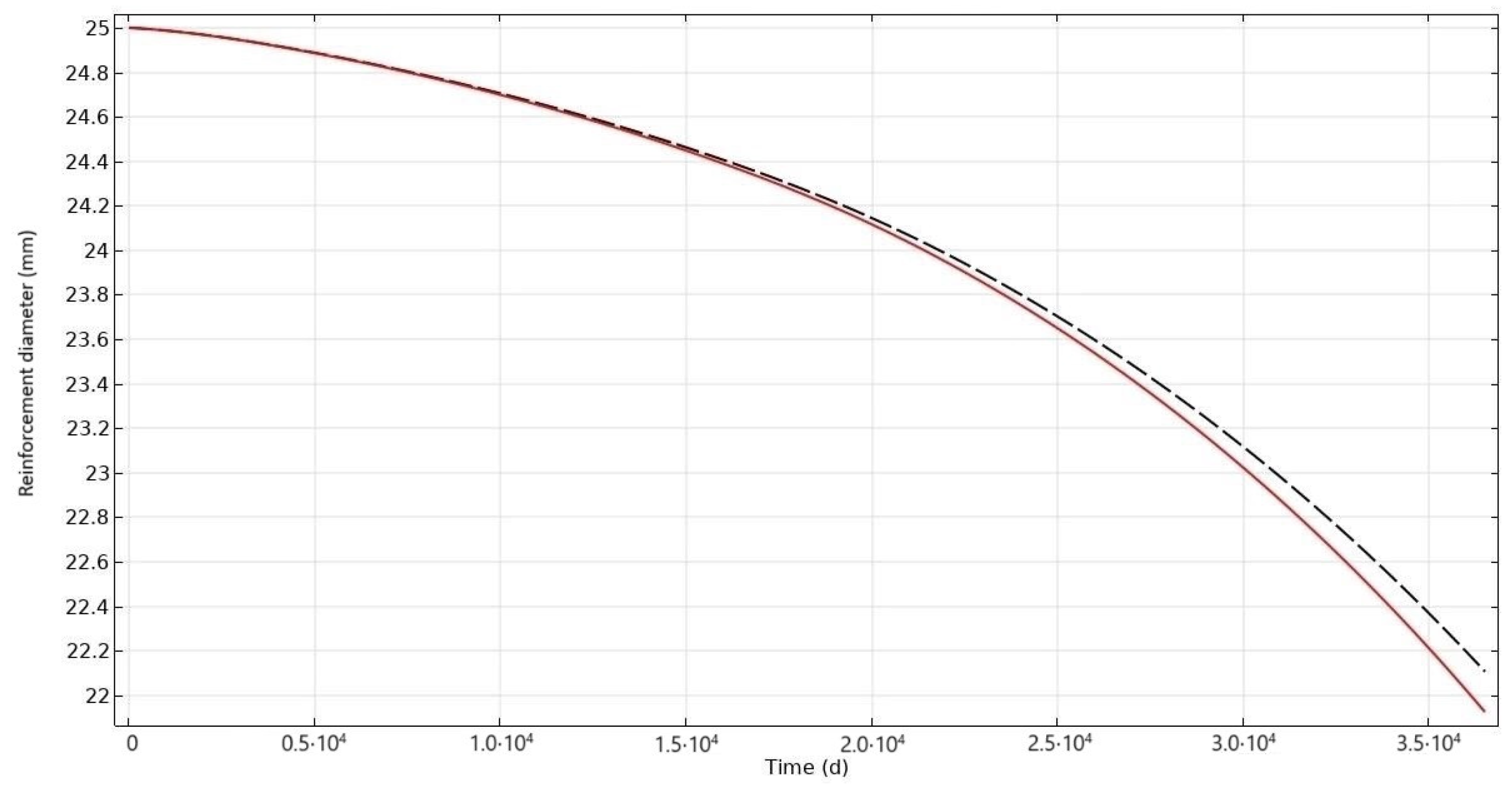

3.2. Modeling of Chemical Radiation-Induced Corrosion Processes Using the COMSOL Software Package

4. Conclusions

- -

- Operating environments, namely, the presence of chlorides, ions of magnesium and carbon; temperature and humidity characteristics (higher radiolytic damage and accelerated carbonization were observed in the RH range of 50 to 75%, and similarly corrosion processes accelerated in steel elements in concrete under the combined effect of temperature (including radiation heating).

- -

- Conditions of oxygen supply to a structure.

- -

- Presence of residual water (initial water–cement ratio).

5. Future Directions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

| AFe | iron oxidation on the Tafel slope; |

| AH2 | hydrogen evolution on the Tafel slope; |

| AO2 | oxygen reduction on the Tafel slope; |

| CO2_ref | oxygen reference concentration; |

| CO2_ref_9_100 | oxygen concentration after 9 years; |

| Eeq_Fe | equilibrium oxidation potential of iron; |

| Eeq_H2 | equilibrium potential of hydrogen evolution; |

| Eeq_O2 | equilibrium potential of oxygen reduction; |

| I0_Fe | exchange current density of iron oxidation; |

| I0_H2 | current density of hydrogen evolution; |

| I0_O2 | current density of exchange during oxygen reduction; |

| L | length of concrete segment; |

| Rreinforcement bar | reinforcement radius; |

| S | thickness of concrete; |

| W | width of concrete segment; |

| PS | pore saturation. |

References

- Huet, B.; L’Hostis, V.; Idrissi, H.; Tovena, I.A. Review on Corrosion Mechanisms of Reinforced Concrete Degradation. In Proceedings of the International Conference on Environmental Degradation of Engineering Materials (EDEM 2003), Bordeaux, France, 29 June–2 July 2003; p. 8. [Google Scholar]

- Noh, H.M.; Sonoda, Y. Potential Effects of Corrosion Damage on the Performance of Reinforced Concrete Member. MATEC Web Conf. 2016, 47, 02007. [Google Scholar] [CrossRef]

- Loukil, O.; Adelaide, L.; Bouteiller, V.; Chaussadent, T.; Ragueneau, F. Corrosion-Induced Degradation of Reinforced Concrete Elements: Preliminary Results. In Service Life and Durability of Reinforced Concrete Structures, Proceedings of the Selected Papers of the 8th International RILEM PhD Workshop, Marne-la-Vallée, France, 26–27 September 2016; Springer Nature Link: Cham, Switzerland, 2016; pp. 129–140. [Google Scholar] [CrossRef]

- Quraishi, M.; Nayak, D.; Kumar, R.; Kumar, V. Corrosion of Reinforced Steel in Concrete and Its Control: An overview. J. Steel Struct. Constr. 2017, 3, 1000124. [Google Scholar] [CrossRef]

- Zhang, Z.; Angst, U.M.; Michel, A. A framework for modelling corrosion-related degradation in reinforced concrete. In Life Cycle Analysis and Assessment in Civil Engineering: Towards an Integrated Vision, Proceedings of the Sixth International Symposium on Life-Cycle Civil Engineering (IALCCE 2018), Ghent, Belgium, 28–31 October 2018; Taylor & Francis: Abingdon, UK, 2018; pp. 979–986. [Google Scholar]

- Goyal, A.; Pouya, H.S.; Ganjian, E.; Claisse, P. A Review of Corrosion and Protection of Steel in Concrete. Arab. J. Sci. Eng. 2018, 43, 5035–5055. [Google Scholar] [CrossRef]

