Abstract

Shape-memory polyester films having functional groups were prepared and further grafted onto poly(N-isopropylacrylamide) (PNIPAAm) via atom-transfer radical polymerization. The grafting point of PNIPAAm was controlled by changing the composition of good and poor solvents. In the case of graft polymerization using only good solvents, the film swells, and polymerization proceeds not only from the surface but also from the internal polymerization initiation points. By increasing the proportion of poor solvents, PNIPAAm was grafted onto the surface of the film without swelling. The samples grafted to the interior regions of the film exhibited a decrease in the shape-memory recovery rate and recovery speed, whereas the samples grafted only to the surface of the film exhibited high shape-memory properties. Furthermore, contact-angle measurements revealed that the surface-grafted polymer exhibited changes in surface properties in response to film deformation. Because the deformation of the film is a large change, on the order of several millimeters, the deformation of the manually stretched film was shown to control molecular-level changes on the surface.

1. Introduction

Composite materials using polymers have attracted wide attention, and various synthetic methods have been developed, including organic–inorganic composites [1,2], polymer blends [3,4], in-situ polymerization [5], and graft polymerization onto polymer substrates [6,7,8]. Graft polymerization can be used to prepare composites of different polymers and inorganic materials [9].

Grafting techniques can be broadly classified into two categories. The grafting-to technique involves modifying a functionalized polymer [10] by introducing a reactive moiety at the side chain or polymer terminal to the base material. In the grafting-from technique, polymerization occurs directly on the substrate after modifying it with a small-molecule initiator [11]. The grafting-to technique directly modifies a polymer with a larger hydrodynamic radius than the grafting-from technique, resulting in a mushroom-like structure that is highly dependent on the molecular weight. This approach limits the grafting density, which can result in the properties desired for an intended application not being achieved [4]. In particular, the grafting-from technique has led to significant progress in the development of living-radical polymerization (LRP) [12]. Before the advent of LRP, radical polymerization from the surface of substrates with peroxide or azo compound modification or irradiation with high-energy electron beams or γ-rays was common [13,14,15]. However, controlling the molecular weight distribution of grafted polymers and achieving surface uniformity were challenging. In contrast, LRP facilitates the creation of grafted surfaces with controlled molecular weights and molecular weight distributions, and numerous methods for preparing uniform surfaces have been developed. Notably, atom-transfer radical polymerization (ATRP), in which ATRP-dormant groups such as haloesters and halosulfonyl groups are introduced into the base material, has enabled high-density graft polymerization and the development of polymer brushes, which had been difficult to achieve by the grafting-to technique [16,17].

We previously reported the successful synthesis of a polyester-based shape-memory film with a surface capable of functional modifications [18]. This shape-memory film is based on poly(caprolactone), and the functional moiety is copolymerized with α-chloro caprolactone (α-ClCL) as a comonomer to introduce chloro groups. The shape-memory property is exhibited by the softening point of the film due to crystal melting, and the chloro group is converted to an azide group by NaN3, which allows for the click reaction known as Huisgen cycloaddition. If the azidation reaction occurs while the film swells in the presence of a good solvent, the chloro groups inside the film become azidized, leading to a reduction in shape memory. Therefore, to selectively react with the film surface, a solvent that is neither too good nor too poor should be used. The azidation reaction was performed using dimethylsulfoxide (DMSO) as a poor solvent for the film, which did not cause swelling. As a result, both shape-memory and surface functionalization were successfully achieved, although selective surface reactions remain challenging.

In this study, we addressed the challenge of selective surface reactions on shape-memory films, confirming the functional expression of grafted polymers on surfaces and the control of surface states using shape-memory properties. Specifically, the surface of the shape-memory film serves as the starting point for ATRP due to the presence of chloro groups derived from α-ClCL. Poly(N-isopropylacrylamide) (PNIPAAm) exhibits a low critical solution temperature (LCST) of approximately 32 °C in water, and molecular-weight control of PNIPAAm is achieved through ATRP graft polymerization. The aim is to hybridize the shape-memory properties triggered by the softening point of the film and the solution properties of PNIPAAm in water by grafting. The successful grafting of PNIPAAm onto the shape-memory film using ATRP was confirmed, with the grafted film surface switching between the hydrophilic and hydrophobic states in response to temperature changes, as evidenced by contact-angle measurements in water. Furthermore, contact angle measurements suggested that the surface density of the grafted polymer changed with the deformation of the grafted film, utilizing the shape-memory properties, when the graft polymer was modified to the surface by appropriately controlling the graft polymerization conditions. The PNIPAAm grafted surface changed reversibly as the film returned to its original shape. The change in the graft-polymer density can be controlled by altering the shape of the film, such as by hand stretching, representing hand-operated nanotechnology [19,20,21] that translates macroscopic mechanical changes into molecular-level modifications.

It is interesting to study the surface wettability of shape-memory materials because it allows for the control and fixation of surface microstructures based on their properties using the microfabrication technique [22]. In these cases, non-composite materials were used. According to these studies, superhydrophobicity is realized by microstructural shape design by the shape-memory materials. On the other hand, several studies have reported dealing with the combination of PCL and PNIPAAm, but their purpose was mainly to mechanically reinforce soft hydrogels or nanofibers, and not for the control of surface properties [23]. In this study, we aimed to investigate the concept of surface wettability control by the shape-memory properties of the base substrate using composite materials and to establish a methodology to synthesize them.

2. Materials and Methods

2.1. Materials

The synthesis of polyesters for graft substrate films and the graft polymerization of PNIPAAm from polyester films by ATRP were conducted as outlined in Scheme 1. α-chloro-ε-caprolactone (α-ClCL) was prepared and purified by a previous report [24]. Toluene was pre-dried using CaH2 and was distilled immediately prior to use. ε-Caprolactone (ε-CL) was dried in a flask with molecular sieve 3A under an Ar atmosphere for more than 3 days before polymerization. Dichloromethane (DCM), dry tetrahydrofuran (THF), and dry N,N-dimethylformamide (DMF) were purchased from Kanto Chemical Co., Inc. (Tokyo, Japan) and used without further purification. 2-chlorocyclohexanone, 3-chloroperoxybenzoic acid (mCPBA:Purity > 65%), trimethylolpropane (TMP), dibutyltin dilaurate (DBTDL), L-ascorbic acid, and 2-hydroxy-4′-(2-hydroxyethoxy)-2-methylpropiophenone (HHMPP) were obtained from Tokyo Chemical Industry Co., Ltd. (Tokyo, Japan) and used as received. Diphenyl phosphate (DPP) was purchased from Sigma Aldrich (St. Louis, USA). CuCl and tris [2-(dimethylamino)ethyl]amine (Me6TREN) were acquired from Fujifilm Wako Pure Chemicals (Tokyo, Japan). 2-isocyanatoethyl acrylate was kindly provided by Resonac Co. (Tokyo, Japan) N-isopropylacrylamide (NIPAAm) was obtained from KJ Chemical (Tokyo, Japan). Other reagents were used as received.

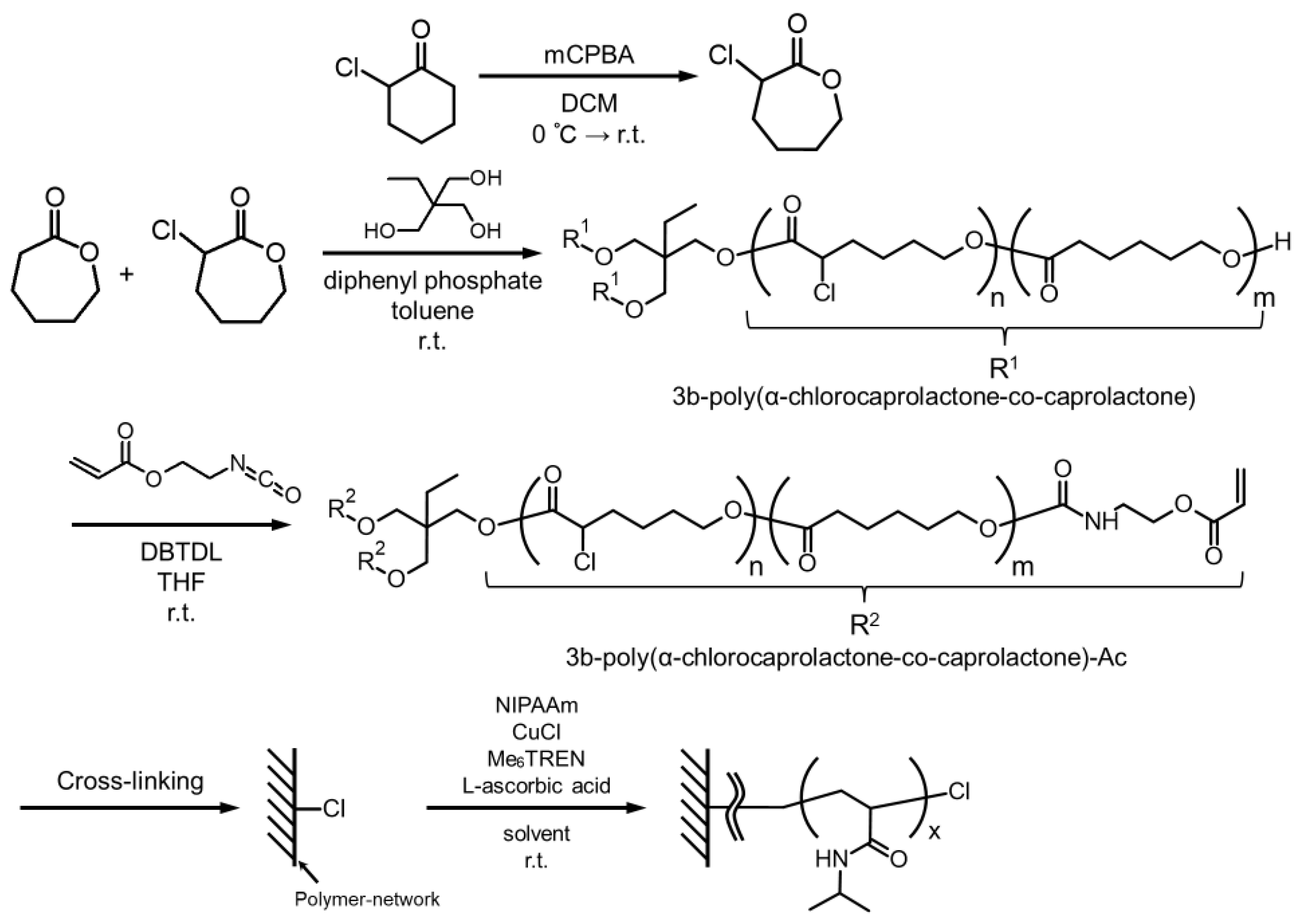

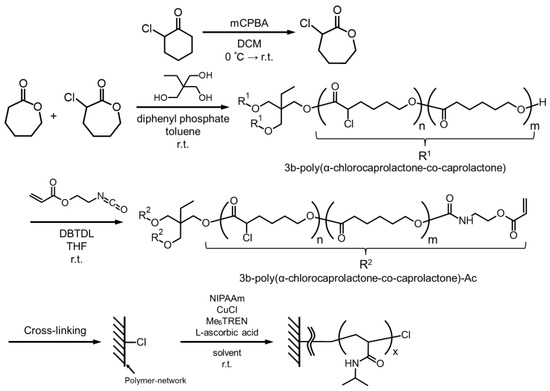

Scheme 1.

