A New Approach to Characterize Superplastic Materials from Free-Forming Test and Inverse Analysis

Abstract

Featured Application

Abstract

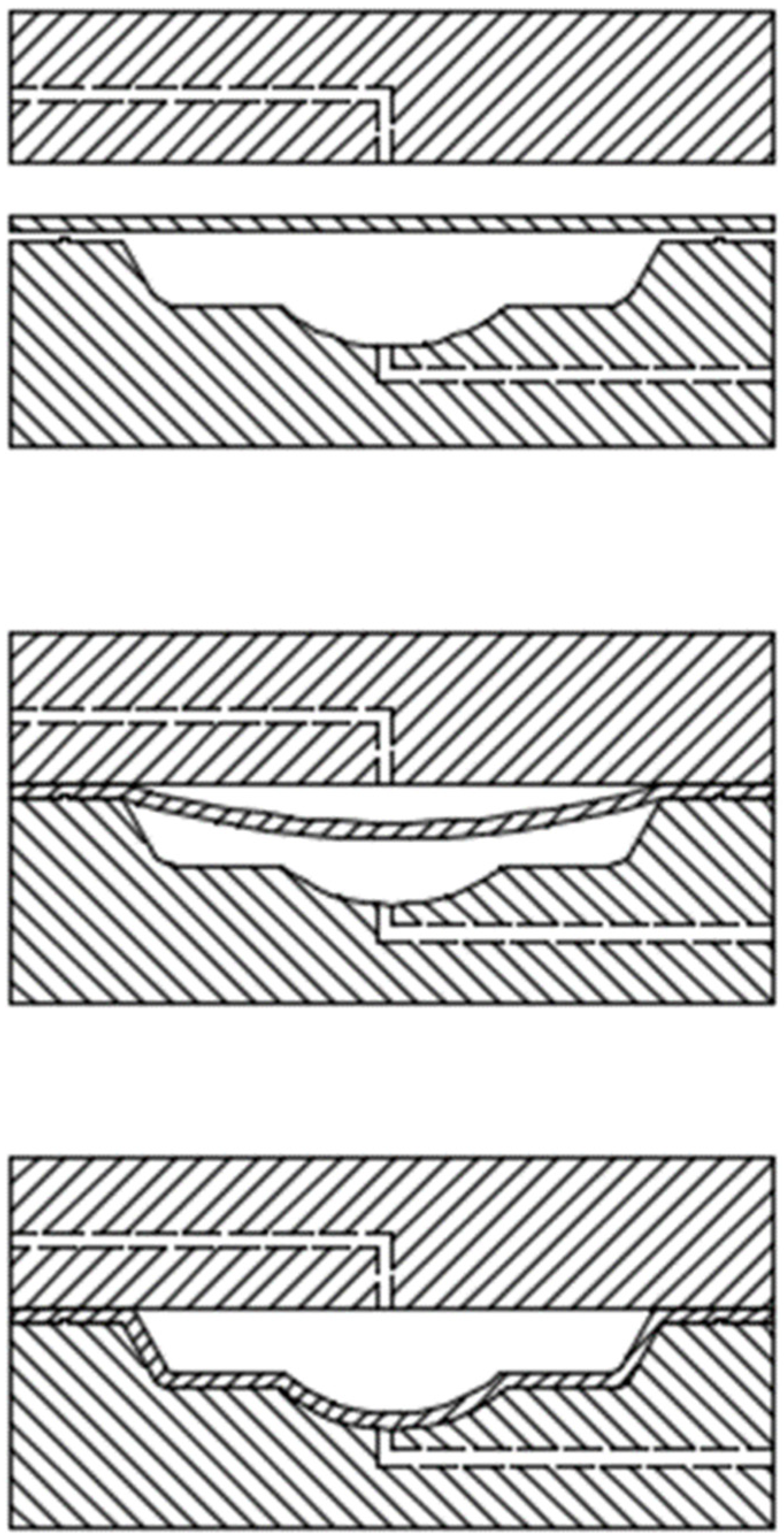

1. Introduction

2. Materials and Methods

- -

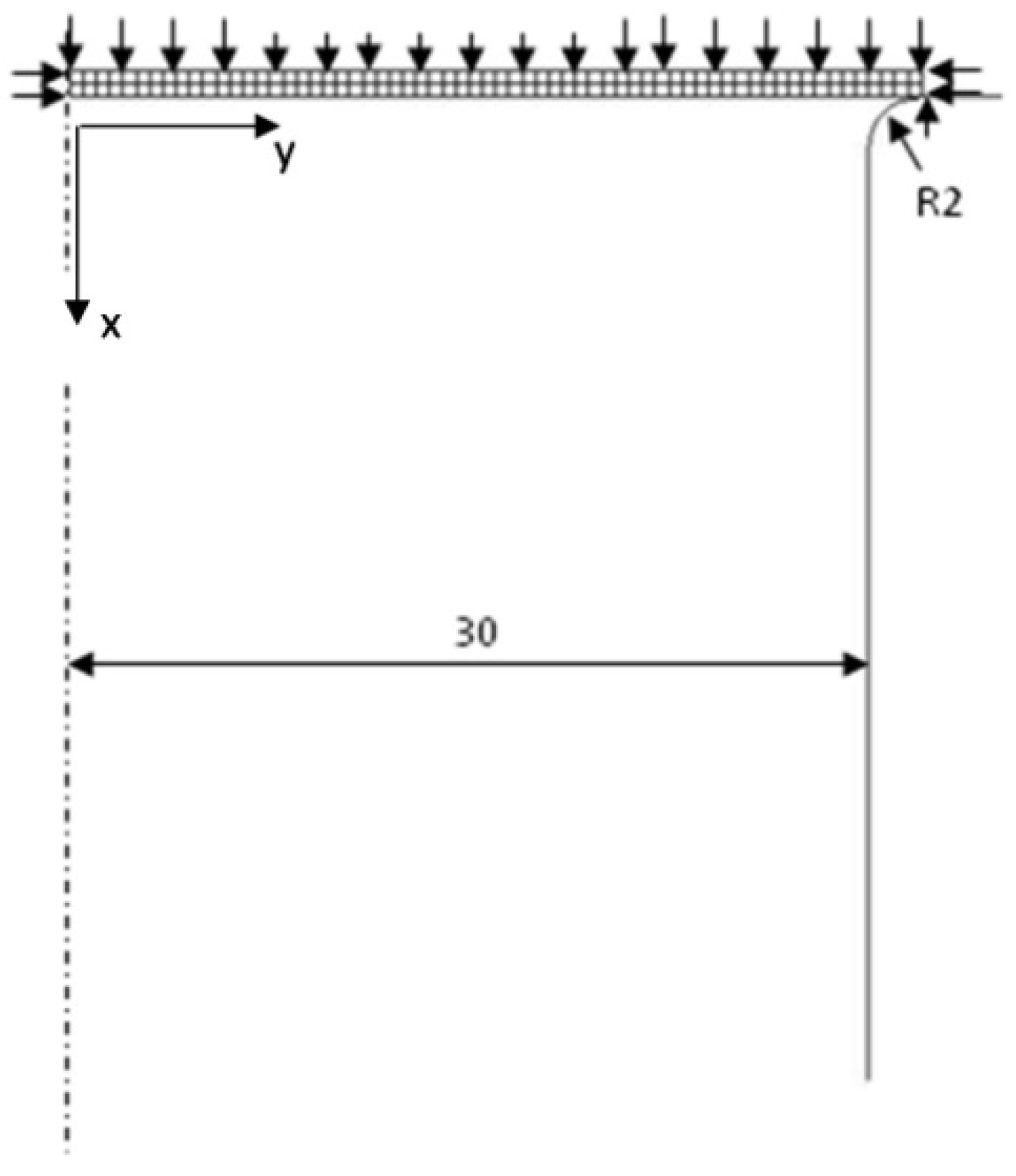

- For the node in contact with the die and placed on the external edge of the metal sheet, ux = 0 and uy = 0 (where u is the displacement of the node);

- -

- For the nodes on the external edge (not in contact with the die) uy = 0;

- -

- For all the nodes on the axis of symmetry (condition of axisymmetry) uy = 0;

- -

- The upper edges of the metal sheet are subjected to a uniform pressure (in one case p = 0.2 MPa and in the other case p = 0.4 MPa).