- Ueli, M.A. Challenges and opportunities in corrosion of steel in concrete. Mater. Struct. 2018, 51, 4. [Google Scholar] [CrossRef]

- Andrade, C. Propagation of reinforcement corrosion: Principles, testing and modelling. Mater. Struct. 2019, 52, 2. [Google Scholar] [CrossRef]

- Raczkiewicz, W.; Wojcicki, A.; Grzmil, W.; Zapala-Slaweta, J. Impact of Environment Conditions on the Degradation Process of Selected Reinforced Concrete Elements. IOP Conf. Ser. Mater. Sci. Eng. 2019, 471, 032048. [Google Scholar] [CrossRef]

- Huang, L.; Ye, H.; Jin, X.; Jin, N.; Xu, Z. Corrosion-induced shear performance degradation of reinforced concrete beams. Constr. Build. Mater. 2020, 248, 118668. [Google Scholar] [CrossRef]

- Song, Y.; Wightman, E.; Kulandaivelu, J.; Bu, H.; Wang, Z.; Yuan, Z.; Jiang, G. Rebar corrosion and its interaction with concrete degradation in reinforced concrete sewers. Water Res. 2020, 182, 115961. [Google Scholar] [CrossRef]

- Mirsayapov, I.; Yakupov, S.; Hassoun, M. About concrete and reinforced concrete corrosion. IOP Conf. Ser. Mater. Sci. Eng. 2020, 890, 012061. [Google Scholar] [CrossRef]

- Nour, N. Reinforcement corrosion in reinforced concrete Structures: Classification and overview. Int. J. Adv. Eng. Sci. Appl. 2021, 2, 19–24. [Google Scholar] [CrossRef]

- Tang, F.; Lin, Z.; Qu, H.; Chen, G. Investigation into corrosion-induced bond degradation between concrete and steel rebar with acoustic emission and 3D laser scan techniques. J. Infrastruct. Preserv. Resil. 2022, 3, 5. [Google Scholar] [CrossRef]

- Jung, J.-S.; Jeong, J.-W.; Lee, K.-S. Structural Performance Degradation of Corrosion-Damaged Reinforced Concrete Beams Based on Finite Element Analysis. Appl. Sci. 2022, 12, 2090. [Google Scholar] [CrossRef]

- Jabed, A.; Tusher, M.H.; Shuvo, I.A. Corrosion of Steel Rebar in Concrete: A Review. Corros. Sci. Technol. 2023, 22, 273–286. [Google Scholar] [CrossRef]

- Karka, B.R.; Bruno, B.; Ngarmaïm, N.; Rimbarngaye, A. The Effects of Degradation Phenomena of the Steel-Concrete Interface in Reinforced Concrete Structures. J. Mater. Sci. Chem. Eng. 2023, 11, 1–21. [Google Scholar] [CrossRef]

- De Domenico, D.; Messina, D.; Recupero, A. Seismic vulnerability assessment of reinforced concrete bridge piers with corroded bars. Struct. Concr. 2023, 24, 56–83. [Google Scholar] [CrossRef]

- IAEA. IAEA Nuclear Energy Series (No. NP-T-3.5). Ageing Management of Concrete Structures in Nuclear Power Plants; International Atomic Energy Agency: Vienna, Austria, 2016. [Google Scholar]

- Rasheed, P.A.; Nayar, S.K.; AlFantazi, A. Concrete corrosion in nuclear power plants and other nuclear installations and its mitigation techniques: A review. Corros. Rev. 2023, 42, 57–73. [Google Scholar] [CrossRef]

- Rodrigues, R.; Gaboreau, S.; Gance, J.; Ignatiadis, J.; Betelu, S. Reinforced concrete structures: A review of corrosion mechanisms and advances in electrical methods for corrosion monitoring. Constr. Build. Mater. 2021, 269, 121240. [Google Scholar] [CrossRef]

- Smolyago, G.A.; Kryuchkov, A.A.; Drokin, S.V.; Dronov, A.V. Study of aspects of chloride fixation of reinforced concrete structures. Vestn. BGTU Im. V.G. SHuhova 2014, 2, 22–24. [Google Scholar]

- Wang, Y.; Zhang, A.; Wang, H. Electrochemical investigation on the effect of chloride ion concentration on the corrosion of concrete reinforcement using in-situ nano-Ag/AgCl electrode. Alex. Eng. J. 2023, 66, 451–456. [Google Scholar] [CrossRef]

- Li, H.; Li, L.; Zhou, G.; Xu, L. Time-dependent Seismic Fragility Assessment for Aging Highway Bridges Subject to Non-uniform Chloride-induced Corrosion. J. Earthq. Eng. 2022, 26, 3523–3553. [Google Scholar] [CrossRef]

- Montemor, M.; Simões, A.; Ferreira, M. Chloride-induced corrosion on reinforcing steel: From the fundamentals to the monitoring techniques. Cem. Concr. Compos. 2003, 25, 491–502. [Google Scholar] [CrossRef]

- Nayak, A.R.; Dominic, D.M. Corrosion of Reinforced Concrete: A Review. Int. Res. J. Eng. Technol. 2021, 8, 1691–1700. [Google Scholar]

- Ali, M.; Shams, M.A.; Bheel, N.; Almaliki, A.H.; Mahmoud, A.S.; Dodo, Y.A.; Benjeddou, O. A review on chloride induced corrosion in reinforced concrete structures: Lab and in situ investigation. R. Soc. Chem. 2024, 14, 37252–37271. [Google Scholar] [CrossRef] [PubMed]

- Zhang, F.; Xi, X.; Yang, S. Research Progress in Corrosion Mechanism of Reinforced Alkali-Activated Concrete Structures. Corros. Mater. Degrad. 2021, 2, 641–656. [Google Scholar] [CrossRef]

- Imam, A.; Mishra, S.; Bind, Y.K. Review study towards corrosion mechanism and its impact on the durability of concrete structures. AIMS Mater. Sci. 2018, 5, 276–300. [Google Scholar] [CrossRef]

- Medvedev, V.; Pustovgar, A. A review of concrete carbonation and approaches to its research under irradiation. Buildings 2023, 13, 8. [Google Scholar] [CrossRef]

- IAEA. Special Safety Guide No. SSG-48. Ageing Management and Development of a Long-Term Operation Programme for Nuclear Power Plants; International Atomic Energy Agency: Vienna, Austria, 2023. [Google Scholar]

- NP-099-17; Federal Norms and Rules in the Field of Atomic Energy Use. Requirements for the Composition and Content of the Report on the Justification of the Safety of Radioactive Waste Storage Facilities. Federal Service for Environmental, Technological and Nuclear Supervision: Moscow, Russia, 2017.

- GOST 27751-2014; Reliability of Building Structures and Foundations. Basic Provisions (Amendment 1). Standartinform: Moscow, Russia, 2019.

- Technical Regulations on the Safety of Buildings and Structures: Federal Law of 30.12.2009 No. 384-FZ. Official Internet Portal “ConsultantPlus”. Available online: https://www.consultant.ru/document/cons_doc_LAW_95720/ (accessed on 1 October 2024).

