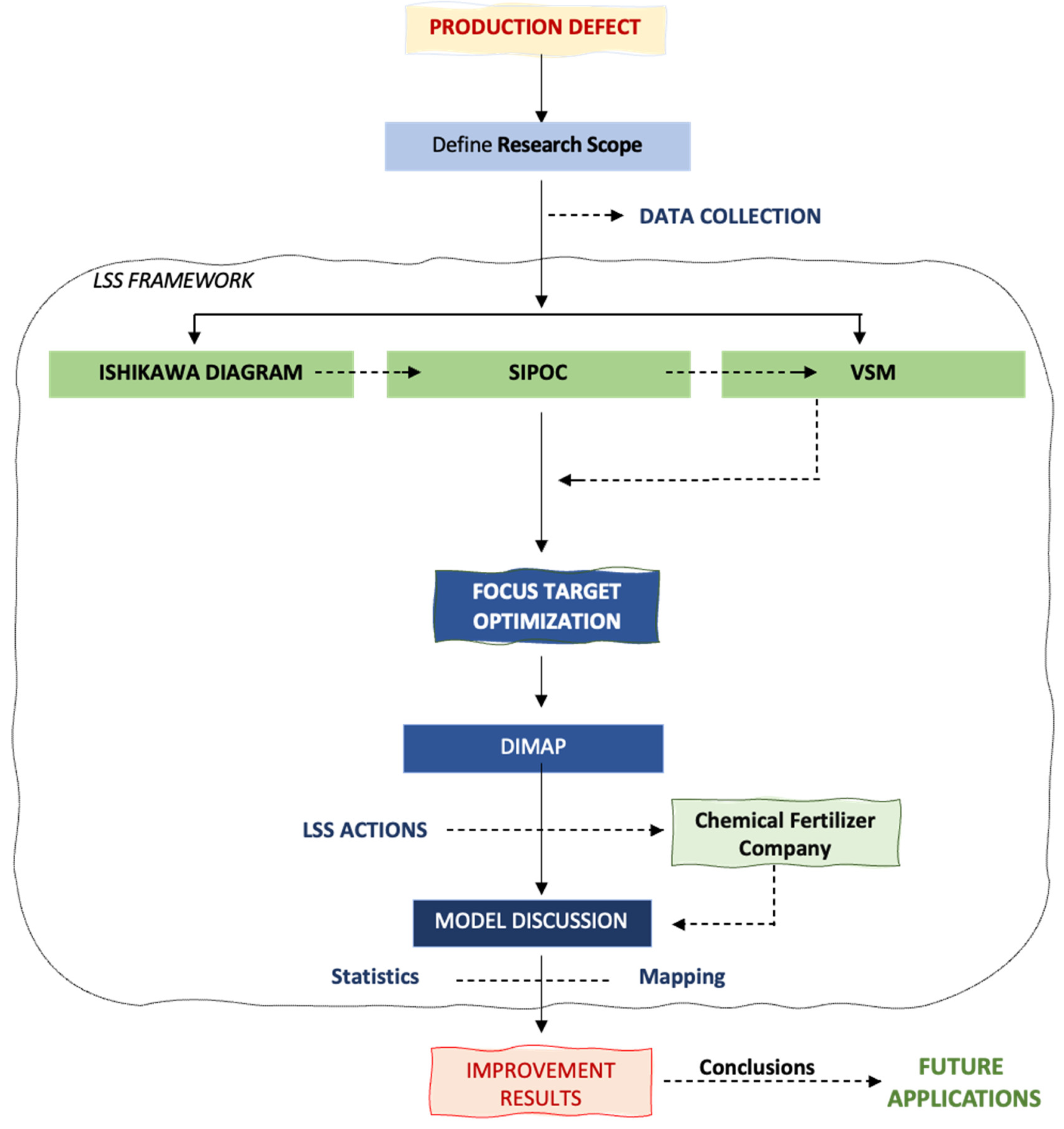

An Integrated Lean and Six Sigma Framework for Improving Productivity Performance: A Case Study in a Spanish Chemicals Manufacturer

