1. Introduction

Dynamic analysis of complex systems, such as vehicles, robots, and machining equipment, has been an area of extensive research, leading to the development of diverse methodologies. Predictive methods like Finite Element Modal Analysis (FEMA) and Dynamic Substructuring (DS) are widely used during the design phase to model and predict dynamic responses, providing insights into natural frequencies, mode shapes, and substructure interactions. On the other hand, diagnostic approaches such as Root Cause Analysis (RCA) and Transfer Path Analysis (TPA) focus on identifying and mitigating vibration issues in operational systems by analyzing energy transmission paths and the sources of vibrational behavior.

Van der Seijs et al. (2016) [

1] discussed TPA as a diagnostic tool for vibration and noise issues, classifying it into classical, component-based, and transmissibility-based methods. Similarly, Tuninetti et al. (2021) [

2] applied RCA combined with FEMA to diagnose vibration issues using structured cause–effect diagrams. Kong et al. (2024) [

3] advanced operational TPA by addressing the challenge of reliable motor controller unit analysis in electric vehicles under real-world conditions. However, their approach lacks a generalized framework for modeling system-wide dynamics.

De Klerk, Rixen, and Voormeeren (2008) [

4] provided an extensive framework for DS, a methodology for analyzing complex systems by dividing them into smaller, manageable substructures for independent analysis. DS facilitates modular analysis while maintaining computational efficiency, utilizing techniques such as Component Mode Synthesis (CMS), Impulse-Based Substructuring (IBS), state–space coupling, and Frequency-Based Substructuring (FBS). CMS simplifies large finite element models by retaining key mode shapes (mode truncation), making it suitable for low-frequency applications. State–space coupling complements this by modeling substructures through first-order differential equations and enforcing compatibility at interfaces.

The FBS and IBS approaches are effective for high-frequency applications due to their direct incorporation of receptance or Frequency Response Function (FRF) matrices, preserving damping and complex modes. While IBS leverages impulse response functions (IRFs) for transient or impact loading scenarios in the time domain, FBS synthesizes FRFs in the frequency domain, avoiding mode truncation and ensuring high-frequency dynamics are preserved. Among these, FBS has emerged as a modular approach for analyzing system dynamics by coupling subsystems using experimentally or numerically derived FRFs. Receptance coupling (RC), a subset of FBS, dynamically combines receptance matrices by enforcing compatibility (displacement/moment continuity) and equilibrium (force/moment balance) at subsystem interfaces.

The concept of receptance coupling was first introduced by Bishop and Johnson [

5], with subsequent advancements by Gordis, Bielawa, and Flannelly [

6] in integrating structural coupling and modification within Finite Element Analysis (FEA). Further advancements were made by Duarte and Ewins [

7], who explored translational and rotational parameters for structural coupling analysis using the finite-difference technique. Among the various FBS techniques, the generalized receptance coupling method introduced by Jetmundsen in 1988 [

8] and the Lagrange Multiplier Frequency-Based Substructuring (LM FBS) method developed by De Klerk et al. in 2006 [

9] are particularly notable and widely utilized. Since their pioneering contributions, the field of FBS and receptance coupling has evolved significantly. Recent innovations have mostly expanded upon these foundational works by incorporating advanced methodologies and cutting-edge technologies.

Liu and Ewins [

10] quantified errors arising from neglecting rotational degrees of freedom (DOFs) in FRF coupling analysis, underscoring the importance of including rotational dynamics in structural analyses. Sattinger [

11] developed methods for experimentally determining rotational mobilities, while Schmitz [

12] introduced Receptance Coupling Substructure Analysis (RCSA) to synthesize FRFs at various locations for predicting assembly dynamics. Building on this, Schmitz and colleagues [

13,

14,

15,

16,

17,

18,

19] extended RCSA to predict tool-point dynamics in machining, integrating analytic, experimental, and empirical connection parameters. Hou et al. [

20] proposed Generalized RCSA (GRCSA) for parameter-varying mechanical systems, and Wang et al. [

21] integrated TPA with RCSA for machining applications using impact tests. Filiz et al. [

22] further enhanced tool-holder models by incorporating Timoshenko beam equations for predicting tool-point frequency responses. These advancements collectively provide foundational tools for advancing vibration analysis and dynamic system design.

The authors have recently introduced innovative and practical methodologies in dynamic system modeling and vibration analysis. The first paper introduces foundational approaches for modular modeling, featuring partitioning schemes such as the Minimal Segmentation Approach (MSA) and Systematic Element Partitioning (SEP), validated through analytical solutions. It also presents a computationally efficient method for identifying natural frequencies via subsystems’ receptance coupling, even without a physical or FEM model of the entire system [

23]. The second paper develops a reduced-order modeling framework for both lumped and distributed parameter systems using Receptance Coupling methods using Frequency-Based Substructuring (RCFBS), delivering enhanced accuracy and efficiency for system identification. The RCFBS method demonstrates superior accuracy for high-frequency dynamics in systems with flexible or distributed parameters, showing closer alignment with FEA and direct solution techniques compared to traditional modal analysis, effectively addressing mode truncation issues [

24]. The third paper introduced generalized receptance coupling methods using Frequency-Based Substructuring (GRCFBS), which indirectly incorporated rotational DoFs, obtaining full dynamics. The application of this method is demonstrated in the development of a half-vehicle model, enabling modular analysis of dynamic interactions between subsystems like the chassis and suspension [

25].

Recent advancements in dynamic substructuring have explored the integration of data-driven techniques, such as machine learning (ML), to enhance predictive capabilities and improve computational efficiency. For instance, Baqir et al. (2024) [

26] proposed a hybrid approach that combines traditional finite element (FE) models with ML-based meta-models in the frequency domain. This approach allows for the coupling of physics-based models with data-driven methods, offering improved predictions and computational efficiency.

Despite these developments, most generalized receptance coupling methods using FBS either overlook rotational dynamics, leading to inaccuracies, or implicitly include full dynamics, resulting in redundancy in generalized coordinates during the coupling process, particularly at connection points. To address these challenges, this study builds on Jetmundsen’s foundational work, extending GRCFBS to explicitly incorporate rotational DoFs, thereby enhancing the accuracy of system dynamics and synthesizing weak and strong coupling scenarios at interfaces. This explicit approach provides a comprehensive description of the relationship between rotational and translational dynamics, improving system behavior predictions for complex interactions at interfaces and avoiding redundancy issues encountered in methods like LM-FBS. The methodology is demonstrated through two case studies: coupling two flexible components of a cantilever beam and integrating flexible and rigid components.

