Studying the Constitutive Model of Damage for a Stainless Steel Argon–Oxygen Decarburization Slag Mixture

Abstract

1. Introduction

2. Raw Materials and Sample Preparation

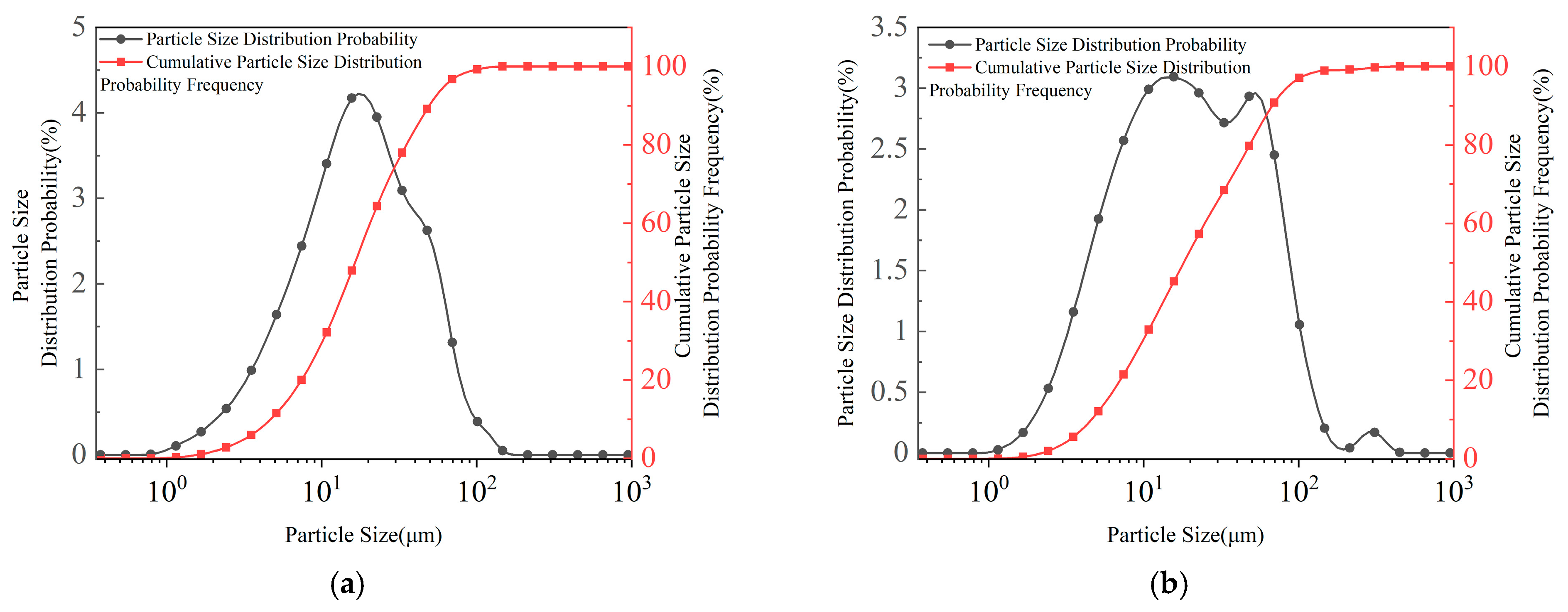

2.1. Raw Materials

2.2. Mix Proportion Design

2.3. Sample Preparation and Testing Instrument

3. Test Results and Analysis

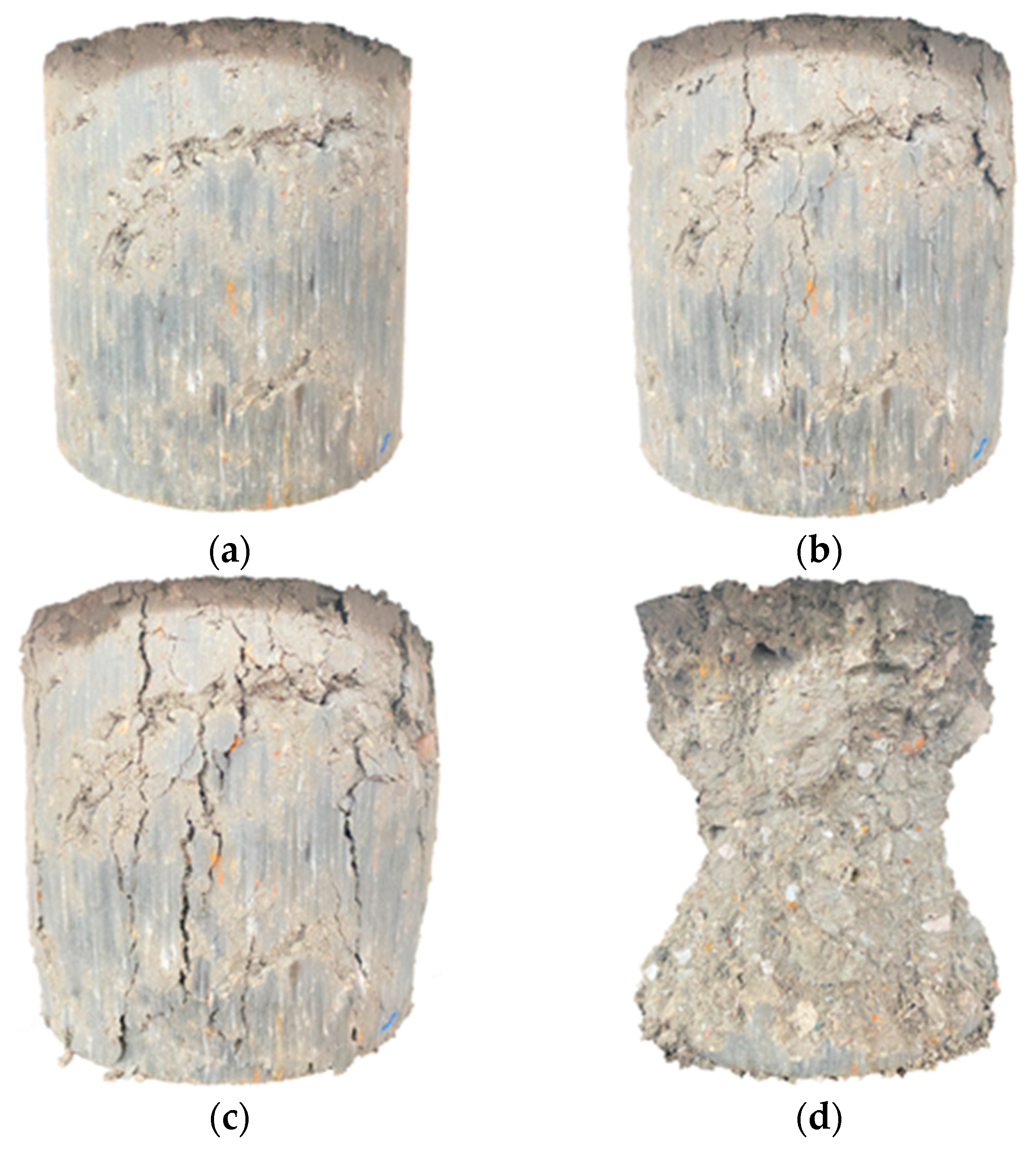

3.1. Damage Phenomenon

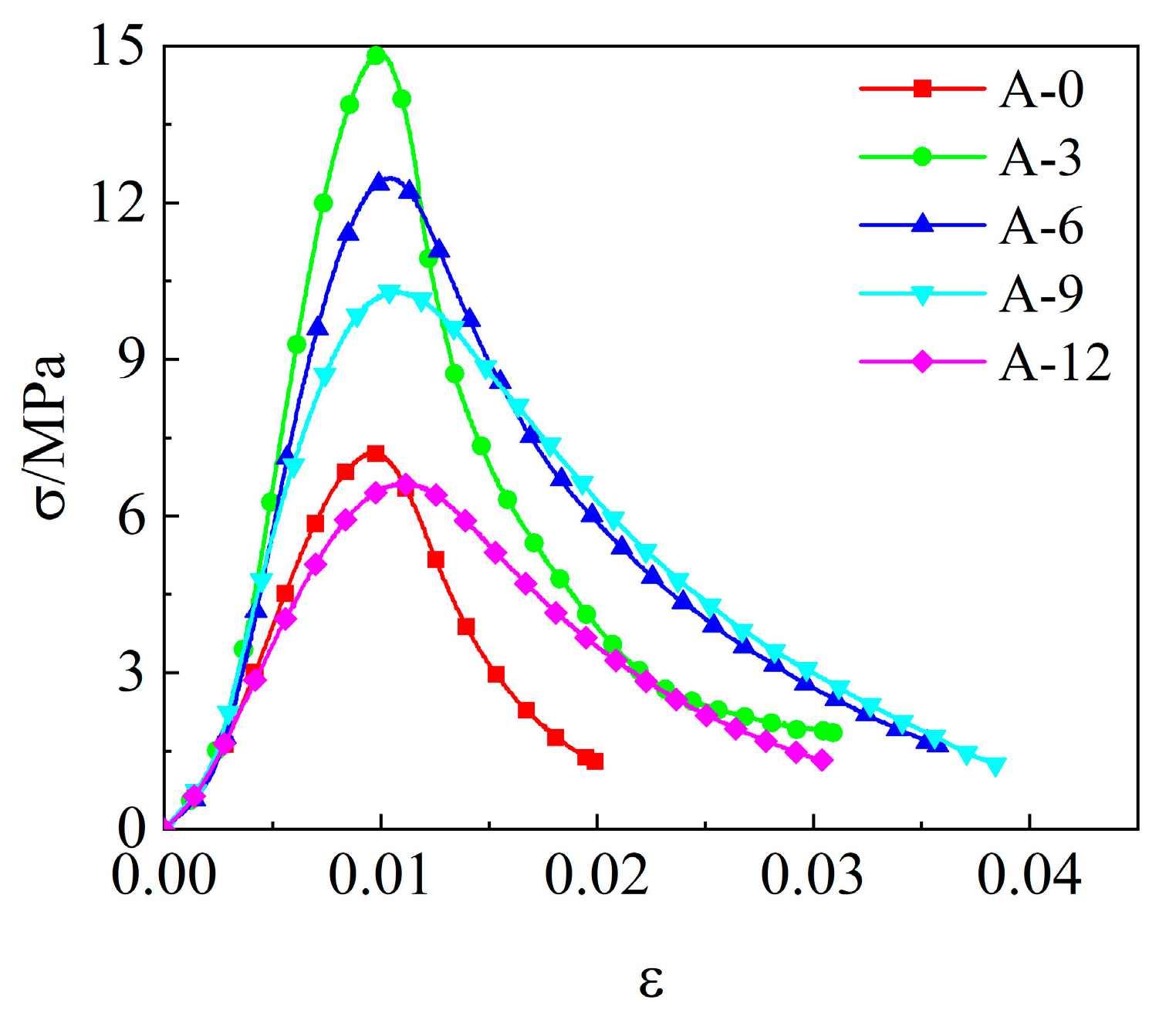

3.2. Stress–Strain Curve

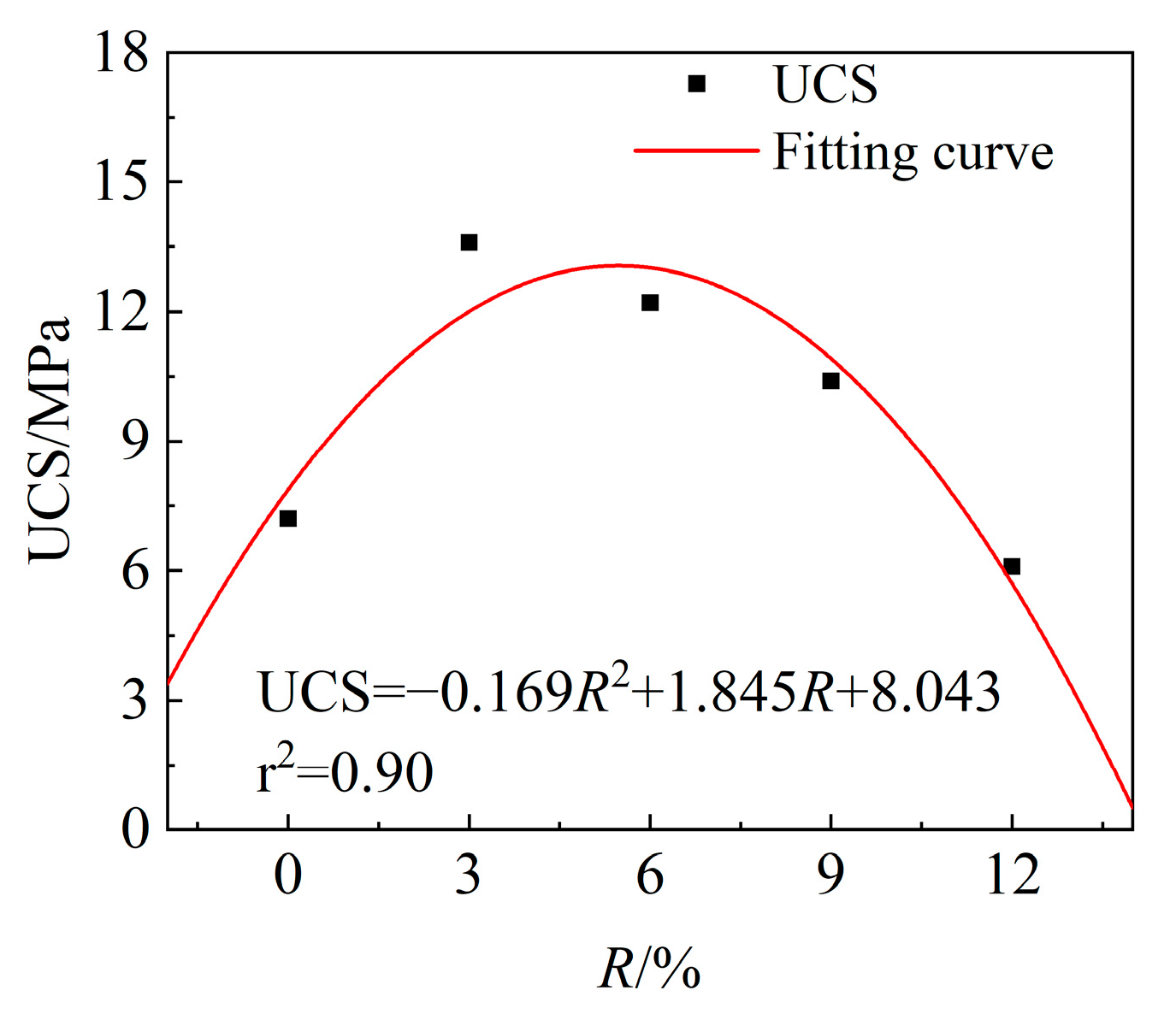

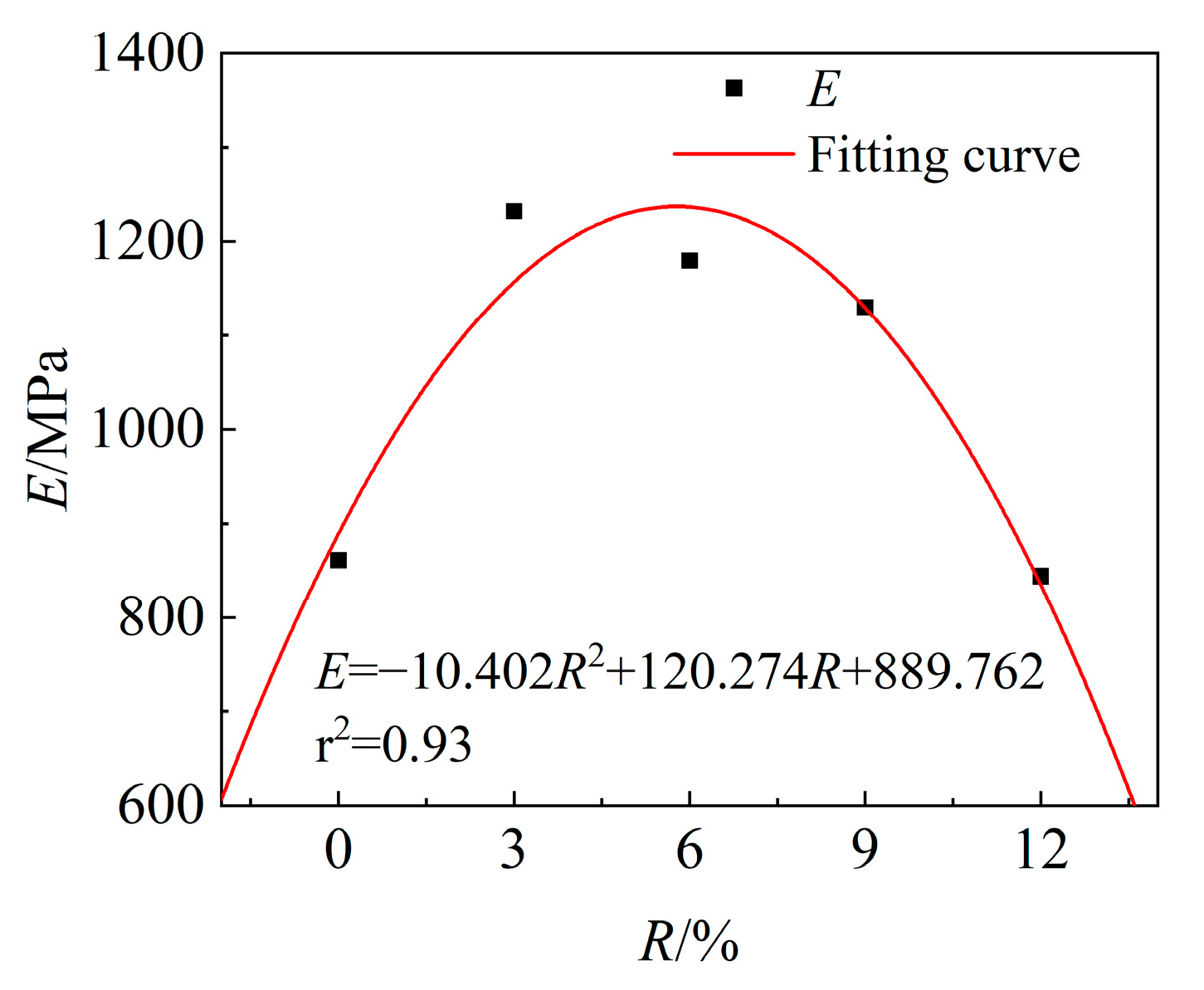

3.3. Feature Analysis

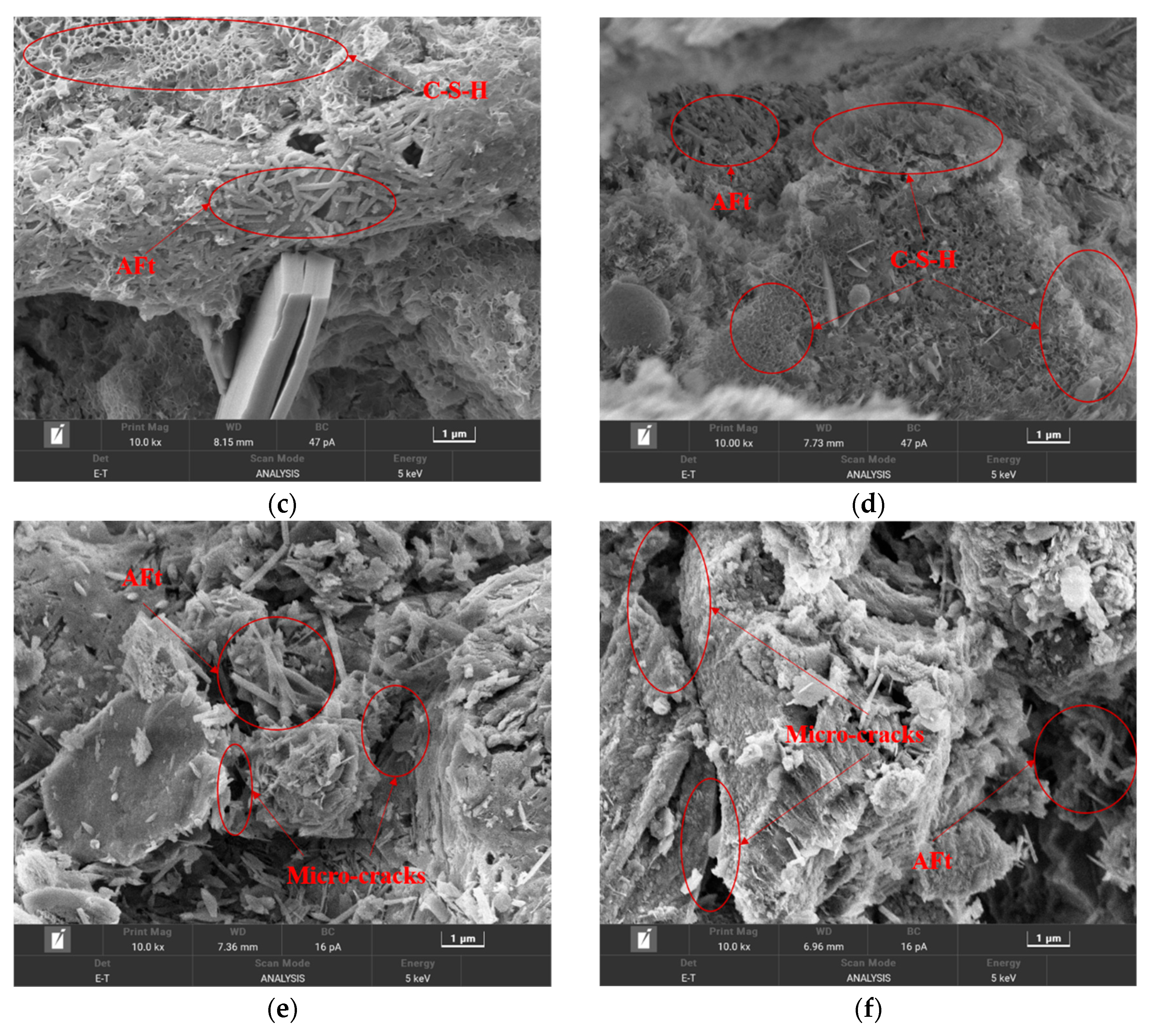

3.4. Microscopic Analysis

4. Damage Constitutive Model

4.1. Deduction of Damage Constitutive Model

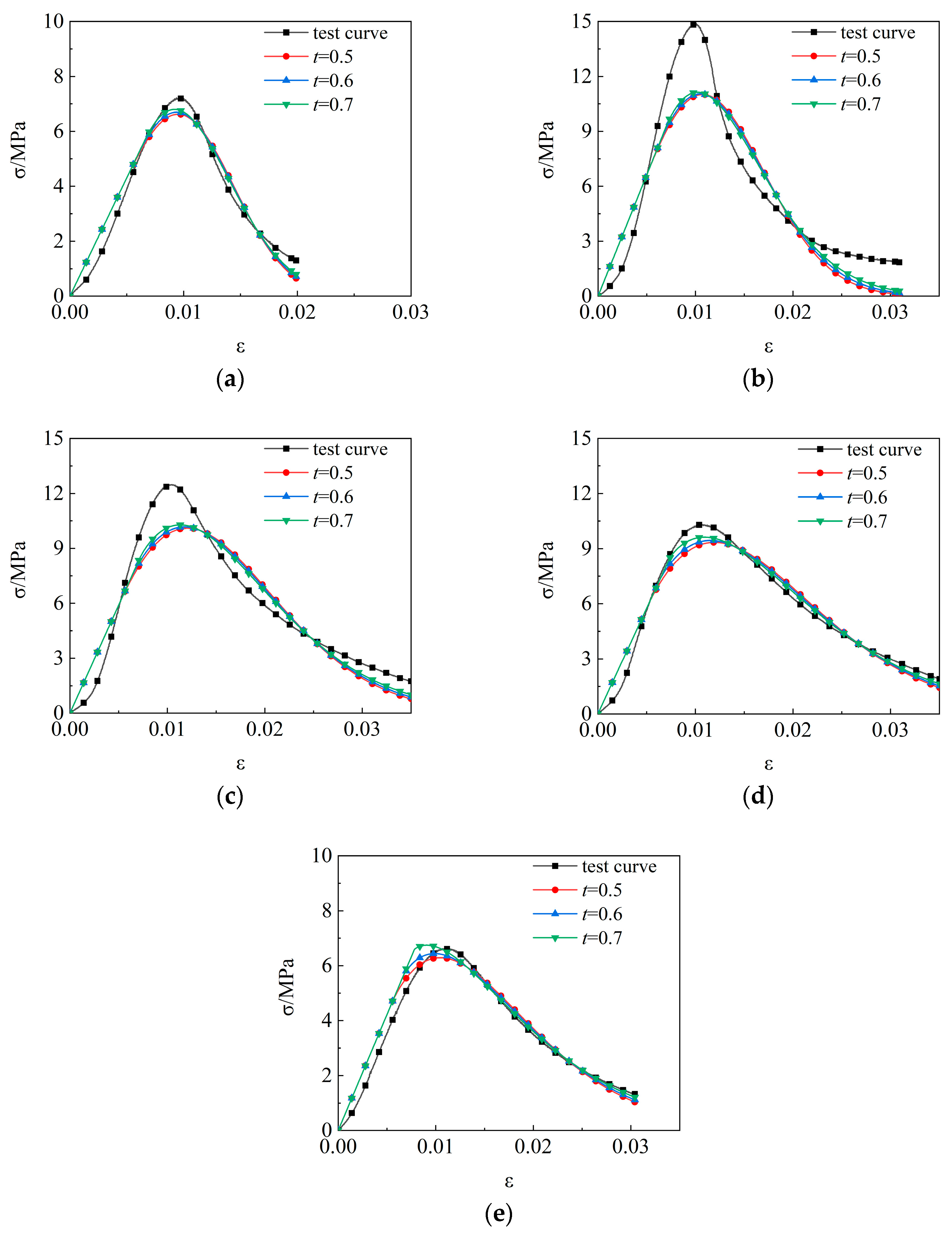

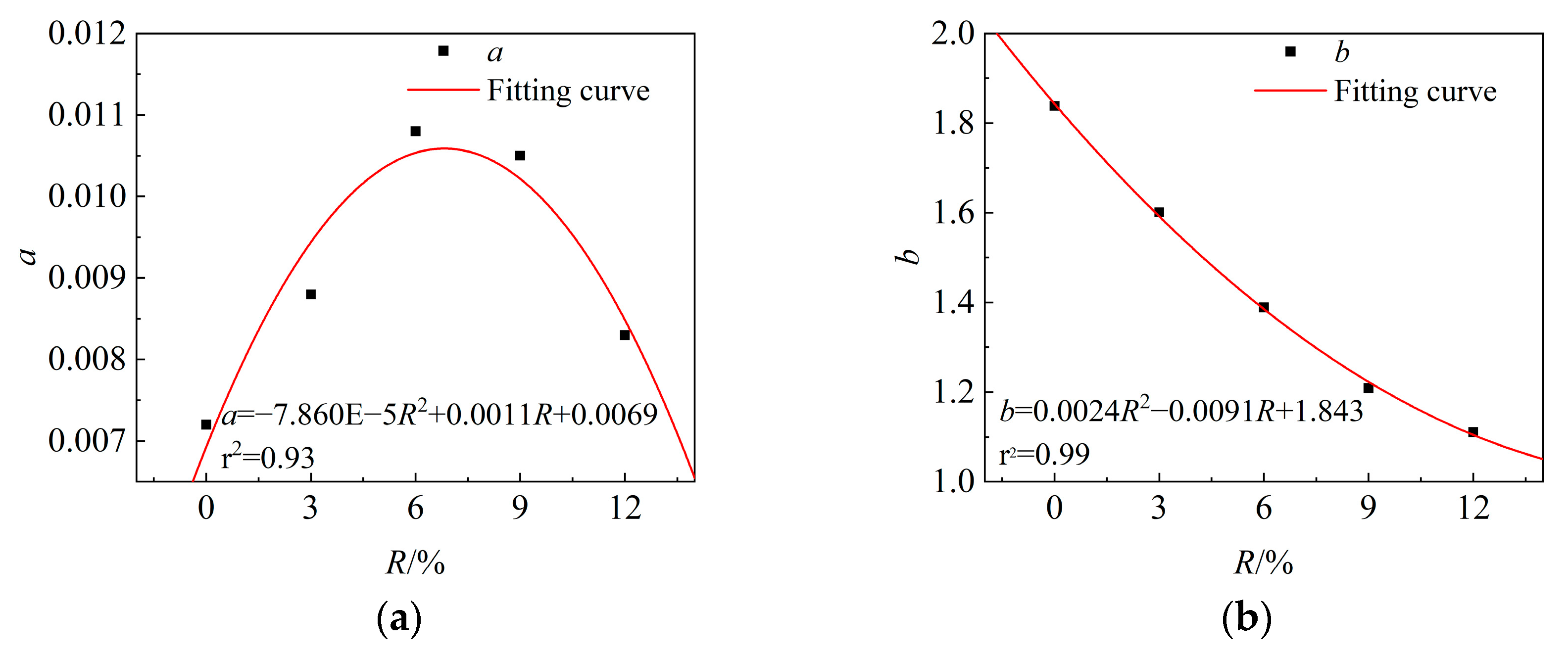

4.2. Model Parameter Analysis

4.3. Model Establishment

4.4. Analysis of Changes in Damage Variables

