The Influences of Selected Factors on Bending Moment Capacity of Case Furniture Joints

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Experimental Design

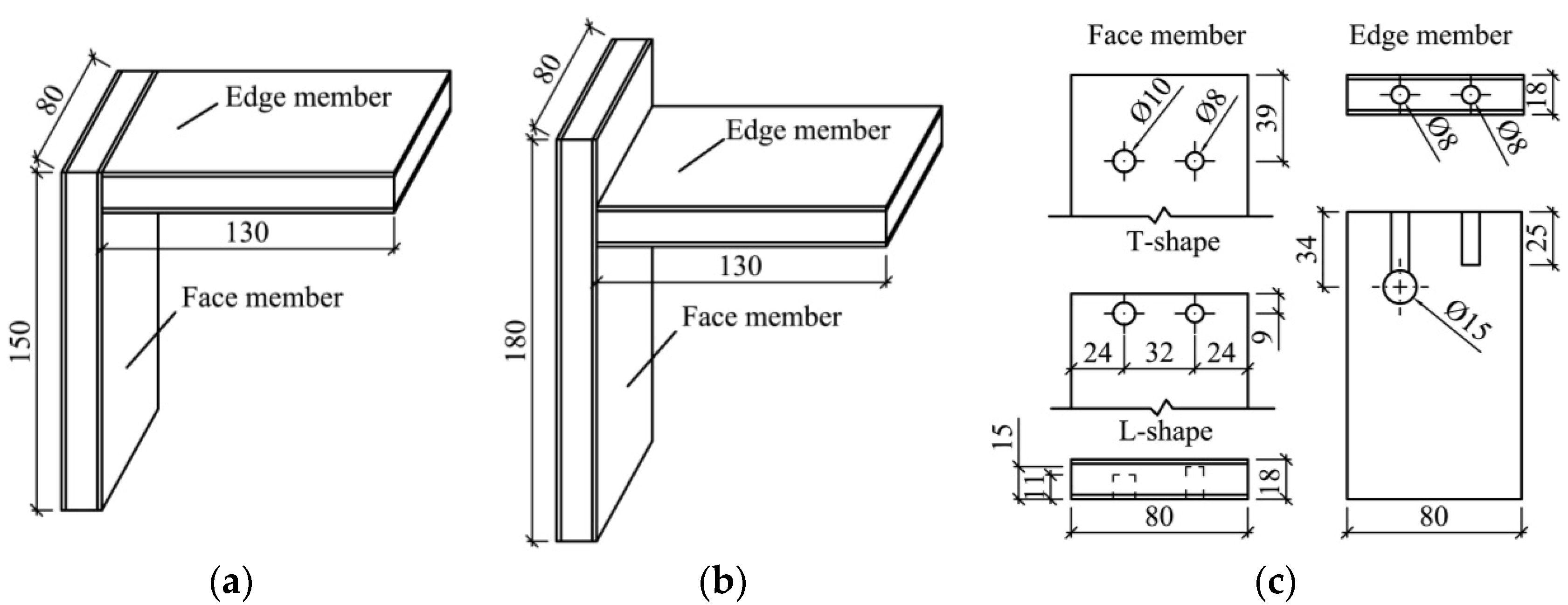

2.2.1. Material Type of Members and Joint Shape Effects on BMC