- Otieno, M.B.; Beushausen, H.D.; Alexander, M.G. Modelling corrosion propagation in reinforced concrete structures—A critical review. Cem. Concr. Compos. 2011, 33, 240–245. [Google Scholar] [CrossRef]

- Vorechovská, D.; Vorechovsky, M. Modeling of reinforcement corrosion in concrete. In Proceedings of the Engineering Mechanics International Conference, Svratka, Czech Republic, 14–17 May 2007; pp. 1–11. [Google Scholar]

- Shi, R.; Pan, Z.; Lun, P.; Zhan, Y.; Nie, Z.; Liu, Y.; Mo, Z.; He, Z. Research on Corrosion Rate Model of Reinforcement in Concrete under Chloride Ion Environments. Buildings 2023, 13, 965. [Google Scholar] [CrossRef]

- Castorena-González, J.H.; Martin, U.; Gaona-Tiburcio, C.; Núñez-Jáquez, R.E.; Almeraya-Calderón, F.M.; Bastidas, J.M.; Bastidas, D.M. Modeling Steel Corrosion Failure in Reinforced Concrete by Cover Crack Width 3D FEM Analysis. Sec. Struct. Mater. 2020, 7, 41. [Google Scholar] [CrossRef]

- Isgor, O.B.; Razaqpur, A.G. Advanced modelling of concrete deterioration due to reinforcement corrosion. Can. J. Civ. Eng. 2006, 33, 707–718. [Google Scholar] [CrossRef]

- Ožbolt, J.; Oršanić, F.; Balabanić, G. Modeling corrosion-induced damage of reinforced concrete elements with multiple-arranged reinforcement bars. Mater. Corros. 2016, 67, 542–552. [Google Scholar] [CrossRef]

- Lu, Z.-H.; Lun, P.-Y.; Li, W.; Luo, Z.; Li, Y.; Liu, P. Empirical model of corrosion rate for steel reinforced concrete structures in chloride-laden environments. Adv. Struct. Eng. 2018, 22, 223–239. [Google Scholar] [CrossRef]

- Ožbolt, J.; Balabanić, G.; Oršanić., F. Modelling corrosion of steel reinforcement in concrete. IOP Conf. Ser. Mater. Sci. Eng. 2019, 615, 012011. [Google Scholar] [CrossRef]

- Felix, E.F.; Rodrigues Balabuch, T.J.; Corrêa Posterlli, M.; Possan, E.; Carrazedo, R. Service life analysis of reinforced concrete structure under uniform corrosion through ANN model coupled to the FEM. Rev. ALCONPAT 2018, 8, 1–15. [Google Scholar] [CrossRef]

- Felix, E.F.; Carrazedo, R.; Possan, E.; Ramos, E.S. Development and analysis of a numerical model of the reinforced concrete expansion due to uniform corrosion. Rev. ALCONPAT 2020, 10, 300–316. [Google Scholar] [CrossRef]

- King, F.; Kolár, M. Lifetime predictions for nuclear waste disposal containers. Corrosion 2019, 75, 309–323. [Google Scholar] [CrossRef]

- WPS/890/01; Waste Package Specification and Guidance Documentation Guidance on the Design of Waste Containers for Waste Packages Containing Low Heat Generating Waste. Nuclear Decommissioning Authority: London, UK, 2019.

- NEDO-33926 (rev. 1); BWRX-300 Steel-Plate Composite Containment Vessel (SCCV) and Reactor Building (RB) Structural Design—Non-Proprietary Information. GE-Hitachi Nuclear Energy Americas, LLC.: Wilmington, NC, USA, 2023.

- Naus, D.J.; Oland, C.B.; Ellingwood, B.R. Report on Aging of Nuclear Power Plant Reinforced Concrete Structures; NUREG/CR-6424; Oak Ridge National Laboratory: Oak Ridge, TN, USA, 1996. [Google Scholar]

- Pustovgar, A.; Potapov, V.; Adamtsevich, A.; Ilyin, V.; Adamtsevich, L. Managing the aging of concrete structures of nuclear power plants. Energy Policy 2023, 8, 70–81. [Google Scholar]

- Arezou, A.; Gencturk, B.; Hanifehzadeh, M.; Willam, K. Accelerated aging of concrete dry cask storage systems for nuclear waste. J. Adv. Concr. Technol. 2016, 14, 299–310. [Google Scholar] [CrossRef]

- Bilcik, J.; Benko, V.; Fillo, L. Ageing of concrete containers for the disposal of nuclear waste. In IABSE Symposium Report; International Association for Bridge and Structural Engineering: Zurich, Switzerland, 2002. [Google Scholar] [CrossRef]

- Denisov, A.V. Radiation changes in concrete of the shaft of water-cooled power reactors during the extension of the operation of NPPs. Eng. Bull. Don. 2023, 3, 634–661. [Google Scholar]

- Glinicki, M.A.; Dąbrowski, M.A.A.; Kinga, D.; Sikorin, S.; Fateev, V.; Povolansky, E. Gamma irradiation sensitivity of early hardening cement mortar. Cem. Concr. Compos. 2022, 126, 104327. [Google Scholar] [CrossRef]

- Rasheed, P.A.; Nayar, S.K.; Barsoum, I.; Alfantazi, A. Degradation of concrete structures in nuclear power plants: A review of the major causes and possible preventive measures. Energies 2022, 15, 8011. [Google Scholar] [CrossRef]

- Yusuke, O.; Satoru, S.; Shigeru, K.; Deguchi, A. Re-evaluation of the required thickness of the carbon steel overpack for high-level radioactive waste disposal in Japan based on the latest scientific and engineering knowledge. Corros. Eng. Sci. Technol. 2017, 52, 204–209. [Google Scholar] [CrossRef]

- Glass, R.S.; Overturf, G.E.; Van Konynenburg, R.A.; McCright, R.D. Gamma radiation effects on corrosion. I. Electrochemical mechanisms for the aqueous corrosion processes of austenitic stainless steels relevant to nuclear waste disposal in tuff. Corros. Sci. 1986, 26, 577–590. [Google Scholar] [CrossRef]

- Fujita, N.; Matsuura, C.; Saigo, K. Radiation-induced preferential dissolution of specific planes of carbon steel in high-temperature water. Radiat. Phys. Chem. 2001, 60, 53–60. [Google Scholar] [CrossRef]

- Smart, N.R.; Rance, A.P.; Werme, L.O. The effect of radiation on the anaerobic corrosion of steel. J. Nucl. Mater. 2008, 379, 97–104. [Google Scholar] [CrossRef]

- Reches, Y. A multi-scale review of the effects of gamma radiation on concrete. Results Mater. 2019, 2, 100039. [Google Scholar] [CrossRef]

- Dąbrowski, M.; Glinicki, M.A.; Kuziak, J.D.K.; Dziedzic, K. Effects of 2 MGy gamma irradiation on the steel corrosion in cement-based composites. Constr. Build. Mater. 2022, 342, 127967. [Google Scholar] [CrossRef]

- Crusset, D.; Deydier, V.; Necib, S.; Gras, J.-M.; Combrade, P.; Féron, D.; Burger, E. Corrosion of carbon steel components in the French high-level waste programme: Evolution of disposal concept and selection of materials. Corros. Eng. Sci. Technol. 2017, 52, 17–24. [Google Scholar] [CrossRef]

