Abstract

Food packaging plays an essential role in preserving food quality. However, heavy metals found in packaging materials—whether intentionally incorporated or not—can migrate into food. This study aims to evaluate the migration of specific heavy metals (Ba, Co, Cu, Zn, Al, Ni, Li, Fe, Pb, Cd, Cr, Sb) from plastic food packages (films and bags) obtained from various materials (PE, PP, PVC, composite materials) into food simulant B (3% acetic acid) using inductively coupled plasma mass spectrometry (ICP-MS). Migration tests was conducted according to EU regulations, using OM2 conditions (10 days at 40 °C). The obtained results were lower than the specific migration limits set by EU Regulation no. 10/2011 (Annex II). Both carcinogenic and non-carcinogenic risk assessments were carried out based on the specific migration data, estimating the exposure, average daily dose (ADD), hazard quotient (HQ), hazard index (HI), cancer risk (CR), and total cancer risk (TCR). The exposure values were found to be below the recommended tolerable daily intake (TDI) levels for each metal tested. Both HQ and HI values were under the limit value of 1. The average total cancer risk was 1.73 × 10−4, indicating that approximately 1.73 consumers out of 10,000 may develop a type of cancer due to chronic exposure to the tested metals. These results highlight the importance of continuous monitoring of chemical migrants from food contact materials.

1. Introduction

Food production and consumption have increased in recent years due to accelerated urbanization and globalization, leading to the expansion of sectors related to food production, such as the packaging industry. This industry generates about 2% to the gross national product in developed countries, and about 50% of the total production of packaging is dedicated to the food industry [1].

Packaging plays a vital role in the food industry, contributing to the production, processing, transport, and storage of food and beverages. Food packaging also supports the global food system and increases convenience for consumers [2].

Additionally, food packaging offers physical protection, barrier protection, and improved food preservation, which extends the shelf life of products [3] and provides useful information to consumers about the ingredients, storage conditions, and environmental performances of the products [1].

Among food packages, plastic materials, especially polypropylene (PP), polystyrene (PS), polyethylene terephthalate (PET), and polyethylene (PE), are commonly used in the food industry. These materials can pose a risk for food safety due to the migration of harmful substances from the packaging into the contained food product [4].

These chemical compounds, known as food contact chemicals (FCCs), can migrate from food contact materials into food products. This migration process is influenced by factors such as temperature, storage time, chemistry of the packaging material and food product, thickness of the contact layer, and package size (smaller packages having proportionally greater migration due to increased surface-to-volume ratio) [5]. Bisphenols, phthalates and their alternatives, metals, and volatile organic compounds have been frequently detected food contact materials (FCMs) [6].

Trace and toxic metal contamination of food packaging materials is a significant concern, because these contaminants can be released into food products during storage. Metals are often added as chemical additives such as light stabilizers, flame retardants [7], antioxidants, plasticizers, UV and thermal stabilizers, pigments, lubricants, and fillers [8], to improve the properties of plastic materials. Since these additives are not chemically bound to the polymer matrix, they can migrate from the plastic material under the action of different physical–chemical factors related to either the packaging material or the food product [7].

The majority of FCCs that migrate in contact with food possess toxic properties, which can lead to different effects depending on the dose, timing of exposure, mode of action, and other factors. Many of these chemical contaminants have either not been subjected to hazard testing or have only limited toxicity data available [5]. For example, trace and toxic metals can reach into the body through consumption of food contaminated with migrated heavy metals. These contaminants can accumulate in the body and affect biological functions, leading to various diseases even at low concentrations. Among their non-carcinogenic and carcinogenic effects are intestinal disorders, tremors, diarrhea, hemoglobinuria, stomatitis, convulsions, depression, poor fetal development, various types of cancer [8], as well as brain and kidney damage, cirrhosis liver, neurological dysfunction, osteoporosis, immunotoxicity, and dermatitis [9]. The health risks associated with the materials and chemicals used in food packaging must be carefully assessed and monitored periodically. To prevent potential migration of carcinogenic compounds in food, such FCCs should be reduced [10]. In addition, reliable analytical control methods are needed to detect and quantify these chemical migrants [3].

For this reason, this study aimed to examine the migration of 12 toxic metals (Ba, Co, Cu, Zn, Mn, Ni, Li, Fe, Pb, Cd, Cr, and Sb), from 30 samples of plastic films and bags available on the Romanian market, using the ICP-MS technique. The migration tests were conducted under worst-case conditions, specifically 10 days at 40 °C (OM2 conditions). Based on the migration levels detected, the non-carcinogenic and carcinogenic risks of the tested elements were assessed using parameters such as exposure dose, average daily dose, hazard quotient, hazard index, cancer risk, and total cancer risk. Finally, the exposure doses were compared to the tolerable doses for the tested elements.

2. Materials and Methods

2.1. Sample Collection

For this study, 30 plastic film and bag samples intended for use in the food industry were selected, including 18 PP samples, 4 PE samples, 1 PVC sample, and 7 samples of plastic composite materials. All samples were purchased from various Romanian food packaging producers. A summary of the tested samples is presented in Table 1.

Table 1.

Presentation of tested samples and testing methods.

2.2. Migration Experiments

The migration experiments were designed to accurately reflect the real use of the tested food packaging. The aim was to evaluate the migration of chemicals from the packaging under difficult conditions. As many of the materials are designed for long-term contact, Overall Migration 2 (OM2) conditions, specifically 10 days at 40 °C, have been used. These conditions are recommended for long-term storage at room temperature or below [11]. The samples were prepared according to SR EN 1186-3:2002 [12] for total immersion and SR EN 1186-7:2002 [13] for the pouch filling method. To simulate the migration of toxic metals, food simulant B (3% acetic acid) was used, because food contact materials containing acid-soluble components should be tested with 3% acetic acid as a worst-case scenario [14].

In the total immersion method, which is considered more drastic than other global migration test methods (such as the bag and stuffing), both the surface of the package in contact with the food product and the outer layer are in contact with the food simulant. Thus, the total exposed surface is 2 dm2, although only 1 dm2 (the area in direct contact with the food product) is taken into account for the final result. The ratio between the surface of the tested package and the volume of the food simulant is 1:1. For the bag method, the total exposed surface area is also 2 dm2 per 100 mL of food simulant, with a 2:1 ratio between the tested packaging and the volume of food simulant. In this case, only the inner surface of the tested material is considered [15]. All the experiments were conducted in triplicate.

2.3. Equipment

A NexION 300 Q inductively coupled plasma mass spectrometer (ICP-MS) (Perkin Elmer, Waltham, MA, USA) provided with nickel cone, a cross-flow nebulizer, and a standard ICP quartz torch was used for quantitative analysis of toxic metals in 3% acetic acid. Samples and standards were introduced via a peristaltic pump. Prior to analysis, the equipment was optimized using a NexION setup solution containing 1 µg/L of Be, Ce, Fe, In, Li, Mg, Pb, and U in 1% HNO3 [4]. All elements were measured in standard mode using argon as carrier gas. The operating conditions of the ICP-MS are detailed in Table 2.

Table 2.

Instrument operating conditions for metals analysis by ICP-MS.

