Enhanced Crashworthiness Parameters of Nested Thin-Walled Carbon Fiber-Reinforced Polymer and Al Structures: Effect of Using Expanded Polypropylene Foam

Abstract

1. Introduction

2. Materials and Experimental Studies

3. Crashworthiness Parameters

4. Results and Discussion

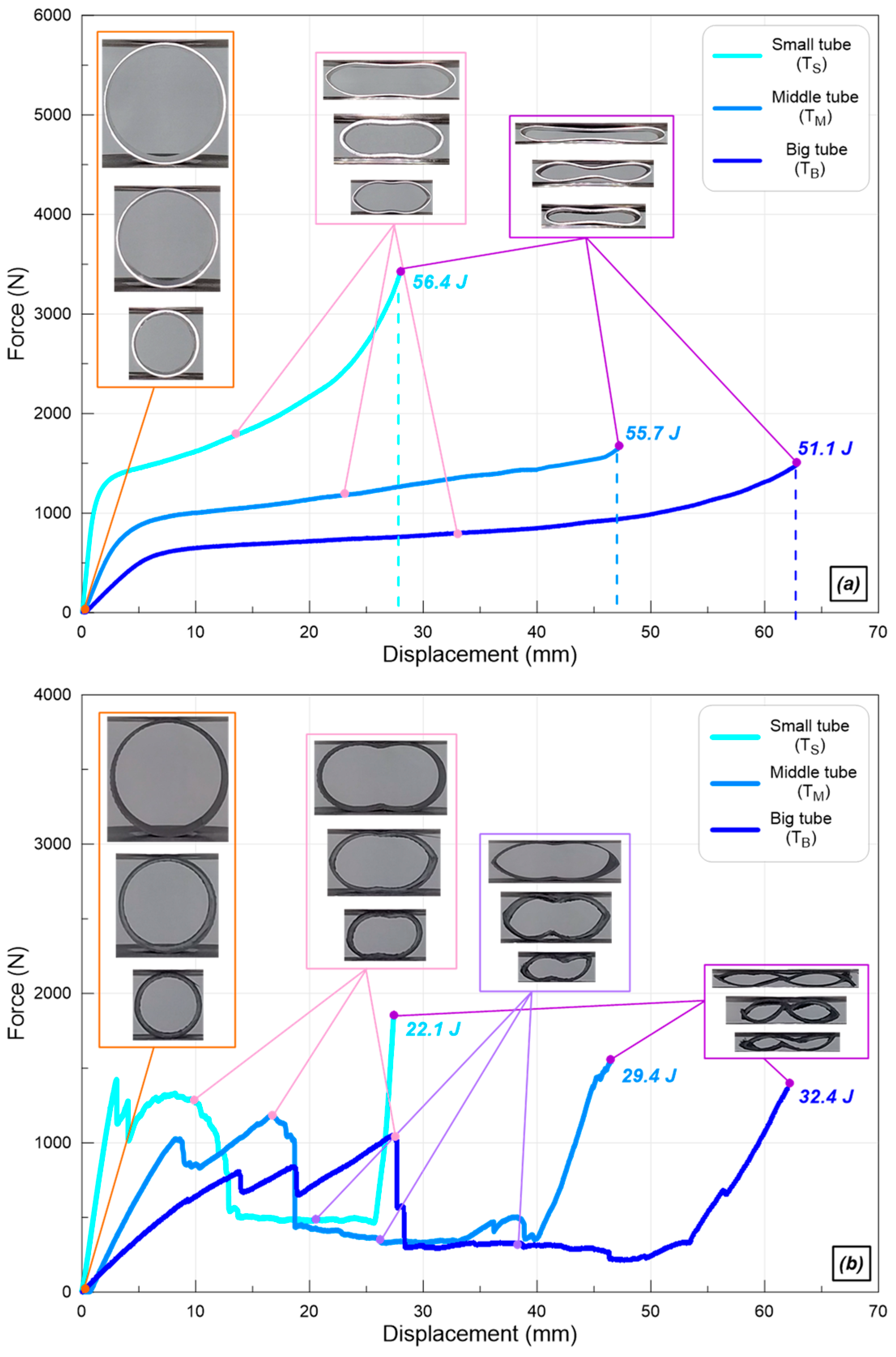

4.1. Single Tubes