- Compaction Phase: In this initial phase, the mixture contains voids, preventing immediate damage upon the application of a load. During this loading period, no visible signs of distress are observed, and no microcracks form within the mixture. The material undergoes compaction as the voids are gradually eliminated under stress.

- Crack Propagation Phase: As strain increases, cracks become visually apparent on the surface of the mixture, eventually extending vertically and penetrating throughout the entire body of the mixture. Corresponding to a decline in stress, aggregate particles on the surface begin to detach. This stage features the highest rate of increase in the damage variable, indicative of rapid crack development and material degradation.

- Damage Phase: Even after the surface aggregates have detached, the mixture maintains some residual load-bearing capacity. Further loading leads to the gradual flattening of the stress–strain curve until the mixture ultimately fails. During this final stage, the rate of increase in the damage variable decelerates, gradually approaching and eventually reaching 1.0, signifying the completion of the damage process and the material’s total failure.

5. Conclusions

- Microscopic analysis shows that adding an appropriate amount of AOD slag to the mixture can cause hydration reactions and improve its mechanical properties.

- In this study, the damage constitutive model based on a three-parameter Weibull distribution and the Lemaitre strain equivalence principle could effectively describe the stress–strain relationship of the AOD slag mixtures under unconfined compression. The correlation coefficient is above 0.85.

