1. Introduction

In its traditional form, the Japanese art of paper folding enables the creation of various three-dimensional shapes by simply folding two-dimensional sheets of paper. In recent decades, this so-called origami principle has increasingly become an effective source of inspiration for engineering solutions [

1]. In engineering solutions, the origami principle is actualised as technical folding. Technical folding systems do not consist of thin paper like origami folding, but of thick, rigid panels that are additionally connected to each other by joint elements. Due to their foldable structure, technical folding systems can realise lightweight structures that have a high load-bearing capacity. The application of technical folding according to this definition is the subject of the research paper.

Scalability and flexibility of technical folding, its inherent motion, and the possibility of reconfiguration offer high potential and versatile benefits in fields far beyond art and aesthetics. Up to now, technical folding has been applied in the following fields of engineering application: Industrial Packaging [

2,

3,

4], Optics [

5,

6], Biomedical Engineering [

7,

8,

9], Robotics [

10,

11,

12,

13,

14], Aerospace [

15,

16], Consumer Products [

8,

17,

18], Electronics [

19,

20], and Architecture [

21,

22]. However, these applications represent singular solutions, meaning that the overall prevalence of technical folding is low. Infrequent application of the solution principle of technical folding in the context of product development is mainly due to the following challenge. In early phases of a function-oriented product development process, product developers without high expertise in technical folding are not able to decide whether technical folding is a suitable solution principle for their technical problem because:

Thus, non-expert product developers can potentially make decisions for or against the solution principle of technical folding without knowing the advantages or disadvantages of it compared to other possible solution principles. In order to solve these challenges and effectively strengthen the application of the solution principle in industrial practice, an evaluation process should be defined. To address challenge (a), expert knowledge about technical folding systems must be elaborated and made available for a structured and effective decision-making process. For example, development data of known technical folding solutions from the literature can be used to define expert knowledge. This expert knowledge should then be formalised in such a way that it is comparable with the information available for a new technical problem in the early phases of a function-oriented product development process. Based on the formalised expert knowledge, in order to address challenge (b), a structured and effective decision-making process must be developed that adequately evaluates the applicability of technical folding to a new technical problem. The process enables the reuse of expert knowledge, the continuous expansion of expert knowledge to include newly developed technical folding solutions, and thus an increasingly precise evaluation based on expert knowledge. In order to efficiently generate objective and consistent decision results and to facilitate the decision-making process for inexperienced product developers, the process developed here should be implemented in software. The method on which the process is based is referred to below as EvalTech.

Problem Identification and Research Need

The following chapter discusses which data from early phases of the function-oriented product development process can be considered as a knowledge database for the software-supported applicability evaluation. It also defines the research questions arising from the use of these data as a basis for software-supported evaluation of a solution principle.

In function-oriented product development processes, requirements, functions, and function structures of a product are available as a knowledge database for evaluating the applicability of solution principles [

23,

24,

25]. Requirements are regulatory restrictions in product development, quantifiable limitations of the product, or describe the desired product behaviour [

23,

24]. Requirements can be formalised using standardised, syntactic sentence structure patterns [

24]. As their formalisation is a challenge for a concise and software-supported evaluation due to the high variability of syntax and semantics, requirements should not be used as a database for software-supported applicability evaluation.

Based on requirements, functions are derived during the product development process. Functions describe the desired product behaviour in a solution-neutral manner using the so-called subject-verb method and the definition of an incoming and outgoing function flow (e.g., “reduce product size”, “enlarge system”, or “direct force”) [

23,

24]. The overall function of a product describes its overall purpose and can be decomposed into sub-functions down to elementary functions. Elementary functions usually form the deepest level of the function structure and cannot be subdivided further. The meaningful linking of subfunctions and elementary functions to the overall function leads to the function structure [

23,

24,

26]. Based on the functions, suitable principle solutions are sought using their physical effect [

23,

24]. While functions describe the changes between incoming and outgoing function flows, physical effects concretise how this change is physically actualised [

24]. Therefore, elementary functions and physical effects are linked to each other in order to work out a principle solution. As the assignment between elementary functions and physical effects of technical folding systems is not known so far, this assignment must be newly created. Alternatively, the assignment between functions (main or sub-functions) and solutions can also be derived backwards from the solution knowledge about existing technical folding systems [

26]. Since technical folding systems are solutions in the sense of product development, the basic applicability of a solution can be identified on the basis of its functions. However, this raises the following main research question and subordinate research questions (1)–(3):

How can the applicability of technical folding be assessed on the basis of function structures?

- (1)

What known technical folding solutions exist, and what do the associated function structures look like?

- (2)

How can functions and function structures of published technical folding solutions be modelled in a formalised form as a knowledge database?

- (3)

How can this knowledge database be used in a software-supported method to assess the applicability of technical folding solutions to the current development task of a product developer?

To answer these research questions, the EvalTech method based on case-based reasoning methods is designed in

Section 3. Its central elements are developed in

Section 4 and implemented in a MATLAB

® application (The MathWorks Inc., MATLAB version: 9.13.0 (R2022b), Natick, MA, USA) in

Section 5. The application is intra-operable with the systems engineering tool Cameo Systems Modeler

® (Dassault Systèmes, Cameo Systems Modeler version: 19.0, Vélizy-Villacoublay, France).

2. State of the Art

The following chapter describes the state of the art of software-supported methods that enable evaluations on the basis of expert knowledge and justifies the choice of the case-based reasoning method. In addition, the expert knowledge on technical folding systems described in the literature is presented.

2.1. Experience-Based Intelligent Systems

In the software-supported problem-solving process based on expert knowledge, artificially intelligent (AI) systems built with the help of case-based reasoning (CBR) have proven their worth [

27,

28]. CBR is a problem-solving method that focuses on how problems can be solved with the help of experience-based knowledge. Experience-based knowledge is formalised in the form of so-called

cases, which are stored in a

case base as a special form of knowledge base [

29]. According to Aamodt and Plaza [

29], the new technical problem is solved by

retrieving one or more previously experienced

cases from the

case base,

reusing the

case with the best match,

revising the new solution based on

reusing a previous case, and

retaining the new experience by incorporating it into the existing

database [

29]. The four processes each involve a number of more specific steps. CBR differs from conventional problem-solving methods of artificial intelligence, such as natural language processing (NLP) or deep learning, essentially in the following aspects: The learning process of CBR is based on

analogy, as opposed to learning by

induction or

deduction. CBR does not work predominantly with generalised knowledge of a problem domain. It makes no assumptions about relationships between attributes of a problem description and no inferences that result from the existence of specific problem attribute values [

27,

29]. In contrast, CBR usually uses specific knowledge of already known, concrete problem-solving from the experience of experts and is not dependent on large amounts of data [

27,

29,

30]. However, the case base must be sufficiently representative to suggest meaningful solutions. On the other hand, a case base that is too large can require significant storage resources or slow down the search for similar cases. Another difference in data-driven AI systems is that solved problems can be stored as

case studies and thus be applicable in new problem situations [

29].

In this research paper, CBR methods were used to answer the research questions mainly for the following reasons: CBR systems imitate experience-based decision-making and can therefore provide inexperienced engineers with adequate support in the applicability assessment. Furthermore, in contrast to conventional AI systems, CBR systems deliver good results even with small amounts of data, such as the amount of data from the expert knowledge of existing technical folding systems (see

Section 2.2).

2.2. Expert Knowledge of Technical Folding

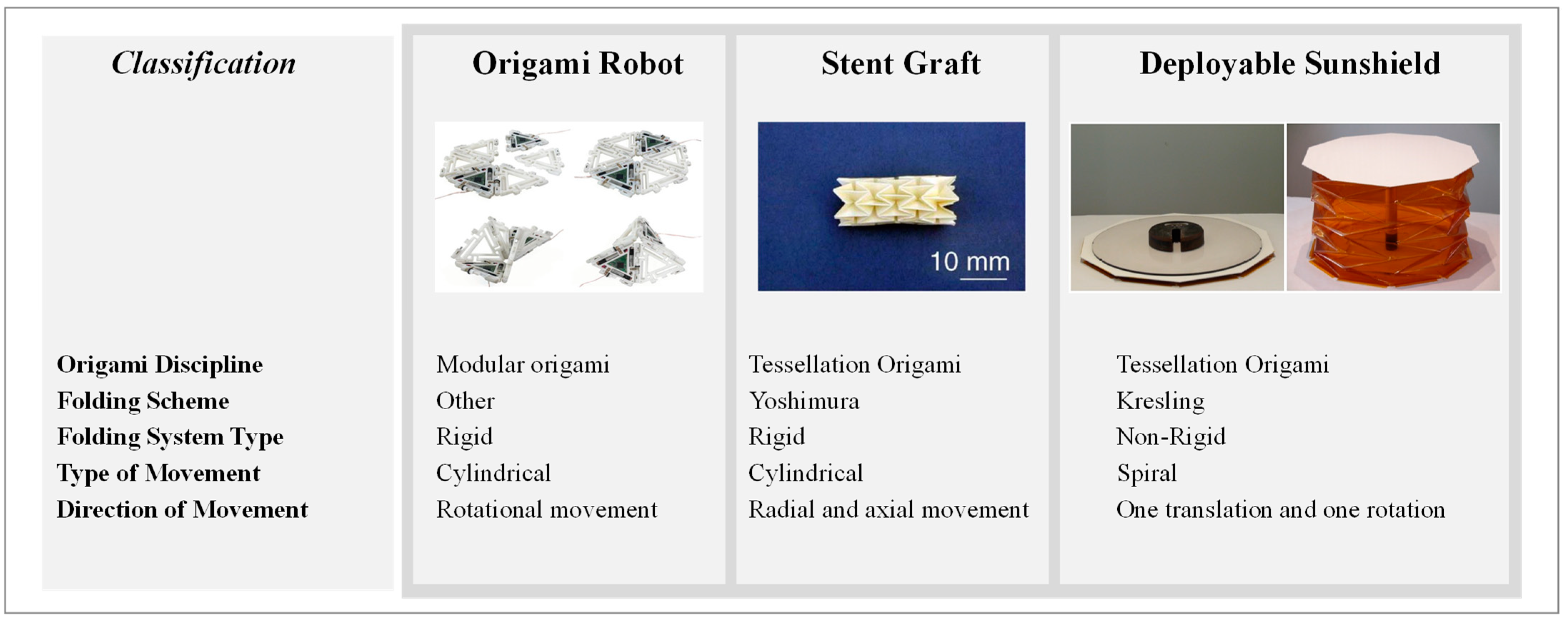

Specific knowledge of a total of 21 solutions that have successfully applied the solution principle of technical folding are known from previous publications described above. From these publications, the following classifications for the respective technical folding system can be obtained: Overall Purpose, Origami Discipline, Folding Scheme, Type of Folding System (rigid/non-rigid system), Type of Movement, and Direction of Movement. The expression of the classifications is either described textually in previous publications or can partly be taken from the published illustrations of the manufactured product. Expressions of the classifications for technical folding systems are given in non-formalised form.