All the steps involved in synthesizing polyesters up to grafting by the ATRP method.

2.2. Preparation of 3Brunched-Chlorinated Poly(caprolactone) (3b-PCL-Cl)

In a two-neck flask, α-ClCL (15.0 mmol, 2228.9 mg), ε-CL (60.0 mmol, 6848.4 mg), and TMP (0.400 mmol, 53.7 mg) were dissolved in 60.0 mL of toluene. DPP (1.20 mmol, 300.2 mg) was then added, and the reaction was allowed to proceed for 48 h at room temperature. The entire process was conducted under an Ar atmosphere. The polymerization was quenched by adding Et3N as a polymerization inhibitor. The reaction mixture was precipitated by dropwise addition to hexane, recovered, and dried under reduced pressure. The desired 3b-PCL-Cl was obtained as a white powder (yield 92.0%). To calculate the monomer content and molecular weight in the copolymer, 1H NMR spectra were recorded using a JEOL RESONANCE spectrometer (JNM-ECP500; Tokyo, Japan) operated at 400 MHz. Deuterated chloroform (CDCl3) was used as a solvent, and chemical shifts of the peaks were recorded according to tetramethylsilane (TMS).

2.3. Addition Reaction of 3b-PCL-Cl to the Primary Alcohol at the Ends of the Polymer

The synthesized 3b-PCL-Cl (5184 mg, Mn: 2.07 × 104 by 1H-NMR) was dissolved in 43.0 mL of dry THF in a two-neck flask. The reaction was conducted under an Ar atmosphere, and 2-isocyanatoethyl acrylate (2.16 mmol, 270 μL) and DBTDL (0.108 mmol, 65.0 μL) were sequentially added, followed by a 24 h reaction period at room temperature. The reaction mixture was precipitated by dropwise addition to hexane, recovered, and dried under reduced pressure. The desired 3b-PCL-Cl, with introduced acryloyl groups, was obtained as a white powder. The introduction rate of the acryloyl group from 1H NMR was 90.0%.

2.4. Preparation of Shape-Memory Film Using Acrylated 3b-PCL-Cl

Acrylated 3b-PCL-Cl (1.00 g) was added to a solution of HHMPP (10.0 mg) in DMF (1.5 mL), and the mixture was stirred. This solution was poured into a PTFE mold (50 × 50 × 1 mm) sandwiched between a PP film and a glass plate (1 mm thick). By using a high-pressure mercury lamp (UVL-100HA, 100 W, Rikokagaku Co., Tokyo, Japan), the surfaces were exposed to light for 10 min to initiate the photocrosslinking reaction. A high-pressure mercury lamp was used without filters at wavelengths of 254, 313, 365 (main), 405, and 436 nm. The resulting 3b-PCL-Cl film underwent a 4 h washing with acetone via a Soxhlet extractor. A white film was subsequently obtained through vacuum drying. Film samples surface via the scanning electron microscopy (SEM) images and energy dispersive X-ray spectroscopy (EDS) analysis were obtained at JEOL using a JSM-5500 with tungsten source. The deposited samples were mounted using carbon support.

2.5. Atom Transfer Radical Polymerization of N-Isopropylacrylamide Grafted 3b-PCL-Cl Film

NIPAAm (30 mmol, 3395 mg), CuCl (0.60 mmol, 86.1 mg), L-ascorbic acid (7.5 mmol, 1321 mg), and 3b-PCL-Cl films (10 × 10 mm) were added to Solution I in a 50 mL volumetric two-neck flask. Solution I was prepared by dissolving in 25 mL of dry DMF or a DMF/H2O mixture (13 mL/12 mL). DMF was used as a good solvent (indicated in “G”) and DMF/H2O was used as a poor solvent (indicated in “P”). For Solution II, Me6TREN (1.2 mmol, 325 µL) was dissolved in 5.0 mL of dry DMF in a 20 mL Schlenk tube. All solutions were bubbled with Ar for 15 min to eliminate dissolved O2. The reaction was initiated by mixing solutions I and II. Following the reaction, polymerization was quenched by exposing the solutions to air, and the PNIPAAm-grafted films were washed in a Soxhlet extractor, using acetone as the extraction solvent, for more than 4 h. The washed films were dried under reduced pressure at room temperature overnight. PNIPAAm-grafted surface characteristics were studied according to the Fourier transform infrared (FTIR) spectra recorded by the Spectrum One system (PerkinElmer, Billerica, MA, USA). Reflection spectra were performed in the region of 650–4000 cm−1 with a resolution of 1 cm−1 (24 scans). The grafting ratio of the film sample obtained was calculated by the following equation

where W0 is the initial weight of the film before being grafted from polymerization and Wt is the weight of the film after being grafted from polymerization.

2.6. Crystallinity Evaluation of Film Samples

The softening point and crystallinity of the film were measured by differential scanning calorimetry (DSC) and wide-angle X-ray diffraction (XRD) as physical properties related to the film’s shape-memory properties. DSC used a DSC-60 plus Shimadzu Corporation (Tokyo, Japan) to estimate the thermos-responsive profile of the polymer film. DSC was carried out between −100 and 100 °C at a scanning rate of 5.0 °C/min in the heating process. The film samples were placed in aluminum pans, which were then crimped before DSC measurements were carried out. XRD measurement was carried out using an X’Pert PRO MPD (Malvern Panalytical, Tokyo, Japan) operated at 45 kV and 40 mA to generate a Ni-filtered Cu-Kα X-ray beam. The scanning speed was 0.02°/s, and the measurement range was from 5–70° at room temperature.

2.7. Evaluation of Shape-Memory Properties of Films by Graft Polymerization

Dynamic thermomechanical analysis (DMA) was used to evaluate the shape-memory properties of PNIPAAm-grafted films. DMA was performed using a DMS6100 by Seiko Instruments, Inc. (Chiba, Japan). All shape-memory tests were conducted in stress-controlled thin-film tension mode with a heating rate of 10 °C/min, cooling rate of 10 °C/min, nitrogen flow rate of 200 mL/min, and a grip interval of 5 mm. The shape-fixation rates (Rf) and the shape-recovery rates (Rr) of the film sample were calculated by Equations (2) and (3)

To find Rf with strain-controlled programming protocol, Rf is given by the ratio of the strain in the stress-free state after the withdrawal of the tensile stress in the Nth cycle εu(N) to the maximum strain εm. Where εm − εp (N − 1) is the strain that occurs during the programming step in the Nth cycle. The stress-free state before application of yield stress is represented by εp (N − 1) and εp (N) [25].

2.8. Observation of Hydrophilicity–Hydrophobicity by Contact Angle Measurement on the Film Surface

Contact angle (CA) measurements were made with DMO-501 by Kyowa Interface Science Co., Ltd. (Saitama, Japan) using a captive air bubble within a water-filled temperature-controlled cell by a water bath. The temperature was regulated by a Peltier element connected to a stabilized power supply unit. In the captive air bubble method, the PNIPAAm-grafted film was immersed face-down in pure water to attain an equilibrium temperature state within the temperature-controlled cell for 15 min before bringing the air bubble into contact with the surfaces of the film. As a result, an air bubble (ca. 2 μL) was trapped underneath the polymer-grafted membranes in water and equilibrated until the chemical potential of water vapor in the vapor-saturated air bubble equaled that of liquid water [17]. The reported values are averages of five measurements from different areas of the sample surface.