2.4. Instrumental Analysis

The method used in this study is validated for all metals analyzed. Calibration curves were obtained with five concentration points: 10 µg/L, 20 µg/L, 30 µg/L, 40 µg/L, and 50 µg/L, obtained from a multi-element standard solution 6 for ICP-MS (Sigma Aldrich, St. Louis, MO, USA) with a concentration of 100 mg/L for each element. Analytical performance, including repeatability, intermediate precision, and recovery, is detailed in Table 3. As can be seen, the calibration curves demonstrated good linearity, with correlation coefficients (r) exceeding 0.993 for the analyzed elements. Limits of detection (LOD) calculated based on three times the standard deviation from 10 consecutive blank measurements met the performance criteria imposed by the laboratory. The high recovery rates confirm the accuracy of the method and the absence of interferences.

Table 3.

Analytical parameters of the method.

2.5. Exposure and Human Health Risk Assessment

A human health risk assessment involves estimating the likelihood of adverse health effects in people exposed to different chemical contaminants [16]. These risks are usually classified as carcinogenic or non-carcinogenic. Carcinogenic risks assess the likelihood of developing cancer following long-term exposure to a single pollutant or a combination of pollutants, while non-carcinogenic risks focus on exposure-related effects, including genetic and teratogenic outcomes [17].

2.5.1. Exposure Assessment

The assessment of exposure to heavy metals from the tested food packaging was calculated using the model proposed by Makkaew et al. (2022) [16] and Pocas and Hogg (2007) [18], employing Equation (1).

where migration is the quantity of chemical migrants detected in the food product or food simulant.

In Europe, the default worst-case assumption is that an adult consumes 1 kg of food per day, packed in a 1 dm3 container with an area of 6 dm2. This forms the basis for the standard food contact rate of 6 dm2 per person per day [19].

The estimated exposure values obtained with Equation (1) were used to calculate the average daily dose (ADD) of each metal, using Equation (2) [16,18]. The assessment of ADD was performed for an adult consumer of 40 years and with a body weight of 70 kg.

where ADD is average daily dose (mg/kg bw/day), EF is exposure frequency (days/year), ED is exposure duration (years), and BW is body weight (kg).

2.5.2. Non-Carcinogenic Analysis

Risk assessment is usually expressed as a hazard quotient (HQ), which compares the estimated intake of a contaminant by a consumer with an acceptable daily intake [16]. It is calculated by dividing the average daily dose (ADD) of released toxic metals by the corresponding reference threshold, such as reference dose (RfD) or tolerable daily intake (TDI) (Equation (3)). The HQ helps assess potential risks to human health. According to the U.S. EPA, if the HQ value is higher than or equal to 1, there may be potential health risks from chemicals and elements in food packaging. If the HQ value is less than 1, there is no apparent risk to human health [20].

where ADD is average daily dose (mg/kg bw/day), TDI is tolerable daily intake of each element (mg/kg bw/day), and RfD is the reference dose of each element (mg/kg bw/day) [16]. The values of reference dose and tolerable daily intake are presented in Table 4.

Based on the individual HQ values, the hazard index (HI) was estimated to assess the cumulative risk of exposure to all heavy metals analyzed in this study. This parameter was estimated using Equation (4).

An HI value below 1 suggests no significant non-carcinogenic health risks. However, HI values higher than or equal to 1 indicate a potential non-carcinogenic risk for consumers’ health [21].

Table 4.

Reference dose (RfD), tolerable daily intake (TDI), and cancer slope factor (CSF) values of tested metals.

Table 4.

Reference dose (RfD), tolerable daily intake (TDI), and cancer slope factor (CSF) values of tested metals.

| Element | TDI (mg/kg bw/day) | RfD Ingestion (mg/kg bw/day) | CSF Ingestion (mg/kg bw/day) |

|---|---|---|---|

| Ba | 2.0 × 10−1 a | - | - |

| Co | 1.40 × 10−3 b | - | 2.7 × 101 h |

| Cu | 7.0 × 10−2 c | - | - |

| Zn | - | 3.0 × 10−1 d,e | - |

| Mn | - | 4.60 × 10−2 e | - |

| Ni | 1.30 × 10−2 f | - | 90 × 10−1 h |

| Li | 2.0 × 10−2 g | - | - |

| Fe | 7.0 × 10−1 g | - | - |

| Pb | - | 3.50 × 10−3 d,e | 8.50 × 10−3 h,i,j |

| Cd | - | 1.0 × 10−3 d,e,g | 1.5 × 100 h |

| Cr | - | 3.0 × 10−3 d,e | 4.2 × 10−1 h |

| Sb | 4.0 × 10−4 g | - | - |

a—SCHER 2012 [22]; b—AFSSA 2010 [23]; c—EFSA 2023 [24]; d—Wang et al., 2019 [25]; e—Oyebamiji et al., 2023 [26]; f—EFSA 2020 [27]; g—EPA 2007 [28]; h—OEHHA, 2020 [29]; i—Onuoha et al., 2015 [30]; j—Miletic et al., 2023 [31].

2.5.3. Carcinogenic Analysis

Carcinogenic analysis refers to the probability of developing a type of cancer following exposure to a given dose of the contaminant. This analysis can be evaluated using cancer risk (CR) and total cancer risk (TCR) parameters. Cancer risk associated with oral ingestion can be estimated using Equation (5) [32].

where ADD is average daily dose (mg/kg bw/day) and CSF is cancer slope factor (mg/kg bw/day). The values of cancer slope factor are presented in Table 4. This carcinogenic analysis was focused on Pb, Cd, Cr, and Ni, because these metals are recognized as carcinogenic elements. According to the IARC classification, Pb is categorized into three carcinogenicity groups, such as group 2A for inorganic compounds of Pb, group 2B for metallic lead, and group 3 for organic compounds of Pb. CrVI is classified in group 1, while CrIII is included in group 3. The metallic and compounds of Cd, as well as metallic and compounds of Ni, are categorized in group 1. The metallic Co and water-insoluble compounds of Co are included in group 2B. Group 1 is assigned to compounds that are carcinogenic to humans, group 2A to compounds that are probably carcinogenic to humans, group 2B to compounds that are possibly carcinogenic to humans, and group 3 to those not classifiable as to human carcinogens [33].

Based on the obtained values, cancer risk can be classified as follows: high risk (CR > 1.0 × 10−3), moderate risk (CR ≥ 1.0 × 10−4 and <1.0 × 10−3), low risk (CR ≥ 1.0 × 10−6 and <1.0 × 10−4), and very low risk (CR < 1.0 × 10−6) [34].

Using the individual values of cancer risk of the tested carcinogenic elements, the total cancer risk parameter can be evaluated to determine the cumulative risk of exposure to carcinogenic heavy metals. This can be calculated using Equation (6) [35]. This parameter can be classified, based on obtained values, into three risk groups, including tolerable risk (TCR < 1.0 × 10−6), acceptable-range risk (TCR < 1.0 × 10−6 and >1.0 × 10−4), and harmful risk (TCR > 1.0 × 10−4) [35].