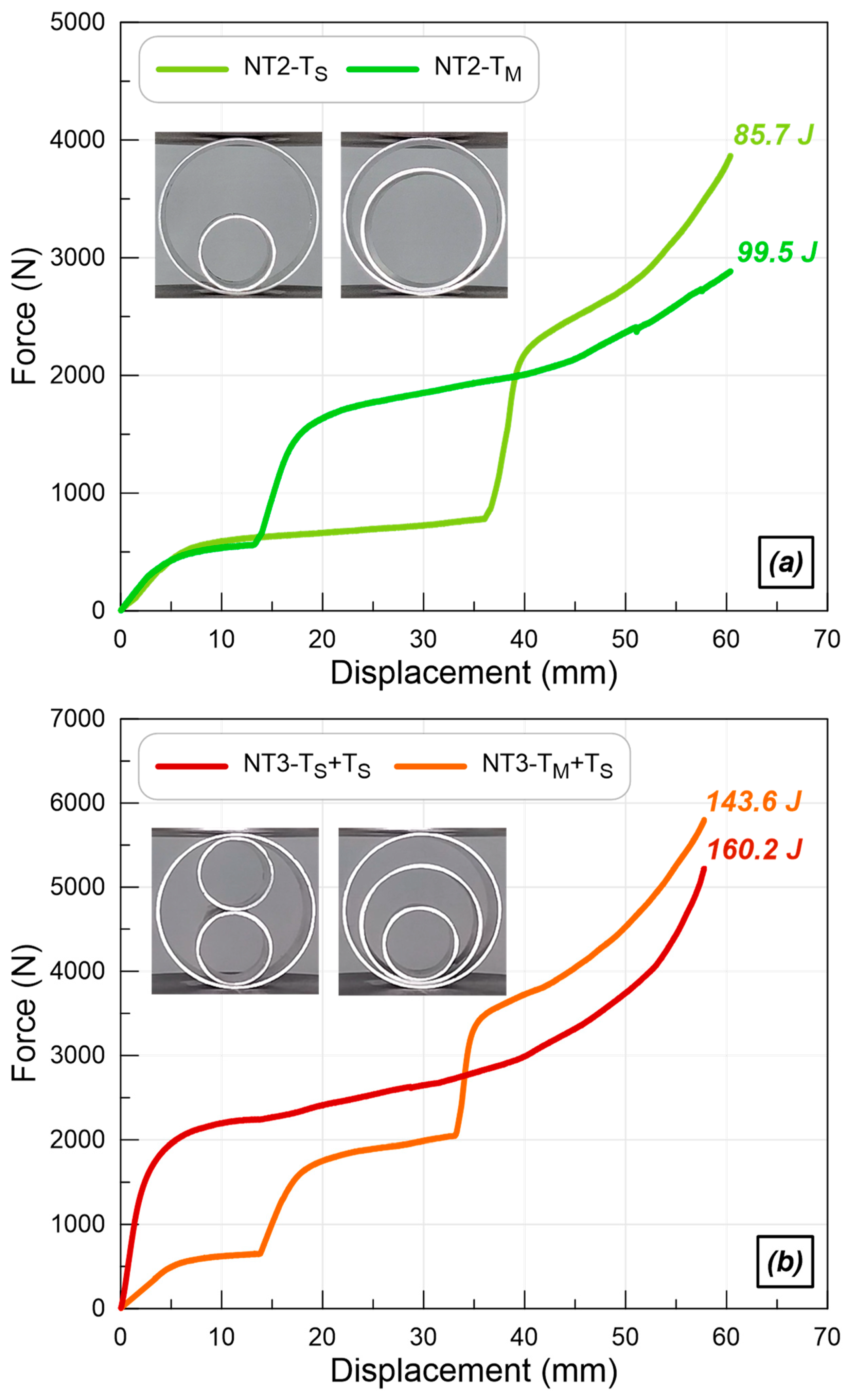

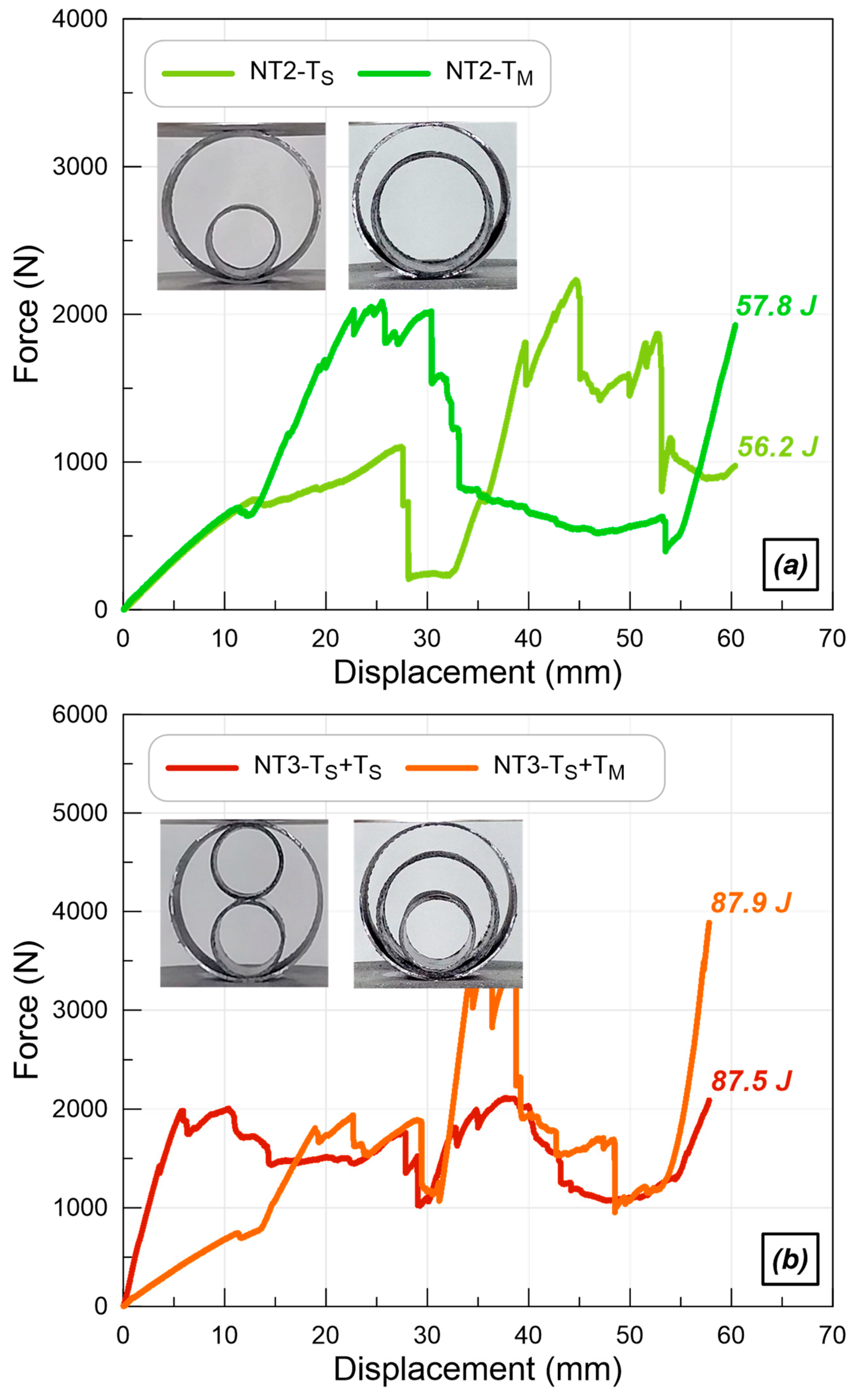

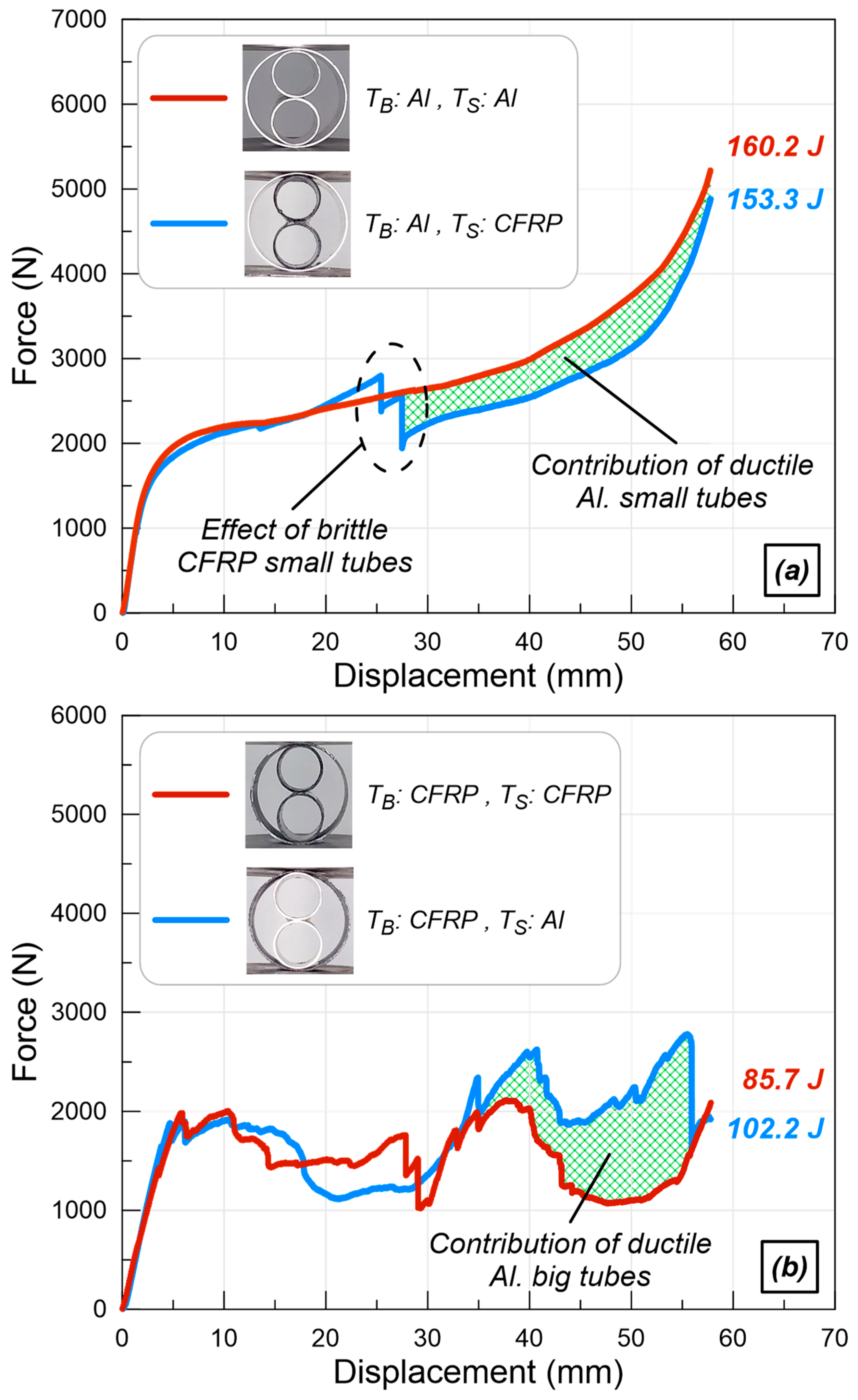

4.2. Nested Tubes

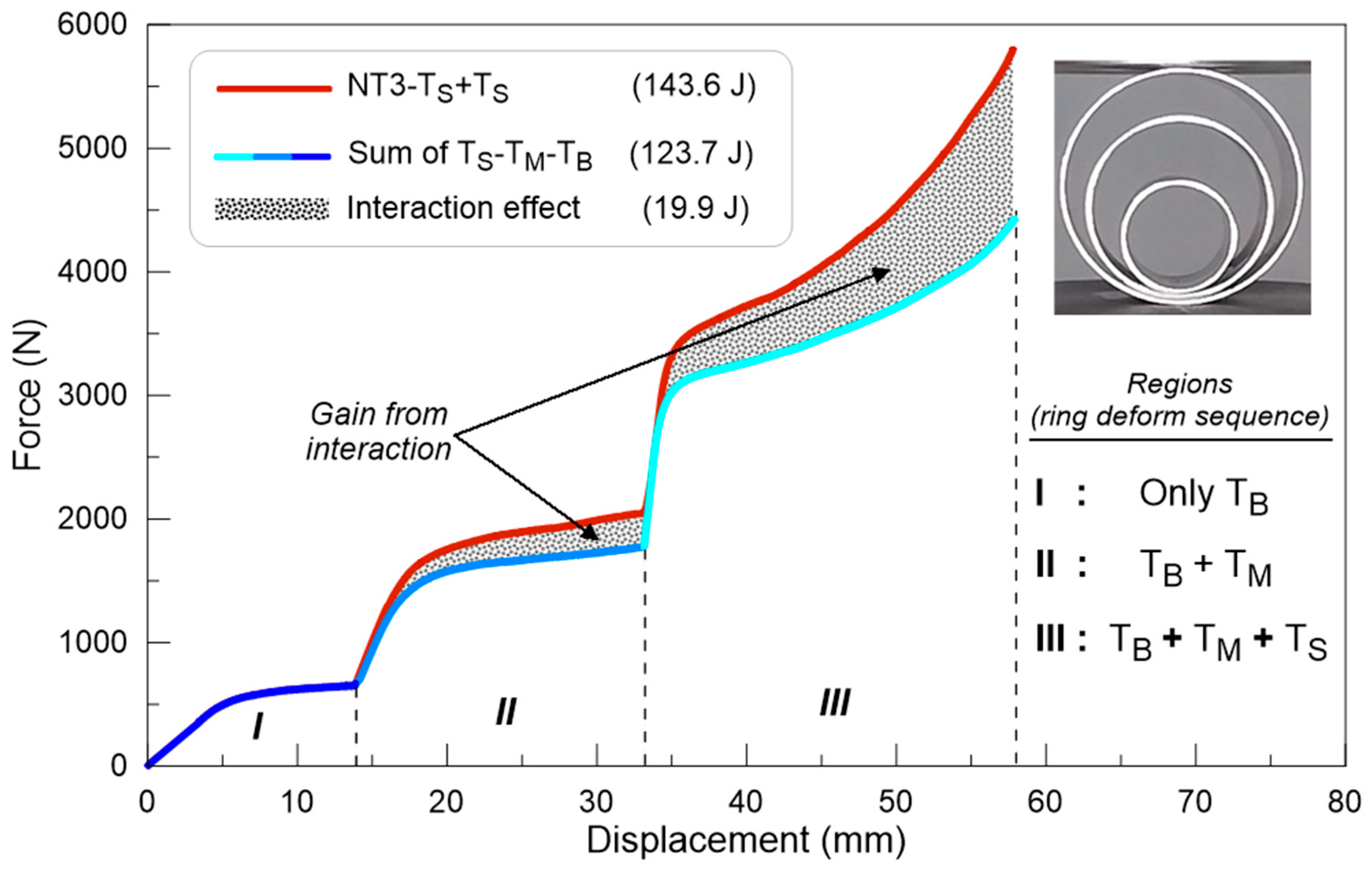

4.3. The Interaction Occurred in the Nested Sample

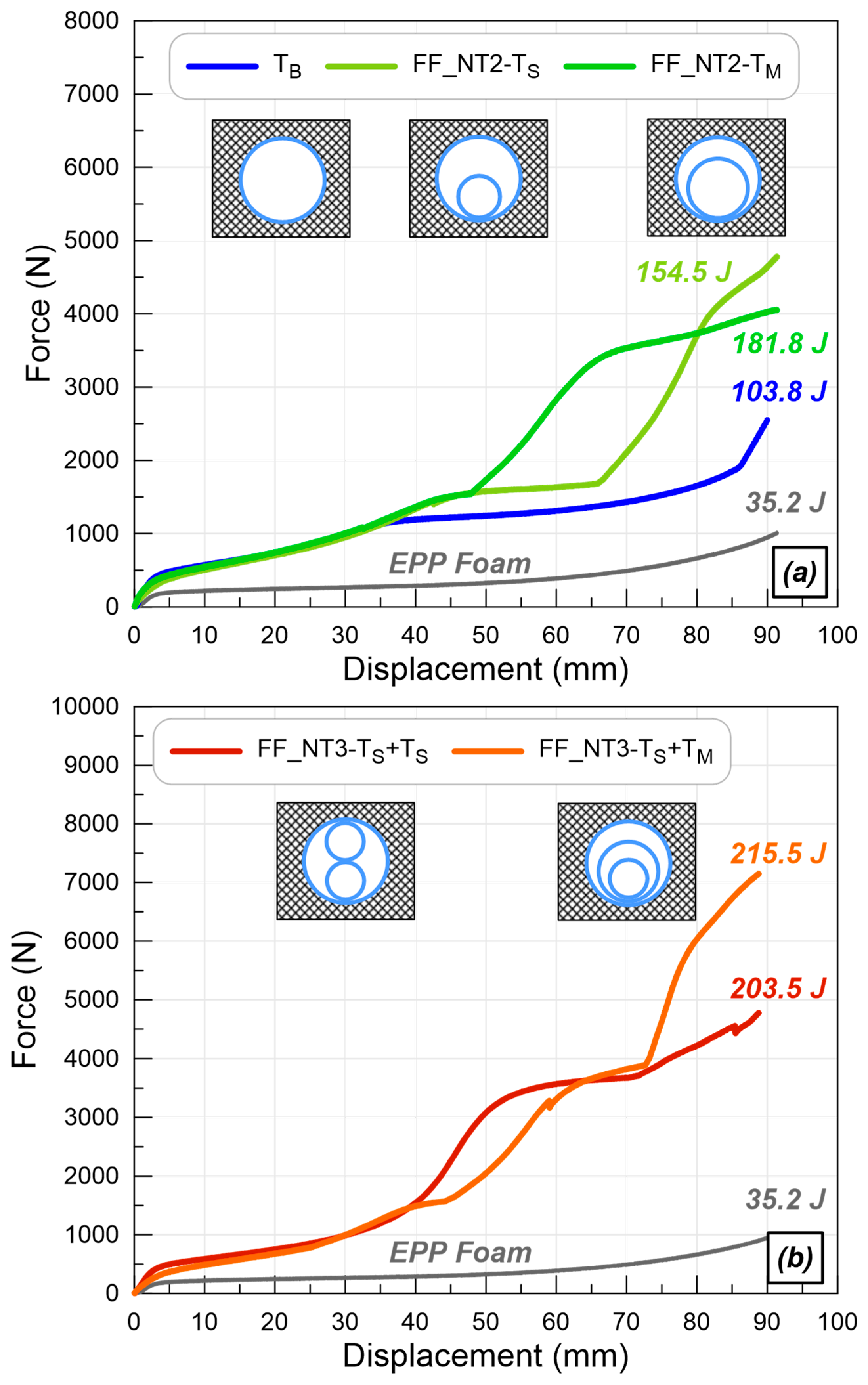

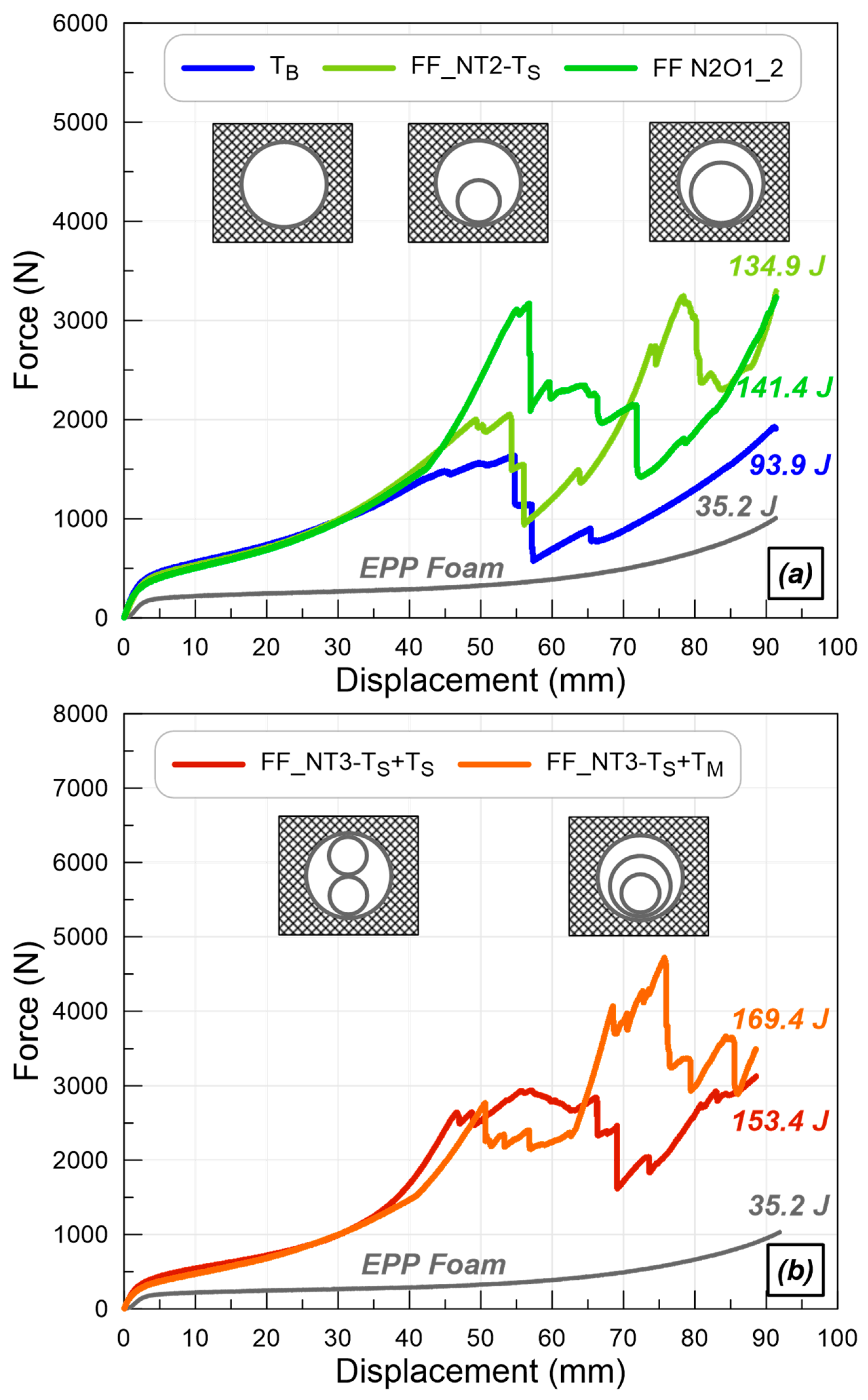

4.4. Nested Tube-Reinforced EPP Foams

4.5. Crashworthiness

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Tran, T.; Hou, S.; Han, X.; Nguyen, N.; Chau, M. Theoretical prediction and crashworthiness optimization of multi-cell square tubes under oblique impact loading. Int. J. Mech. Sci. 2014, 89, 177–193. [Google Scholar] [CrossRef]

- Nia, A.A.; Chahardoli, S. Mechanical behavior of nested multi-tubular structures under quasi-static axial load. Thin-Walled Struct. 2016, 106, 376–389. [Google Scholar] [CrossRef]

- Usta, F.; Türkmen, H.S. Experimental and numerical investigation of impact behavior of nested tubes with and without honeycomb filler. Thin-Walled Struct. 2019, 143, 106256. [Google Scholar] [CrossRef]

- Wang, Y.; He, Q.; Li, L.; Jiang, Y. Mechanical properties of a novel nested tube and its application as anti-explosion layer. Mater. Today Commun. 2022, 31, 103242. [Google Scholar] [CrossRef]

- Yang, K.; Chen, Y.; Liu, S.; Qiao, C.; Yang, J. Internally nested self-locked tube system for energy absorption. Thin-Walled Struct. 2017, 119, 371–384. [Google Scholar] [CrossRef]