Abstract

1. Introduction

Literature Review

2. Materials and Methods

2.1. Lean Tools Deployment

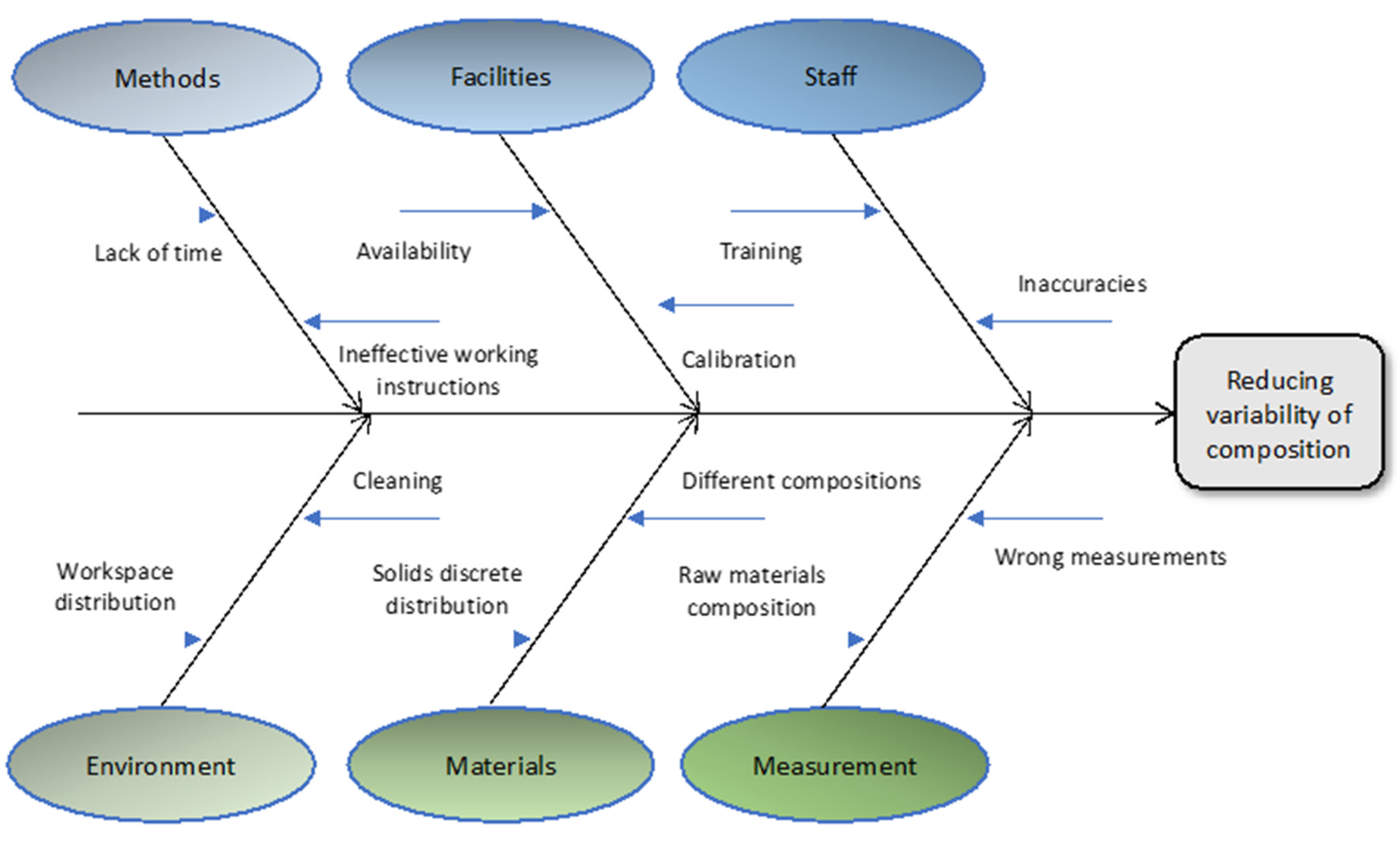

2.1.1. Ishikawa Diagram

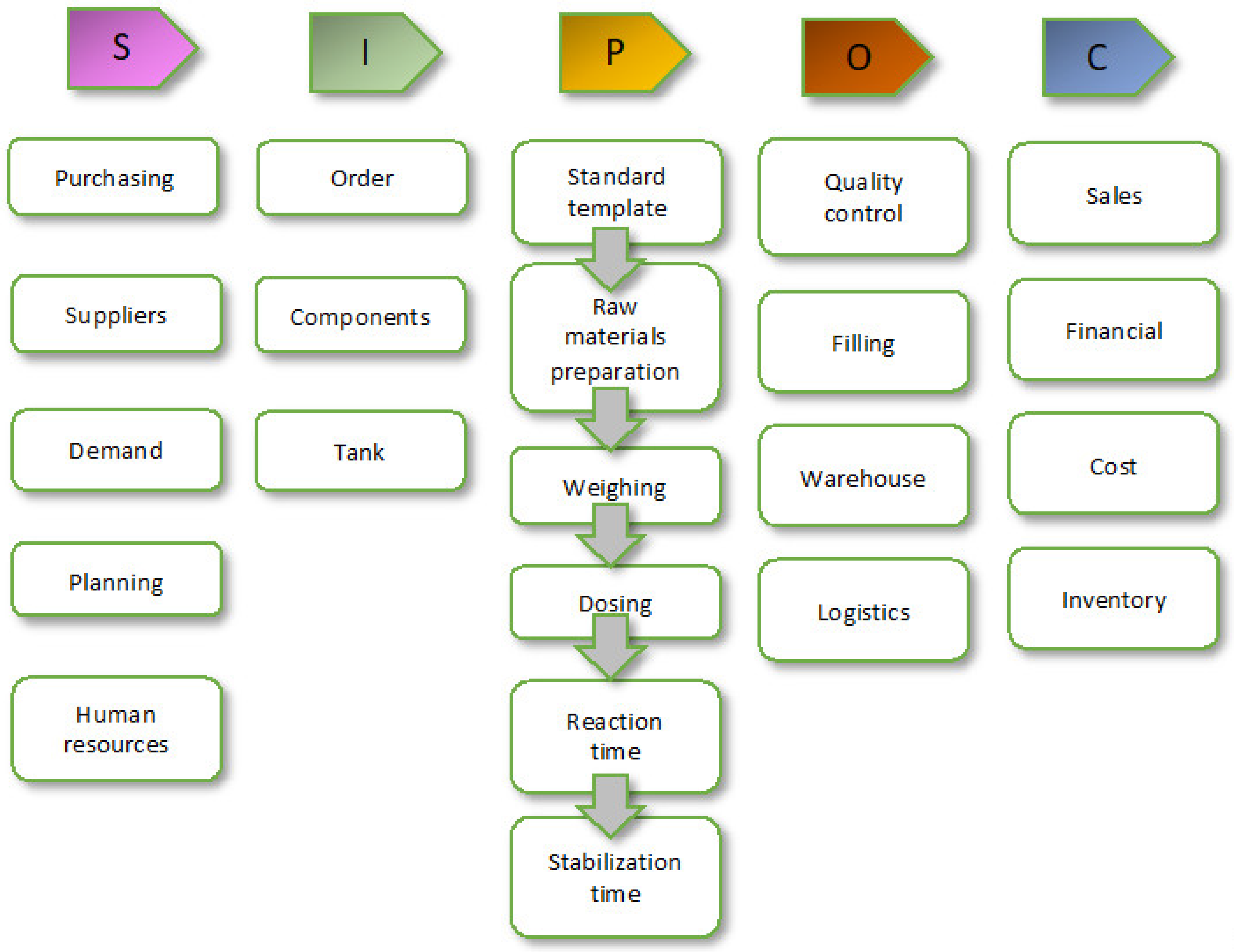

2.1.2. SIPOC Diagram

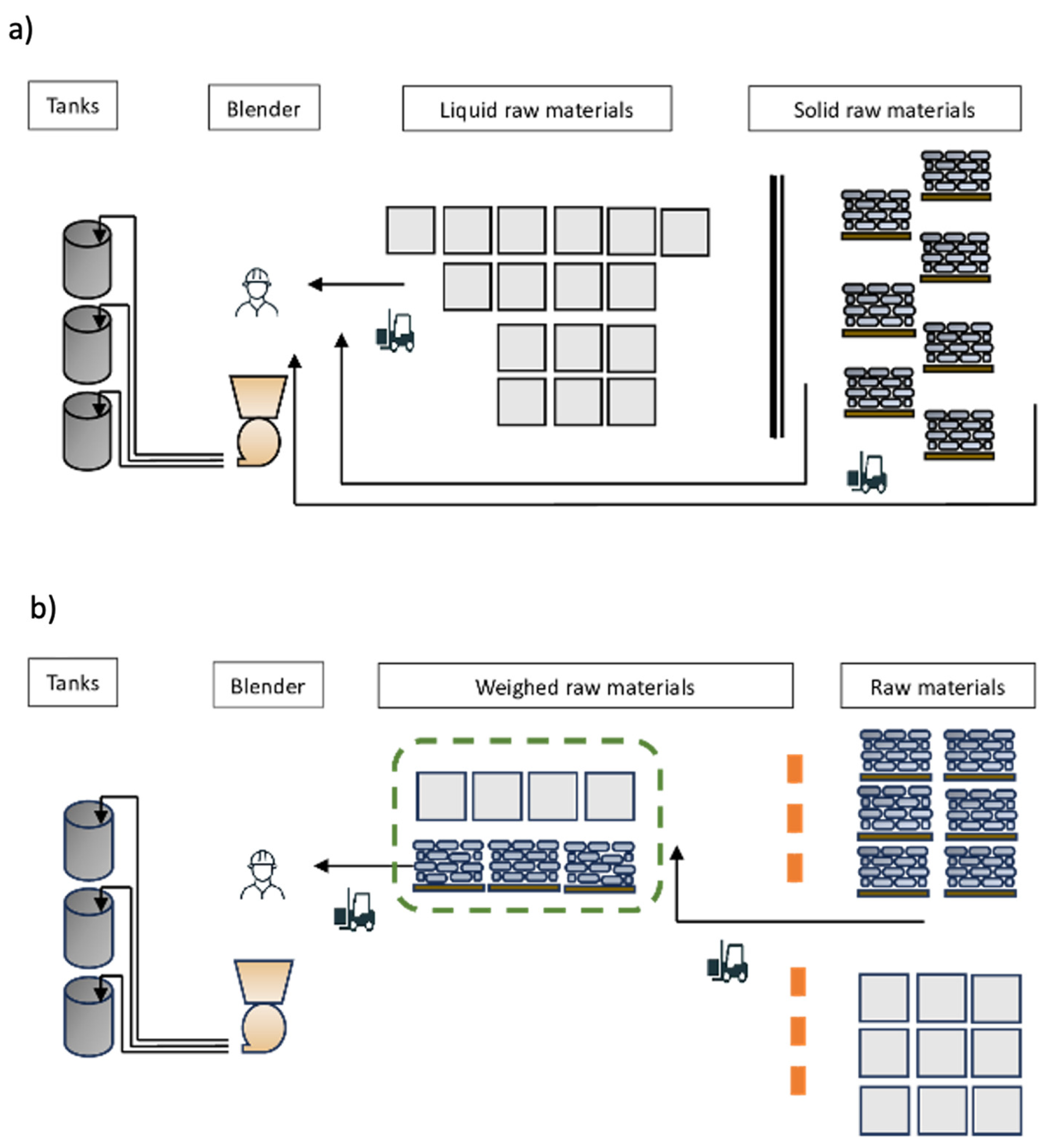

2.1.3. Value Stream Map

3. Results and Discussion

3.1. Define

3.2. Measure

| Test | D2R kg/L | Y21R kg C21R/kg T | Y22R kg C22R/kg T | Y21T − Y21R kg C21/kg T | Y22T − Y22R kg C22/kg T | D2T − D2R kg/L |

|---|---|---|---|---|---|---|

| 1 | 1.328 | 0.610 | 0.031 | −0.010 | −0.001 | 0.002 |

| 2 | 1.328 | 0.610 | 0.031 | −0.010 | −0.001 | 0.002 |

| 3 | 1.332 | 0.603 | 0.032 | −0.003 | −0.002 | −0.002 |

| 4 | 1.309 | 0.596 | 0.031 | 0.004 | −0.001 | 0.021 |

| 5 | 1.328 | 0.610 | 0.033 | −0.010 | −0.003 | 0.002 |

| 6 | 1.324 | 0.599 | 0.030 | 0.001 | 0.000 | 0.006 |

| 7 | 1.325 | 0.600 | 0.030 | 0.000 | 0.000 | 0.005 |

| 8 | 1.325 | 0.600 | 0.030 | 0.000 | 0.000 | 0.005 |

| 9 | 1.328 | 0.600 | 0.030 | 0.000 | 0.000 | 0.002 |

| 10 | 1.328 | 0.598 | 0.028 | 0.002 | 0.002 | 0.002 |

| 11 | 1.328 | 0.600 | 0.030 | 0.000 | 0.000 | 0.002 |

| 12 | 1.330 | 0.598 | 0.030 | 0.002 | 0.000 | 0.000 |

| 13 | 1.331 | 0.591 | 0.030 | 0.009 | 0.000 | −0.001 |

| 14 | 1.333 | 0.602 | 0.031 | −0.002 | −0.001 | −0.003 |