- King, F.; Kolàř, M.; Briggs, S.; Behazin, M.; Keech, P.; Diomidis, N. Review of the modelling of corrosion processes and lifetime prediction for HLW/SF Containers. Part 1: Process Models. Corros. Mater. Degrad. 2024, 5, 124–199. [Google Scholar] [CrossRef]

- Giannakandropoulou, S.-I. Hydrogen Production by Anoxic Corrosion of Steel Under Gamma Radiation. Ph.D. Thesis, Université Paris-Saclay, Gif-sur-Yvette, France, 2022; 204p. [Google Scholar]

- Winsley, R.; Smart, N.; Rance, A.; Fennell, P.; Nandakiran, R.B.; Kursten, B. Further studies on the effect of irradiation on the corrosion of carbon steel in alkaline media. Corros. Eng. Sci. Technol. 2011, 46, 111–116. [Google Scholar] [CrossRef]

- Ibragimov, R.; Korolev, E.; Deberdeev, T.; Dolbin, I. Influence of electromagnetic radiation on degradation of reinforced concrete structures. Review. Case Stud. Constr. Mater. 2022, 17, e01454. [Google Scholar] [CrossRef]

- Dewynter-Marty, V.; Chomat, L.; Guillot, W.; Amblard, E.; Durand, D.; Cornaton, M.; Bourbon, X. Concrete radiolysis effect on steels corrosion and comparison with non-irradiated material. In Proceedings of the EUROCORR 2017 20th International Corrosion Congress/Process Safety Congress, Prague, Czech Republic, 3–7 September 2017. [Google Scholar]

- Canshuai, L.; Jianqiu, W.; Zhiming, Z.; En-Hou, H.; Wei, L.; Dong, L.; Zhongtian, Y.; Xingzhong, C. Effect of cumulative gamma irradiation on microstructure and corrosion behaviour of X65 low carbon steel. J. Mater. Sci. Technol. 2018, 34, 2131–2139. [Google Scholar] [CrossRef]

- Shoesmith, D.W.; Ikeda, B.M.; King, F. Effect of radiation on the corrosion of candidate materials for nuclear waste containers. MRS Proc. 1991, 257, 407. [Google Scholar] [CrossRef]

- Dąbrowski, M.; Kuziak, J.; Dziedzic, K.; Glinicki, M.A. Influence of environmental conditions on steel corrosion in concrete exposed to gamma radiation. Mater. Proc. 2023, 13, 44. [Google Scholar] [CrossRef]

- Jóźwiak-Niedźwiedzka, D.; Brandt, A. The influence of ionizing radiation on microstructure and properties of concrete shields. Cem. Wapno Beton 2013, 18, 1–22. [Google Scholar]

- Khmurovska, Y.; Štemberk, P. Mechanisms behind radiation-induced deterioration of concrete. IOP Conf. Ser. Mater. Sci. Eng. 2019, 596, 012035. [Google Scholar] [CrossRef]

- Fillmore, D. Literature Review of the Effects of Radiation and Temperature on the Aging of Concrete; Idaho National Engineering and Environmental Laboratory: Idaho Falls, ID, USA, 2004. [Google Scholar]

- Pomaro, B. A review on radiation damage in concrete for nuclear facilities: From experiments to modeling. Model. Simul. Eng. 2016, 2016, 4165746. [Google Scholar] [CrossRef]

- Craeye, B.; De Schutter, G.; Vuye, C.; Gerardy, I. Cement-waste interactions: Hardening self-compacting mortar exposed to gamma radiation. Prog. Nucl. Energy 2015, 83, 212–219. [Google Scholar] [CrossRef]

- Hlaváč, Z.; Zatloukalová, J.; Košťál, M.; Losa, E. Study of a gamma radiation impact on concrete properties under severe accident conditions. J. Nucl. Eng. Radiat. Sci. 2021, 7, 022001. [Google Scholar] [CrossRef]

- Soo, P.; Milian, L.M. The effect of gamma radiation on the strength of Portland cement mortars. J. Mater. Sci. Lett. 2001, 20, 1345–1348. [Google Scholar] [CrossRef]

- Robira, M.; Hilloulin, B.; Loukili, A.; Potin, G.; Bourbon, X.; Abdelouas, A. Multi-scale investigation of the effect of γ irradiations on the mechanical properties of cementitious materials. Constr. Build. Mater. 2018, 186, 484–494. [Google Scholar] [CrossRef]

- Vodák, F.; Trtík, K.; Sopko, V.; Kapičková, O.; Demo, P. Effect of γ-irradiation on strength of concrete for nuclear-safety structures. Cem. Concr. Res. 2005, 35, 1447–1451. [Google Scholar] [CrossRef]

- Khmurovska, Y.; Štemberk, P.; Sikorin, S.; Žák, J.; Kaladkevich, Y.; Pavalanski, E.; Fatseyeu, V. Cement mortar creep under exposure of gamma-ray irradiation. J. Nucl. Res. Dev. 2019, 18, 24–28. [Google Scholar]

- Čuba, V.; Múčka, V.; Pospíšil, M. Radiation induced corrosion of nuclear fuel and materials. In Advances in Nuclear Fuel; Revankar, S.T., Ed.; IntechOpen: London, UK, 2012; pp. 27–52. [Google Scholar]

- Angst, U.M.; Isgor, O.B.; Hansson, C.M.; Sagues, A.M.; Geiker, R. Beyond the chloride threshold concept for predicting corrosion of steel in concrete. Appl. Phys. Rev. 2022, 9, 011321. [Google Scholar] [CrossRef]

- Appuhamy, J.M.R.S.; Ohga, M.; Kaita, T.; Fujii, K.; Dissanayake, P.B.R. Development of analytical method for predicting residual mechanical properties of corroded steel plates. Int. J. Corros. 2011, 2011, 385083. [Google Scholar] [CrossRef]

- Pellizzer, G.P.; Leonel, E.D.; Nogueira, C.G. Numerical approach about the effect of the corrosion on the mechanical capacity of the reinforced concrete beams considering material nonlinear models. Rev. IBRACON Estrut. Mater. 2018, 11, 26–51. [Google Scholar] [CrossRef][Green Version]

- Naus, D.J. The management of aging in nuclear power plant concrete structures. JOM 2009, 61, 35–41. [Google Scholar] [CrossRef]

- Xu, J.; Jiang, L.; Wang, Q. Finite element model of reinforcement corrosion in concrete. Water Sci. Eng. 2009, 2, 71–78. [Google Scholar]

- Permeh, S.; Lau, K. Identification of carbonation-induced corrosion of steel in concrete by electrochemical testing. Mater. Corros. 2024, 75, 738–749. [Google Scholar] [CrossRef]

- Muehlenkamp, E.B.; Koretsky, M.D.; Westall, J.C. Effect of moisture on the spatial uniformity of cathodic protection of steel in reinforced concrete. CORROSION 2005, 61, 519–533. [Google Scholar] [CrossRef]

- In-Seok, Y. Comprehensive approach to calculate oxygen diffusivity of cementitious materials considering carbonation. Int. J. Concr. Struct. Mater. 2018, 12, 16. [Google Scholar] [CrossRef]