- Baroutaji, A.; Sajjia, M.; Olabi, A.-G. On the crashworthiness performance of thin-walled energy absorbers: Recent advances and future developments. Thin-Walled Struct. 2017, 118, 137–163. [Google Scholar] [CrossRef]

- Magliaro, J.; Altenhof, W.; Alpas, A.T. A review of advanced materials, structures and deformation modes for adaptive energy dissipation and structural crashworthiness. Thin-Walled Struct. 2022, 180, 109808. [Google Scholar] [CrossRef]

- Dehghanpour, S.; Safari, K.H.; Barati, F.; Attar, M.M. Comparative Analysis of Energy Absorption Capacity of Single and Nested Metal Matrix Composite Tubes Under Quasi-Static Lateral and Axial Loading. J. Solid Mech. 2021, 13, 134–143. [Google Scholar] [CrossRef]

- Yao, R.; Pang, T.; Zhang, B.; Fang, J.; Li, Q.; Sun, G. On the crashworthiness of thin-walled multi-cell structures and materials: State of the art and prospects. Thin-Walled Struct. 2023, 189, 110734. [Google Scholar] [CrossRef]

- Wang, H.; Yang, J.; Liu, H.; Sun, Y.; Xu, T.X. Internally nested circular tube system subjected to lateral impact loading. Thin-Walled Struct. 2015, 91, 72–81. [Google Scholar] [CrossRef]

- Xu, B.; Wang, C.; Xu, W. An efficient energy absorber based on fourfold-tube nested circular tube system. Thin-Walled Struct. 2019, 137, 143–150. [Google Scholar] [CrossRef]

- Wang, Y.; Zhai, X.; Liu, S.; Lu, J.; Zhou, H. Energy absorption performance of a new circular–triangular nested tube and its application as sacrificial cladding. Thin-Walled Struct. 2020, 157, 106992. [Google Scholar] [CrossRef]

- Ying, L.; Wang, S.; Gao, T.; Dai, M.; Hu, P.; Wang, Y. Crashworthiness analysis and optimization of multi-functional gradient foam-aluminum filled hierarchical thin-walled structures. Thin-Walled Struct. 2023, 189, 110906. [Google Scholar] [CrossRef]

- Al Galib, D.; Limam, A. Experimental and numerical investigation of static and dynamic axial crushing of circular aluminum tubes. Thin-Walled Struct. 2004, 42, 1103–1137. [Google Scholar] [CrossRef]

- Mahdi, E.-S.; El Kadi, H. Crushing behavior of laterally compressed composite elliptical tubes: Experiments and predictions using artificial neural networks. Compos. Struct. 2008, 83, 399–412. [Google Scholar] [CrossRef]

- Elahi, S.A.; Rouzegar, J.; Niknejad, A.; Assaee, H. Theoretical study of absorbed energy by empty and foam-filled composite tubes under lateral compression. Thin-Walled Struct. 2017, 114, 1–10. [Google Scholar] [CrossRef]

- Niknejad, A.; Elahi, S.A.; Liaghat, G.H. Experimental investigation on the lateral compression in the foam-filled circular tubes. Mater. Des. 2012, 36, 24–34. [Google Scholar] [CrossRef]

- Ding, H.; Zhu, G.; Xiang, C.; Pei, F.; Chen, J.; Wang, Y.; Chen, Q. Excellent combination of plasticity and ultra-high strength in a low-alloy automotive steel treated by conventional continuous annealing. Mater. Sci. Eng. A 2020, 791, 139694. [Google Scholar] [CrossRef]

- Adanur, Ö.; Varol, F. Investigation of the effect of friction force on the energy absorption characteristics of thin-walled structures loaded with axial impact force. Mater. Today Commun. 2023, 36, 106420. [Google Scholar] [CrossRef]

- Dubey, P.P.; Rex, A.V.; Raj, A.; Paul, S.K. Influence of pre-strain on tensile response of extra deep drawing (EDD) steel under varying strain rates and crash performance. J. Alloy. Met. Syst. 2023, 4, 100036. [Google Scholar] [CrossRef]

- Shabani, B.; Rad, S.G.; Alijani, A.; Darvizeh, A.; Rajabiehfard, R. Dynamic plastic behavior of single and nested rings under lateral impact. Thin-Walled Struct. 2021, 160, 107373. [Google Scholar] [CrossRef]

- Olabi, A.G.; Morris, E.; Hashmi, M.S.J.; Gilchrist, M.D. Optimised design of nested circular tube energy absorbers under lateral impact loading. Int. J. Mech. Sci. 2008, 50, 104–116. [Google Scholar] [CrossRef]

- Baroutaji, A.; Gilchrist, M.D.; Olabi, A.G. Quasi-static, impact and energy absorption of internally nested tubes subjected to lateral loading. Thin-Walled Struct. 2016, 98, 337–350. [Google Scholar] [CrossRef]

- Kahraman, Y.; Akdikmen, O. Experimental investigation on deformation behavior and energy absorption capability of nested steel tubes under lateral loading. Eng. Sci. Technol. Int. J. 2021, 24, 579–588. [Google Scholar] [CrossRef]

- Atxaga, G.; Arroyo, A.; Canflanca, B. Hot stamping of aerospace aluminium alloys: Automotive technologies for the aeronautics industry. J. Manuf. Process. 2022, 81, 817–827. [Google Scholar] [CrossRef]

- Hatzigeorgiou, G.D.; Beskos, D.E. Minimum cost design of fibre-reinforced concrete-filled steel tubular columns. J. Constr. Steel Res. 2005, 61, 167–182. [Google Scholar] [CrossRef]

- Wu, J.; Zhang, Y.; Li, J.; Lai, X.; Duan, N. Energy absorption characteristics of nested corrugated-elliptical tubes subjected to a lateral crushing load. Compos. Struct. 2022, 297, 115926. [Google Scholar] [CrossRef]