3. Theory

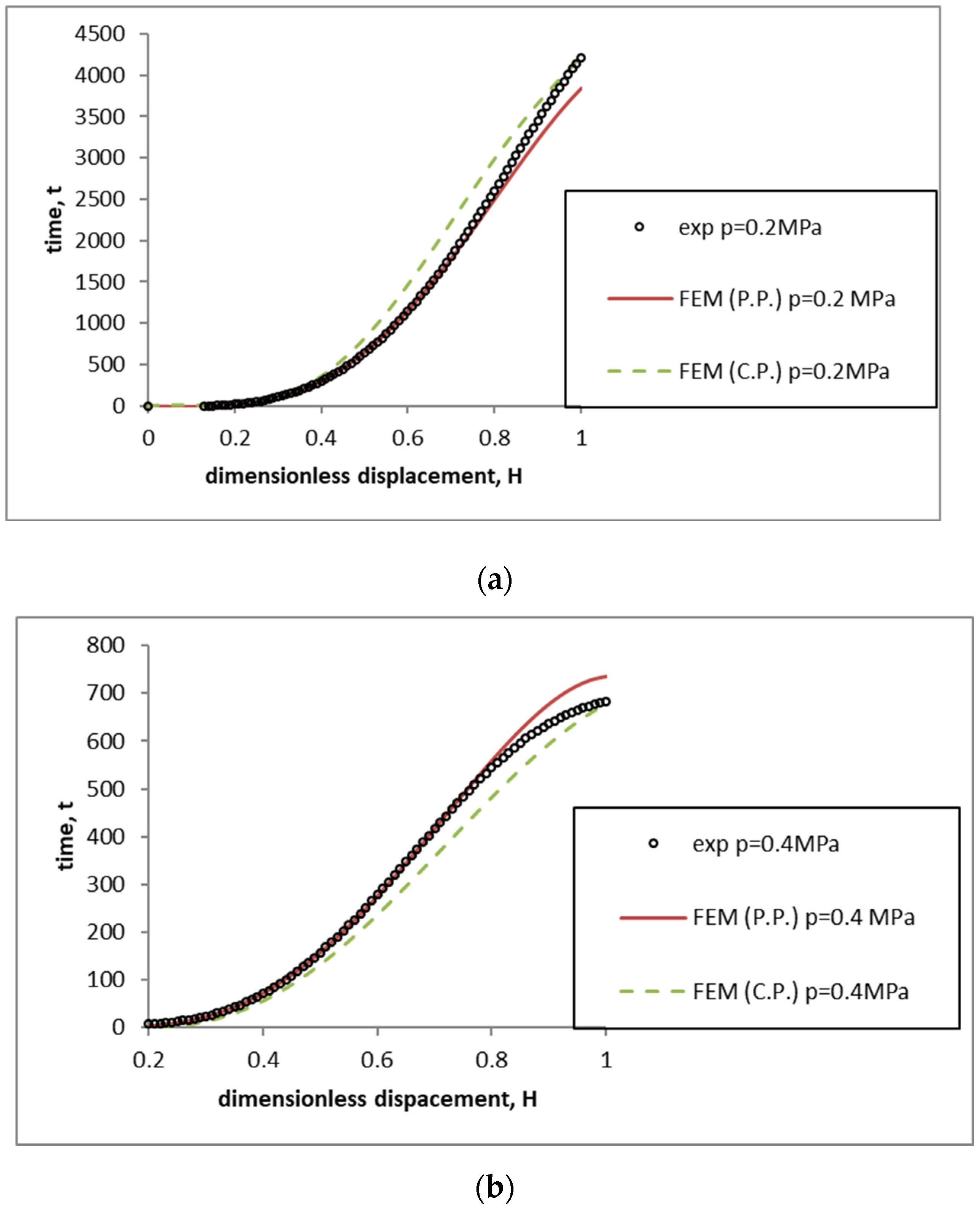

4. Results and Discussion

- -

- The parameters coming from the conventional procedure (C.P.) adopted to identify them (dotted line—FEM C.P.);

- -

- The parameters coming from the proposed procedure (P.P.) adopted to identify them (solid line—FEM P.P.).

5. Conclusions

- The proposed procedure turned out to be more effective than the conventional procedure, since it involves a reduction in the percentage difference from the experimental results;

- The predicted forming time envisaged by the FEM differs from the experimental value at most by 20% for the conventional procedure and 8% for the proposed procedure;

- The procedure proposed in this paper allows for a reduction in the number of constants needed to determine the material constitutive equation, thereby requiring low simulation time;

- The proposed procedure is more suitable for being used in the industrial field.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Li, J.; Wang, Z.; Zhang, S.; Lin, Y.; Jiang, L.; Tan, J. Task incremental learning-driven Digital-Twin predictive modeling for customized metal forming product manufacturing process. Robot. Comp.-Integr. Manuf. 2024, 85, 102647. [Google Scholar] [CrossRef]