Additionally, Euler–Bernoulli beam theory (EBT) is employed to derive reduced-order, explicit receptance matrices for substructures, capturing translational and rotational dynamics effectively. This method is particularly valuable for systems like vehicle structures, where moments and forces are applied at connection nodes. While EBT remains a suitable approximation for subsystem modeling, Timoshenko beam theory is recommended for higher-frequency ranges to account for inertial effects and achieve greater accuracy.

Furthermore, EBT is employed to derive reduced-order and explicit receptance matrices for substructures, capturing the full dynamics of both translational and rotational behaviors at DoFs of interest. By explicitly determining the receptance matrix components corresponding to flexible substructures, EBT provides a reliable approximation for both rotational and translational properties at critical points within subsystems. This approach is particularly effective for systems like vehicle structures, where translational forces and moments are applied at nodes, connection points, and coupling regions, accurately accounting for all relevant DoFs within a reduced-order model.

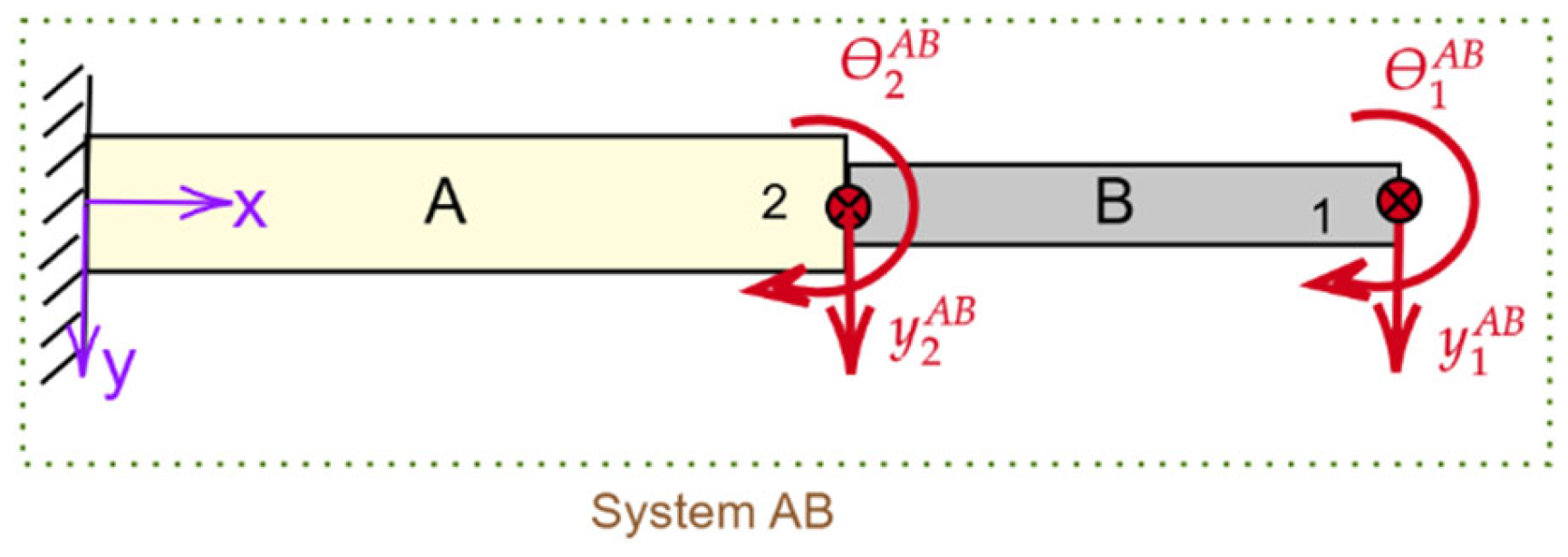

The novelty of this study lies in the development of a practical, generalized formulation for determining the receptance matrix at each substructure node while explicitly incorporating both translational and rotational DoFs (as detailed in

Section 2.1). Existing generalized receptance coupling methods, such as those by Jetmundsen, do not fully address the integration of translational and rotational dynamics in their formulations. The explicit definition of rotational dynamics within this framework improves the integrity and comprehensive modeling of the receptance at the critical points, with particular emphasis on connection points, ensuring that both translational and rotational effects are effectively captured. This clarity in system behavior modeling is particularly valuable when addressing complex interactions between substructures. To illustrate this, this paper presents the derivation of receptance coupling formulations for two subsystems, A and B, each with two DoFs (one translational and one rotational). This simplified formulation demonstrates the core mathematical principles without compromising generality or completeness.

For subsystems exhibiting bending and translational dynamics, where experimental receptance data may be unavailable due to measurement challenges, the EBT-based model offers a robust method for estimating the required receptance functions. This capability enables broader applications in structural dynamics and aligns with findings presented in high-speed machining systems (e.g., Schmitz and Duncan, 2005) [

15].

The accuracy of the proposed approach is validated through numerical FEA and comparisons of coupled receptance response elements. The alignment of natural frequencies and the identification of resonance and anti-resonance peaks demonstrate consistent and reliable predictions across various excitation conditions. While EBT serves as a reliable approximation for subsystem receptance modeling, Timoshenko beam theory is recommended for higher frequency ranges, where inertial and shear deformation effects become significant for achieving more accurate predictions.

Although this paper focuses on linear systems and modular substructuring, the proposed framework has the potential to be extended to nonlinear systems under certain conditions. Nonlinear joints can be approximated through linearization, and local nonlinear dynamics of substructures can be incorporated as additional dynamic stiffness or represented experimentally as black-box receptance measurements at critical points. These approximations and measurements can then be integrated into the GRCFBS methodology, enabling its application to nonlinear subsystems within a limited range of operating conditions.

