Abstract

Mattress comfort, often associated with firmness, is a complex construct influenced by factors such as material composition, construction, and personal preference. In this short communication paper, we indirectly investigated the effects of long-term mattress use on its hardness and sleep quality by observing the changes in the mattress. A mechanical durability test was performed on two structurally different mattress samples (with polyurethane core and pocket spring core) using a modified method based on the EN 1957 standard, aiming to understand the long-term effects of mattress characteristics on sleep quality. Preliminary results confirm that the mattress samples can maintain firmness and support during long-term use. The polyurethane foam mattress experienced initial compression but quickly stabilized, while the pocket spring mattress showed slight softening, maintaining overall firmness. For the polyurethane mattress, after the initial drop, the hardness value stabilized, varying between 7.53 and 9.03 N/mm, and at the end of the test, it stopped at 8.60 N/mm. The firmness rating stabilized at 4.3, showing minimal fluctuation between 4.0 and 4.6 throughout the process, while the total height loss was 3.79 mm. The hardness value of pocket spring mattresses generally decreased with increasing test cycles (it started at 5.86 N/mm and ended at 5.21 N/mm). The firmness remained relatively stable, varying between 7.3 and 7.1, and the total height loss was only 2.86 mm. The findings suggest that the firmness of a mattress can be changed with its use, highlighting the need for further research on a larger number of samples in the direction of the long-term implications of these changes on sleep comfort.

1. Introduction

Sleep quality promotes health and well-being, and extensive research has highlighted its profound effects on cognitive function, emotional balance, and physical energy. The environment in which we sleep is of paramount importance, with mattresses being a primary component in creating conditions that make sleep comfortable and restorative. The imperative of mattress comfort for promoting good sleep is widely accepted; however, academic scrutiny of the effects of long-term mattress use on sleep quality is relatively rare [1,2,3].

The notion of mattress comfort, frequently equated with perceived firmness or hardness, embodies a multifaceted construct influenced by an array of factors including material composition, structural design, and individual preferences. The subjective nature of mattress comfort underscores its profound impact, directly shaping an individual’s capacity to attain and sustain restful sleep. Empirical evidence consistently demonstrates that discomfort experienced on a mattress correlates with disruptions in sleep continuity, heightened nocturnal awakenings, and overall dissatisfaction with sleep quality. Although initial investigations have shed light on the immediate effects of mattress comfort on sleep quality, there is burgeoning recognition of the intricate and evolving relationship between mattress hardness and sleep quality over protracted periods [4,5,6]. The protracted use of mattresses introduces distinctive challenges, as these bedding surfaces undergo gradual alterations in hardness, which are attributed to phenomena such as compression, mechanical wear, and material degradation. These longitudinal changes have the potential to compromise the supportive characteristics of the mattress, thereby influencing the spinal alignment, pressure distribution, and overall sleep comfort.

Despite the growing interest in the long-term implications of mattress comfort on sleep quality, a glaring gap remains in the scientific discourse regarding the precise mechanisms and consequences of fluctuations in mattress firmness over time. Addressing this gap is imperative for advancing our understanding of optimizing the sleep environment and improving sleep quality outcomes [6,7,8]. Consequently, the main idea of this research is to lay the groundwork for future investigations of the intricate relationship between mattress comfort and sleep quality in the context of long-term mattress use.

The primary aim of this study was to investigate how mattress firmness might change over time and what impact this change can have on mattress behavior in future long-term research. To achieve this, the study will involve a review of relevant literature, complemented by the results of a mechanical test of the durability of a mattress under laboratory conditions using a modified test method according to EN 1957 [9].

1.1. Importance of Mattress Comfort and Its Impact on Sleep Quality

Research has consistently shown the importance of sleep quality and duration for overall health, whereas mattress comfort significantly affects sleep quality by influencing factors such as sleepiness, maintenance of sound sleep, anxiety levels, overall sleep quality, and ease of entering a sleep state [10,11]. The importance of a comfortable mattress in enhancing sleep quality, reducing pain perception, and improving overall health is emphasized [6]. The quality of a mattress in direct contact with the human body is crucial for sleep comfort [12]. Chronic lower back pain is a common issue that can be exacerbated by poor sleep, and there is a bidirectional relationship between the two [13]. Contrary to traditional beliefs, bed rest is not an effective treatment for acute low back pain, and staying active is recommended for faster recovery [14]. More recent research has found that different mattress types, such as medium–firm mattresses, have been found to reduce back pain, improve sleep quality, and decrease stress levels, leading to better sleep outcomes [4,6]. Various technological solutions and methods, including polysomnography and actigraphy, have been used to evaluate the impact of mattresses on sleep quality, highlighting the complexity of the relationship between mattress comfort and sleep outcome [2].

Mattress hardness significantly affects different aspects of sleep, and choosing the correct level of mattress hardness is crucial for promoting better sleep and overall well-being. The level of mattress hardness can influence sleep quality and comfort [15]. Users believe that the appropriate elasticity of a mattress can improve sleep quality, leading to a sense of security and enjoyment in life [16]. Studies have shown that the firmness of a mattress can affect pain-related disability and the intensity of pain while lying in bed and rising [17]. The use of a medium–firm mattress has been associated with more frequent discontinuation of drug treatment and relevant improvements in pain and disability for chronic low-back pain patients [10]. The firmness of a mattress also affects pressure distribution and muscular function when lying in bed, which can contribute to overall sleep quality [18].