The overall purpose of previous technical folding systems is, for example, to reduce the overall installation space for transporting the system [

7,

16] or to change the overall installation space for discrete-time shielding of solar radiation [

21]. Every known technical folding system from the literature can be assigned to a folding system type (rigid, non-rigid) and an origami discipline, such as

Tessellation Origami,

Curved Folding Origami, or

Modular Origami. In addition, the folding scheme on which the movement of the folding system is based, such as

Miura-Ori,

Yoshimura,

Chickenwire, or

Waterbomb, can be clearly identified. Further classifications are type of movement (planar, cylindrical, helical, spherical) and direction of movement of the technical folding system. The classification was derived from the cited sources and discussed with experts in the field.

Figure 1 illustrates the classifications of technical folding using the example of three folding systems from the literature.

3. Concept of the EvalTech Method

Based on the general methods of CBR, the CBR system with its specific elements (

database,

case bases and

cases) according to Aamodt and Plaza [

29] is defined in the following

Section 3.1.

Section 3.2 describes how the specific elements of the CBR system are used in the typical processes of

retrieving and

retaining. The

retrieving and

retaining sub-processes according to Aamodt and Plaza [

29] (

identify features,

initially match,

specify features and

select) are defined here, which are implemented in MATLAB

® for successful applicability evaluation.

3.1. Elements of the CBR System

According to Aamodt and Plaza [

29], a CBR system consists of its typical elements

database,

case base and the

new case of the current technical problem.

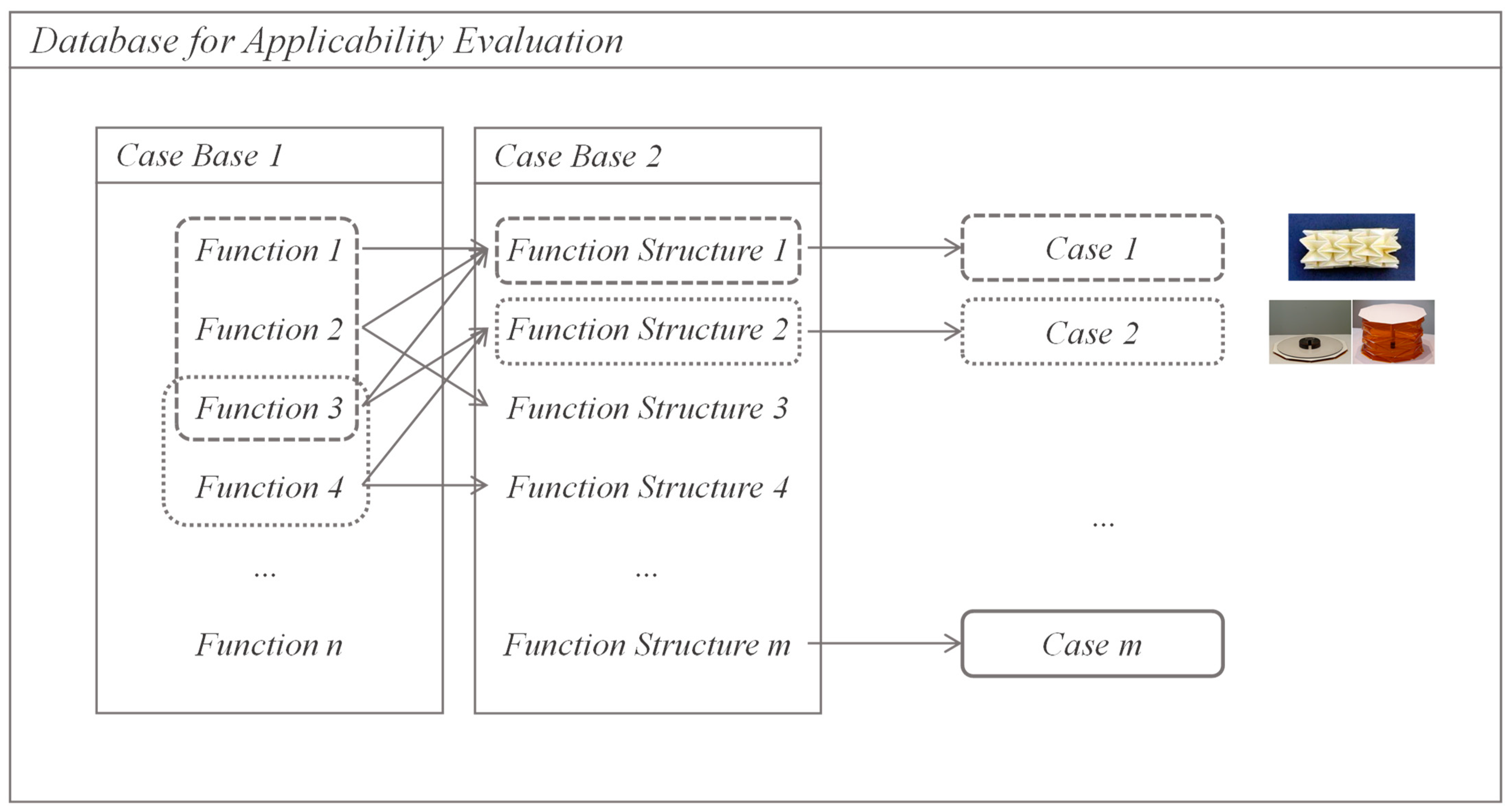

The

database comprises the entire formalised expert knowledge on the basis of which the applicability assessment is carried out [

29]. In this research paper, functions and function structures of known technical folding systems in connection to solutions form the initial

database of technical folding.

Cases bases are part of the

database. A

case base is a collection of stored knowledge elements. Functions and function structures of known technical folding systems form the stored knowledge elements. A

case contains a description of a problem and an associated solution. A case here comprises functions and functional structures of known folding systems. As functions and function structures are to be used independently for a two-stage applicability assessment, functions are grouped in

case base 1 and function structures in

case base 2. A concrete problem situation according to Aamodt and Plaza [

29], for which a decision is to be found, is a

new case. Functions and the function structure of a new technical problem each correspond to a specific

new case.In

Figure 2, the elements of the defined CBR system as the base of the EvalTech method are illustrated.

3.2. Concept of Using the CBR System for the Applicability Evaluation

In this paper, the applicability evaluation of technical folding is carried out by implementing the processes according to Aamodt and Plaza [

29] in a software application:

retrieving process and its specific subprocesses:

identify features,

initially match,

specify features and

select. The

reusing and

revising processes have not been implemented in this research paper. EvalTech ends with the

visualisation of those technical folding systems whose functions and function structures are most similar to the functions and function structures of the new product development task.