2. Methodology

This section presents the methodology for analyzing the dynamic characteristics of mechanical systems using GRCFBS. This approach decomposes complex dynamic systems into simpler substructures, enabling the calculation and analytical coupling of their FRFs. The overall system response is then determined through a generalized coupling algorithm, which effectively combines these subsystems as black boxes carrying receptance matrices. This approach accounts for the interfaces between subsystems. This methodology is evaluated for both flexible-to-flexible and flexible-to-rigid subsystem couplings. Such analysis is essential, as ignoring the flexibility of certain subsystems can introduce significant errors due to incorrect assumptions regarding component rigidity and DoFs. The approach facilitates constructing reduced-order models, where subsystems are modeled by simple geometries, focusing on both rotational and translational DoFs associated with points of interest such as measurement points at connection interfaces or internal points. The inherent properties of each subsystem are incorporated at these points, defined by generalized coordinates in the dynamic model.

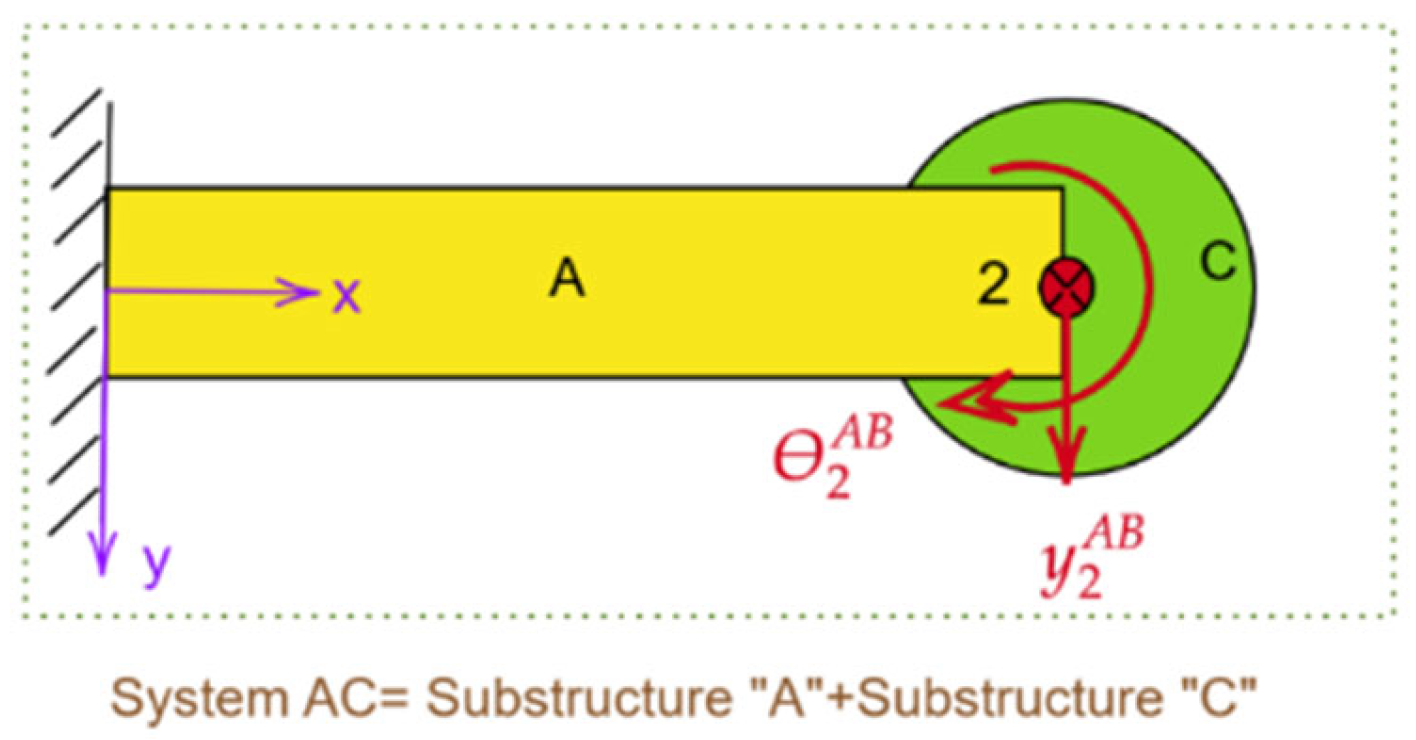

This hybrid method aids in predicting vibrational performance for system identification or subsystem decomposition in early development stages, allowing for efficient evaluation of different subsystem combinations. System performance is influenced by the FRF properties of subsystems, which implicitly include stiffness, mass, and damping characteristics, as well as the configuration of coupling and connection joints. Extensive research has demonstrated that the receptance coupling method effectively models vibrations by breaking down complex systems into manageable substructures. The FRFs of these subsystems can be derived experimentally or numerically. To illustrate the analytical solution using GRCFBS, this study simplifies a cantilever beam structure into two substructures, coupled in two ways: first, as a system of two flexible beam elements representing subsystems, and second, as a flexible beam element coupled with a rigid mass. The FRF matrix for flexible subsystems, modeled as simple beam elements, is derived using EBT which assumes small deformations and neglects shear deformation and rotary inertia, making it suitable for linear elastic analysis.

2.1. Review of GRCFBS Methodology

The GRCFBS technique provides a robust framework for coupling receptance matrices of subsystems, derived analytically or experimentally through substructuring methods in the frequency domain. Building on the Jetmundsen formulation [

27], this method has been further refined and adapted to suit the specific case studies discussed in this paper. These refinements have introduced innovative equations to facilitate the generalized coupling of multiple subsystems, significantly improving the accuracy of dynamic response predictions. Notably, the sequence in which the FRF matrices are assembled is determined by the number of coordinates involved in the coupling, independent of each subsystem’s DoFs. This method reduces the complexity of the equations needed to describe the entire reconfigurable dynamic system. Fundamentally, the relationship between force excitation (input) and vibration response (output) for a linear system is expressed as follows:

where

is the vector of the output response at the p-th generalized coordinate or measurement point,

is the vector of the input excitation force at the q-th generalized coordinate, and

represents the component of the receptance matrix between generalized coordinates p and q which may include both rotational and translational DoFs in the general case. The matrix

consists of transfer function components that relate the complex rotational or translational displacement amplitudes at measurement points on a dynamic structure to the complex excitation force or moment amplitudes applied at the same or other points, as represented by generalized coordinates. While measuring translational displacements and forces is relatively straightforward, the measurement of rotational displacements and moments presents a greater challenge in dynamic systems. For an arbitrary subsystem, the linear form of the equations of motion, involving direct and indirect receptance components, can be written as follows:

Assuming harmonic force excitation and steady-state responses, the equations governing rotational and translational displacements for a single-node system, across all DoFs, can be expressed as follows:

where

x,

y, and

z are the translational displacements, and

represent the angular displacements about the x, y, and z coordinate axes, respectively. By partitioning Equation (3), the condensed form shown in Equation (4) is obtained:

where

and

represent the translational and rotational components of displacement, respectively, and

,

,

, and

represent the translational response to translational force excitation, translational response to couple excitation, rotational displacement to translational force excitation, and rotational response to couple excitation, respectively.