| 15 | 1.331 | 0.582 | 0.030 | 0.018 | 0.000 | −0.001 |

| 16 | 1.332 | 0.592 | 0.032 | 0.008 | −0.002 | −0.002 |

| 17 | 1.335 | 0.598 | 0.031 | 0.002 | −0.001 | −0.005 |

| 18 | 1.330 | 0.593 | 0.028 | 0.007 | 0.002 | 0.000 |

| 19 | 1.327 | 0.600 | 0.030 | 0.000 | 0.000 | 0.003 |

| 20 | 1.336 | 0.600 | 0.029 | 0.000 | 0.001 | −0.006 |

| 21 | 1.320 | 0.595 | 0.025 | 0.005 | 0.005 | 0.010 |

| 22 | 1.320 | 0.595 | 0.025 | 0.005 | 0.005 | 0.010 |

| 23 | 1.328 | 0.598 | 0.029 | 0.002 | 0.001 | 0.002 |

| 24 | 1.327 | 0.600 | 0.028 | 0.000 | 0.002 | 0.003 |

| 25 | 1.328 | 0.598 | 0.028 | 0.002 | 0.002 | 0.002 |

| 26 | 1.328 | 0.598 | 0.028 | 0.002 | 0.002 | 0.002 |

| 27 | 1.327 | 0.598 | 0.030 | 0.002 | 0.000 | 0.003 |

| 28 | 1.328 | 0.600 | 0.035 | 0.000 | −0.005 | 0.002 |

| 29 | 1.330 | 0.600 | 0.030 | 0.000 | 0.000 | 0.000 |

| 30 | 1.332 | 0.595 | 0.030 | 0.005 | 0.000 | −0.002 |

| 31 | 1.300 | 0.590 | 0.027 | 0.010 | 0.003 | 0.030 |

| 32 | 1.332 | 0.597 | 0.028 | 0.003 | 0.002 | −0.002 |

| 33 | 1.332 | 0.596 | 0.028 | 0.004 | 0.002 | −0.002 |

| 34 | 1.330 | 0.600 | 0.030 | 0.000 | 0.000 | 0.000 |

| 35 | 1.331 | 0.600 | 0.030 | 0.000 | 0.000 | −0.001 |

| Test | D3R kg/L | Y31R kg C31R/kg T | Y31T − Y31R kg C31/kg T | D3T − D3R kg/L |