- The parameters in the damage constitutive model have physical meanings, which reflect the mechanical properties of the mixture. Parameters a and b reflect the peak stress, strain, and brittleness of the mixture, respectively. Parameter t reflects strain at the beginning of cracking.

- Because the increase in elastic modulus of AOD is less than the increase in strength, it is impossible to make a stronger mixture than A-3 and A-6. In the future, improving the constitutive model by adding new parameters can achieve better fitting.

- Because of the difficulty of sample preparation, this paper only discusses AOD slag as an admixture. In the future, other mineral powders should be used as admixtures, and a damage constitutive model should be constructed for analysis.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhang, Z.Z.; Pan, Z.S.; Che, D.; Yan, Q.; Wu, Q. Chromite ore resources characteristic and analysis of supply and demand situation from 2021 to 2035 in China. Geol. China 2023, 51, 1191–1209. [Google Scholar]

- Lan, S.W.; Zhang, Z.W.; Hong, O.W.; Wang, X.; Xu, H. Research Status of Comprehensive Utilization of Stainless Steel Slag. Metall. Eng. 2019, 6, 34–39. [Google Scholar]

- Li, X.M.; Li, W.F.; Wang, S.J.; Shi, L.G. Research status on comprehensive utilization of stainless steel slag. Hydrometall. China 2012, 31, 5–8. [Google Scholar]

- Zhang, H. Research on the current situation of urban construction waste treatment and resource utilisation. Green Environ. Prot. Build. Mater. 2021, 178, 31–32. [Google Scholar]

- Huang, F.; Zhu, W.W.; Yan, S.Y. Development and Analysis of Smelting Process of Stainless Steel. Heavy Cast. Forg. 2017, 178, 50–59. [Google Scholar]

- Rosales, J.; Cabrera, M.; Agrela, F. Effect of stainless steel slag waste as a replacement for cement in mortars. Mechanical and statistical study. Constr. Build. Mater. 2017, 142, 444–458. [Google Scholar] [CrossRef]

- Zhang, C.H.; Liao, J.L.; Qu, J.; Dang, Y.J. Treatment Process and Utilization Technology of Steel Slag in China and Abroad. J. Iron Steel Res. 2013, 25, 1–4. [Google Scholar] [CrossRef]

- Zhao, H.J.; Yu, Q.J.; Wei, J.X.; Li, J.X.; Gong, C.C. Influence on Composition and Morphology of Mineral of Steel Slag and Cementitious Property. J. Wuhan Univ. Technol. 2013, 25, 1–4. [Google Scholar]

- Dai, J.; Chen, P.; Zhao, Y.R.; Liu, R.J.; Wei, J.Z. Study on the coagulation properties of stainless steel AOD slag. Concrete 2019, 353, 94–96. [Google Scholar]

- Gupta, T.; Sachdeva, S.N. Laboratory investigation and modeling of concrete pavements containing AOD steel slag. Cem. Concr. Res. 2009, 44, 91–94. [Google Scholar] [CrossRef]

- Zhen, Y.P.; Zong, Y.B.; Cang, D.Q.; Chen, G.Y.; Ding, C.L. Study on Effects of Adding Fly Ash to Molten Steel Slag. Iron Steel 2009, 44, 91–94. [Google Scholar]