2.2. Development of General Coupling Formulas with Full DoFs Using GRCFBS

The receptance coupling method, initially formulated by Jetmundsen, describes the coupling of two subsystems (A and B) to yield the assembled subsystem receptance matrix at the interface and internal coordinates, as expressed as follows [

8]:

In this formulation, subscripts

a and

b refer to the internal DoFs within substructures

A and

B, while subscript

c corresponds to the connection DoFs between subsystems. In this paper, it is assumed that no internal generalized coordinates within the subsystems are involved, meaning that the points of interest are limited to the connection nodes for simplicity. This assumption does not impact the generality of the procedure. Emphasis is placed on determining

, which captures the direct receptance at the interface based on the individual subsystems’ receptance matrices at the connection coordinates. Under various coupling assumptions,

can be expanded for two conditions of weak and strong coupling between rotational and translational DoFs at the interfaces. From Equation (5),

can be expressed in terms of

and

as follows:

Using Equations (4) and (6), the receptance coupling for the assembled system AB can be defined as follows:

where the matrix

D denotes receptance at the connection points and is expressed as follows:

Assuming a negligible coupling between the translational and rotational DoFs at the connection points between subsystems A and B—meaning that the off-diagonal terms

and

in the coupling matrix are approximately zero—the simplified Equation (7) is as follows:

Due to the principle of reciprocity in dynamic systems, the cross-receptances are equal ( = ) to maintain the symmetry of the system.

The coupling between translational and rotational DoFs at each node is typically weak or negligible under conditions where either the structural or dynamic properties of the connection points or interfaces inherently limit rotational–translational interactions (e.g., pinned connections or hinges), or the physical layout or symmetry of the nodes reduces the likelihood of significant cross-influence. This simplification applies in cases where the stiffness or mass matrix contributions from rotational–translational coupling are minimal, such as in structures with highly localized DoF constraints or when modeling low-frequency dynamics in certain rigid body approximations. Rearranging Equation (9) results in the following:

In Equation (10), the third term,

, represents the effects of the rotational DoFs of the connection points. If only translational DoFs are considered, the equation simplifies to the following:

where

and

denote the translational and rotational components of dynamic stiffness at the connection area, respectively. For more general scenarios where coupling between rotational and translational DoFs at the interface is significant, the cross-receptance terms,

and

, of matrix D at the connection zone must be considered, resulting in a more complex form of the equation.

Using the definition of

, the inverse matrix

can be determined as follows:

The receptance matrices

for the coupled system AB are determined for a single node c representing the connection point:

where

,

,

, and

represent the coupling parameters for translational DoFs (where the excitation load is a force and the measured displacement is translational), while

,

,

, and

represent the coupling parameters for rotational DoFs (where the external excitation is a moment). The terms like