3. Results

3.1. Heavy Metals Migration

In accordance with Regulation EC no. 1935/2004 (Regulation 1935) [36], materials and articles must be obtained in accordance with good manufacturing practices [37] to ensure that, under normal or foreseeable conditions of use, packaging materials do not release their constituents into food in quantities that could: (a) present a risk to human health, (b) cause an unacceptable change in the composition of the food, or (c) lead to a decrease in its organoleptic properties [36].

The regulations on good manufacturing practices should be applicable to all groups of materials and articles intended to come into contact with foodstuffs, listed in Annex I of Regulation 1935 [36]. In addition, good manufacturing practice must apply to those materials already in contact with food and intended for that purpose as well as those that can reasonably be expected to come into contact with food or transfer their constituents to food in normal or foreseeable conditions of use [37].

For plastic materials, EU Regulation no. 10/2011 (Regulation 10) [11] establishes quality standards for packaging materials in contact with food and emphasizes that these materials must not present a risk to human health [8]. According to this regulation, plastic materials and articles will not transfer their constituents to food in quantities that exceed the overall migration limit (OML) and specific migration limits (SML) established by Regulation 10 [11]. Overall migration represents all the compounds that can migrate from a packaging material into a food product or food simulant, having an overall migration limit of 10 mg/dm2 or 60 mg/kg. Specific migration is the maximum allowable amount of a given substance released from a material or article into food or food simulants. In Regulation 10 [11] are presented the SMLs of various non-intentionally and intentionally added substances (NIAS) from plastic materials. The SMLs of all investigated trace and toxic metals from this study are presented in Table 5.

Table 5.

Trace and heavy metals migration from plastic FCMs (µg/kg).

As can be seen, the measured concentrations of tested elements in the food simulant are significantly lower than the specific migration limits set by Regulation 10 [11] and subsequent changes and presented in Table 5. All tested plastic films released relatively low concentrations of heavy metals, with a maximum concentration of 4.38 mg/kg in the case of Fe, indicating minimal contamination of food products packaged in these materials during real use conditions. The results of heavy metal migration from all tested samples are presented in Table S1.

Specifically, Fe, Zn, Ba, Mn, and Cu were the metals most concentrated in the food simulants released from the tested samples. These results are consistent with the findings of Zeng et al. (2023) [38], who identified Zn, Ba, V, Mn, Cr, Be, Ni, Co, and Sb as the most concentrated metals in food simulants used to evaluate metal migration from disposable paper or plastic containers. In contrast, our study did not detect Pb, Cd, or Cr in any of the food simulants.

The highest migration of Fe was observed in sample 21, while Zn reached the maximum concentration in sample 15, Ba in sample 11, Mn in sample 29, and Cu in sample 30. These concentrations were measured for packages obtained from different raw materials, specifically Fe and Zn in PE materials, Ba and Cu in PP materials, and Zn and Mn in composite materials, which demonstrated that the raw material does not influence the migration of heavy metals. Li et al. (2019) [39] also demonstrated that the amounts of heavy metals released from plastics varied between different packaging materials. Their study revealed that Zn, Fe, and Al were the predominant elements migrated from PE, while Al, Zn, and Cu migrated the most from PS and PP materials. They also reported that migration of Pb, Cd, and Cr was not detected in any plastic.

Excepting Li, Pb, Cd, and Cr, the detection frequency of each metal exceeds 60%, indicating their presence in the tested films. The highest detection frequency was obtained for Zn, followed by Cu, Ba, Ni, and Fe. In contrast, Pb, Cd, and Cr had the lowest detection frequency, as they were not detected in any sample. Additionally, the detection frequency of metals such as Pb, Sb, Cd, Co, Mn, Sn, and As tested by [40] Han et al. (2022) exceeds 80%, suggesting that these metals were widely present in plastic take-out food containers.

A possible explanation for the presence of these metals is that Fe and Mn may be obtained from manganese iron trioxide (CAS 12062-81-6) used as an additive. Co and Fe are also components of the cobalt iron chromite black spinel additive (CAS 68186-97-0) [41]. Zn is incorporated as zinc borate in plastics, an inorganic, non-reactive compound used at concentrations between 0.7% and 3% (w/w) as a flame retardant. In addition, zinc sulfide and zinc oxide are used as inorganic pigments at concentrations between 0.01% and 10%, while zinc oxide is also used as a filler at levels up to 50%. Iron is included as iron oxide (an inorganic pigment) at concentrations of 0.01% to 10%. Barium is used as a thermal stabilizer at levels between 0.5% and 3% or as filler (barium sulfate) up to 50% (w/w) [42]. In addition, copper ions (Cu2+) show considerable mobility in aqueous solutions, indicating their ability to easily detach from plastics and dissolve in food or liquids with which they come into contact. Consequently, the probability of Cu migration from plastics is higher than that of other base materials [43].

Previous literature studies also confirmed that the migration rate of toxic and heavy metals from different materials can vary, suggesting that their release from food contact materials also depends on many other factors [40]. Table 6 presents the migration values of various metals from different plastic materials into various food simulants. The tested samples were subjected to different testing conditions according to their real use.

Table 6.

Literature study of heavy metals migration from plastic food contact articles (FCAs) by ICP-MS.

The concentrations of Ba from our study (<0.03–19.90 µg/kg) were lower than those reported by Li et al. (2019) [39] (7.14 to 22.90 µg/kg). All values presented in Table 6 are below the imposed limit of 1000 µg/kg [11].

For Co release, the lowest concentration was reported by Li et al. (2019) [39], for PP containers and PE films (<0.006 µg/kg). The highest concentration was found by Ghuniem (2024) [9] (<20 µg/kg). In our study, the highest release was recorded for PE films, ranging from <0.02 to 0.49 µg/kg. All results presented in Table 6 were below the imposed limit of 50 µg/kg [11].

Concerning Cu, Ghuniem (2024) [9] obtained higher migration rates (<400 to 510 µg/kg) compared with the other studies. Lee et al. (2022) [44] recorded the lowest concentrations across all tested materials, ranging from 0.021 to 0.195 µg/kg. All the reported values are below the imposed limit of 5000 µg/kg [11]. In our study, the Cu varied between <0.04 and 31.90 µg/kg, which is comparable to the findings of Li et al. (2019) [39]. We observed increased migration rates for PP films and composite materials, whereas Li et al. (2019) [39] reported a higher migration rate in PS containers.

In terms of Zn migration, all the results shown in Table 5 are below the imposed limit of 5000 µg/kg [11]. The highest concentrations were reported by Ghuniem (2024) [9] (<400 to 4650 µg/kg). Li et al. (2019) [39] reported the highest migration value for PE film, whereas in our study the highest migration rate was obtained from composite materials.

Ghuniem (2024) [9] also obtained the highest migration levels for Mn (<20 to 460 µg/kg), while Lee et al. (2022) [44] found the lowest concentration in PVC samples (0.02 µg/kg), but also found low values for PP, PS, and PVC (0.06 to 0.22 µg/kg). In our study, the Mn levels in the food simulant were notably higher than those presented in Table 6, with concentrations ranging from <0.18 to 0.637 µg/kg. All the reported concentrations were below the imposed limit of 600 µg/kg [11].

