A Fundamental Study on an SAP Mixed Asphalt Mixture for Reducing the Urban Heat Island Effect

Abstract

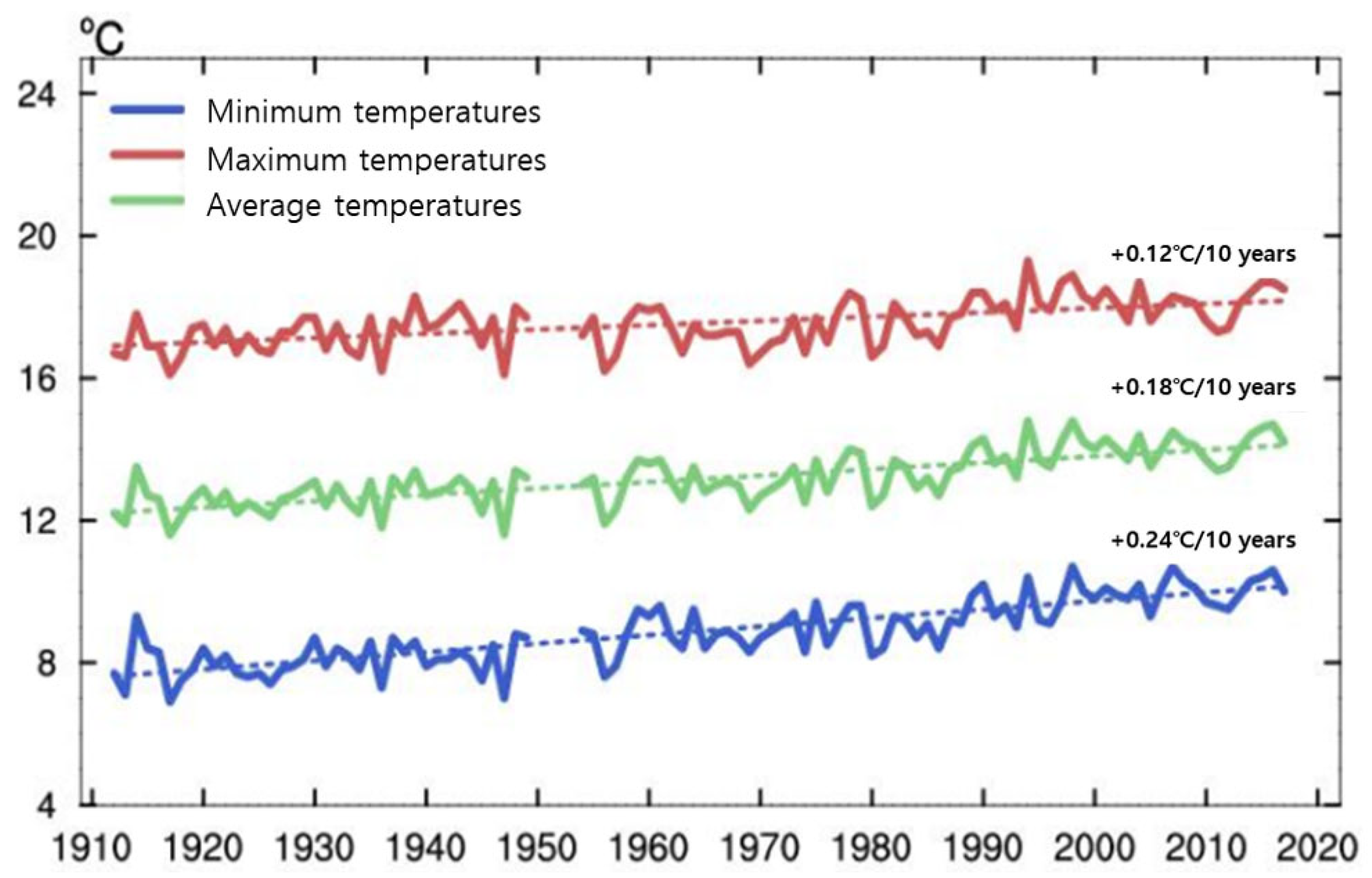

1. Introduction

2. Materials and Methodology

2.1. SAP (Super Absorbent Polymer)

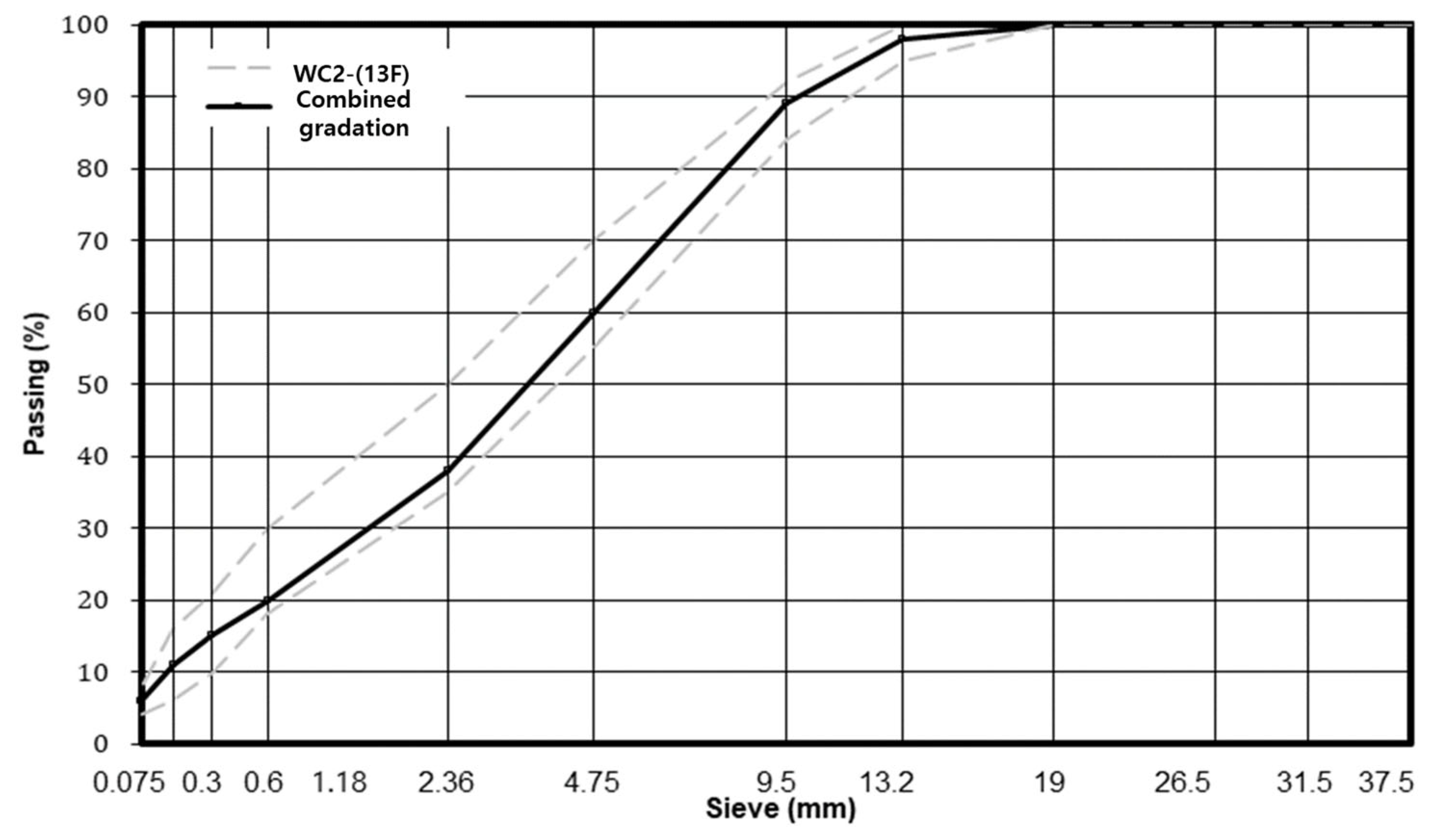

2.2. Asphalt Mixture

2.3. Performance Evaluation of SAP Asphalt Mixture

2.4. Evaluation of Thermal Characteristics

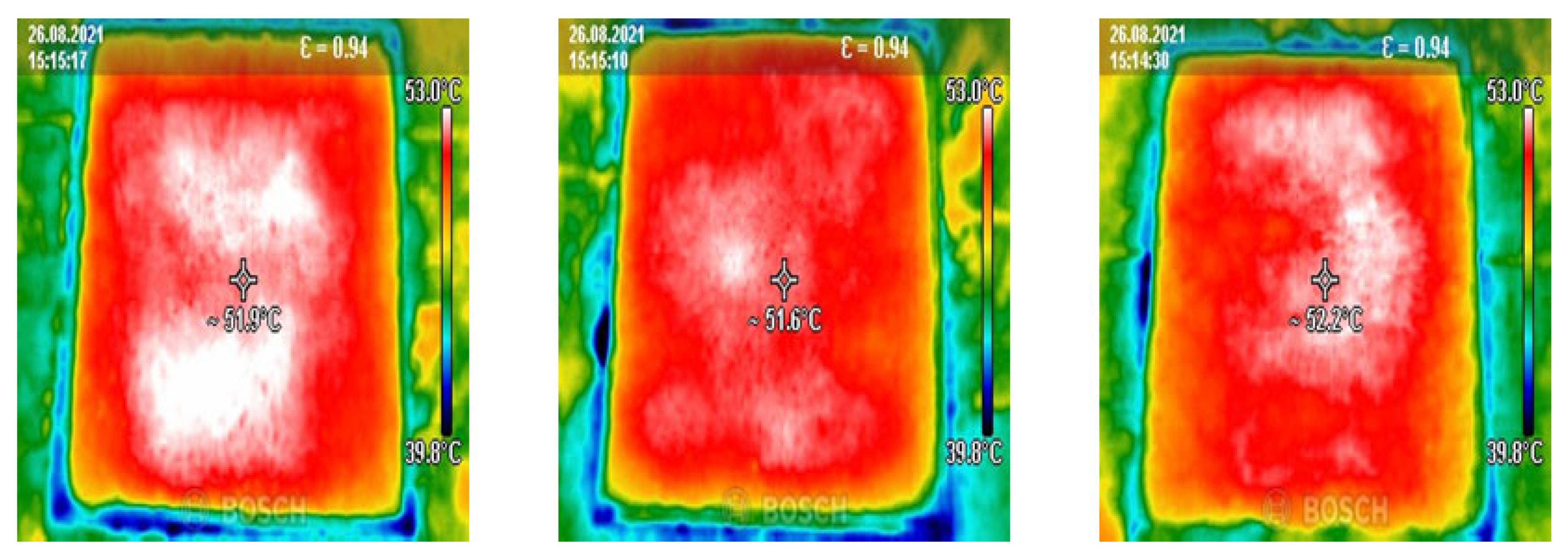

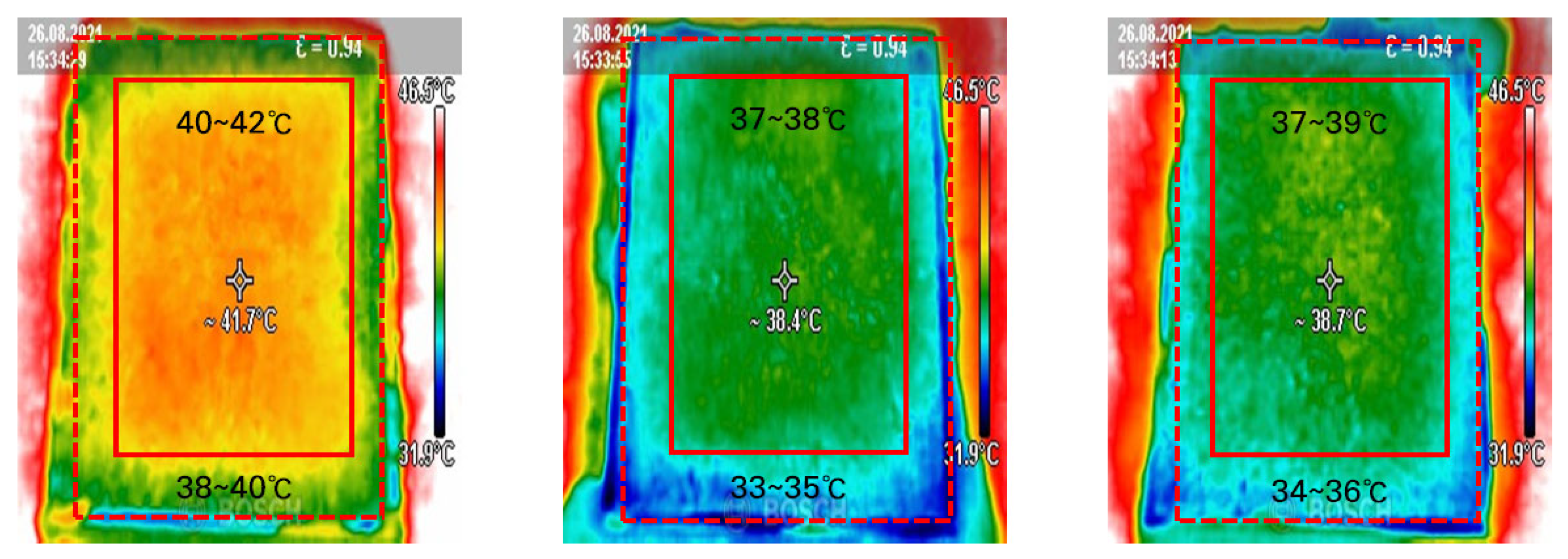

2.4.1. An Indoor Experiment

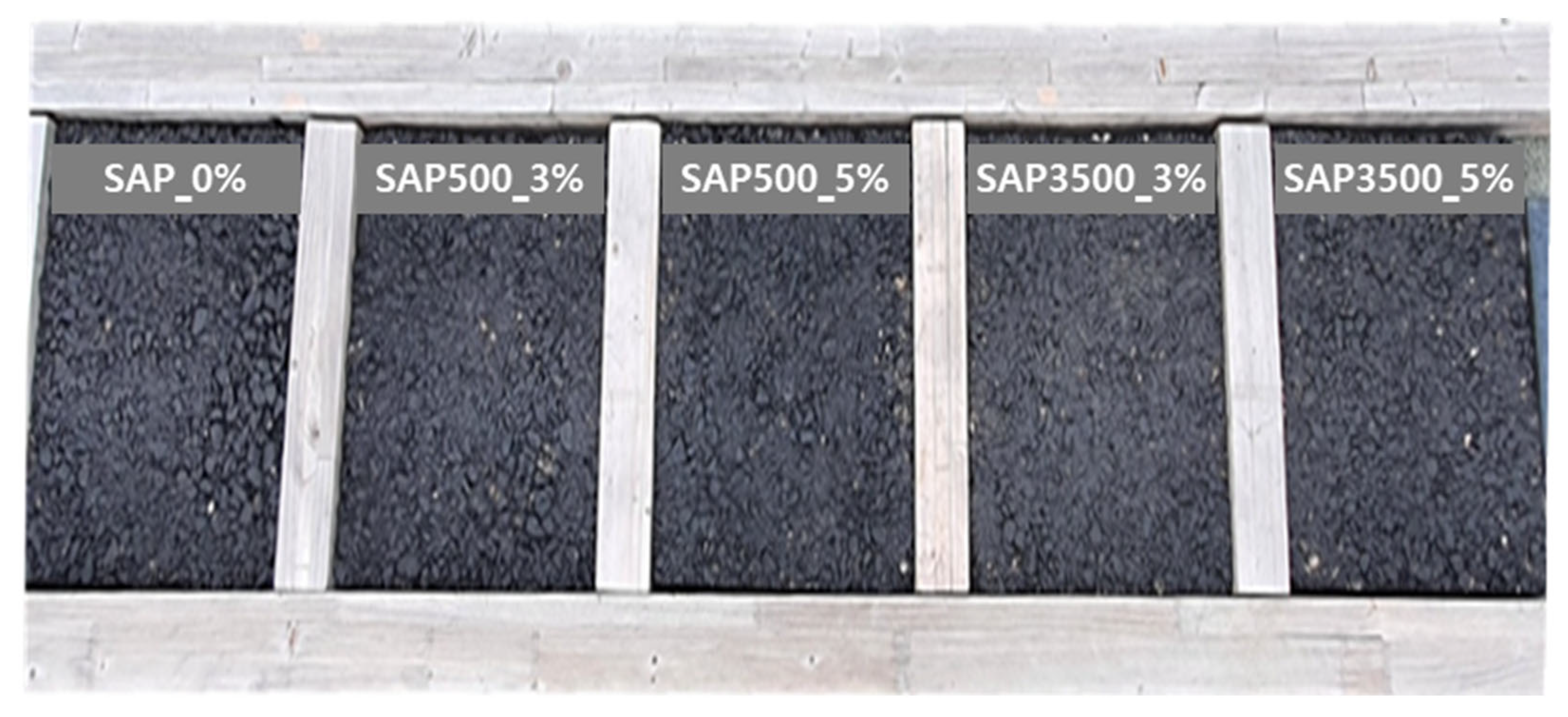

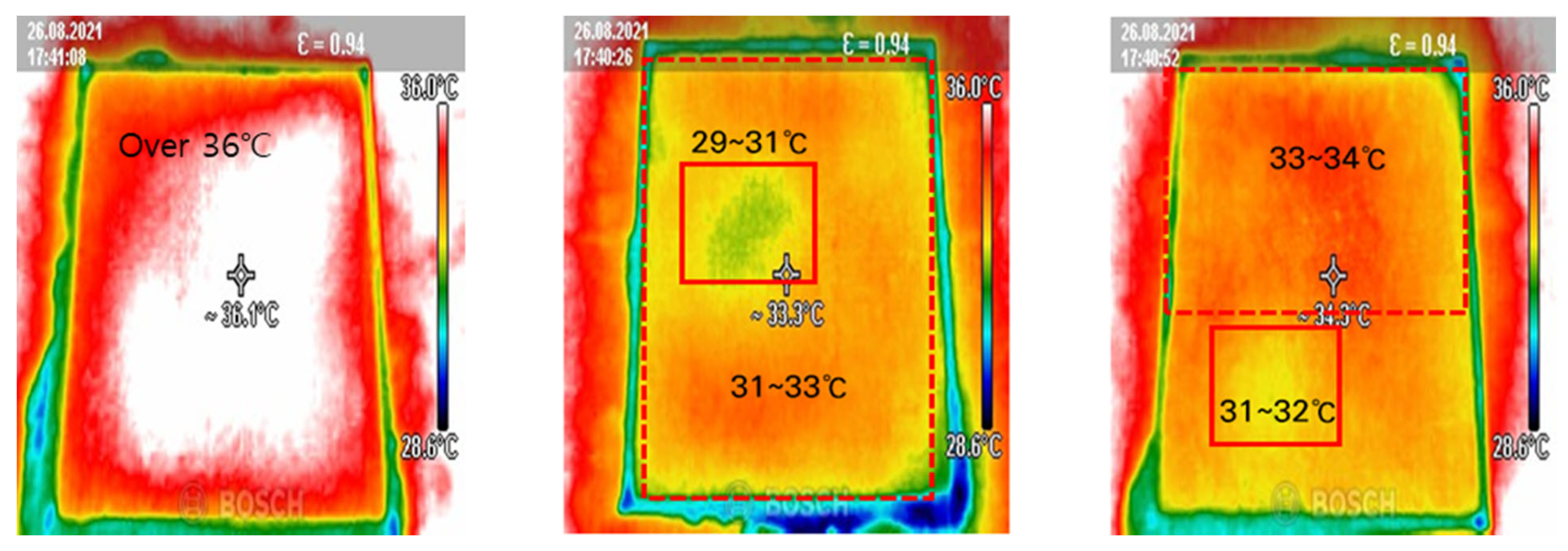

2.4.2. Outdoor Experiment

3. Results and Discussion

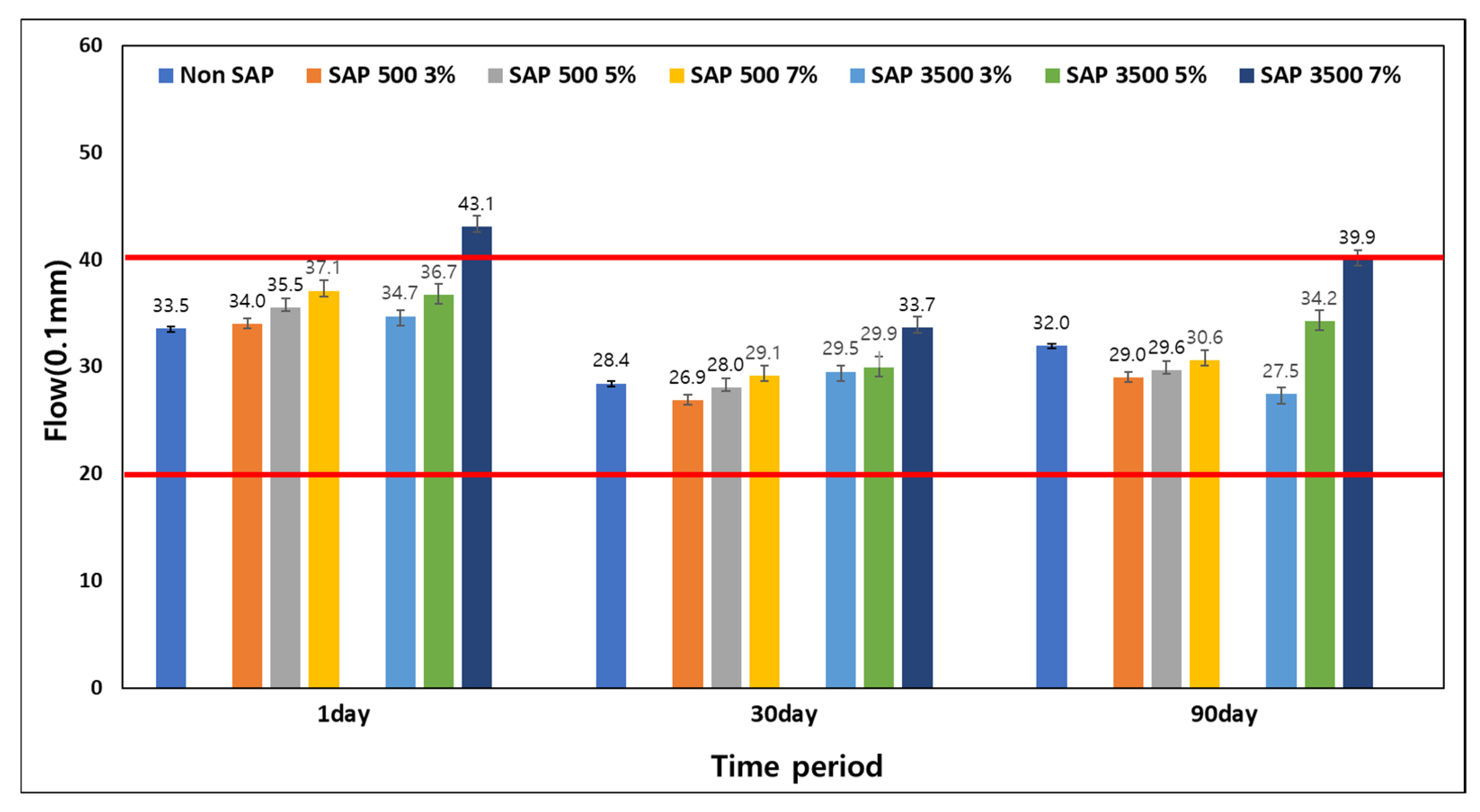

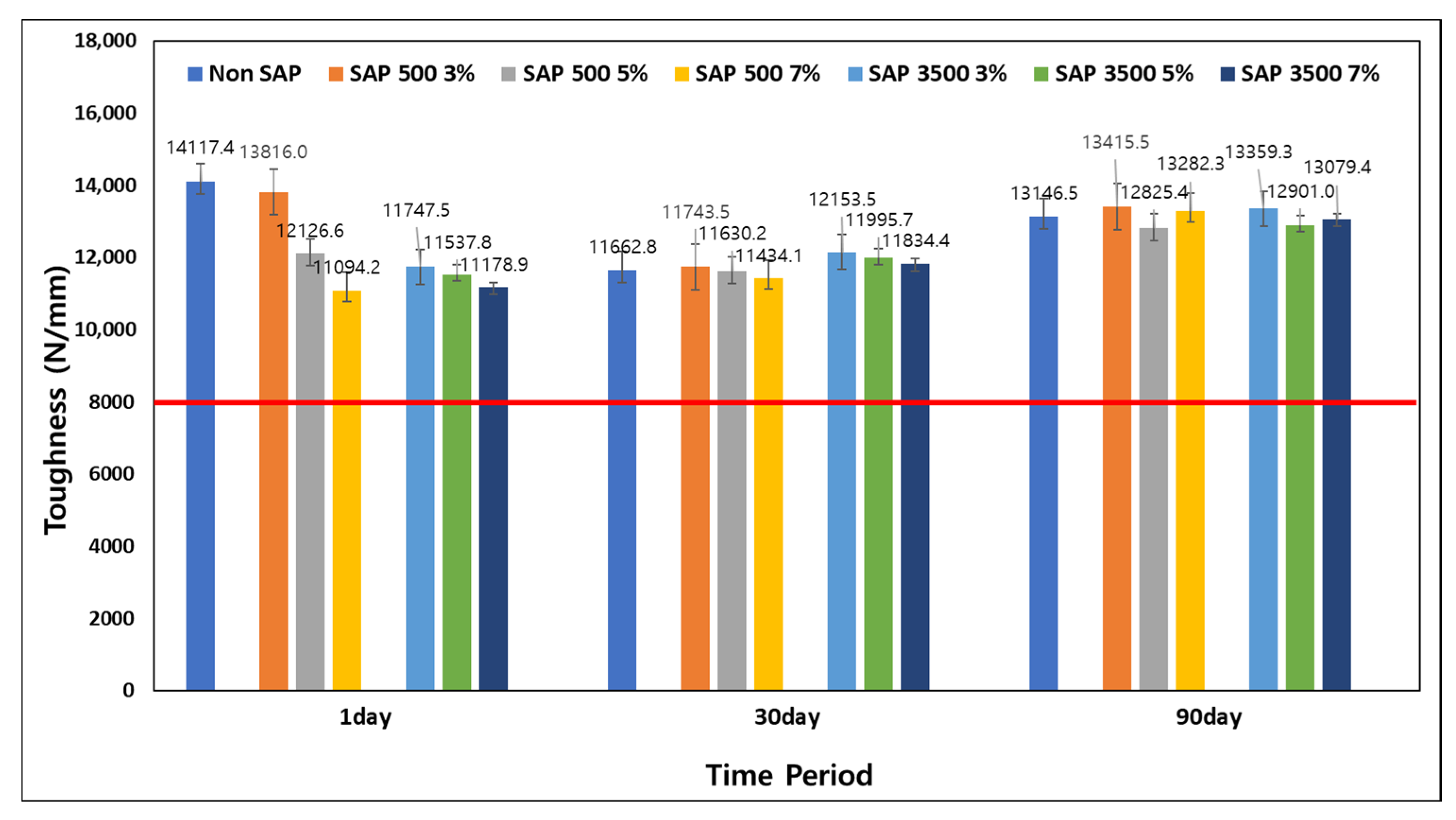

3.1. Strength Characteristics of the SAP Asphalt Mixtures