- Yang, X.; Ma, J.; Sun, Y.; Yang, J. An internally nested circular-elliptical tube system for energy absorption. Thin-Walled Struct. 2019, 139, 281–293. [Google Scholar] [CrossRef]

- Altin, M.; Acar, E.; Güler, M.A. Foam filling options for crashworthiness optimization of thin-walled multi-tubular circular columns. Thin-Walled Struct. 2018, 131, 309–323. [Google Scholar] [CrossRef]

- Altin, M.; Güler, M.A.; Mert, S.K. The effect of percent foam fill ratio on the energy absorption capacity of axially compressed thin-walled multi-cell square and circular tubes. Int. J. Mech. Sci. 2017, 131–132, 368–379. [Google Scholar] [CrossRef]

- Wang, S.; Zhang, M.; Pei, W.; Yu, F.; Jiang, Y. Energy-absorbing mechanism and crashworthiness performance of thin-walled tubes diagonally filled with rib-reinforced foam blocks under axial crushing. Compos. Struct. 2022, 299, 116149. [Google Scholar] [CrossRef]

- Xu, B.; Wang, C.; Yuen, S.C.K. Deformation Pattern and Energy Absorption Characteristics of A Four-Tube Nested System Under Lateral and Oblique Loadings. Lat. Am. J. Solids Struct. 2021, 18, e388. [Google Scholar] [CrossRef]

- Wang, Y.; Zhang, R.; Liu, S.; Zhai, X.; Zhi, X. Energy absorption behaviour of an aluminium foam-filled circular-triangular nested tube energy absorber under impact loading. Structures 2021, 34, 95–104. [Google Scholar] [CrossRef]

- Zhang, W.; Xu, J. Advanced lightweight materials for Automobiles: A review. Mater. Des. 2022, 221, 110994. [Google Scholar] [CrossRef]

- Fontana, M.; Araujo, A.L.; Madeira, J.F.A. Optimization of a thin-walled composite crash absorber. Thin-Walled Struct. 2020, 155, 106826. [Google Scholar] [CrossRef]

- Sun, G.; Chen, D.; Zhu, G.; Li, Q. Lightweight hybrid materials and structures for energy absorption: A state-of-the-art review and outlook. Thin-Walled Struct. 2022, 172, 108760. [Google Scholar] [CrossRef]

- Patel, V.; Tiwari, G.; Dumpala, R. Review of the crushing response of collapsible tubular structures. Front. Mech. Eng. 2020, 15, 438–474. [Google Scholar] [CrossRef]

- Magliaro, J.; Rahimidehgolan, F.; Altenhof, W.; Alpas, A.T. Superior energy dissipation mechanisms compounded within composite AA6061/H130 foam structures. Int. J. Mech. Sci. 2023, 238, 107843. [Google Scholar] [CrossRef]

- Gupta, N.K.; Sekhon, G.S.; Gupta, P.K. Study of lateral compression of round metallic tubes. Thin-Walled Struct. 2005, 43, 895–922. [Google Scholar] [CrossRef]

- Zhang, Z. Theoretical prediction of cross-sectional deformation of circular thin-walled tube in large elastic–plastic deformation stage under lateral compression. Thin-Walled Struct. 2022, 180, 109957. [Google Scholar] [CrossRef]

- Kumar, A.P.; Nagarjun, J.; Ma, Q. Potentiality of MWCNT fillers on the lateral crashworthiness behaviour of polymer composite cylindrical tubes under quasi-static loading. J. Ind. Text. 2022, 51, 7014S–7033S. [Google Scholar] [CrossRef]

- Sun, G.; Guo, X.; Li, S.; Ruan, D.; Li, Q. Comparative study on aluminum/GFRP/CFRP tubes for oblique lateral crushing. Thin-Walled Struct. 2020, 152, 106420. [Google Scholar] [CrossRef]

- Wazeer, A.; Das, A.; Abeykoon, C.; Sinha, A.; Karmakar, A. Composites for electric vehicles and automotive sector: A review. Green Energy Intell. Transp. 2022, 2, 100043. [Google Scholar] [CrossRef]

- Tran, T.N.; Le, D.H.; Baroutaji, A. Theoretical and numerical crush analysis of multi-stage nested aluminium alloy tubular structures under axial impact loading. Eng. Struct. 2019, 182, 39–50. [Google Scholar] [CrossRef]

- Bhutada, S.; Goel, M.D. Crashworthiness parameters and their improvement using tubes as an energy absorbing structure: An overview. Int. J. Crashworthiness 2021, 1–32. [Google Scholar] [CrossRef]

- Alagesan, P.K.; Dirgantara, T.; Jusuf, A.; Gladys, A.K.; Ma, Q. Comparison of the lateral crushing response of thin-walled aluminum-thermoplastic polymer composite cylindrical shells. Mech. Adv. Mater. Struct. 2024. [Google Scholar] [CrossRef]

- Yang, H.; Guo, X.; Wang, H.; Qu, J.; Ma, Y.; Lei, H.; Chen, H. Low-velocity impact performance of composite-aluminum tubes prepared by mesoscopic hybridization. Compos. Struct. 2021, 274. [Google Scholar] [CrossRef]