These findings suggest that mattress firmness can change with mattress use. Several studies (quoted in [15]) found that the pressure on the body increased with the hardness of the mattress, with the softest mattress resulting in the lowest pressure and the hardest mattress resulting in the highest pressure. Mattress stiffness can affect the distribution of pressure and muscular function while lying in bed, which may contribute to the clinical course of low-back pain [16]. A study on the effects of different mattresses on sleep quality found that mattress research and development have shifted towards regional customization, with adjustments made to different zones to accommodate physiological spine curvature [19]. Different factors, such as body characteristics and mattress configuration, contribute to variations in the spinal angles and curvature on different mattresses [20]. Mattress firmness can significantly affect sleep quality, pain reduction, and daytime functioning [21]. However, individuals may not always choose mattresses that optimize their sleep, indicating the need for better methods of aiding in the mattress selection process [22].

1.2. Relationship Between Mattress Firmness, Sleeping Position and Sleep Quality

The firmness of a mattress can significantly impact sleep quality, with some individuals reporting better sleep on softer mattresses and others reporting better sleep on firmer ones [23]. The choice of mattress hardness coupled with optimal sleeping position plays an important role in determining sleep quality and overall health outcomes. Mattress hardness, sleep position, and sleep quality are interconnected factors that influence one another. Mattress firmness affects spinal alignment, muscle relaxation, and sleep quality [24]. The relationship between mattress density, body mass, and sleep efficiency has been explored, highlighting the impact of these factors on sleep quality, particularly in the elderly [25]. Furthermore, the use of flexible sensors to monitor sleep positions and body movements during sleep has provided insight into how different positions affect sleep quality [26]. A firm mattress can have various effects on sleep quality. Medium–firm mattresses may lead to lower back pain and better sleep quality than firmer mattresses [27]. Another study that focused on reducing the spinal curvature in lateral sleeping positions found that an experimental mattress led to lower pain scores while lying down and higher comfort ratings, indicating potential benefits for sleep quality [28]. Furthermore, a study comparing sleep on a memory foam mattress to participants’ original mattresses showed improvements in sleep quality, including less wake time after sleep onset, fewer awakenings, better sleep efficiency, and overall better-perceived sleep outcomes when using a memory foam mattress [20].

From a mechanical point of view, the production of plastic-deformable polyurethane foam involves a complex chemical process, including the reaction of polyisocyanates and polyhydroxy compounds, which can be tailored to achieve the desired mechanical properties. Flexible polyurethane foams exhibit complex deformation behaviors under loads, characterized by both elastic and plastic responses. The initial stages of compression are typically dominated by the elastic bending of the foam struts, which are inclined in the compression direction. As the strain increased, the foam underwent a transition to plastic deformation, marked by the collapse of structural bands and densification, particularly at strains above 23% and up to 63% [29]. Research on plastic deformation loads for flexible polyurethane foams covers a range of topics, from viscoelastic behavior under cyclic loading to structural analysis under compression. These topics were researched by the authors of [30], who investigated the viscoelastic properties of aged polyurethane foams under cyclic loading, emphasizing the stiffness and energy dissipation across different temperatures and strain amplitudes. Onwards, Long and Hamel [31] focused on the anisotropic elastic response of low-density foams and modeled and parameterized their behavior under different loading conditions, whereas Chernous and Shil’ko [32] analyzed the large elastic strains in plastic foams and compared the computational results with experimental data to better understand deformation mechanics, which are mentioned here only as an introduction to the experimental part of the research.

The hypothesis of this preliminary research is that the functional properties of the mattress change with the duration of its use, its hardness, firmness and height change, and that this depends on the materials incorporated into the product.

The research is important from the users’ viewpoint who want their mattress to be of constant quality during use and to not significantly change its functional and mechanical properties, so that in the long term, it could have a positive impact on the user’s sleep and general well-being and does not begin to negatively affect the quality of their sleep.

Unlike similar research, this one tried to find out if there were any changes in the response of the mattress after more than 30,000 standardized cycles of exposure to the dynamic load of its surface by measuring the functional characteristics. When the quality of the mattress is tested using the specified method [9], after the defined 30,000 cycles, the mattress is inspected externally and internally, and if there is no visible damage (e.g., spring breakage, wear or penetration of the surface layer of the fabric, etc.), it is considered to be a mattress of sufficient quality for its many years of use. In determining how many years of use a mattress should have, the following questions arose: What happens to the mattress in the next 30,000 cycles, and the next…, and how long can it last? What are its properties after double or triple exposure to the load? How do they change, and can these changes affect the user experience? We obtained some answers through this research, and for some, it will be necessary to conduct a new, more extensive study including additional subjective and objective methods.

2. Materials and Methods

Two mattress samples were used in this study: one with a polyurethane foam core (marked as PUR) and the other with an innerspring pocket core (marked as TFK) (Figure 1).

Figure 1.

Samples of the mattresses: (a) TFK prepared for rolling, (b) PUR during the measurement of functional characteristics (©Klarić, 2023).

Mattress types with top global market share were chosen for this research: innerspring and foam [33], and those with very common materials, which provide a good representation of the usual choice of customers. The innerspring category was the most popular, accounting for over 45% of the market share in 2023. This is largely due to its popularity among Europeans. In addition, innersprings are particularly favored in the Eastern and Central regions of Europe, as they provide a range of benefits, such as cooling, bounce, and strong edge support [34].

2.1. Mattress Samples “PUR” and “TFK”

The nominal dimensions of the PUR sample were 190 × 90 × 19 cm. The core of the mattress consists of one block of high-resilience polyurethane foam with a density of 30 kg/m3. A leotard served as protection against wear between the core and cover. The cover consisted of decorative fabric made of polyester fibers and polyester wadding with a surface mass of 275 g/m2.