3. Results

3.1. Preparation of Polyester Films for the Graft Polymerization of PNIPAAm

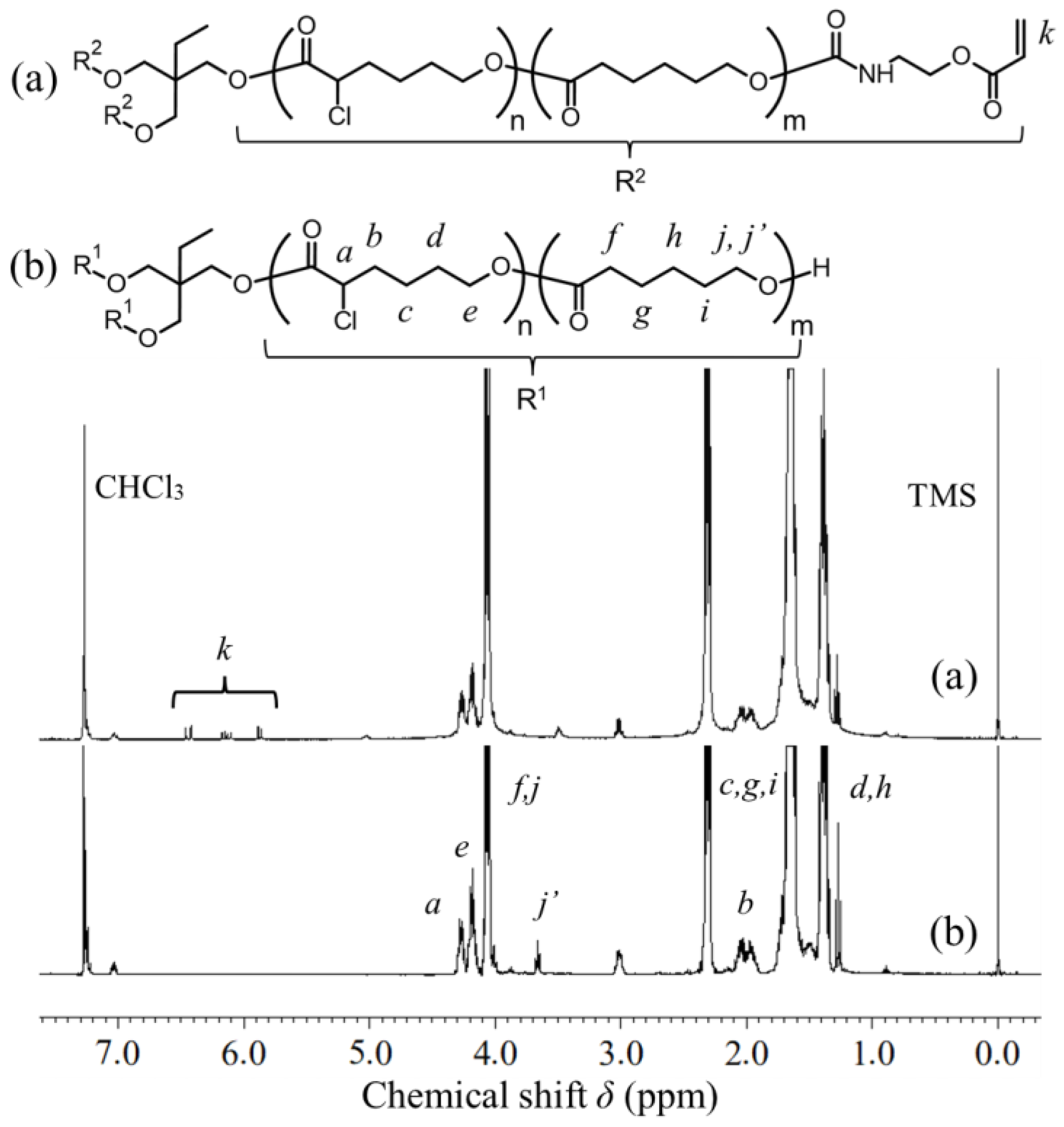

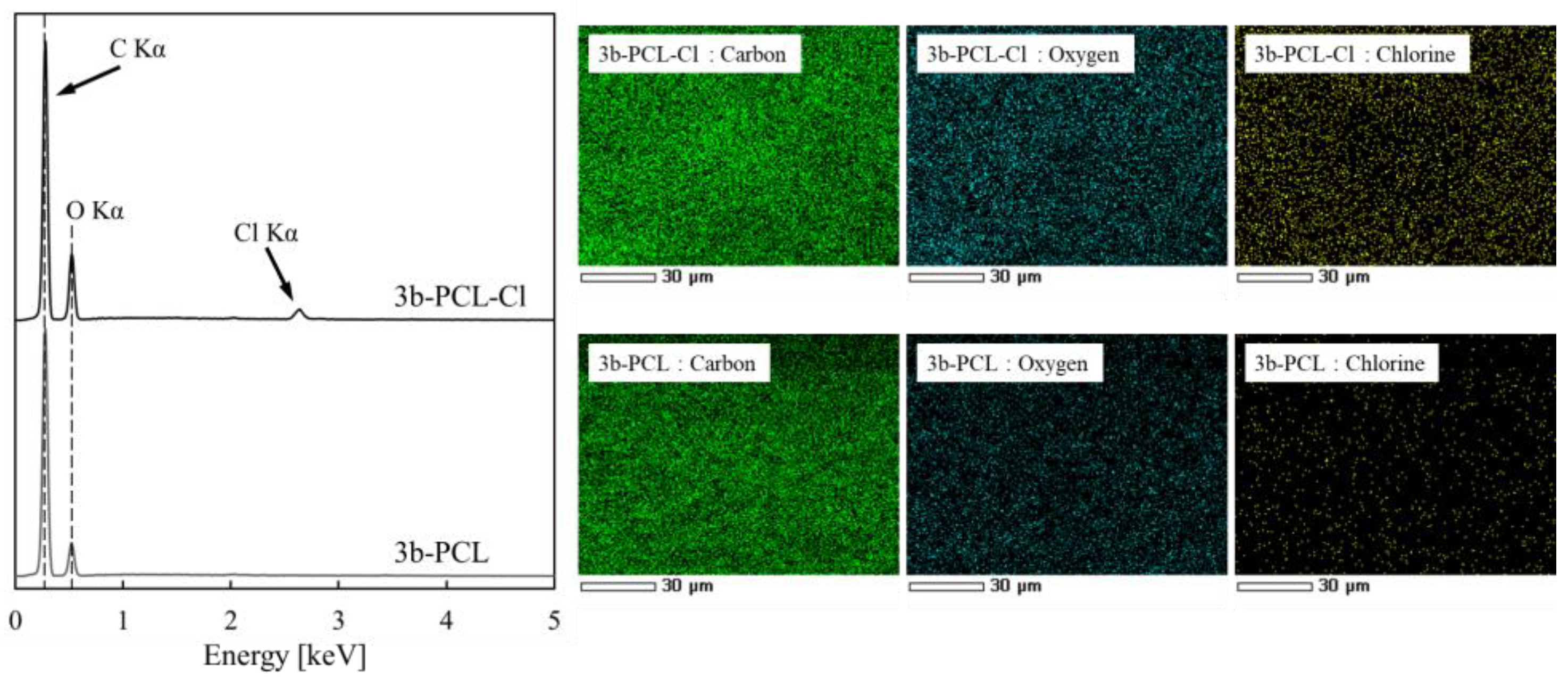

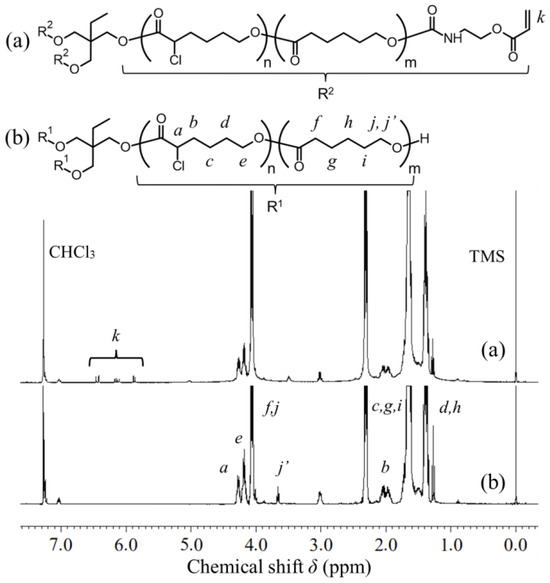

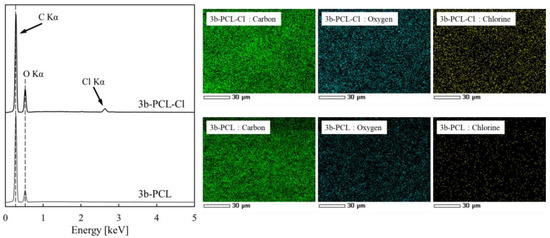

Polymers for reactive surface films were synthesized by ring-opening copolymerization of ε-CL and α-ClCL. Gao et al. reported the use of the five-membered ring lactone α-bromo-γ-butyrolactone (α-BrBL) as a polymerization initiating point for the ATRP of polyester side chains [26]. Furthermore, shape-memory polyester films were prepared using α-BrBL as a comonomer, and cationic groups were introduced on the film surface [27]. However, 5-membered lactones are thermodynamically challenging to polymerize, which complicates the control of the copolymer composition [28,29]. In this study, α-ClCL, a 7-membered lactone showing good ring-opening polymerization properties, was selected as a comonomer. α-ClCL was copolymerized with ε-CL using trimethylolpropane as an initiator (monomer ratio: α-ClCL:ε-CL = 20:80 mol%, copolymer composition: α-ClCL:ε-CL = 15.2:84.8 mol%), with a yield of 92.0%. The acryloyl group was introduced into the terminal hydroxyl group of the synthesized polyester (3b-PCL-Cl) using 2-isocyanatoethyl acrylate, and each proton was assigned in the 1H NMR spectrum (Figure 1). The 3b-PCL-Cl films were formed by photocrosslinking following the method used in a previous study [18,27]. The presence of the desired chlorine in the 3b-PCL-Cl film was confirmed by surface elemental mapping from EDS peak analysis (Figure 2). 3b-PCL-Cl film detected a chlorine-derived peak that was not observed in 3b-PCL film. The mapping images show that chlorine is uniformly distributed throughout the film. In conclusion, the successful introduction of chloro groups into crosslinked polyester films was achieved by using α-ClCL as a comonomer.

Figure 1.

1H-NMR spectra of the synthesized polyester. The spectra were recorded with TMS as standard in CDCl3: (a) acryloyl group added reaction after 3b-PCL-Cl; (b) 3b-PCL-Cl.

Figure 2.

SEM-EDS images of polyester film surfaces with EDS peak detection and elemental mapping.