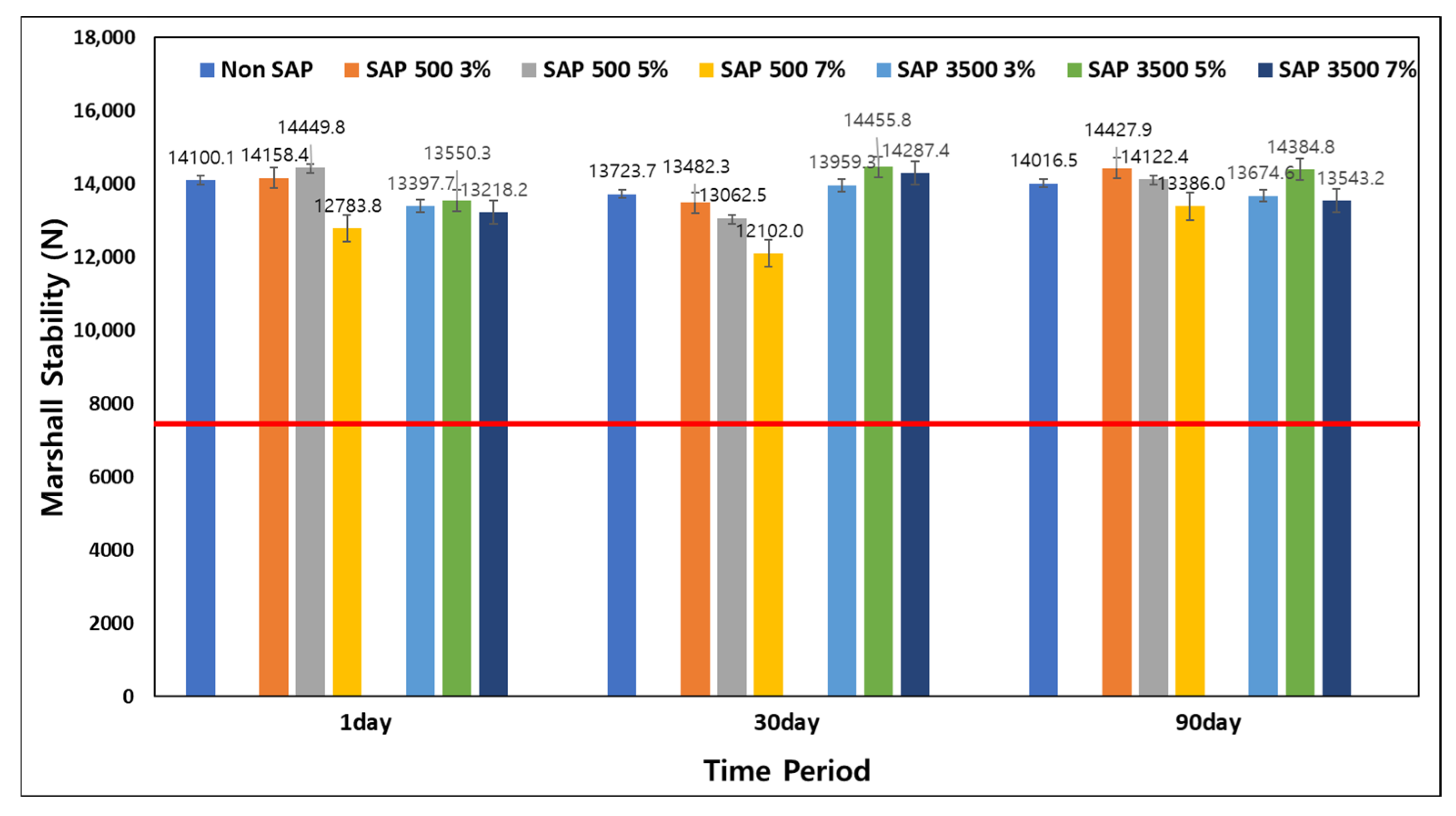

3.1.1. Marshall Stability Results

3.1.2. Indirect Tensile Strength Result

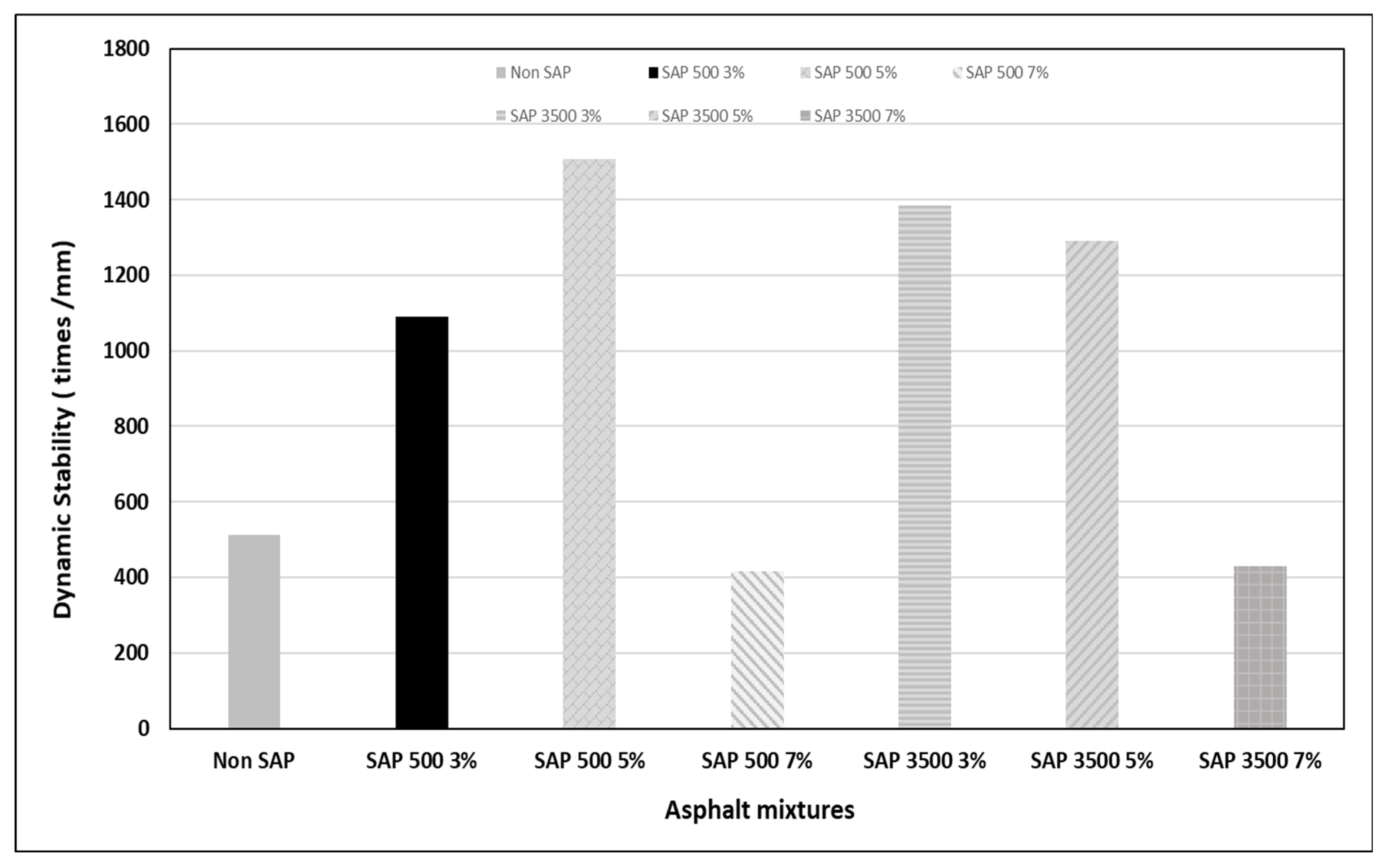

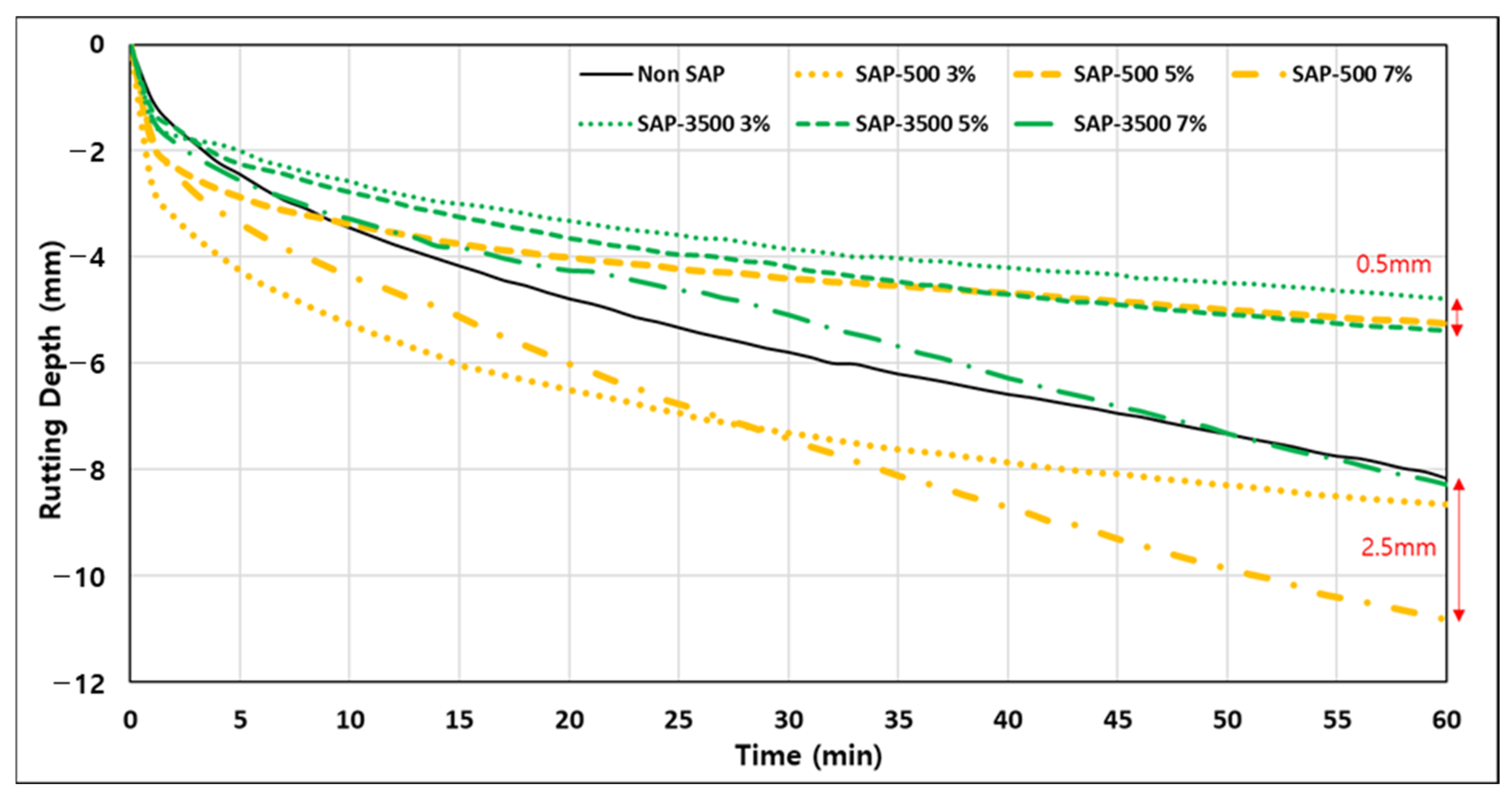

3.1.3. Dynamic Stability Test Result

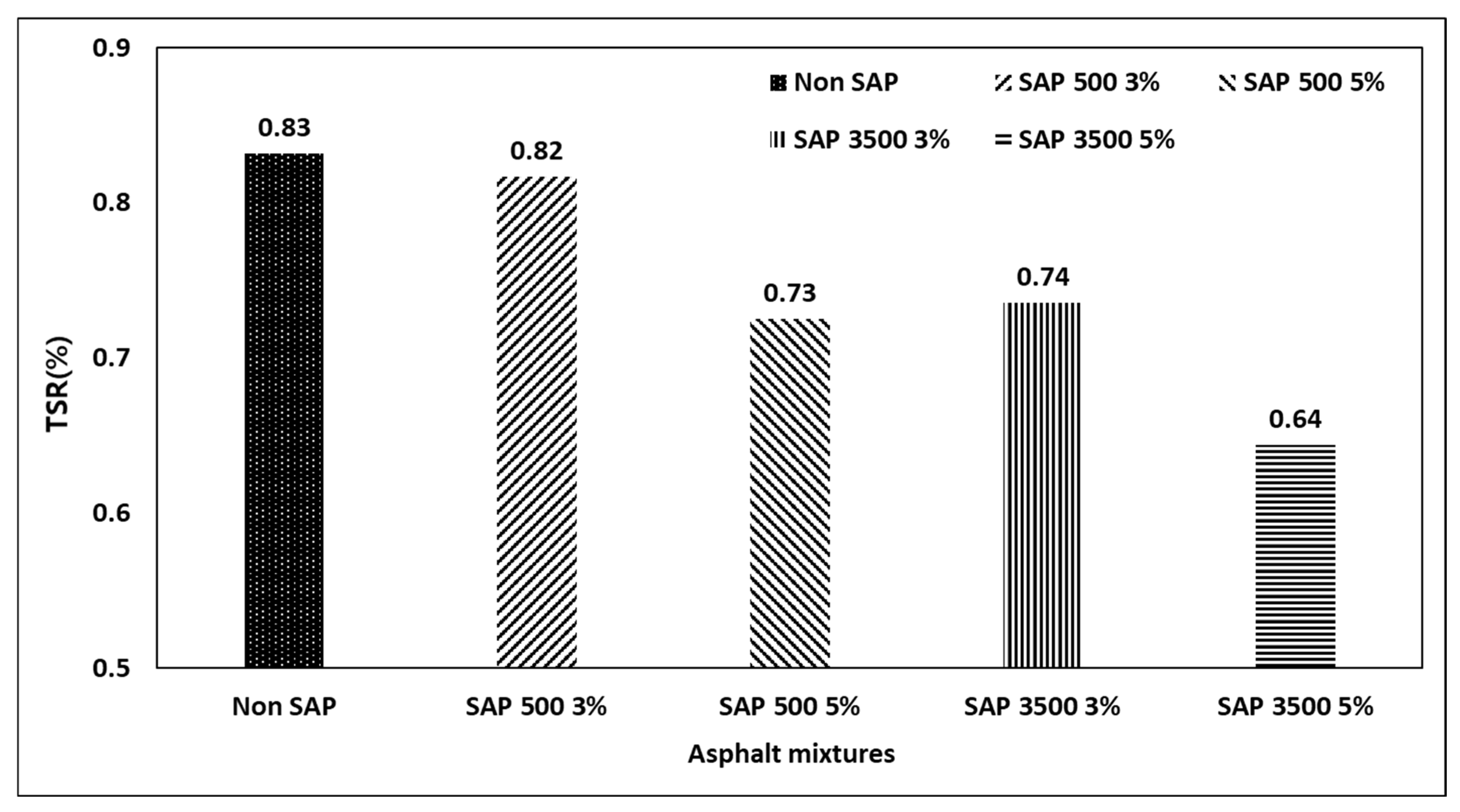

3.1.4. Tensile Strength Ratio (TSR) Results

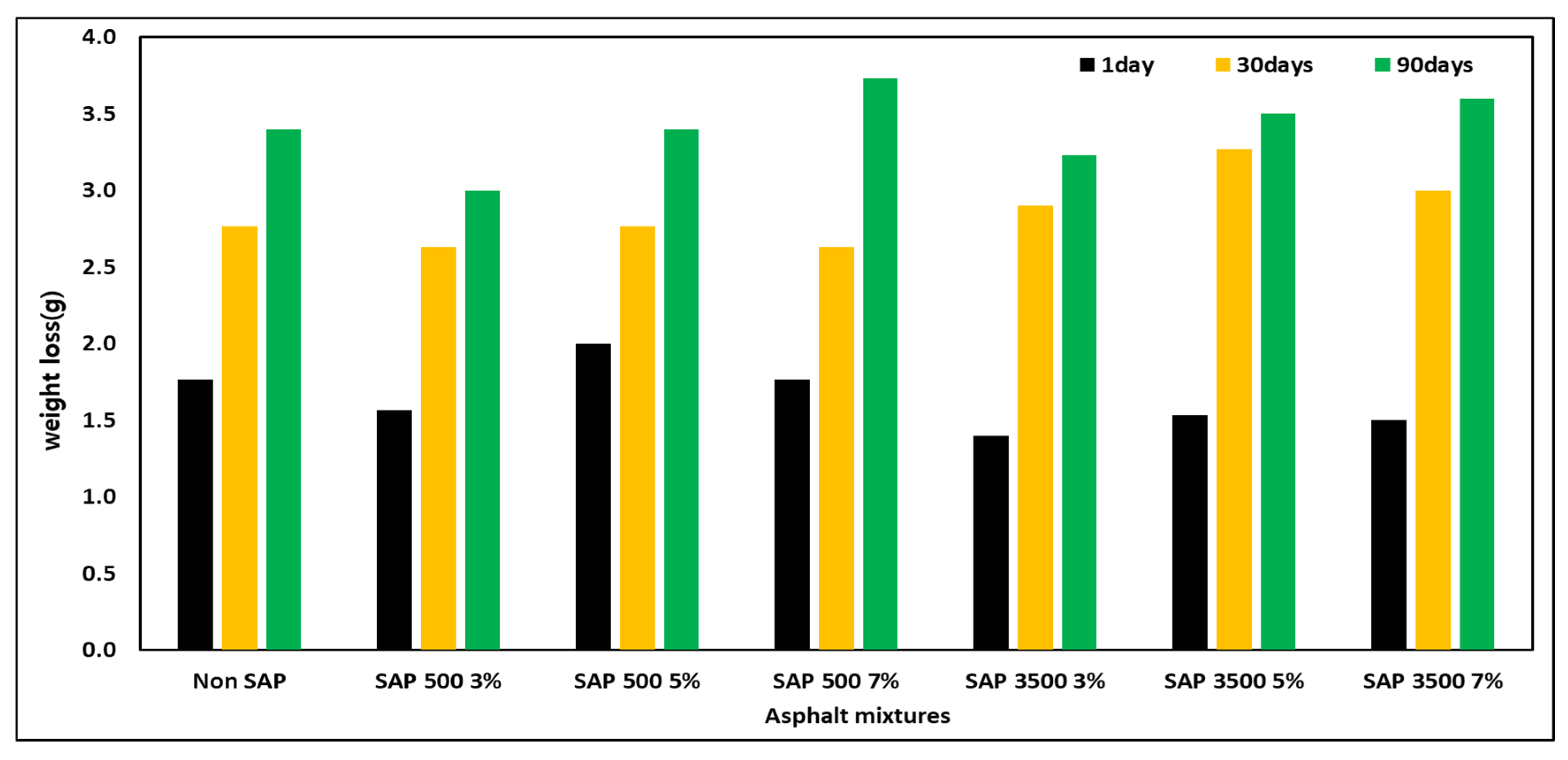

3.1.5. Dynamic Immersion Results

3.2. Thermal Properties Results

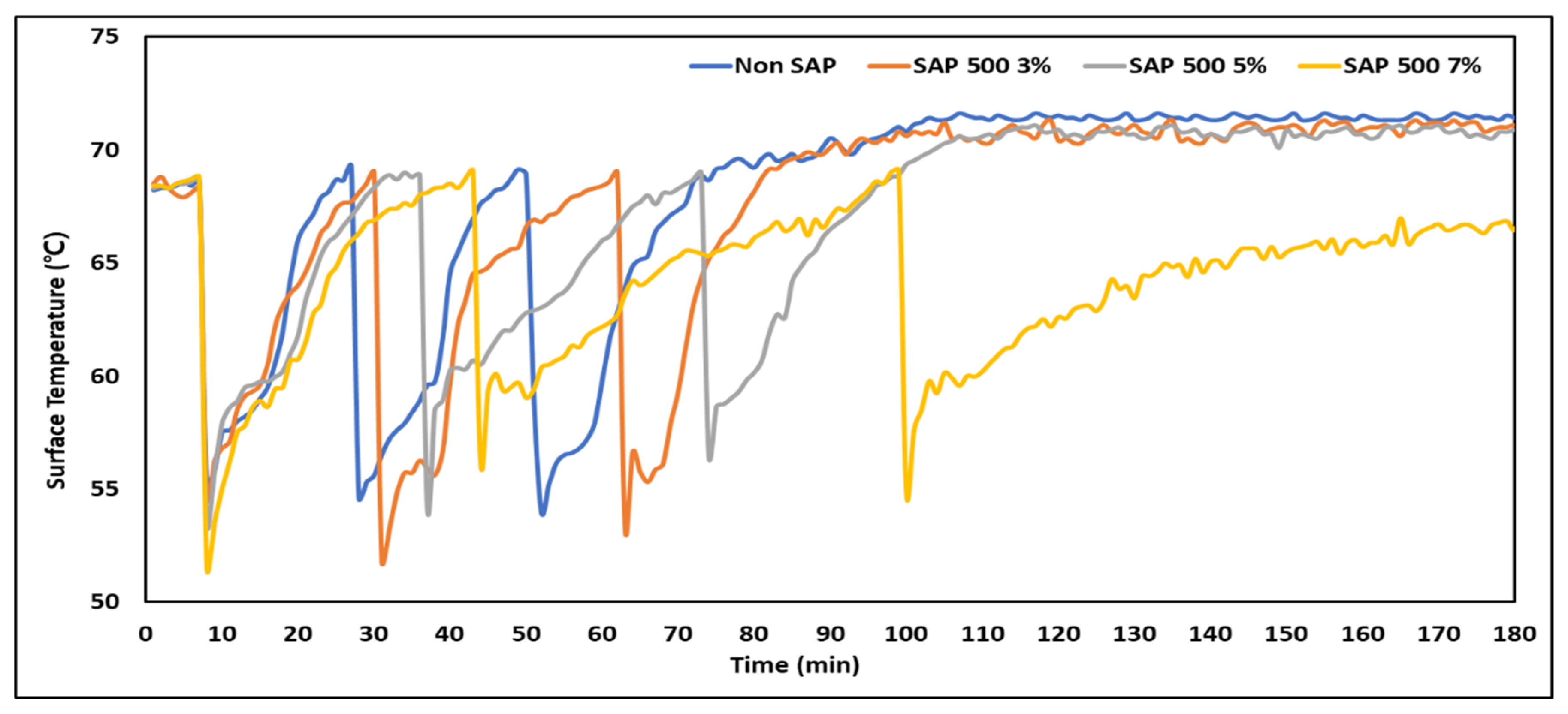

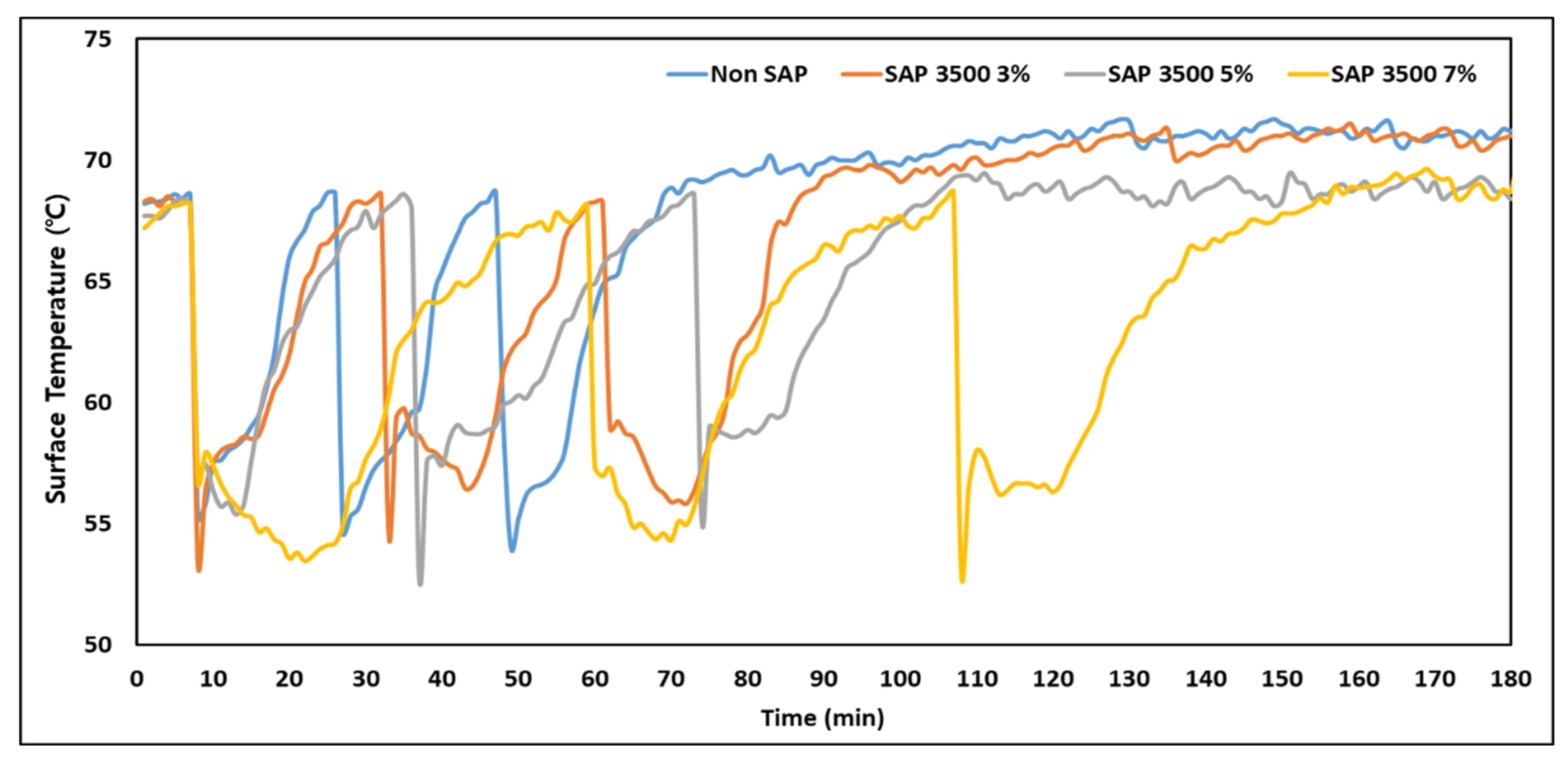

3.2.1. Results of Indoor SAP Asphalt Thermal Characteristics

3.2.2. Results of Outdoor SAP Asphalt Thermal Properties

4. Conclusions

- Based pm the results of the performance of the asphalt mixture mixed with an SAP, when the SAP content was less than 7% the