|---|---|---|---|---|

| 1 | 1.162 | 0.052 | −0.011 | −0.012 |

| 2 | 1.162 | 0.052 | −0.011 | −0.012 |

| 3 | 1.163 | 0.051 | −0.010 | −0.013 |

| 4 | 1.163 | 0.047 | −0.006 | −0.013 |

| 5 | 1.145 | 0.047 | −0.006 | 0.005 |

| 6 | 1.145 | 0.045 | −0.004 | 0.005 |

| 7 | 1.159 | 0.047 | −0.006 | −0.009 |

| 8 | 1.160 | 0.045 | −0.004 | −0.010 |

| 9 | 1.160 | 0.047 | −0.006 | −0.010 |

| 10 | 1.160 | 0.042 | −0.001 | −0.010 |

| 11 | 1.160 | 0.042 | −0.001 | −0.010 |

| 12 | 1.145 | 0.039 | 0.002 | 0.005 |

| 13 | 1.145 | 0.038 | 0.003 | 0.005 |

| 14 | 1.162 | 0.041 | 0.000 | −0.012 |

| 15 | 1.142 | 0.044 | −0.003 | 0.008 |

| 16 | 1.142 | 0.044 | −0.003 | 0.008 |

| 17 | 1.144 | 0.045 | −0.004 | 0.006 |

| 18 | 1.144 | 0.045 | −0.004 | 0.006 |

| 19 | 1.149 | 0.047 | −0.006 | 0.001 |

| 20 | 1.163 | 0.041 | 0.000 | −0.013 |

| 21 | 1.161 | 0.047 | −0.006 | −0.011 |

| 22 | 1.161 | 0.049 | −0.008 | −0.011 |

| 23 | 1.160 | 0.045 | −0.004 | −0.010 |

| 24 | 1.145 | 0.045 | −0.004 | 0.005 |

| 25 | 1.145 | 0.045 | −0.004 | 0.005 |

| 26 | 1.153 | 0.047 | −0.006 | −0.003 |

| 27 | 1.160 | 0.048 | −0.007 | −0.010 |

| 28 | 1.160 | 0.048 | −0.007 | −0.010 |

| 29 | 1.172 | 0.048 | −0.007 | −0.022 |

| 30 | 1.173 | 0.050 | −0.009 | −0.023 |

| 31 | 1.173 | 0.052 | −0.011 | −0.023 |

| 32 | 1.179 | 0.049 | −0.008 | −0.029 |

| 33 | 1.157 | 0.046 | −0.005 | −0.007 |

| 34 | 1.172 | 0.040 | 0.001 | −0.022 |

| 35 | 1.153 | 0.037 | 0.004 | −0.003 |

3.3. Analyze

3.4. Improve

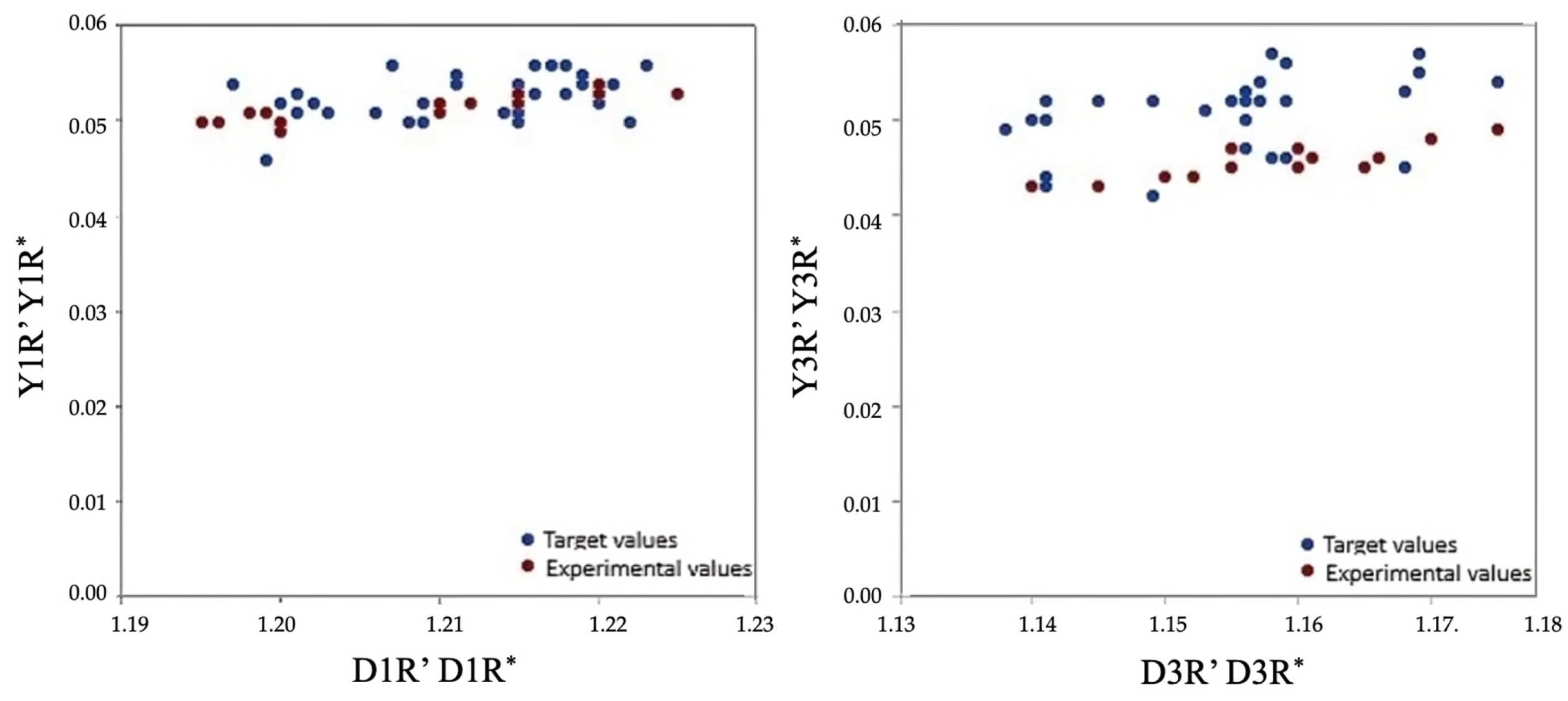

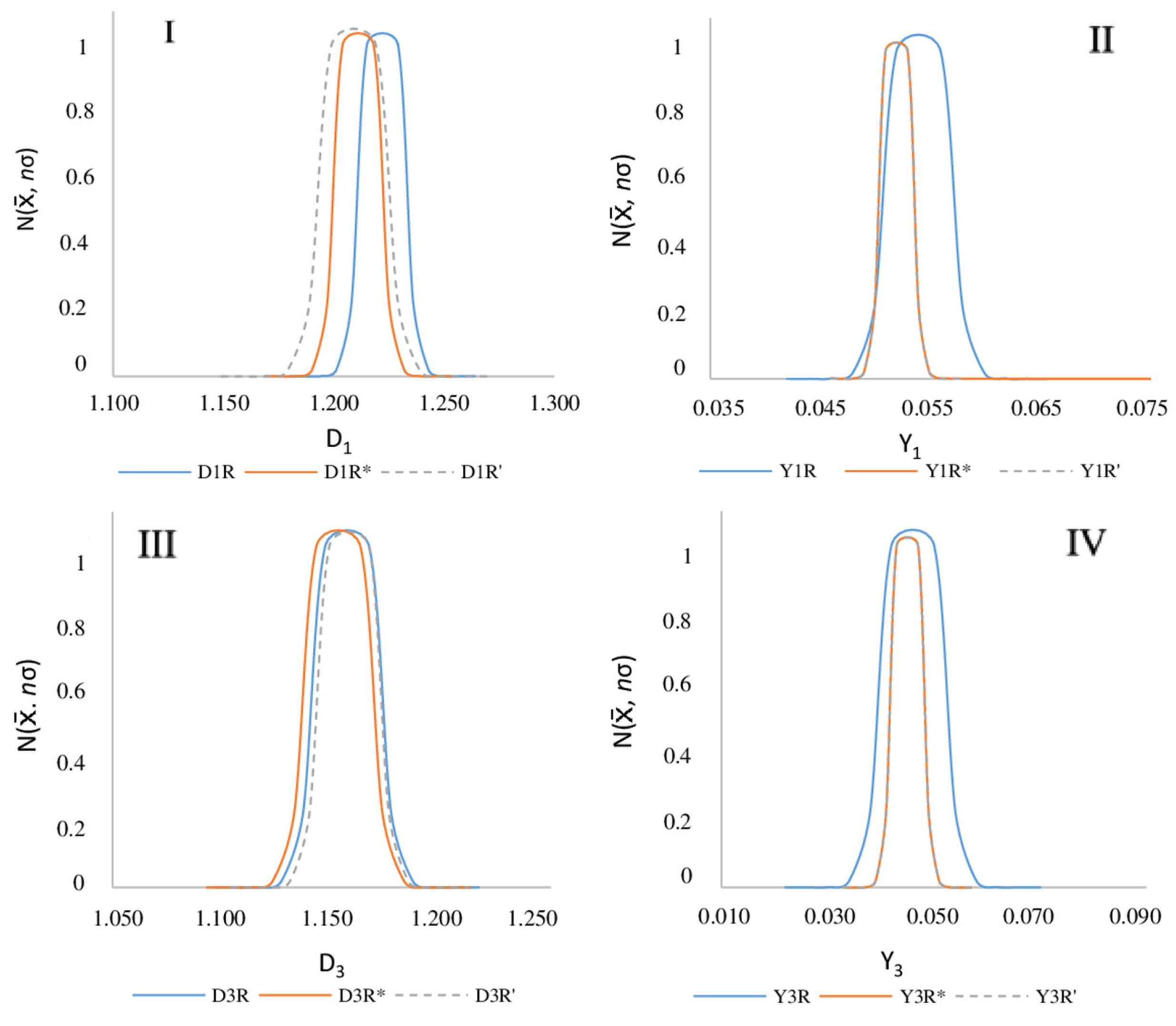

3.5. Control

| Test | D3R’ kg/L | D3T − D3R’ kg/L | Y31R’ kg C31/kg T |

|---|---|---|---|

| 1 | 1.140 | 0.010 | 0.043 |

| 2 | 1.165 | −0.015 | 0.045 |

| 3 | 1.150 | 0.000 | 0.044 |

| 4 | 1.155 | −0.005 | 0.047 |

| 5 | 1.175 | −0.025 | 0.049 |

| 6 | 1.160 | −0.010 | 0.047 |