3.2. Surface Analysis of PNIPAAm-Grafted Polyester Composite

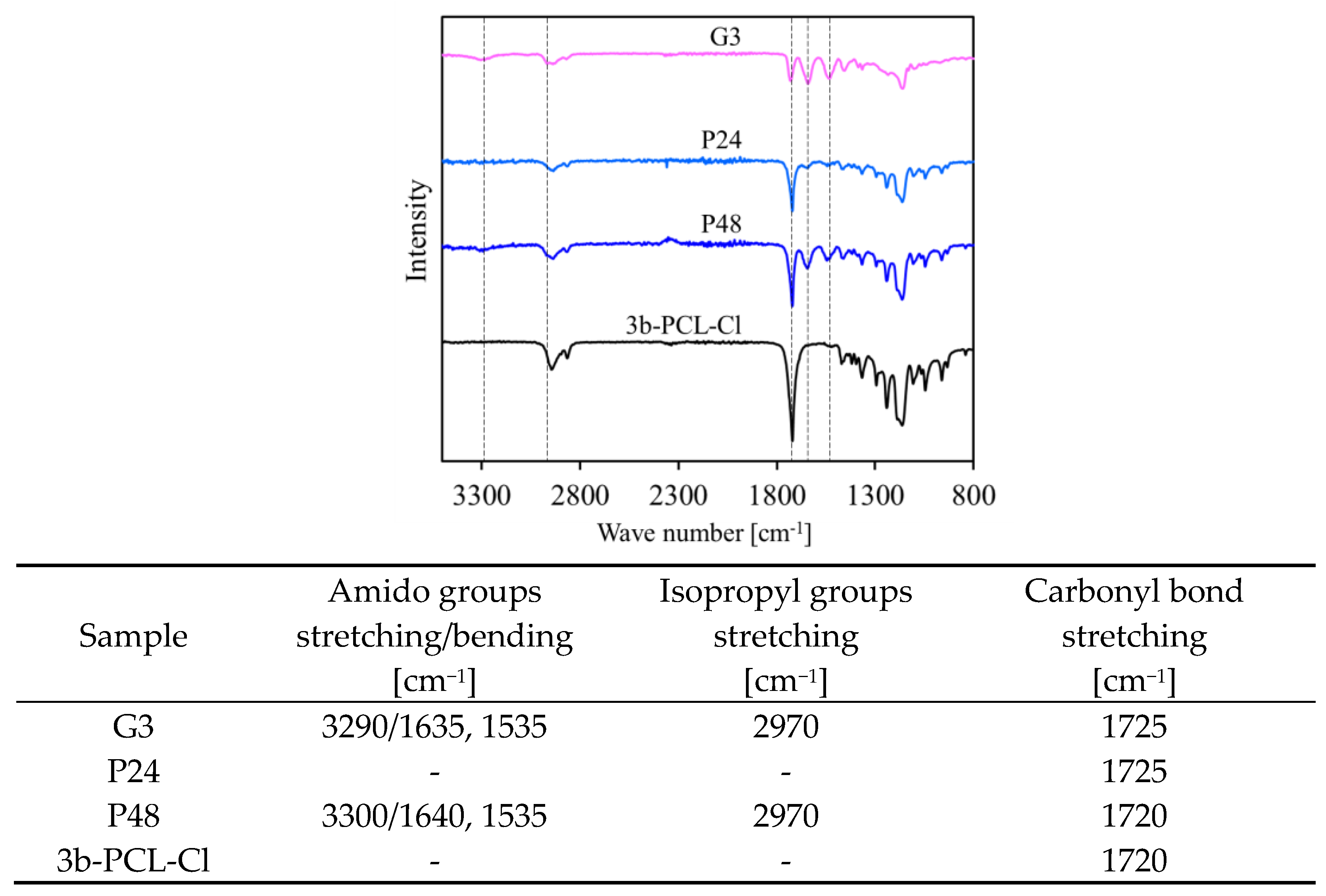

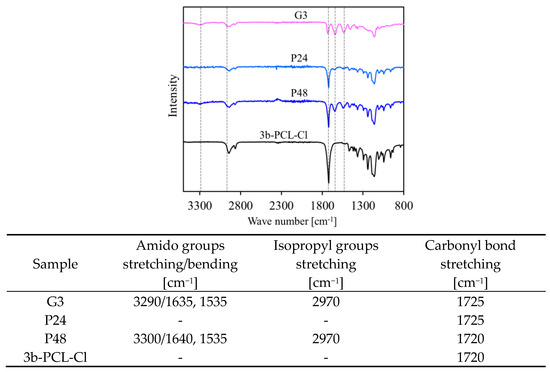

The 3b-PCL-Cl film was grafted with PNIPAAm via surface-initiated ATRP, using CuCl as the catalyst, Me6TREN as the ligand, and ascorbic acid as the reducing agent [30,31]. When the 3b-PCL-Cl film swelled, the NIPAAm monomer penetrated the film, and the graft polymerized inside the chloro groups of the films. When the ATRP of PNIPAAm was performed using a poor solvent for 3b-PCL-Cl, the NIPAAm monomer did not penetrate the interior of the film, leading to graft polymerization occurring exclusively on the surface. In this study, DMF was employed as a good solvent (G), whereas a mixture of DMF and water served as a poor solvent (DMF:H2O = 3:2 v/v) (P); DMF dissolved free 3b-PCL-Cl and PNIPAAm effectively. Polymerization with water as a poor solvent was also attempted; however, graft polymerization did not proceed. Thus, graft polymerization proceeded efficiently when the substrate was partially dissolved by added DMF. This result is consistent with the findings of Andersen et al. in their study of photoinitiated graft polymerization on urethane polymer films [32]. In graft polymerization that is allowed to proceed for 3 h using a good solvent, the film (as represented in “G3”) exhibited a weight gain of 129.2% after polymerization (see Figure 3). In contrast, when using a poor solvent, no significant weight gain was observed after polymerization. This negligible weight gain is consistent with the results of previous studies [6], indicating that graft polymerization by ATRP occurs primarily on the surface. The surface analysis of the synthesized PNIPAAm-grafted film was conducted via FTIR, with the results obtained by the ATR method shown in Figure 3. Sample G3 showed, in addition to the carbonyl bond (C=O: 1721 cm−1) derived from the 3b-PCL-Cl film, an amide bond (O=C–N: 1535 and 1635 cm−1) and the isopropyl group (–CH–(CH3)2: 2970 cm−1), as part of the primary structure of PNIPAAm, appeared newly compared to the sample before reaction (Figure 3) [33]. The sample grafted with the poor solvent DMF/H2O (P) showed only minimal PNIPAAm-derived absorption after 24 h of reaction (as represented in “P24” in Figure 3). Therefore, the reaction time was increased to 48 h (P48). For sample P48, the absorption attributed to PNIPAAm appeared more clearly. In the poor-solvent sample, the absorption intensity of the carbonyl bond derived from the 3b-PCL-Cl film, which is the substrate for graft polymerization, was compared with the intensity of each absorption derived from PNIPAAm, revealing a stronger carbonyl bond absorption from the 3b-PCL-Cl film. The stronger absorption intensity of the carbonyl bond suggests that the ratio of PNIPAAm in the sample with a poor solvent was relatively low. The infrared light used in the FTIR measurements slightly penetrates the sample surface [34], indicating that the PNIPAAm-derived absorption is strong in samples where PNIPAAm polymerizes internally, as it does in good solvents, whereas the absorption is weak in samples processed in poor solvents, where graft polymerization occurs only on the surface.

Figure 3.

FTIR spectra and assigned absorption peaks of PNIPAAm grafted films.