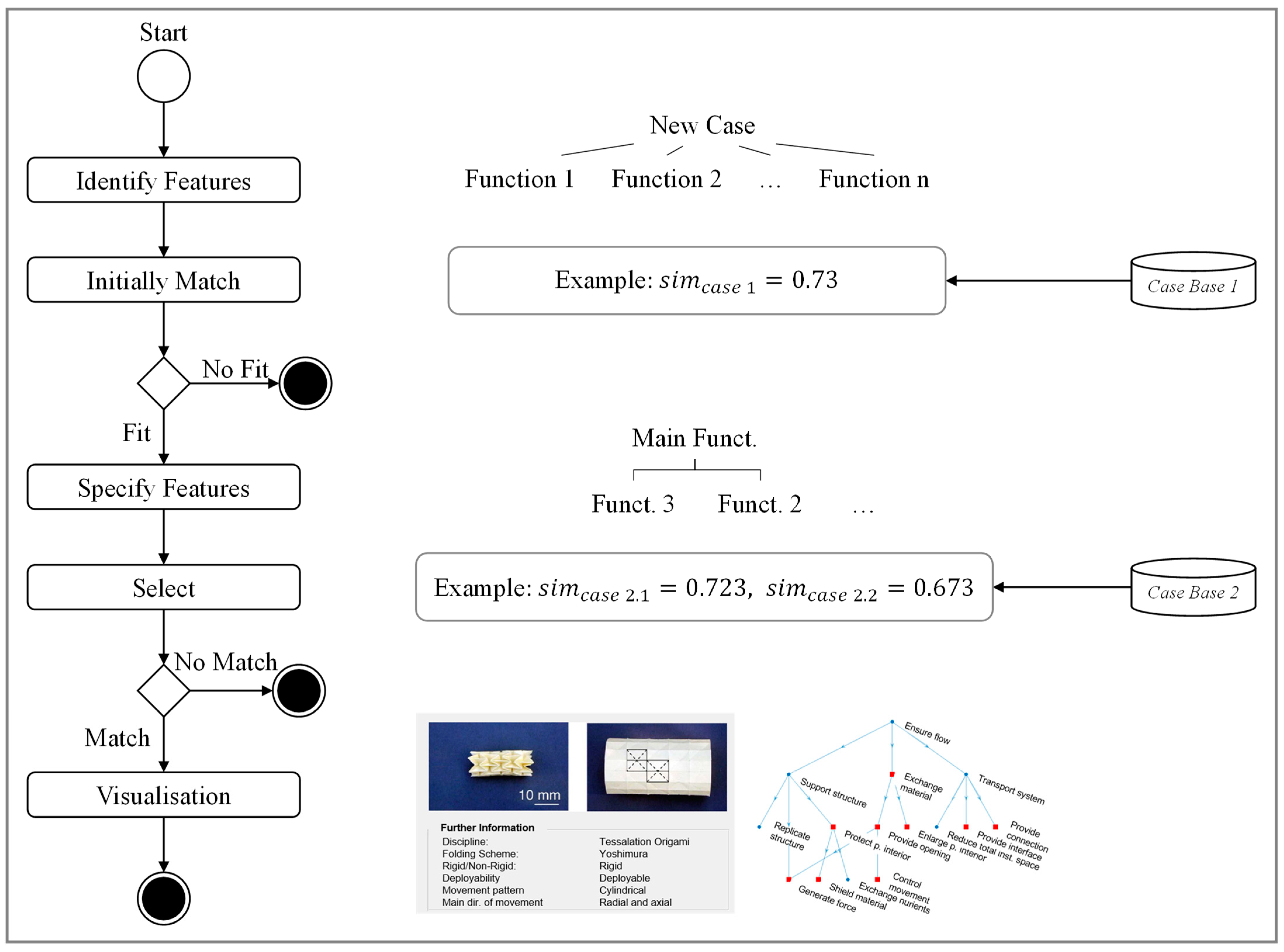

Figure 3 below illustrates the elaborated process steps of the EvalTech method.

The software-supported applicability evaluation starts with the subprocess

identify features. In this step, the functions of the new technical problem (

new case 1) can be defined with the support of the software application. The functions of the new technical problem are evaluated in the subsequent step,

initially match. The functions are compared with functions of known technical folding systems (

case base 1). If no similarity to technical folding systems is calculated, a folding system is most likely not an appropriate solution for the technical problem. In this case, consideration must be given to using a different principle solution for the technical problem. If there is an initial fit between the designed functions and the functions of known technical folding systems, the

specify features subprocess step is carried out. In the subsequent process step,

specify features, relationships between the functions are determined based on the defined functions, and so the hierarchical function structure of the new technical problem is designed. This is followed by the calculation of the similarity between the designed hierarchical function structure (

case 2) and the function structures of technical folding (

case base 2) in the sub-process

select. For the calculation of the similarity, algorithms are elaborated in

Section 4.2 to answer research question 2, which finds the most similar

case based on attributes and the organisation of the

database. The results of the similarity calculations are values between 0 and 1. The value 0 describes those

cases from the

database that have no similarity to the new technical problem and 1 those

cases with the highest similarity. Based on the result of the similarity calculation of functions and function structures, the software can recommend to the product developer whether technical folding can be applied to the new technical problem. If there is a low degree of similarity, a different solution should be selected for realisation.

The developed EvalTech method is implemented in a MATLAB

® application to efficiently support the product developer. The method is initially tested using a concept development of one new product, cf.

Section 6.

4. Developing the Central Elements of the EvalTech Method

In order to realise the concept of the EvalTech method described above, the initial solution database and the similarity equations between functions and functional structures are developed below as central elements of the CBR method.

4.1. Setting Up the Initial Database

In order to create the initial

database, functions of known, successfully implemented technical folding systems (cf.

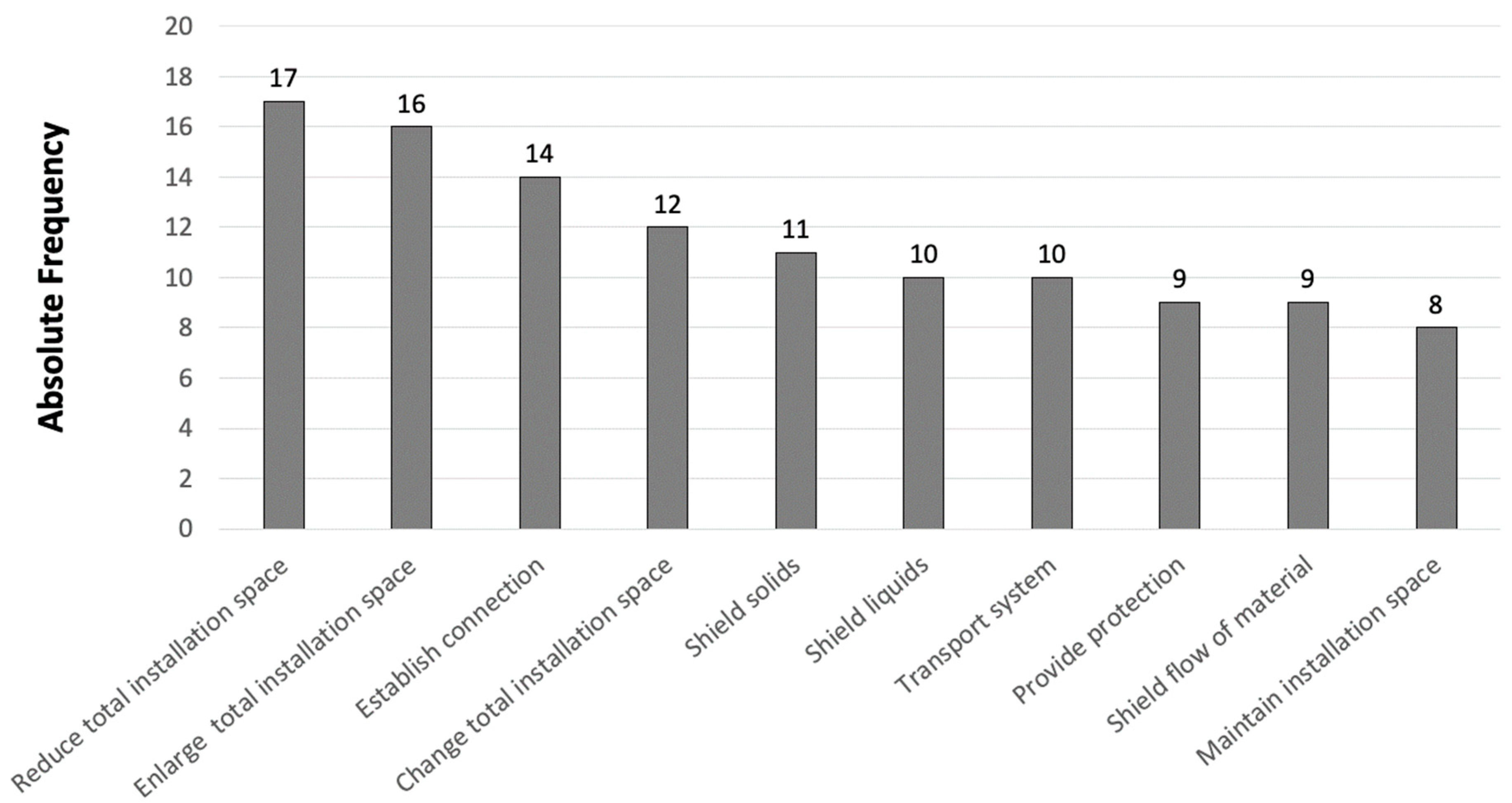

Section 2.2) are derived from the identified overall purpose and stored in a list. These functions are consolidated in a next step, and their duplicates removed. In this way, a total of 110 different functions could be identified. The functions identified include main functions, sub-functions, and elementary functions of technical folding systems. The main functions of technical folding systems are, for example, “protect system”, “transport system” or “replicate structure”. The main functions are divided into its sub-functions, such as “reduce overall installation space”, “establish connection” or “guide system”. Examples of identified elementary functions in folding systems are “directing force”, “collecting liquid” or “directing material” clearly assigned to the elementary functions. These examples clearly show that main and sub-functions describe the specific product behaviour of technical folding systems, while elementary functions must be fulfilled in most mechanical and mechatronic systems and are therefore not specific to the technical folding solution principle. For this reason, elementary functions are not suitable for evaluating the applicability of the solution to the new technical problem and are deleted from the list. Subsequently, the frequency distribution of all functions remaining in the list was evaluated, and the ten most frequent functions were defined as

characteristic functions of technical folding, cf.

Figure 4. For example, the function “reduce total installation space” was identified in 17 out of a total of 21 technical folding systems, “enlarge total installation space” in 16 cases and “establish connection” in 14 cases. Functions that have been identified in more than 1/3 of the cases count as

characteristic functions in the context of this research paper.

The naming of these functions has been worked out specifically for technical folding systems in the context of the DFG-funded project E

2F, cf.

Section 6.1.

The

characteristic functions are stored as a part of

case base 1 of the CBR system, cf.

Section 3.1.

Case base 2 of the general concept is created by forming the hierarchical function structures of 21 known technical folding systems on the basis of derived functions. The function structures are each stored in standardised adjacency matrices. Consequently, the

case base 2 database consists of 21 cases. Folding-specific information about the technical folding system, such as the folding discipline, the folding scheme or the type of movement, cf.

Section 2.2, are assigned as metadata to each

case. Each

case thus corresponds to a function structure and metadata of a solution that has been successfully realised with technical folding.