2.2.2. Joint Type and Materials Type Effects on BMC of L-Shaped Joints

2.3. Experimental Procedure

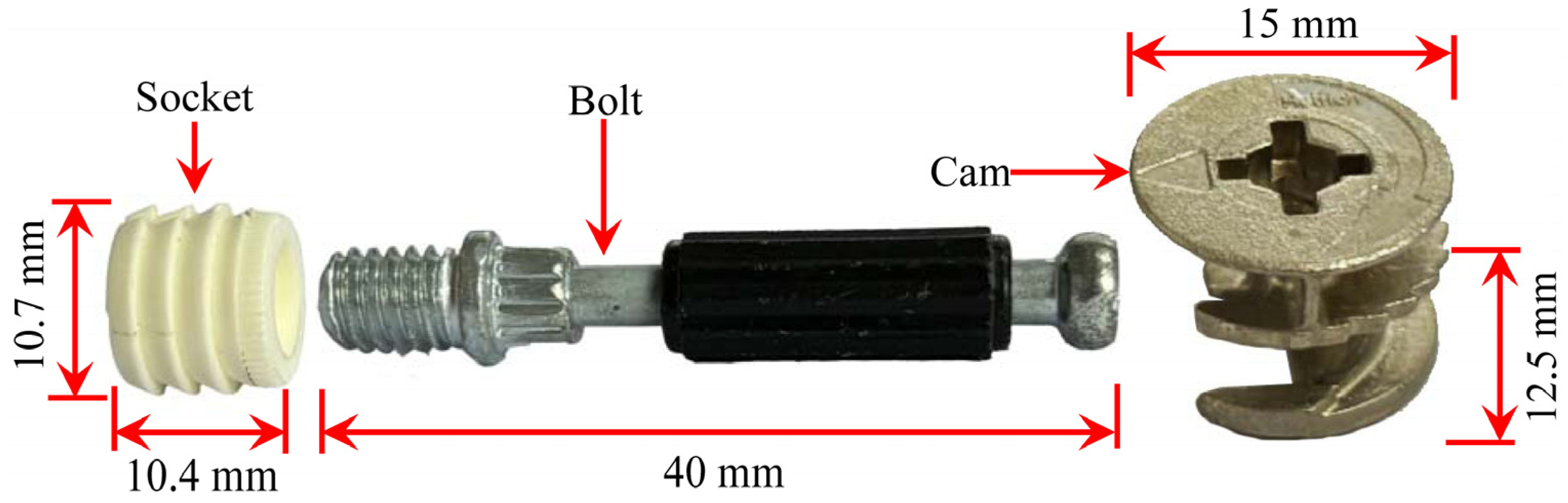

2.3.1. Sample Preparation

2.3.2. Test Method

2.4. Statistical Analysis

3. Results and Discussion

