1. Introduction

Manufacturing processes are an important component of industrial activity and occupy an essential position in the global economy. Manufacturing equipment supports raw materials’ metamorphosis into products through such processes by consuming, almost every time, electric energy. As manufacturing occurs, unwanted waste and emissions are generated at the same time with the added value. Lowering the consumption of all kinds of resources involved in manufacturing—electric energy the first of them—without affecting the process performance, became a sine qua non condition to be met for reaching sustainable manufacturing. In general, this can be achieved by increasing its efficiency.

The energy efficiency in metal cutting is, sometimes, very low. For sampling, recent studies [

1,

2] show that the energy consumed through chip detaching represents only about 15% of the total energy involved in hard and fragile materials machining. Despite this, until a few years ago, the optimization of machining operations from an energy efficiency point of view was not convincingly approached, with productivity and costs being the main targets. Due to the well-known problems generated by human activities that impact the environment, with negative and unpredictable consequences, the situation has dramatically changed. Producing electricity sustainably and energy efficiency have become top priorities on a worldwide scale, and the manufacturing domain is no exception.

This study [

3] has established a framework for energy performance improvement in manufacturing and subdivides the methods to be used for this purpose into four aspects: energy monitoring, evaluation, optimization, and benchmarking. Moreover, the available solutions for energy optimization are the improvement of manufacturing equipment, the optimization of processes and parameters, appropriate production scheduling, and a management system.

In the part machining process, cutting parameters have a huge impact on energy and material consumption, cutting the time and economy of the manufacturing system. Many researchers have been engaged in energy-efficient cutting parameter optimization, and a significant amount of the dedicated literature has been published in recent years. For sampling, paper [

4] presents a method for such optimization, aiming to balance cutting indexes, i.e., carbon emissions, cutting time and cutting cost, in the part machining process, by using non-cooperative game theory integrated NSGA-II. The article [

5] shows an integrated model for machining energy consumption, designed to enable the use of the Simulated Annealing technique to find the optimal spindle rotation speed and feed rate that result in the minimum machining energy consumption by also considering the non-cutting energy consumption. Other research [

6,

7,

8] approaches the same type of problem based on different energy models and optimization techniques. Paper [

9] analyzes energy-efficient cutting parameter optimization using the experimental design method.

Gears are the most common solution to transmitting rotation motion with power between mW and hundreds of kW in devices from the medical domain to heavy, energy-producing, or aircraft industries [

10]. Naturally, there is a significant number of gears in worldwide machinery, among which one can find many types of gears and a certain number of shapes for tooth profiles, as well. The most used types of gears are cylindrical gears, bevel gears, and worm gears [

11], while the most popular tooth profile is the involute, due to its unbeatable advantages regarding contact between conjugated teeth profiles [

10,

11].

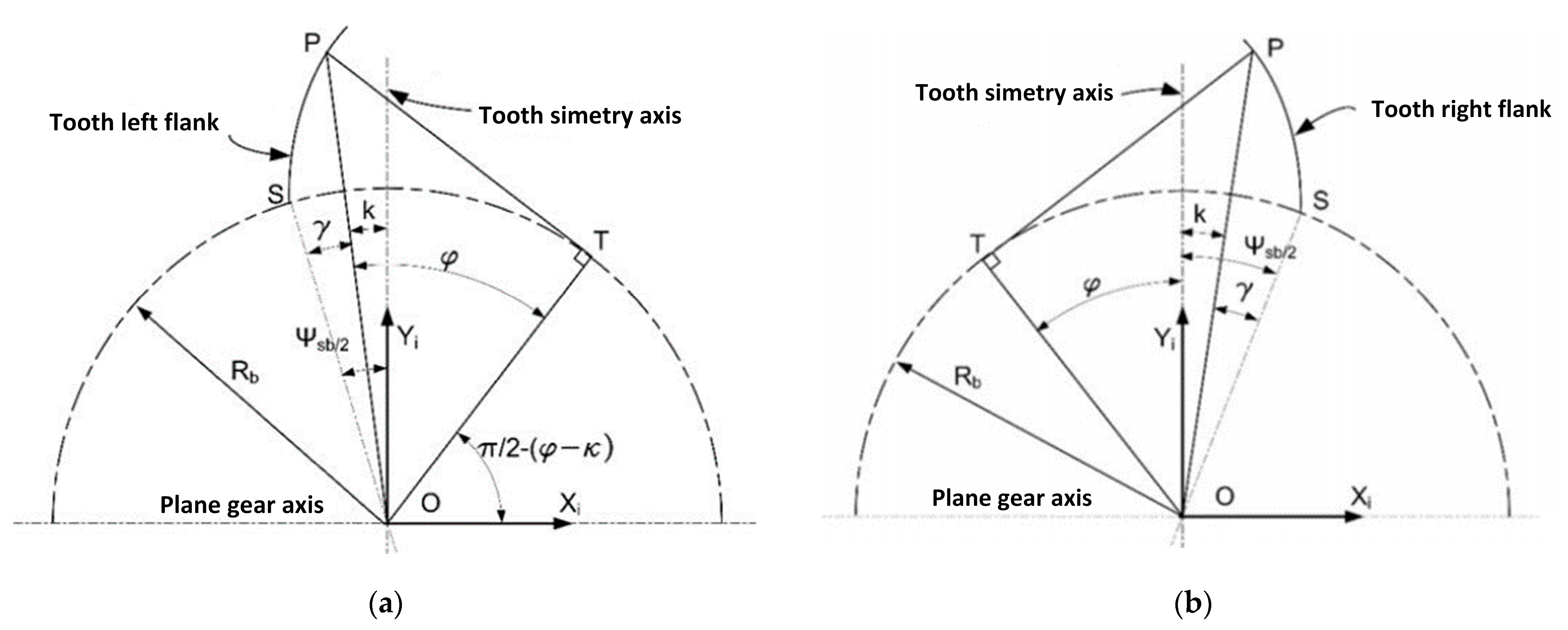

In gear manufacturing, the most particular issue of concern is teeth machining. Here, the generating of involute teeth profiles can be performed by copying the tool axial profile or by applying the so-called “rolling method”, which is the currently applied solution [

12]. The teeth flanks generated by rolling involve, besides common cutting motions (specific to turning/milling/grinding/slotting, depending on the applied process), a feed motion precisely reproducing the relative motion between the centrodes associated with the cutting tool and the machined part—the rolling motion [

12]. In all cases, the speed of this motion is set at the beginning of teeth cutting and is kept unchanged throughout the process [

13].

Despite the inexistence of a precise formula for calculating the cutting force in a given cutting process, all the existing formulas, proposed by different researchers, accept the direct connection between the cutting force magnitude and the area of the detached chip section [