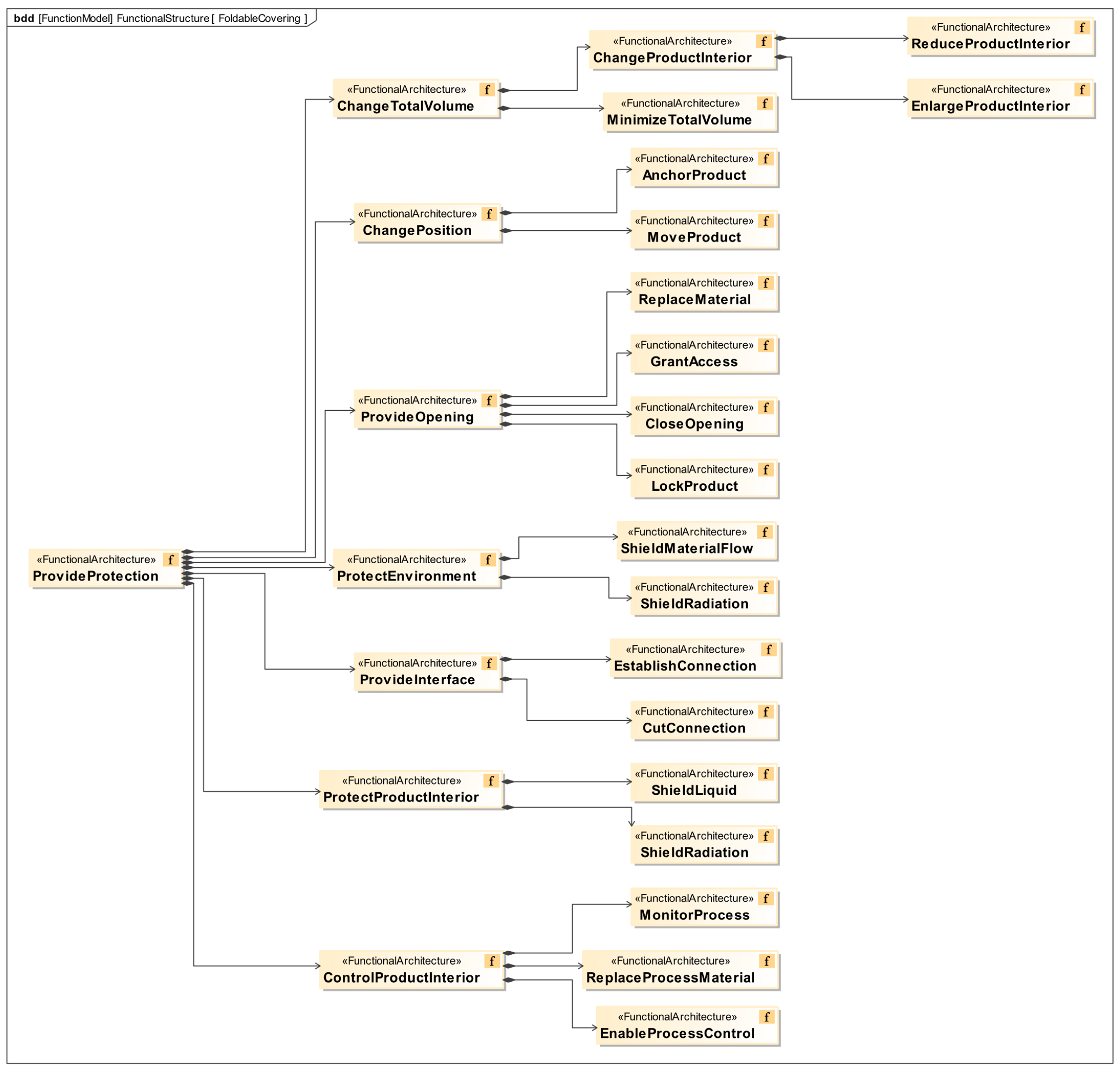

The following

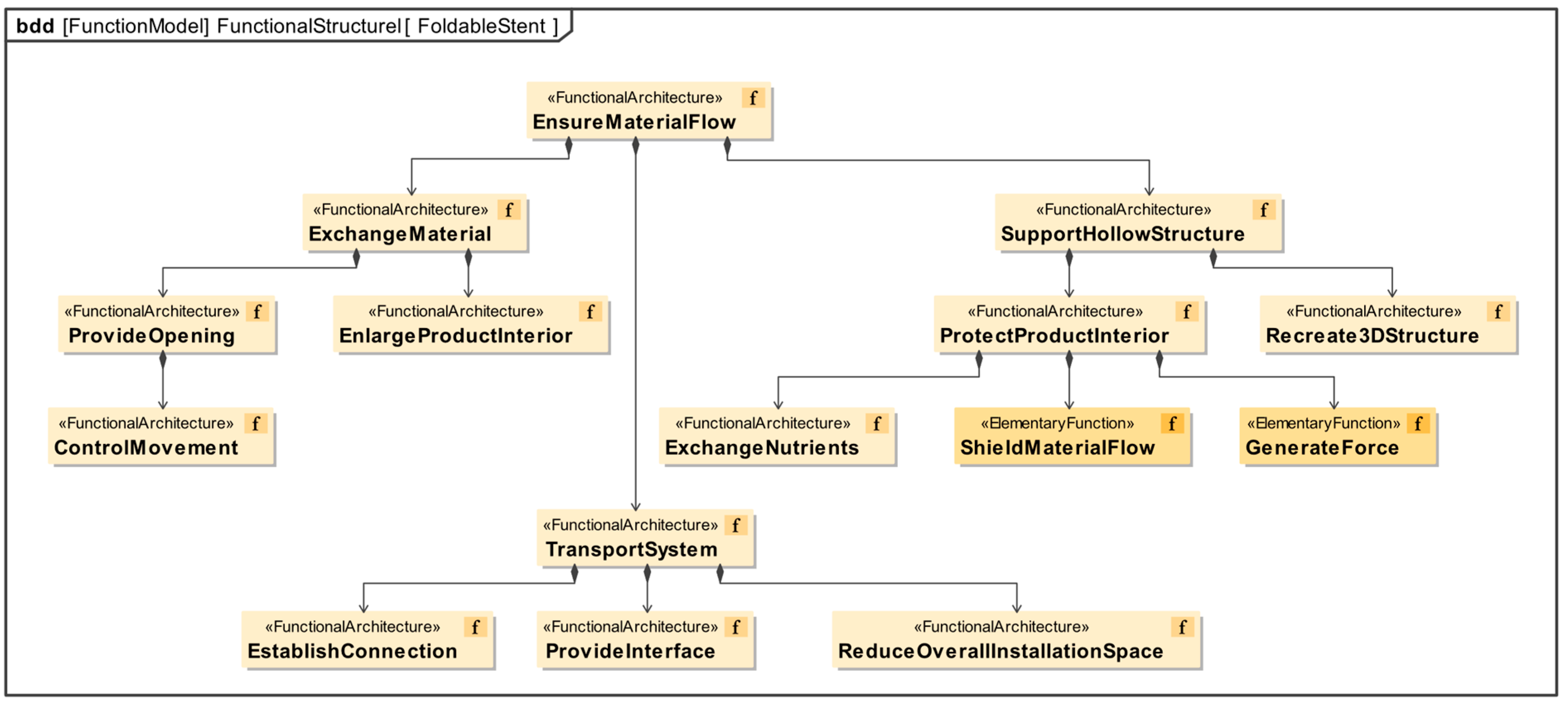

Figure 5 shows the hierarchical functional structure using the example of a self-deployable stent [

7]. The model of each functional structure is created as a block definition diagram using the software Cameo Systems Modeler

® (Dassault Systèmes, France). For the formation and further use of the respective adjacency matrix, the block definition diagram is exported as a CSV file, and the adjacency matrix is derived.

4.2. Definition of Equations for Similarity Analysis

Based on the

database, in order to find functions and function structures that are most similar to those of the new development task, functions for calculating similarity are developed below. Depending on the size of the

database, different machine learning methods can be used to analyse similarity. The most commonly used methods are

nearest neighbour,

induction,

knowledge guided induction, and

template retrieval [

30]. The time to find the most similar

case increases in proportion to the size of the

database. Since the

nearest neighbour method predominantly delivers efficient results for small

databases such as the one in this research paper, it is used in this research. In machine learning, it was developed to recognise data patterns without requiring an exact match with stored

cases. Similar

cases are close to each other, and

cases with low similarity are far away from each other. Therefore, the distance between a function or function structure from the

database with the new function or function structure can be used as a measure of its similarity [

30]. The attributes of functions defined for similarity analysis are their literal naming according to Lindemann’s subject-verb method and the graph-based relationship between functions in the hierarchical levels. The similarities are usually at a value between 0 and 1. A value of 0 means that the two cases are absolutely not similar; in contrast to the value of 1, the case is absolutely similar. The general similarity equation according to Watson and Marir is formulated as follows [

30]:

where T = new case; S = existing case in solution database; n = number of attributes; i = number of attributes each case; f = similarity equation of T and S attribute; w

i = attribute weighting to i.

The general Equation (1) forms the basis for developing the following specific similarity equations for analysing the similarity of functions and function structures.

4.2.1. Calculating the Similarity Between Functions

For determining the similarity between functions of the new technical problem and characteristic functions from the solution database, the similarity equation sim

case1 is defined. This equation basically determines whether a characteristic function i is used in the new, technical problem or not. The weighting w

i also considers the importance of the respective function in the context of technical folding. The weighting w

i corresponds to the absolute frequency of a used function in relation to the absolute frequency of all other used characteristic functions. For example, one function of the use case used here is “shield material flow”. According to Case Base 1, this function is a characteristic function of technical folding. It occurs a total of 9 times in 21 cases, cf.

Figure 3. Within these cases, the total number of different functions is 110. For example, in the comparison of the functions of the use case with the characteristic function “shield material flow”, the parameter o

i is equal to 1 and the weighting w

i is equal to 9/110. To calculate, the parameters o

i and w

i must then be determined for the comparison with each of the other nine characteristic functions, and the multiplication of the respective parameters is added.