3.1. Effects of Joint Shape and Members’ Material Type on BMC of Joints

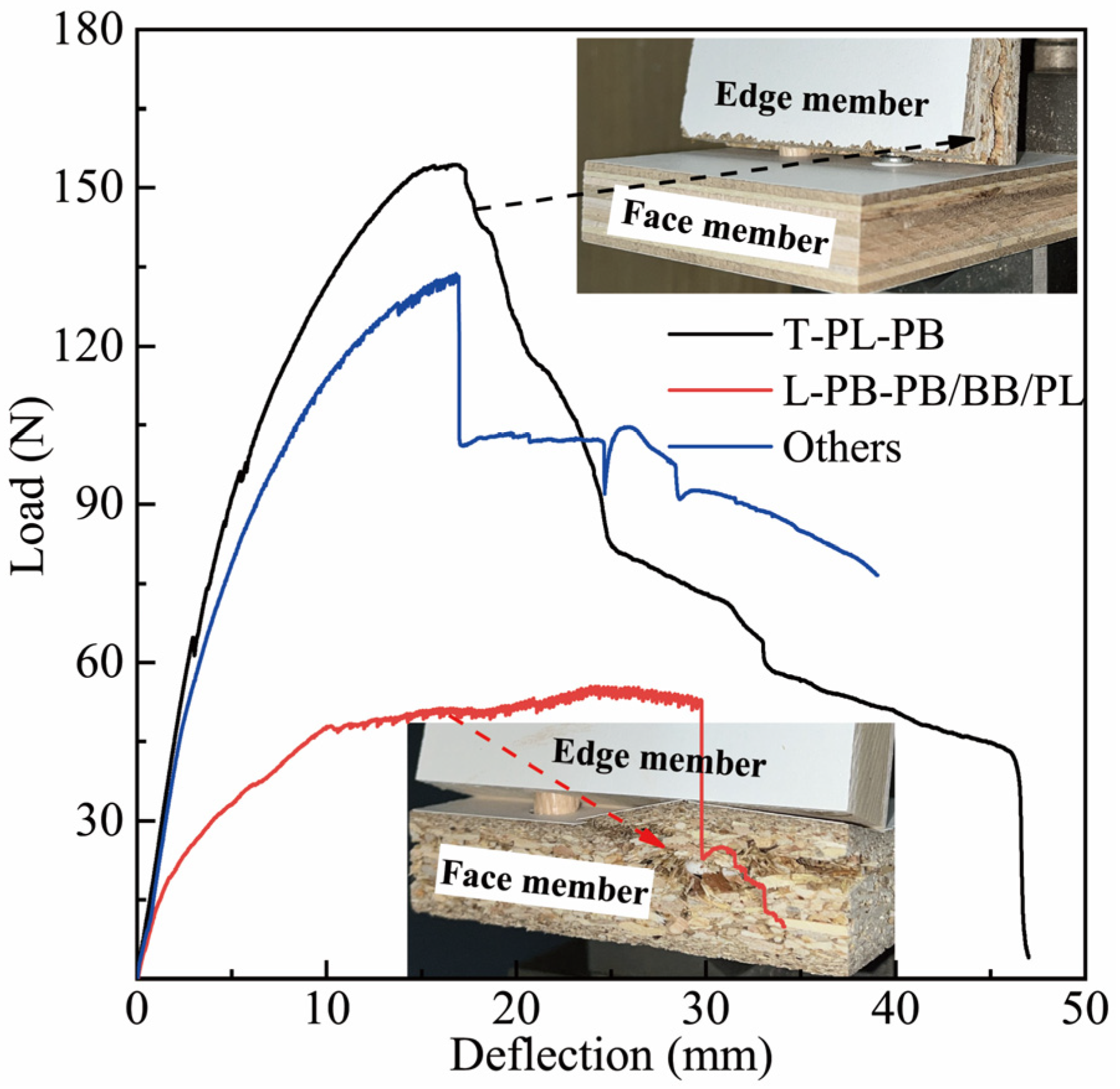

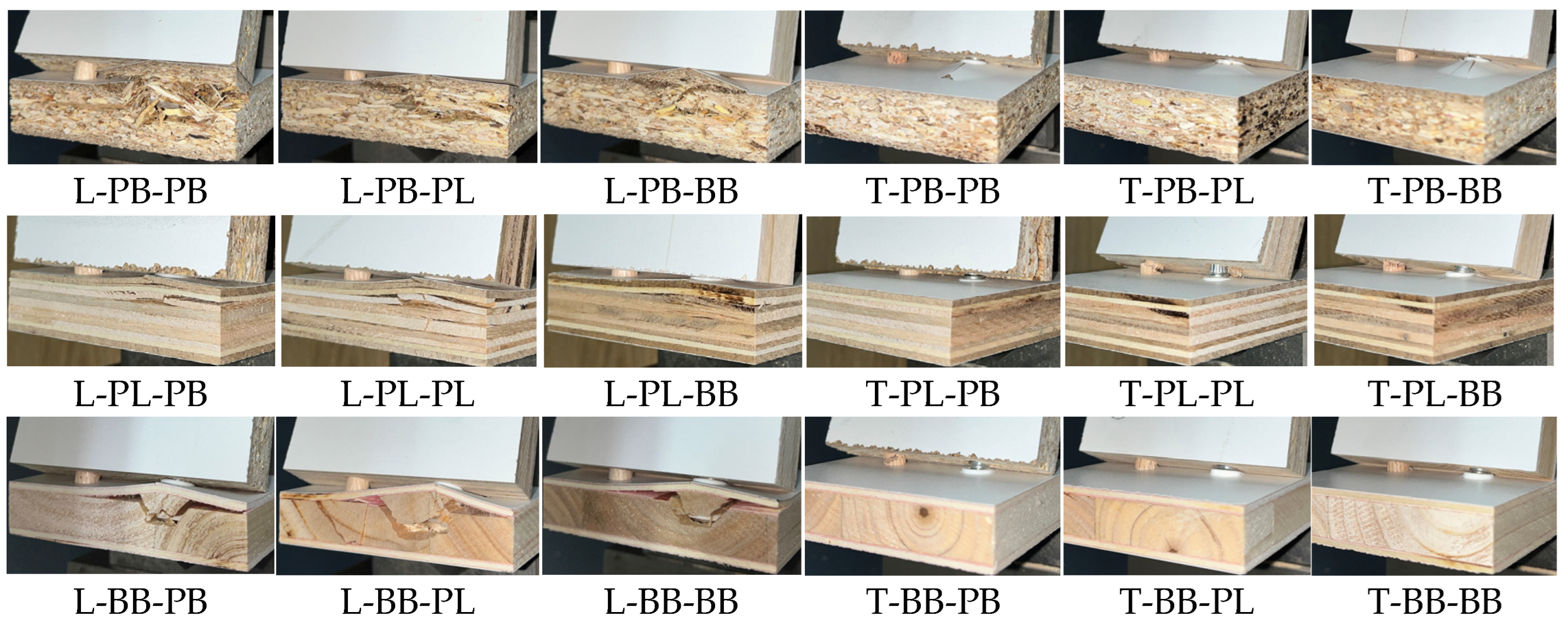

3.1.1. Typical Load–Deflection Curve and Failure Modes of Joints

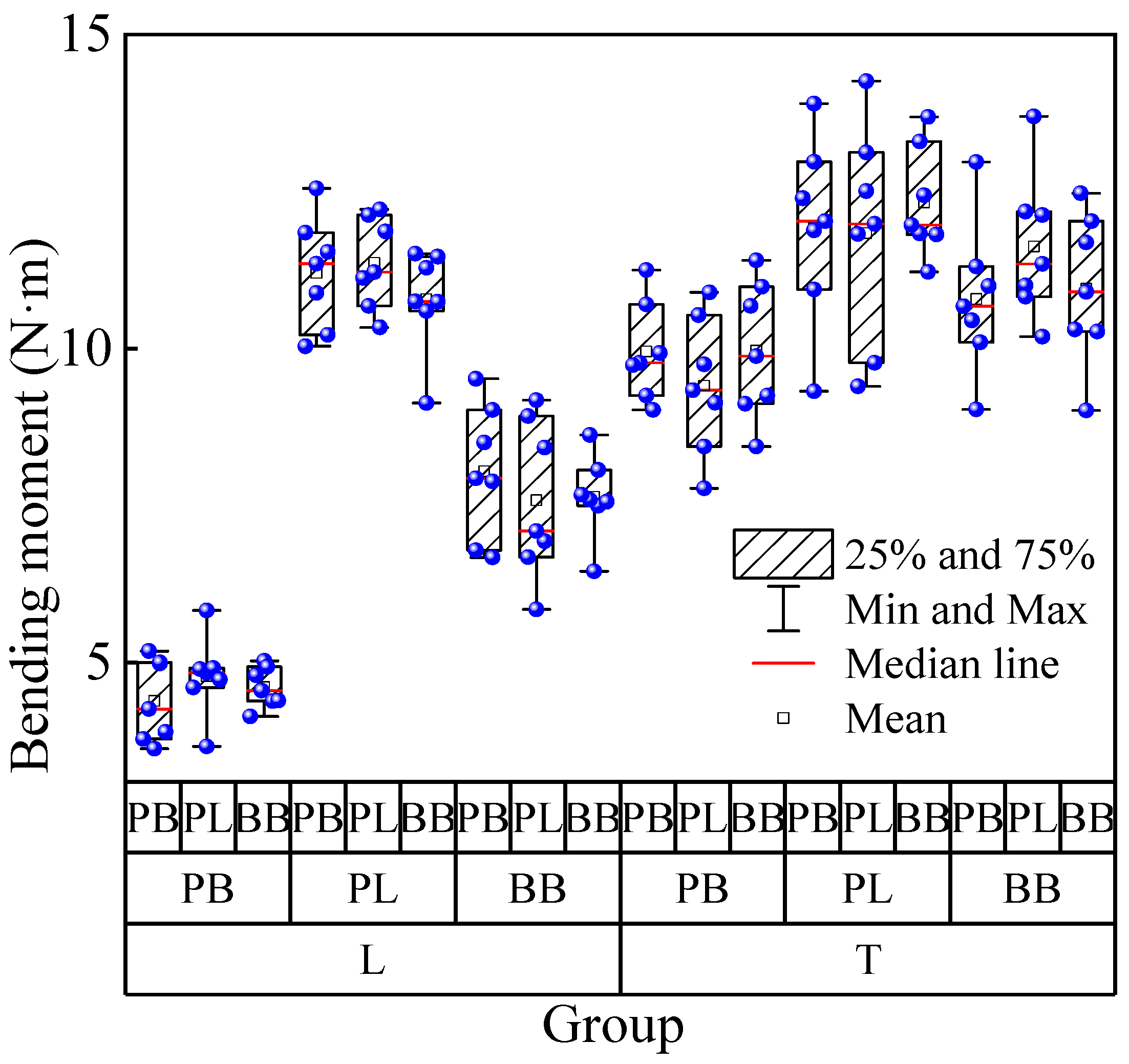