| 7 | 1.166 | −0.016 | 0.046 |

| 8 | 1.170 | −0.020 | 0.048 |

| 9 | 1.152 | −0.002 | 0.044 |

| 10 | 1.160 | −0.010 | 0.045 |

| 11 | 1.145 | 0.005 | 0.043 |

| 12 | 1.150 | 0.000 | 0.044 |

| 13 | 1.155 | −0.005 | 0.045 |

| 14 | 1.161 | −0.011 | 0.046 |

| 15 | 1.160 | −0.010 | 0.045 |

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Instituto Nacional de Estadística. Agricultura y Ganadería en España y Europa 2020. Available online: https://www.ine.es/censoagrario/censoag_folleto.pdf (accessed on 3 October 2023). (In Spanish).

- Elferink, M.; Schierhorn, F. Global demand for food is rising. Can we meet it. Harv. Bus. Rev. 2016, 7, 2016. [Google Scholar]

- Hereu-Morales, J.; Vinardell, S.; Valderrama, C. Towards climate neutrality in the Spanish N-fertilizer sector: A study based on radiative forcing. Sci. Total Environ. 2024, 946, 174131. [Google Scholar] [CrossRef]

- Baýa, A.P. Achieving customer specifications through process improvement using six sigma: Case study of NutriSoil—Portugal. Qual. Manag. J. 2015, 22, 48–60. [Google Scholar] [CrossRef]

- Patyal, V.S.; Modgil, S.; Koilakuntla, M. Application of Six Sigma methodology in an Indian chemical company. Int. J. Product. Perform. Manag. 2021, 70, 350–375. [Google Scholar] [CrossRef]

- Krogstie, L.; Martinsen, K. Beyond lean and six sigma; cross-collaborative improvement of tolerances and process variations-a case study. Procedia Cirp 2013, 7, 610–615. [Google Scholar] [CrossRef][Green Version]

- Papic, L.; Mladjenovic, M.; Carríon Garcia, A.; Aggrawal, D. Significant factors of the successful lean six-sigma implementation. Int. J. Math. Eng. Manag. Sci. 2017, 2, 85–109. [Google Scholar] [CrossRef]

- Singh, B.; Garg, S.K.; Sharma, S.K.; Grewal, C. Lean implementation and its benefits to production industry. Int. J. Lean Six Sigma 2010, 1, 157–168. [Google Scholar] [CrossRef]

