Probabilistic Analysis of Low-Emission Hydrogen Production from a Photovoltaic Carport

Abstract

1. Introduction

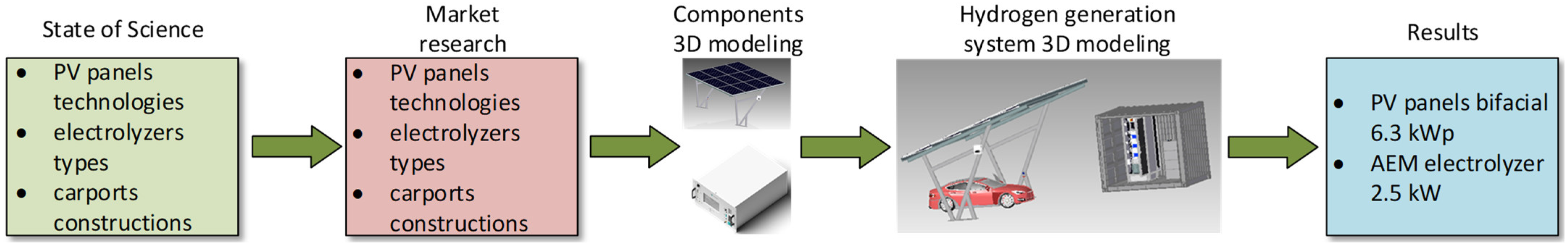

2. Materials and Methods

3. Components of the Low-Emission Hydrogen Generation System

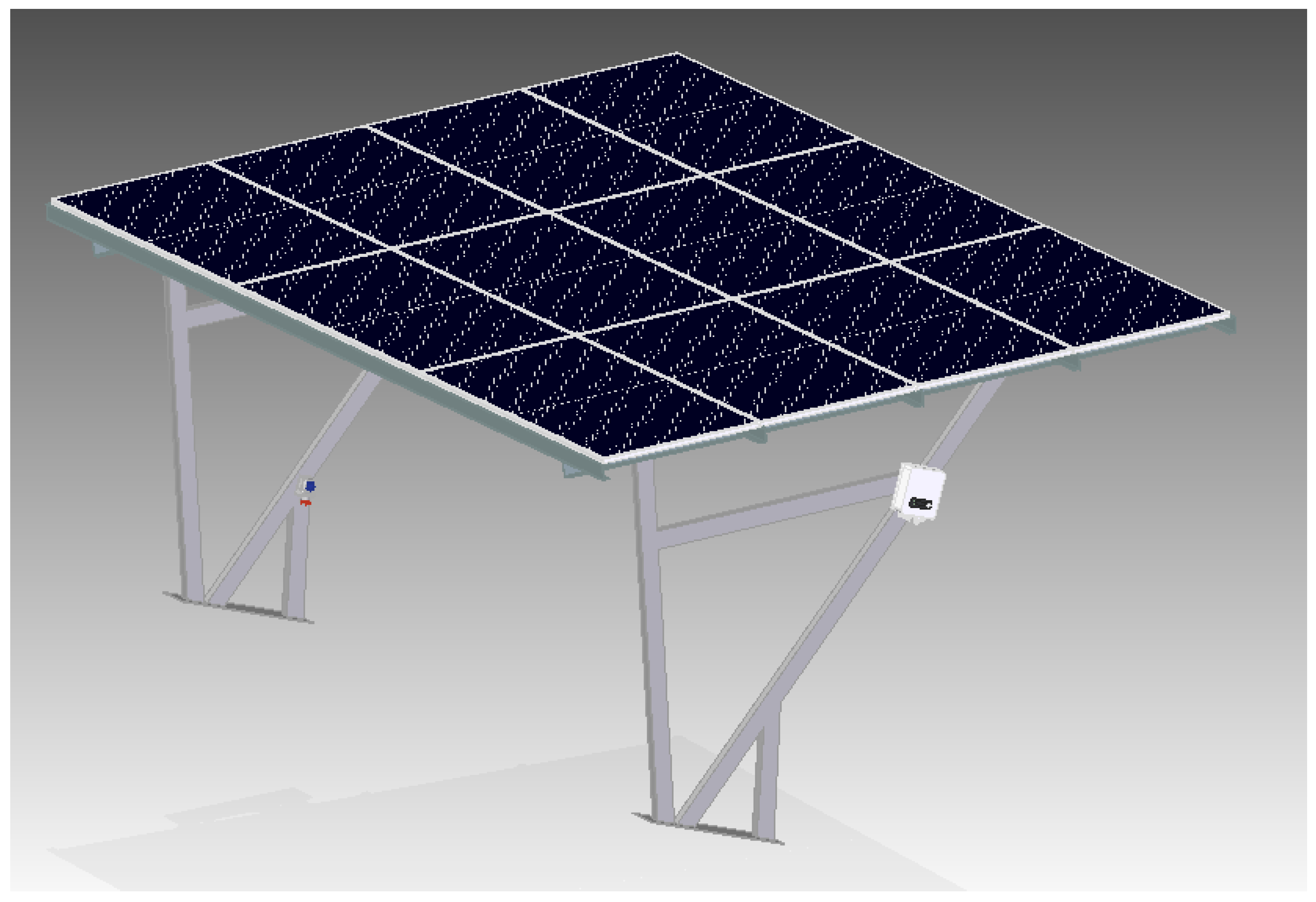