,

,

, and

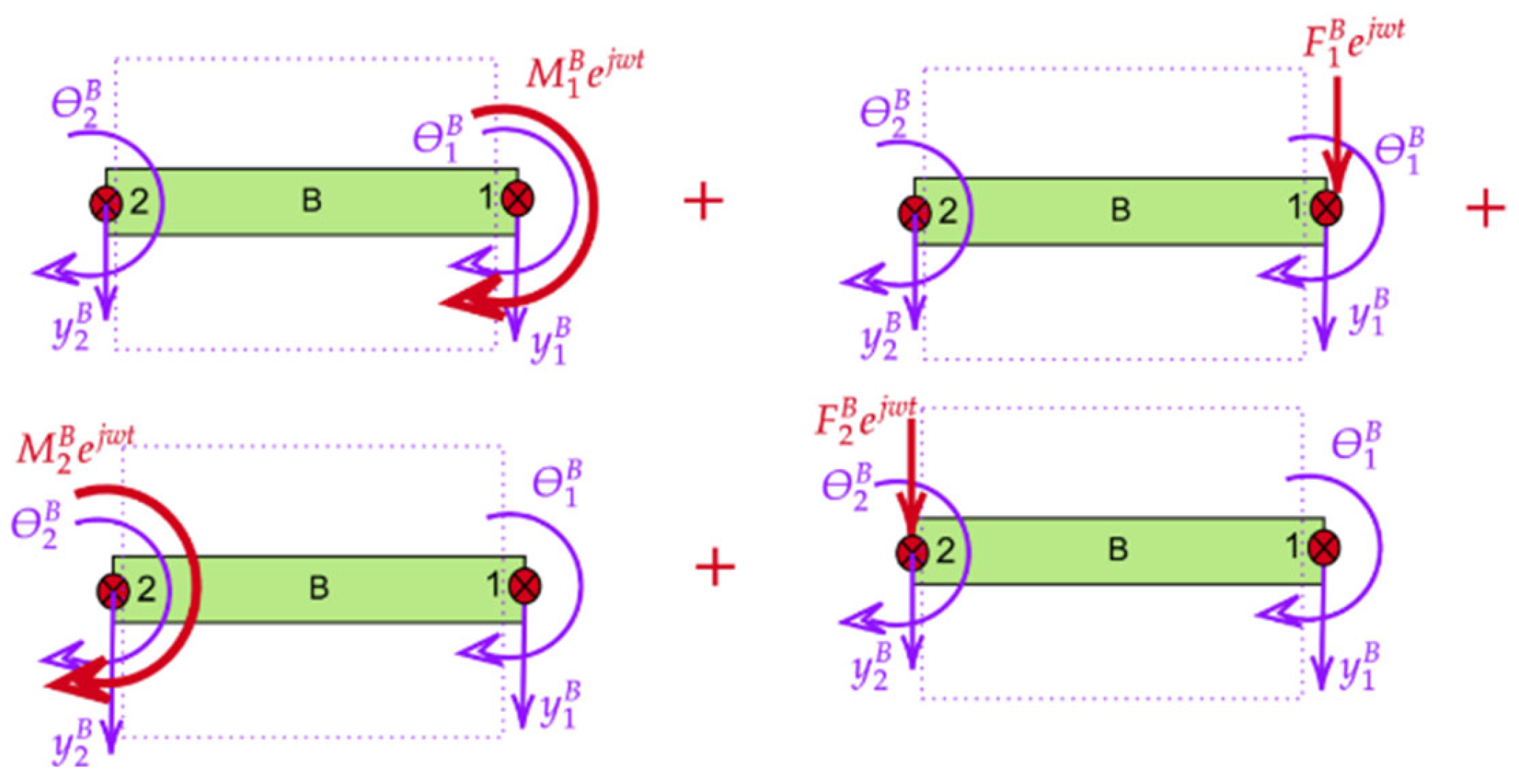

represent the coupling parameters between translational displacement and rotational excitation load (moment) and vice versa. For simplicity, the coupling of two subsystems A and B, each with two DoFs (one translational and one rotational) has been considered. For subsystem A, the equation of motion determining the displacement vector of the generalized coordinate

in terms of the generalized receptance matrix

and the generalized excitation forces

(including both translational force

and moment

) can be expressed as follows:

For subsystem B, with two generalized coordinates

and

, the equation of motion can be expressed in terms of the generalized receptance matrices

and

and the generalized excitation forces

:

Equation (15) can be expressed in the matrix form as follows:

where

and

are the generalized excitation forces, expressed as follows:

For the assembled system AB, the equation of motion determines the generalized coordinates

in terms of the generalized receptance matrices

and

, and the generalized excitation forces

and

can be expressed as follows:

Assuming rigid coupling between subsystems A and B, the compatibility condition

, and the equilibrium condition at the interface

. Using these conditions, the assembly receptance AB can be expressed in terms of the receptance matrices of subsystems A and B as follows:

To demonstrate the application of this method, two examples are provided in the following section.

6. Conclusions

This study evaluates the effectiveness and limitations of the GRCFBS method, which integrates generalized receptance coupling with FBS approaches. By developing explicit rotational DoFs, this approach improves the prediction accuracy of dynamic systems that experience both translational and rotational motions. Building on Jetmundsen’s foundational work, the proposed framework introduces a practical, generalized formulation that explicitly incorporates full translational and rotational dynamics at each substructure node. This explicit formulation accounts for both translational and rotational displacements, enhancing the model’s capability to predict the dynamic behavior of coupled systems more efficiently. The refinement of the GRCFBS method, which integrates rotational DoFs into the system formulation, provides a more comprehensive approach to capturing the dynamics of flexible structures and their interactions under complex loading conditions.

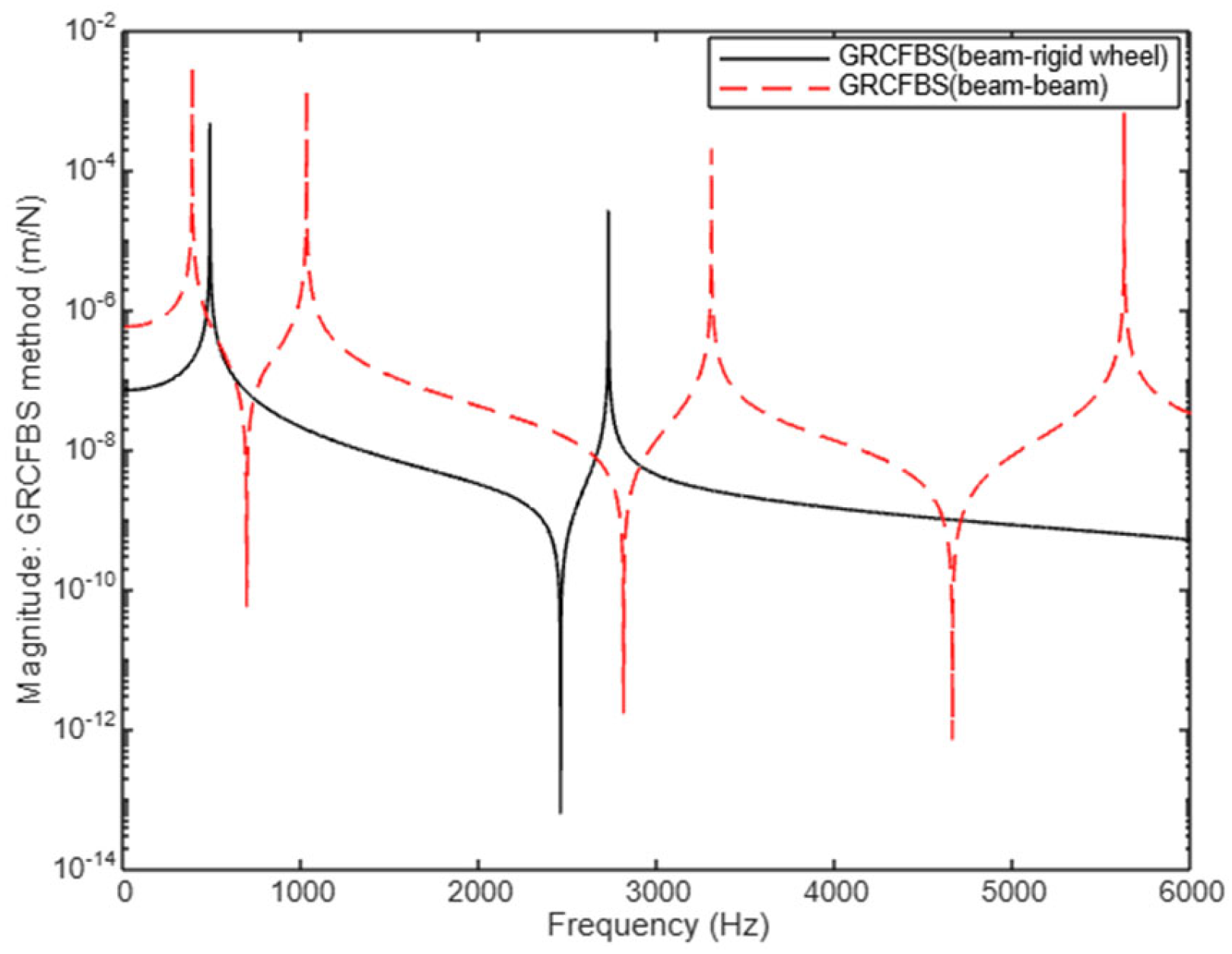

This study focuses on two case studies: a flexible beam–beam coupling and a flexible beam–rigid wheel coupling, validating the performance of the GRCFBS method in these configurations.