The similarity equation, sim

case1, is calculated by the equation below, where SuD stands for System under Development:

The equation simcase1 always calculates the parameters oi and wi on the basis of the current case 1 and determines the characteristic functions using the latest data. This makes the equation flexible with regard to extensions of case 1.

4.2.2. Calculating the Similarity Between Function Structures

For detailed determination of the similarity between the hierarchical function structure of the new technical problem and the function structures from the case base 2, two independent similarity equations were defined: The equation of general functional similarity of functions simcase2.1 without considering the hierarchical structure and the function of structural similarity of functions considering the hierarchical levels of the functional structure simcase2.2.

The equation of general functional similarity of functions sim

case2.1 is calculated as shown below, where FS stands for one

Function Structure of case base 2. For each of the n functions of the function structure of the current development task, it is checked to what extent a function used matches functions of the function structures from case 1 of the database.

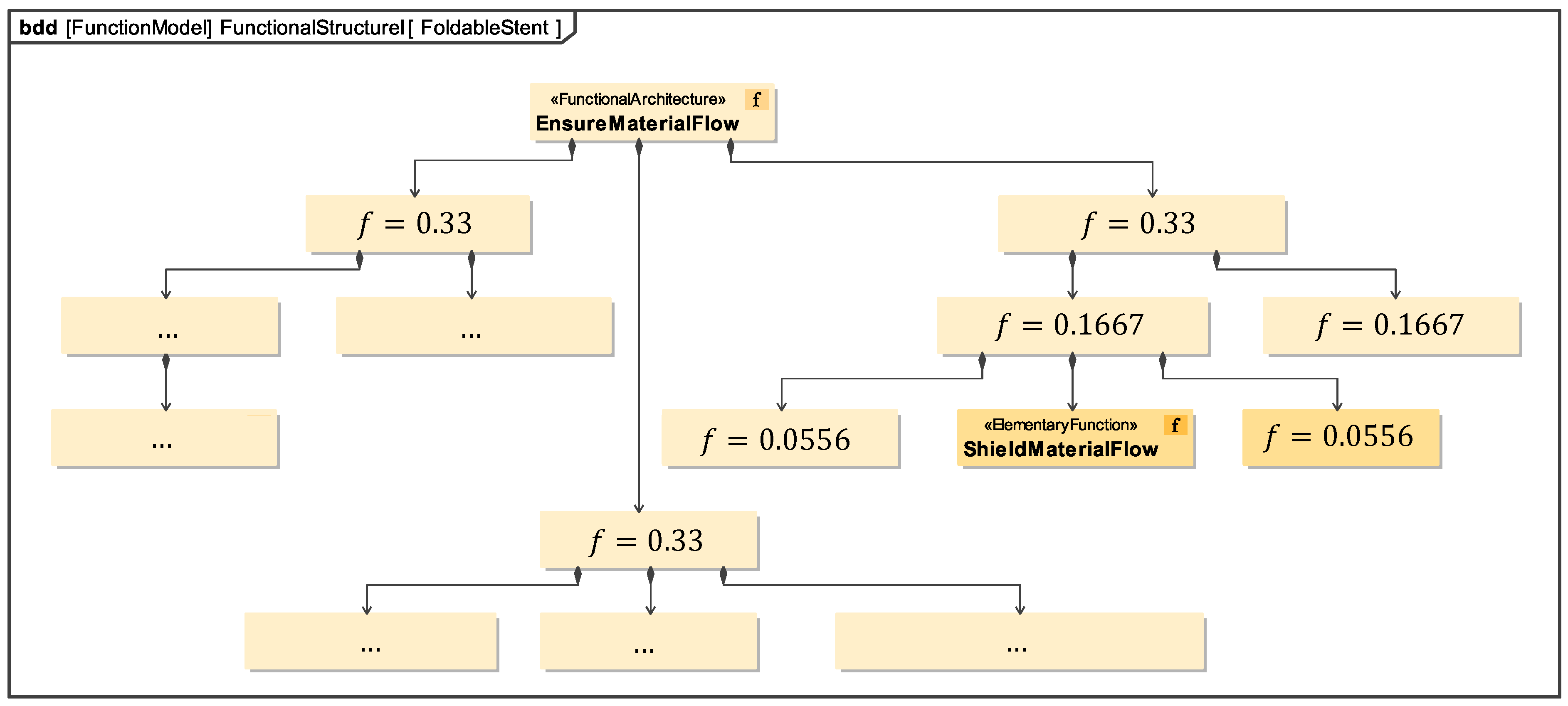

In order to consider the hierarchical structure of the functional architecture as well as the importance of the functions for the fulfilment of the overall function of the product within the framework of the similarity analysis, the similarity equation sim

case2.2 is defined. The equation is calculated as follows:

The similarity equation simcase2.2 depends on the percentage fi. fi is the product of the percentages of functions of a hierarchical level. For example, if the main function consists of 3 functions, fi of the 1st hierarchy level is: fi = 1 × 1/3 = 0.33. If a function of the 1st hierarchy level consists of 2 sub-functions, then fi = 1 × 1/3 × 1/2 = 0.1667. To calculate the similarity equation, the functions of the function structure of the current development task are each compared with functions of the function structures from case base 2. If a function matches the function of a successful folding system, the percentage fi of the function of the successful folding solution is determined and added to the similarity equation. All subsequent functions of lower hierarchical levels are then not considered further.

For example, the overall function of the self-deployable stent is decomposed into three main functions, and each main function is decomposed into two or three sub-functions. The function “protect product interior” is then decomposed into three more sub-subfunctions. For example, the function “shield material flow” of the use case used here is also used in the function structure of the self-deployable stent, at the fourth hierarchical level, cf.

Figure 6. Therefore, in this case, f

i = 0.0556 would be added.

5. Implementation of the EvalTech Method in a Software Application

The

database and the process steps

identify features, initially match, specify features, select, and

visualisation of the general concept of the EvalTech method (cf.

Section 3.2), which is implemented in a software application. The three-part software application is implemented to evaluate the general technological fit (

EvalTech Questionnaire), design a machine-readable function structure of the new technical problem (

Hierarchical Function Structure Builder), and perform the similarity calculations (

Function Structure Analysis). Each algorithm as well as the GUI of the software application has been implemented in MATLAB

® (The MathWorks Inc., USA). The entire software application supports the inexperienced product developer from the subprocess

initially match, after the functions of the new technical problem have been designed within the process

identify features.

To digitally support the process initially match, the MATLAB® function questionnaire.m is developed and implemented for the partial automation of the initial evaluation of the technological fit of the subprocess initially match. The EvalTech Questionnaire automatically determines the characteristic functions of technical folding systems based on case base 1, saves them in an Excel list and uses them for the similarity calculation .

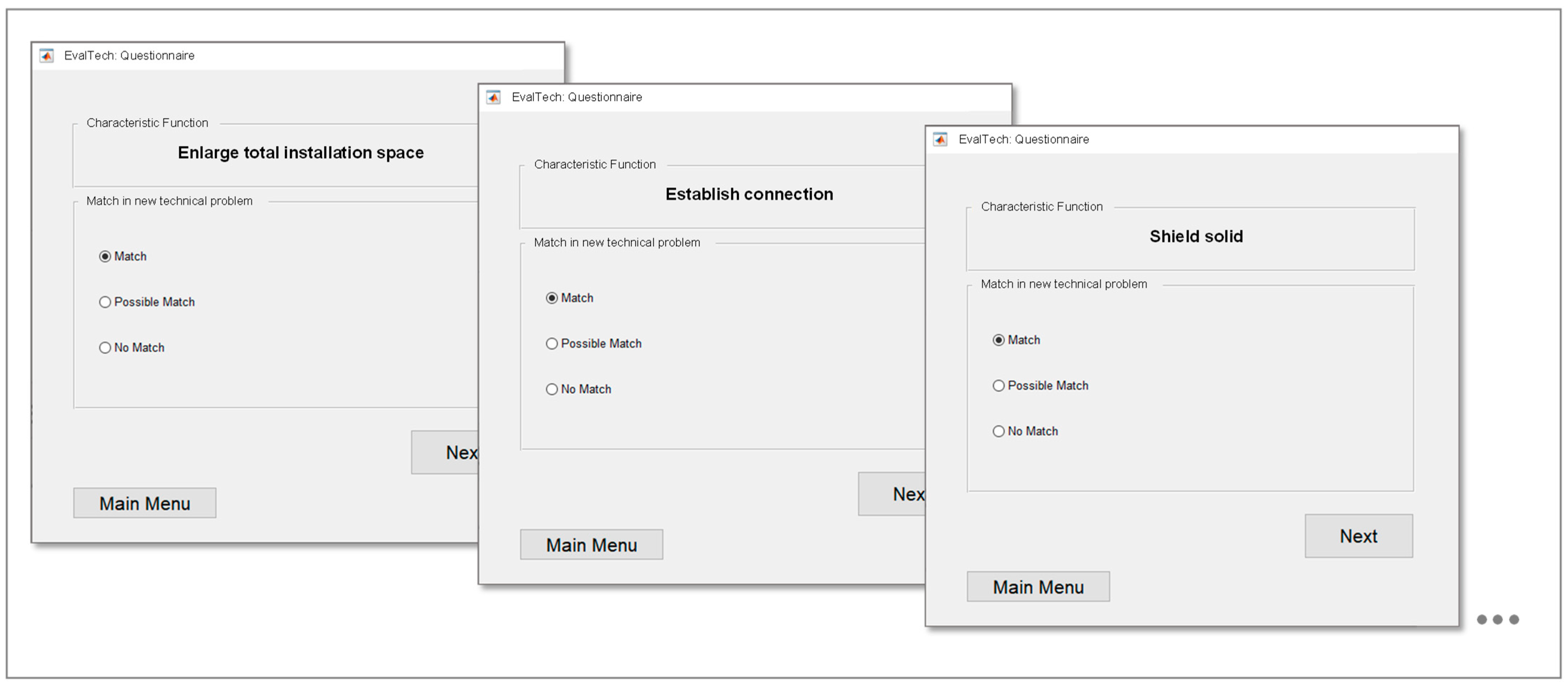

The inexperienced product developer uses the

EvalTech Questionnaire during concept development before deciding on a solution principle. He answers the

EvalTech Questionnaire by comparing the listed characteristic functions with functions of the new technical problem. For each characteristic function listed, the user can select whether this function corresponds exactly (

match), corresponds analogously (

possible match), or does not correspond at all (

no match) to a function of his technical problem, cf.