The nominal dimensions of the TFK sample were 200 × 90 × 25 cm. The springs inside the pocket core are made of steel wire with a 1.8 mm diameter with six threads. Other spring properties were not considered necessary for this research. The mattress filling consists of sides composed of polyurethane foam with a density of 25 kg/m3, felt with a surface mass of 450 g/m2, and fiselin with a surface mass of 30 g/m2. The mattress cover consisted of decorative fabric made of polyester fibers and polyester wadding with a surface mass of 300 g/m2.

Both samples were previously conditioned in laboratory climate air conditions of 23 ± 2 °C and 50 ± 5% relative humidity in accordance with the requirements of EN 1957:2012. Brand new, previously unused mattresses were used for this research.

2.2. Methods

After the conditioning, the samples were subjected to durability tests and hardness measurements. The durability test simulated the repeated application of loads and movement of mattress components occurring over long-term use and assessed the strength of the mattress under such conditions. This procedure is mainly intended to evaluate the change in the properties of the test sample caused by repeated loadings by means of a roller using a specialized device.

Hardness measurements consisted of determining the load/deflection curve and three parameters: hardness value (H), firmness rating (Hs), and height loss. The load unit used in this study was an Inspekt S (load range 0–2 kN, H&P MPT GmbH, Dresden, Germany). The hardness value and firmness rating were calculated using the software LabMaster (ver. 3.0.5.26, H&P MPT GmbH), whereas height loss is the difference between the initial measurement of height at 100 cycles and after testing (measured under a force of 50 N acting on the sample surface). Functional characteristic measurements (including load/deflection curve, hardness value (H), firmness rating (Hs), and height loss) were fully compliant with the standardized procedure described in EN 1957:2012.

A detailed description of the standardized durability test method is provided in EN 1957:2012. For the purpose of this research, a modified method was used, which differed from the standard method in the part related to rolling the mattress in such a way that the machine was stopped every 7500 cycles, and intermediate measurements were taken. As a reminder, with the standardized method, after the initial 100 cycles, the mattress was tested for an additional 29,900 cycles without interruption, after which the hardness measurements were carried out, and the test was completed. Before the research, no standardized tests were performed on these samples.

The termination of the test was due to mechanical damage to the mattress or, for the purposes of this study, when the values of the firmness rating (Hs) did not differ significantly in the last three measurements. The firmness rating is an expression of the subjective assessment of the number of persons lying on a number of mattresses of varying degrees of firmness. The method for determining firmness ratings (i.e., subjective firmness) is based on empirical research and is determined from the hardness value of the mattress. The firmness rating (Hs) is a number on a scale of 1 (firm) to 10 (soft) [9]. The 7500 rolling cycles, approximately eight (8) hours, perfectly simulated the duration of a night’s sleep for healthy adults. For the other 16 h, the mattress was recovering from the test, which roughly equates to the daytime during which the mattress cools, dries, and recovers after a night’s sleep.

3. Results and Discussion

Since this is a preliminary study with the aim of revealing the behavior of two different mattresses and their individual properties during long-term exposure to the durability test, i.e., prolonged use, the results presented here do not compare the two researched samples with each other. One long-term test and related measurements (H, Hs and height loss) were performed on each of the investigated mattresses (PUR and TFK); therefore, statistical processing and analysis of the results are not intended to be carried out. The intention was to show the trend and provide guidelines for future research, which is explained in the continuation of this discussion and is the basis of which certain conclusions were drawn.

Creating a load/deflection curve is a prerequisite for the evaluation of the characteristic parameters, that is, determining the hardness value, firmness rating, and height loss. The load/deflection curves show the results of the initial measurements (after 100 cycles) and at the end of the test (after 82,500 or 90,000 cycles, depending on the sample). Charts with the results of measuring mattress heights, hardness values, and firmness ratings show data every 7500 cycles, with an emphasis on initial measurements, measurements after 30,000 and those at the end of the test.

3.1. Test Results of the “PUR” Sample

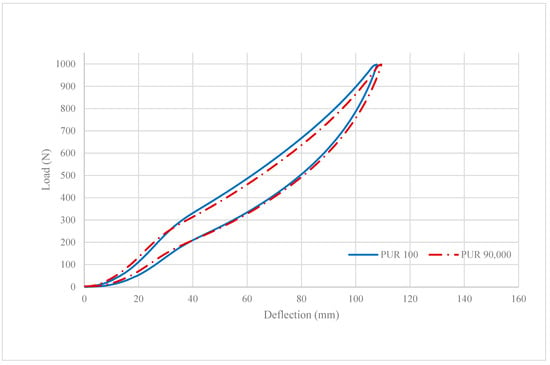

The load/deflection curves of the PUR samples are shown in Figure 2. At the beginning of the research, a force of 1000 N caused the maximum deflection of 107.79 mm (PUR 100), while at the end, it was 109.43 mm (PUR 90,000).

Figure 2.

Load/deflection curve for PUR sample after 100 and 90,000 cycles.

The nearly identical shapes of the curves suggest similar load-bearing characteristics but with some offsets. The load/deflection curves for PUR 100 and PUR 90,000 show the typical behavior expected of polyurethane foam, with initial linear elasticity, a plateau for energy absorption, and a final steep densification phase. The primary distinction between the two types of curves lies in their initial stiffness and the slight variations in their load-bearing capacities. PUR 90,000 appears to have a slightly steeper initial slope than PUR 100, suggesting that PUR 90,000 may be slightly stiffer in this initial phase.