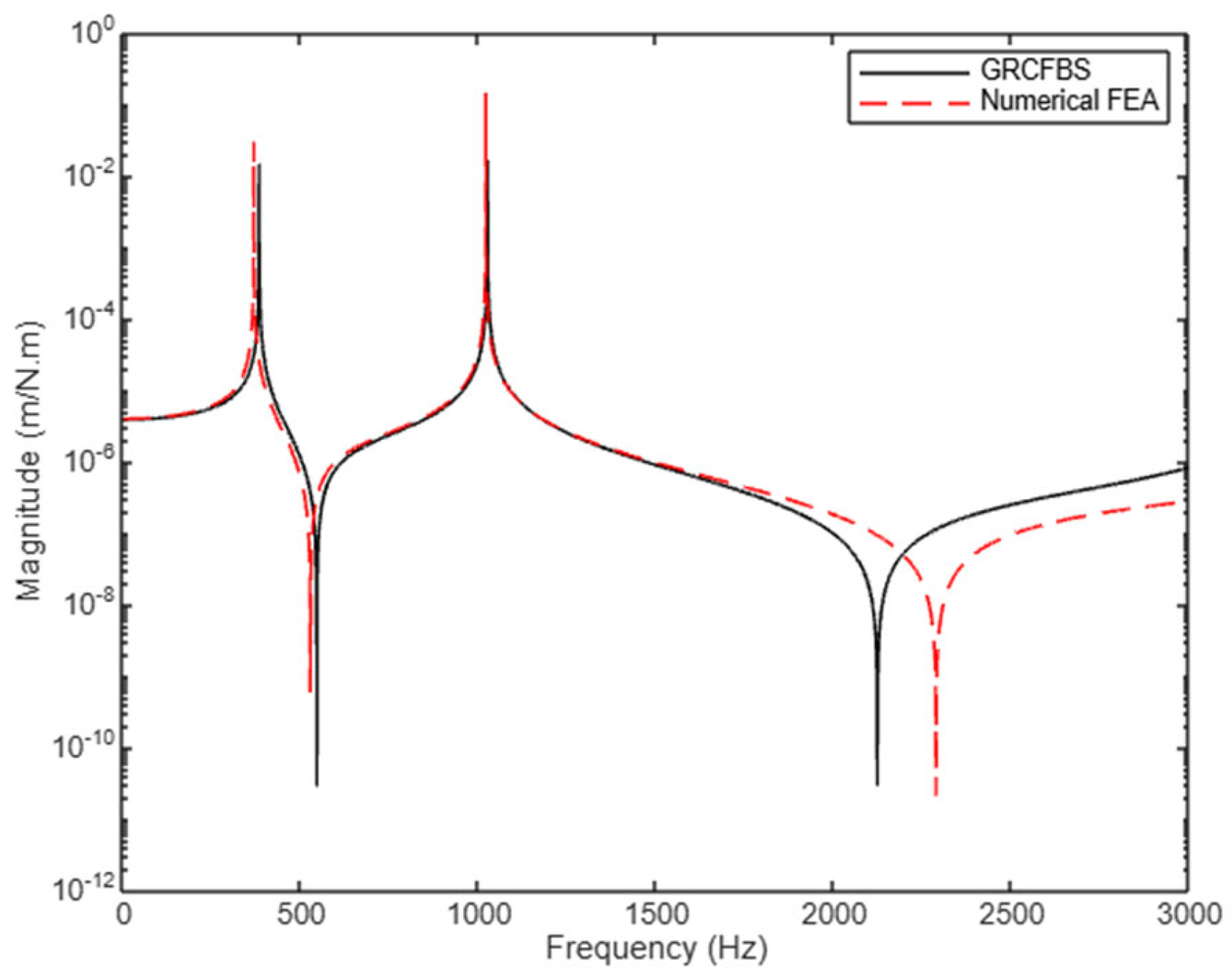

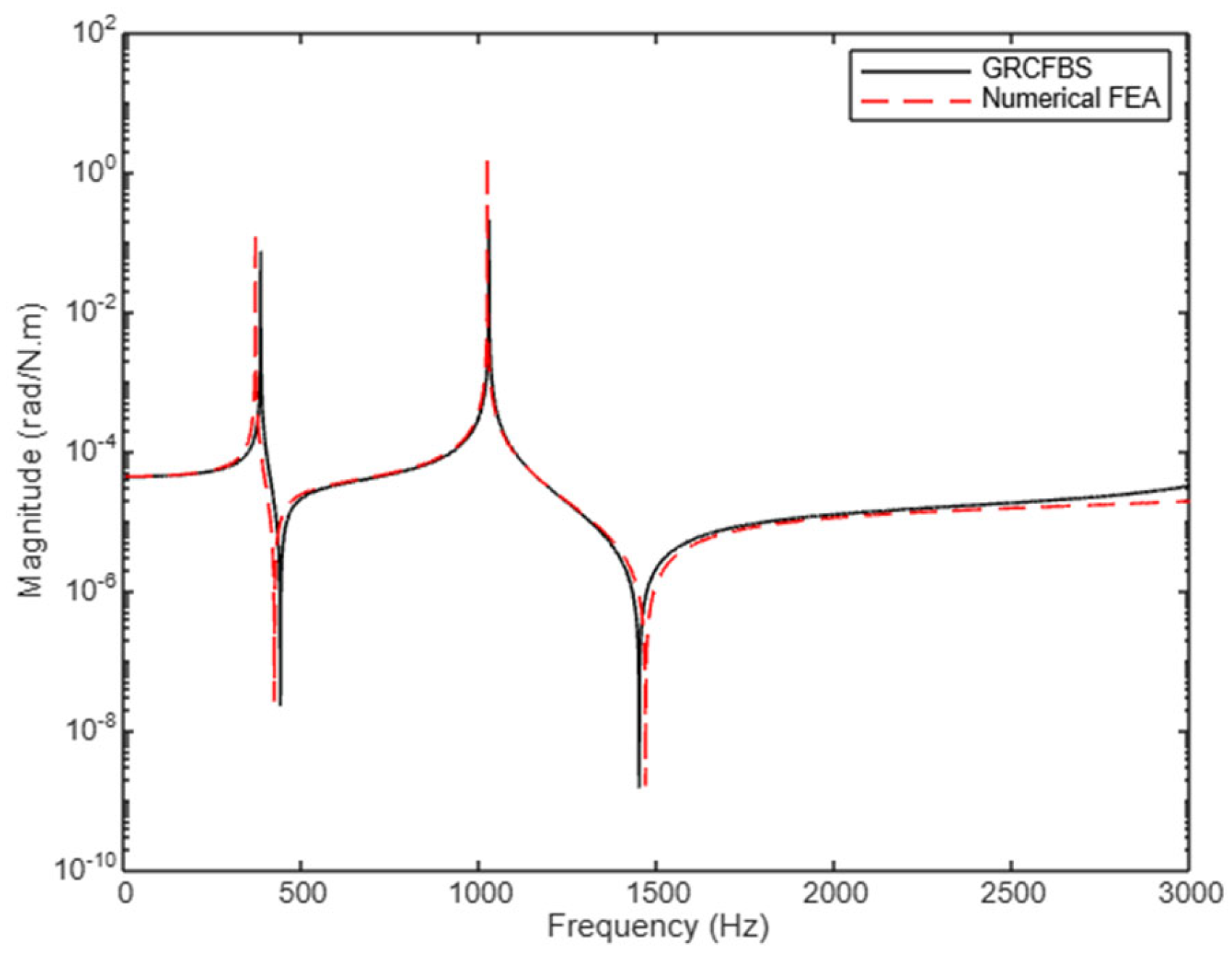

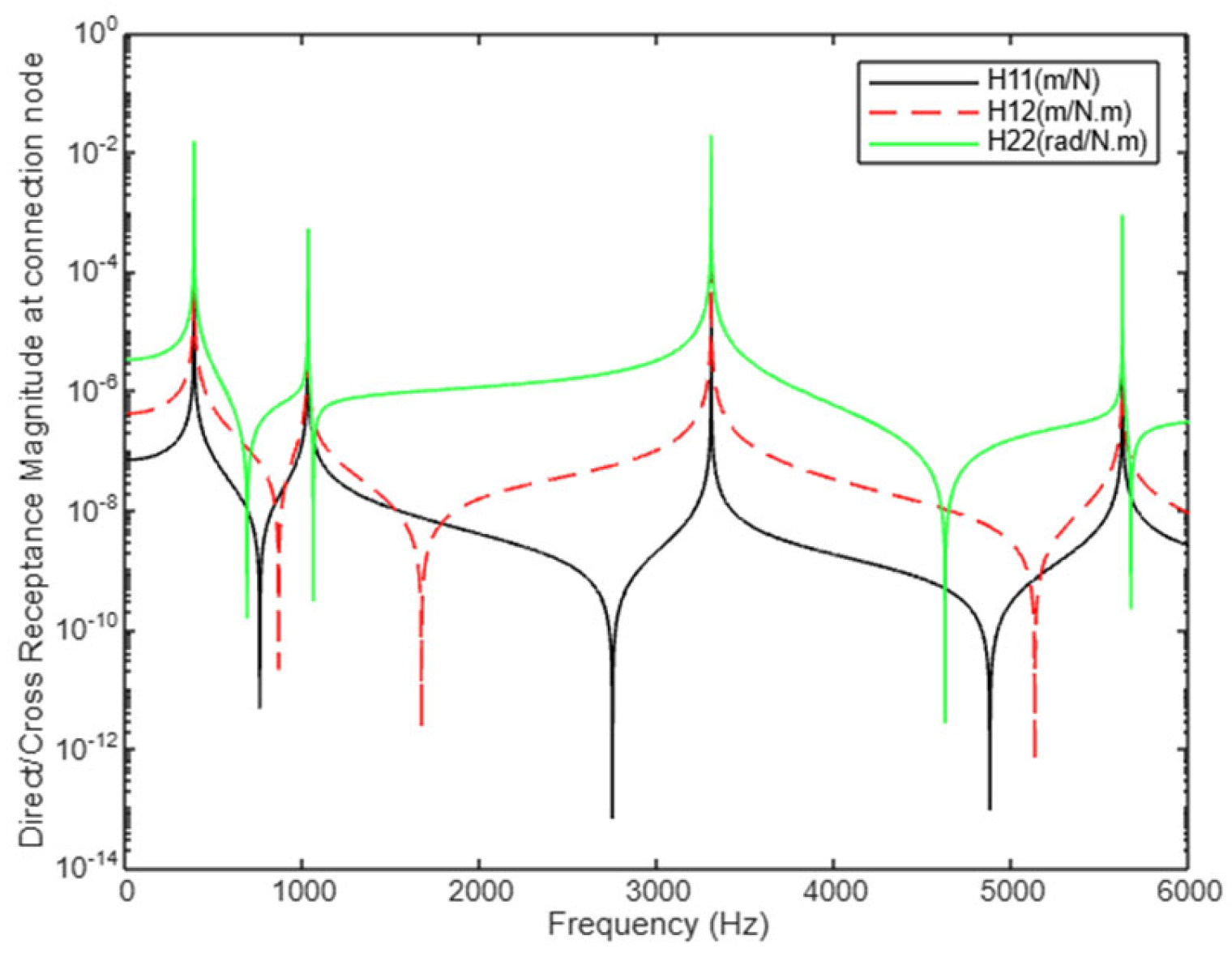

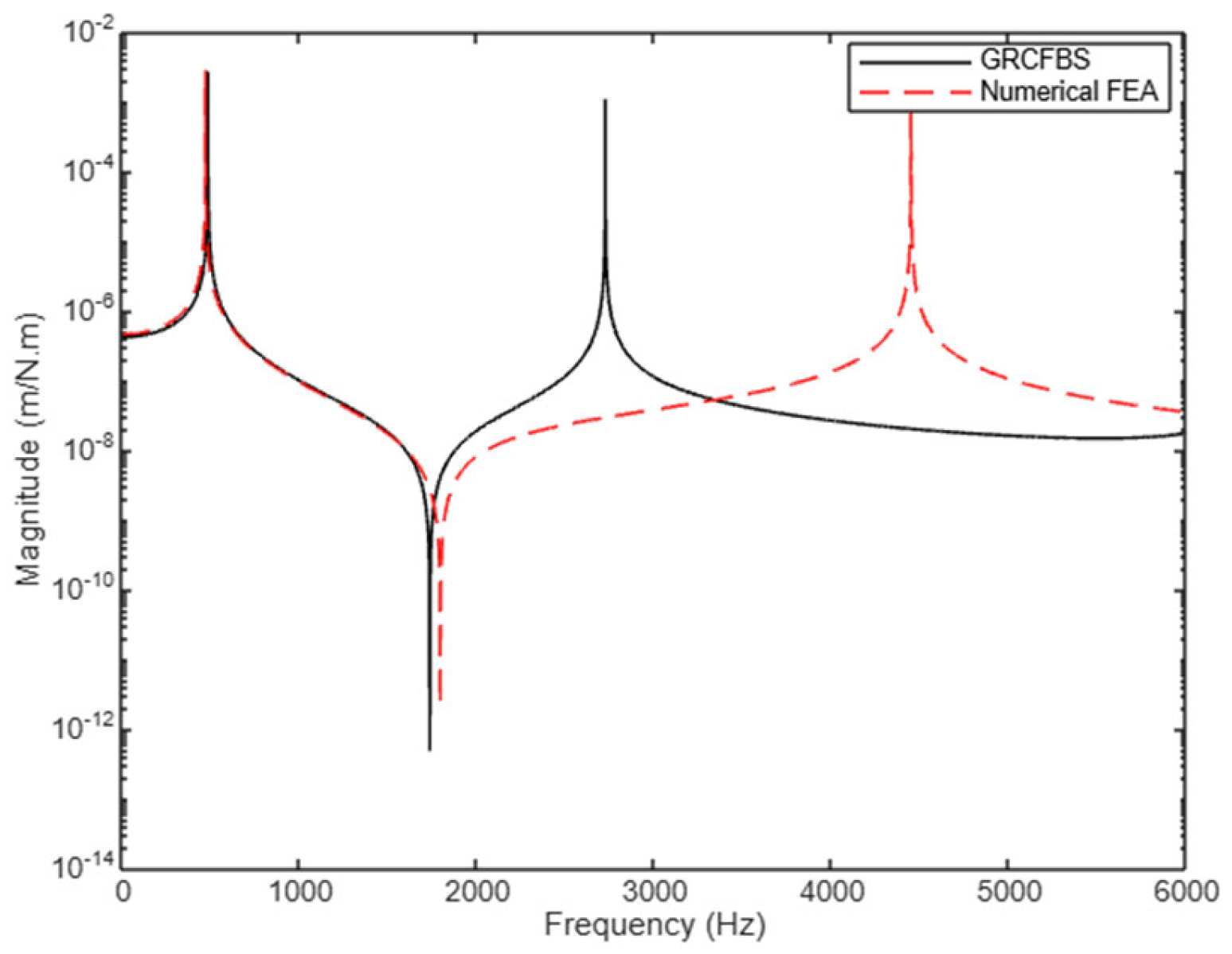

The results demonstrate that the GRCFBS method, when employing the EBT, accurately predicts system vibrational characteristics, especially at a lower range of frequencies (up to 2000 Hz), where it shows strong alignment with FEA. Specifically, the relative error in predicting resonance frequencies at lower frequencies is found to be less than 5%, indicating a high degree of accuracy for these ranges. Both direct and cross-receptance components show good agreement in predicting natural frequencies and dynamic responses. In the case of the beam–beam coupling, the presence of four resonance peaks and the higher response magnitudes are attributed to the inclusion of both translational and rotational DoFs, providing more complex dynamic behavior.

While the GRCFBS method demonstrates strong agreement with FEA for both resonance and anti-resonance frequencies below 2000 Hz (with errors typically below 5%), discrepancies become