Figure 7.

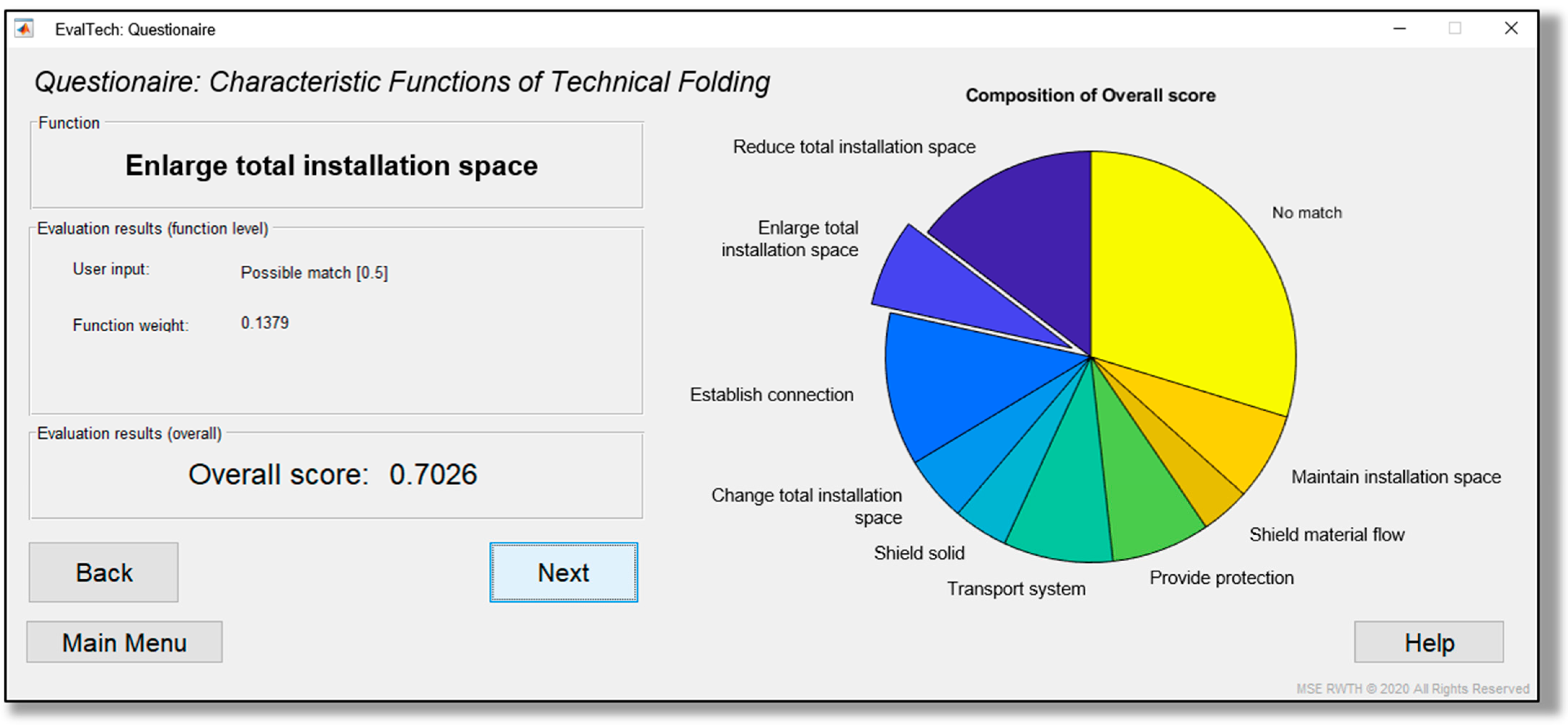

Subsequently, the similarity equation

is calculated and its result is visualised as

overall score, cf.

Figure 8. In addition, all matching functions are displayed in a pie chart. Selecting a specific function from the pie chart also shows the significance of the respective function and the user’s response.

For the subsequent process,

specify features, the user designs a machine-readable, hierarchical function structure of the new technical problem with the help of the

Hierarchical Function Structure Builder (HFSB). The HFSB is implemented as the MATLAB

® function

fsb.m, cf.

Figure 9. The HFSB supports the user by providing the functions derived from technical folding systems (

function catalogue) for selection and the option of designing new functions. These functionalities, as well as a general consistency check (

test) of the function architecture (including unique relationships, use of the subject–verb method), help standardise the designed function structure and ensure high-quality input for the sub-process step

select.

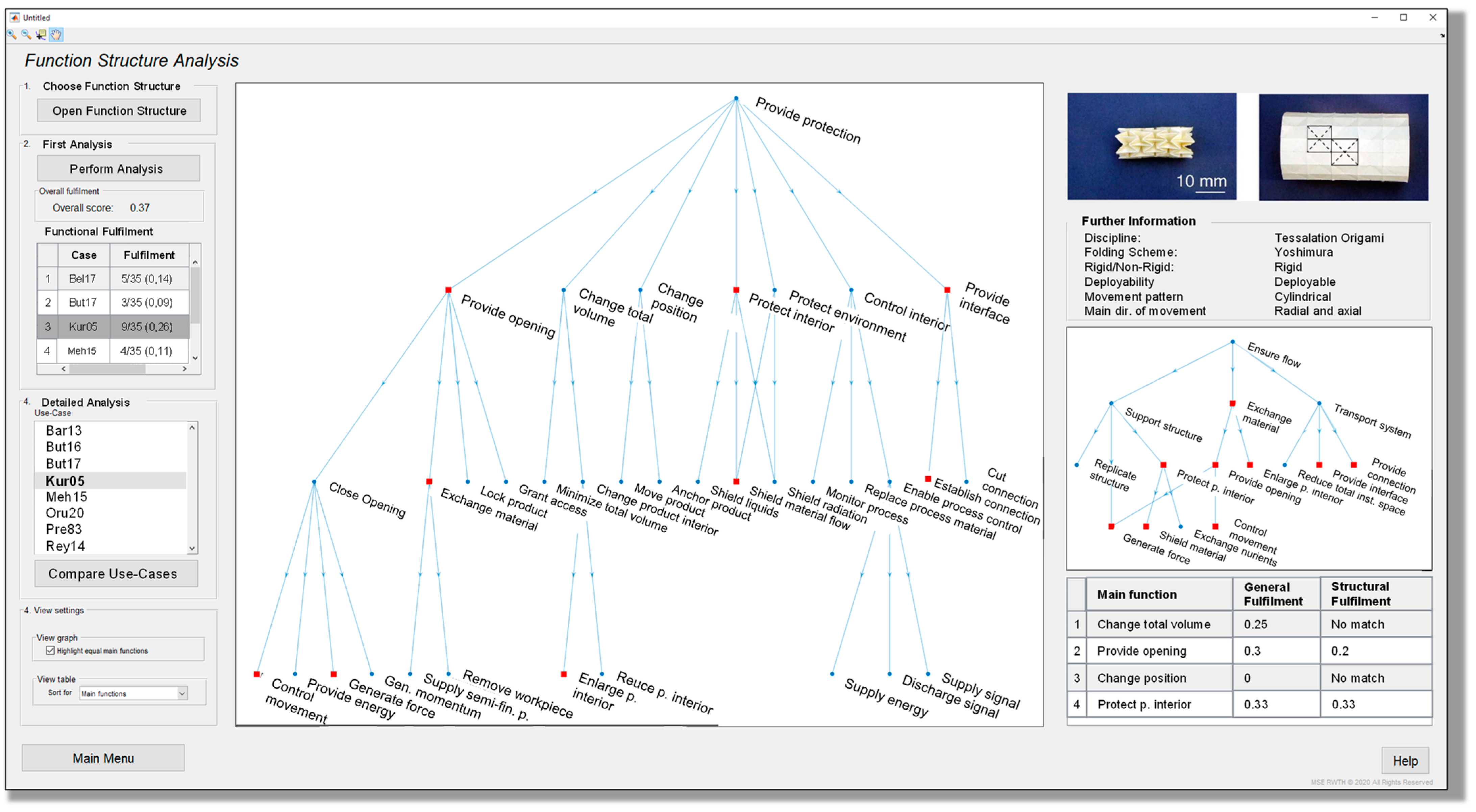

In the subsequent process,

select, the calculation of similarity between the designed function structure and function structures of

case base 2 is carried out automatically by the further execution of the MATLAB

® function

fsa.m. For this purpose, the similarity equations

and

are calculated for each successfully applied product from

case base 2. Within the user interface, the similarity equation

is listed for each case from

case base 2 as “functional fulfilment in use case”. For a detailed view of the result of

for a

case of interest, this

case can be selected and the result of the comparison visualised. For this purpose, the function structure of the new technical problem task is visualised centrally. The function structure of the selected

case is shown in a right window of the user interface. Identical functions are marked in red. The result of the respective similarity analysis of main functions with the function structure of the

case under consideration is listed in detail, cf.

Figure 10.

In addition to the function structure and the calculated similarity equations, the classification of the folding system is listed, cf.

Section 2.2: Origami discipline, folding scheme, changeability, type of movement, and main direction of movement. Based on the result of the function structure analysis and additional information, solution concepts for the current development task can be developed analogy-based.