mixture design criteria of the mixture were satisfied. In the case of indirect tensile strength, the Marshall stability and crack resistance of the Non-SAP asphalt mixture had better results than the asphalt mixtures with SAP. However, the dynamic stability results showed that the rutting resistance increased by more than three times for asphalt mixtures with the SAP compared to the Non-SAP asphalt mixture.

- As a result of the indoor experiment on the thermal characteristics of the SAP asphalt, it was confirmed that the effect of delaying the temperature recovery was improving as the content of the SAP increased. Compared to the Non-SAP asphalt, the surface temperature immediately after spraying decreased by 10 °C, and the temperature recovery was delayed by 5 to 30 min depending on the SAP content.

- In the case of a high content of the SAP (7% or higher), the surface temperature lowered after spraying was maintained or tended to rise after lowering. This thermal behavior is generally the same as the temperature change behavior of the porous asphalt surface, which has the effect of improving the temperature recovery delay effect similar to that of the SAP asphalt mixture with a high content of 7% or more.

- The SAP asphalt indoor and outdoor experiments showed that the delay effect became better as the SAP content increased when a sufficient amount of spray was applied. The recovery temperature was delayed for more than 1 h after the surface temperature decreased by about 10 °C, and there was a clear difference in the Non-SAP.

- Although an SAP of 7% or higher exhibits thermal behavior characteristics similar to porous asphalt, the most important thing is to establish an SAP optimal content and required porosity that can exhibit temperature recovery delay effects while ensuring the porosity of asphalt. There is a space for absorbing the expansion stress of the SAP. It is concluded that further research on porosity and thermal behavior is needed by applying the SAP to porous asphalt.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- National Institute of Meteorological Science. 100 Years Climate Change of the Korean Peninsula; National Institute of Meteorological Science: Jeju, Republic of Korea, 2018.

- Lee, J.H.; Kim, D.H. Projecting the Elderly Population at Heat Wave Risk for Climate Change: A spatial Approach. Korean Geogr. Soc. 2022, 57, 269–283. [Google Scholar] [CrossRef]