14,

15,

16,

17,

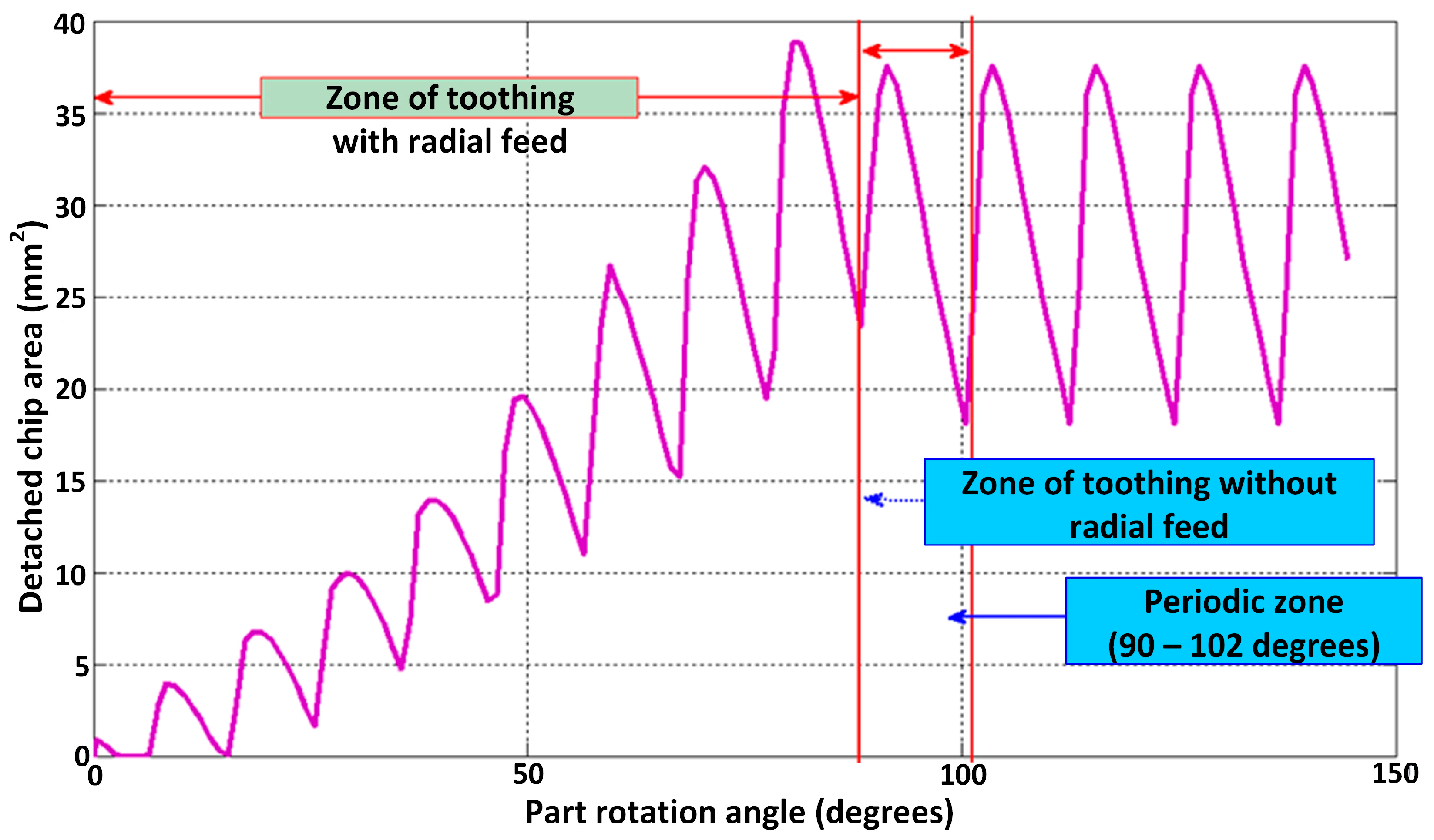

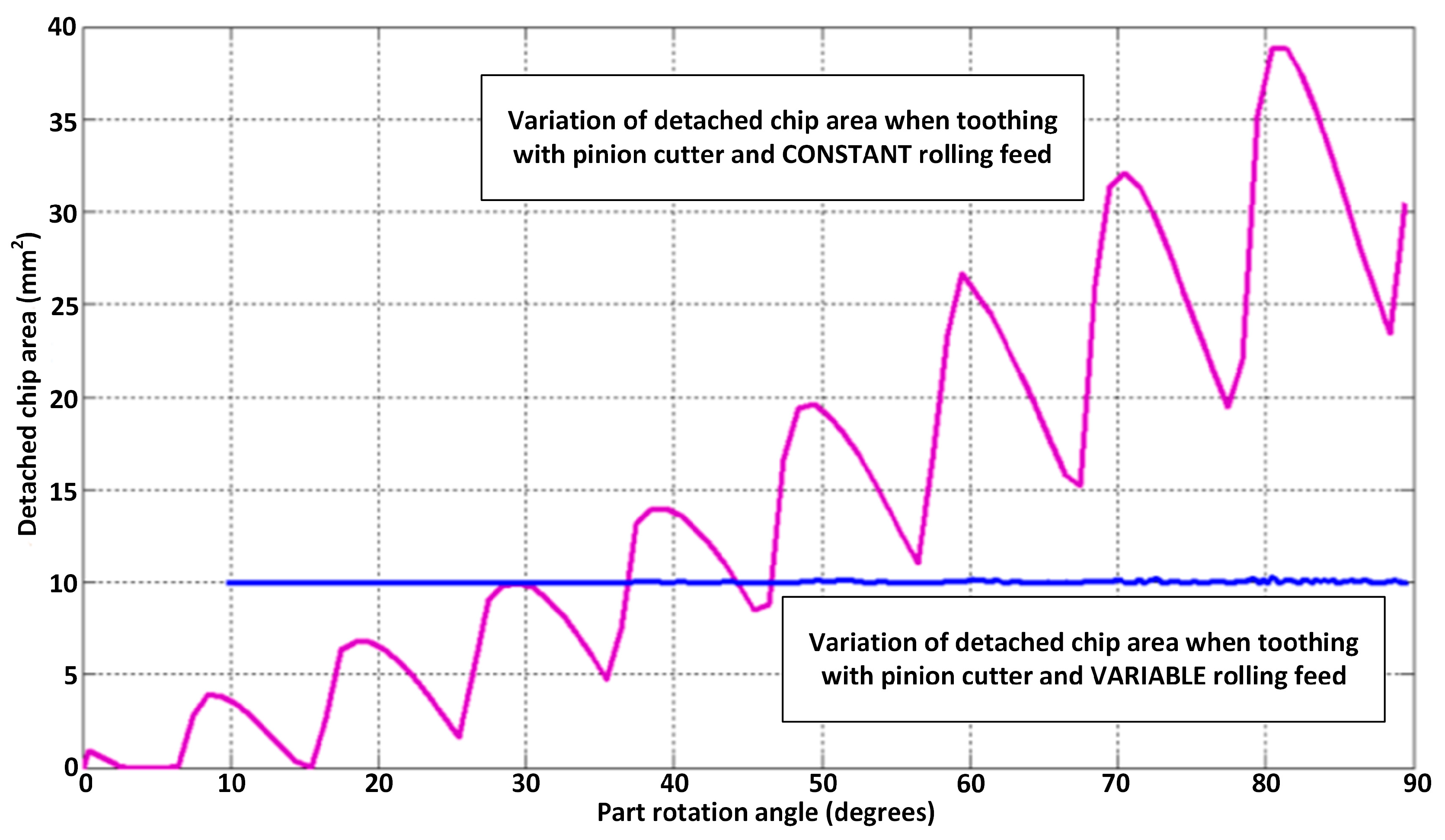

18]. The modeling of the gear teeth-cutting processes [

19,

20] shows a significant variation in this area during teeth machining, which further leads to a high time variation in the cutting force. In other words, the teeth machining process is characterized by important non-uniformity from an energetic point of view. This indicates the variation in the electric power absorbed by the driving system of the used machine tool and determines, obviously, the diminishment of energy efficiency.

The authors of [

21] analyzed the influence of the cutting force on machining process efficiency and found that to increase energy efficiency, the cutting force must be reduced, for example, by reducing the depth of the cut and by increasing the feed rate. However, they have addressed the case when the given machining operation is performed by using an unchanged regime, during which the cutting force is considered quasi-constant. When the cutting force significantly varies, the above-presented situation specific to gear teeth cutting makes the cutting parameter optimization aiming for energy efficiency less applicable according to the current general approach.

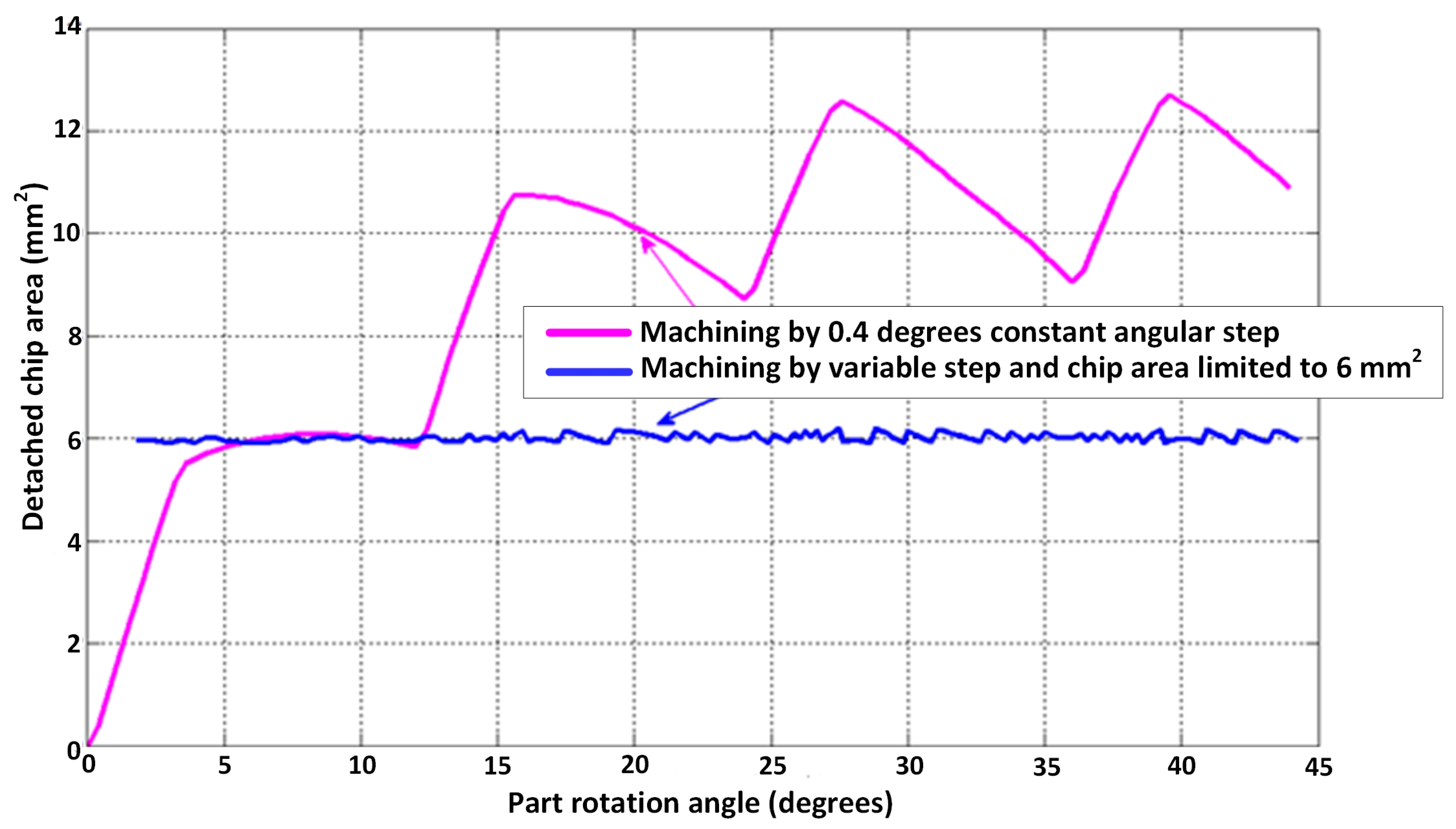

The present paper proposes an innovative approach leading to an energy efficiency increase in gear teeth cutting characterized by a new strategy: the smoothing of the cutting force variation during the machining process. A dedicated method, which enables the implementation of this strategy, based on playing the rolling motion with a variable and convenient speed was developed accordingly.

The present paper is structured as follows:

Section 2 deals with describing this method,

Section 3 presents method application in the cases of some typical methods for gear teeth cutting,

Section 4 describes a technical solution proposed for method implementation, and

Section 5 presents the conclusions.

2. Method Description

2.1. Principle of the Method

Smoothing of cutting force variation requires that the area of the detached chip section remains quasi-constant during the cutting process (see the previous section). In gear teeth machining, there are two potential solutions to achieve this result:

- -

The constructive modification of the cutting tool;

- -

The appropriate variation in the cutting tool feed relative to the worked piece.

Both solutions start from finding the variation law for the area of the detached chip section, which can be found by modeling the toothing process. Such modeling was realized by analytical and specific numerical methods [

19] in the cases of gear teeth machining by slotting (with a rack tool or with a pinion cutter) and by hobbing.

For sampling the tool constructive modification, in the case of the rack tool, it may consist of giving different angles of inclination to the successive teeth flanks or adopting different heights or different thicknesses for the successive teeth [

19,

20]. However, this solution is difficult to apply due to the complex geometry of the tool, which becomes expensive, while the induced results have shown only a partial smoothing of the chips section area, hence a partial smoothing of the cutting force.

Concerning cutting force smoothing by appropriate variation in the cutting tool feed rate, there are few mentioned results. When toothing by employing the rolling method on conventional equipment, the tool feed motion is mechanically controlled through elements of the rolling kinematical chain in a discrete manner. The pre-established increment of motion is impossible to modify throughout the process.

The principle of the proposed method is to perform the teeth-cutting process by rolling with variable increments, according to an appropriate, previously established law. This can be reached by modifying the rolling kinematical chain, such as the tool feed motion, which is independently driven by a numerically controlled stepper motor.

The implementation of the proposed method requires the steps presented below.