3.3. Contact Angle of PNIPAAm-Grafted Polyester Composite

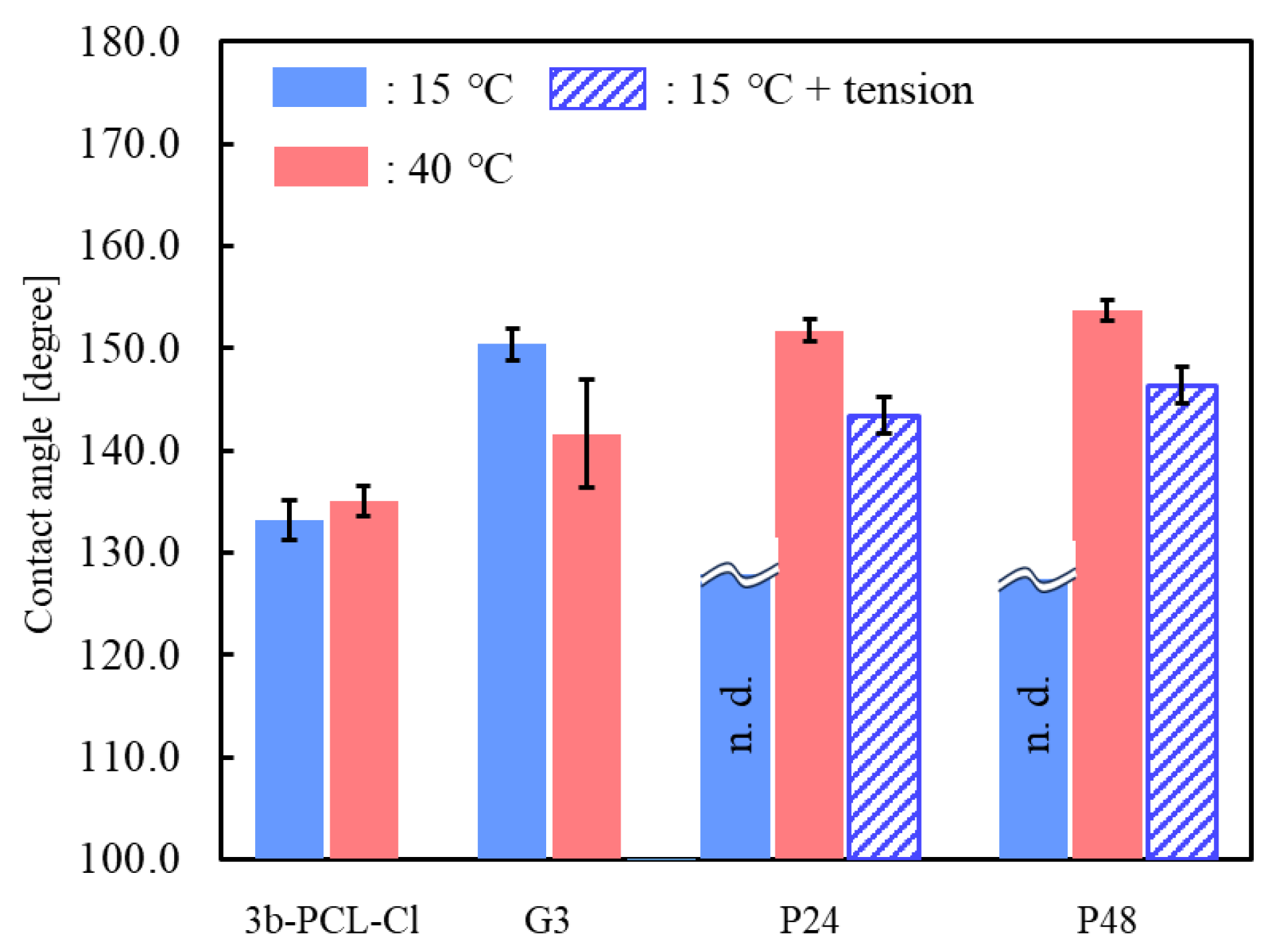

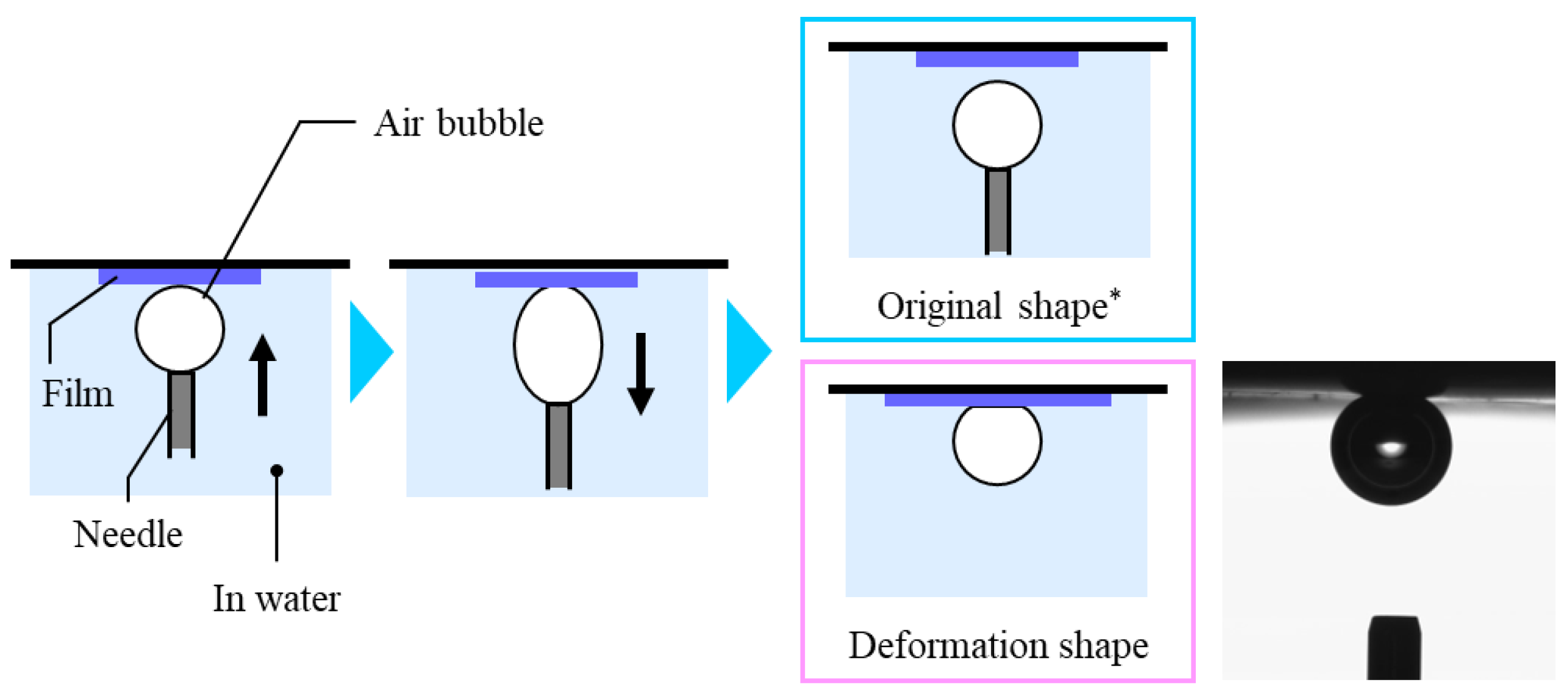

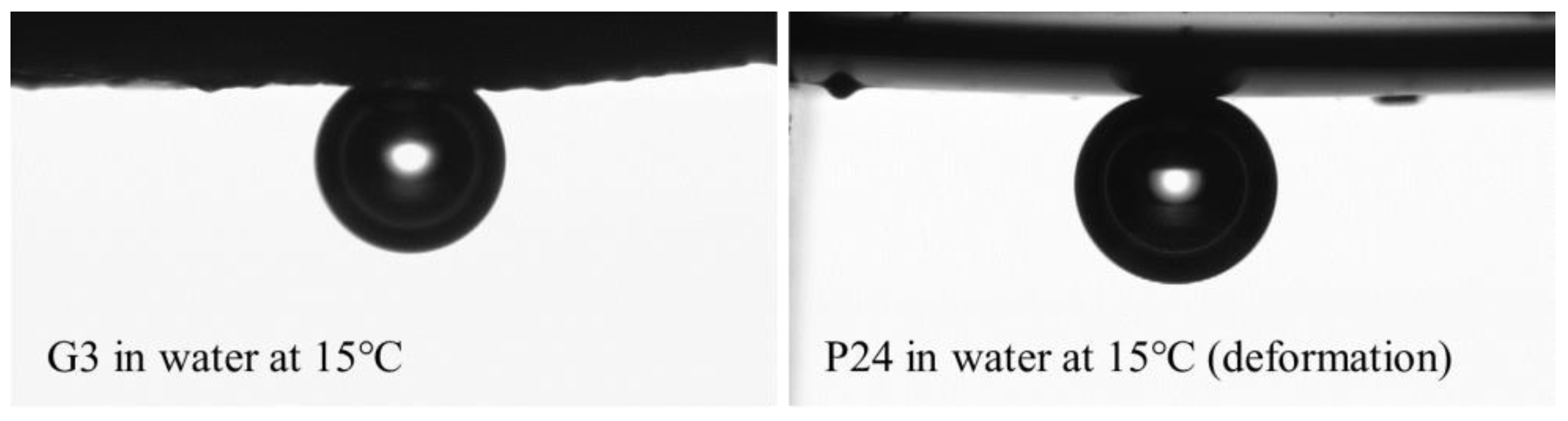

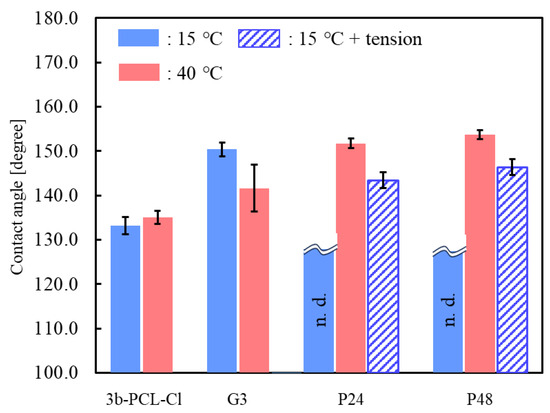

The CAs were measured by bringing air bubbles into contact with the film in water. The grafted film prepared using a good solvent (G3 in Figure 4), intended as a comparison sample, absorbed water over time when the contact angle was measured with a drop of water in the atmosphere. Therefore, the grafted film was used as a control sample by performing contact-angle measurements in water after allowing sufficient water absorption to eliminate the effects of further water absorption.

Figure 4.

Contact angle of air bubble underneath PNIPAAm-grafted films in water. The designation “n.d.” indicates there was no contact with the air bubble, and there was no detectable.

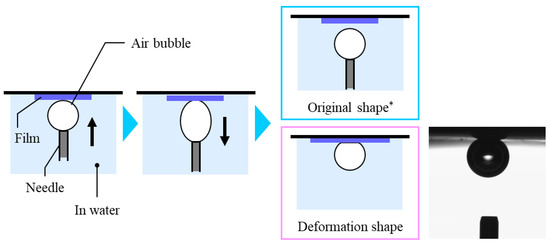

As shown in Figure 4, the film before graft polymerization showed no change in CA with varying water temperatures. In contrast, the contact angle of the G3 film was 150.4 ± 1.57° at 15 °C and 141.6 ± 5.3° at 40 °C. Thus, the unmodified film did not undergo temperature-dependent changes, confirming that the graft polymerization of PNIPAAm imparts the LCST and thermo-responsive behavior of PNIPAAm on the film surface of G3. Interestingly, the P24 and P48 films failed to allow hydrophobic air bubbles to contact the film surface at a water temperature of 15 °C. It means that the surface is so hydrophilic to prevent contact with air at this temperature. However, when the water temperature was raised to 40 °C and the air bubbles were reintroduced, the film surface became hydrophobic, allowing the air bubbles to adhere. The contact angles were 151.7 ± 1.1° in 40 °C water for P24 and 153.7 ± 1.0° for P48. The films grafted with a poor solvent exhibited improved surface hydrophilicity, regardless of the water temperature changes, compared to those grafted with a good solvent. Furthermore, results supporting the surface-selective response of graft polymerization in a poor solvent were obtained with the film stretched in water at 15 °C. The stretched film showed a contact angle of 143.4 ± 1.8° for P24 and 146.4 ± 1.8° for P48, confirming a hydrophobic surface compared to the original shape, as bubbles were observed adhering to the film. As shown in Figure 5, no bubbles adhered to the film before deformation, whereas bubbles adhered to the film after deformation as the graft-polymer density decreased and the surface became hydrophobic. The contact angle values of deformation samples at 15 °C were equivalent to those of the G3 film at a water temperature of 40 °C. The reason for the hydrophobicity at 15 °C, below the LCST of PNIPAAm, is that stretching the film reduces the graft-polymer density per unit area, exposing the hydrophobic film surface. However, the presence of even a small amount of PNIPAAm under poor solvent conditions rendered the contact angle more hydrophilic than that of the unmodified 3b-PCL-Cl film. The stretched film, after being returned to its original shape, did not allow bubbles to contact the surface during the subsequent CA measurement in water at 15 °C. P24 and P48 confirmed that the thermo-responsive functionality of the PNIPAAm on the film surface could be repeatedly activated.

Figure 5.

Explanatory diagram of contact-angle measurements for shape changes in P24 and P48. * The test was not measurable.

3.4. Elucidating the Shape-Memory Mechanism of PNIPAAm-Grafted Polyester Composite

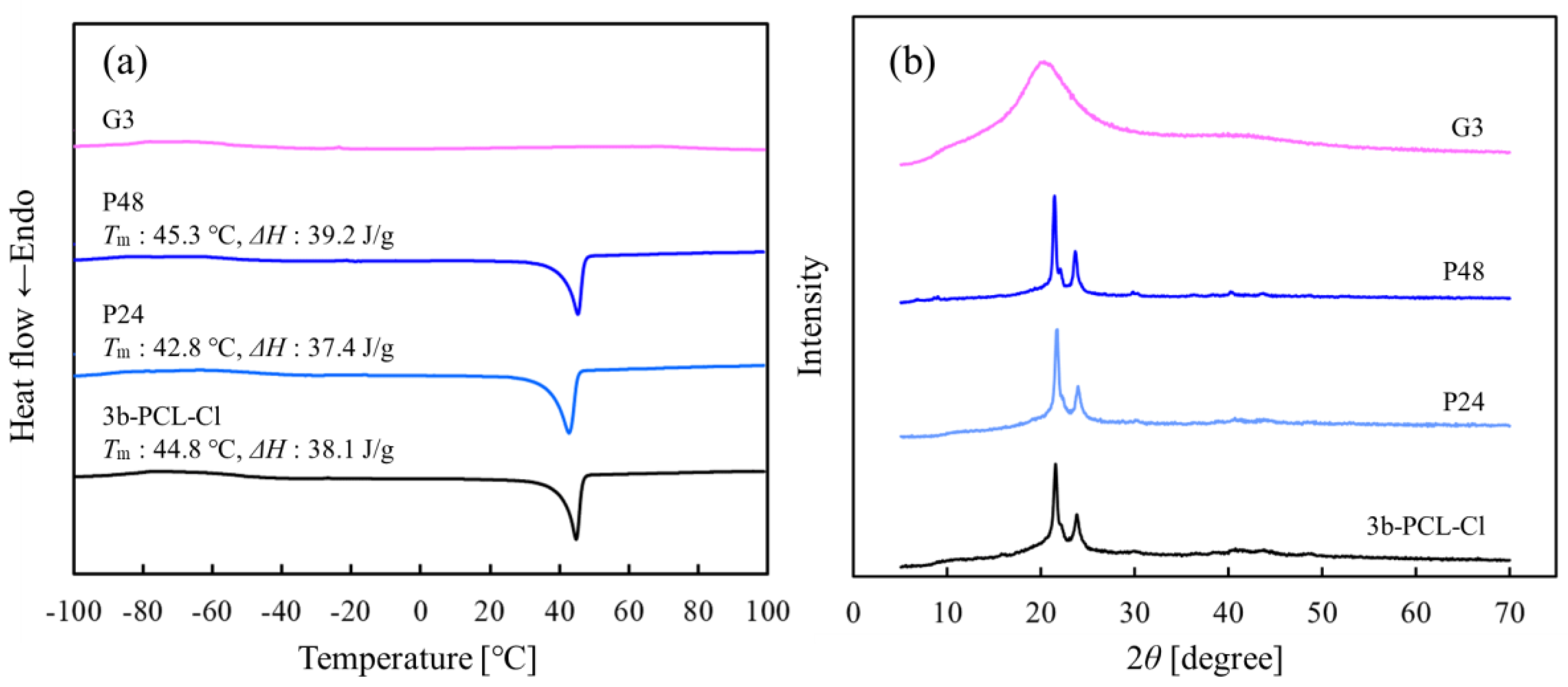

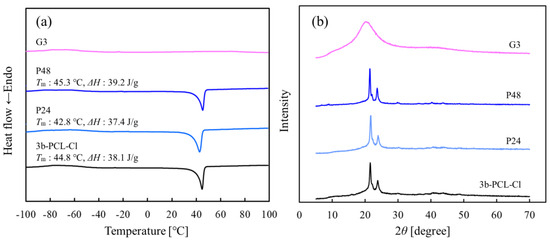

PCL-based shape-memory exhibits shape-memory properties due to the softening of the film caused by crystal melting [35,36]. Therefore, the endothermic peak originating from crystal melting was confirmed by DSC measurements. Before graft polymerization, a clear unimodal endothermic peak appeared at 44.8 °C in the film (3b-PCL-Cl in Figure 6a). Before crosslinking, the polymer exhibited a bimodal DSC curve at the peak top of the endothermic peak (Tm: 42.2 °C and 47.2 °C, ΔH: 47.5 J/g). The crystalline melting temperature and enthalpy of crosslinked polymers are lower than those of non-crosslinked polymers [35]. In this study, copolymers with a composition ratio of 20:80 (feed ratio) of α-ClCL to ε-CL were primarily used. However, when copolymers with other composition ratios were synthesized, the crystal melting temperature at room temperature disappeared once the α-ClCL to ε-CL ratio reached 40:60 (feed ratio) at the maximum. The disappearance of the crystal melting temperature in α-ClCL and ε-CL copolymers with increasing α-ClCL composition was also reported by Lenoir et al. [37].

Figure 6.

The results of crystalline evaluation for shape-memory properties: (a) DSC curves; (b) XRD diffraction patterns.