6. Testing of the EvalTech Method

The EvalTech method was initially tested using the following use case.

6.1. Use Case for Testing

As part of the DFG-funded research project “Design and Development of Convertible Folding Systems” (E2F, project number 289387994), the EvalTech method developed here is being applied and tested to the concept development of a large-scale covering for industrial welding robots.

The overall purpose of the covering to be developed for industrial robots is to provide protection of the environment from, for example, flying sparks during welding, thermal hazards, or optical radiation emitted by the robot during the welding process. Other essential requirements placed on the cover are, for example, opening and closing the cover in order to exchange the components to be welded or enabling flexible positioning of the cover in the working environment of the welding robot.

The essential functions that the covering for welding robots to be developed must fulfil are, for example, “protect product interior”, “change total volume”, “protect environment”, “shield material flow”, or “change position”.

The identified functions form the starting point of the initial testing of the EvalTech method by product developers.

6.2. Initial Testing of the EvalTech Method

The main functions and their sub-functions of the large-scale covering for industrial welding form the starting point for testing the applicability of technical folding using the EvalTech method implemented in the software application. The

EvalTech Questionnaire is qualitatively validated by the product developers by applying it to the concept development of the covering and three successfully realised technical folding systems: the modular origami robot [

12], the stent [

7], and the origami folding for 3D optics [

6].

Answering the EvalTech Questionnaire is user-friendly, and the subsequent automated calculation of the initial match can be calculated successfully: the comparison of the main functions and sub-functions with the functions of case base 1 yields a fit of 0.7026 (=70.26%) for the concept of the covering. The comparison of the functions of the three successfully realised technical folding systems yields a high fit as expected: 0.635 for the robot, 0.693 for the stent, and 0.755 for the origami folding for 3D optics.

The EvalTech Questionnaire provides the best results if the functions match literally. Functions that are described with synonymous words or contain grammatical errors or errors in their spelling cannot be considered in the similarity calculation. Functions that correspond in meaning to the functions of the EvalTech Questionnaire can also be selected, but this choice depends on the user’s subjective interpretation of the functions of the new technical problem.

In the subsequent process step, specify features, the specific function structure is efficiently worked out with the help of the HFSB. The function catalogue stored here facilitates the development of the function structure and recommends useful functions for the function structure. Own functions can be added as desired and used for the development of the function structure.

For better visualisation, the designed function structure of the covering is shown as a block definition diagram in the following

Figure 11.

Using a deliberate development of non-standardised function structures, it was also possible to validate that the integrated test for checking the quality of the function structure (adherence to the subject-verb method, use of only one main function, connection of at least two sub-functions to a superordinate function) works.

In the subsequent process select, the automatic calculation of the similarity equations and can be performed successfully with the help of the MATLAB® function, Function Structure Analysis. The function structure of the covering most closely matches the function structure of the self-deployable stent. The higher the result of the similarity analysis 2.1 and 2.2, the more similar the functions or function structures of the application are to those of an already successfully used folding mechanism. With high values, the application is promising for technical folding. The general functional similarity is 0.2571 (=25.71%) and the structural similarity is 0.5556 (=55.56%). The solution concept of the self-deployable stent is based on the folding scheme Chickenwire and allows a cylindrical movement in radial and axial directions. In addition to the matching with this solution concept, the matches with other solution concepts can be visualised.

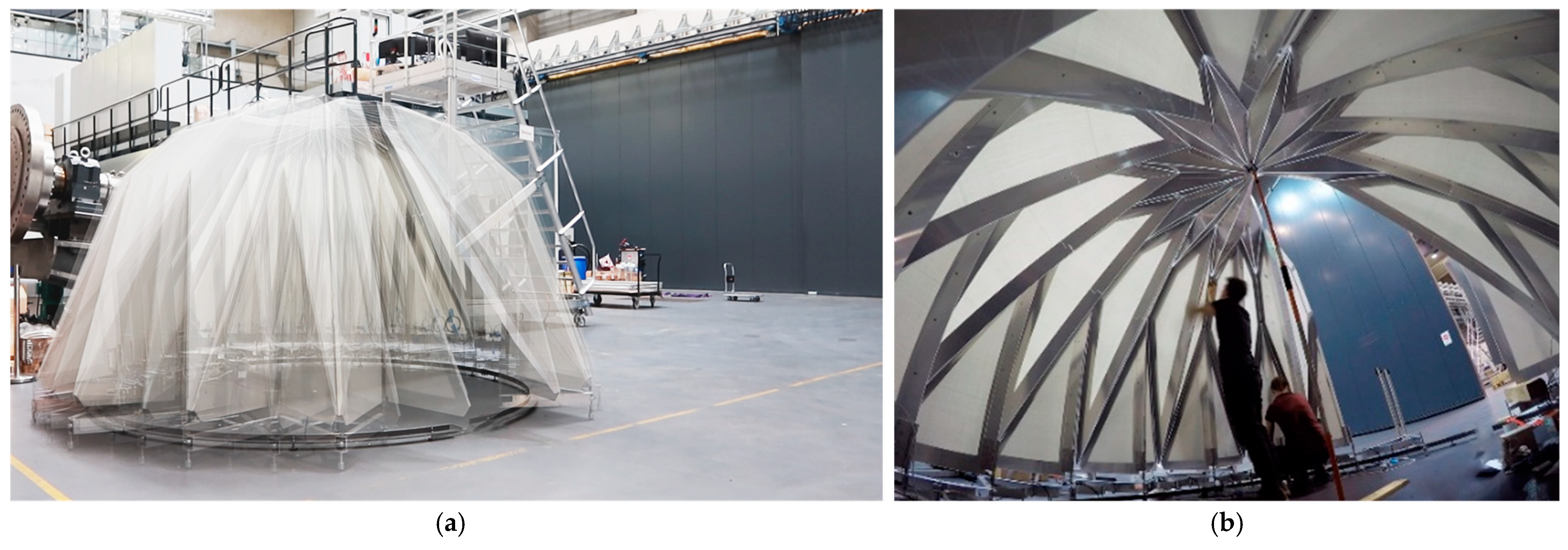

Based on the result of the calculated match and the visualisation of further solution concepts, the hurdle for the development of a covering based on the solution principle of technical folding has been taken. The solution concept for a foldable covering successfully developed within the research project E2F is based on a folding scheme similar to the self-deployable stent, the so-called Chickenwire folding scheme, which enables a cylindrical opening and closing of the covering.

The solution concept has been successfully implemented and manufactured within the research project E

2F, cf.

Figure 12 [

31].

7. Discussion and Conclusions

Despite its promising potential, technical folding has rarely been implemented in technical systems so far. This is often due to a lack of expertise and experience on the part of engineers, who are unable to apply the solution principle to their current task during concept development. Inexperienced product developers tend to choose known solution principles instead of utilising the potential of technical folding. To overcome these challenges, the research paper developed the EvalTech method and implemented it in a software application for efficient utilisation. EvalTech helps inexperienced product developers to decide whether the solution principle of technical folding and which classification of technical folding systems can be used in concept development. This applicability evaluation was performed on the basis of functions and function structures of successfully developed folding systems from the literature. The research focused on answering the research question of how function structures can be used as databases for applicability evaluation.

To answer the research question, first functions of existing technical folding systems were derived from literature. Then, functions were formalised using the subject-verb method and stored in a database (case base 1). The machine-readable subject and verb of a function were used as attributes for the similarity calculations between functions of the new technical problem and characteristic functions of technical folding. Hierarchical function structures were formalised using functions of case base 1 and directed graphs between functions and stored in another database (case base 2). The graph-based relationship between functions in the hierarchical levels was used as an attribute for the similarity calculation between function structures of the new technical problem and function structures of technical folding.

The equations for the similarity calculations were each defined using the machine-learning method nearest neighbour. The result of the similarity calculation between functions depends strongly on the selected words. Functions that are described with synonymous words or contain grammatical errors or errors in their spelling cannot be considered in the similarity calculation. In contrast, the similarity calculation between function structures is more precise. The results of both similarity calculations are values between 0 (=not similar) and 1 (=identical). So far, however, the software application does not provide a purely objective recommendation as to which similarity value makes an application successful. Instead, in addition to the similarity value, the software application presents the assigned technical folding system with its properties, such as the overall purpose or the direction of movement. The final decision is therefore not made by the computer alone, but also by humans.

The developed similarity calculations and

case bases are used as part of the CBR process,

retrieving, and its specific subprocesses according to Aamodt and Plaza [

29]. The subprocesses of

retrieving are implemented in a software application for the efficient support of inexperienced developers. The implementation of the further

reusing and

revising based on the result of the applicability evaluation is not covered by the software application. Nevertheless, based on the visualised concepts of known folding systems, it is possible to design your own development task by analogy.

The EvalTech method developed was initially tested using the concept development of a covering for industrial robots. The result of the initial evaluation of technological fit was also tested using the successfully realised concepts of known technical folding systems. The EvalTech method and its implementation in software is limited to the evaluation of only one solution principle, namely the technical folding.

8. Outlook

Although CBR methods are less prominent compared to other machine learning approaches (e.g., deep learning or artificial neural networks), this research was able to show that in areas with standardised structures, such as product development with standardised function structures, CBR systems are a viable method for decision-making. Nevertheless, the improvements described below should be researched and developed in order to make the applicability evaluation more precise but also generally usable.

In order to use the EvalTech method to accurately identify features of the new system and to compare them well with the experiences of experts, features should be described clearly and precisely, and not just by a subject–verb method. Unambiguous and precise functions can be functions that are defined using the so-called input–output method according to Lindemann et al. [

26]. These functions thus describe the functionality of the system in a solution-neutral manner by clearly defining the translation of an input into an output.