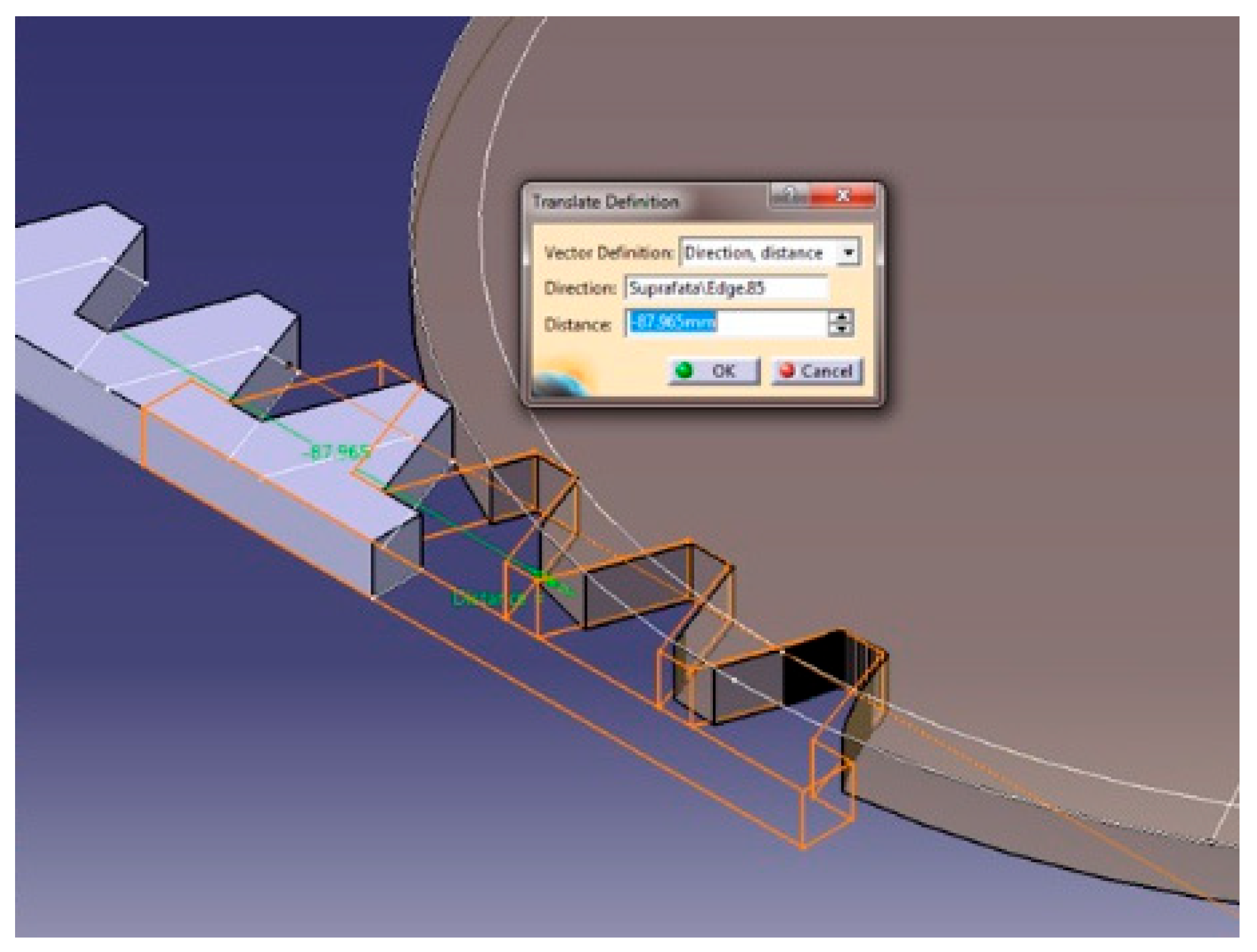

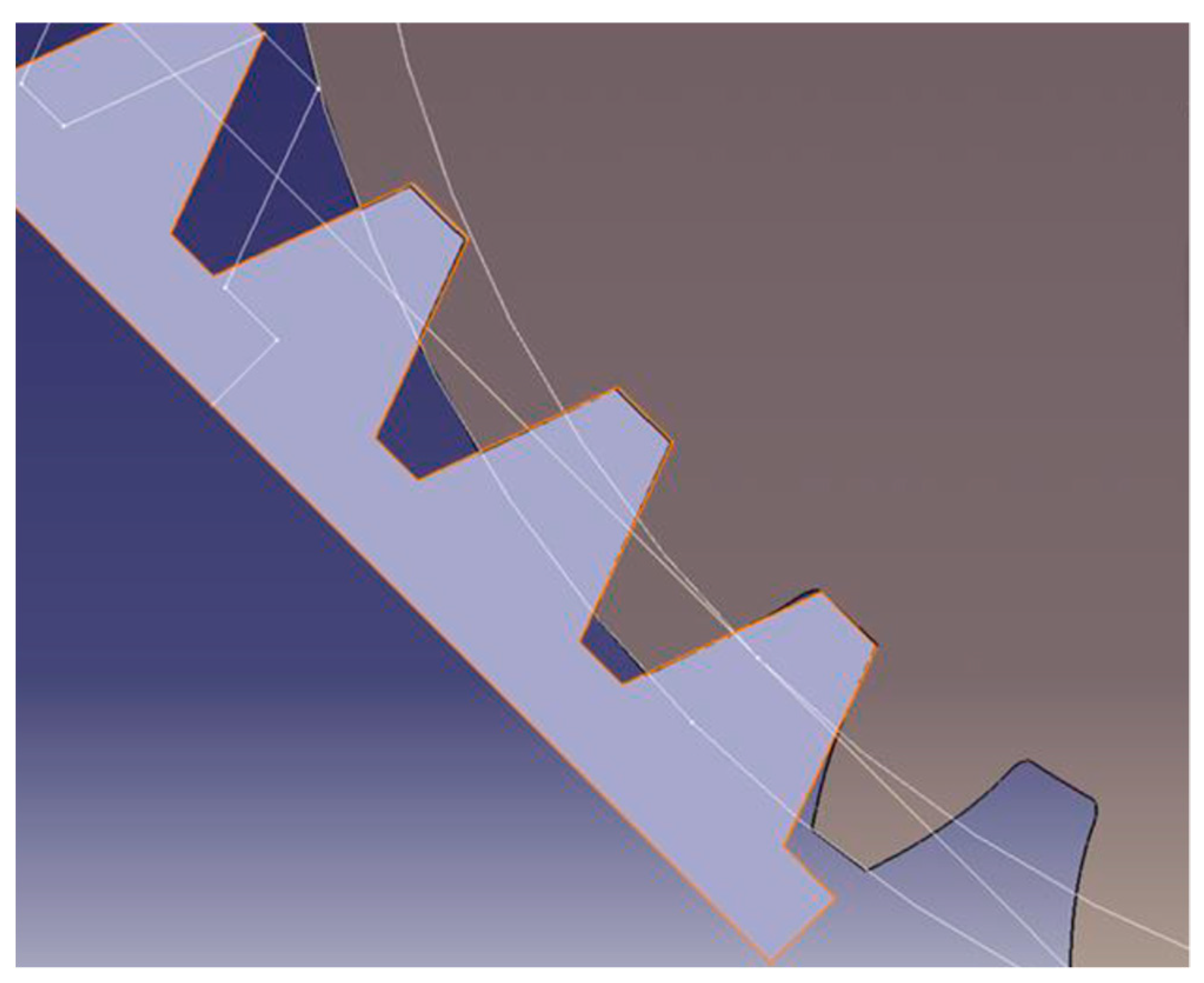

2.2. Graphical Modeling of the Gear Cutting Process

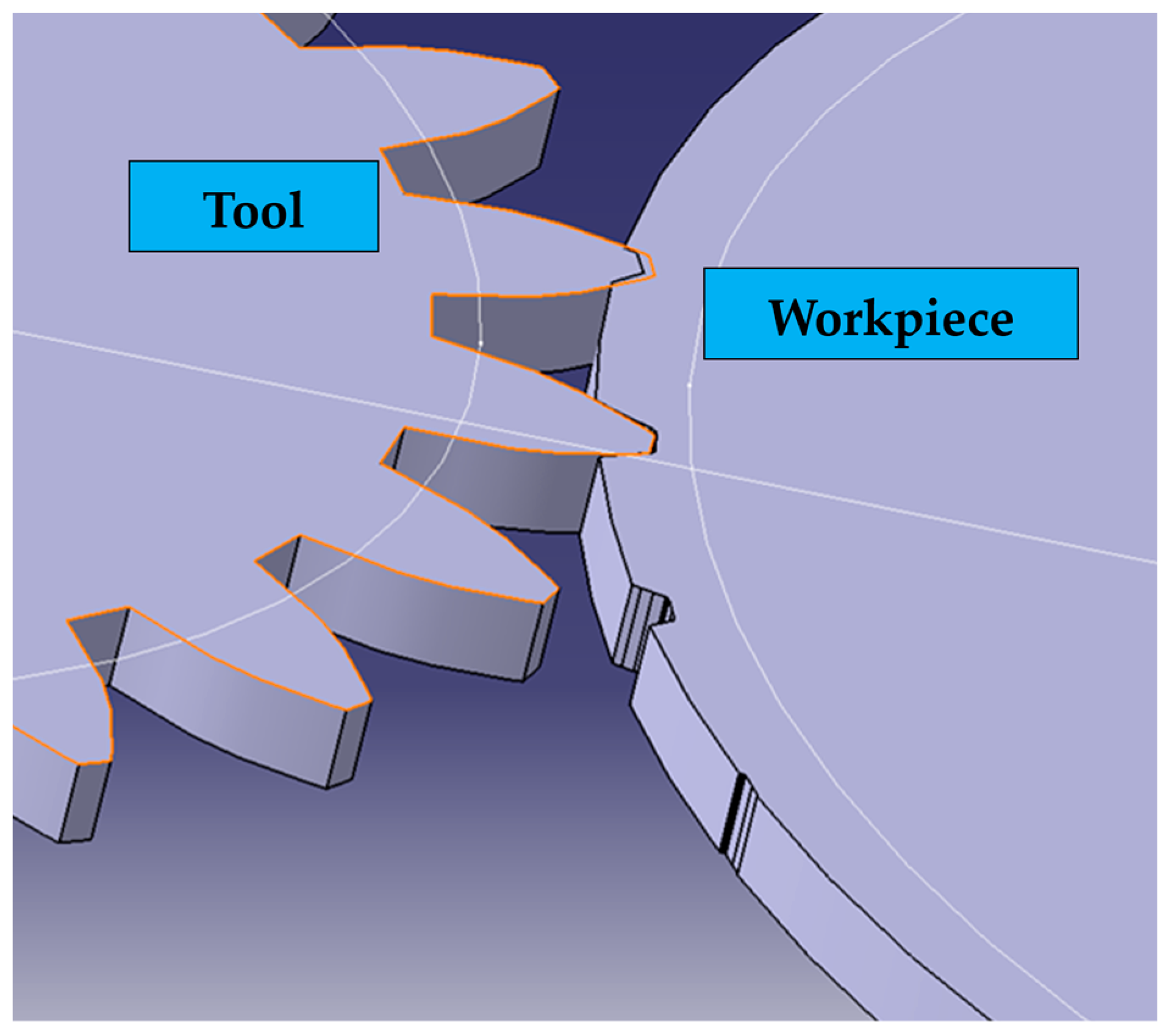

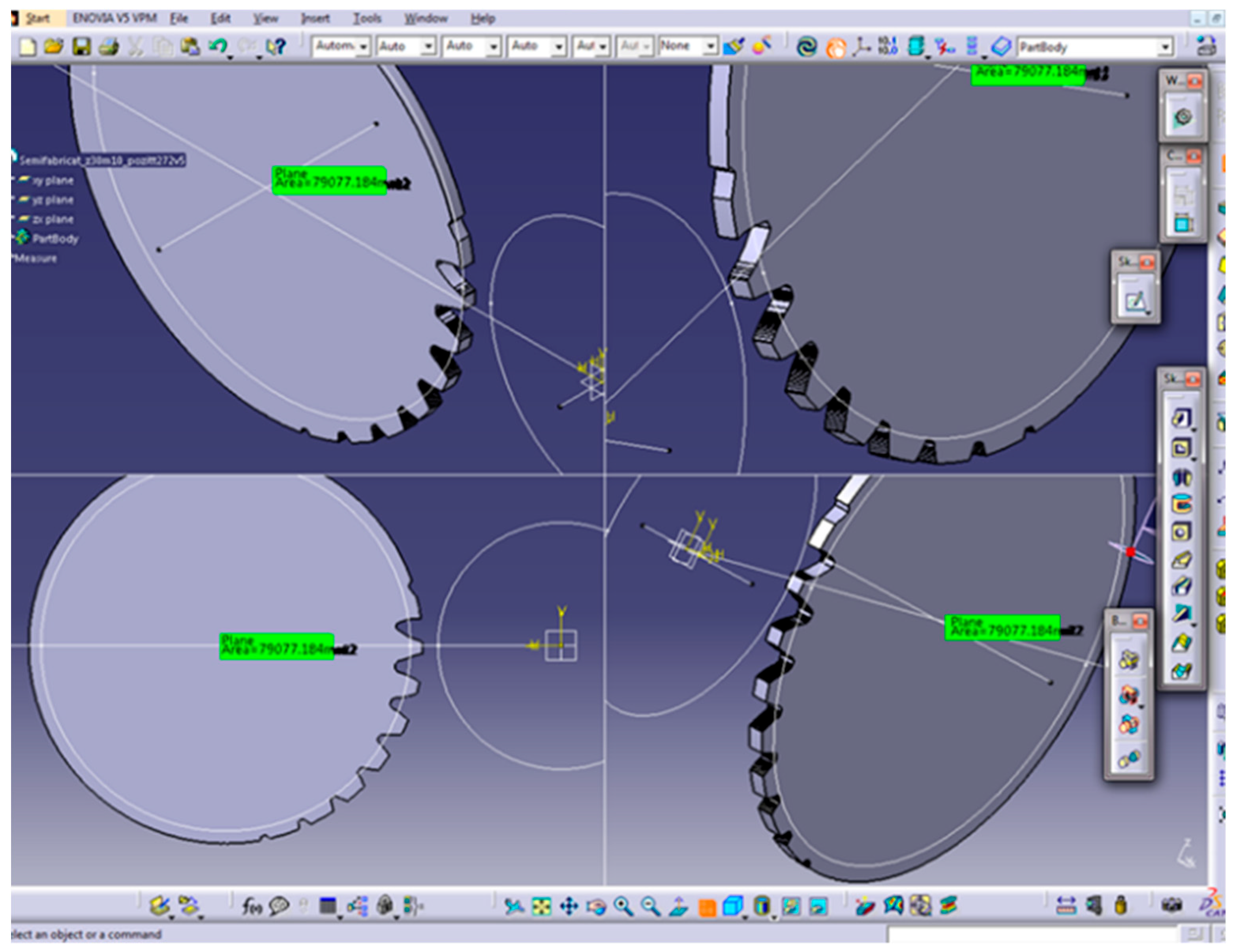

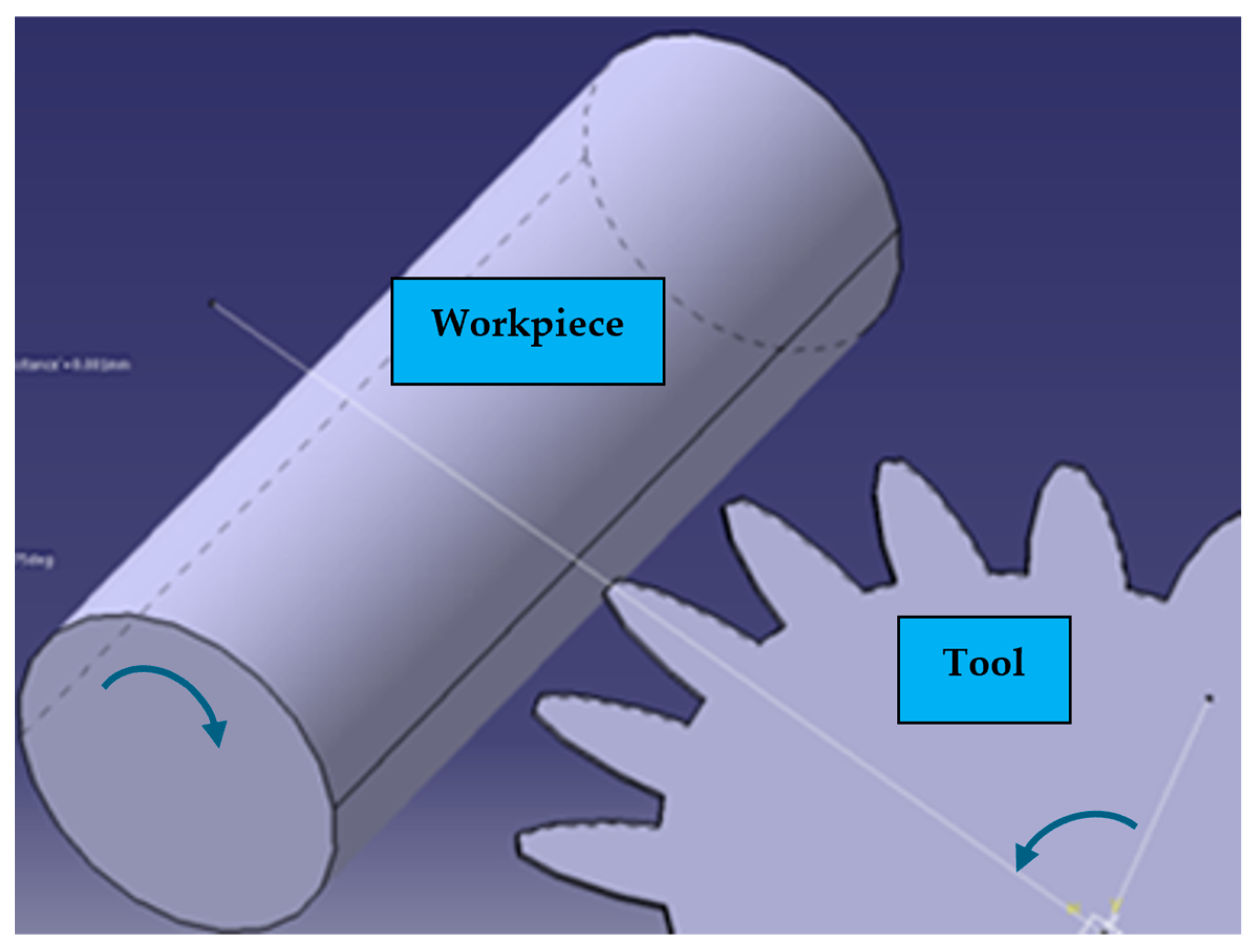

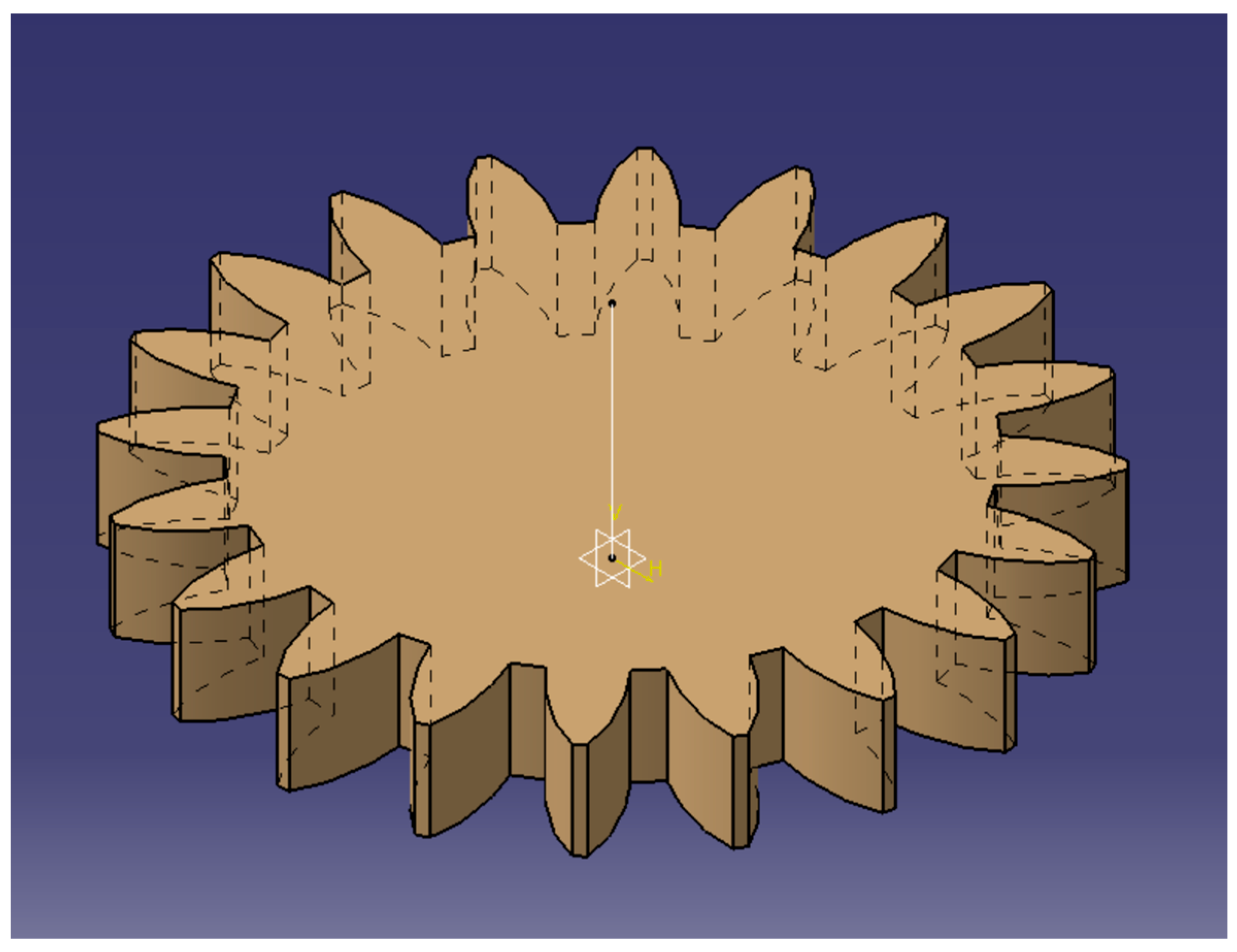

Unlike the already existing solutions for analytical modeling of the toothing process, here, we propose the application of graphical modeling in specialized software, namely CATIA. Thus, one can take full advantage of the available facilities and the accuracy of the results.

Graphical modeling starts with the creation, in separate files, of the models for both the worked piece and the cutting tool. The models are obtained by extruding with a Pad tool [

22] at convenient dimensions. Drawings are executed in the Sketch module of CATIA, in which the dimensions correspond to the active tool part and the gear exterior diameter.