- Yang, H.; Ren, Y. On energy absorption capability and controllable failure modes of CFRP circular tube using numerical simulation. Thin-Walled Struct. 2024, 205. [Google Scholar] [CrossRef]

| NT2-TS | |||

|  |  |  |

| NT2-TM | |||

|  |  |  |

| NT3-TS+TS | |||

|  |  |  |

| NT3-TM+TS | |||

|  |  |  |

| NT2-TS | |||

|  |  |  |

| NT2-TM | |||

|  |  |  |

| NT3-TS+TS | |||

|  |  |  |

| NT3-TM+TS | |||

|  |  |  |

| FF_NT2-TS | ||||

|  |  |  |  |

| FF_NT2-TM | ||||

|  |  |  |  |

| FF_NT3-TS+TS | ||||

|  |  |  |  |

| FF_NT3-TS+TM | ||||

|  |  |  |  |

| FF_NT2-TS | ||||

|  |  |  |  |

| FF_NT2-TM | ||||

|  |  |  |  |

| FF_NT3-TS+TS | ||||

|  |  |  |  |

| FF_NT3-TS+TM | ||||

|  |  |  |  |

| Sample Combination | Crushability Ratio, eg, (mm/mm) | Sample Weight (g) | Fmean (N) | Fmax (N) | Absorbed Energy, EA, (J) | Specific Energy Absorption, SEA, (J/g) | Crush Force Efficiency, CFE, (%) | Work Effectiveness, Weff, (J/g) | ||

|---|---|---|---|---|---|---|---|---|---|---|

| Aluminum based samples | Single rings | TB | 0.82 | 46.5 | 812 | 1491 | 51.1 | 1.10 | 54 | 0.90 |

| TM | 0.81 | 39.2 | 1150 | 1640 | 55.7 | 1.42 | 70 | 1.15 | ||

| TS | 0.78 | 23.3 | 1952 | 4141 | 56.4 | 2.42 | 47 | 1.89 | ||

| Nested tube samples | NT2-TS | 0.78 | 69.8 | 1420 | 3865 | 85.7 | 1.23 | 37 | 0.96 | |

| NT2-TM | 0.78 | 85.7 | 1649 | 2884 | 99.5 | 1.16 | 57 | 0.91 | ||

| NT3-TS+TS | 0.75 | 93.1 | 2772 | 5219 | 160.2 | 1.72 | 53 | 1.29 | ||

| NT3-TS+TM | 0.75 | 109 | 2484 | 5799 | 143.6 | 1.32 | 43 | 0.99 | ||

| Nested tube reinforced EPP foam | FF_TB | 0.82 | 59.2 | 1105 | 2550 | 103.8 | 1.75 | 43 | 1.43 | |

| FF_NT2-TS | 0.78 | 82.5 | 1692 | 4781 | 154.6 | 1.87 | 35 | 1.47 | ||

| FF_NT2-TM | 0.78 | 98.4 | 1990 | 4058 | 181.8 | 1.85 | 49 | 1.45 | ||

| FF_NT3-TS+TS | 0.75 | 105.8 | 2292 | 4774 | 203.5 | 1.92 | 48 | 1.44 | ||

| FF_NT3-TS+TM | 0.75 | 121.8 | 2427 | 7148 | 215.5 | 1.77 | 34 | 1.33 | ||

| CFRP based samples | Single rings | TB | 0.82 | 25.3 | 515 | 1367 | 32.4 | 1.28 | 38 | 1.05 |

| TM | 0.81 | 20.5 | 607 | 1544 | 29.4 | 1.43 | 39 | 1.16 | ||

| TS | 0.78 | 10.6 | 765 | 1858 | 22.1 | 2.08 | 41 | 1.63 | ||

| Nested tube samples | NT2-TS | 0.78 | 35.9 | 931 | 2234 | 56.2 | 1.57 | 42 | 1.23 | |

| NT2-TM | 0.78 | 45.8 | 958 | 2087 | 57.8 | 1.26 | 46 | 0.99 | ||

| NT3-TS+TS | 0.75 | 46.5 | 1514 | 2113 | 87.5 | 1.88 | 72 | 1.41 | ||

| NT3-TS+TM | 0.75 | 56.4 | 1521 | 3886 | 87.9 | 1.56 | 39 | 1.17 | ||

| Nested tube reinforced EPP foam | FF_TB | 0.82 | 38 | 1000 | 1925 | 93.9 | 2.47 | 52 | 2.02 | |

| FF_NT2-TS | 0.78 | 48.6 | 1477 | 3295 | 134.9 | 2.78 | 45 | 2.18 | ||

| FF_NT2-TM | 0.78 | 58.5 | 1548 | 3233 | 141.4 | 2.42 | 48 | 1.89 | ||

| FF_NT3-TS+TS | 0.75 | 59.2 | 1727 | 3128 | 153.4 | 2.59 | 55 | 1.95 | ||

| FF_NT3-TS+TM | 0.75 | 69.1 | 1908 | 4718 | 169.4 | 2.45 | 40 | 1.84 | ||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yalçın, M.M.; Özsoy, M.İ. Enhanced Crashworthiness Parameters of Nested Thin-Walled Carbon Fiber-Reinforced Polymer and Al Structures: Effect of Using Expanded Polypropylene Foam. Appl. Sci. 2024, 14, 9635. https://doi.org/10.3390/app14219635

Yalçın MM, Özsoy Mİ. Enhanced Crashworthiness Parameters of Nested Thin-Walled Carbon Fiber-Reinforced Polymer and Al Structures: Effect of Using Expanded Polypropylene Foam. Applied Sciences. 2024; 14(21):9635. https://doi.org/10.3390/app14219635

Chicago/Turabian StyleYalçın, Muhammet Muaz, and Mehmet İskender Özsoy. 2024. "Enhanced Crashworthiness Parameters of Nested Thin-Walled Carbon Fiber-Reinforced Polymer and Al Structures: Effect of Using Expanded Polypropylene Foam" Applied Sciences 14, no. 21: 9635. https://doi.org/10.3390/app14219635

APA StyleYalçın, M. M., & Özsoy, M. İ. (2024). Enhanced Crashworthiness Parameters of Nested Thin-Walled Carbon Fiber-Reinforced Polymer and Al Structures: Effect of Using Expanded Polypropylene Foam. Applied Sciences, 14(21), 9635. https://doi.org/10.3390/app14219635