- Kumar, M.; Antony, J.; Singh, R.K.; Tiwari, M.K.; Perry, D. Implementing the Lean SixSigma framework in an Indian SME: A case study. Prod. Plan. Control 2006, 17, 407–423. [Google Scholar] [CrossRef]

- Pyzdek, T. The Six Sigma Project Planner: A Step-by-Step Guide to Leading a Six Sigma Project Through DMAIC; McGraw-Hill: New York, NY, USA, 2003. [Google Scholar]

- Womack, J.P.; Jones, D.T. Lean thinking—Banish waste and create wealth in your corporation. J. Oper. Res. Soc. 1997, 48, 1148. [Google Scholar] [CrossRef]

- Harry, M.J. Six Sigma: A breakthrough strategy for profitability. Qual. Prog. 1998, 31, 60–64. [Google Scholar]

- Patyal, V.; Koilakuntla, M. Relationship between organisational culture, quality practices and performance: Conceptual framework. Int. J. Product. Qual. Manag. 2016, 19, 319–344. [Google Scholar] [CrossRef]

- Harmon, P. Business Process Change. A Guide for Business Managers and BPM and Six Sigma Professionals; MK/OMG Press: Burlington, MA, USA, 2007. [Google Scholar]

- Baker, B. Lean Six Sigma: Combining Six Sigma Quality With Lean Speed. Qual. Prog. 2003, 36, 96. [Google Scholar]

- Kanike, U.K. Factors disrupting supply chain management in manufacturing industries. J. Supply Chain Manag. Sci. 2023, 4, 1–24. [Google Scholar] [CrossRef]

- Sunder, M.V.; Ganesh, L.S.; Marathe, R.R. Lean Six Sigma in consumer banking—An empirical inquiry. Int. J. Qual. Reliab. Manag. 2019, 36, 1345–1369. [Google Scholar] [CrossRef]

- Thomas, A.; Antony, J.; Haven-Tang, C.; Francis, M.; Fisher, R. Implementing Lean Six Sigma into curriculum design and delivery—A case study in higher education. Int. J. Product. Perform. Manag. 2017, 66, 577–597. [Google Scholar] [CrossRef]

- Furterer, S.L. Applying Lean Six Sigma methods to reduce length of stay in a hospital’s emergency department. Qual. Eng. 2018, 30, 389–404. [Google Scholar] [CrossRef]

- Mallali, P.D.; Gopalkrishna, B. Six Sigma approach for reducing the SLA’s resolution time: A case in IT Services enabled industry. Int. J. Mech. Eng. Technol. 2019, 10, 1080–1094. [Google Scholar]

- Guerrero, J.E.; Leavengood, S.; Gutiérrez-Pulido, H.; Fuentes-Talavera, F.J.; Silva-Guzmán, J.A. Applying lean six sigma in the wood furniture industry: A case study in a small company. Qual. Manag. J. 2017, 24, 6–19. [Google Scholar] [CrossRef]

- Alarcón, F.J.; Calero, M.; Pérez-Huertas, S.; Martín-Lara, M.Á. State of the Art of Lean Six Sigma and Its Implementation in Chemical Manufacturing Industry Using a Bibliometric Perspective. Appl. Sci. 2023, 13, 7022. [Google Scholar] [CrossRef]

- Muganyi, P.; Madanhire, I.M.; Mbohwa, E. Business survival and market performance through Lean Six Sigma in the chemical manufacturing industry. Int. J. Lean Six Sigma 2019, 10, 566–600. [Google Scholar] [CrossRef]

- Motwani, J.; Kumar, A.; Antony, J. A business process change framework for examining the implementation of six sigma: A case study of Dow Chemicals. TQM Mag. 2004, 16, 273–283. [Google Scholar] [CrossRef]

- Harry, M.J.; Linsenmann, D.R. The Six Sigma Field Book: How Dupont Successfully Implemented the Six Sigma Breakthrough Strategy; Doubleday Business of Random House, Inc.: New York, NY, USA, 2007. [Google Scholar]

- Dönmez, C.Ç.; Yakar, B. A systematic perspective on supply chain improvement by using lean six sigma and an implementation at a fertilizer company. Electron. J. Soc. Sci. 2019, 18, 1377–1396. [Google Scholar] [CrossRef]

- Calcutti, T. Why is Six Sigma so successful? J. Appl. Stat. 2001, 3, 301–306. [Google Scholar] [CrossRef]

- Lande, M.; Shristava, R.L.; Seth, D. Critical success factors for Lean Six Sigma in SMEs (small and medium enterprises). TQM J. 2016, 28, 613–635. [Google Scholar] [CrossRef]

- Arone, A.; Pariona, M.; Hurtado, Á.; Chichizola, V.; Alvarez, J.C. Improvement of Chemical Processes for the Analysis of Mineral Concentrates Using Lean Six Sigma; Iano, Y., Arthur, R., Saotome, O., Vieira Estrela, V., Loschi, H.J., Eds.; Springer: Cham, Switzerland, 2019; Volume 140, pp. 533–540. [Google Scholar]

- Ishak, A.; Mohamad, E.; Arep, H.; Linarti, U.; Larasti, A. Application of Lean Six Sigma for enhancing performance in the poultry wastewater treatment. J. Adv. Manuf. Technol. 2022, 16, 53–66. [Google Scholar]

- Wegner, K.A. Process improvement for regulatory analyses of custom-blend fertilizers. J. AOAC Int. 2014, 97, 759–763. [Google Scholar] [CrossRef]

- Yin, R.K. Case Study Research: Design and Methods, 4th ed.; Sage: Riverside, CA, USA, 2009. [Google Scholar]

- Botezatu, C.; Condrea, I.; Oroian, B.; Hrituc, A. Use of the Ishikawa diagram in the investigation of some industrial processes. IOP Conf. Ser. Mater. Sci. Eng. 2019, 682, 012012. [Google Scholar] [CrossRef]

- Singh, B.J.; Khanduja, D. Does analysis matter in Six Sigma? A case study. Int. J. Data Anal. Tech. Strateg. 2011, 3, 300–324. [Google Scholar] [CrossRef]

- Meeuwse, M. The use of Lean Six Sigma methodology in increasing capacity of a chemical production facility at DSM. Chimia 2018, 72, 133–138. [Google Scholar] [CrossRef]

- Silva, J.; Avila, P.; Patricio, L.; Sá, J.C. Improvement of planning and time control in the project management of a metalworking industry—Case study. Procedia Comput. Sci. 2022, 196, 288–295. [Google Scholar] [CrossRef]

- Lu, K.-H.; Liu, W.-C. Improving the In-House company’s material distribution efficiency with Lean Six Sigma methodology. J. Qual. 2018, 25, 380–398. [Google Scholar]