In this study, a composition ratio of 20:80 (feed ratio) between α-ClCL and ε-CL was adopted to evaluate shape-memory properties, as the polymer exhibits an appropriate crystal melting temperature and allows for sufficient initiation of graft polymerization. The shape-memory property of a film is influenced by the thermophysical properties of film constituent polymers. The properties of polymers can be controlled by the copolymerization ratio of monomers. Copolymer confirmed that an increase in the copolymerization ratio of α-ClCL, then the polymer was losing crystallinity at room temperature. Therefore, the copolymer ratio used in this study is considered to be capable of modifying as many polymers as possible by graft polymerization and shape memory at room temperature. For example, graft polymerization of 2-methacryloyloxyethyl phosphorylcholine (MPC) with a betaine structure on the side chain produces highly anti-thrombogenic surfaces through poly(MPC). Additionally, pH-responsive polymers are used in sensors and other applications because they change shape and color in response to environmental pH. Graft polymerization onto 3b-PCL-Cl film enables the modification of its properties through shape-memory effects. For PNIPAAm-grafted films prepared using a poor solvent, the onset of the crystal melting temperature was confirmed by DSC, regardless of the graft polymerization reaction time (Figure 6a). Furthermore, XRD measurements of the sample polymerized in a poor solvent showed the same PCL-derived crystal diffraction peaks as those of the sample before polymerization [35]. However, no crystal melting peak appeared in the sample polymerized using a good solvent (Figure 6-G3) when measured by DSC, and the XRD diffraction pattern showed a halo peak observed in the sample synthesized with a good solvent. Therefore, the use of a good solvent inhibits the crystallinity of the film by impregnating the NIPAAm monomer and randomly polymerizing it at the chloro groups present in the film as grafting points. The results for the samples synthesized using a good solvent suggest that graft polymerization with poor solvent proceeds clearly and selectively on the surface. These results suggest that the choice of solvent for graft polymerization can influence the material properties when graft polymerization of soft materials, such as gels, is carried out, regardless of whether the polymers are in film or sheet form.

3.5. Influence of PNIPAAm Grafting onto Polyester Films on Shape-Memory Properties

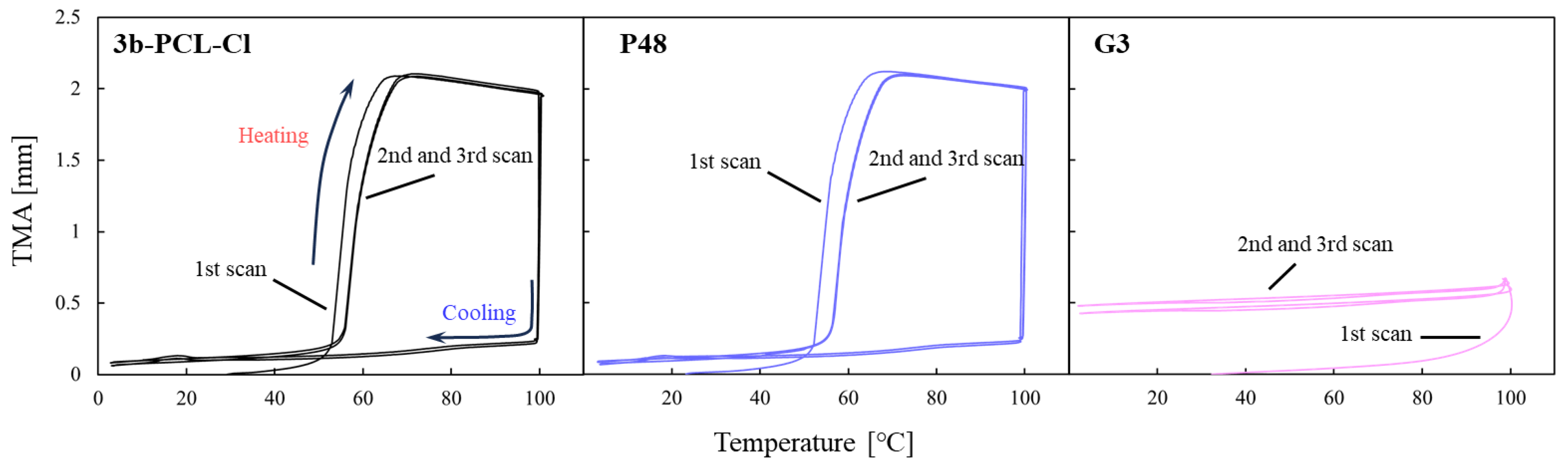

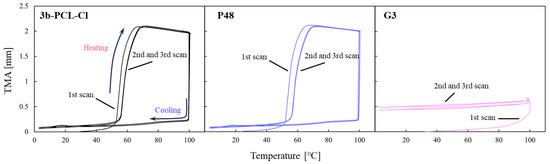

Several previous studies of ATRP from the side chains of polyesters using α-ClCL have been reported [24,37,38], and all previous studies have shown successful graft polymerization onto degradable polyesters. In particular, Li et al. reported the self-assembly of PNIPAAm grafted onto polyester side chains in water and the relationship between this self-assembly and thermos-responsiveness [39]. The graft polymerization of PNIPAAm into polyester side chains resulted in a material that exhibited the properties of PNIPAAm; however, the polyester, which is the substrate for graft polymerization, still serves merely as a degradable material. Therefore, polymer modification by graft polymerization onto a polyester material with shape-memory properties will result in a composite material that can fully utilize both the thermos-responsiveness of the polyester material and the properties of the grafted polymer. The physical properties of the grafted PNIPAAm were evaluated, as discussed in Section 3.4. Therefore, the next step was to evaluate the bulk properties of the film, including its softening temperature (Figure 7) and shape-memory properties (Figure 8), using TMA.

Figure 7.

Film softening point measurement by TMA.

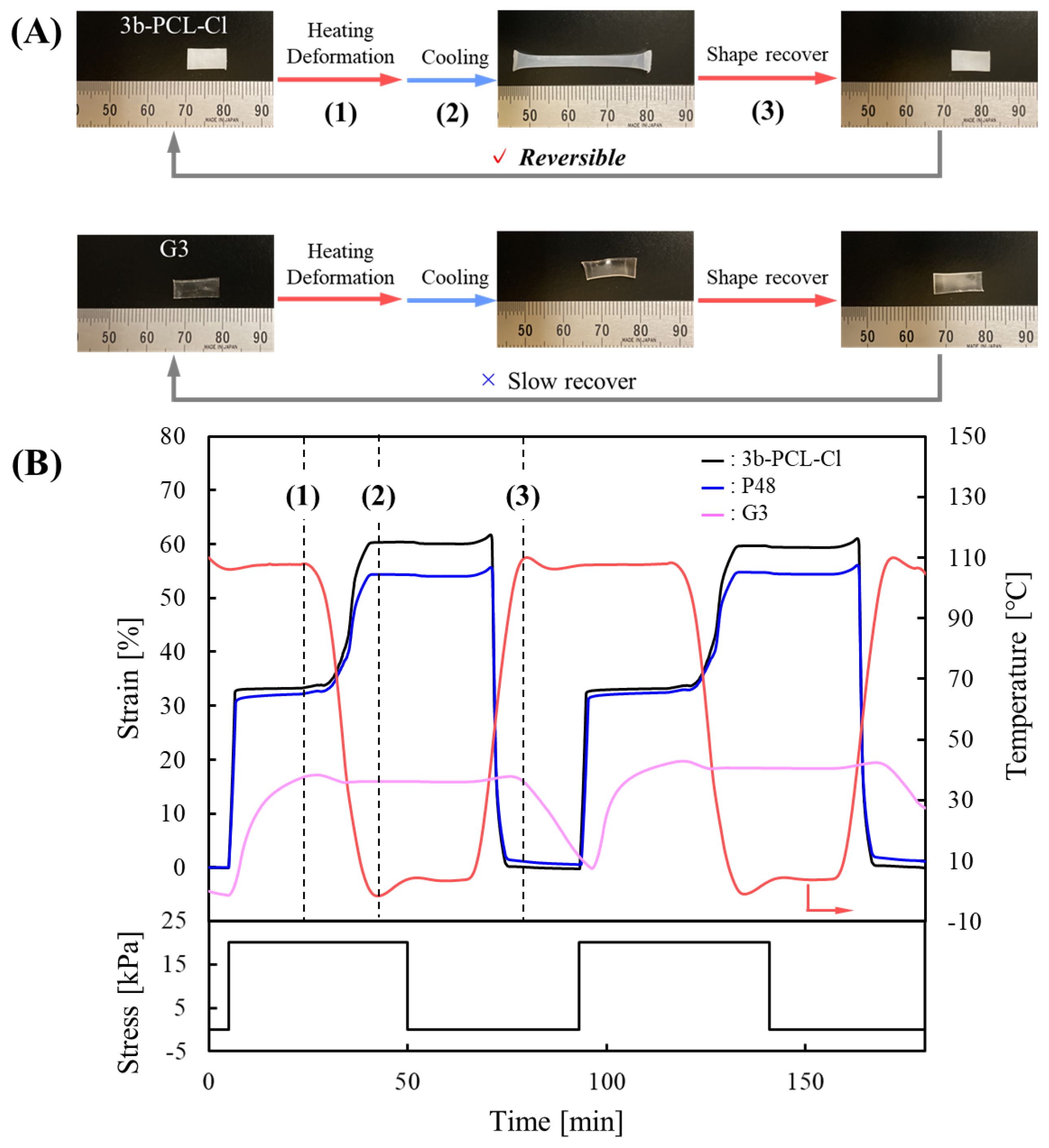

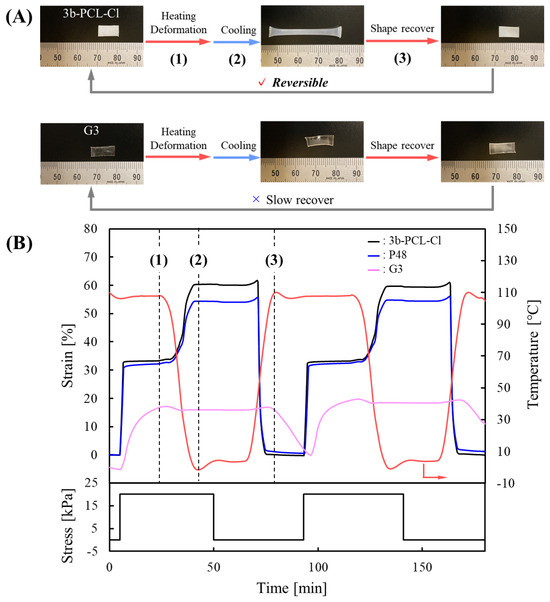

Figure 8.

Evaluation of PNIPAAm-grafted film and 3b-PCL-Cl film shape-memory properties. (A); Qualitative view of shape memory. (B); Strain and Stress profiles for time.