- Wang, Z.; Zhou, T.; Zhang, S.; Sun, C.; Li, J.; Tan, J. Bo-LSTM based cross-sectional profile sequence progressive predictionmethod for metal tube rotate draw bending. Adv. Eng. Inf. 2023, 58, 102152. [Google Scholar] [CrossRef]

- Pilling, J.; Ridley, N. Superplasticity in Crystalline Solids; Institute of Metals: London, UK, 1989. [Google Scholar]

- Ortiz, M.; Penalva, M.; Iriondo, E.; Lòpez de Lacalle, L.N. Investigation of Thermal-Related Effects in Hot SPIF in Ti-6Al-4V Alloy. Int. J. Precis. Eng. Manuf—Green. Techn 2020, 7, 299–317. [Google Scholar] [CrossRef]

- Pearce, R. Superplasticity. AGARD Lect. Ser. 1989, 168, 1.1–1.24. [Google Scholar]

- Kim, Y.H.; Lee, J.M.; Hong, S.S. Optimal design of superplastic forming processes. J. Mater. Proc. Technol. 2001, 12, 166–173. [Google Scholar] [CrossRef]

- Doltsinis, J.S.; Loginsland, J.; Nolting, S. Some Developments in the Numerical Simulation of Metal Forming Processes. In Proceedings of the International Conference on Computational Plasticity, Barcelona, Spain, 6–10 April 1987. [Google Scholar]

- Chandra, N. Analysis of superplastic metal forming by a finite element method. Int. J. Numer. Meth. Eng. 1988, 26, 1925–1944. [Google Scholar] [CrossRef]

- Carrino, L.; Giuliano, G.; Palmieri, C. Analysis of superplastic bulge forming by the finite element method. Mater. Technol. 2001, 16, 237–241. [Google Scholar] [CrossRef]

- Kim Yong, H.; Hong, S.S.; Lee, J.S.; Wagoner, R.H. Analysis of superplastic forming processes using a finite-element method. J. Mater. Proc. Technol. 1996, 62, 90–99. [Google Scholar]

- Wood, R.D.; Bonet, J. A review of the numerical analysis of superplastic forming. J. Mater. Proc. Technol. 1996, 60, 45–53. [Google Scholar] [CrossRef]

- Watanabe, H.; Mukai, T.; Ishikawa, K.; Mohri, T.; Mabuchi, M.; Higashi, K. Superplasticity of a particle strengthened WE43 magnesium alloy. Mater. Trans. 2001, 42, 157–162. [Google Scholar] [CrossRef]

- Mabuchi, M.; Ameyama, K.; Iwasaki, H.; Higashi, K. Low temperature superplasticity of AZ91 magnesium alloy with non-equilibrium grain boundaries. Acta Mater. 1999, 47, 2047–2057. [Google Scholar] [CrossRef]

- Kim, W.; Kim, M.; Wan, J. Superplastic behaviour of a fine-grained ZK60 magnesium alloy processed by high-ratio differential speed rolling. Mater. Sci. Eng. A 2009, 527, 322–327. [Google Scholar] [CrossRef]

- Zhang, D.-T.; Xiong, F.; Zhang, W.-W.; Qiu, C.; Zhang, W. Superplasticity of AZ31 magnesium alloy prepared by friction stir processing. Trans. Nonfer Met. Soc. China 2011, 21, 1911–1916. [Google Scholar] [CrossRef]

- Chung, S.W.; Higashi, K.; Kim, W.J. Superplastic gas pressure forming of fine-grained AZ61 magnesium alloy sheet. Mater. Sci. Eng. A 2004, 372, 15–20. [Google Scholar] [CrossRef]

- Lee, C.J.; Huang, J.C. Cavitation characteristics in AZ31 Mg alloys during LTSP or HSRSP. Acta Mater. 2004, 52, 3111–3122. [Google Scholar] [CrossRef]

- Miao, Q.; Hu, L.; Wang, X.; Wang, E. Grain growth kinetics of a fine-grained AZ31 magnesium alloy produced by hot rolling. J. Alloy. Comp. 2010, 493, 87–90. [Google Scholar] [CrossRef]

- Neugebauer, R.; Altan, T.; Geiger, M.; Kleiner, M.; Sterzing, A. Sheet metal forming at elevated temperatures. Ann. CIRP 2006, 55, 793–816. [Google Scholar] [CrossRef]

- Boissiere, R.; Terzi, S.; Blandin, J.J.; Salvo, L. Quick-plastic forming: Similarities and differences with super-plastic forming. In Proceedings of the 6th EUROSPF Conference, Carcassonne, France, 3–5 September 2008. [Google Scholar]