- Lin, Z.T.; Tao, H.Z.; Tu, C.H. Research for Increasing the Activation of Steel Slage and Fly Ash. J. Wuhan Univ. Technol. 2001, 23, 4–7. [Google Scholar]

- Huang, B.; Wang, X.; Kua, H.; Geng, Y.; Bleischwitz, R.; Ren, J. Construction and demolition waste management in China through the 3R principle. Resour. Conserv. Recycl. 2018, 21, 511–522. [Google Scholar] [CrossRef]

- Xiao, J.; Ma, H.F.; Wu, C.F.; Yang, M.; Zhang, J.S. Study on Performance of Construction and Demolition Waste Recycled Aggregate Base Mixture. J. Build. Mater. 2018, 21, 511–515+522. [Google Scholar]

- Hu, H.M.; Sun, Y.X. Experimental research on the design of the mix proportion of recycled cement-stabilized aggregates and the strength rule. J. Hefei Univ. Technol. (Nat. Sci.) 2009, 32, 238–240. [Google Scholar]

- Ehsan, Y.B.; Asmaa, A.T.; Mahd, D.F.; Sam, F.; Maurice, G.; Ernie, G. Cement and fly ash-treated recycled aggregate blends for backfilling trenches in trafficable areas. Transp. Geotech. 2023, 42, 101091. [Google Scholar]

- Ning, J.G. The developments of dynamice constitutive behavior of concrete. Adv. Mech. 2006, 36, 389–405. [Google Scholar]

- Jang, X.C.; Xie, H.P.; Zhou, H.W. Analysis of relationship between macro-scopic damage and mesoscopic damage variables for micro-crack damage of quasi-brittle materials under tension. Chin. J. Rock Mech. Eng. 2007, 26, 2648–2653. [Google Scholar]

- Feng, X.Q.; Yu, S.W. Mesoscopic Damage Mechanics of Quasi-Brittle Materials; China Higher Education Press: Beijing, China, 2002. [Google Scholar]

- Kai, C.; Roberto, C.; Andres, P. Assessment method for determining rock brittleness based on statistical damage constitutive relations. Geomech. Energy Environ. 2024, 37, 100517. [Google Scholar]

- Qin, F.F.; Cheng, J.X.; Sheng, D.F.; Chai, Z.Y.; Huo, X.W. A phenomenologically based dam age model for strain-softening fiber reinforced concrete. J. Build. Eng. 2023, 58, 105418. [Google Scholar]

- Fang, J.Y.; Yuan, Z.L.; Liang, J.Y.; Li, S.T.; Qin, Y. Research on compressive damage mechanism of concrete based on material heterogeneity. J. Build. Eng. 2023, 79, 107740. [Google Scholar] [CrossRef]

- Dinesh, K.S.; Sonalisa, R. Wavelet entropy-based damage characterization and material phase differentiation in concrete using acoustic emissions. Eng. Fail. Anal. 2024, 160, 108144. [Google Scholar]

- Ren, C.H.; Yu, J.; Liu, Z.Q.; Zhang, Z.Q.; Cai, Y.Y. Cyclic constitutive equations of rock with coupled damage induced by compaction and cracking. Int. J. Min. Sci. Technol. 2022, 32, 1153–1165. [Google Scholar] [CrossRef]

- Shen, P.W.; Tang, H.M.; Ning, Y.B.; Xia, D. A damage mechanics based on the constitutive model for strain-softening rocks. Eng. Fract. Mech. 2019, 216, 106521. [Google Scholar] [CrossRef]

- Dai, J.; Yang, Q.Q.; Zhang, M.; Jiang, H.X.; Wang, L.T. Constitutive Model of Granite Uniaxial Compression Damage under Microwave Irradiation. Sci. Technol. Eng. 2023, 23, 8350–8357. [Google Scholar]

- Ji, Y.C.; Wang, D.Y. Constitutive model of waste brick concrete based on Weibull strength theory. Case Stud. Constr. Mater. 2023, 18, e01738. [Google Scholar] [CrossRef]

- Huo, Y.; Qiu, J.S.; Feng, Z.P.; Yang, M.M.; Xiao, Q.H.; Guan, X. Acoustic emission characteristics of recycled brick-concrete aggregate concrete under freeze-thaw-load coupling action and damage constitutive model. J. Build. Eng. 2023, 79, 107930. [Google Scholar] [CrossRef]

- Wu, Q.Y.; Ma, Q.Y.; Zhang, J.S. Mechanical properties and damage constitutive model of concrete under low-temperature action. Constr. Build. Mater. 2022, 348, 128668. [Google Scholar] [CrossRef]

- Liu, Y.; Wang, Y.C.; Zhong, Z.B.; Li, Q.L.; Zuo, Q.L. Constitutive Model for Grouted Rock Mass by Macro-Meso Damage. Materials 2023, 16, 4859. [Google Scholar] [CrossRef]

- Han, Z.; Zhang, Y.S.; Qiao, H.X.; Feng, Q.; Xue, C.Z.; Shang, M.G. Study on axial compressive behavior and damage constitutive model of manufactured sand concrete based on fluidity optimization. Constr. Build. Mater. 2022, 345, 128176. [Google Scholar] [CrossRef]

- Li, B.; Chen, Z.K.; Wang, S.N.; Xu, L.H. A review on the damage behavior and constitutive model of fiber reinforced concrete at ambient temperature. Constr. Build. Mater. 2024, 412, 134919. [Google Scholar] [CrossRef]

- Kohout, J. Three-parameter Weibull distribution with upper limit applicable in reliability studies and materials testing. Microelectron. Reliab. 2022, 137, 114769. [Google Scholar] [CrossRef]

- Serkan, N. Three-parameter (3P) weibull distribution for characterization of strength of ceramics showing R-Curve behavior. Ceram. Int. 2021, 47, 2270–2279. [Google Scholar]

- Yu, S.W. Damage Mechanics; Tsinghua University Press: Beijing, China, 1997. [Google Scholar]

- GB.175-2020; Common Portland Cement. People’s Transport Publishing House: Beijing, China, 2020.