- Mitsugi, S.; Owaki, E.; Masuda, H.; Shimamoto, R. Accelerated concrete carbonation and resulting rebar corrosion under a high temperature condition in nuclear power plants. J. Adv. Concr. Technol. 2021, 19, 382–394. [Google Scholar] [CrossRef]

- Field, K.G.; Remec, I.Y.; Pape, L. Radiation effects in concrete for nuclear power plants. Part I: Quantification of radiation exposure and radiation effects. Nucl. Eng. Des. 2015, 282, 126–143. [Google Scholar] [CrossRef]

- Le Pape, Y.; Field, K.G.; Remec, I. Radiation effects in concrete for nuclear power plants. Part II: Perspective from micromechanical modeling. Nucl. Eng. Des. 2015, 282, 144–157. [Google Scholar] [CrossRef]

- Denisov, A.V. Analytical determination of radiation changes in radiation protection materials. Vestn. MGSU 2009, S2, 187–190. [Google Scholar]

- Denisov, A.V. Radiation-thermal changes in serpentine concretes of “dry” protection of water-cooled power reactors of NPPs during their extended operation. Eng. Bull. Don. 2024, 3, 537–563. [Google Scholar]

- Jing, Y.; Xi, Y. Long-term neutron radiation levels in distressed concrete biological shielding walls. J. Hazard. Mater. 2019, 363, 376–384. [Google Scholar] [CrossRef]

- Denisov, A.V. Influence of superplasticizers on radiation changes in Portland cement stone and concrete. Eng. Constr. J. 2017, 5, 70–87. [Google Scholar]

- Hajdú, D.; Török, S.; Sugár, V.; Alnatour, L. The impact of neutron irradiation on concrete structures. In Proceedings of the International Conference Nuclear Energy for New Europe, Bled, Slovenia, 6–9 September 2021. [Google Scholar]

- Weiping, Z.; Hui, L.; Yong, Z.; Kaixing, L.; Ying, H. Effect of neutron irradiation on densities and elastic properties of aggregate-forming minerals in concrete. Nucl. Eng. Technol. 2023, 55, 2147–2157. [Google Scholar]

- Sariyer, D.; Küçer, R. Effect of different materials to concrete as neutron shielding application. Acta Phys. Pol. A 2020, 137, 477–479. [Google Scholar] [CrossRef]

- Jing, Y.; Xi, Y. Theoretical modeling of the effect of neutron irradiation on properties of concrete. J. Eng. Mech. 2017, 143, 12. [Google Scholar] [CrossRef]

- Rosseel, T.M.; Gussev, M.N.; Mora, L.F. The effect of neutron irradiation on the mechanical properties of mineral analogues of concrete aggregated. In Proceedings of the 18th International Conference on Environmental Degradation of Materials in Nuclear Power Systems—Water Reactors; Springer Nature Link: Cham, Switzerland, 2019; pp. 1367–1377. [Google Scholar]

- Zalegowski, K.; Tomasz, T.; Garbacz, A.; Adamczewski, G. Relation between microstructure, technical properties and neutron radiation shielding efficiency of concrete. Constr. Build. Mater. 2020, 235, 117389. [Google Scholar] [CrossRef]

- Hlavac, Z.; Balak, J.; Maruyama, I.; Kontani, O.; Takizawa, M. Non-destructive testing of concrete irradiated by neutrons. In Proceedings of the International Ultrasonic Testing Online Conference, Online, 1–30 November 2021. [Google Scholar]

- Kazushige, F.; Masanobu, I.; Miwa, S.; Hideo, T.; Kiyoshi, H.; Kunio, O.; Masahide, S.; Hiroo, A. Experimental Study of the Effect of Radiation Exposure to Concrete. In Proceedings of the 20th International Conference on Structural Mechanics in Reactor Technology (SMiRT-20), Helsinki, Finland, 9–14 August 2009. [Google Scholar]

- Remec, I.; Rosseel, T.M.; Field, K.G.; Le Pape, Y. Radiation-Induced Degradation of Concrete in NPPs. In Reactor Dosimetry: 16th International Symposium; The American Society of Mechanical Engineering: Houston, TX, USA, 2017; pp. 201–211. [Google Scholar] [CrossRef]

- Acevedo, C.E.; Serrato, M.G. Determining the Effects of Radiation on Aging Concrete Structures of Nuclear reactors. In Proceedings of the WM2010: Waste Management Symposia, Phoenix, AZ, USA, 7–11 March 2010. [Google Scholar]

- Dubrovskii, V.B.; Ibragimov, S.S.; Ladygin, A.Y.; Pergamenshchik, B.K. Effect of neutron irradiation on some properties of heat-resistant concretes. At. Energy 1966, 21, 740–744. [Google Scholar] [CrossRef]

- Popa, A.; Pantazi, D.; Nistor, C. Radiation effects on the properties of concrete used in nuclear power plants. Energy. Environ. Effic. Resour. Glob. 2021, 7, 133–150. [Google Scholar] [CrossRef]

- Eid, M.S.; Bondouk, I.I.; Saleh, H.M.; Omar, K.M.; Diab, H.M. Investigating the effect of gamma and neutron irradiation on Portland cement provided with waste silicate glass. Sustainability 2023, 15, 763. [Google Scholar] [CrossRef]

- Le Pape, Y.; Sanahuja, J.; Alsaid, M.H.F. Irradiation-induced damage in concrete-forming aggregates: Revisiting literature data through micromechanics. Mater. Struct. 2020, 53, 62. [Google Scholar] [CrossRef]

- Hlaváč, Z.; Blažek, J.; Sirotenko, G. Changes in Concrete Subjected to Neutron Irradiation. In Modern Building Materials, Structures and Techniques; Springer Nature Link: Cham, Switzerland, 2023; pp. 99–108. [Google Scholar] [CrossRef]

- Hohmanna, B.P.; Esselmana, T.C.; Wallb, J.J. Irradiated Concrete in Nuclear Power Plants: Bridging the Gap in Operational Experience; IAEA-CN-194-095; International Atomic Energy Agency: Vienna, Austria, 2012. [Google Scholar]

- Biwer, B.; Ma, D.; Xi, Y.; Jing, Y. Review of Radiation-Induced Concrete Degradation and Potential Implications for Structures Exposed to High Long-Term Radiation Levels in Nuclear Power Plants; NUREG/CR-7280, ANL/EVS-20/8; Office of Nuclear Regulatory Research U.S. Nuclear Regulatory Commission: Washington, DC, USA, 2021. [Google Scholar]

- Hilsdorf, H.K.; Kropp, J.; Koch, H.J. The Effects of Nuclear Radiation on the Mechanical Properties of Concrete; ACI SP 55-10; Douglas McHenry International Symposium on Concrete and Concrete Structures: Detroit, MI, USA, 1978; Available online: http://large.stanford.edu/courses/2015/ph241/anzelmo1/docs/hilsdorf.pdf (accessed on 1 October 2024).