- Giuliano, G.; Samani, F. Comparison between superplastic and non-superplastic grade AA 5083. J. Test. Eval. 2016, 44, 2114–2119. [Google Scholar] [CrossRef]

- Giuliano, G.; Polini, W. Influence of the initial blank geometry on the final thickness distribution of the hemispheres in superplastic AZ31 alloy. Appl. Sci. 2022, 12, 1912. [Google Scholar] [CrossRef]

- Sorgente, D.; Palumbo, G.; Scintilla, L.D.; Tricarico, L. Gas forming of an AZ31 magnesium alloy at elevated strain rates. Int. J. Adv. Manuf. Technol. 2016, 83, 861–872. [Google Scholar] [CrossRef]

- Hamilton, C.H.; Ghosh, A.K. Superplastic sheet forming. In Metals Handbook; ASM: Metals Park, OH, USA, 1988; pp. 852–873. [Google Scholar]

- Giuliano, G.; Polini, W. Influence of blank variable thickness on the material formability in hot gas sheet metal forming process. Manuf. Lett. 2020, 24, 72–76. [Google Scholar] [CrossRef]

- Akkus, N.; Suzuki, K.; Kawahara, M.; Nishimura, H. Influence of performing on the final thickness distribution of the superplastically deformed domes. Mater. Sci. Form. 1999, 304–306, 759–764. [Google Scholar] [CrossRef]

- Luckey, G.; Friedman, P.; Weinmann, K. Design and experimental validation of a two-stage superplastic forming die. J. Mater. Proc. Technol. 2009, 209, 2152–2160. [Google Scholar] [CrossRef]

- Giuliano, G.; Corrado, A.; Polini, W. Influence of multiphase forming approach on the thickness uniformity of components from superplastic PbSn60 alloy. Manuf. Lett. 2018, 18, 16–19. [Google Scholar] [CrossRef]

- Huang, A.; Lowe, A.; Cardew-Hill, M.J. Experimental validation of sheet thickness optimization for superplastic forming of engineering structures. J. Mater. Proc. Technol. 2001, 112, 136–143. [Google Scholar] [CrossRef]

- Dutta, A. Thickness-profiling of initial blank for superplastic forming of uniformly thick domes. Mater. Sci. Eng. A 2004, 371, 79–81. [Google Scholar] [CrossRef]

- Giuliano, G.; Polini, W. Optimal design of blank thickness in superplastic AZ31 alloy to decrease forming time and product weight. Int. J. Adv. Manuf. Technol. 2022, 118, 2153–2162. [Google Scholar] [CrossRef]

- Lin, J.; Yang, J. GA based multiple objective optimization for determining viscoplastic constitutive equations for superplastic alloys. Int. J. Plast. 1999, 15, 1181–1196. [Google Scholar] [CrossRef]

- Kim, T.W.; Dunne, F.P.E. Determination of superplastic constitutive equations and strain rate sensitivity for aerospace alloys. Proc. Inst. Mech. Eng. Part. G J. Aerosp. Eng. 1997, 211, 367–380. [Google Scholar] [CrossRef]

- Cheong, B.H. Modelling of Microstructural and Damage Evolution in Superplastic Forming. Ph.D. Thesis, University of Birmingham, Birmingham, UK, 2022; pp. 96–97. [Google Scholar]

- Lin, J.; Cheong, B.H.; Yao, X. Universal multi-objective function for optimising superplastic-damage constitutive equations. J. Mater. Proc. Technol. 2022, 125–126, 199–205. [Google Scholar] [CrossRef]

- Majidi, O.; Jahazi, M.; Bombardier, N. A viscoplastic model based on a variable strain rate sensitivity index for superplastic sheet metals. Int. J. Mater. Form. 2019, 12, 693–702. [Google Scholar] [CrossRef]

- Jovane, F. An approximate analysis of the superplastic forming of a thin circular diaphragm: Theory and experiments. Int. J. Mech. Sci. 1968, 10, 403–427. [Google Scholar] [CrossRef]

- Giuliano, G.; Franchitti, S. On the evaluation of superplastic characteristics using the finite element method. Int. J. Mach. Tools Manuf. 2007, 47, 471–476. [Google Scholar] [CrossRef]

- Aksenov, S.A.; Kolesnikov, A.V.; Mikhaylovskaya, A.V. Design of a gas forming technology using the material constants obtained by tensile and free bulging testing. J. Mater. Proc. Technol. 2016, 237, 88–95. [Google Scholar] [CrossRef]