The highest concentrations of Ni in food simulant (<210–570 µg/kg), obtained by Ghuniem (2024) [9], exceed the imposed limit of 20 µg/kg [11]. The lowest concentrations were recorded by Lee et al. (2022) [44] (0.01–0.04 µg/kg). In our study, the highest Ni concentrations were found in PP packages, whereas Li et al. (2019) [39] observed the highest value in PS packages.

Regarding Li, the concentrations obtained in our study (<0.06–0.72 µg/kg) are comparable to those reported by Li et al. (2019) [39] (<0.64). All of these values are well below the SML of 600 µg/kg, set by Regulation 10 [11].

Ghuniem (2024) [9] reported the highest concentration of migrated Fe (<800–6630 µg/kg). In our study, its lowest migration rate was observed for PP packaging. All Fe migration values presented in Table 6 are below the imposed limit of 48,000 µg/kg [11].

As can be seen from Table 6, the highest concentration of Pb was reported by Ghuniem (2024) [9], the obtained values (<20–570 µg/kg) exceeding the limit set by Regulation 10 [11]. In contrast, Cho et al. (2022) [45] found very low concentrations, particularly in PET samples, ranging from <0.011 to 0.18 µg/kg.

Concerning the migration of Cd, Cho et al. (2022) [45] reported the lowest concentration in the food simulant for PET packages, measuring < 0.007 µg/kg. Similarly, very low concentrations were observed for other materials, such as PS, PP, and PVC, ranging from <0.007 to 0.05 µg/kg.

For Cr migration, highest concentrations were obtained by Ghuniem (2024) [9] (<20 to 200 µg/kg). According to Regulation 10 [11], this element must be undetectable in food simulants. In our study, we found reduced levels of Cr (<1.0 µg/kg). Reduced concentrations were also obtained by Lee et al. (2022) [44] (0.06–0.19 µg/kg) and by Li et al. (2019) [39] in PP containers (0.15 µg/kg) and PE films (0.84 µg/kg).

Regarding Sb, Lee et al. (2022) [44] reported very low concentrations in PE samples (0.01 µg/kg). Ghuniem (2024) [9] found the highest levels of migration, ranging from <20 to 120 µg/kg, which are higher than the maximum imposed limit of 40 µg/kg [11]. In our study, the highest concentrations were observed in the multilayer composite materials, ranging from <0.03 to 1.50 µg/kg. The results of our research were consistent with those obtained by Lee et al. (2022) [44], which ranged from 0.01 to 2.35 µg/kg.

Concerning Al migration, the highest concentrations were reported by Ghuniem (2024) [9] (<800–9630 µg/kg), exceeding the EU regulatory limit of 1000 µg/kg set by Regulation 10 [11] and its amendments. Low migration rates were reported by Li et al. (2019) [39] (49.30–135 µg/kg), the highest concentration being obtained for PE film.

As can be seen, excepting Pb, Ni, Cr, and Sb, which were detected by Ghuniem (2024) [9] in concentrations higher than the specific migration limits, all the other metals were detected in food simulants at concentrations below the imposed limits. The variations in metal release can be attributed to several factors, including the type of packaging material (impermeable, permeable, or porous), the physicochemical properties of the migrating substance, the type of food (high-fat foods tend to show higher migration levels) or food simulant, duration of contact (longer contact times increase migration), storage temperature (higher temperatures accelerate migration), pH levels (strongly acidic foods increase migration), and the packaging-to-food ratio (smaller packaging has a larger surface-to-volume ratio) [2,8,10,16,46]. Differences in manufacturing technology and pretreatment methods used in different studies also contribute to the variability in metal release [38].

3.2. Health Risk Analysis

Exposure to heavy metals through contaminated food is a common pathway that can lead to various diseases in humans if it exceeds recommended limits. It was found that all the tested samples release heavy metals in 3% acetic acid, in relatively low concentrations, indicating a potential chemical contamination of packaged foods with these metals [8].

3.2.1. Exposure Dose Assessment

The exposure assessment results from our study for 40-year-old adults presented in Table S2 indicate that the average estimated exposure values are below the tolerable daily intake (TDI) limits established by the U.S. EPA and EFSA. These limits include 3.5 × 10−2 mg/kg bw/day for Ba, 4.0 × 10−2 mg/kg bw/day for Cu, 3.0 × 10−1 mg/kg bw/day for Zn, 1.4 × 10−1 mg/kg bw/day for Mn, 2.0 × 10−2 mg/kg bw/day for Ni, 2.0 × 10−2 mg/kg bw/day for Li, 7.0 × 10−1 mg/kg bw/day for Fe, 1.0 × 10−3 mg/kg bw/day for Cd, 4.0 × 10−4 mg/kg bw/day for Sb [28], 3.50 × 10−3 mg/kg bw/day for Pb [47], 3.0 × 10−1 mg/kg bw/day for Cr [48], and 1.40 × 10−3 mg/kg bw/day for Co [23]. Thus, the assessment results indicate a low risk level.

The exposure dose results obtained in our study are higher than those reported by Han et al. (2024) [4] for Sb (1.70 × 10−7 mg/kg bw/day), Ni (1.0 × 10−6 mg/kg bw/day), and Co (1.0 × 10−6 mg/kg bw/day). However, daily dose values obtained by Han et al. (2024) [4] for Sb (9.76 × 10−4–1.15 × 10−3 mg/kg/day), Co (3.0 × 10−5–5.20 × 10−5 mg/kg/day), and Mn (4.12 × 10−3–1.75 × 10−3 mg/kg/day) are higher than those obtained in our study. The results of average daily dose for all tested samples are presented in Table S3.

To reduce exposure to trace and toxic metals, it is recommended that food be stored and consumed in glass containers recognized by the FDA as safe for food contact [49]. In addition, when consuming delivered packaged food, it is recommended to transfer the food to a container made of another material, rather than storing it in its packaging for a long period of time. This practice helps minimize exposure to metals and metalloids, as food ingredients can influence their dissolution and migration [4].

3.2.2. Non-Carcinogenic Risk Analysis

The assessment of non-carcinogenic risk was carried out by estimating the hazard quotient (HQ) and the hazard index (HI) for adults, using ingestion as the route of exposure.

The hazard quotient (HQ) is a risk index developed by the U.S. EPA to assess potential health risks from exposure to chemical contaminants. The use of HQ provides an in-depth understanding of the possible health effects of chemical exposure, helping to create effective risk management strategies [21]. HQ values for ingestion obtained in our study are presented in Table 7.

Table 7.

The obtained values of exposure, average daily dose (ADD), and hazard quotient (HQ) for tested elements.

HQ values for metals in adults were less than 1, decreasing in the following order: Sb > Ni > Fe > Zn > Cu > Mn > Co > Ba > Li > Pb > Cd. These findings indicate that chronic exposure to the tested metals may pose a non-negligible non-carcinogenic risk. Table S4 presents the HQ values for all tested samples and elements.

HI is an essential parameter to evaluate the overall health impact and safety of the tested samples [17]. The HI values obtained in our study ranged from 7.27 × 10−6 to 1.46 × 10−1 (Table S4). The cumulative hazard index of the 30 samples was found to be 6.82 to 137.552 times lower than the threshold value of 1, indicating that no adverse non-carcinogenic health effects are expected from exposure to the tested contaminants through food intake [21].