- Lee, K.H.; Kim, S.K. Thermo-physical Properties of the Asphalt Pavement by Solar Energy. J. Korea Acad.-Ind. 2020, 21, 717–724. [Google Scholar] [CrossRef]

- Kim, D.W.; Jung, J.H.; Lee, J.S.; Lee, J.S. Characteristics of Heat wave Mortality in Korea. Korea Meteorol. 2014, 42, 114–118. [Google Scholar] [CrossRef]

- Harlan, S.L.; Declet-Barreto, J.H.; Stefanov, W.L.; Petitti, D.B. Neighborhood effects on heat deaths: Social and environmental predictors of vulnerability in Maricopa County, Arizona. Environ. Health Perspect. 2013, 121, 197–204. [Google Scholar] [CrossRef]

- O’Malley, C.; Piroozfar, P.; Farr, E.R.; Pomponi, F. Urban Heat Island (UHI) mitigating strategies: A case-based comparative analysis. Sustain. Cities Soc. 2015, 19, 222–235. [Google Scholar] [CrossRef]

- Hogrefe, C.; Lynn, B.; Civerolo, K.; Ku, J.Y.; Rosenthal, J.; Rosenzweig, C.; Kinney, P.L. Simulating changes in regional air pollution over the eastern United States due to changes in global and regional climate and emissions. J. Geophys. Res. Atmos. 2004, 109, 1–13. [Google Scholar] [CrossRef]

- Jansson, C.E.J.P.; Jansson, P.E.; Gustafsson, D. Near surface climate in an urban vegetated park and its surroundings. Theor. Appl. Climatol. 2007, 89, 185–193. [Google Scholar] [CrossRef]

- Middel, A.; Selover, N.; Hagen, B.; Chhetri, N. Impact of shade on outdoor thermal comfort—A seasonal field study in Tempe, Arizona. Int. J. Biometeorol. 2016, 60, 1849–1861. [Google Scholar] [CrossRef]