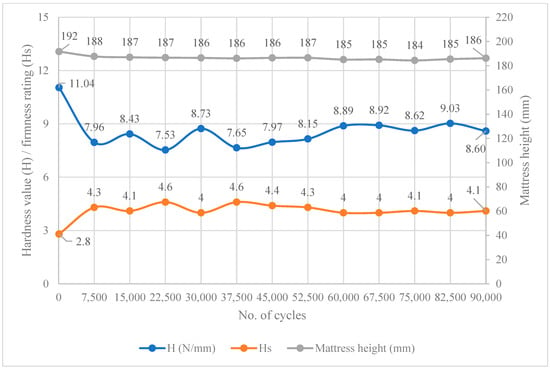

After the initial 100 cycles, the height of the unloaded surface of the mattress with a PUR core was 192 mm (Figure 3 and Figure 4). The height decreased slowly and slightly, reaching 186 mm by the 90,000th cycle. The mattress height showed a consistent slightly downward trend, suggesting gradual compression over time. The initial hardness value (H) and firmness rating (Hs) of the mattress were 11.04 N/mm and 2.8, respectively (Figure 3).

Figure 3.

Hardness value (H) and firmness rating (Hs) for sample PUR.

Figure 4.

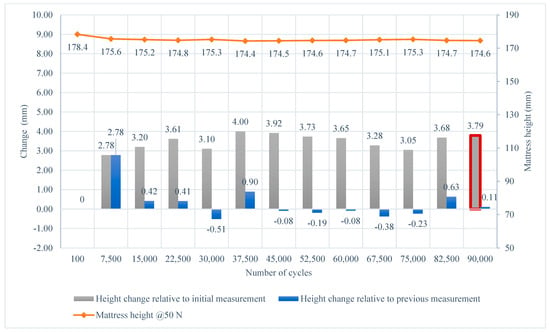

Mattress height, height changes and height loss for sample PUR. The framed bar represents the total height loss.

Between 100 and 7500 cycles, the largest changes in hardness and firmness occurred when the hardness value decreased by 28% to approximately 8 N/mm and the firmness rating increased by more than 50% at 4.3. After its initial drop, the hardness value stabilizes, fluctuating slightly between 7.53 N/mm and 9.03 N/mm to maintain a value of 8.60 N/mm at the end of the test. After 30,000 cycles, which represents the end of the test according to the standardized procedure, the value of H was 8.73 N/mm, and the value of Hs was 4. These values are very close to the final values achieved by this mattress at 90,000, which may indicate that testing the mattress for 30,000 cycles is sufficient to assess its quality.

After 90,000 cycles, the test of the PUR sample was stopped owing to the stagnation of the firmness results in the last three measurements; however, there was no visible damage on the surface or inside the mattress. After reaching 4.3, the firmness rating stabilizes, showing minimal fluctuation between 4.0 and 4.6 throughout the remaining cycles. The firmness rating did not show significant changes after the initial increase, indicating a stable firmness over time (Figure 3).

To determine the height loss, mattress heights were measured under a load of 50 N. As shown in Figure 4, the initial height of the mattress was 178.4 mm, which decreased slightly over the cycles. This indicates gradual compression of the mattress material under repeated loading. By 90,000 cycles, the height was 174.6 mm, which means that the height loss of the PUR mattress was 3.79 mm.

Observing height change relative to the initial measurement, there is a height change of 2.78 mm at 7500 cycles. The height change relative to the initial measurement increases progressively, peaking at 4.00 mm at 37,500 cycles. After 37,500 cycles, the height change decreases slightly, fluctuating between 3.28 mm and 3.79 mm. This indicates that the mattress experienced the most significant compression in the early cycles and stabilized afterward.

The height changes relative to the previous measurement showed both positive and negative values, indicating minor fluctuations in height from one measurement to the next. Initial cycles of up to 7500 show a significant positive change (2.78 mm). Negative changes occur at 22,500 cycles (−0.51 mm) and at other intervals, suggesting a slight recovery or settling between measurements. The final height change at 90,000 cycles was very small (0.11 mm), indicating stabilization.

3.2. Test Results of the “TFK” Sample

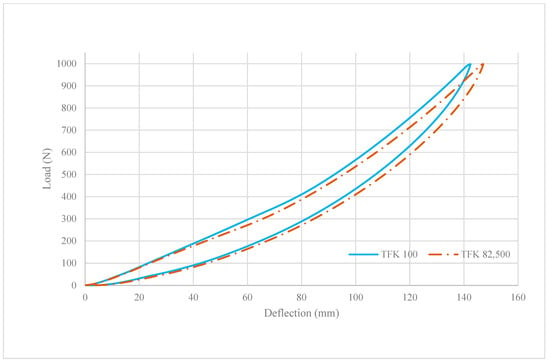

The load/deflection curves of the TFK sample are shown in Figure 5. At the beginning of the research, a force of 1000 N caused the maximum deflection of 142.43 mm (TFK 100), while at the end, it was 147.13 mm (TFK 82,500).

Figure 5.

Load/deflection curve for TFK sample after 100 and 82,500 cycles.

Both curves exhibited a nonlinear increase in load with deflection, indicating the elastic and nonlinear deformation properties of the mattresses. At lower loads and deflections (up to approximately 40 mm), the curves are relatively similar, indicating a comparable initial stiffness. As the load increased, the differences between the two curves became more apparent, with TFK 100 supporting a slightly higher load at the same deflection than TFK 82,500. TFK 100 exhibited a higher load support capability, particularly at deflections greater than 80 mm. The TFK 82,500 supports a slightly lower load at the same deflection, indicating that it may be softer or more compliant.