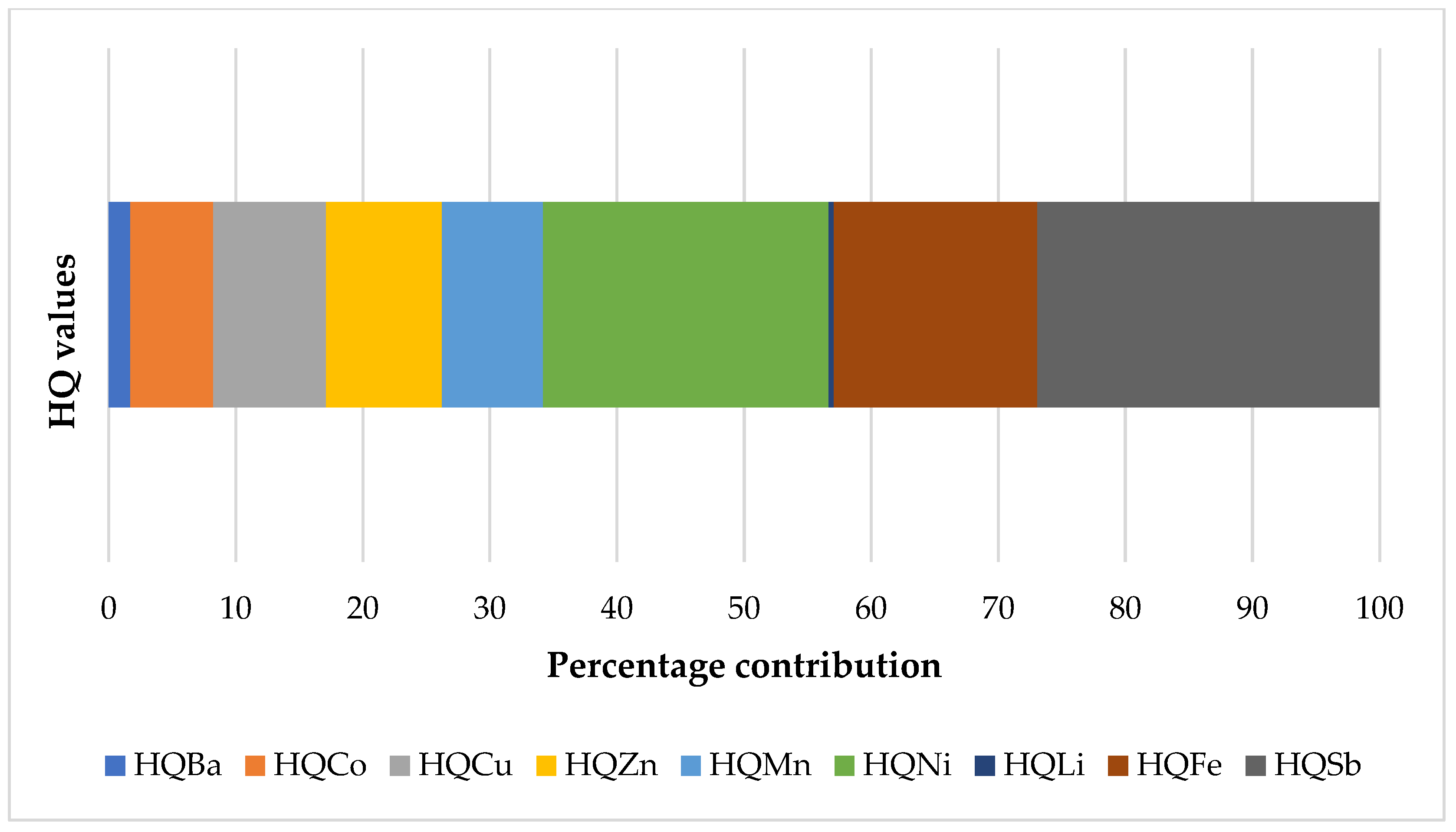

As shown in Figure 1, Sb had the highest contribution to the hazard index (26.92%), followed by Ni (22.48%), Fe (16%), Zn (9.11%), Cu (8.90%), Mn (7.96%), Co (6.51%), Ba (1.70%), and Li (0.41%). Since Pb, Cd, and Cr were not detected in the food simulants, these elements did not contribute to the hazard index value.

Figure 1.

The percentage contributions of hazard quotient of tested elements to the hazard index.

The results for average daily dose, hazard quotient, and hazard index indicate that the risk associated with the migration of toxic metals during long-term storage at 40 °C is low and negligible.

3.2.3. Carcinogenic Risk Analysis

Carcinogenic risks assess the likelihood of developing cancer due to prolonged exposure to a pollutant or a combination of contaminants [17]. Cancer risk (CR) and total cancer risk (TCR) of Pb, Cd, Cr, Ni, and Co were estimated based on the assumption that the detected levels would migrate into the packaged food products of the tested samples.

For Ni, the CR parameter ranged from 0 to 2.56 × 10−4, while for Co, from 0 to 3.83 × 10−4 (Table S5). Based on the average values, the cancer risk of the tested metals ranked in the following order: Ni > Co > Pb > Cd > Cr. None of the samples fell into the high-risk interval in the case of Ni, but 36.67% of samples were in the moderate-risk interval, 53.33% in the low-risk interval, and 10% in the very-low-risk interval. Similarly, for Co, none of the samples were in the high-risk interval, 30% were in the moderate-risk interval, 46.67% in the low-risk interval, and 23.33% in the very-low-risk interval. Since Pb, Cd, and Cr were not detected in any sample, their cancer risk was not assessed. Overall, Ni had more samples in the moderate- and low-risk categories compared to Co, while Co had a greater percentage of samples in the very-low-risk interval. This highlights that Ni poses a greater carcinogenic risk than Co after long-term exposure to the tested samples.

The CR oral values reported by Eid et al. (2024) [17] for adults ranged between 3.0 × 10−4 and 3.0 × 10−2 for Cd, 2.26 × 10−5 and 1.8 × 10−1 for Cr, and 3.16 × 10−5 and 3.0 × 10−2 for Pb. Their results fall in the high-risk, moderate-risk, and low-risk intervals, and are higher than the values obtained in our study.

Regarding the total cancer risk, which varied between 0 and 4.97 × 10−4 (Table S5), 10% of the tested samples fell within the tolerable range, 20% within the acceptable range, and 70% within the harmful range. The mean value of TCR was 1.73 × 10−4, which means that approximately 1.73 consumers out of 10,000 could potentially develop cancer as a result of chronic exposure to the tested metals. This indicates that the cancer risks associated with Ni and Co are not negligible for humans [38]. Han et al. (2022) [40] found that around 80.6% of total samples were within the acceptable risk level (1.0 × 10−6), while 1.44% of samples exceeded the harmful threshold of 1.0 × 10−4.

Based on the mean values, Co and Ni contributed 51.65% and 48.35%, respectively, to the total carcinogenic risk. Han et al. (2022) [40] showed that Co, Ni, Cd, and Pb contributed 44.5%, 45.0%, 9.7%, and 0.8%, respectively, of the total carcinogenic risks. The percentage contributions of Co and Ni in our study are similar to those reported by Han et al. (2022) [40].