- Realyvásquez Vargas, A.; García Alcaraz, J.L.; Satapathy, S.; Díaz-Reza, J.R. Case Study 2. Raw Material Receipt Process Optimization. In The PDCA Cycle for Industrial Improvement; Synthesis Lectures on Engineering, Science, and Technology; Springer: Cham, Switzerland, 2023; pp. 47–77. [Google Scholar]

| Phase | Contents | Application |

|---|---|---|

| Define | Indicate the main objective of the application, as well as the critical project to be developed | Reducing possible losses of ingredients used in manufacturing. Associated with this are also the purchasing process, the generation of waste, and the use of energy resources |

| Measure | Develop a data collection plan and compare data to identify problems and gaps | Analysis of manufactured products. Relationship with the composition of raw materials and the reliability of added quantities |

| Analyze | Determine the causes of defects and the sources of variation | Establish relationships between the data obtained through analysis using graphical techniques, statistics, etc. |

| Improve | Propose measures to reduce or eliminate variations | Study trends and possible corrective measures to be implemented |

| Control | Check that the process variations comply with the established requirements | Determine the impact of the proposed changes on the processes and their follow-up |

| Test | D1R kg/L | Y11R kg C11R/kg T | Y11T − Y11R kg C11/kg T | D1T − D1R kg/L |

|---|---|---|---|---|

| 1 | 1.222 | 0.057 | −0.002 | −0.029 |

| 2 | 1.222 | 0.057 | −0.002 | −0.027 |

| 3 | 1.226 | 0.051 | 0.004 | −0.019 |

| 4 | 1.229 | 0.055 | 0.000 | −0.008 |

| 5 | 1.227 | 0.053 | 0.002 | −0.013 |

| 6 | 1.219 | 0.054 | 0.001 | −0.029 |

| 7 | 1.208 | 0.047 | 0.008 | −0.010 |

| 8 | 1.213 | 0.052 | 0.003 | −0.026 |

| 9 | 1.229 | 0.051 | 0.004 | −0.026 |

| 10 | 1.210 | 0.051 | 0.004 | −0.020 |

| 11 | 1.226 | 0.057 | −0.002 | −0.027 |

| 12 | 1.226 | 0.056 | −0.001 | −0.030 |

| 13 | 1.220 | 0.057 | −0.002 | −0.028 |

| 14 | 1.227 | 0.052 | 0.003 | −0.025 |

| 15 | 1.230 | 0.052 | 0.003 | −0.012 |

| 16 | 1.228 | 0.052 | 0.003 | −0.014 |

| 17 | 1.225 | 0.055 | 0.000 | −0.030 |

| 18 | 1.212 | 0.055 | 0.000 | −0.032 |

| 19 | 1.214 | 0.052 | 0.003 | −0.017 |

| 20 | 1.230 | 0.051 | 0.004 | −0.026 |

| 21 | 1.232 | 0.051 | 0.004 | −0.033 |

| 22 | 1.217 | 0.054 | 0.001 | −0.012 |

| 23 | 1.226 | 0.052 | 0.003 | −0.012 |

| 24 | 1.233 | 0.057 | −0.002 | −0.034 |

| 25 | 1.212 | 0.051 | 0.004 | −0.019 |

| 26 | 1.212 | 0.052 | 0.003 | −0.026 |

| 27 | 1.234 | 0.053 | 0.002 | −0.020 |

| 28 | 1.219 | 0.054 | 0.001 | −0.027 |

| 29 | 1.226 | 0.053 | 0.002 | −0.011 |

| 30 | 1.220 | 0.053 | 0.002 | −0.031 |

| 31 | 1.227 | 0.057 | −0.002 | −0.018 |

| 32 | 1.211 | 0.057 | −0.002 | −0.018 |

| 33 | 1.231 | 0.057 | −0.002 | −0.029 |

| 34 | 1.218 | 0.057 | −0.002 | −0.027 |

| 35 | 1.218 | 0.051 | 0.004 | −0.019 |

| Pi | x | Δx (%) | LI | ΔLI (%) | LS | ΔLS (%) | σ |

|---|---|---|---|---|---|---|---|

| D1R | 1.222 | 1.83 | 1.208 | 0.67 | 1.234 | 2.83 | 0.007 |

| Y11R | 0.054 | −1.82 | 0.047 | −14.55 | 0.057 | 3.64 | 0.002 |

| D2R | 1.327 | −0.23 | 1.300 | −2.26 | 1.336 | 0.45 | 0.007 |

| Y21R | 0.598 | −0.33 | 0.582 | −3.00 | 0.610 | 1.67 | 0.005 |

| Y22R | 0.030 | 0.00 | 0.025 | −16.67 | 0.035 | 16.67 | 0.002 |

| D3R | 1.157 | 0.61 | 1.142 | −0.70 | 1.179 | 2.52 | 0.010 |

| Y31R | 0.046 | 12.20 | 0.037 | −9.75 | 0.052 | 26.83 | 0.004 |

| Pi | PT L | kg/L | ΔPT kg | kg CijR/kg T | ΔYij kg CijR/kg T | ΔMPij kg |

|---|---|---|---|---|---|---|

| P1 | 193,440 | −0.022 | −4255.68 | 0.054 | −229.81 | −919.23 |

| P2 | 72,160 | 0.003 | 216.48 | 0.598 0.030 | 129.46 6.49 | 199.16 25.98 |

| P3 | 130,080 | −0.007 | −910.56 | 0.046 | −41.89 | −598.43 |

| Loss estimation P1, kg | −2127.84 |

| Average value (D1T − D1R), kg/L | −0.011 |

| Estimated average value D1R, kg/L | 1.211 |

| Variation of D1R over D1T, % | 0.92 |

| Loss estimation MP11, kg | −468.97 |

| Loss estimation Y11, kg C11/kg tot | −114.91 |

| Loss estimation P3, kg | −459.62 |

| Average value (D3T − D3R), kg/L | −0.004 |

| Estimated average value D3R, kg/L | 1.154 |

| Variation of D3R over D3T, % | 0.35 |

| Loss estimation MP31, kg | −299.22 |

| Loss estimation Y31, kg C31/kg tot | −20.95 |

| Category | Causes | Action | Involved | Result/Cost | Time |

|---|---|---|---|---|---|

| Methods | Production programming | MP production and procurement plan Demand for updated sales forecasts | Planning and Purchasing Commercial | Gant diagrams. ERP adaptationCRM EUR 5000 | 3–6 months |

| Standardization manufacturing procedures | Specific working instructions | Production | Detailed working procedure | 2 months | |