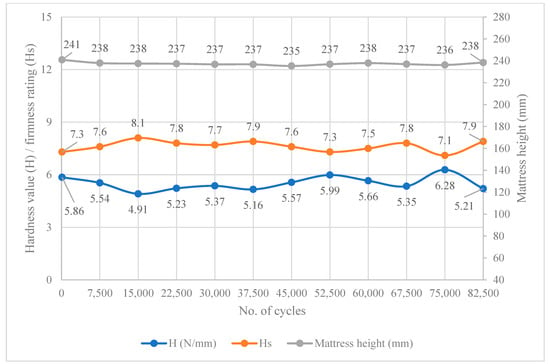

The mattress height of the unloaded surface (Figure 6) remained relatively constant, starting at 241 mm and ending at 236 mm, indicating a minimal change in the mattress thickness over the cycles. The mattress height exhibited minimal changes, indicating good structural integrity and resistance to permanent deformation. This consistency suggests that the materials, both springs and foam, maintained their shape and support during prolonged use.

Figure 6.

Hardness value (H) and firmness rating (Hs) for sample TFK.

The hardness value (H) fluctuated slightly but generally decreased with an increase in the number of cycles. It starts at 5.86 N/mm and ends at 5.21 N/mm, with some variations between cycles. The hardness value exhibited some variability, with peaks at certain cycles (e.g., 4.91 at 15,000 cycles and 5.96 at 45,000 cycles). This variability may indicate the response of mattress materials (inner pocket springs and polyurethane foam) to cyclic loading and unloading. At 30,000 cycles (i.e., the end of the standardized procedure), the values of H and the Hs are 5.37 N/mm and 7.7, respectively. These values were also very close to the final values achieved by the mattress at 82,500. Similar to the case of PUR, this may indicate that 30,000 cycles are sufficient to assess the main characteristics of the mattress.

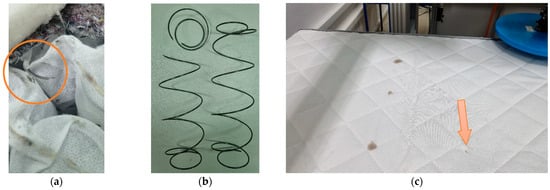

The test for the TFK sample was stopped after 82,500 cycles due to the broken pocket spring (Figure 7a,b). The surface of the mattress above the broken spring exhibited damage to the fabric, indicating changes in its interior (Figure 7c). However, the location of the break was sufficiently far from the loading location of the loading pad; therefore, the break did not affect the measurement results.

Figure 7.

(a) Core of the mattress at the point of breakage (broken spring is circled), (b) broken and whole spring, (c) location of damage on mattress surface.

The firmness rating (Hs) remained relatively stable, starting at 7.3 and ending at 7.1, with minor fluctuations throughout the cycles. The firmness rating remained more stable than the hardness value, which indicates that the subjective firmness (perceived comfort) of the mattress did not change significantly over the cycles. Minor fluctuations in Hs suggest that while the material properties might be altered slightly, the overall user experience in terms of firmness remains consistent.

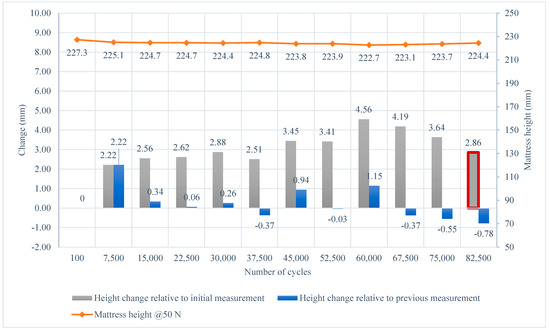

The mattress height at a 50 N load remained relatively stable, starting at 227.3 mm and ending at 224.4 mm (Figure 8). Minor fluctuations in height were observed, but overall, the mattress maintained its height well under a 50 N load. This stability is crucial to ensure consistent support and comfort over the lifespan of a mattress. In the final cycles, the height was 224.4 mm, indicating a height loss of the TFK mattress of 2.86 mm.

Figure 8.

Mattress height, height changes and height loss for sample TFK. The framed bar represents the total height loss.

Initially, the mattress height increases, reaching a maximum change of 4.56 mm at 60,000 cycles. Beyond 60,000 cycles, the height change begins to decrease slightly, ending at 2.86 mm at 82,500 cycles. The initial increase in height suggests that mattress materials may expand or settle into a more stable configuration under cyclic loading.

The height changes relative to the previous measurement fluctuated, indicating both increases and decreases in the height over the cycles. Notable changes occur at specific cycles (e.g., a decrease of −0.37 mm at 37,500 cycles and −0.78 mm at 82,500 cycles). After reaching a peak, a slight decrease in the height change indicated some level of material compression or settling. The largest negative change relative to the previous measurement suggests the beginning of the material fatigue or permanent deformation.

The obtained results support the previous findings of similar research [35,36,37,38,39]—similar in terms of the assumption that the quality of the mattress affects the quality of sleep, which means that the next more comprehensive experiment could obtain results that will contribute to a better understanding of the relationship between long-term use of the mattress, changes in its structure and materials, and retention essential mechanical properties, leading to longer-lasting sleep comfort.