First, the softening points of the films were evaluated by measuring temperature changes at a constant load of 20 kPa. The average softening points (n = 3) for the 3b-PCL-Cl and P48 films were 52.2 °C and 49.4 °C, respectively. Samples with shape-memory properties were measured repeatedly using this program (Figure 7). During the first temperature increase (1st scan), a lower softening point was observed compared to the other temperature-increase processes. The softening point of the first scan shifted to a lower temperature because of the thermal response, including the thermal history [40,41]. As seen in Figure 7, G3 did not show a clear softening point at the first scan, unlike the other samples, and the shape changed gradually with increasing temperature from above 50 °C. The TMA results for G3 were consistent with the DSC and XRD results. The absence of crystalline melting peaks in the DSC results and the appearance of halo peaks in the XRD results indicate that G3 inhibited the crystallinity of 3b-PCL-Cl before grafting because of the progressive polymerization of PNIPAAm inside the film. Therefore, the film became rubbery, and no shape change due to the temperature was observed by TMA under a constant load.

The shape-memory properties of the 3b-PCL-Cl and PNIPAAm-grafted films were first evaluated qualitatively by photographing the samples as their shape changed with temperature, as shown in Figure 8. As shown in the figure, 3b-PCL-Cl exhibited shape memory. However, although G3 could be deformed by heating to approximately twice its original size, the deformation did not persist upon cooling, resulting in the shape shown in the photograph being only slightly deformed due to shrinkage. Temperature ranges (1)–(3) in Figure 8A correspond to the temperature range in Figure 8B. The shape-memory properties of the 3b-PCL-Cl films were confirmed by TMA measurements, as evidenced by qualitative shape-memory characterization. Rf for 3b-PCL-Cl and P48 were 99.5% and 99.3%, respectively, and Rr was 99.1% and 97.9%, respectively. 3b-PCL-Cl and P48 exhibited excellent shape-memory properties, with Rr values close to 100%.

4. Discussion

The CA measurements confirmed that the surfaces of P24 and P48 films became hydrophilic in water at 15 °C, preventing bubbles from coming into contact. The improved hydrophilicity of the film surface supports the successful grafting of PNIPAAm. Interestingly, the sample treated with poor solvent allows for bubble contact by mechanically stretching the film and then submerging it in water at 15 °C again. That is, the surface of the film has become hydrophobic. The increased hydrophobicity of the film surface can be attributed to the reduction in PNIPAAm per surface area caused by the stretching of the film, allowing more contact with air bubbles. Thus, we have successfully demonstrated a method to reversibly alter the surface density of molecules on the film through macroscopic mechanical manipulation.

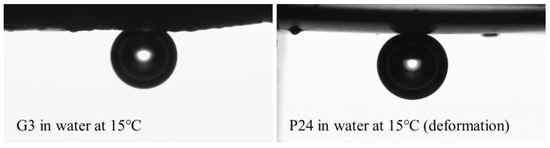

However, G3 did not show a hydrophilic surface like P24 and P48 by the CA measurements in water at 15 °C. The lack of a hydrophilic surface was likely due to the roughness of the film. The CA measurement was performed when the PNIPAAm-grafted film was sufficiently swollen with water. The G3 film clearly swelled more in size compared to P24 and P48. Swollen by water affected not only the size of the film but also its surface. Figure 9 shows images of P24 (under tension) and G3 in water at 15 °C. The boundary between the air bubble and the surface of the P24 film is clear. In contrast, the surface of the G3 film appears rough. The reduced hydrophilicity of the G3 surface compared to P24 may be attributed to the increased surface roughness caused by water swelling.

Figure 9.

Contact angle of samples prepared with different solvents from a side view in water at 15 °C.

The 3b-PCL-Cl film and P48 showed no significant difference in the maximum strain values. The shape-memory property was repeatedly observed, indicating that the polymer was successfully grafted without interfering with the bulk properties of the film from using a poor solvent. This result is consistent with the DSC, XRD, and TMA results, suggesting that it is the result of the selective surface-modification method.

The rapid elongation of the film on the 1st cycle at about 30 min during the shape-memory property evaluation shown in Figure 8 was also observed in other PCL-based shape-memory materials, and the cause remains unclear [40,41,42]. One possible cause is that the film stretches as a result of polymer molecule rearrangement during the cooling process. No crystallinity was observed in the G3 film based on the DSC and XRD results. Additionally, the film’s softening point was not detected by TMA in the range of 0 °C to 100 °C. However, contrary to expectations, the shape-memory properties of the film exhibited shape changes as observed by DMA. The shape change in G3 with temperature is attributed to the thermophysical properties of PNIPAAm. PNIPAAm has a glass transition temperature of 130 °C [43]. However, the PNIPAAm within the G3 film is a graft polymer and, unlike free polymers, exhibits a lower glass transition and melting temperature [44]. Thus, the film stretching during shape-memory evaluation occurred because the graft polymer exceeded its glass transition temperature. Upon reheating, the deformation was eliminated, resulting in elastic recovery. The P48 film was deformed rapidly by the shape-memory property compared to the elastic deformation of the G3 film. This indicates that controlling the graft-polymerization density affects the physical properties of the grafted substrate.

The results of this research are expected to contribute to cell-sheet engineering. Recently, several types of cell sheets have been produced using temperature-responsive cell culture dishes and are being applied to clinical trials. It is known that cell adhesiveness differs depending on the type of cells. This fact suggests that it is necessary to prepare a lineup of culture dishes for each cell, but the material in this research can solve this problem. This is because the wettability of the dish surface and adhesiveness of cells are expected to be controlled simply by stretching and fixing them with temperature control, taking advantage of the shape-memory properties.

5. Conclusions

Shape-memory films prepared using α-ClCL exhibited the introduction of chloro groups on the surface. Furthermore, graft polymerization of PNIPAAm by ATRP was successfully achieved using the introduced chloro groups as reaction sites. The graft polymerization of PNIPAAm onto the films was conducted in a poor solvent that did not cause swelling, enabling selective graft polymerization onto the film surfaces. The graft polymerization conditions significantly influenced the shape-memory properties of the film. In particular, surface-selective graft polymerization produced a multi-temperature-responsive material that exhibited shape memory based on the softening point of the film and the LCST of the grafted PNIPAAm. Furthermore, the film surface, which was hydrophilic below the LCST of PNIPAAm, as measured by the contact angle in water, became hydrophobic upon stretching and deformation. Stretching the film reduced the surface density of the grafted polymer, thereby exposing the hydrophobic substrate. Macroscopic changes, such as film deformation, successfully controlled the molecular-level changes in the graft-polymer density.

Consequently, in this study, we succeeded in the surface-selective modification using temperature-responsive polymer and shape-memory materials. This methodology can be applied to other types of stimuli-responsive polymers, such as pH-responsive or light-responsive ones and so on, and they surely contribute to the research fields.

Author Contributions

Conceptualization, T.Y. and T.A.; data curation, T.Y.; formal analysis, T.Y., T.H. and T.A.; funding acquisition, T.H. and T.A.; investigation, T.Y.; methodology, T.Y., T.H. and T.A.; project administration, T.Y. and T.A.; supervision, T.H. and T.A.; writing—original draft, T.Y.; writing—review and editing, T.Y., T.H. and T.A. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The original contributions presented in this study are included in the article, and further inquiries can be directed to the corresponding authors.

Acknowledgments

Scanning electron microscopy and energy-dispersive X-ray spectroscopy were performed at the Joint Research Center for Environmentally Conscious Technologies in Materials Science at ZAIKEN, Waseda University. The authors are grateful to Akira Matsumoto for the contact angle measurements.

Conflicts of Interest

The authors declare no competing interests.

References

- Pech-Cohuo, S.C.; de Atocha Dzul-Cervantes, M.A.; Pérez-Pacheco, E.; Rosado, J.A.C.; Chim-Chi, Y.A.; Ríos-Soberanis, C.R.; Cuevas-Carballo, Z.B.; Uc-Cayetano, E.G.; Can-Herrera, L.A.; Ortíz-Fernández, A.; et al. Effect of Clays Incorporation on Properties of Thermoplastic Starch/Clay Composite Bio-Based Polymer Blends. Sci. Rep. 2024, 14, 19669. [Google Scholar] [CrossRef] [PubMed]

- Komatsu, S.; Ikedo, Y.; Asoh, T.-A.; Ishihara, R.; Kikuchi, A. Fabrication of Hybrid Capsules via CaCO3 Crystallization on Degradable Coacervate Droplets. Langmuir 2018, 34, 3981–3986. [Google Scholar] [CrossRef] [PubMed]

- Pekdemir, M.E.; Özen Öner, E.; Kök, M.; Cherkezova, A. Thermo-Responsive Shape Memory Polymer Blends Based on Polylactic Acid and Polyethylene Glycol. Macromol. Res. 2024. [Google Scholar] [CrossRef]

- Öner, E.Ö.; Kök, M.; Pekdemir, M.E.; Aydoğmuş, E.; Saydam, S.; Aydoğdu, Y. Production of Smart Polymer Blend Filament from Waste PET Obtained Water Bottles: Investigation of Thermal and Shape Memory Behavior. Macromol. Res. 2024. [Google Scholar] [CrossRef]

- Hoshi, T.; Sawaguchi, T.; Konno, T.; Takai, M.; Ishihara, K. Preparation of Molecular Dispersed Polymer Blend Composed of Polyethylene and Poly(Vinyl Acetate) by in Situ Polymerization of Vinyl Acetate Using Supercritical Carbon Dioxide. Polymer 2007, 48, 1573–1580. [Google Scholar] [CrossRef]

- Ishihara, R.; Tanabe, K.; Inomata, S.; Matsui, R.; Kitane, R.; Hosokawa, K.; Maeda, M.; Kikuchi, A. Fabrication of Storable Surface-Functionalized Power-Free Microfluidic Chip for Sensitive MicroRNA Detection Utilizing Ultraviolet Grafting. Ind. Eng. Chem. Res. 2020, 59, 10464–10468. [Google Scholar] [CrossRef]

- Psarra, E.; König, U.; Ueda, Y.; Bellmann, C.; Janke, A.; Bittrich, E.; Eichhorn, K.-J.; Uhlmann, P. Nanostructured Biointerfaces: Nanoarchitectonics of Thermoresponsive Polymer Brushes Impact Protein Adsorption and Cell Adhesion. ACS Appl. Mater. Interfaces 2015, 7, 12516–12529. [Google Scholar] [CrossRef]

- Li, T.; Chen, S.; Li, H.; Li, Q.; Wu, L. Preparation of an Ion-Imprinted Fiber for the Selective Removal of Cu2+. Langmuir 2011, 27, 6753–6758. [Google Scholar] [CrossRef] [PubMed]

- Tymetska, S.; Shymborska, Y.; Stetsyshyn, Y.; Budkowski, A.; Bernasik, A.; Awsiuk, K.; Donchak, V.; Raczkowska, J. Thermoresponsive Smart Copolymer Coatings Based on P(NIPAM-Co-HEMA) and P(OEGMA-Co-HEMA) Brushes for Regenerative Medicine. ACS Biomater. Sci. Eng. 2023, 9, 6256–6272. [Google Scholar] [CrossRef]

- Freichels, H.; Alaimo, D.; Auzély-Velty, R.; Jérôme, C. α-Acetal, ω-Alkyne Poly(Ethylene Oxide) as a Versatile Building Block for the Synthesis of Glycoconjugated Graft-Copolymers Suited for Targeted Drug Delivery. Bioconjugate Chem. 2012, 23, 1740–1752. [Google Scholar] [CrossRef]