3.1.2. Comparisons of Joint Shape and Material Type Effects on BMC of Joints

3.2. Effects of Material Type and Joint Type on BMC

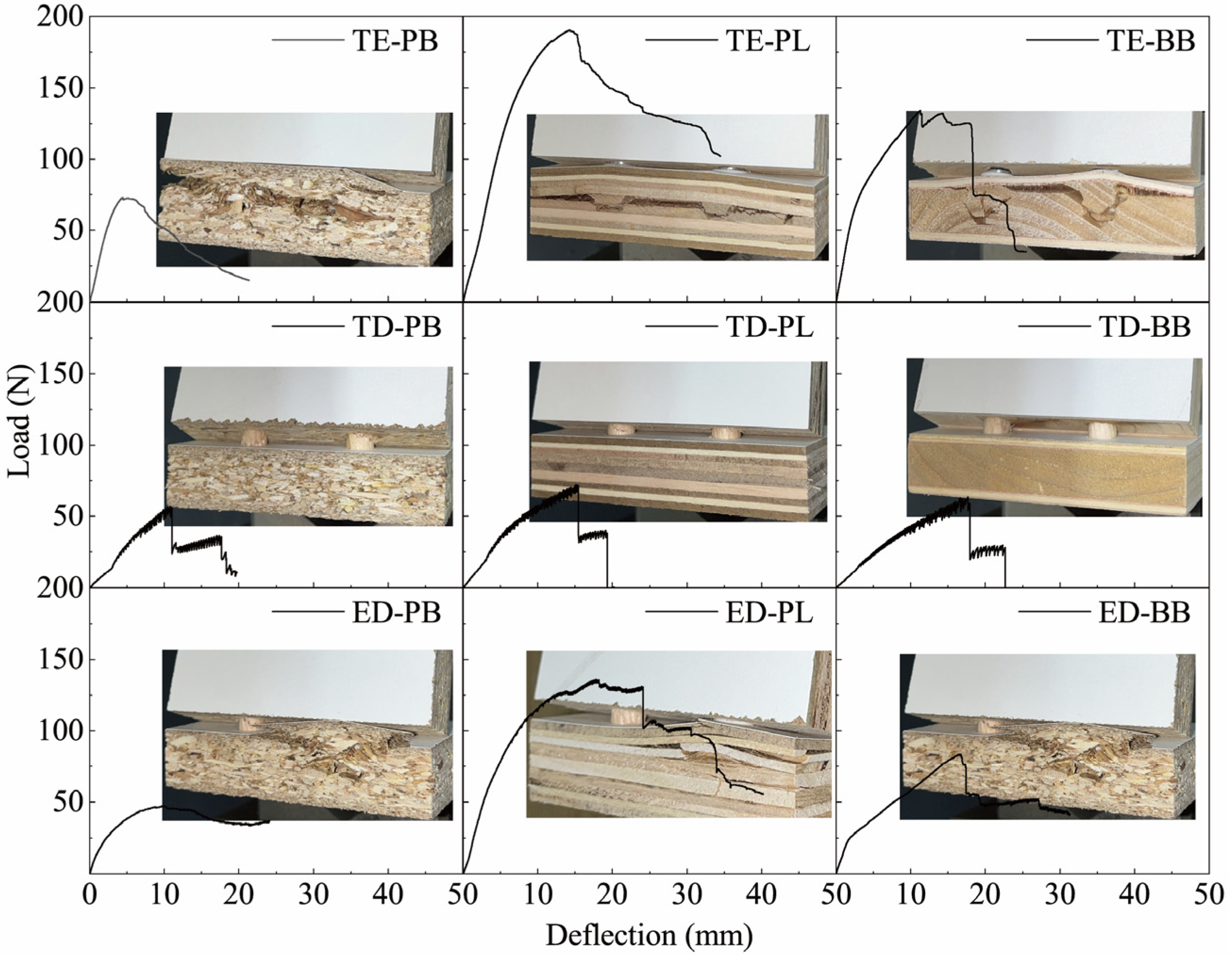

3.2.1. Typical Load and Deflection Curve and Failure Modes

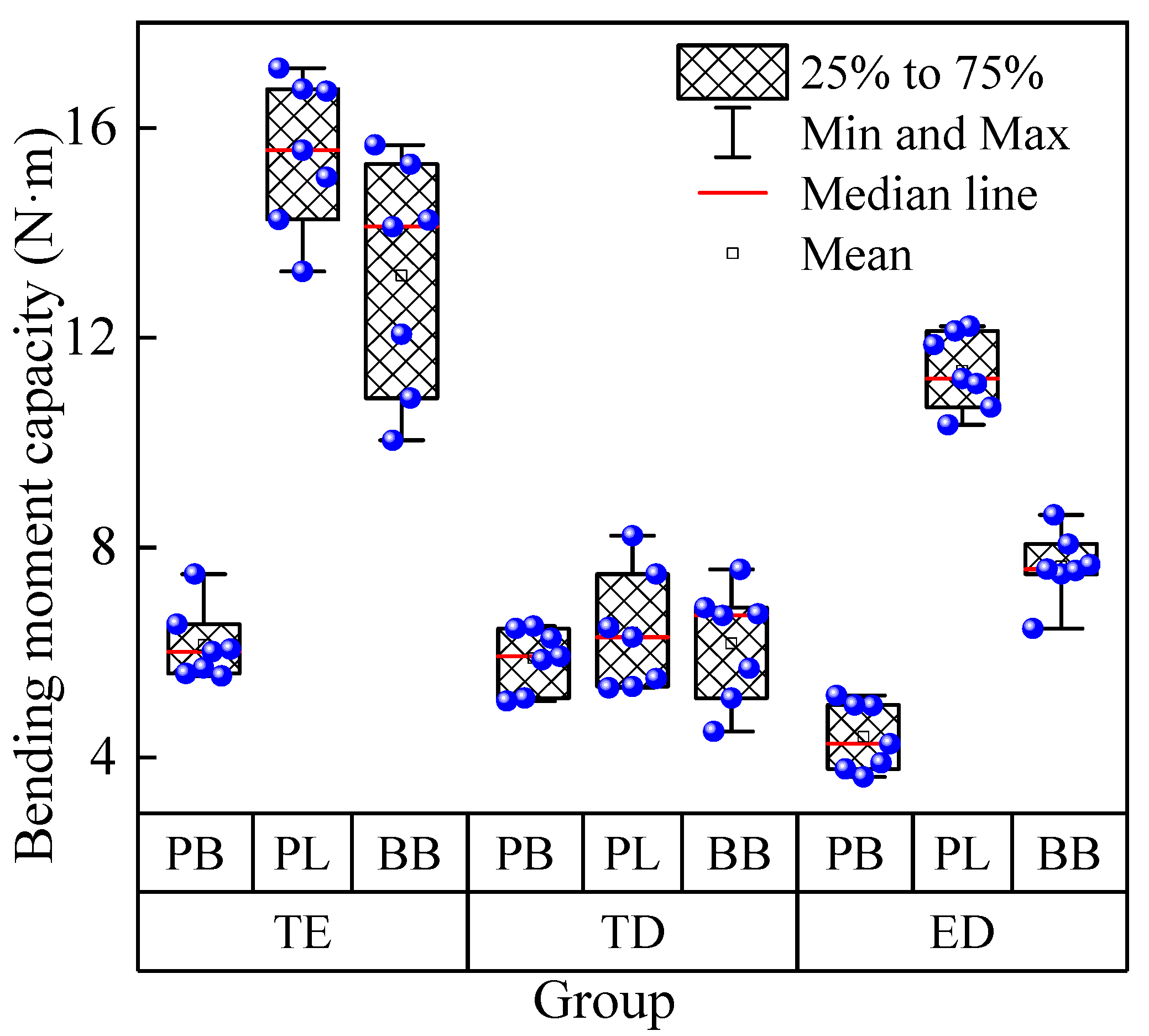

3.2.2. Comparisons of BMC Considering Joint Type and Material Type

4. Conclusions

- (1)

- Joint shape, face member material, and joint type significantly influenced the BMC of case furniture joints, while the edge member material had no significant effect.