For example, the hardness and firmness of a mattress significantly influence its comfort and support, which are critical for sleep quality and overall satisfaction [35]. The hardness value of polyurethane foam is a critical factor influencing the firmness rating of mattresses, both essential for optimizing mattress performance. Hardness (assessed through indentation force/load deflection), quantifies the resistance of the foam to compression. A higher hardness value typically correlates with a firmer mattress. Practically, this means that it ensures less immersion and envelopment, which, for example, can affect the prevention of pressure ulcers. Conversely, lower hardness values indicate softer foams that allow for greater immersion and envelopment, potentially enhancing comfort and pressure relief. That relationship between hardness and firmness is essential for optimizing mattress performance [36,37].

A well-balanced firmness level is essential to achieve optimal comfort and support in mattress design. Investigating the objective and subjective comfort of mattresses with different hardnesses, Hu et al. [35] identified optimal hardness values that correlate with improved comfort, suggesting that the hardness rating of pocket spring mattresses should be aligned with the resulting hardness recommendations in order to improve the quality of sleep. The study by Shen et al. [38] highlights that the structural properties of spring mattresses, including the bedding materials and mattress core, significantly affect sleep quality. An optimal combination of these elements can enhance mattress comfort, leading to improved sleep depth and quality. Zhu et al. [39] show in their study that the hardness of pocket spring mattresses directly affects their firmness rating, which in turn affects overall comfort and support. According to their findings, the hardness of a mattress is related to its ability to conform to the body’s natural curves, ensuring proper spinal alignment and reducing pressure points, thereby improving sleep quality and comfort ratings.

Over time, mattresses undergo changes in hardness due to compression, wear, and material degradation. Changes in mattress firmness over prolonged use can compromise supportive properties and sleep comfort. This study aimed to investigate the possible effects of long-term mattress use on firmness and sleep quality, but indirectly, by investigating changes in mattress properties. Understanding how changes in mattress hardness over time might influence sleep quality can have significant implications for both sleep science and mattress design industries. By studying this relationship, future research can contribute valuable insights into optimizing mattress design, enhancing sleep quality, and potentially even addressing sleep-related health issues.

4. Conclusions

The preliminary results showed that the PUR sample demonstrated good durability and stable mechanical performance after the initial break-in period (Figure 2 and Figure 3), making it suitable for long-term applications in which repeated loading is expected. The sample experienced an initial phase of significant compression, followed by a stabilization period in which the height changes were minimal (Figure 4). After the initial phase, the properties of the foam stabilized, showing consistent hardness and firmness values until the end at 90,000 cycles. The material showed good durability with minor fluctuations in height change, suggesting slight recovery and minor compression.

From the TFK sample, users can expect consistent firmness and support from the beginning and throughout their usage. The sample featuring inner pocket springs and polyurethane foam exhibited strong performance characteristics and durability (Figure 5 and Figure 6). Over an extensive testing period, the mattress showed only a slight decrease in the hardness value, indicative of minor material softening. However, the firmness rating remained largely stable, ensuring consistent support and comfort for the users. The mattress height changed minimally (Figure 8), demonstrating the structural integrity and resistance to deformation of the product up to 82,500 cycles when spring breakage occurred. These results highlight the ability of the mattress to provide long-term reliability and support on sleeping surfaces.

The proposed hypothesis was confirmed, but not to the extent and intensity as expected. Namely, changes in the hardness, firmness and height loss of the mattress occurred during the experiment (i.e., use of mattress), but they were not expressed to the extent that a decrease in the quality of the mattress is observed; on the contrary, the samples proved to be very stable. Indirectly, these limited results indicate that the impact of changes on sleep quality can be negligible. The cause of such results surely lies in the insufficient number of tested samples and their composition.

Although this was not the aim of the research, the results indicated that 30,000 cycles can be sufficient to assess mattress quality; however, it should be kept in mind that this research included only one sample of each type of mattress, which is certainly not enough to draw conclusions.

The limitations of this study are the small sample size and lack of variability in mattress types.

The results of this preliminary study show possible expectations that have yet to be confirmed by testing a larger number of samples with more diversity in types of mattresses. It is necessary to include mattresses with innersprings (Bonnell, pocket), foams (polyfoams, viscoelastic, gel-infused), latex and hybrid (e.g., visco-foam, innerspring and latex), or special poly-foams and latex intended for use in “medical” or “therapeutic” products—all in combination with different top layer types and thicknesses. In addition, to better understand the broader context of sleep comfort, future research should include comparisons of the results of subjective assessments supported by body pressure distributions.

Author Contributions

Conceptualization, Z.V. and N.K.; methodology, Z.V.; validation, Z.V., N.K., and D.D.; formal analysis, N.K.; investigation, N.K.; resources, Z.V.; data curation, Z.V.; writing—original draft preparation, Z.V. and N.K.; writing—review and editing, Z.V. and D.D.; visualization, Z.V. and N.K.; supervision, Z.V. and D.D.; funding acquisition, Z.V. and D.D. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

All relevant data are within the paper. The raw data supporting the conclusions of this article will be made available by the authors on request.