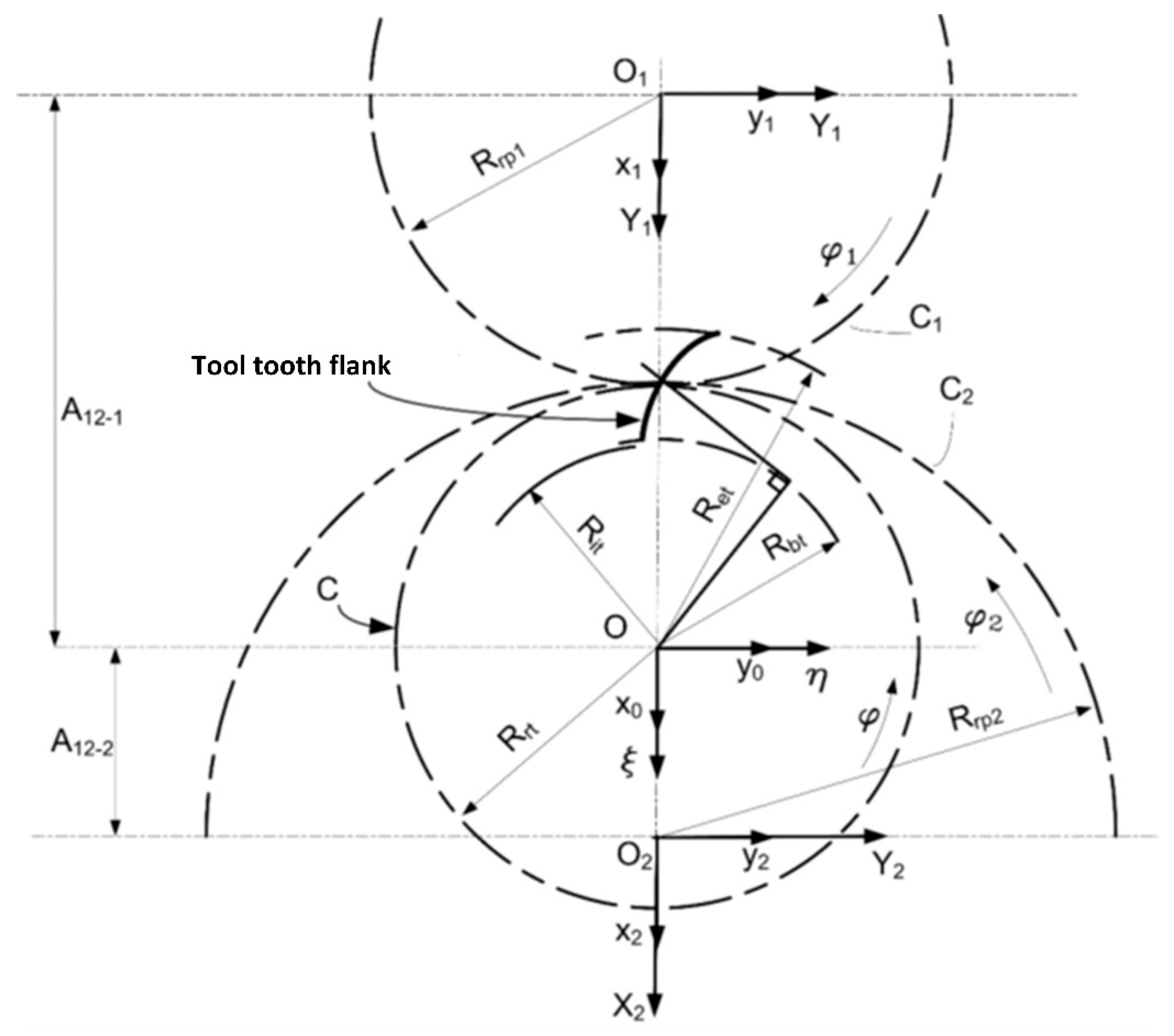

Certain geometrical and dimensional restrictions are imposed on these models, such as the correct relative positioning between the tool and the worked piece, meaning that the tangency between their associated centrodes is reached [

23].

Subsequently, the type of motion (rotation and/or translation) and the motion increments to be applied to the models are established so that the kinematics of the addressed cutting process are correctly reproduced and obey the specific rolling condition [

11].

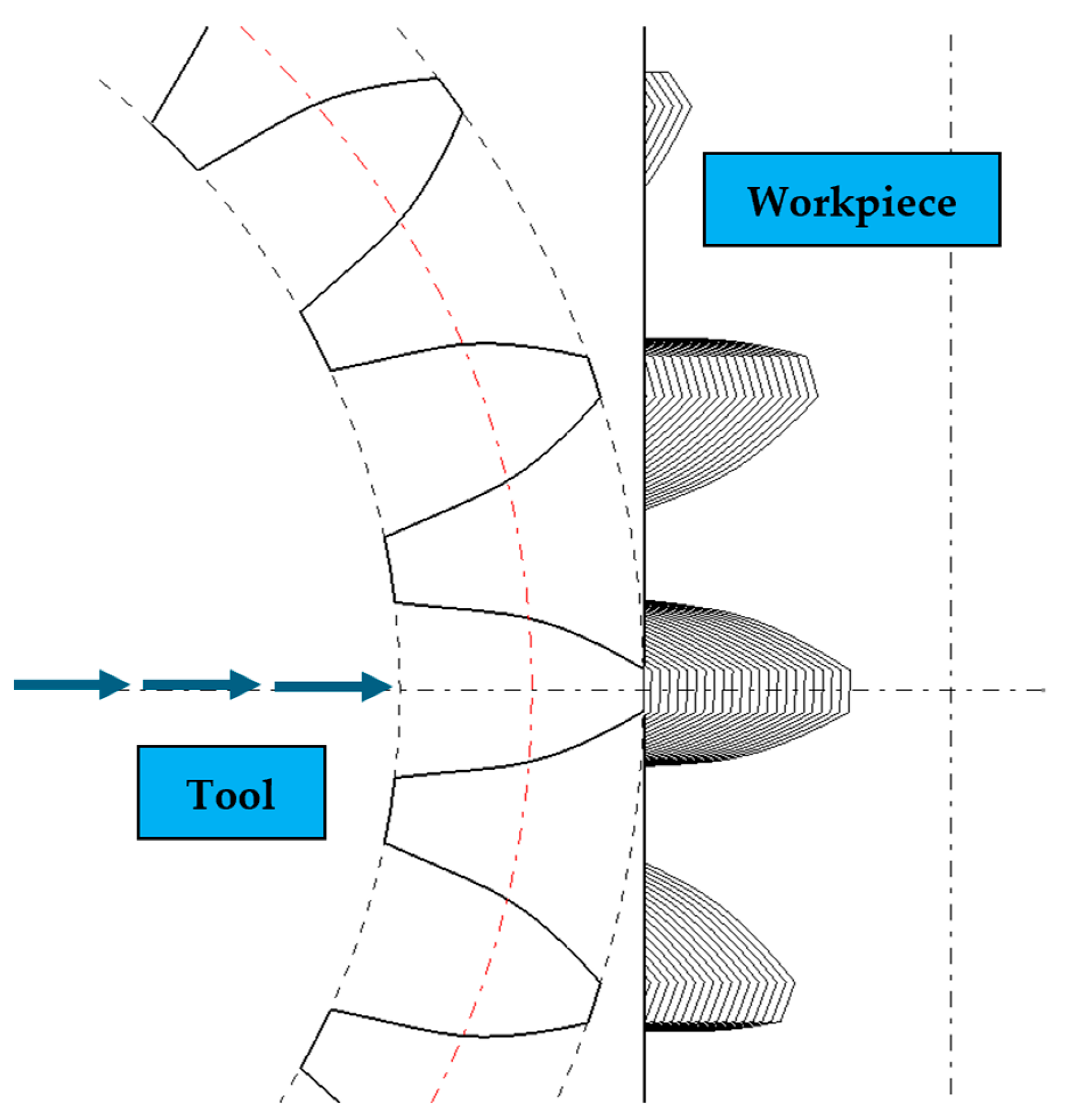

When addressing the most usual case of machining the teeth of a cylindrical gear, the workpiece model is very simple, i.e., a disc having the radius and the thickness equal to the ones of the blank considered for starting the process. Concerning the cutting tool model, this depends on the considered toothing solution, which may use a rack tool, a pinion cutter, a rotating cutter, etc.