Both the results obtained in our study and those in the literature highlight that prolonged exposure to increased levels of non-carcinogenic and carcinogenic metals from food packaging can lead to cumulative effects over time. However, it is important to mention that health risks related to trace and heavy metals exposure may differ depending on factors such as type and concentration of the pollutant, individual susceptibility, exposure duration (acute, intermediate, chronic), pathway of exposure (ingestion, inhalation, dermal contact), body weight, age group, sex, genetics, and dietary status [50]. Long-term exposure to heavy metals potentially leads to various types of cancer, as well as mental retardation, and diseases of the neurological, cardiovascular, kidney, and skeletal systems [51]. Thus, continuous monitoring and regular assessments of heavy metal levels both in the environment and in food products and food packaging are crucial for protecting the long-term health and well-being of the community [52].

4. Limitations and Recommendation

The novelty of this study lies in its being one of the first investigations into the health risks associated with heavy metal migration from food contact materials in Romania. It provides scientific evidence on potential hazards, particularly under long-term exposure. However, the study has limitations: (1) only four materials (PP, PE, PVC, and composites) were examined, and others like PS and PET should be included for a comprehensive risk assessment; (2) the sample size was limited; (3) only metals were considered, excluding other chemical contaminants (e.g., bisphenol A, phthalates); (4) additional toxic metals (As, Hg, Al) were not assessed; and (5) testing was conducted solely under long-term exposure, so further research is needed for different conditions (e.g., high temperatures, short contact times).

Although the release of heavy metals from plastics is generally low, caution is advised. Prolonged or repeated used of plastics, especially with hot food, can increase the risk of ingesting harmful heavy metals or other chemical migrants. Based on these findings, several recommendations are suggested: (1) Clear plastic containers are preferable as they tend to release fewer particles, organic compounds, and heavy metals. (2) Reducing meal time can minimize plastic particles ingestion [38]. Ideally, glass containers should replace plastic for hot foods and beverages [53]. Moreover, further scientific research and public education are necessary to provide solid evidence and raise awareness about potential health risks [38].

5. Conclusions

The results indicate that the release of the tested trace and heavy metals from plastic food packages after 10 days at 40 °C was below specific migration limits, resulting in no harmful metal levels in 3% acetic acid. Exposure values, based on migration results, were below tolerable daily levels recommended by the U.S. EPA and EFSA. Non-carcinogenic risk assessments showed that all hazard quotient and hazard index values were under the threshold limit of 1, with Sb contributing the most, followed by Ni, Fe, Zn, Cu, Mn, Co, Ba, and Li. Since Pb, Cd, and Cr were not detected, they did not contribute to the hazard index.

Ni had more samples in the moderate- and low-risk categories compared to Co, which had a higher percentage in the very-low-risk range. As a result, Ni presented a greater carcinogenic risk than Co after long-term exposure.

Regarding total cancer risk, 70% of tested samples fell within the harmful range. The mean value of TCR, 1.73 × 10−4, suggests that approximately 1.73 out of 10,000 consumers may develop cancer due to chronic exposure to the tested metals. This indicates that the cancer risks from Ni and Co are not negligible.

Although heavy metals release from plastics materials is low, prolonged exposure to increased levels of both non-carcinogenic and carcinogenic metals can result in cumulative effects. Thus, continuous monitoring and regular assessments of food packaging are essential to prevent chemical contamination and safeguard long-term community health.

Supplementary Materials

The following supporting information can be downloaded at: https://www.mdpi.com/article/10.3390/app142310985/s1, Table S1: Trace and heavy metals migration from plastic food contact materials (µg/kg) ± SD. Table S2: Exposure to trace and toxic metals migrating from plastic food contact materials (mg/kg bw/day). Table S3: Average daily dose (ADD) (mg/kg bw/day) of ingested migrated trace and heavy metals for a 70 kg adult and an average age of 40 years. Table S4: Hazard quotient (HQ) and hazard index (HI) values of ingested migrated trace and heavy metals for a 70 kg adult and an average age of 40 years. Table S5: Cancer risk (CR) and total cancer risk (TCR) values of ingested migrated trace and heavy metals for a 70 kg adult and an average age of 40 years.

Author Contributions

Conceptualization, E.L.U. and G.M.; methodology, E.L.U. and G.M.; validation, E.L.U. and G.M.; formal analysis, C.A.S. and A.L.M.; investigation, E.L.U., A.L.M. and C.A.S.; data curation, G.M.; writing—original draft preparation, E.L.U.; writing—review and editing, G.M.; visualization, G.M.; supervision, G.M.; project administration, G.M.; funding acquisition, G.M. All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported by three grants from the Ministry of Research, Innovation, and Digitization, CNCS/CCCDI—UEFISCDI [PN-IV-P8-8.1-PRE-HE-ORG-2023-0018, PN-IV-P8-8.1-PRE-HE-ORG-2023-0165, and PN-IV-P8-8.1-PRE-HE-ORG-2023-0168] within PNCDI IV.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The original contributions presented in the study are included in the article, further inquiries can be directed to the corresponding author.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Arfelli, F.; Roguszewska, M.; Torta, G.; Iurlo, M.; Cespi, D.; Ciacci, L.; Passarini, F. Environmental impacts of food packaging: Is it all a matter of raw materials? Sustain. Prod. Consum. 2024, 49, 318–328. [Google Scholar] [CrossRef]

- Geueke, B.; Hennig, K.; Boucher, J.M.; Muncke, J. Chemical Migration from Packaging into Foods and Beverages: A Framework to Evaluate Different Packaging Options. Food Packaging Forum. August 2022. Available online: https://foodpackagingforum.org/news/bio-suisse-integrates-chemical-migration-scoring (accessed on 28 August 2024).

- Onyeaka, H.; Ghosh, S.; Obileke, K.; Miri, T.; Odeyemi, O.A.; Nwaiwu, O.; Tamasiga, P. Preventing chemical contaminants in food: Challenges and prospects for safe and sustainable food production. Food Control 2024, 155, 110040. [Google Scholar] [CrossRef]

- Han, Y.; Ryu, K.; Song, N.; Seo, J.; Kang, I.; Chung, H.-J.; Park, R. Potential migration and health risks of heavy metals and metalloids in take-out food containers in South Korea. Int. J. Environ. Res. Public 2024, 21, 139. [Google Scholar] [CrossRef] [PubMed]

- Muncke, J.; Andersson, A.M.; Backhaus, T.; Boucher, J.M.; Almroth, B.C.; Castillo, A.C.; Chevrieri, J.; Demeeix, B.A.; Emmanuel, J.A.; Fini, J.B.; et al. Impacts of food contact chemicals on human health: A consensus statement. Environ. Health 2020, 19, 25. [Google Scholar] [CrossRef] [PubMed]

- Geueke, B.; Parkinson, L.V.; Groh, K.J.; Kassotis, C.D.; Maffini, M.V.; Martin, O.V.; Zimmermann, L.; Scheringer, M.; Muncke, J. Evidence for widespread human exposure to food contact chemicals. J. Expo. Sci. Environ. Epidemiol. 2024. [Google Scholar] [CrossRef] [PubMed]