Acknowledgments

The authors express their gratitude to Ivan Žulj and Danijel Mežnarić, from the Laboratory for Furniture (LIN), for their assistance during the preparation of the experimental tests.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Tonetti, L.; Martoni, M.; Fabbri, M.; Natale, V. Relationship between Mattress Technological Features and Sleep Quality: An Actigraphic Study of Healthy Participants. Biol. Rhythm. Res. 2011, 42, 247–254. [Google Scholar] [CrossRef]

- Zhong, S.; Shen, L.; Zhou, L.; Guan, Z. Predict Human Body Indentation Lying on a Spring Mattress Using a Neural Network Approach. Proc. Inst. Mech. Eng. H. 2014, 228, 787–799. [Google Scholar] [CrossRef] [PubMed]

- Vitale, J.A.; Borghi, S.; Bassani, T.; Messina, C.; Sconfienza, L.M.; Galbusera, F. Effect of a Mattress on Lumbar Spine Alignment in Supine Position in Healthy Subjects: An MRI Study. Eur. Radiol. Exp. 2023, 7, 47. [Google Scholar] [CrossRef] [PubMed]

- Jacobson, B.H.; Boolani, A.; Smith, D.B. Changes in Back Pain, Sleep Quality, and Perceived Stress after Introduction of New Bedding Systems. J. Chiropr. Med. 2009, 8, 1–8. [Google Scholar] [CrossRef]

- Hogan, S.O.; Edinger, J.D.; Bieler, G.S.; Krystal, A.D. Choosing the Best Mattress: An Experiment in Testing Whether Individuals Choose a Bed That Leads to Improved Sleep; RTI Press: Research Triangle Park, NC, USA, 2011. [Google Scholar] [CrossRef]

- Breus, M.; Hooper, S.L.; Lynch, T.; Barragan, M.; Hausenblas, H.A. Effectiveness of a Grid Mattress on Adults’ Sleep Quality and Health: A Quasi-Experimental Intervention Study. Health Sci. Rep. 2024, 7, e2046. [Google Scholar] [CrossRef]

- Jacobson, B.H.; Moghaddam, M.; Estrada, C.A. Mattress Coil Spring Fatigue and Weight-Bearing Support: Comparison of Weight-Bearing and Non–Weight-Bearing Springs. J. Manip. Physiol. Ther. 2022, 45, 323–328. [Google Scholar] [CrossRef]

- Ancuelle, V.; Zamudio, R.; Mendiola, A.; Guillen, D.; Ortiz, P.J.; Tello, T.; Vizcarra, D. Effects of an Adapted Mattress in Musculoskeletal Pain and Sleep Quality in Institutionalized Elders. Sleep Sci. 2015, 8, 115–120. [Google Scholar] [CrossRef]

- EN 1957; Furniture-Beds and Mattresses-Test Methods for the Determination of Functional Characteristics and Assessment Criteria. European Committee for Standardization (CEN): Brussels, Belgium, 2012.

- Lee, H.; Park, S. Quantitative Effects of Mattress Types (Comfortable vs. Uncomfortable) on Sleep Quality through Polysomnography and Skin Temperature. Int. J. Ind. Ergon. 2006, 36, 943–949. [Google Scholar] [CrossRef]

- St-Onge, M.P.; Grandner, M.A.; Brown, D.; Conroy, M.B.; Jean-Louis, G.; Coons, M.; Bhatt, D.L. Sleep Duration and Quality: Impact on Lifestyle Behaviors and Cardiometabolic Health: A Scientific Statement from the American Heart Association. Circulation 2016, 134, e367–e386. [Google Scholar] [CrossRef]

- Yoshida, H.; Kamijo, M.; Shimizu, Y. A Study to Investigate the Sleeping Comfort of Mattress Using Finite Element Method. Kansei Eng. Int. J. 2012, 11, 155–162. [Google Scholar] [CrossRef][Green Version]

- Kelly, G.A.; Blake, C.; Power, C.K.; Okeeffe, D.; Fullen, B.M. The Association between Chronic Low Back Pain and Sleep: A Systematic Review. Clin. J. Pain 2011, 27, 169–181. [Google Scholar] [CrossRef]

- Waddell, G.; Feder, G.; Lewis, M. Systematic Reviews of Bed Rest and Advice to Stay Active for Acute Low Back Pain. Br. J. Gen. Pract. 1997, 47, 647–652. [Google Scholar] [PubMed]

- Wong, D.W.C.; Wang, Y.; Lin, J.; Tan, Q.; Chen, T.L.W.; Zhang, M. Sleeping Mattress Determinants and Evaluation: A Biomechanical Review and Critique. PeerJ 2019, 7, e6364. [Google Scholar] [CrossRef] [PubMed]

- Tonetti, L.; Martoni, M.; Natale, V. Effects of Different Mattresses on Sleep Quality in Healthy Subjects: An Actigraphic Study. Biol. Rhythm. Res. 2011, 42, 89–97. [Google Scholar] [CrossRef]

- Lin, Y.-L.; Jhan, Y.-C.; Lin, H.-W. A Good Partner in Sleeping: A Research on Customer Value Regarding Mattresses. Eur. J. Bus. Manag. Res. 2020, 5, 1–6. [Google Scholar] [CrossRef]

- Kovacs, F.M.; Abraira, V.; Peña, A.; Martín-Rodríguez, J.G.; Sánchez-Vera, M.; Ferrer, E.; Ruano, D.; Guillén, P.; Gestoso, M.; Muriel, A.; et al. Effect of Firmness of Mattress on Chronic Non-Specific Low-Back Pain: Randomised, Double-Blind, Controlled, Multicentre Trial. Lancet 2003, 362, 1599–1604. [Google Scholar] [CrossRef]

- Tamura, T.; Simane, U.; Sunsuku, H.; Yoshida, M. Evaluation of Comfort and Health of Mattresses from Mechanical. J. Home Econ. Jpn. 1989, 40, 705–711. [Google Scholar] [CrossRef]