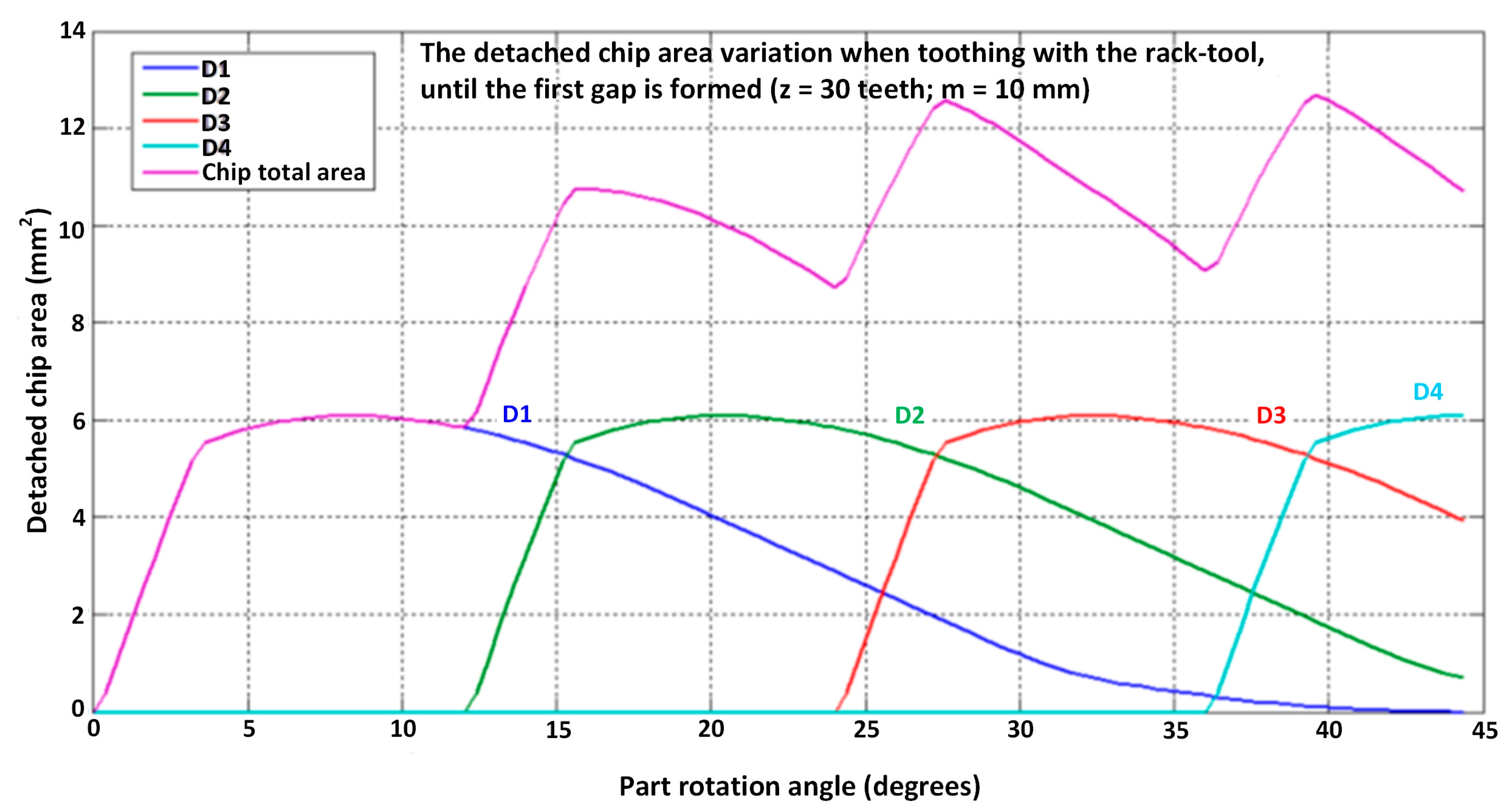

2.3. Finding the Variation Law for Detached Chip Area

As already mentioned in the previous section, there is a close link between the cutting force magnitude and the detached chip area. For simplicity, without any direct impact on the proposed method’s effectiveness, we will further accept a proportional relation between them. Hereby, the shape of the cutting force variation law is similar to the shape of variation for the detached chip area.

Given the periodicity of the process (except for tool engagement and disengagement phases) and due to the successive machining of consecutive teeth, it is sufficient to look for the variation law during (i) the tool engagement phase, (ii) the complete machining of a tooth, and (iii) the tool disengagement phase.

Finding the variation law for detached chip area starts by determining the detached chip area for each increment of the toothing process, which corresponds to an increment of the rolling motion, respectively, to one kinematical cycle of the cutting motion. In order to do so, the next four-step algorithm must be followed:

- (a)

Firstly, the tool model is imported into the file which contains the workpiece model.

- (b)

The toothing process is then simulated by giving each of the two items (the cutting tool and the workpiece) the motion corresponding to the one increment of the rolling motion, after which the two items are overlapped.

- (c)

The option

Remove of Operation modeling tool [

22] is subsequently applied; thus, one item is subtracted from the other, the result being a new item, which is the workpiece from which the common region (corresponding to the detached chip) was eliminated.

- (d)

The detached chip area is, finally, calculated as the difference between the workpiece area that was measured before and after the intersection, by using the

Measure Item tool from the

Measure toolbar [

22].

Here, we must mention that the accuracy of the area measurement we thus achieved, if performed as suggested above, is 10−3 mm2.