- Nguyen, V.T.; Linh, T.T.T.; Vo, T.K.; Nguyen, Q.H.; Van, T.K. Analytical techniques for determination of heavy metal migration from different types of locally made plastic food packaging materials using ICP-MS. Food Sci. Nutr. 2023, 11, 4030–4037. [Google Scholar] [CrossRef]

- Eti, S.A.; Islam, M.S.; Shourove, J.H.; Saha, B.; Ray, S.K.; Sultana, S.; Shaikh, M.A.A.; Rahman, M.M. Assessment of heavy metals migrated from food contact plastic packaging: Bangladesh perspective. Heliyon 2023, 9, e19667. [Google Scholar] [CrossRef]

- Ghuniem, M.M. Determination of some element’s migrants in aqueous simulant from plastic food contact products by Inductively Coupled Plasma Mass Spectrometer. Food Anal. Methods 2024, 17, 1497–1510. [Google Scholar] [CrossRef]

- Alamri, M.S.; Qasem, A.A.A.; Mohamed, A.A.; Hussain, S.; Ibraheem, M.A.; Shamlan, G.; Algah, H.A.; Qasha, A.S. Food packaging’s materials: A food safety perspective. Saudi J. Biol. Sci. 2021, 28, 4490–4499. [Google Scholar] [CrossRef]

- Commission Regulation (EU). No 10/2011 of 14 January 2011 on Plastic Materials and Articles Intended to Come into Contact with Food. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/PDF/?uri=CELEX:02011R0010-20230831 (accessed on 18 August 2024).

- SR EN 1186-3:2002; Materials and Articles in Contact with Foodstuffs—Plastics—Part 3: Test Methods for Overall Migration into Aqueous Food Simulants by Total Immersion. Romanian Standardization Association (ASRO): Bucharest, Romania, 2002.

- SR EN 1186-7:2002; Materials and Articles in Contact with Foodstuffs—Plastics—Part 7: Test Methods for Overall Migration into Aqueous Food Simulants Using a Pouch. Romanian Standardization Association (ASRO): Bucharest, Romania, 2002.

- Nerin, C.; Bourdoux, S.; Faust, B.; Gude, T.; Lesueur, C.; Simat, T.; Stoermer, A.; Hoek, E.; Oldring, P. Guidance in selecting analytical techniques for identification and quantification of non-intentionally added substances (NIAS) in food contact materials (FCMS). Food Addit. Contam. Part A 2022, 39, 620–643. [Google Scholar] [CrossRef]

- SR EN 1186-1:2002; Materials and Articles in Contact with Foodstuffs—Plastics—Part 1: Guide to the Selection of Conditions and Test Methods for Overall Migration. Romanian Standardization Association (ASRO): Bucharest, Romania, 2002.

- Makkaew, P.; Chaloeijitkul, K.; Vattanasit, U. Health risk assessment of dietary exposure to phthalates from plastic-coated paper among university students. Food Sci. Technol. 2022, 42, e112521. [Google Scholar] [CrossRef]

- Eid, M.H.; Eissa, M.; Mohamed, E.A.; Ramadan, H.S.; Tamas, M.; Kovacs, A.; Szucs, P. New approach into human health risk assessment associated with heavy metals in surface water and groundwater using Monte Carlo Method. Sci. Rep. 2024, 14, 1008. [Google Scholar] [CrossRef] [PubMed]

- Pocas, M.F.; Hogg, T. Exposure assessment of chemicals from packaging materials in foods: A review. Trends Food Sci. Technol. 2007, 18, 219–230. [Google Scholar] [CrossRef]

- Plastics Europe. Risk Assessment of Non-Listed Substances (NLS) and Non-Intentionally Added Substance (NIAS) Under Article 19 of Commission Regulation EU No. 10/2011 of 14 January 2011 on Plastic Materials and Articles Intended to Come into Contact with Food. September 2014. Available online: https://plasticseurope.org/wp-content/uploads/2021/11/risk-assesment-of-non-listed-substances-and-non-assesed-substances.pdf (accessed on 10 August 2024).

- Yang, Q.H.; Lin, Q.B.; Hua, X.Y.; Liao, J.; Lu, S.Q.; Yan, L.Y.; Ma, H.S. Identification and health risk assessment of volatile and semi-volatile migrants along with chemical elements in food contact water-borne coating paper. Food Packag. Shelf Life 2024, 45, 101337. [Google Scholar] [CrossRef]

- Isci, G.; Dagdemir, E. Human health risk assessment of phthalate esters and antimony levels in beverages packaged in polyethylene terephthalate under different storage conditions. J. Food Compos. Anal. 2024, 126, 105922. [Google Scholar] [CrossRef]

- SCHER (Scientific Committee on Health and Environmental Risks). Assessment of the Tolerable Daily Intake of Barium. 22 March 2012. Available online: https://ec.europa.eu/health/scientific_committees/environmental_risks/docs/scher_o_161.pdf (accessed on 14 August 2024).

- AFSSA (Agence Francaise de Securite Sanitaire Des Aliments). OPINION of the French Food Safety Agency on a Request for Scientific and Technical Support Regarding the Migration of Cobalt from Porcelain Oven-Dishes Intended to Come in Contact with Food. 11 May 2010. Available online: https://www.anses.fr/en/system/files/MCDA2010sa0095EN.pdf (accessed on 15 August 2024).

- EFSA (European Food Safety Authority). Total Copper Intakes Below New Safe Level. 17 January 2023. Available online: https://www.efsa.europa.eu/en/news/total-copper-intakes-below-new-safe-level (accessed on 14 August 2024).

- Wang, N.; Han, J.; Wei, Y.; Li, G.; Sun, Y. Potential Ecological Risk and Health Risk Assessment of Heavy Metals and Metalloid in Soil around Xunyang Mining Areas. Sustainability 2019, 11, 4828. [Google Scholar] [CrossRef]

- Oyebamiji, O.O.; Olaniyan, S.; Idowu, P.O.; Ojo, O.; Oladepo, J. Assessment of some heavy metals in soil samples around identified metal workshops in Otun-Etiki, Nigeria. WES 2023, 4, 28–39. [Google Scholar]

- EFSA (European Food Safety Authority). Update of the Risk Assessment of Nickel in Food and Drinking Water. 5 November 2020. Available online: https://www.efsa.europa.eu/en/efsajournal/pub/6268 (accessed on 15 August 2024).

- EPA 2007 Non-Carcinogen Tolerable Daily Intake (TDI) Values from US EPA. US EPA Region III. Available online: http://www.popstoolkit.com/tools/HHRA/TDI_USEPA.aspx (accessed on 11 August 2024).

- OEHHA (California Office of Environmental Health Hazard Assessment). Technical Support Document for Cancer Potency Factors, 2009. Appendix A: A Lookup Table Containing Unit Risk and Cancer Potency Values, 16 October 2020 (Updated April 2023). 2009. Available online: https://oehha.ca.gov/media/downloads/crnr/appendixa.pdf (accessed on 1 October 2024).