- Rosseel, T.M.; Maruyama, I.; Le Pape, Y.; Kontani, O.; Giorla, A.B.; Remec, I.; Wall, J.J.; Sircar, M.; Andrade, C.; Ordonez, M. Review of the current state of knowledge on the effects of radiation on concrete. J. Adv. Concr. Technol. 2016, 14, 368–383. [Google Scholar] [CrossRef]

- Xi, Y.; Jing, Y. Radiation Effects on Concrete; RIL 2021-07/ANL/EVS-20/18; Office of Nuclear Regulatory Research U.S. Nuclear Regulatory Commission: Washington, DC, USA, 2021. [Google Scholar]

- Kyoungsoo, P.; Hyung-Tae, K.; Tae-Hyun, K.; Eunsoo, C. Effect of neutron irradiation on response of reinforced concrete members for nuclear power plants. Nucl. Eng. Des. 2016, 310, 15–26. [Google Scholar] [CrossRef]

- Dubrovsky, V.D.; Pergamenshchik, B.K.; Soloviev, V.N. Radiation Resistance of Materials; Lavdansky, P.A., Ed.; Atomizdat: Moscow, Russia, 1973; 264p. [Google Scholar]

- Holmboe, M.; Norrfors, K.K.; Jonsson, M.; Wold, S. Effect of γ-radiation on radionuclide retention in compacted bentonite. Radiat. Phys. Chem. 2011, 80, 1371–1377. [Google Scholar] [CrossRef]

- Varlakov, A.P.; Kapustin, V.V.; Varlakova, G.A.; Zherebtsov, A.A.; Petrov, V.G.; Shirshin, E.A.; Kalmykov, S.N. The effect of radiation doses typical for high-level waste on the properties of the cement matrix. Radioact. Waste 2018, 1, 63–68. [Google Scholar]

- Rosnovsky, S.V.; Povarov, V.P. Ensuring radiation safety during temporary storage of solidified radioactive waste in light hangar-type facilities. Nucl. Energy Technol. 2021, 7, 195–199. [Google Scholar] [CrossRef]

- Denisov, A.V. Radiation changes of concrete aggregates under the influence of gamma radiation. Mag. Civ. Eng. 2020, 4, 94–109. [Google Scholar] [CrossRef]

- Onaizi, A.M.; Amran, M.; Tang, W.; Betoush, N.; Alhassan, M.; Rashid, R.S.M.; Yasin, M.F.; Bayagoob, K.H.; Onaizi, S.A. Radiation-shielding concrete: A review of materials, performance, and the impact of radiation on concrete properties. J. Build. Eng. 2024, 97, 110800. [Google Scholar] [CrossRef]

- Zatloukalová, J.; Dewynter Marty, V.; Zatloukal, J.; Kolář, K.; Hlaváč, Z.; Konvalinka, P. Mechanical properties of irradiated cement pastes for immobilization of evaporator concentrates. Prog. Nucl. Energy 2020, 127, 103437. [Google Scholar] [CrossRef]

- Dąbrowski, M.; Glinicki, M.; Dziedzic, K.; Jóźwiak-Niedźwiedzka, D.; Sikorin, S.; Fateev, V.; Povalansky, E. Early age hardening of concrete with heavy aggregate in gamma radiation source—Impact on the modulus of elasticity and microstructural features. J. Adv. Concr. Technol. 2021, 19, 555–570. [Google Scholar] [CrossRef]

- Rezaei, O.D.; Azim, K.S.; Gasemzadeh, M.H. Effect of gamma and lead as an additive material on the resistance and strength of concrete. Nucl. Eng. Des. 2011, 241, 2359–2363. [Google Scholar] [CrossRef]

- Potts, A.; Butcher, E.; Cann, G.; Leay, L. Long term effects of gamma irradiation on in-service concrete structures. J. Nucl. Mater. 2021, 548, 152868. [Google Scholar] [CrossRef]

- Anopko, D.V.; Honchar, O.A.; Kochevykh, M.O.; Kushnierova, L.O. Radiation protective properties of fine-grained concretes and their radiation resistance. IOP Conf. Ser. Mater. Sci. Eng. 2020, 907, 012031. [Google Scholar] [CrossRef]

- Vodák, F.; Vydra, V.; Trtík, K.; Kapičková, O. Effect of gamma irradiation on hardened cement paste. In Proceedings of the Second International Conference on Sustainable Construction Materials and Technologies, Ancona, Italy, 28–30 June 2010. [Google Scholar]

- Bykov, G.L.; Gordeev, A.V.; Yurik, T.K.; Ershov, B.G. Gas formation upon g-irradiation of cement material. High Energy Chem. 2008, 42, 211–214. [Google Scholar] [CrossRef]

- Operation Manual SNCI.421313.031 RE. Electric Linear Actuators MEP-A. Available online: https://www.tehprom21.ru/images/banners/doki/mep-aes/mep-a-421313031-re_v-4.pdf (accessed on 1 October 2024).

- Reches, Y. Quantification and modeling of the interactions of gamma radiation with concrete from bulk-scale observations. Int. J. Concr. Struct. Mater. 2019, 13, 59. [Google Scholar] [CrossRef]

- Kaspar, W.; Yunping, X.; Dan, N. A Review of the Effects of Radiation on Microstructure and Properties of Concretes Used in Nuclear Power Plants; NUREG/CR-7171/ORNL/TM-2013/263; Division of Engineering Office of Nuclear Regulatory Research U.S. Nuclear Regulatory Commission: Washington, DC, USA, 2013; 104p. [Google Scholar]

- Hamadouche, M.; Boudechicha, I. Influence du Milieu Acide sur la Corrosion du Plomb. Master’s Thesis, Université Mohamed El-Bachir El-Ibrahimi, Galbois, Algeria, 2020. [Google Scholar]

- Potts, A.; Leay, L. Evidence for pore water composition controlling carbonate morphology in concrete and the further effect of gamma radiation. Constr. Build. Mater. 2021, 275, 122049. [Google Scholar] [CrossRef]

- Shaikh, F.U.A. Effect of cracking on corrosion of steel in concrete. Int. J. Concr. Struct. Mater. 2018, 12, 3. [Google Scholar] [CrossRef]

- Craeye, B.; De Schutter, G.; Gerardy, I. Effect of gamma radiation and elevated temperatures on the strength of cementitious barriers for rad waste disposal. J. Chin. Ceram. Soc. 2012, 40, 33–38. [Google Scholar]

- 10 CFR 72.48. Evaluation Summary Report. Attachment 1. Monticello SLRA: Supplemental Audit. Questions TRP 76: Irradiation Effects on Biological Shield Concrete and Structural Steel. 2023. Available online: https://www.nrc.gov/docs/ML2328/ML23289A152.pdf (accessed on 1 October 2024).