apparent at higher frequencies (above 2000 Hz), where the accuracy decreases, resulting in relative errors exceeding 10% for non-rotational receptances. These discrepancies highlight the need for refinement of the theory of node receptance description in GRCFBS and the use of more accurate beam elements in FEA. Such advancements could better capture higher-order dynamic behaviors and further enhance the predictive accuracy of the method in these frequency ranges.

However, both the FEA and GRCFBS methods exhibit similar trends in resonance and anti-resonance peaks, with a noticeable frequency shift observed beyond 2000 Hz.

As an interesting observation, the rotational receptance components (both direct and cross) maintain a good agreement beyond 2000 Hz, confirming that the GRCFBS method remains accurate in predicting the rotational response at higher frequencies despite the overall magnitude discrepancies.

To improve accuracy at high frequencies, future work could incorporate more advanced theories such as the Timoshenko beam theory, which accounts for shear deformation and rotational inertia, along with the inclusion of material damping, which plays a critical role in high-frequency vibration attenuation.

In conclusion, while the GRCFBS method remains a valuable tool for dynamic system analysis, particularly at lower frequencies, future research should focus on enhancing its accuracy at higher frequencies. This could involve the integration of Timoshenko beam theory and improved damping models, enabling the method to better capture high-frequency behavior and extend its applicability to a wider range of structural configurations.

Additionally, incorporating data-driven methods, such as machine learning (ML), holds great potential for improving the predictive capabilities and computational efficiency of this methodology, particularly in complex and real-world applications.

By addressing these limitations and exploring the integration of data-driven approaches, the GRCFBS method could significantly improve vibration and dynamic modeling, offering robust solutions for a broad range of industries such as the automotive, aerospace, robotics, and manufacturing industries.