- (2)

- The BMC of joints constructed with TE was significantly higher than those with ED, followed by TD. The ratios of the BMC of joints with ED to half the sum of TE and TD were 1.04, 0.73 and 0.79 for joints made of PL, PB, and BB, respectively.

- (3)

- The face member material primarily determined the BMC of joints, indicating the potential for cost savings by using mixed materials in case furniture manufacturing.

- (4)

- Variability in the experimental results was primarily attributed to the characteristics of block board (BB), which has a solid wood core. This core introduces fluctuations in mechanical properties due to variations in moisture content, density, and natural defects, resulting in greater discrepancies in BMCs for joints with block board compared to those with engineered wood products.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhu, L.; Qi, X.; Song, W. Research advances and prospects of intelligent technologies in the Chinese wood-based panel manufacturing. J. For. Eng. 2023, 8, 1–12. [Google Scholar]

- Wang, C.; Zhang, C.; Zhu, Y. Reverse design and additive manufacturing of furniture protective foot covers. BioResources 2024, 19, 4670–4678. [Google Scholar] [CrossRef]

- Xu, X.; Xiong, X.; Yue, X.; Zhang, M. A parametric optimized method for three-dimensional corner joints in wooden furniture. Forests 2023, 14, 1063. [Google Scholar] [CrossRef]

- Zhu, L.; Yan, Y.; Lv, J. A bibliometric analysis of current knowledge structure and research progress related to sustainable furniture design systems. Sustainability 2023, 15, 8622. [Google Scholar] [CrossRef]

- Zhang, Z.; Zhu, J.; Qi, Q. Research on the recyclable design of wooden furniture based on the recyclability evaluation. Sustainability 2023, 15, 16758. [Google Scholar] [CrossRef]

- Chen, Y.; Xu, Z. Research on the evaluation model for the tactile feel of custom wardrobe furniture finishes. BioResources 2024, 19, 5262–5287. [Google Scholar] [CrossRef]

- Zhang, J.; Chen, Y. Research on color and texture characteristics and visual perception of custom wardrobe finishes. BioResources 2024, 19, 5109–5128. [Google Scholar] [CrossRef]

- Zhou, C.; Zhang, Z.; Huang, T.; Gu, W.; Kaner, J. A bibliometric analysis of interaction interface aging research: From 2003 to 2022. Sage Open 2024, 14, 21582440241252225. [Google Scholar] [CrossRef]

- Kłos, R.; Langová, N. Determination of reliability of selected case furniture constructions. Appl. Sci. 2023, 13, 4587. [Google Scholar] [CrossRef]

- Yuksel, M.; Yildirim, N.; Kasal, A.; Erdil, Y.Z.; Demirci, S. Effect of the panel type and panel thickness on moment resistance of screw-jointed corner joints and stiffness of four-member cabinets. BioResources 2014, 9, 6340–6349. [Google Scholar] [CrossRef]

- Wu, S.S.; Zhou, J.C.; Xu, W. A convenient approach to manufacturing lightweight and high-sound-insulation plywood using furfuryl alcohol/multilayer graphene oxide as a shielding layer. Wood Mater. Sci. Eng. 2024, 19, 1–8. [Google Scholar] [CrossRef]

- Luo, Z.; Xu, W.; Wu, S. Performances of green velvet material (PLON) used in upholstered furniture. BioResources 2023, 18, 5108–5119. [Google Scholar] [CrossRef]

- Zhu, J.; Niu, J. Green material characteristics applied to office desk furniture. BioResources 2022, 17, 2228–2242. [Google Scholar] [CrossRef]

- Fu, Y.; Chen, J. Reversibly photochromic wood constructed by electric field-assisted self-assembled chitosan and tungsten trioxidecoatings. Wood Mater. Sci. Eng. 2024, 19, 1–9. [Google Scholar] [CrossRef]

- Zou, Y.; Xia, Y.; Yan, X. Effects of compound use of two UV coating microcapsules on the physicochemical, optical, mechanical, and self-healing performance of coatings on fiberboard surfaces. Coatings 2024, 14, 1012. [Google Scholar] [CrossRef]

- Zou, Y.; Xia, Y.; Yan, X. Effect of UV top coating microcapsules on the coating properties of fiberboard surfaces. Polymers 2024, 16, 2098. [Google Scholar] [CrossRef]

- Hang, J.; Yan, X.; Li, J. A review on the effect of wood surface modification on paint film adhesion properties. Coatings 2024, 14, 1313. [Google Scholar] [CrossRef]

- Li, D.; Li, W.; Mei, C. The relationship of bending strength, deformation and VDP of OSB. J. For. Eng. 2023, 8, 52–57. [Google Scholar]

- Petrova, B.; Jivkov, V.; Yavorov, N. Possibilities for efficient furniture construction made of thin and ultra-thin materials by using mitre joints. Materials 2023, 16, 6855. [Google Scholar] [CrossRef]

- Norvydas, V.; Baltrušaitis, A.; Juodeikienė, I. Investigation of miter corner joint strength of case furniture from particleboard. Mater. Sci. 2012, 18, 352–357. [Google Scholar] [CrossRef]