3.1. Photovoltaic Carport with Hybrid Inverter

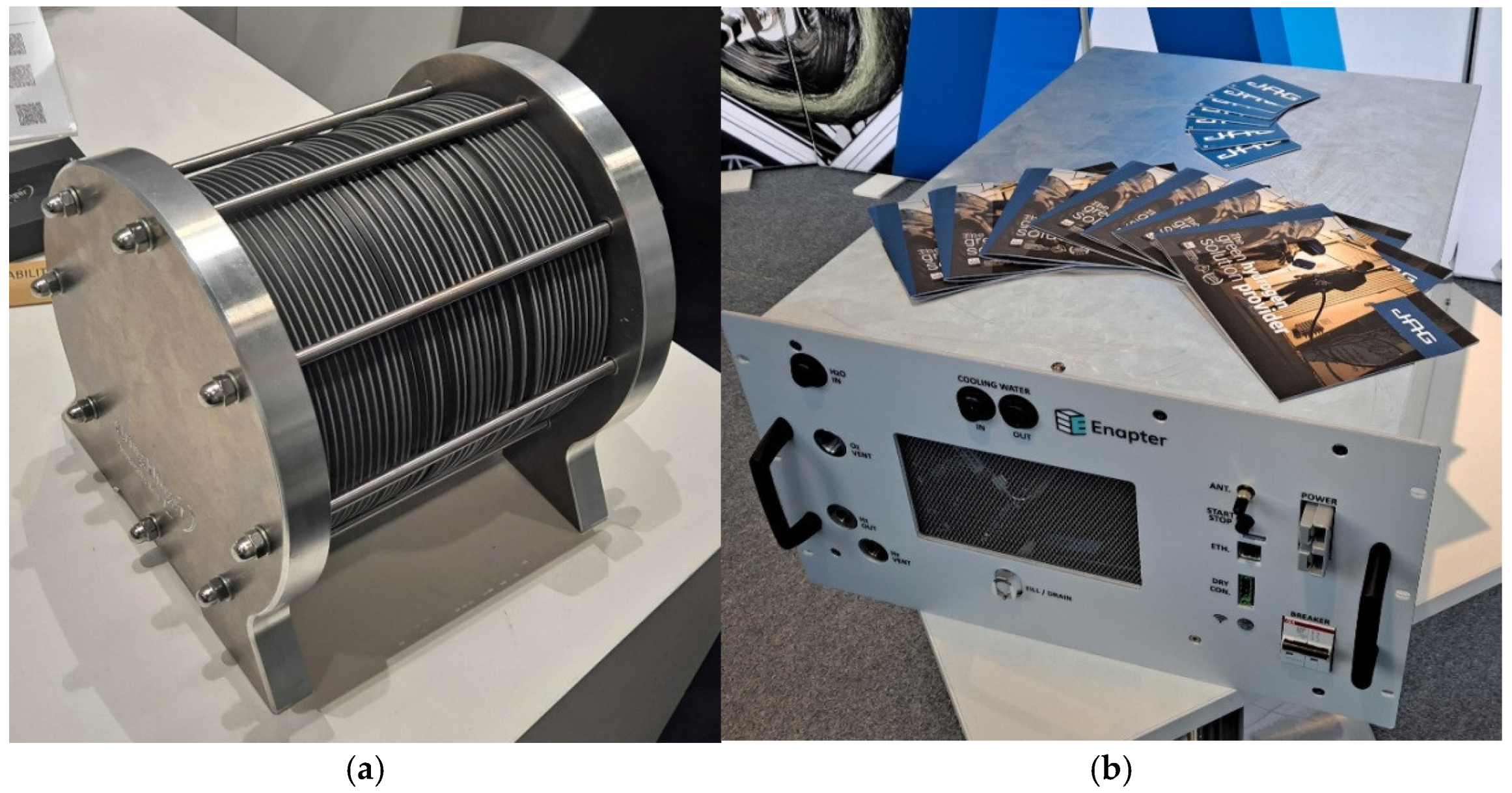

3.2. Hydrogen Electrolyzer

3.3. Energy Storage

4. Results

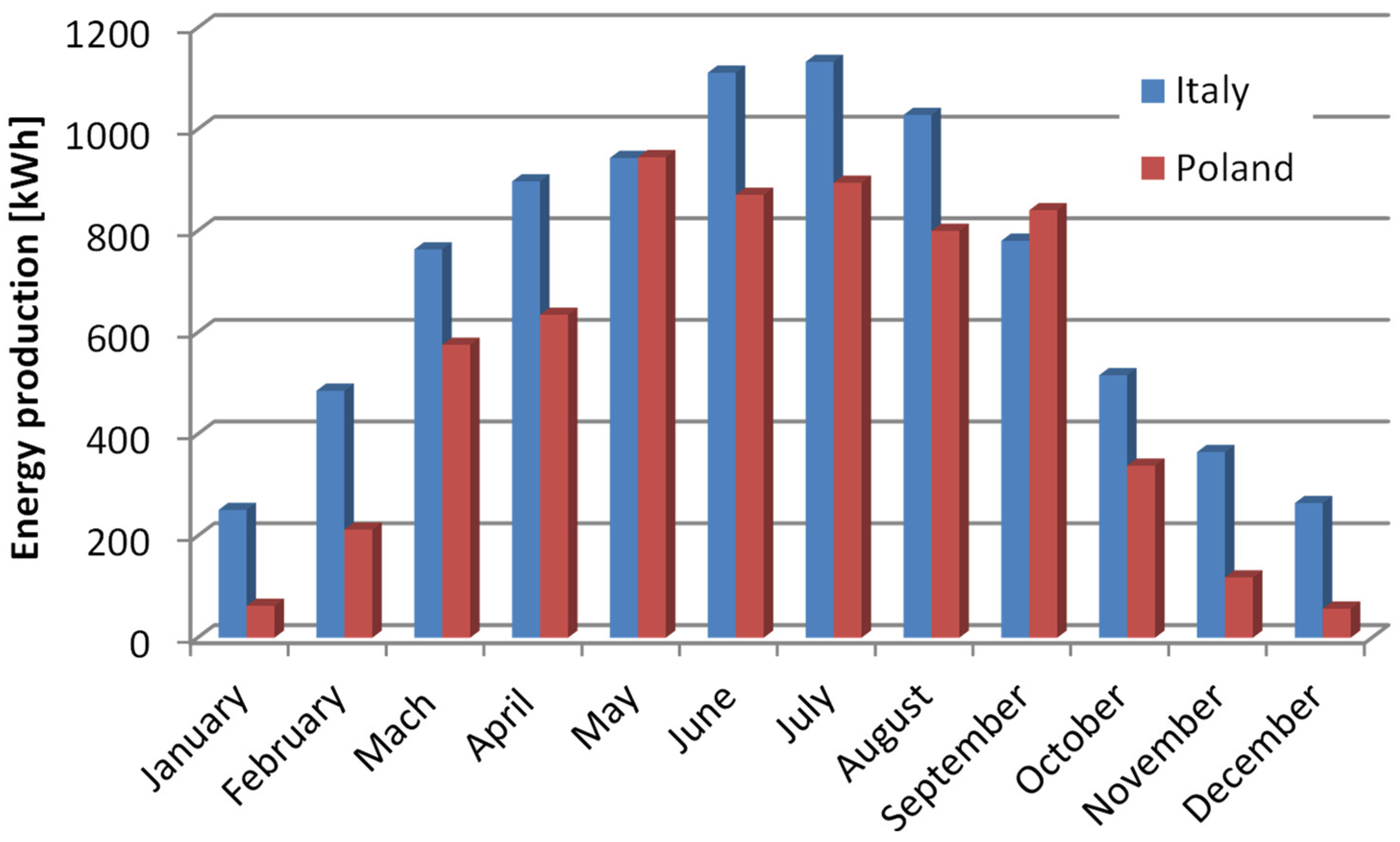

4.1. Comparison of the Amount of Energy Produced in Poland and Italy

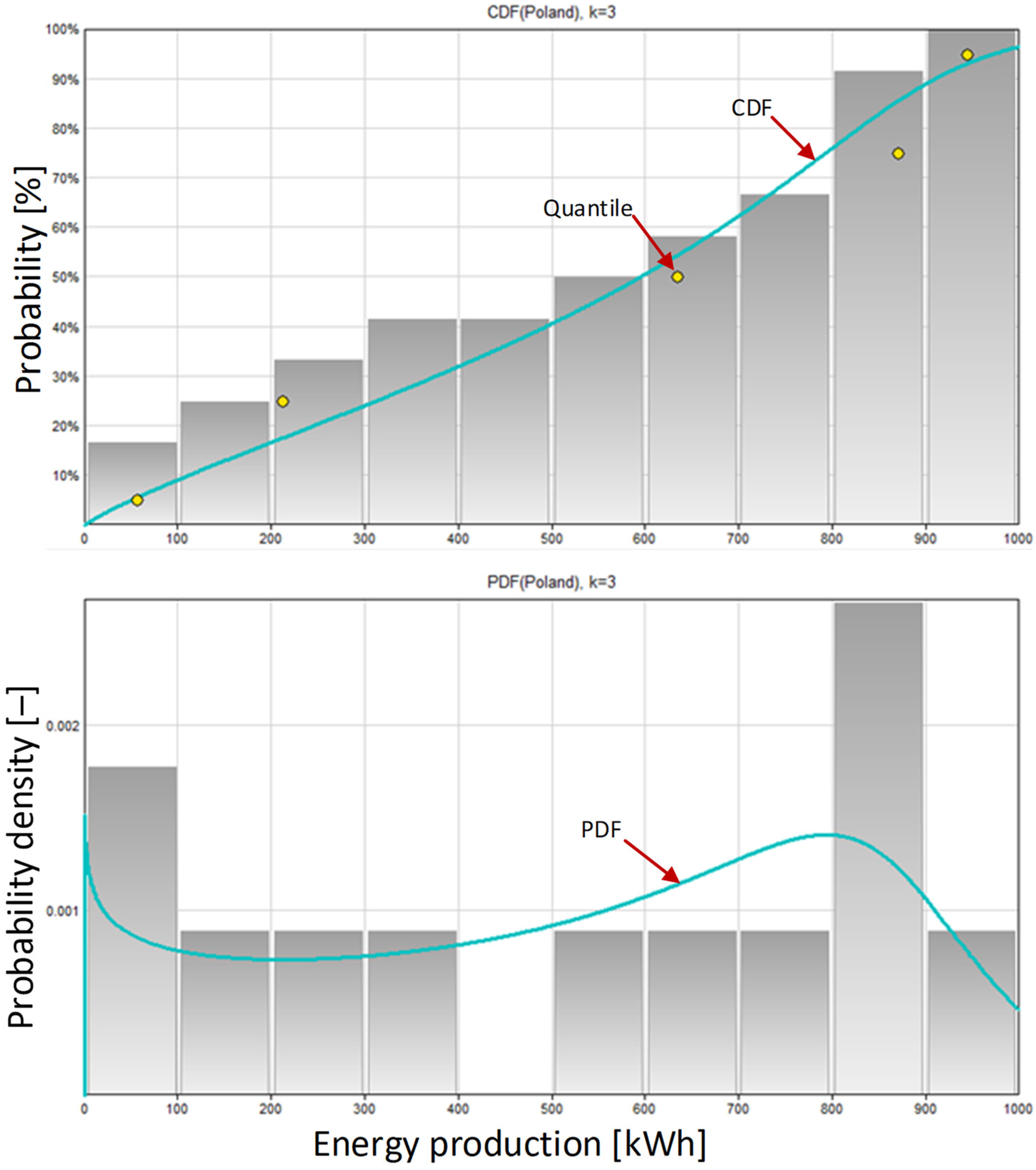