- Le Caër, S. Water radiolysis: Influence of oxide surfaces on H2 production under ionizing radiation. Water 2011, 3, 235–253. [Google Scholar] [CrossRef]

- Daub, K.; Zhang, X.; Noel, J.; Wren, J. Effects of γ-radiation versus H2O2 on carbon steel corrosion. Electrochim. Acta 2010, 55, 2767–2776. [Google Scholar] [CrossRef]

- Gallé, C.; Peycelon, H.; Le Bescop, P.; Bejaoui, S.; L’Hostis, V.; Bary, B.; Bouniol, P.; Richet, C. Concrete long-term behaviour in the context of nuclear waste management: Experimental and modelling research strategy. J. Phys. IV 2006, 136, 25–38. [Google Scholar] [CrossRef]

- Oberson, G.; Dunn, D.; Hiser, M.; Torres, R.; Tripathi, B.; Wise, J.; Wong, E.; Pan, Y.; He, X.; Chowdhury, A.; et al. Identification of potential degradation phenomena for spent fuel dry cask storage systems. In Proceedings of the 17th International Conference on Environmental Degradation of Materials in Nuclear Power Systems—Water Reactors, Ottawa, ON, Canada, 9–12 August 2015; pp. 1–12. [Google Scholar]

- Maruyama, I.; Ishikawa, S.; Yasukouchi, J.; Sawada, S.; Kurihara, R.; Takizawa, M.; Kontani, O. Impact of gamma-ray irradiation on hardened white Portland cement pastes exposed to atmosphere. Cem. Concr. Res. 2018, 108, 59–71. [Google Scholar] [CrossRef]

- Ferreira, E.; Vicente, R.; Turrillas, X.; Yokaichiya, F.; Franco, M.; Martinez, L.G.; Carvalho, A.; Marumo, J.T. Effects of gamma radiation on cementitious materials in repository environment—16300. In Proceedings of the WM2016 Conference, Phoenix, AZ, USA, 6–10 March 2016; pp. 1–10. [Google Scholar]

- Stefanoni, M.; Angst, U.; Elsener, B. Corrosion rate of carbon steel in carbonated concrete—A critical review. Cem. Concr. Res. 2018, 103, 35–48. [Google Scholar] [CrossRef]

- Elsalamawy, M.; Ashraf, R.M.; Kamal, E.M. The role of relative humidity and cement type on carbonation resistance of concrete. Alex. Eng. J. 2019, 58, 1257–1264. [Google Scholar] [CrossRef]

- Thiel, C.; Kratzer, J.; Grimm, B.; Kränkel, T.; Gehlen, C. Effect of internal moisture and outer relative humidity on concrete carbonation. CivilEng 2022, 3, 1039–1052. [Google Scholar] [CrossRef]

- Gjörv, O.E.; Vennesland, Ø.E.; El-Busaidy, A. Electrical resistivity of concrete in the oceans. In Proceedings of the 9th Annual Offshore Technology Conference, Houston, TX, USA, 2–5 May 1977; pp. 581–588. [Google Scholar]

- López, W.; González, J.A. Influence of the degree of pore saturation on the resistivity of concrete and the corrosion rate of steel reinforcement. Cem. Concr. Res. 1993, 23, 368–376. [Google Scholar] [CrossRef]

- Parrot, L.J.; Chen, Z.H. Some factors influencing air permeation measurements in cover concrete. Mater. Struct. 1991, 24, 403–408. [Google Scholar] [CrossRef]

- Moreno, E.I.; Cob, E.; Castro-Borges, P. Corrosion from carbonated concrete specimes. In Proceedings of the CORROSION 2004 Symposium, New Orleans, LA, USA, 28 March 2004; p. 04439. [Google Scholar]

- Sumanth, H.; Vasugi, K. Effect of w/c ratio on the corrosion of reinforcement bar embedded in high strength concrete. J. Corros. Sci. Eng. 2020, 23, 14. [Google Scholar]

- Vazquez, D.; Duffó, G. Monitoring reinforcement corrosion of concretes designed for nuclear facilities. Rev. Matéria 2018, 23, 2. Available online: https://www.scielo.br/j/rmat/a/BfBXTRc3tDHbWBbRSfmNFDf/?lang=en (accessed on 1 October 2024).

- IAEA. Assessment and Management of Ageing of Major Nuclear Power Plant Components Important to Safety: Concrete Containment Building; IAEA-TECDOC-1025; International Atomic Energy Agency: Vienna, Austria, 1998; 157p. [Google Scholar]

- Badet, H. Effet de la Radiolyse sur les Systèmes de Corrosion Anoxiques à Très Long Terme des Alliages Ferreux. Ph.D. Thesis, Université Pierre et Marie Curie, Paris, France, 2013. [Google Scholar]

- Daub, K.; Zhang, X.; Noël, J.J.; Wren, J.C. Gamma radiation-induced carbon steel corrosion. Electrochem. Soc. ECS Trans. 2011, 33, 25. [Google Scholar] [CrossRef]

- Marsh, G.P.; Taylor, K.J. An assessment of carbon steel containers for radioactive waste disposal. Corros. Sci. 1988, 28, 289–320. [Google Scholar] [CrossRef]

- Aljohani, T.A.; Geesi, M.H.; Kaiba, A.; Al-Mayouf, A.M.; Khoshnaw, F. Characterization of gamma-ray irradiation influence on the corrosion behaviour of austenitic stainless steel. Mater. Today Commun. 2020, 24, 101242. [Google Scholar] [CrossRef]

- Shoesmith, D.W.; King, F. The Effects of Gamma Radiation on the Corrosion of Candidate Materials for the Fabrication of Nuclear Waste Packages; Engineered Barriers and Analysis Branch, Whiteshell Laboratories: Pinawa, MB, Canada, 1999. [Google Scholar]

- Aljohani, T.; Al-Mayouf, A.; Geesi, M.; Kaiba, A.; Khoshnaw, F. The impact of gamma radiation on the corrosion properties of carbon steel and stainless steel. In Proceedings of the EUROCORR19, Seville, Spain, 9–13 September 2019. [Google Scholar]

- Giannakandropoulou, S.I.; Desjonqueres, H.; Wittebroodt, C.; Baldacchino, G. Impact of γ-radiation on carbon steel anaerobic corrosion and H2 production. Radiat. Phys. Chem. 2023, 206, 110742. [Google Scholar] [CrossRef]

- Gulikers, J. Numerical modelling of reinforcement corrosion in concrete. In Corrosion in Reinforced Concrete Structures; Woodhead Publishing: Sawston, UK, 2005; pp. 71–90. [Google Scholar] [CrossRef]

- Bossio, A.; Monetta, T.; Bellucci, F.; Lignola, G.P.; Prota, A. Modeling of concrete cracking due to corrosion process of reinforcement bars. Cem. Concr. Res. 2015, 71, 78–92. [Google Scholar] [CrossRef]

- Habibi, S. Finite Element Modelling of Corrosion Damaged Reinforced Concrete Structures. Master’s Thesis, Department of Civil Engineering, University of Toronto, Toronto, ON, Canada, 2017. [Google Scholar]

- Michel, A. Reinforcement Corrosion: Numerical Simulation and Service Life Prediction. Ph.D. Thesis, Technical University of Denmark, Kongens Lyngby, Denmark, 2013. [Google Scholar]

- NUREG/CR-5466 (INISTIR 89-4086); Service Life of Concrete. National Institute of Standards and Technology: Gaithersburg, MD, USA, 2013; 104p.