- Yerlikaya, N.Ç.; Aktaş, A. Enhancement of load-carrying capacity of corner joints in case-type furniture. Mater. Des. 2012, 37, 393–401. [Google Scholar] [CrossRef]

- Kłos, R.; Fabisiak, B.; Ng, H.K.T. Comparative reliability analysis of selected joints for case furniture. BioResources 2018, 13, 5111–5123. [Google Scholar] [CrossRef]

- Tankut, A.N.; Tankut, N. Effect of some factors on the strength of furniture corner joints constructed with wood biscuits. Turk. J. Agric. For. 2004, 28, 301–309. [Google Scholar]

- Kociszewski, M. Stiffness and load capacity of biscuit corner joints. Folia For. Pol. 2005, 36, 39–47. [Google Scholar]

- Uysal, M.; Tasdemir, C.; Memis, D. Effect of epoxy resin reinforcement on screw withdrawal strength of fiberboard and particleboard used in furniture industry. Drv. Ind. 2023, 74, 491–500. [Google Scholar] [CrossRef]

- Kasal, A.; Erdil, Y.Z.; Zhang, J.; Efe, H.; Avci, E. Estimation equations for moment resistances of L-type screw corner joints in case goods furniture. For. Prod. J. 2008, 58, 21–27. [Google Scholar]

- Kasal, A.; Smardzewski, J.; Kuşkun, T.; Güray, E. Analyses of L-type corner joints connected with auxetic dowels for case furniture. Materials 2023, 16, 4547. [Google Scholar] [CrossRef]

- Chen, G.; Wang, C.; Wu, J.; Zhang, E.; Wu, D. Mechanical performance of nailed connections between laminated bamboo lumber and oriented strand board. J. For. Eng. 2023, 8, 75–81. [Google Scholar]

- Miao, Y.; Pan, S.; Xu, W. Staple holding strength of furniture frame joints constructed of plywood and solid wood. Forests 2022, 13, 2006. [Google Scholar] [CrossRef]

- Yuksel, M.; Kasal, A.; Erdil, Y.Z.; Acar, M.; Kuşkun, T. Effects of the panel and fastener type on bending moment capacity of L-type joints for furniture cases. Pro Ligno. 2015, 11, 426–443. [Google Scholar]

- Tankut, A.N.; Tankut, N. Investigations the effects of fastener, glue, and composite material types on the strength of corner joints in case-type furniture construction. Mater. Des. 2009, 30, 4175–4182. [Google Scholar] [CrossRef]

- Zhu, Y.; Wang, Y.; Yan, X. The effects of urea-formaldehyde resin-coated Toddalia asiatica (L.) Lam extract microcapsules on the properties of surface coatings for poplar wood. Coatings 2024, 14, 1011. [Google Scholar] [CrossRef]

- Śmietańska, K.; Mielczarek, M. Strength properties of furniture corner joints constructed with different wooden connectors and wood-based materials. Ann. Wars. Univ. Life Sci. SGGW For. Wood Technol. 2022, 118, 55–66. [Google Scholar] [CrossRef]

- Deng, J.; Ding, T.; Yan, X. Effect of two pomelo peel flavonoid microcapsules on the performance of waterborne coatings on the surface of poplar boards. Coatings 2024, 14, 937. [Google Scholar] [CrossRef]

- Sydor, M.; Kwapich, A.; Pohl, P. Strength comparative analysis of furniture joints made of various materials. Ann. WULS-SGGW For. Wood Technol. 2021, 113, 89–97. [Google Scholar] [CrossRef]

- Atar, M.; Ozcifci, A.; Altinok, M.; Celikel, U. Determination of diagonal compression and tension performances for case furniture corner joints constructed with wood biscuits. Mater. Des. 2009, 30, 665–670. [Google Scholar] [CrossRef]

- Maleki, S.; Haftkhani, A.R.; Dalvand, M.; Faezipour, M.; Tajvidi, M. Bending moment resistance of corner joints constructed with spline under diagonal tension and compression. J. For. Res. 2012, 23, 481–490. [Google Scholar] [CrossRef]

- Džincic, I.; Palija, T.; Miric-Milosavljevic, M.; Mihailovic, V. Size and character of the loads in corner joints within storage furniture. Wood Res. 2017, 62, 451–458. [Google Scholar]

- Zhang, J.L.; Eckelman, C.A. The bending moment resistance of single-dowel corner joints in case construction. For. Prod. J. 1993, 43, 19. [Google Scholar]

- Zhang, J.L.; Eckelman, C.A. Rational design of multi-dowel corner joints in case construction. For. Prod. J. 1993, 43, 52–58. [Google Scholar]

- Liu, W.; Eckelman, C.A. Effect of number of fasteners on the strength of corner joints for cases. For. Prod. J. 1998, 48, 93–95. [Google Scholar]

- Karaman, A. The effects of wooden dowel species and the end distance of miniflex fastener on the shear force capacity for h-type furniture joints. Wood Fiber Sci. 2024, 5, 1–8. [Google Scholar]

- Simek, M.; Haviarova, E.; Eckelman, C.A. The effect of end distance and number of ready-to-assemble furniture fasteners on bending moment resistance of corner joints. Wood Fiber Sci. 2010, 42, 92–98. [Google Scholar]