- Nazarian, N.; Krayenhoff, E.S.; Bechtel, B.; Hondula, D.M.; Paolini, R.; Vanos, J.; Cheung, T.; Chow, W.T.L.; de Dear, R.; Jay, O.; et al. Integrated Assessment of Urban Overheating Impacts on Human Life. Adv. Earth Space Sci. 2022, 10, e2022EF002682. [Google Scholar] [CrossRef]

- Baldwin, J.W.; Benmarhnia, T.; Ebi, K.L.; Jay, O.; Lutsko, N.J.; Vanos, J.K. Humidity’s Role in Heat-Related Health Outcomes: A Heated Debate. Environ. Health Perspect. 2023, 131, 119–126. [Google Scholar] [CrossRef]

- Seto, K.C.; Güneralp, B.; Hutyra, L.R. Global forecasts of urban expansion to 2030 and direct impacts on biodiversity and carbon pools. Proc. Natl. Acad. Sci. USA 2012, 109, 16083–16088. [Google Scholar] [CrossRef] [PubMed]

- Scherer, D.; Fehrenbach, U.; Lakes, T.; Lauf, S.; Meier, F.; Schuster, C. Quantification of heat-stress related mortality hazard, vulnerability and risk in Berlin, Germany. DIE ERDE–J. Geogr. Soc. Berl. 2013, 144, 238–259. [Google Scholar] [CrossRef]

- Santamouris, M. Using cool pavements as a mitigation strategy to fight urban heat island—A review of the actual developments. Renew. Sustain. Energy Rev. 2013, 26, 224–240. [Google Scholar] [CrossRef]

- Li, H.; Harvey, J.; Kendall, A. Field measurement of albedo for different land cover materials and effects on thermal performance. Build. Environ. 2013, 59, 536–546. [Google Scholar] [CrossRef]

- Gustavsson, T.; Bogren, J.; Green, C. Road climate in cities: A study of the Stockholm area, south-east Sweden. Meteorol. Appl. 2001, 8, 481–489. [Google Scholar] [CrossRef]

- Krasnopeeva, E.L.; Panova, G.G.; Yakimansky, A.V. Agricultural applications of superabsorbent polymer hydrogels. Int. J. Mol. Sci. 2022, 23, 15134. [Google Scholar] [CrossRef]

- Oladosu, Y.; Rafii, M.Y.; Arolu, F.; Chukwu, S.C.; Salisu, M.A.; Fagbohun, I.K.; Haliru, B.S. Superabsorbent polymer hydrogels for sustainable agriculture: A review. Horticulturae 2022, 8, 605. [Google Scholar] [CrossRef]

- Geng, J.; Chen, M.; Shang, T.; Li, X.; Kim, Y.R.; Kuang, D. The Performance of super absorbent polymer (SAP) water-retaining asphalt mixture. Materials 2019, 12, 1964. [Google Scholar] [CrossRef] [PubMed]

- Hendel, M.; Colombert, M.; Diab, Y.; Royon, L. An analysis of pavement heat flux to optimize the water efficiency of a pavement-watering method. Appl. Therm. Eng. 2015, 78, 658–669. [Google Scholar] [CrossRef]

- Jiang, W.; Sha, A.; Xiao, J.; Wang, Z.; Apeagyei, A. Experimental study on materials composition design and mixture performance of water-retentive asphalt concrete. Constr. Build. Mater. 2016, 111, 128–138. [Google Scholar] [CrossRef]

- Sun, Y.; Song, W.; Wu, H.; Zhan, Y.; Wu, Z.; Yin, J. Investigation on Performances and Functions of Asphalt Mixtures Modified with Super Absorbent Polymer (SAP). Materials 2023, 16, 1082. [Google Scholar] [CrossRef] [PubMed]

- Lee, M.S. The Analysis of Indirect Tensile Strength (ITS) Characteristic using Physical Properties of Asphalt Mixture. Int. J. Highw. Eng. 2014, 16, 19–25. [Google Scholar] [CrossRef]

- Cho, G.T.; Kim, Y.S.; Kim, S.U.; Kim, K.W. Problems in dynamic stability assessment of asphalt concrete in Korea and suggestion. J. Korean Asph. Inst. 2020, 10, 14–26. [Google Scholar] [CrossRef]

- Kim, K.W.; Doh, Y.S.; Lee, M.S.; Ko, T.Y. Dynamic stability calculation based on actual deformation of asphalt mixture. In Proceedings of 2005 Conference of Korean Society of Road Engineers, Republic of Korea; 2005, pp. 215–226. Available online: https://koreascience.kr/article/CFKO200515637510438.page?&lang=en (accessed on 10 December 2024).

- EN 12697-11; Bituminous mixtures—Test methods for hot mix asphalt—Part 11: Determination of the affinity between aggregate and bitumen. National Standards Authority of Ireland: Dublin, Ireland, 2012.

- Qin, Y. A review on the development of cool pavements to mitigate urban heat island effect. Renew. Sustain. Energy Rev. 2015, 52, 445–459. [Google Scholar] [CrossRef]

- Stempihar, J.J.; Pourshams-Manzouri, T.; Kaloush, K.E.; Rodezno, M.C. Porous asphalt pavement temperature effects for urban heat island analysis. Transp. Res. Rec. 2012, 2293, 123–130. [Google Scholar] [CrossRef]

- Yang, J.; Wang, Z.H.; Kaloush, K.E. Environmental impacts of reflective materials: Is high albedo a ‘silver bullet’ for mitigating urban heat island. Renew. Sustain. Energy Rev. 2015, 47, 830–843. [Google Scholar] [CrossRef]

| Content | Damage Type | 2015 | 2016 | 2017 | 2018 | 2019 | Unit | |

|---|---|---|---|---|---|---|---|---|

| Health | A person with a fever | Thermal disease monitoring system | 1056 | 2125 | 1574 | 4526 | 1841 | Person |

| National health insurance DB | 21,398 | 30,602 | 27,032 | 44,094 | - | Person | ||

| A death from a heat illness | Thermal disease monitoring system | 11 | 17 | 11 | 48 | 11 | Person | |

| Statistics on causes of death by the national statistical office | 39 | 67 | 35 | 145 | - | Person | ||

| Animal husbandry | Chicken death | - | 2573 | 5772 | 6426 | 5391 | Heads | |

| Duck death | - | 80 | 196 | 265 | 139 | Heads | ||

| Pig death | - | 5 | 38 | 71 | 40 | Heads | ||

| Property | SAP-500 | SAP-3500 |

|---|---|---|

| Retained capacity (g/g) | Min. 31 | Min. 25 |

| Volume density (g/mL) | 0.6 ± 0.05 | 0.52 ± 0.05 |

| Absorption under pressure (mL/g) | Min. 26 | Min. 22 |

| Particle Size Distribution (%) | ||

| 850 μm remaining | Max. 2 | Max. 1 |

| 850∼500 μm | Max. 25 | Max. 45 |

| 500∼150 μm | 50–75 | |

| 150 μm passing | Max. 7 | Min. 40 |

| Content | 1~2 Times Spraying | 2~3 Times Spraying |

|---|---|---|

| SAP-500 3% | +5 min | +12 min |

| SAP-500 5% | +9 min | +24 min |

| SAP-500 7% | +16 min | +49 min |

| SAP-3500 3% | +6 min | +14 min |

| SAP-3500 5% | +10 min | +26 min |

| SAP-3500 7% | +33 min | +60 min |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jang, D.-S.; Lim, C.-S.; Lee, K.; Baek, C. A Fundamental Study on an SAP Mixed Asphalt Mixture for Reducing the Urban Heat Island Effect. Appl. Sci. 2024, 14, 11785. https://doi.org/10.3390/app142411785

Jang D-S, Lim C-S, Lee K, Baek C. A Fundamental Study on an SAP Mixed Asphalt Mixture for Reducing the Urban Heat Island Effect. Applied Sciences. 2024; 14(24):11785. https://doi.org/10.3390/app142411785

Chicago/Turabian StyleJang, Dae-Seong, Chi-Su Lim, Kanghwi Lee, and Cheolmin Baek. 2024. "A Fundamental Study on an SAP Mixed Asphalt Mixture for Reducing the Urban Heat Island Effect" Applied Sciences 14, no. 24: 11785. https://doi.org/10.3390/app142411785

APA StyleJang, D.-S., Lim, C.-S., Lee, K., & Baek, C. (2024). A Fundamental Study on an SAP Mixed Asphalt Mixture for Reducing the Urban Heat Island Effect. Applied Sciences, 14(24), 11785. https://doi.org/10.3390/app142411785