- JTG/T F20-2015; Technical Guidelines for Construction of Highway Roadbases. Ministry of Transport of the People’s Republic of China: Beijing, China, 2015.

- JTG E51-2009; Test Methods of Materials Stabilized with Inorganic Binders for Highway Engineering. Ministry of Transport of the People’s Republic of China: Beijing, China, 2009.

- Huang, L.Y.; Wei, G.G.; Lan, Z.Z.; Chen, Y.L.; Tun, L. Preparation and Mechanism Analysis of Stainless Steel AOD Slag Mixture Base Materials. Materials 2024, 17, 970. [Google Scholar] [CrossRef] [PubMed]

- JTG D50-2017; Design Specification for Asphalt Pavement of Highways. Ministry of People’s Transport Publishing House: Beijing, China, 2009.

- Lemaitre, J. How to use damage mechanics. Nucl. Eng. Des. 1984, 80, 233–245. [Google Scholar] [CrossRef]

- Xue, Y.L.; Li, Z.L.; Lin, F.; Xun, H.B. Study of damage constitutive model of SFRC considering effect of damage threshold. Rock Soil Mech. 2009, 30, 1987–1999. [Google Scholar]

| CaO/(%) | SiO2/(%) | Fe2O3/(%) | MgO/(%) | TiO2/(%) | Cr2O3/(%) | MnO/(%) | K2O/(%) | SO3/(%) |

|---|---|---|---|---|---|---|---|---|

| 47.38 | 26.20 | 13.80 | 5.29 | 3.39 | 2.31 | 1.22 | 0.18 | 0.11 |

| Specimen Identification Number | Inorganic Binder Blend Ratio | Cement/(g) | Fly Ash/(g) | AOD Slag/(g) | RA 1/(g) | Optimum Moisture Dosage/(%) | Maximum Dry Density/(g/cm3) |

|---|---|---|---|---|---|---|---|

| R = 0% | 1:4:0 | 162.3 | 649.2 | 0.0 | 4597.2 | 7.7 | 2.082 |

| R = 3% | 1:3:1 | 161.0 | 483.0 | 161.0 | 4562.0 | 8.7 | 2.066 |

| R = 6% | 1:2:2 | 160.0 | 320.0 | 320.0 | 4533.1 | 9.6 | 2.053 |

| R = 9% | 1:1:3 | 159.1 | 159.1 | 477.2 | 4506.6 | 10.2 | 2.041 |

| R = 12% | 1:0:4 | 158.2 | 0.0 | 632.8 | 4482.3 | 10.9 | 2.030 |

| (a) | |||||||

| Specimen Identification Number | a Fitted Value | a Calculated Value | Ratio | b Fitted Value | b Calculated Value | Ratio | |

| A-0 | 0.0072 | 0.0679 | 0.10 | 1.838 | 2.695 | 0.68 | |

| A-3 | 0.0088 | 0.0554 | 0.16 | 1.601 | −2.367 | −0.68 | |

| A-6 | 0.0108 | 17.2923 | 0.0006 | 1.389 | −40.601 | −0.03 | |

| A-9 | 0.0105 | 0.0311 | 0.34 | 1.209 | 1.705 | 0.71 | |

| A-12 | 0.0082 | 0.0058 | 1.43 | 1.111 | 0.717 | 1.55 | |

| Mean value Coefficient of variation | 0.41 | 0.45 | |||||

| 1.28 | 1.69 | ||||||

| (b) | |||||||

| Specimen Identification Number | Damage Constitutive Model | t | r2 | RMSE 1 | |||

| A-0 | 0.0066 | 0.967 | 0.396 | ||||

| A-3 | 0.0070 | 0.869 | 1.55 | ||||

| A-6 | 0.0072 | 0.922 | 1.01 | ||||

| A-9 | 0.0074 | 0.982 | 0.430 | ||||

| A-12 | 0.0078 | 0.957 | 0.392 | ||||

| (c) | |||||||

| p-Value of a | p-Value of b | ||||||

| A-0 | 7.1434 × 10−153 | 5.8342 × 10−88 | |||||

| A-3 | 2.141 × 10−162 | 1.0824 × 10−82 | |||||

| A-6 | 5.6294 × 10−202 | 6.1464 × 10−130 | |||||

| A-9 | 5.0837 × 10−282 | 1.6415 × 10−220 | |||||

| A-12 | 6.8385 × 10−202 | 6.384 × 10−153 | |||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Huang, L.; Lan, Z.; Wei, G.; Chen, Y.; Li, T. Studying the Constitutive Model of Damage for a Stainless Steel Argon–Oxygen Decarburization Slag Mixture. Appl. Sci. 2024, 14, 10006. https://doi.org/10.3390/app142110006

Huang L, Lan Z, Wei G, Chen Y, Li T. Studying the Constitutive Model of Damage for a Stainless Steel Argon–Oxygen Decarburization Slag Mixture. Applied Sciences. 2024; 14(21):10006. https://doi.org/10.3390/app142110006

Chicago/Turabian StyleHuang, Liuyun, Zhuxin Lan, Guogao Wei, Yuliang Chen, and Tun Li. 2024. "Studying the Constitutive Model of Damage for a Stainless Steel Argon–Oxygen Decarburization Slag Mixture" Applied Sciences 14, no. 21: 10006. https://doi.org/10.3390/app142110006

APA StyleHuang, L., Lan, Z., Wei, G., Chen, Y., & Li, T. (2024). Studying the Constitutive Model of Damage for a Stainless Steel Argon–Oxygen Decarburization Slag Mixture. Applied Sciences, 14(21), 10006. https://doi.org/10.3390/app142110006