- El-Morsy, A.W.; Manabe, K. FE simulation of rectangular box forming using material characteristics from the multi-dome forming test. J. Mater. Proc. Technol. 2002, 125–126, 772–777. [Google Scholar] [CrossRef]

- Yoo, J.T.; Yoon, J.H.; Lee, H.S.; Youn, S.K. Material characterization of Inconel 718 from free bulging test at high temperature. J. Mech. Sci. Technol. 2012, 26, 2101–2105. [Google Scholar] [CrossRef]

- Aksenov, S.A.; Chumachenko, E.N.; Kolesnikov, A.V.; Osipov, S.A. Determination of optimal gas forming conditions from free bulging tests at constant pressure. J. Mater. Proc. Technol. 2015, 217, 158–164. [Google Scholar] [CrossRef]

- Enikeev, F.U.; Kruglov, A.A. An analysis of the superplastic forming of a thin circular diaphragm. Int. J. Mech. Sci. 1995, 37, 473–483. [Google Scholar] [CrossRef]

- Sorgente, D.; Palumbo, G.; Piccininni, A.; Guglielmi, P.; Tricarico, L. Modelling the superplastic behaviour of the Ti6Al4V-ELI by means of a numerical/experimental approach. Int. J. Adv. Manuf. Technol. 2017, 90, 1–10. [Google Scholar] [CrossRef]

- Giuliano, G.; Polini, W. Characterization of the superplastic magnesium alloy AZ31 through free-forming tests and inverse analysis. Appl. Sci. 2023, 13, 2730. [Google Scholar] [CrossRef]

- Giovinco, G.; Giuliano, G.; Testa, G. Forming apparatus to investigate the effect of temperature on the superplastic behaviour of alloys. AIP Conf. Proc. 2010, 1252, 304–311. [Google Scholar]

- Giuliano, G. Modelling of Superplastic Forming of AZ31 Magnesium Alloy. AIP Conf. Proc. 2011, 1315, 1651–1656. [Google Scholar]

- Chandra, N.; Chandy, K. Superplastic process modelling of plan strain components with complex shapes. J. Mater. Shap. Technol. 1993, 1, 813–822. [Google Scholar]

- Cheng, J.H. The determination of material parameters from superplastic inflation tests. J. Mater. Proc. Technol. 1996, 58, 233–246. [Google Scholar] [CrossRef]

| Dimensionless Displacement H | Strain Rate Sensitivity Index, m, of Conventional Procedure | Strain Rate Sensitivity Index, m, of Proposed Procedure |

|---|---|---|

| 0 ≤ H ≤ 1 | 0.381 | / |

| 0 ≤ H ≤ 0.2 | / | 0.703 |

| 0.2 ≤ H ≤ 0.4 | / | 0.465 |

| 0.4 ≤ H ≤ 0.6 | / | 0.495 |

| 0.6 ≤ H ≤ 0.8 | / | 0.406 |

| 0.8 ≤ H ≤ 1 | / | 0.284 |

| Dimensionless Displacement H | Strain Hardening Index, n, of Conventional Procedure | Strength Coefficient, K, of Conventional Procedure | Strength Coefficient, C, of Proposed Procedure |

|---|---|---|---|

| 0 ≤ H ≤ 1 | 0.1 | 163.24 | / |

| 0 ≤ H ≤ 0.2 | / | / | 862.875 |

| 0.2 ≤ H ≤ 0.4 | / | / | 241.357 |

| 0.4 ≤ H ≤ 0.6 | / | / | 346.950 |

| 0.6 ≤ H ≤ 0.8 | / | / | 198.300 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Giuliano, G.; Polini, W. A New Approach to Characterize Superplastic Materials from Free-Forming Test and Inverse Analysis. Appl. Sci. 2024, 14, 11113. https://doi.org/10.3390/app142311113

Giuliano G, Polini W. A New Approach to Characterize Superplastic Materials from Free-Forming Test and Inverse Analysis. Applied Sciences. 2024; 14(23):11113. https://doi.org/10.3390/app142311113

Chicago/Turabian StyleGiuliano, Gillo, and Wilma Polini. 2024. "A New Approach to Characterize Superplastic Materials from Free-Forming Test and Inverse Analysis" Applied Sciences 14, no. 23: 11113. https://doi.org/10.3390/app142311113

APA StyleGiuliano, G., & Polini, W. (2024). A New Approach to Characterize Superplastic Materials from Free-Forming Test and Inverse Analysis. Applied Sciences, 14(23), 11113. https://doi.org/10.3390/app142311113