For the future, more precise decisions that can be validly made by the computer, the similarity calculations must be extended for the comparison between functions with identical meanings or functions that contain grammatical errors and spelling mistakes. Further possibility for a more precise similarity calculation is the formalisation of functions through additional attributes, such as function flows, which clearly describe the behaviour of the product via inputs and outputs. In further developments, functional structures should be built up from functions with function flows and by an input–output method in order to describe the system’s functionality precisely and to specify the similarity calculations.

In addition, for a meaningful validation, the method must be applied and evaluated not only on the basis of one concept development but on several future developments. For the simultaneous evaluation of the applicability of other innovative solution principles, the CBR system must be expanded to include solutions and thus functions and function structures of other innovative solution principles. This extension could, for example, create a general

database for searching and finding suitable solution principles on the basis of functions and function structures. Specific methods and tools for realising the missing CBR processes,

reusing and

revising, according to Aamodt and Plaza [

29] must be researched and developed in future studies in order to detail these process steps for the realisation of the entire CBR process.

Author Contributions

Conceptualization, F.W. and S.S.; Supervision, G.J.; Writing—review and editing, K.B., C.K., J.M., K.M.G. and A.S. All authors have read and agreed to the published version of the manuscript.

Funding

This research work was funded by the Deutsche Forschungsgemeinschaft (DFG, engl. German Research Foundation) as part of the project “Entwurf und Entwicklung von wandelbaren Faltwerken” (engl. Design and Development of Convertible Folding Systems, project number 289387994).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The raw data supporting the conclusions of this article will be made available by the authors on request.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Avila, A.; Magleby, S.P.; Lang, R.J.; Howell, L.L. Origami fold states: Concept and design tool. Mech. Sci. 2019, 10, 91–105. [Google Scholar] [CrossRef]

- Turner, N.; Goodwine, B.; Sen, M. A review of origami applications in mechanical engineering. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2015, 230, 2345–2362. [Google Scholar] [CrossRef]

- Cannella, F.; Dai, J.S. Origami-carton tuck-in with a reconfigurable linkage. In Proceedings of the 2009 ASME/IFToMM International Conference on Reconfigurable Mechanisms and Robots, London, UK, 22–24 June 2009; pp. 512–520. [Google Scholar]

- Konings, R.; Thijs, R. Foldable Containers: A New Perspective on Reducing Container-Repositioning Costs. Eur. J. Transp. Infrastruct. Res. 2001, 1. [Google Scholar] [CrossRef]

- Tremblay, E.J.; Stack, R.A.; Morrison, R.L.; Ford, J.E. Ultrathin cameras using annular folded optics. Appl. Opt. 2007, 46, 463–471. [Google Scholar] [CrossRef] [PubMed]

- Cho, J.-H.; Keung, M.D.; Verellen, N.; Lagae, L.; Moshchalkov, V.V.; van Dorpe, P.; Gracias, D.H. Nanoscale origami for 3D optics. Small 2011, 7, 1943–1948. [Google Scholar] [CrossRef] [PubMed]

- Kuribayashi, K.; Tsuchiya, K.; You, Z.; Tomus, D.; Umemoto, M.; Ito, T.; Sasaki, M. Self-deployable origami stent grafts as a biomedical application of Ni-rich TiNi shape memory alloy foil. Mater. Sci. Eng. A 2006, 419, 131–137. [Google Scholar] [CrossRef]

- Francis, K.C.; Rupert, L.T.; Lang, R.J.; Morgan, D.C.; Magleby, S.P.; Howell, L.L. From Crease Pattern to Product: Considerations to Engineering Origami-Adapted Designs. In Proceedings of the ASME 2014 International Design Engineering Technical Conferences and Computers and Information in Engineering Conference, Buffalo, NY, USA, 17–20 August 2014. [Google Scholar]

- Sargent, B.; Butler, J.; Seymour, K.; Bailey, D.; Jensen, B.; Magleby, S.; Howell, L. An Origami-Based Medical Support System to Mitigate Flexible Shaft Buckling. J. Mech. Robot. 2020, 12, 041005. [Google Scholar] [CrossRef]

- Onal, C.D.; Wood, R.J.; Rus, D. An Origami-Inspired Approach to Worm Robots. IEEE/ASME Trans. Mechatron. 2013, 18, 430–438. [Google Scholar] [CrossRef]

- Onal, C.D.; Tolley, M.T.; Wood, R.J.; Rus, D. Origami-Inspired Printed Robots. IEEE/ASME Trans. Mechatron. 2015, 20, 2214–2221. [Google Scholar] [CrossRef]

- Belke, C.H.; Paik, J. Mori: A Modular Origami Robot. IEEE/ASME Trans. Mechatron. 2017, 22, 2153–2164. [Google Scholar] [CrossRef]

- Hawkes, E.; An, B.; Benbernou, N.M.; Tanaka, H.; Kim, S.; Demaine, E.D.; Rus, D.; Wood, R.J. Programmable matter by folding. Proc. Natl. Acad. Sci. USA 2010, 107, 12441. [Google Scholar] [CrossRef] [PubMed]

- Pooya, S.; Chermprayong, P.; Emmanuelli, M.; Nadeem, H.; Kovac, M. Rotorigami: A rotary origami protective system for robotic rotorcraft. Sci. Robot. 2018, 3, eaah5228. [Google Scholar] [CrossRef]

- Butler, J.; Morgan, J.; Pehrson, N.; Tolman, K.; Bateman, T.; Magleby, S.P.; Howell, L.L. Highly Compressible Origami Bellows for Harsh Environments. In Proceedings of the ASME 2016 International Design Engineering Technical Conferences and Computers and Information in Engineering Conference, Charlotte, NC, USA, 21–24 August 2016. [Google Scholar]

- Natori, M.C.; Sakamoto, H.; Katsumata, N.; Yamakawa, H.; Kishimoto, N. Conceptual model study using origami for membrane space structures—A perspective of origami-based engineering. Mech. Eng. Rev. 2015, 2, 14-00368. [Google Scholar] [CrossRef]

- Oru Kayak Inc. The Original Origami Kayak. Available online: https://www.orukayak.com/ (accessed on 16 December 2021).

- N. N. Consumer Product Design—Foldable Footwear—Ideal Travel Footwear Offering Ultimate Portability. Available online: https://www.tataelxsi.com/services/industrial-design-innovation/product-design-cs/foldablefootware.html (accessed on 25 August 2020).

- Sterman, Y.; Demaine, E.D.; Oxman, N. PCB Origami: A Material-Based Design Approach to Computer-Aided Foldable Electronic Devices. J. Mech. Des. 2013, 135, 114502. [Google Scholar] [CrossRef]

- Hester, J.G.; Kim, S.; Bito, J.; Le, T.; Kimionis, J.; Revier, D.; Saintsing, C.; Su, W.; Tehrani, B.; Traille, A.; et al. Additively Manufactured Nanotechnology and Origami-Enabled Flexible Microwave Electronics. Proc. IEEE 2015, 103, 583–606. [Google Scholar] [CrossRef]

- Macri, S. Practical Applications of Rigid Thick Origami in Kinetic Architecture; University of Hawaii at Manoa: Honolulu, HI, USA, 2015. [Google Scholar]

- N. N. Al Bahr Towers. Available online: https://www.ahr.co.uk/projects/al-bahr-towers (accessed on 16 December 2021).

- Feldhusen, J. (Ed.) Pahl/Beitz Konstruktionslehre: Methoden und Anwendung erfolgreicher Produktentwicklung; 8., vollst. überarb. Aufl.; Springer: Berlin/Heidelberg, Germany, 2013; ISBN 3642295681. [Google Scholar]

- Jacobs, G.; Konrad, C.; Berroth, J.; Zerwas, T.; Höpfner, G.; Spütz, K. Function-Oriented Model-Based Product Development. In Design Methodology for Future Products; Krause, D., Heyden, E., Eds.; Springer International Publishing: Cham, Switzerland, 2022; pp. 243–263. ISBN 978-3-030-78367-9. [Google Scholar]

- Verein Deutscher Ingenieure e. V. VDI 2221. 2019. Available online: https://www.vdi.de/en/home/vdi-standards/details/vdi-2221-blatt-1-design-of-technical-products-and-systems-model-of-product-design (accessed on 25 August 2020).

- Handbuch Produktentwicklung; Lindemann, U., Ed.; Carl Hanser Verlag GmbH & Co. KG: München, Germany, 2016; ISBN 9783446450929. [Google Scholar]

- Bergmann, R.; Minor, M.; Bach, K.; Althoff, K.-D.; Munoz-Avila, H. 9 Fallbasiertes Schließen. In Handbuch der Künstlichen Intelligenz; Görz, G., Schmid, U., Braun, T., Eds.; De Gruyter: Berlin, Germany, 2020; pp. 343–394. ISBN 9783110659948. [Google Scholar]

- Krampe, D. Fallbasiertes Schließen. In Wiederverwendung von Informationssystementwürfen; Krampe, D., Ed.; Deutscher Universitätsverlag: Wiesbaden, Germany, 1999; pp. 45–53. ISBN 978-3-8244-2121-3. [Google Scholar]

- Aamodt, A.; Plaza, E. Case-Based Reasoning: Foundational Issues, Methodological Variations, and System Approaches. AI Commun. 1994, 7, 39–59. [Google Scholar] [CrossRef]

- Watson, I.; Marir, F. Case-based reasoning: A review. Knowl. Eng. Rev. 1994, 9, 327–354. [Google Scholar] [CrossRef]

- Moreno Gata, K.; Seiter, A.; Musto, J.; Merz, J.; Wieja, F.; Jacobs, G.; Corves, B. Design and Development of a Foldable and Transformable Hemispherical Enclosure for Robotic Manufacturing. In Proceedings of the 8th International Meeting on Origami in Science, Mathematics and Education (8OSME), Melbourne, Australia, 15–18 July 2024. [Google Scholar]

| Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).