4.2. Probability of Monthly Energy Production Levels in Poland

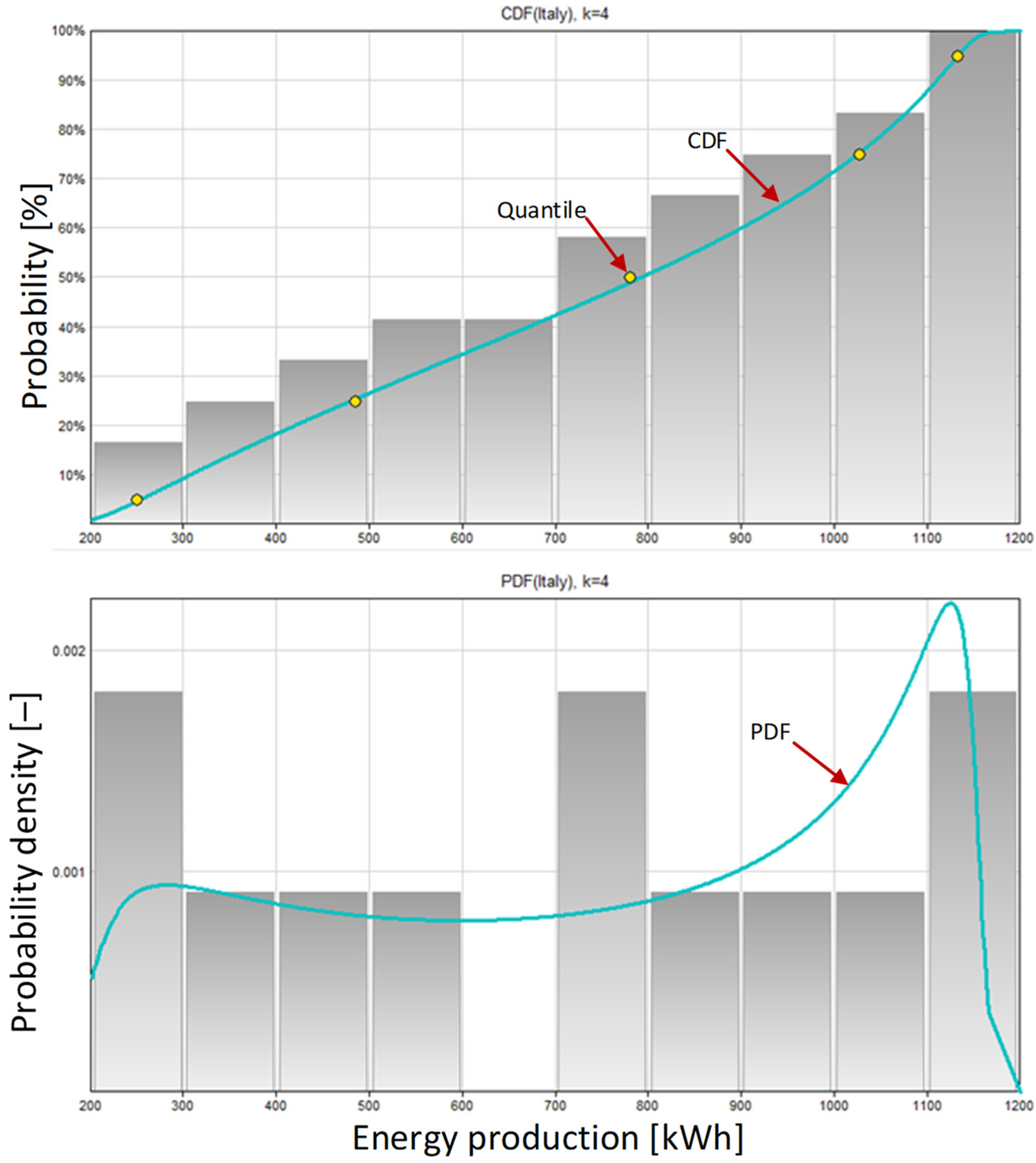

4.3. Probability of Monthly Energy Production Levels in Italy

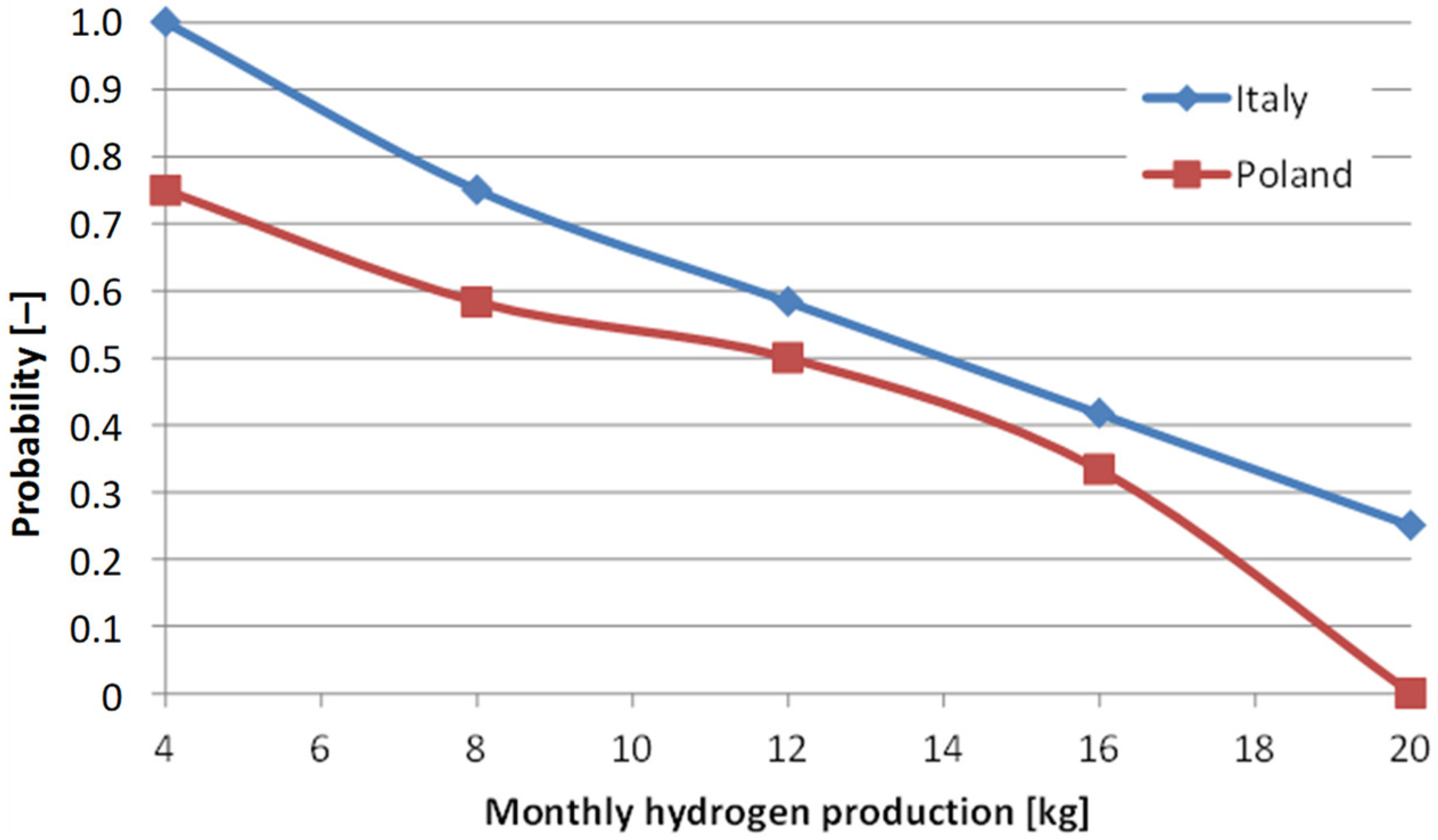

4.4. Comparison of Monthly Energy Production Probability Levels in Poland and Italy

5. Discussion

- (1)

- All energy produced by the photovoltaic system will be used to produce hydrogen. For this purpose, it is necessary to use an energy storage device that is able to accumulate excess electricity and use it to power the electrolyzer during periods of lower sunlight or at night.

- (2)

- To produce 1 kg of hydrogen, 50 kWh of electricity is needed. This is a significant simplification because it results from the efficiency of the entire hydrogen generation system. However, it is very useful in quick and approximate calculations.