- Jiang, J.; Yuan, Y. Relationship of moisture content with temperature and relative humidity in concrete. Mag. Concr. Res. 2013, 65, 685–692. [Google Scholar] [CrossRef]

- Bary, B.; Sellier, A. Coupled moisture–carbon dioxide-calcium transfer model for carbonation of concrete. Cem. Concr. Res. 2004, 34, 1859–1872. [Google Scholar] [CrossRef]

- Filipek, R.; Szyszkiewicz-Warzecha, K.; Szczudło, J. Corrosion of steel in concrete—Modeling of electrochemical potential measurement in 3D geometry. Arch. Metall. Mater. 2020, 65, 117–124. [Google Scholar] [CrossRef]

| Research, Year | Composition of the Mixtures of the Studied Specimens | Accumulated Dose of Gamma Radiation | Gamma Radiation Rate | Research Results |

|---|---|---|---|---|

| Khmurovska Y. et al., 2019 [79] | cement (CEM I 42.5R)—33.5%; water—12.7%; sand (0–4 mm)—53.5%; superplasticizer (Glenium ACE 442)—0.3% | 12.0–15.0 MGy (accelerated tests conducted using isotope Co60) | 3.9–4.71 kGy/h | Gamma irradiation greatly reduces compressive strength by an average of 20% |

| Anopko D.V. et al., 2020 [127] | steel fiber cement mixture | 10 MGy, which corresponds to the shelter-type protective structure during 300 years of operation (accelerated testing conducted using isotope Cs137) | 20.0 kGy/h (energy–1.25 MeV) | Higher compressive strength and stable flexural strength limit values |

| Zbyněk Hlaváč et al., 2021 [75] | mixed Portland cement SPC 325—22.2%; quartz sand (0–2.5 mm)—66.7%; water—11.1% | 0.8–1.8 MGy (accelerated testing conducted using isotope Co60) | 1.6 kGy/h (energy–1.17 and 1.33 MeV) | A 30% decrease in strength due to microcracks, bending strength—by 26.3%, compression strength—by 5.3%, and tensile strength—by 30%. The authors attribute these effects to radiolysis |

| Potts A. et al., 2021 [126] | portland cement—8.5%; fly ash—5.6%; limestone as a coarse aggregate (fraction–10 and 20 mm)—46.4%; sand—32.3%; water—7.1%; superplasticizer (Sika 130)—0.1% | 35.8 MGy, which corresponds to storing specimens in a storage facility for 30+ years | 134.4 Gy/h | No decrease in compressive strength was observed |

| Research, Year | The Medium in Which the Study was Conducted | The Temperature for Testing Procedures, °C | pH of the Medium | Gamma Radiation Dose, kGy/h | Test Time, Days | Key Findings |

|---|---|---|---|---|---|---|

| Badet et al., 2014 [154] | Pure water (anoxic conditions) | 25 | 6.5 | 0.3 | up to 99 | In experimental media, acceleration of corrosion was observed under the effect of high-dose gamma radiation. The corrosion rate nearly tripled. The dose rate at which an increase in the corrosion rate was observed is significantly higher than that selected for storage of radioactive waste. |

| Water with carbonates (anoxic conditions) | 7.1 | 0.3 | 15, 109, and 340 | |||

| 1.0 | 109 and 340 | |||||

| Smart N.R. et al., 2008 [58] | Artificial groundwater | 30 | 8.8 | 0.011 | 166 | Gamma radiation increases the rate of anaerobic corrosion of carbon steel in artificial groundwater. At 11 Gy/h the increase lasts only about 7000 h, but at 300 Gy/h it lasts longer and may be continuous. |

| 50 | 10.4 | |||||

| Aljohani T. et al., 2019 [159] | Sodium chloride | not specified | 7.0 | 4.0 | 37.5 and 62.5 | Specimens exposed to high doses of radiation of 150 and 250 kGy showed accelerated corrosion. |

| Marsh G. P. et al., 1988 [156] | Groundwater contacting granite | 90 | 9.4 | 1.0 | 100 and 200 | In slightly saline groundwater contacting granite, at the gamma radiation dose rate of 1.0 kGy/h and a temperature of 90 °C, the corrosion rate increased from less than 0.1 μm/year to 3 μm/year, at a factor of 30. |

| Winsley et al., 2011 [64] | Artificial pore water with high alkali content (anaerobic) | 80 | 13.4 | 0.025 | 230 and 250 | The corrosion rate did not change. The authors believe that apparently the dose rate of 25 Gy/h is not sufficient to accelerate corrosion in general. The presence of chlorides accelerates corrosion, but this acceleration is insignificant. |

| Artificial pore water with high alkali content, with chlorine added (anaerobic) | ||||||

| Artificial pore water with high alkali content (anaerobic) | 25 | 13.4 | 223 | |||

| Giannakandropoulou S.I. et al., 2022 [160] | Ultrapure deaerated water (anaerobic) | not specified | 7.0 | 0.050 | 15 and 16 | Gamma radiation causes a slight decrease in the corrosion rate of carbon steel. |

| Canshuai Liu et al., 2018 [67] | Groundwater (aerobic) | 25 | - | 3.0 (energy—1.25 MeV) | 14.28 and 42 (absorbed doses—1, 2, and 3 mGy, respectively) | Gamma radiation increases lattice defects and reduces the overall electrical potential, accelerating the process of both local and general corrosion. |

| PS (%) | Concrete Resistivity ρ (Ω·m) | Effective Diffusivity of Oxygen DO2·1010 (m2/s) |

|---|---|---|

| 20 | 5.727 | 152 |

| 30 | 1.227 | 115 |

| 40 | 500 | 83 |

| 50 | 205 | 49 |

| 55 | 170 | 39 |

| 60 | 142 | 28 |

| 65 | 125 | 20 |

| 70 | 102 | 15 |

| 75 | 80 | 10 |

| 80 | 64 | 8.5 |

| Parameter * | Expression |

|---|---|

| AFe | 0.41 [V] |

| AH2 | −0.15 [V] |

| AO2 | −0.18 [V] |

| CO2_ref | 9.46 [mol/m3] |

| CO2_ref_9_100 | 8.6 [mol/m3] |

| Eeq_Fe | −0.76 [V] |

| Eeq_H2 | −1.03 [V] |

| Eeq_O2 | 0.189 [V] |

| I0_Fe | 7.1 × 10−5 [A/m2] |

| I0_H2 | 1.1 × 10−2 [A/m2] |

| I0_O2 | 7.7 × 10−7 [A/m2] |

| L | 3.175 × 10−2 [m] |

| Rreinforcement bar | 0.635 × 10−2 [m] |

| S | 2.54 × 10−2 [m] |

| W | 6.35 × 10−2 [m] |

| PS | 0.6 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Omarov, R.; Belov, V.; Morozenko, A. Studying Radiation-Induced Degradation of Reinforced Concrete Structures: Review and Numerical Analysis of Reinforcement Corrosion Processes in Concrete. Appl. Sci. 2024, 14, 11856. https://doi.org/10.3390/app142411856

Omarov R, Belov V, Morozenko A. Studying Radiation-Induced Degradation of Reinforced Concrete Structures: Review and Numerical Analysis of Reinforcement Corrosion Processes in Concrete. Applied Sciences. 2024; 14(24):11856. https://doi.org/10.3390/app142411856

Chicago/Turabian StyleOmarov, Rustem, Vyacheslav Belov, and Andrey Morozenko. 2024. "Studying Radiation-Induced Degradation of Reinforced Concrete Structures: Review and Numerical Analysis of Reinforcement Corrosion Processes in Concrete" Applied Sciences 14, no. 24: 11856. https://doi.org/10.3390/app142411856

APA StyleOmarov, R., Belov, V., & Morozenko, A. (2024). Studying Radiation-Induced Degradation of Reinforced Concrete Structures: Review and Numerical Analysis of Reinforcement Corrosion Processes in Concrete. Applied Sciences, 14(24), 11856. https://doi.org/10.3390/app142411856