- Bolton, R.; Hulshof, H.; Daanen, H.A.M.; van Dieën, J.H. Effects of Mattress Support on Sleeping Position and Low-Back Pain. Sleep Sci. Pract. 2022, 6, 3. [Google Scholar] [CrossRef]

- Caggiari, G.; Talesa, G.R.; Toro, G.; Jannelli, E.; Monteleone, G.; Puddu, L. What Type of Mattress Should Be Chosen to Avoid Back Pain and Improve Sleep Quality? Review of the Literature. J. Orthop. Traumatol. 2021, 22, 1–24. [Google Scholar] [CrossRef]

- DeVocht, J.W.; Wilder, D.G.; Bandstra, E.R.; Spratt, K.F. Biomechanical Evaluation of Four Different Mattresses. Appl. Ergon. 2006, 37, 297–304. [Google Scholar] [CrossRef]

- Bader, G.G.; Engdal, S. The Influence of Bed Firmness on Sleep Quality. Appl. Ergon. 2000, 31, 487–497. [Google Scholar] [CrossRef] [PubMed]

- Cary, D.; Jacques, A.; Briffa, K. Examining Relationships between Sleep Posture, Waking Spinal Symptoms and Quality of Sleep: A Cross Sectional Study. PLoS ONE 2021, 16, e0260582. [Google Scholar] [CrossRef]

- Zhang, Y.; Xiao, A.; Zheng, T.; Xiao, H.; Huang, R. The Relationship between Sleeping Position and Sleep Quality: A Flexible Sensor-Based Study. Sensors 2022, 22, 6220. [Google Scholar] [CrossRef] [PubMed]

- Torobrum, W.; Thavarungkul, N.; Termsuksawad, P.; Srisukhumbowornchai, N. The Influence of Density of the Materials and Body Mass Index on the Elderly’s Sleep Efficiency. Proc. Eng. Technol. Innov. 2017, 7, 8–13. [Google Scholar]

- Rus, H.; Danoff-Burg, S.; Burke, C.; Saba, S.; Weaver, M.; Carmon, K.; Ledesma, D.L.; Upadhyaya, D. Use of an Innerspring Mattress Improves Deep Sleep and WASO. Sleep 2023, 46, A423–A424. [Google Scholar] [CrossRef]

- Barbara, A.M.; Grobelna, A. Therapeutic Mattresses for Chronic Pain. Can. J. Health Technol. 2022, 1–22. [Google Scholar] [CrossRef]

- Elliott, J.A.; Windle, A.H.; Hobdell, J.R.; Eeckhaut, G.; Oldman, R.J.; Ludwig, W.; Boller, E.; Cloetens, P.; Baruchel, J. In-Situ Deformation of an Open-Cell Flexible Polyurethane Foam Characterised by 3D Computed Microtomography. J. Mater. Sci. 2002, 37, 1547–1555. [Google Scholar] [CrossRef]

- Lu, W.-Y.; Neidigk, M.; Wyatt, N. Cyclic Loading Experiment for Characterizing Foam Viscoelastic Behavior. In Experimental and Applied Mechanics; Zhu, Y., Zehnder, A., Eds.; Springer: Cham, Switzerland, 2017; Volume 4, pp. 135–144. [Google Scholar]

- Long, K.; Hamel, C. Stabilized Hyperfoam Modeling of the General Plastics EF4003 (3 PCF) Flexible Foam; Sandia National Lab. (SNL-NM): Albuquerque, NM, USA; Livermore, CA, USA, 2022.

- Chernous, D.A.; Shil’ko, S.V. Large Elastic Strains of Plastic Foams. Mech. Compos. Mater. 2005, 41, 415–424. [Google Scholar] [CrossRef]

- Persistence Market Research. Available online: https://www.persistencemarketresearch.com/market-research/mattress-market.asp (accessed on 15 June 2023).

- Prescient & Strategic Intelligence. Available online: https://www.psmarketresearch.com/market-analysis/european-mattress-industry (accessed on 15 June 2023).

- Hu, H.; Hong, P.; Cai, M.; Luo, H.; Wu, H. Research on Comfort of Mattresses with Different Hardness Based on Body Pressure Distribution. In Advances in Ergonomics in Design; Rebelo, F., Soares, M., Eds.; AHFE 2019; Advances in Intelligent Systems and Computing; Springer: Cham, Switzerland, 2019; pp. 551–560. [Google Scholar]

- Scarfato, P.; Di Maio, L.; D’Arienzo, L.; Rinaldi, S.; Incarnato, L. Composition-Structure-Property Relationships of Commercial Polyurethane Foams for Mattresses. AIP Conf. Proc. 2015, 1695, 020048. [Google Scholar] [CrossRef]

- Soppi, E.; Lehtiö, J.; Saarinen, H. An Overview of Polyurethane Foams in Higher Specification Foam Mattresses. Ostomy Wound Manag. 2015, 61, 38–46. [Google Scholar]

- Shen, L.; Chen, Y.X.; Guo, Y.; Zhong, S.; Fang, F.; Zhao, J.; Hu, T.Y. Research on the Relationship between the Structural Properties of Bedding Layer in Spring Mattress and Sleep Quality. Work 2012, 41, 1268–1273. [Google Scholar] [CrossRef] [PubMed]

- Zhu, Y.D.; Shen, L.M.; Song, J. Body Pressure Distribution Research and Zone Design of Pocket Spring Mattresses. In Proceedings of the 2011 IEEE 18th International Conference on Industrial Engineering and Engineering Management, IE and EM 2011, Changchun, China, 3–5 September 2011; Volume 210037, pp. 1656–1659. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).