- (3)

- The low-emission hydrogen generation system operates reliably. All system components operate with maximum efficiency and do not fail. Under normal operating conditions, certain periodic downtimes related to inspections and maintenance procedures in the operation of the entire system should be expected.

- (4)

- No costs associated with compressing hydrogen to pressures of 350 or 700 bar are included.

6. Conclusions

- (1)

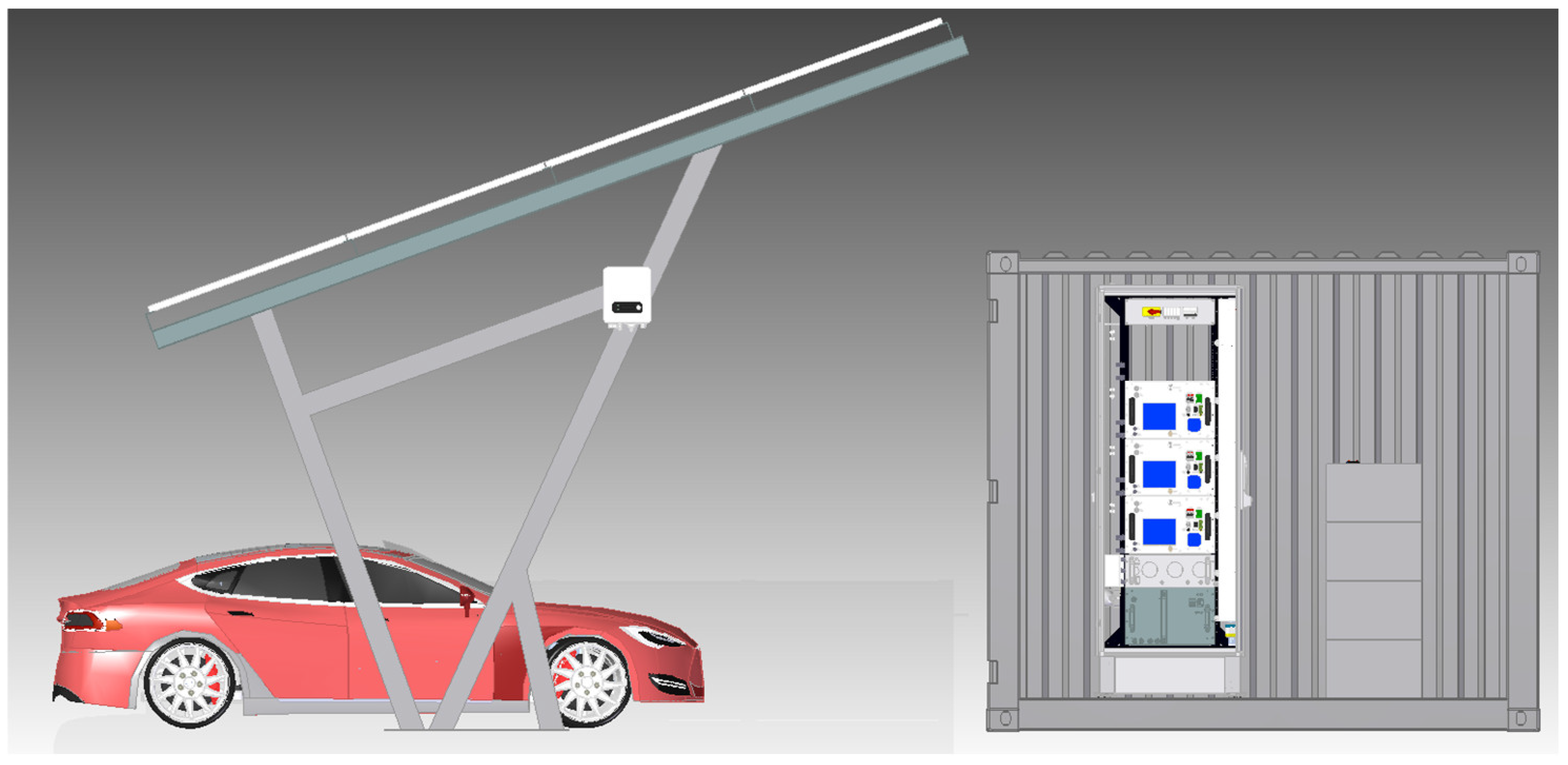

- This article includes the 3D modeling and the probabilistic analysis of a low-emission hydrogen generation system powered by energy from the photovoltaic carport. First, the individual components of the low-emission hydrogen generation system were characterized. Due to the purpose of the produced hydrogen, it was decided that the energy for its production would come from the carport. The 3D modeling presented in this article allows us to estimate the sufficient surface area in order to generate the specific amount of hydrogen. To produce hydrogen in the amount of ¾ kg/day, a photovoltaic carport was designed in 3D using the Solid Edge software with a peak power of 6.36 kWp. The peak power results from the use of twelve bifacial panels with a peak power of 530 Wp. The approximate overall dimensions of the carport will be 6.822 mm × 4.536 mm. With a carport leg spacing of 6000 mm, two compact-class vehicles can be parked under it. The hydrogen generation system, including an electrolyzer, a water preparation station and a hydrogen dryer, as well as an energy storage facility, was placed in a 10-foot ISO shipping container.