- Boday, D.J.; Loy, D.A. Strengthening Silica Aerogels with Surface Initiated ATRP Cross-Linked Poly(Methyl Methacrylate). J. Non-Cryst. Solids 2015, 427, 114–119. [Google Scholar] [CrossRef]

- Wang, J.-S.; Matyjaszewski, K. Controlled/“living” Radical Polymerization. Atom Transfer Radical Polymerization in the Presence of Transition-Metal Complexes. J. Am. Chem. Soc. 1995, 117, 5614–5615. [Google Scholar] [CrossRef]

- Yakushiji, T.; Sakai, K.; Kikuchi, A.; Aoyagi, T.; Sakurai, Y.; Okano, T. Effects of Cross-Linked Structure on Temperature-Responsive Hydrophobic Interaction of Poly(N-Isopropylacrylamide) Hydrogel-Modified Surfaces with Steroids. Anal. Chem. 1999, 71, 1125–1130. [Google Scholar] [CrossRef]

- Okano, T.; Yamada, N.; Okuhara, M.; Sakai, H.; Sakurai, Y. Mechanism of Cell Detachment from Temperature-Modulated, Hydrophilic-Hydrophobic Polymer Surfaces. Biomaterials 1995, 16, 297–303. [Google Scholar] [CrossRef] [PubMed]

- Gotoh, K.; Shohbuke, E.; Kuroda, Y.; Kobayashi, Y. Contamination Control of Polymer Films by Two Atmospheric Pressure Plasma Jet Treatments. Polym. J. 2016, 48, 889–896. [Google Scholar] [CrossRef]

- Kasgoz, H.; Ozbas, Z.; Esen, E.; Sahin, C.P.; Gurdag, G. Removal of Copper(II) Ions with a Thermoresponsive Cellulose-g-poly(N-isopropyl Acrylamide) Copolymer. J. Appl. Polym. Sci. 2013, 130, 4440–4448. [Google Scholar] [CrossRef]

- Gupta, S.; Janata, M.; Čadová, E.; Raus, V. Straightforward Synthesis of Complex Polymeric Architectures with Ultra-High Chain Density. Chem. Sci. 2024, 15, 12739–12753. [Google Scholar] [CrossRef]

- Yoshida, T.; Hoshi, T.; Aoyagi, T. Molecular Design of Reactive Polycaprolactone That Can Be Induced into Shape-Memory Materials Promotes Further Functionalization. Polym. J. 2024, in press. [Google Scholar] [CrossRef]

- Mori, T.; Okamoto, K.; Endo, H.; Hill, J.P.; Shinoda, S.; Matsukura, M.; Tsukube, H.; Suzuki, Y.; Kanekiyo, Y.; Ariga, K. Mechanical Tuning of Molecular Recognition to Discriminate the Single-Methyl-Group Difference between Thymine and Uracil. J. Am. Chem. Soc. 2010, 132, 12868–12870. [Google Scholar] [CrossRef]

- Izawa, H.; Kawakami, K.; Sumita, M.; Tateyama, Y.; Hill, J.P.; Ariga, K. β-Cyclodextrin-Crosslinked Alginate Gel for Patient-Controlled Drug Delivery Systems: Regulation of Host–Guest Interactions with Mechanical Stimuli. J. Mater. Chem. B 2013, 1, 2155. [Google Scholar] [CrossRef]

- Ishikawa, D.; Mori, T.; Yonamine, Y.; Nakanishi, W.; Cheung, D.L.; Hill, J.P.; Ariga, K. Mechanochemical Tuning of the Binaphthyl Conformation at the Air–Water Interface. Angew. Chem. Int. Ed. 2015, 54, 8988–8991. [Google Scholar] [CrossRef] [PubMed]

- Zhang, D.; Cheng, Z.; Kang, H.; Yu, J.; Liu, Y.; Jiang, L. A Smart Superwetting Surface with Responsivity in Both Surface Chemistry and Microstructure. Angew. Chem. Int. Ed. 2018, 57, 3701–3705. [Google Scholar] [CrossRef] [PubMed]

- Jones, D.S.; Andrews, G.P.; Caldwell, D.L.; Lorimer, C.; Gorman, S.P.; McCoy, C.P. Novel Semi-Interpenetrating Hydrogel Networks with Enhanced Mechanical Properties and Thermoresponsive Engineered Drug Delivery, Designed as Bioactive Endotracheal Tube Biomaterials. Eur. J. Pharm. Biopharm. 2012, 82, 563–571. [Google Scholar] [CrossRef] [PubMed]

- Yin, G.; Chen, G.; Zhou, Z.; Li, Q. Modification of PEG-b-PCL Block Copolymer with High Melting Temperature by the Enhancement of POSS Crystal and Ordered Phase Structure. RSC Adv. 2015, 5, 33356–33363. [Google Scholar] [CrossRef]

- Ebara, M.; Kotsuchibashi, Y.; Uto, K.; Aoyagi, T.; Kim, Y.-J.; Narain, R.; Idota, N.; Hoffman, J.M. Smart Biomaterials; NIMS Monographs; Springer: Tokyo, Japan, 2014; pp. 321–336. [Google Scholar]

- Gao, C.; Tsou, C.-H.; Zeng, C.-Y.; Yuan, L.; Peng, R.; Zhang, X.-M. Organocatalyzed Ring-Opening Copolymerization of α-Bromo-γ-Butyrolactone with ε-Caprolactone for the Synthesis of Functional Aliphatic Polyesters—Pre-Polymers for Graft Copolymerization. Des. Monomers Polym. 2018, 21, 193–201. [Google Scholar] [CrossRef]

- Zako, T.; Matsushita, S.; Hoshi, T.; Aoyagi, T. Direct Surface Modification of Polycaprolactone-Based Shape Memory Materials to Introduce Positive Charge Aiming to Enhance Cell Affinity. Materials 2021, 14, 5797. [Google Scholar] [CrossRef]

- Houk, K.N.; Jabbari, A.; Hall, H.K.; Alemán, C. Why δ-Valerolactone Polymerizes and γ-Butyrolactone Does Not. J. Org. Chem. 2008, 73, 2674–2678. [Google Scholar] [CrossRef]

- Moore, T.; Adhikari, R.; Gunatillake, P. Chemosynthesis of Bioresorbable Poly(γ-Butyrolactone) by Ring-Opening Polymerisation: A Review. Biomaterials 2005, 26, 3771–3782. [Google Scholar] [CrossRef]

- Pintauer, T.; Matyjaszewski, K. Atom Transfer Radical Addition and Polymerization Reactions Catalyzed by Ppm Amounts of Copper Complexes. Chem. Soc. Rev. 2008, 37, 1087. [Google Scholar] [CrossRef]

- Matyjaszewski, K.; Dong, H.; Jakubowski, W.; Pietrasik, J.; Kusumo, A. Grafting from Surfaces for “Everyone”: ARGET ATRP in the Presence of Air. Langmuir 2007, 23, 4528–4531. [Google Scholar] [CrossRef]

- Andersen, C.; Madsen, N.J.; Daugaard, A.E. Screening Platform for Identification of Suitable Monomer Mixtures Able to Form Thin-Film Coatings on Polyurethanes by UV-Initiated Free Radical Polymerization. ACS Appl. Polym. Mater. 2019, 1, 3295–3303. [Google Scholar] [CrossRef]

- Massoumi, B.; Abdollahi, M.; Fathi, M.; Entezami, A.A.; Hamidi, S. Synthesis of Novel Thermoresponsive Micelles by Graft Copolymerization of N-Isopropylacrylamide on Poly(ε-Caprolactone-Co-α-Bromo-ε-Caprolactone) as Macroinitiator via ATRP. J. Polym. Res. 2013, 20, 47. [Google Scholar] [CrossRef]

- Ohta, K.; Iwamoto, R. Experimental Proof of the Relation Between Thickness of the Probed Surface Layer and Absorbance in FT-IR/ATR Spectroscopy. Appl. Spectrosc. 1985, 39, 418–425. [Google Scholar] [CrossRef]

- Takao, A.; Fusae, M.; Yu, N. Preparation of Cross-Linked Aliphatic Polyester and Application to Thermo-Responsive Material. J. Control. Release 1994, 32, 87–96. [Google Scholar] [CrossRef]

- Alteheld, A.; Feng, Y.; Kelch, S.; Lendlein, A. Biodegradable, Amorphous Copolyester-Urethane Networks Having Shape-Memory Properties. Angew. Chem. Int. Ed. 2005, 44, 1188–1192. [Google Scholar] [CrossRef]

- Lenoir, S.; Riva, R.; Lou, X.; Detrembleur, C.; Jérôme, R.; Lecomte, P. Ring-Opening Polymerization of α-Chloro-ε-Caprolactone and Chemical Modification of Poly(α-Chloro-ε-Caprolactone) by Atom Transfer Radical Processes. Macromolecules 2004, 37, 4055–4061. [Google Scholar] [CrossRef]

- Riva, R.; Rieger, J.; Jérôme, R.; Lecomte, P.H. Heterograft Copolymers of Poly(Ε-caprolactone) Prepared by Combination of ATRA “Grafting onto” and ATRP “Grafting from” Processes. J. Polym. Sci. Part A Polym. Chem. 2006, 44, 6015–6024. [Google Scholar] [CrossRef]

- Li, M.; Shan, G.; Bao, Y.; Pan, P. Poly(ε-caprolactone)-Graft-poly(N-isopropylacrylamide) Amphiphilic Copolymers Prepared by a Combination of Ring-opening Polymerization and Atom Transfer Radical Polymerization: Synthesis, Self-assembly, and Thermoresponsive Property. J. Appl. Polym. Sci. 2014, 131, 22. [Google Scholar] [CrossRef]

- Defize, T.; Riva, R.; Thomassin, J.; Jérôme, C.; Alexandre, M. Thermo-Reversible Reactions for the Preparation of Smart Materials: Recyclable Covalently-Crosslinked Shape Memory Polymers. Macromol. Symp. 2011, 309–310, 154–161. [Google Scholar] [CrossRef]

- Defize, T.; Thomassin, J.-M.; Ottevaere, H.; Malherbe, C.; Eppe, G.; Jellali, R.; Alexandre, M.; Jérôme, C.; Riva, R. Photo-Cross-Linkable Coumarin-Based Poly(ε-Caprolactone) for Light-Controlled Design and Reconfiguration of Shape-Memory Polymer Networks. Macromolecules 2018, 52, 444–456. [Google Scholar] [CrossRef]

- Defize, T.; Riva, R.; Raquez, J.; Dubois, P.; Jérôme, C.; Alexandre, M. Thermoreversibly Crosslinked Poly(ε-caprolactone) as Recyclable Shape-Memory Polymer Network. Macromol. Rapid Commun. 2011, 32, 1264–1269. [Google Scholar] [CrossRef] [PubMed]

- SmidsrødJ, O.; Guillet, E. Study of Polymer-Solute Interactions by Gas Chromatography. Macromolecules 1969, 2, 272–277. [Google Scholar] [CrossRef]

- Lönnberg, H.; Fogelström, L.; Berglund, L.; Malmström, E.; Hult, A. Surface Grafting of Microfibrillated Cellulose with Poly(ε-Caprolactone)—Synthesis and Characterization. Eur. Polym. J. 2008, 44, 2991–2997. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).