| Facilities | Equipment availability | Specific preventive maintenance plan | Maintenance | Technical services MES 4500 € | 3–6 months |

| Timetable with prioritization of productions | Production | Production program | - | ||

| Staff | Appropriate staff training | Training on product handling and time management | Human Resources | Training program EUR 3000 | 1 week |

| Precise raw materials handling | Training in handling measuring equipment | Production and Human Resources | Training program EUR 1500 | 1 week | |

| Environment | Workspace layout | Elimination of obstacles Tidiness of the work area | Production Production | Reorganization of spaces Good practices | 1 week |

| Delimit a suitable and specific area for raw materials | Raw materials location área Regular audits | Maintenance | Signaling and use of beacons EUR 200 | 2 weeks | |

| Materials | Reduce variability of raw materials composition | Choice of raw materials whose variability in composition is <2% | Purchasing | Search for three suppliers and choose one with the least variability in composition | 1–2 months |

| Measurement | Verification of measurement equipment | Establish a program for the adjustment and calibration of measuring equipment | Quality | Entity official verification EUR 500 | 1 month |

| Test | D1R’ kg/L | D1T − D1R’ kg/L | Y11R’ kg C11/kg T |

|---|---|---|---|

| 1 | 1.200 | 0.000 | 0.049 |

| 2 | 1.215 | −0.015 | 0.053 |

| 3 | 1.220 | −0.020 | 0.054 |

| 4 | 1.199 | 0.001 | 0.051 |

| 5 | 1.196 | 0.004 | 0.050 |

| 6 | 1.215 | −0.015 | 0.052 |

| 7 | 1.225 | −0.025 | 0.053 |

| 8 | 1.210 | −0.010 | 0.051 |

| 9 | 1.220 | −0.020 | 0.053 |

| 10 | 1.215 | −0.015 | 0.053 |

| 11 | 1.195 | 0.005 | 0.050 |

| 12 | 1.198 | 0.002 | 0.051 |

| 13 | 1.200 | 0.000 | 0.050 |

| 14 | 1.212 | −0.012 | 0.052 |

| 15 | 1.210 | −0.010 | 0.052 |

| P1 | P3 | ||

|---|---|---|---|

| D1R* kg/L | Y11R* kg C11/kg T | D3R* kg/L | Y31R* kg C31/kg T |

| 1.211 | 0.054 | 1.158 | 0.057 |

| 1.211 | 0.055 | 1.158 | 0.057 |

| 1.215 | 0.054 | 1.159 | 0.056 |

| 1.218 | 0.056 | 1.159 | 0.052 |

| 1.216 | 0.056 | 1.141 | 0.052 |

| 1.208 | 0.050 | 1.141 | 0.050 |

| 1.197 | 0.054 | 1.155 | 0.052 |

| 1.202 | 0.052 | 1.156 | 0.050 |

| 1.218 | 0.053 | 1.156 | 0.052 |

| 1.199 | 0.046 | 1.156 | 0.047 |

| 1.215 | 0.051 | 1.156 | 0.047 |

| 1.215 | 0.050 | 1.141 | 0.044 |

| 1.209 | 0.050 | 1.141 | 0.043 |

| 1.216 | 0.056 | 1.158 | 0.046 |

| 1.219 | 0.055 | 1.138 | 0.049 |

| 1.217 | 0.056 | 1.138 | 0.049 |

| 1.214 | 0.051 | 1.140 | 0.050 |

| 1.201 | 0.051 | 1.140 | 0.050 |

| 1.203 | 0.051 | 1.145 | 0.052 |

| 1.219 | 0.054 | 1.159 | 0.046 |

| 1.221 | 0.054 | 1.157 | 0.052 |

| 1.206 | 0.051 | 1.157 | 0.054 |

| 1.215 | 0.050 | 1.156 | 0.050 |

| 1.222 | 0.050 | 1.141 | 0.050 |

| 1.201 | 0.053 | 1.141 | 0.050 |

| 1.201 | 0.051 | 1.149 | 0.052 |

| 1.223 | 0.056 | 1.156 | 0.053 |

| 1.208 | 0.050 | 1.156 | 0.053 |

| 1.215 | 0.051 | 1.168 | 0.053 |

| 1.209 | 0.052 | 1.169 | 0.055 |

| 1.216 | 0.053 | 1.169 | 0.057 |

| 1.200 | 0.052 | 1.175 | 0.054 |

| 1.220 | 0.052 | 1.153 | 0.051 |

| 1.207 | 0.056 | 1.168 | 0.045 |

| 1.207 | 0.056 | 1.149 | 0.042 |

| 1.211 | 0.054 | 1.158 | 0.057 |

| D1R* | Y11R* | D1R’ | Y11R’ | D3R* | Y31R* | D3R’ | Y31R’ | |

|---|---|---|---|---|---|---|---|---|

| UL | 1.223 | 0.056 | 1.225 | 0.054 | 1.175 | 0.057 | 1.175 | 0.049 |

| LL | 1.197 | 0.046 | 1.195 | 0.049 | 1.138 | 0.042 | 1.140 | 0.043 |

| x | 1.211 | 0.053 | 1.209 | 0.052 | 1.153 | 0.051 | 1.158 | 0.045 |

| σ | 0.007 | 0.002 | 0.010 | 0.001 | 0.010 | 0.004 | 0.009 | 0.002 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alarcón, F.J.; Calero, M.; Martín-Lara, M.Á.; Pérez-Huertas, S. An Integrated Lean and Six Sigma Framework for Improving Productivity Performance: A Case Study in a Spanish Chemicals Manufacturer. Appl. Sci. 2024, 14, 10894. https://doi.org/10.3390/app142310894

Alarcón FJ, Calero M, Martín-Lara MÁ, Pérez-Huertas S. An Integrated Lean and Six Sigma Framework for Improving Productivity Performance: A Case Study in a Spanish Chemicals Manufacturer. Applied Sciences. 2024; 14(23):10894. https://doi.org/10.3390/app142310894

Chicago/Turabian StyleAlarcón, Francisco J., Mónica Calero, María Ángeles Martín-Lara, and Salvador Pérez-Huertas. 2024. "An Integrated Lean and Six Sigma Framework for Improving Productivity Performance: A Case Study in a Spanish Chemicals Manufacturer" Applied Sciences 14, no. 23: 10894. https://doi.org/10.3390/app142310894

APA StyleAlarcón, F. J., Calero, M., Martín-Lara, M. Á., & Pérez-Huertas, S. (2024). An Integrated Lean and Six Sigma Framework for Improving Productivity Performance: A Case Study in a Spanish Chemicals Manufacturer. Applied Sciences, 14(23), 10894. https://doi.org/10.3390/app142310894