- Lin, Q.; Zhang, X.; Zhu, N.; Kusumah, S.S.; Umemura, K.; Zhao, Z. Preparation and investigation of an eco-friendly plywood adhesive composed of sucrose and ammonium polyphosphate. Wood Mater. Sci. Eng. 2023, 18, 1202–1211. [Google Scholar] [CrossRef]

- Zhu, Y.; Wang, Y.; Yan, X. Preparation of chitosan-coated Toddalia asiatica (L.) Lam extract microcapsules and its effect on coating antibacterial properties. Coatings 2024, 14, 942. [Google Scholar] [CrossRef]

- Wang, Y.; Yan, X. Preparation of Toddalia asiatica (L.) Lam. extract microcapsules and their effect on optical, mechanical and antibacterial performance of waterborne topcoat paint films. Coatings 2024, 14, 655. [Google Scholar] [CrossRef]

- CNS GB/T 17657; Test Methods of Evaluating the Properties of Wood-Based Panels and Surface Decorated Wood-Based Panels. Chinese National Standard: Beijing, China, 2022. (In Chinese)

| Material Type | Density (g/cm3) | Moisture Content (%) |

|---|---|---|

| PB | 0.66(1.7) | 8.83(1.2) |

| PL | 0.70(1.7) | 9.48(2.3) |

| BB | 0.47(7.4) | 9.69(0.9) |

| Sources | F | p-Value |

|---|---|---|

| Joint shape | 69.4 | <0.001 * |

| Face member | 81.6 | <0.001 * |

| Edge member | 0.06 | 0.938 |

| Joint shape × face member | 7.83 | 0.001 * |

| Joint shape × edge member | 0.067 | 0.953 |

| Face member × edge member | 0.023 | 0.999 |

| Joint shape × face member × edge member | 0.434 | 0.784 |

| Face Member | Edge Member | Joint Shape | |

|---|---|---|---|

| L-Shape | T-Shape | ||

| PB | PB | 4.4 ± 0.7 (14.9)Bc | 10.0 ± 0.8 (7.9)Ab |

| PL | 4.9 ± 0.6 (13.2)Bc | 9.4 ± 1.1 (11.7)Ab | |

| BB | 4.6 ± 0.3 (7.0)Bc | 10.0 ± 1.1 (11.0)Ab | |

| PL | PB | 11.2 ± 0.9 (8.0)Aa | 11.9 ± 1.5 (12.3)Aa |

| PL | 11.4 ± 0.7 (7.6)Aa | 11.8 ± 1.7 (14.7)Aa | |

| BB | 10.8 ± 0.8 (6.4)Aa | 12.3 ± 0.9 (7.2)Aa | |

| BB | PB | 8.1 ± 1.1 (13.3)Bb | 10.8 ± 1.2 (11.2)Aa |

| PL | 7.6 ± 1.3 (16.6)Bb | 11.6 ± 1.2 (9.9)Aa | |

| BB | 7.6 ± 0.7 (8.6)Bb | 11.0 ± 1.2 (11.0)Aa | |

| Sources | F | p-Value |

|---|---|---|

| Material type | 131 | <0.001 * |

| Joint type | 128 | <0.001 * |

| Material type × Joint type | 32 | <0.001 * |

| Joint Type | Material Type | ||

|---|---|---|---|

| PB | PL | BB | |

| TE | 6.1 ± 0.7 (11.2)Ca | 15.5 ± 1.4 (9.3)Aa | 13.2 ± 2.2 (16.7)Ba |

| TD | 5.9 ± 0.6 (10.0)Aa | 6.4 ± 1.1 (17.6)Ac | 6.2 ± 1.1 (17.7)Ac |

| ED | 4.4 ± 0.7 (14.9)Cb | 11.4 ± 0.7 (6.4)Ab | 7.6 ± 0.7 (8.6)Bb |

| 1/2(TE + TD) | 6.02 | 10.96 | 9.68 |

| Ratio | 0.73 | 1.04 | 0.79 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hu, W.; Zhao, Y.; Xu, W.; Liu, Y. The Influences of Selected Factors on Bending Moment Capacity of Case Furniture Joints. Appl. Sci. 2024, 14, 10044. https://doi.org/10.3390/app142110044

Hu W, Zhao Y, Xu W, Liu Y. The Influences of Selected Factors on Bending Moment Capacity of Case Furniture Joints. Applied Sciences. 2024; 14(21):10044. https://doi.org/10.3390/app142110044

Chicago/Turabian StyleHu, Wengang, Yuan Zhao, Wei Xu, and Yuanqiang Liu. 2024. "The Influences of Selected Factors on Bending Moment Capacity of Case Furniture Joints" Applied Sciences 14, no. 21: 10044. https://doi.org/10.3390/app142110044

APA StyleHu, W., Zhao, Y., Xu, W., & Liu, Y. (2024). The Influences of Selected Factors on Bending Moment Capacity of Case Furniture Joints. Applied Sciences, 14(21), 10044. https://doi.org/10.3390/app142110044