- (2)

- Among the many available hydrogen production technologies, the AEM electrolyzer technology was selected for producing clean hydrogen that is able to meet the requirements of the automotive industry. The selected 2.4 kW electrolyzer is ideally suited for producing 1 kg of hydrogen per day, provided that the appropriate amount of energy is supplied. In order to ensure the production of low-emission hydrogen with the energy from the photovoltaic carport, it was necessary to store the energy in a stationary storage. The power produced by the carport, which is an excess in relation to the power consumed by the electrolyzer, must be stored in the energy storage and released from it at times of lower power generated from the sun and at night.

- (3)

- A probabilistic analysis of the monthly energy production by two photovoltaic systems located in two European countries, namely Poland and Italy, was then performed. The calculation method presented in this article uses the Metalog probability distribution family. As a result of using the actual monthly energy production by the photovoltaic systems with a peak power of 6.3 kWp located in Poland and Italy for calculations, the probabilistic analysis takes into account the geographical context related to the location of the low-emission hydrogen generation system. The system located in Italy was able to produce approximately 200 kWh more energy per month than its counterpart located in Poland. Higher monthly energy production in Italian geographical and climatic conditions resulted in a higher probability of generating individual energy levels, which directly translated into the probability of generating individual monthly low-emission hydrogen expenditures.

- (4)

- The monthly hydrogen production amounts were compared with the average hydrogen consumption of the two most popular hydrogen fuel cell vehicles. On this basis, it was calculated that the energy produced annually by the 6.3 kWp peak photovoltaic system located in Poland would provide a hydrogen vehicle with a range of over 13,000 km. An identical photovoltaic system located in Italy would provide a hydrogen vehicle with a range of over 17,000 km. The results obtained in the calculations were made based on data from only one year of operation of photovoltaic systems located in two specific locations in Europe, and the conclusions drawn from this cannot be the basis for broader generalizations regarding the amount of energy and hydrogen produced in Poland and Italy. The calculations carried out are to indicate the order of calculations performed using selected calculation tools.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Barreto, L.; Makihira, A.; Riahi, K. The hydrogen economy in the 21st century: A sustainable development scenario. Int. J. Hydrogen Energy 2003, 28, 267–284. [Google Scholar] [CrossRef]

- Minderytė, A.; Pauraite, J.; Dudoitis, V.; Plauškaitė, K.; Kilikevičius, A.; Matijošius, J.; Rimkus, A.; Kilikevičienė, K.; Vainorius, D.; Byčenkienė, S. Carbonaceous aerosol source apportionment and assessment of transport-related pollution. Atmos. Environ. 2022, 279, 119043. [Google Scholar] [CrossRef]

- Stopka, O.; Kampf, R.; Vrábel, J. Deploying the means of transport within the transport enterprises in the context of emission standards. In Transport Means, Proceedings of the International Conference, Juodkrante, Lithuania, 5–7 October 2016; Kaunas University of Technology: Juodkrante, Lithuania, 2016; pp. 185–190. [Google Scholar]

- Beik, Y.; Dziewiątkowski, M.; Szpica, D. Exhaust emissions of an engine fuelled by petrol and liquefied petroleum gas with control algorithm adjustment. SAE Int. J. Engines 2020, 13, 739–759. [Google Scholar] [CrossRef]

- Pivetta, D.; Dall’Armi, C.; Sandrin, P.; Bogar, M.; Taccani, R. The role of hydrogen as enabler of industrial port area decarbonization. Renew. Sustain. Energy Rev. 2024, 189 Pt B, 113912. [Google Scholar] [CrossRef]

- Pivetta, D.; Volpato, G.; Carraro, G.; Dall’Armi, C.; Da Lio, L.; Lazzaretto, A.; Taccani, R. Optimal decarbonization strategies for an industrial port area by using hydrogen as energy carrier. Int. J. Hydrogen Energy 2023, 52, 1084–1103. [Google Scholar] [CrossRef]

- Skrúcaný, T.; Gnap, J. Energy intensity and greenhouse gases production of the road and rail cargo transport using a software to simulate the energy consumption of a train. Commun. Comput. Inf. Sci. 2014, 471, 263–272. [Google Scholar]

- Skrúcaný, T.; Stopková, M.; Stopka, O.; Kalašová, A.; Ovčiarik, P. User’s determination of a proper method for quantifying fuel consumption of a passenger car with compression ignition engine in specific operation conditions. Open Eng. 2021, 11, 151–160. [Google Scholar] [CrossRef]

- Suh, J. Estimation of Photovoltaic Potential of Solar-Powered Electric Vehicle: Case Study of Commuters on Donghae Expressway, Korea. Appl. Sci. 2024, 14, 6574. [Google Scholar] [CrossRef]

- Malek, A.; Niewczas, A. Selected maintenance aspects of traction batteries in electric vehicles. In Proceedings of the 2020 XII International Science-Technical Conference AUTOMOTIVE SAFETY, Kielce, Poland, 21–23 October 2020; pp. 1–6. [Google Scholar] [CrossRef]