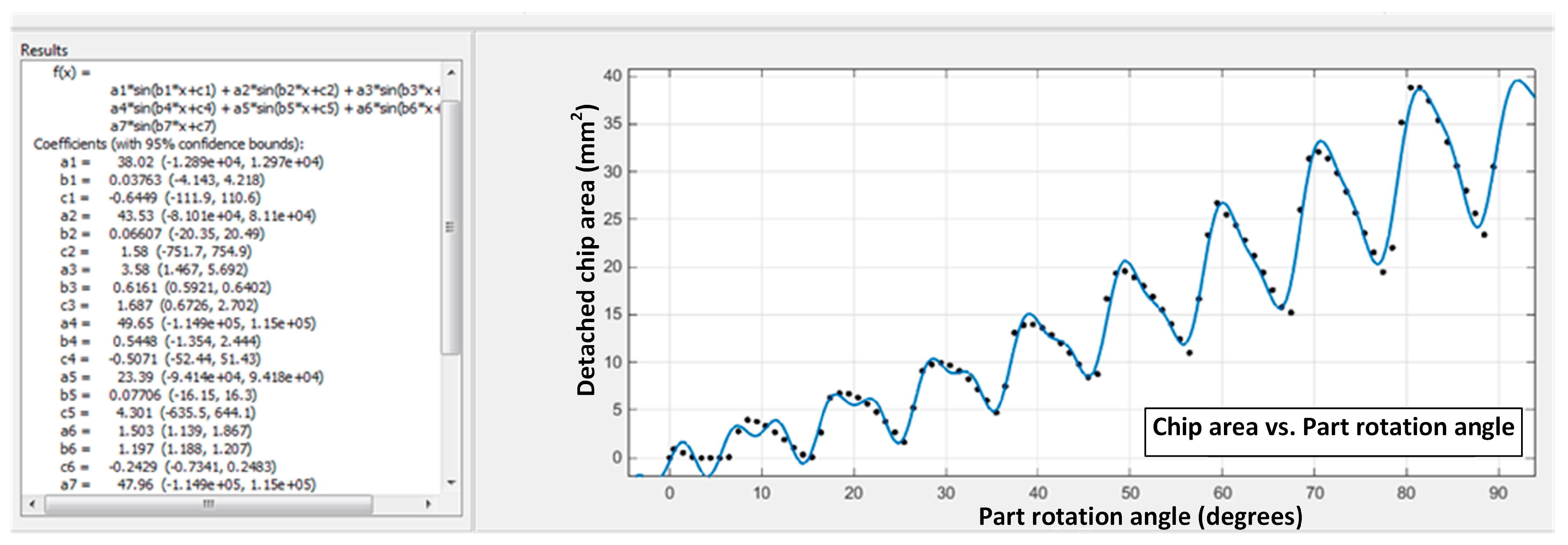

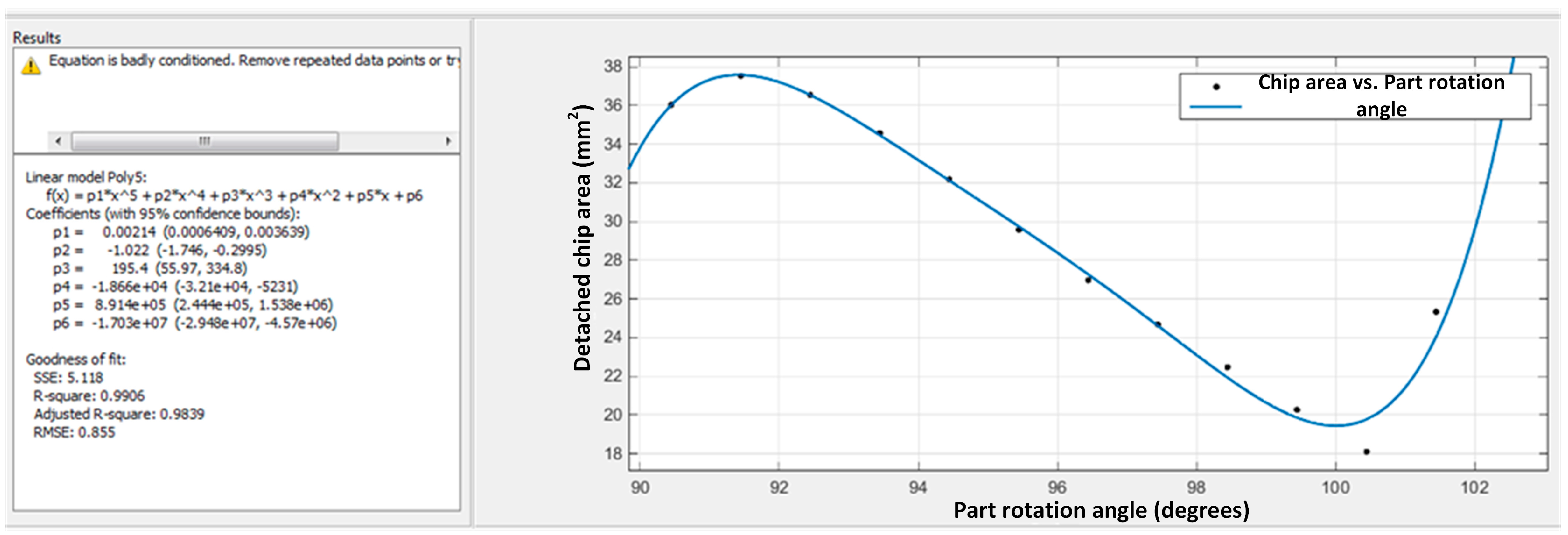

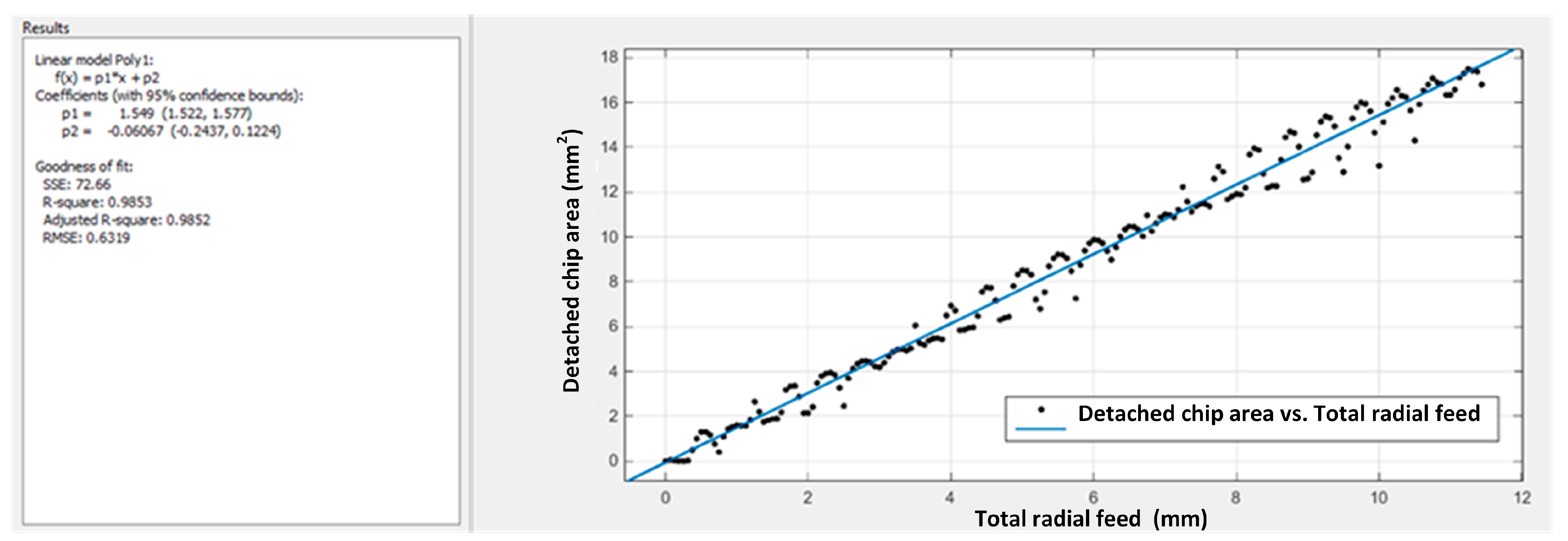

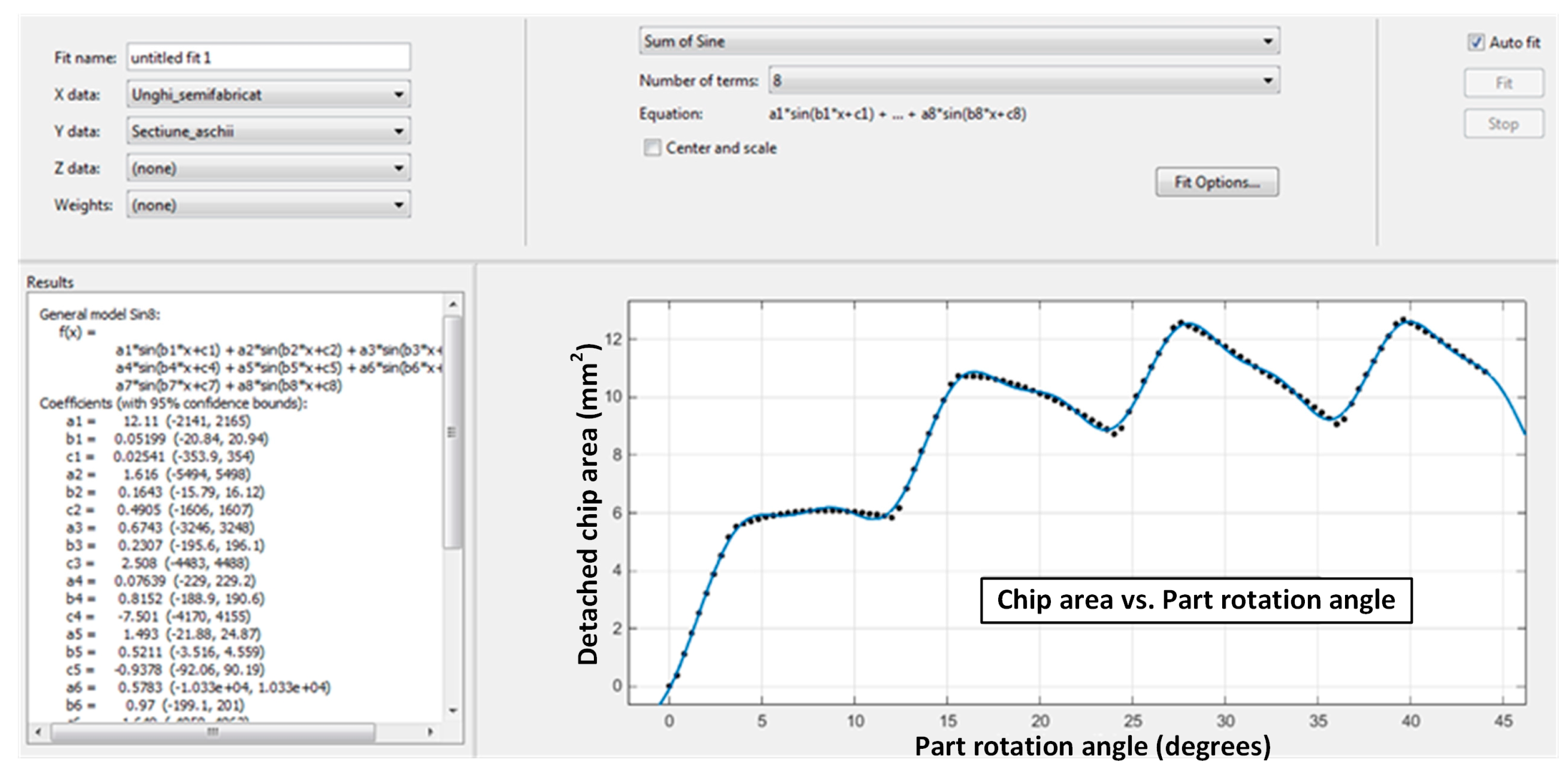

Since the next step requires an analytical expression of the variation law for the detached chip area

A, a function

f approximating the series of areas calculated from the first up to the last contact point between the cutting tool and the worked piece has to be found. The

Curve Fitting toolbox of MatLab may be used, for example, for this purpose [

24].

As in all the gearing processes addressed here, the worked piece has rotational motion, and the position of the coupled cutting tool and worked piece will be defined by the angle

φ made by the worked piece with a reference start position, corresponding to the first contact between the two elements (when

φ = φmin). Obviously, the maximum value

φmax, corresponding to the last contact, depends on the actual conditions of a given process. Thus, it can be written as

2.4. Finding the Feed Motion Variation Law

Let us suppose that the feed increment of the rolling motion corresponds to the workpiece rotation of ∆

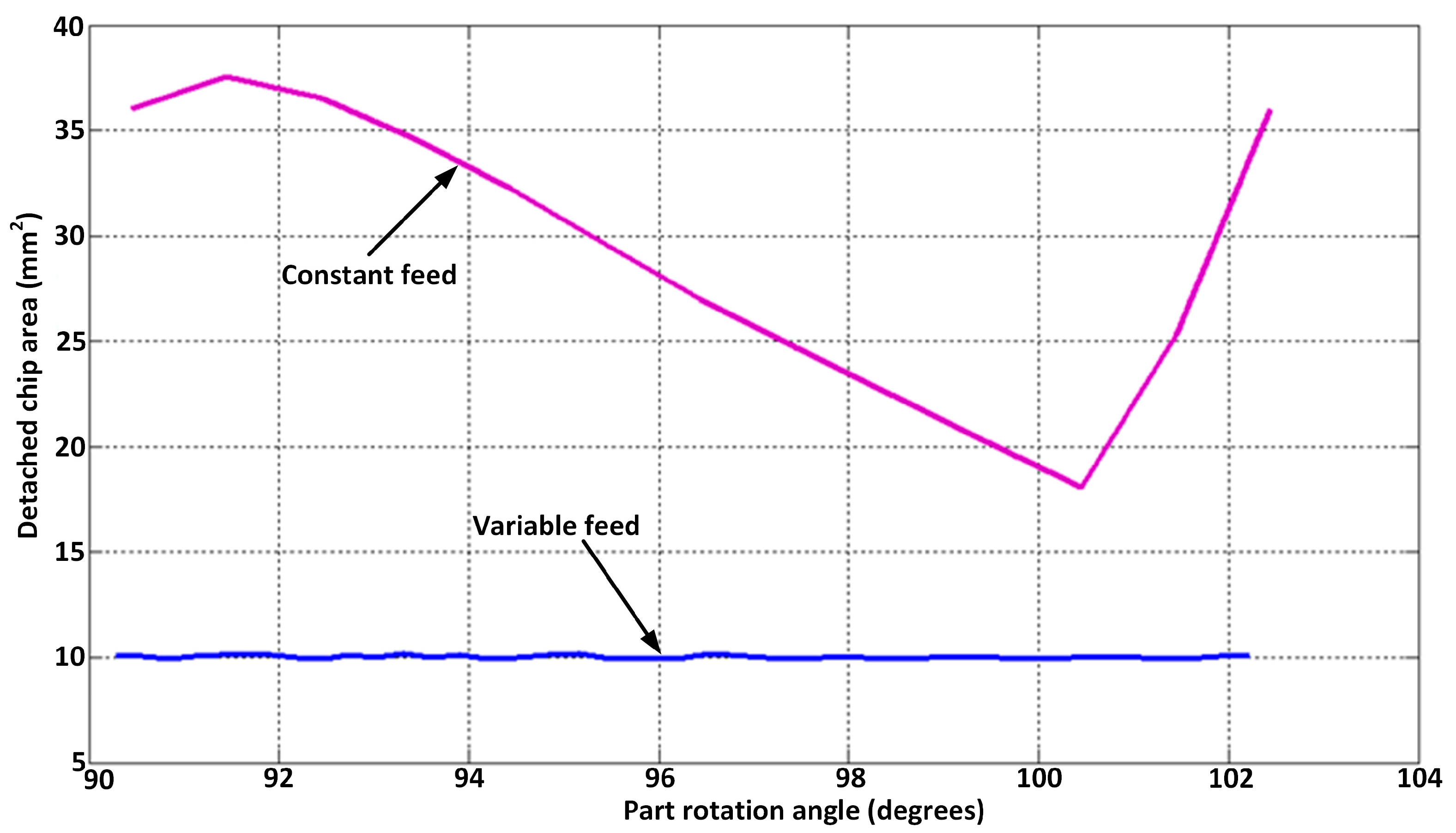

φ0 angle. If we intend to smooth the detached chip area to

Ac value for any

φ ∈ [

φmin … φmax], then the following relations are obtained:

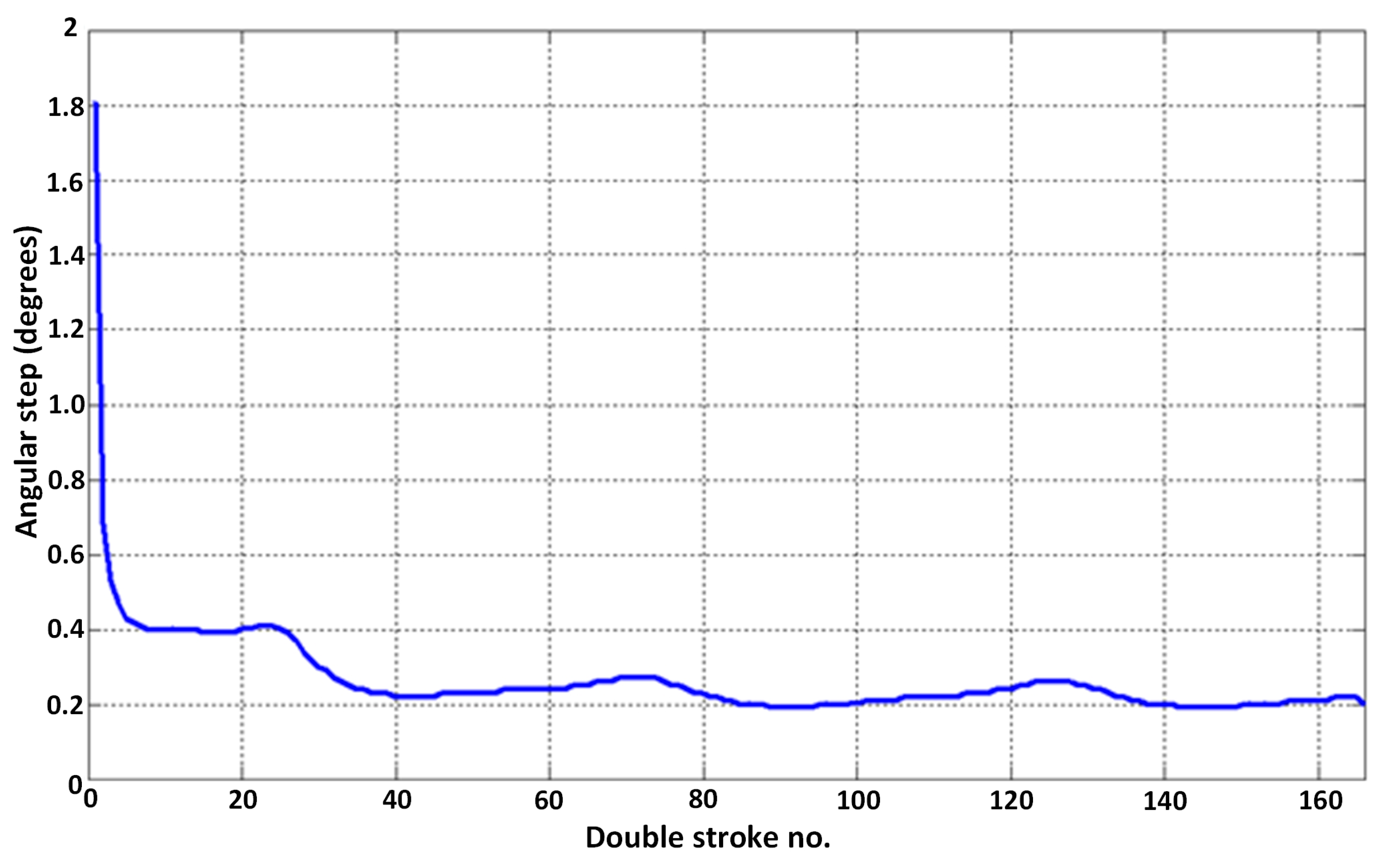

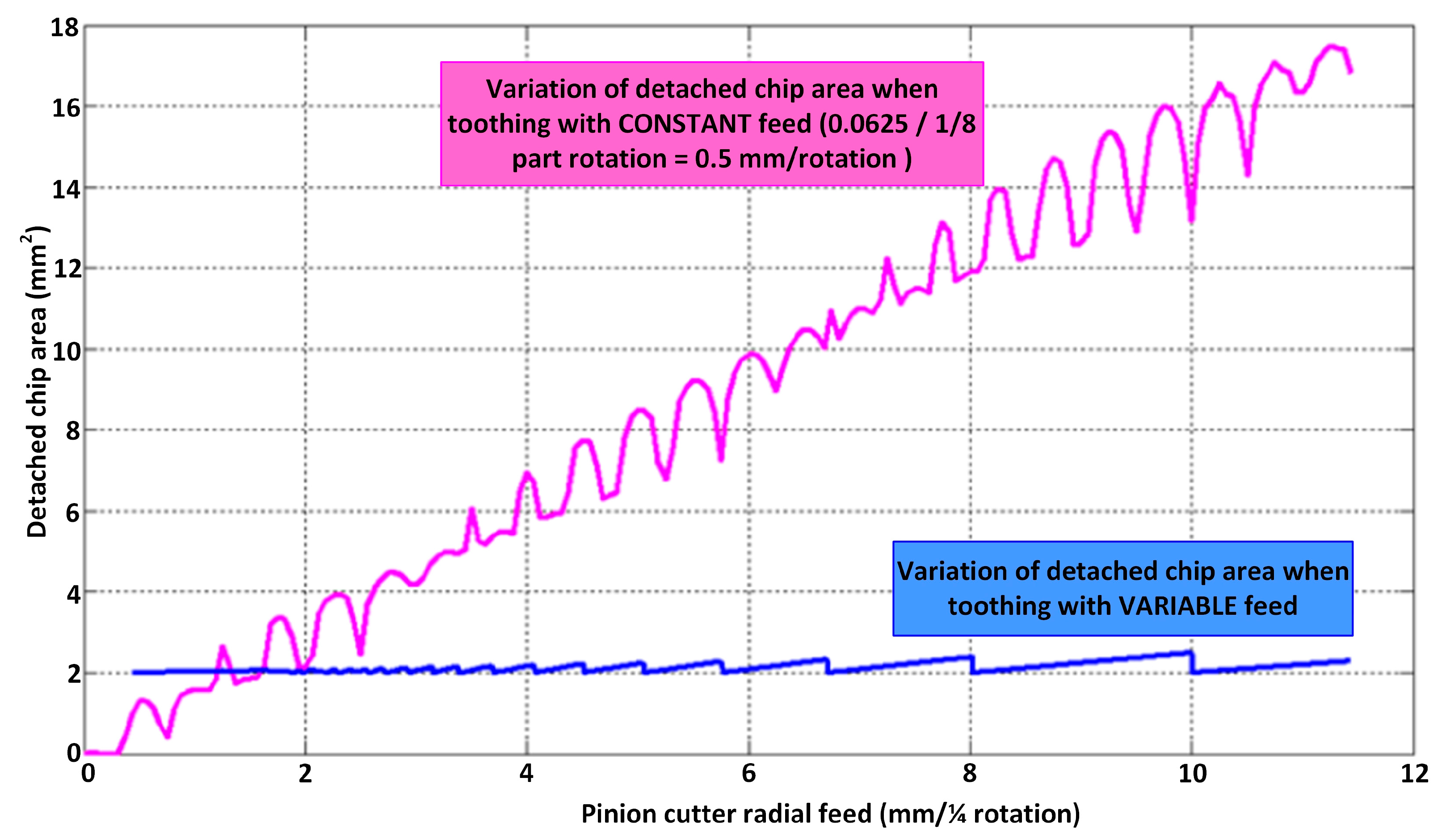

In Equation (2), ∆φ means the rolling motion increment (instead of ∆φ0) required to obtain the Ac value for the detached chip area (instead of A(φ)). Obviously, as f varies with φ, ∆φ also varies, so one can notice that smoothing the detached chip area means working with variable federate after an appropriate variation law. We have developed an original MatLab application to find this law in discrete form, the input data being:

- -

The limits of the variation domain for the workpiece position angle φ, φmin and φmax, corresponding to the machining of a gear tooth interval.

- -

The analytical expression of the f function, meaning the variation law for the detached chip area and the rolling motion increment ∆φ0, based on which this law was determined.

- -

The imposed value for the detached chip area, after variation smoothening, Ac.

- -

Some auxiliary variables, namely the incremental parameter dφ (∆φ following to be determined as ∆φ = i ∙ dφ, i = 1, 2, …), and the maximum admissible deviation from Ac for the value actually obtained of detached chip area Aca during the smoothened process, ε.

The application result consists of a series of (variable) values for the federate of the rolling motion, ∆

φ1, ∆

φ2, …, ∆

φns, such as

In Equation (3), ns means the number of kinematical steps needed for the complete machining of a gear tooth interval, which is obviously different from n number of steps completed when machining the same gear tooth interval with constant increments of the rolling motion, and ε means a quantitative parameter defining the width of the interval within which the detached chip area may vary. These parameters are not specifically related to any toothing method. The parameter ns is related to process productivity, while ε mainly impacts the computing speed of the software used in the method application. The parameters ns and ε should be set according to the manufacturer option.

4. Technical Solution for Method Implementation

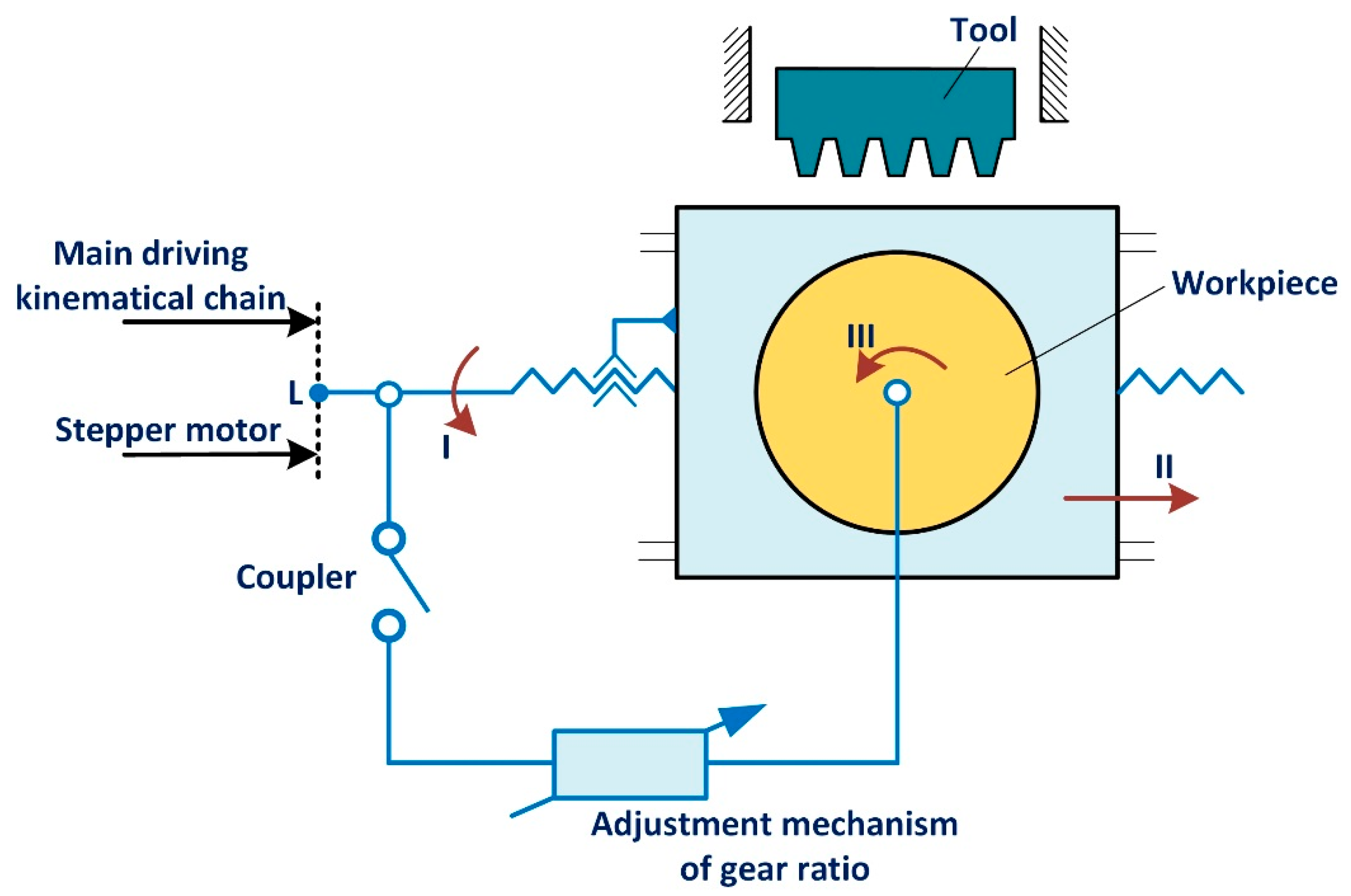

In the case of current toothing equipment, the gear pair located on the machine table ensures both the table translation (motion II) and plate rotation (motion III), as shown in

Figure 22, so that the rolling condition for obtaining involute teeth is realized according to part’s number of teeth and its module.

To implement the method for increasing the efficiency of the previously presented toothing process, the need to adapt the technological equipment must be considered so that the rotational and/or translational motions of the workpiece and the machine table should be controlled in order to vary the rolling motion speed.

Two alternatives for driving the machine table can be approached, which are different from the current mode (equal size steps, leading to the obtaining of detached chips with time-dependent variable sections).

The first alternative consists of actuating the machine table using an electric motor coupled to the connection point L between the mechanism located on the machine table and the classical actuation circuit (with which the kinematic communication will be interrupted). The advantage of this alternative lies in the fact that only one motor and its control circuit are used. Also, the tool vs. part rolling condition is preserved by means of the rigid connection between the two motions through the exchangeable gear pair.

This alternative, however, has the disadvantage that it requires a more powerful electric motor, which should be able to drive the entire mechanism of the table in motion.

The use of a motor, connected in this manner, ensures compliance with the rolling condition by using the wheels of the adjustment mechanisms used in the case of classical machining.