- Onuoha, S.C.; Anelo, P.C.; Nkpaa, K.W. Human Health Risk Assessment of Heavy Metals in Snail (Archachatina marginata) from Four Contaminated Regions in Rivers State, Nigeria. Am. Chem. Sci. J. 2016, 11, 1–8. [Google Scholar] [CrossRef]

- Miletic, A.; Lucic, M.; Onjia, A. Exposure Factors in Health Risk Assessment of Heavy Metal(loid)s in Soil and Sediment. Metals 2023, 13, 1266. [Google Scholar] [CrossRef]

- Mohammadi, A.A.; Zarei, A.; Majidi, S.; Ghaderpoury, A.; Hashempour, Y.; Saghi, M.Y.; Hosseingholizadeh, N.; Ghaderpoori, M. Carcinogenic and non-carcinogenic health risk assessment of heavy metals in drinking water of Khorramabad, Iran. MethodsX 2019, 6, 1642–1651. [Google Scholar] [CrossRef]

- IARC (International Agency for Research and Cancer). IARC Monographs on the Identification of Carcinogenic Hazards to Humans—Agents Classified by the IARC Monographs, Volumes 1–136. 12 September 2024. Available online: https://monographs.iarc.who.int/list-of-classifications (accessed on 15 August 2024).

- Nag, R.; Cummins, E. Human health risk assessment of lead (Pb) through the environmental-food pathway. Sci. Total Environ. 2022, 810, 151168. [Google Scholar] [CrossRef] [PubMed]

- Romero-Estevez, D.; Yanez-Jacome, G.S.; Simbana-Farinango, K.; Navarrete, H. Distribution, Contents and Health Risk Assessment of Cadmium, Lead and Nickel in bananas produced in Ecuador. Foods 2019, 8, 330. [Google Scholar] [CrossRef] [PubMed]

- Regulation (EC) No 1935/2004 of the European Parliament and of the Council of 27 October 2004 on Materials and Articles Intended to Come into Contact with Food and Repealing Directives 80/590/EEC and 89/109/EEC. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/PDF/?uri=CELEX:02004R1935-20210327 (accessed on 12 August 2024).

- Commission Regulation (EC) No 2023/2006 of 22 December 2006 on Good Manufacturing Practice for Materials and Articles Intended to Come into Contact with Food. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/PDF/?uri=CELEX:02006R2023-20080417 (accessed on 12 August 2024).

- Zeng, X.; Liu, D.; Wu, Y.; Zhang, L.; Chen, R.; Li, R.; Gu, W.; Zhang, L.; Liu, C.; Sun, Q. Heavy metal risk of disposable food containers on human health. Ecotoxicol. Environ. Saf. 2023, 255, 114797. [Google Scholar] [CrossRef] [PubMed]

- Li, R.; Lee, X.; Zhan, Z. Application No. AD-0207. Elemental Analysis/ICPMS-2030—Evaluation of Heavy Metal Migration from Plastic Food Packaging Materials to Aqueous Simulants by ICP-MS. 2019. Available online: https://www.shimadzu.com/an/sites/shimadzu.com.an/files/pim/pim_document_file/applications/application_note/13674/apb420008.pdf (accessed on 3 August 2024).

- Han, Y.; Cheng, J.; An, D.; He, Y.; Tang, Z. Occurrence, potential release and health risks of heavy metals in popular take-out food containers from China. Environ. Res. 2022, 206, 112265. [Google Scholar] [CrossRef]

- Klockner, P.; Reemtsma, T.; Wagner, S. The diverse metal composition of plastic items and its implications. Sci. Total Environ. 2021, 764, 142870. [Google Scholar] [CrossRef]

- Hahladakis, J.N.; Velis, C.A.; Weber, R.; Iacovidou, E.; Purnell, P. An overview of chemical additives presents in plastics: Migration, release, fate and environmental impact during their use, disposal and recycling. J. Hazard. Mater. 2018, 344, 179–199. [Google Scholar] [CrossRef]

- Khaled, B.M.; Sina, A.A.; Rasa, M.S.; Alam, S.M.S.; Al Numan, A.; Shammi, M.T.; Parvin, F.; Naznin, T.; Hossain, M.M.; Annana, R.P. Study on the effect of different contact times on the migration of heavy metals into different foodstuffs served in plastic cups. Heliyon 2024, 10, e31627. [Google Scholar] [CrossRef]

- Lee, K.Y.; Kim, H.S.; Jang, D.Y.; Koo, Y.J.; Lee, S.H.; Yeo, H.B.; Yoon, J.S.; Lim, K.M.; Choi, J. Risk Assessment of Heavy Metals Migrated from Plastic Food Utensils, Containers, and Packaging Distributed in Korea. Korean J. Packag. Sci. Technol. 2022, 28, 175–182. [Google Scholar] [CrossRef]

- Cho, H.; Yun, H.C.; Lee, J.Y.; Kwon, H.J.; Jeong, E.J.; Kim, D.Y.; Lee, S.J.; Kang, J.M. Monitoring of heavy metals, bisphenol A and phenol migrated from food packages for delivery. Anal. Sci. Technol. 2022, 35, 15–23. [Google Scholar]

- Kato, L.S.; Conte-Junior, C.A. Safety of Plastic Food Packaging: The Challenges about Non-Intentionally Added Substances (NIAS) Discovery, Identification and Risk Assessment. Polymers 2021, 13, 2077. [Google Scholar] [CrossRef]

- EFSA (European Food Safety Authority). Scientific Opinion on Lead in Food. 22 March 2013. Available online: https://www.efsa.europa.eu/en/efsajournal/pub/1570 (accessed on 11 August 2024).

- EFSA (European Food Safety Authority). Scientific Opinion on the Risks to Public Health Related to the Presence of Chromium in Food and Drinking Water. 12 June 2014. Available online: https://www.efsa.europa.eu/en/efsajournal/pub/3595 (accessed on 10 August 2024).

- Claudio, L. Our Food: Packaging & Public Health. Environ. Health Perspect. 2012, 120, 232–237. [Google Scholar]

- Singh, A.; Kostova, I. Health effects of heavy metal contaminants Vis-à-Vis microbial response in their bioremediation. Inorganica Chim. Acta 2024, 568, 122068. [Google Scholar] [CrossRef]

- Bissang, B.T.; Aragon-Barroso, A.J.; Baba, G.; Gonzalez-Lopez, J.; Osorio, F. Integrated Assessment of Heavy Metal Pollution and Human Health Risks in Waters from a Former Iron Mining Site: A Case Study of the Canton of Bangeli, Togo. Water 2024, 16, 471. [Google Scholar] [CrossRef]

- Radfard, M.; Hashemi, H.; Baghapour, M.A.; Samaei, M.R.; Yunesian, M.; Soleimani, H.; Azhdarpoor, A. Prediction of human health risk and disability-adjusted life years induced by heavy metals exposure through drinking water in Fars Province, Iran. Sci. Rep. 2023, 13, 19080. [Google Scholar] [CrossRef]

- Liu, G.; Wang, J.; Wang, M.; Ying, R.; Li, X.; Hu, Z.; Zhang, Y. Disposable plastic materials release microplastics and harmful substances in hot water. Sci. Total Environ. 2022, 818, 151685. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).