The second alternative consists of the use of two electric motors that generate separate and correlated motions I, (II), and III, respectively. Although the disadvantage would be the need to use two electric motors, with two control circuits, these motors can be smaller and implicitly have a lower purchase cost. Also, these motors, since they are actuated separately, can make the necessary division motion much easier during the workpiece machining.

After a trade-off, we propose, in what follows, the application of the first alternative.

To substitute the classic drive of the workpiece table and plate with an electric motor, the driving system must be chosen, and the set-up must be dimensioned.

The choice and dimensioning of the set-up are imposed by the technological process that is carried out. In this case, the type of electric motor and the set-up are established taking into account the following aspects:

- -

To be able to make frequent starts and stops, because the number of double strokes per minute made by the cutting tool is of the order of tens. On each double stroke, the motor must start, move, or rotate the table on a prescribed distance, and brake. At a speed of 30 double strokes/minute, the motor will have to make approximately 1800 starts/hour, which greatly limits the possibility of choosing the motor type.

- -

To consider the order of magnitude of the power required for operation, investment and exploitation expenses, yield, energy consumption, and others.

Since the motor drive is intermittent, the speed is chosen so that the kinetic energy stored in the motor–machine system is minimal.

When choosing the type of motor for the electrical actuation of the mechanism, theoretically, we can choose from a variety of motors (asynchronous, synchronous, three-phase, single-phase) operated by frequency converters, continuous current motors, and stepper motors.

The large number of starts/stops excludes the possibility of choosing alternative current motors, where the maximum frequency of connection is of the order of hundreds per hour, leaving continuous current motors and stepper motors to be considered.

The option of choosing a stepper motor is therefore proposed as it allows discrete (incremental) angular displacements of its mobile part (the rotor). Moreover, the stepper motor can be programmed to stop at any of these positions, or intermediate positions, when commanded in micro-step mode. It can also synchronize with the command pulses, operating without slippage and allowing sudden starts and stops without loss of steps and at adjustable speeds within very wide limits. In addition, if the sizing is carried out correctly and the specifications are respected, the stepper motor does not need feedback sensors, being able to work in an open loop, thus simplifying the electrical drive scheme. The motion of the motor is enacted with each received command pulse, performing point-by-point positioning. The values of plate displacements having to be made for each tool’s double stroke are introduced into the system using specialized software installed on a computer connected to the control panel of the electric motor.

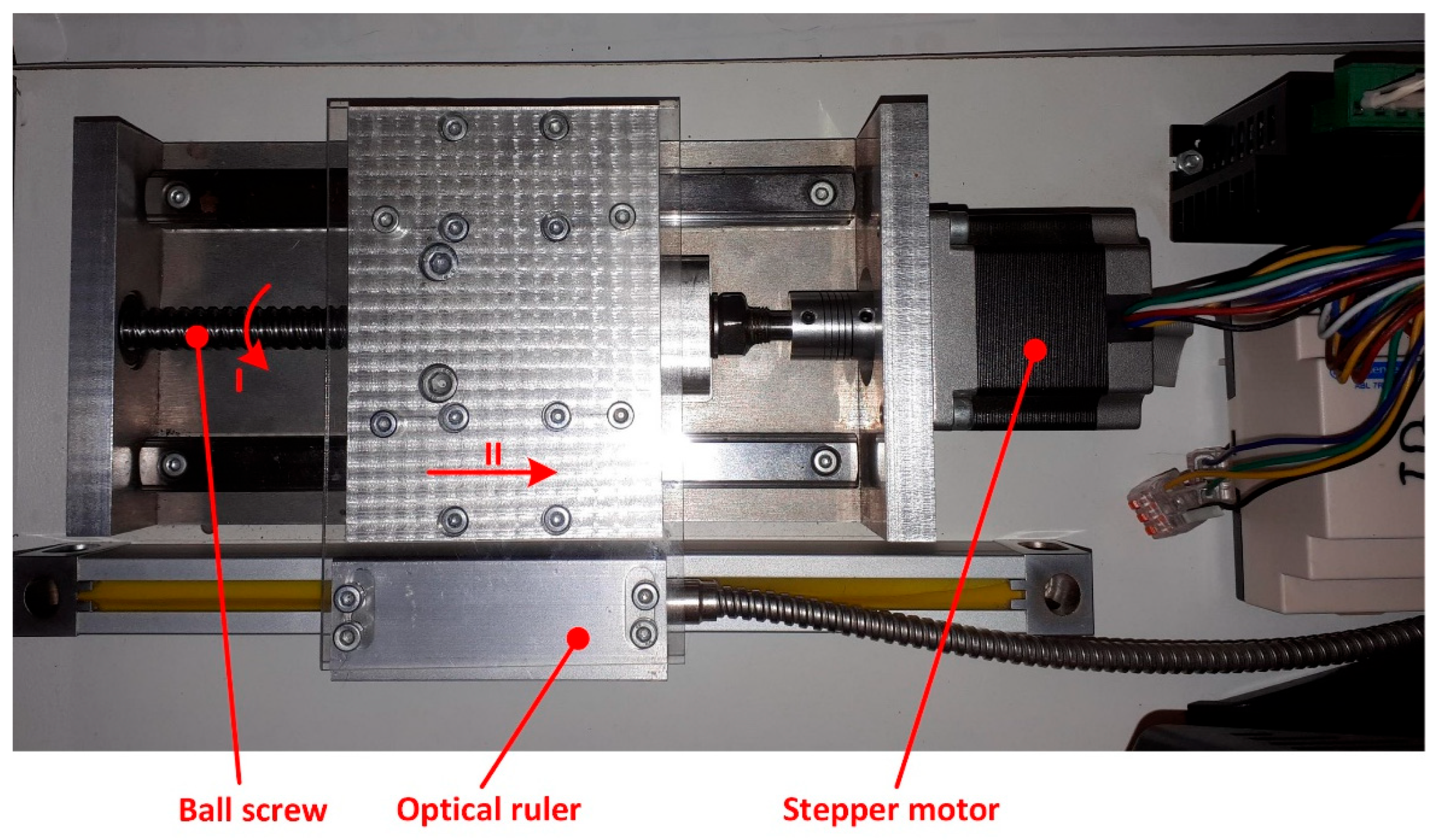

To validate the proposed solution of controlled actuation of a slotting machine table, an experimental stand was designed and executed (

Figure 23) on which controlled motions of the mechanism for translation according to a given law could be obtained.

The experimental set-up contains a translation mechanism actuated by a stepper motor, which is controlled with a DM542H driver (

Figure 24), whose settings allow the obtaining of micro steps up to 360°/25,600 = 0°0′50.63″, so less than a 1′ arc. The driver was powered with a direct voltage obtained from a 220 V AC source/24 V DC, able to provide the required current, so that there is no loss of steps at the motor axis, with bad influences on the accuracy of command execution.

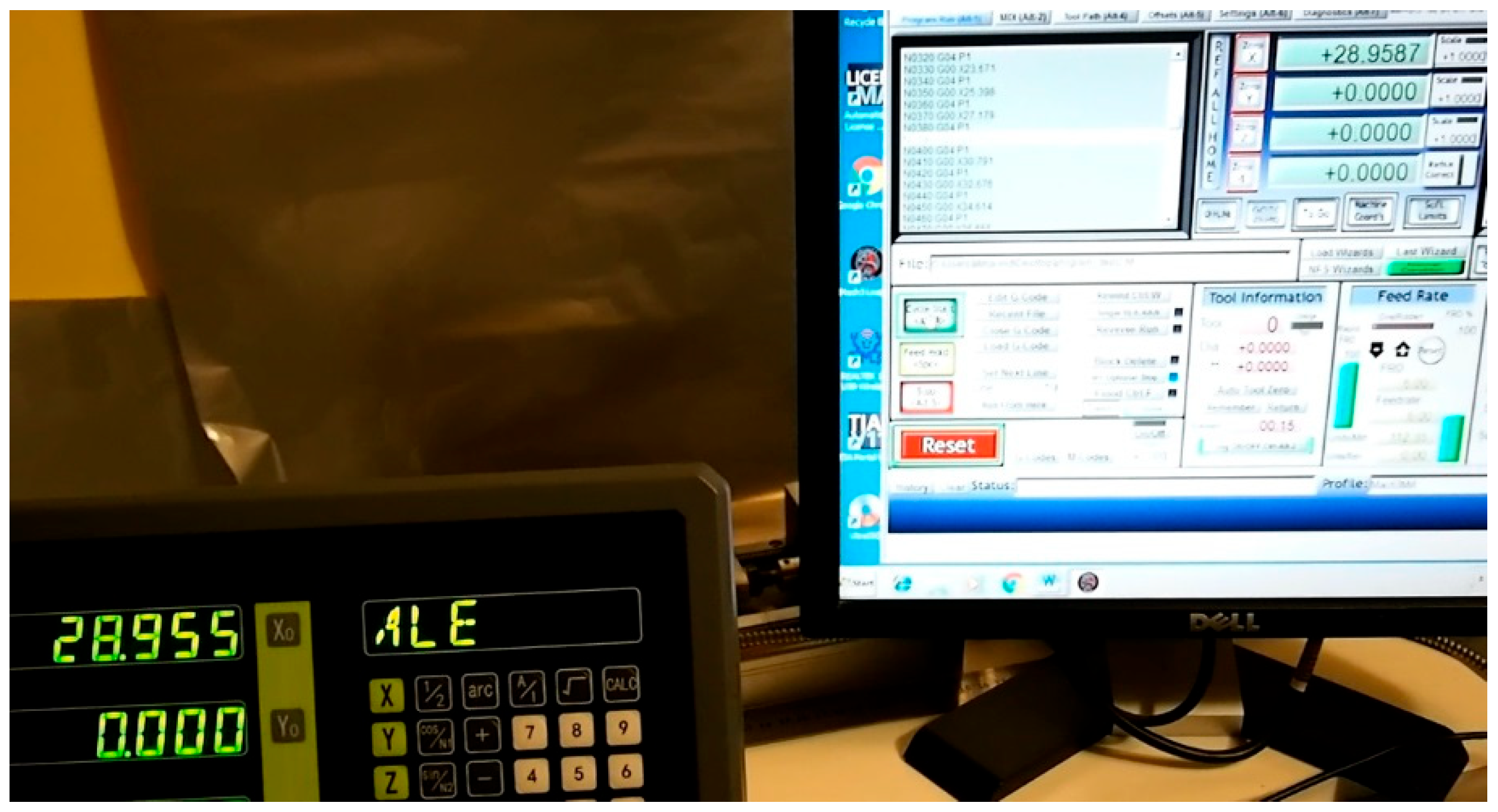

The driving was controlled through the Mach3 software version 3.043.066 installed on a computer that was connected to the stand through the parallel interface (

Figure 25).

The confirmation of displacement accuracy was obtained by actual measurement using a type RV 1846 optical ruler with a resolution of 5 μm mechanically fixed to the movable element of the mechanism and connected to a reading system (see

Figure 23). In addition, to make the axial clearance as small as possible, the movable element was connected to the stepper motor shaft by means of a ball screw, with a pitch of 4 mm.

These components allowed for great motion accuracy, with a 10 μm gear clearance when changing the direction of motion. As the motion is in one direction during the generation of a tooth gap, this clearance can be picked up by the positioning motions.

The tests we carried out showed the feasibility of applying the proposed solution in order to obtain the table motion (motion II,

Figure 22) according to a law resulting from the application of the method of smoothing the detached chip area.

For this purpose, successive intermittent motions of the table were measured (with an optical ruler) and compared with the necessary/imposed ones. The results confirmed the coincidence between these values (with the maximum error of 10 μm).

5. Conclusions

Taking into account the increasing importance of sustainability principles in manufacturing activity, this work presents an original method for improving the energy efficiency of toothing processes.

The method is exemplified in the case of machining involute cylindrical gears with straight teeth by using tools such as the rack tool and the pinion cutter, as well as for machining involute worms with a pinion cutter.

The principle of the method is, however, generally applicable to the processing of any type of tooth and consists of equalizing the magnitude of the cutting force by equalizing the area of the successively detached chip. In order to achieve this result, the modeling of the detached chips area, in the case of conventional processing, with constant feed in the rolling motion, must be carried out first. In the case of the proposed method, this modeling was carried out graphically by means of the CATIA V5R21 dedicated software. Based on the obtained model, the variation law of the feed in the rolling motion is then determined, with the help of specially designed MatLab applications, which, if respected, leads to the detachment of successive chips of quasi-constant area, the size of which is set a priori, depending on technical–economic criteria.

The addressed case studies validated the feasibility of the method application. The work also presents a solution for the practical implementation of the method on conventional toothing machines.

Future research will focus on the application of the method to the processing of other types of teeth (for example, the tooth of involute gears with inclined teeth), or the use of other toothing tools (for example, the worm-milling tool).