- Gawlik, L.; Mokrzycki, E. Analysis of the Polish Hydrogen Strategy in the Context of the EU’s Strategic Documents on Hydrogen. Energies 2021, 14, 6382. [Google Scholar] [CrossRef]

- Ding, S.-L.; Song, E.-Z.; Yang, L.-P.; Litak, G.; Yao, C.; Ma, X.-Z. Investigation on nonlinear dynamic characteristics of combustion instability in the lean-burn premixed natural gas engine. Chaos Solitons Fractals 2016, 93, 99–110. [Google Scholar] [CrossRef]

- Szpica, D.; Czaban, J. Investigating of the combustion process in a diesel engine fueled with conventional and alternative fuels. In Proceedings of the 23rd International Scientific Conference, Transport Means 2019, Palanga, Lithuania, 2–4 October 2019; pp. 176–181. [Google Scholar]

- Dziewiatkowski, M.; Szpica, D.; Borawski, A. Evaluation of impact of combustion engine controller adaptation process on level of exhaust gas emissions in gasoline and compressed natural gas supply process. Eng. Rural. Dev. 2020, 19, 541–548. [Google Scholar] [CrossRef]

- Shahabuddin, M.; Rhamdhani, M.A.; Brooks, G.A. Technoeconomic Analysis for Green Hydrogen in Terms of Production, Compression, Transportation and Storage Considering the Australian Perspective. Processes 2023, 11, 2196. [Google Scholar] [CrossRef]

- Aguilar-García, E.; Pérez-Cruz, M.A.; Sánchez-Cruz, M.; Yee-Madeira, H.; Cruz-Leal, M.; Rubio-Rosas, E.; Hernández-Huesca, R. Hydrogen Production by Hydrogen Sulfide Decomposition Using Cobalt Catalysts Doped in SBA-15 Synthetized by EISA Method. Catal. Lett. 2024, 154, 3724–3737. [Google Scholar] [CrossRef]

- Anastasiadis, A.G.; Papadimitriou, P.; Vlachou, P.; Vokas, G.A. Management of Hybrid Wind and Photovoltaic System Electrolyzer for Green Hydrogen Production and Storage in the Presence of a Small Fleet of Hydrogen Vehicles—An Economic Assessment. Energies 2023, 16, 7990. [Google Scholar] [CrossRef]

- Chakrabarty, P.; Alam, K.C.A.; Paul, S.K.; Saha, S.C. Hydrogen production by electrolysis: A sustainable pathway. In Hydrogen Energy Conversion and Management; Elsevier: Amsterdam, The Netherlands, 2024; pp. 81–102. [Google Scholar] [CrossRef]

- Nadaleti, W.C.; de Souza, E.G.; de Souza, S.N.M. The potential of hydrogen production from high and low-temperature electrolysis methods using solar and nuclear energy sources: The transition to a hydrogen economy in Brazil. Int. J. Hydrogen Energy 2022, 47, 34727–34738. [Google Scholar] [CrossRef]

- Di Micco, S.; Romano, F.; Jannelli, E.; Perna, A.; Minutillo, M. Techno-economic analysis of a multi-energy system for the co-production of green hydrogen, renewable electricity and heat. Int. J. Hydrogen Energy 2023, 48, 31457–31467. [Google Scholar] [CrossRef]

- Shi, J.; Zhu, Y.; Feng, Y.; Yang, J.; Xia, C. A Prompt Decarbonization Pathway for Shipping: Green Hydrogen, Ammonia, and Methanol Production and Utilization in Marine Engines. Atmosphere 2023, 14, 584. [Google Scholar] [CrossRef]

- Wappler, M.; Unguder, D.; Lu, X.; Ohlmeyer, H.; Teschke, H.; Lueke, W. Building the green hydrogen market—Current state and outlook on green hydrogen demand and electrolyzer manufacturing. Int. J. Hydrogen Energy 2022, 47, 33551–33570. [Google Scholar] [CrossRef]

- Fragiacomo, P.; Genovese, M.; Piraino, F.; Massari, F.; Boroomandnia, M. Analysis of a distributed green hydrogen infrastructure designed to support the sustainable mobility of a heavy-duty fleet. Int. J. Hydrogen Energy 2023, 51, 576–594. [Google Scholar] [CrossRef]

- Benalcazar, P.; Komorowska, A. Prospects of green hydrogen in Poland: A techno-economic analysis using a Monte Carlo approach. Int. J. Hydrogen Energy 2022, 47, 5779–5796. [Google Scholar] [CrossRef]

- Lee, Y.; Jung, J.; Song, H. Public acceptance of hydrogen buses through policy instrument: Local government perceptions in Changwon city. Int. J. Hydrogen Energy 2023, 48, 13377–13389. [Google Scholar] [CrossRef]

- Jurkovic, M.; Kalina, T.; Skrúcaný, T.; Gorzelanczyk, P.; L’upták, V. Environmental Impacts of Introducing LNG as Alternative Fuel for Urban Buses—Case Study in Slovakia. Promet-Traffic Transp. 2020, 32, 837–847. [Google Scholar] [CrossRef]

- Gechev, T.; Punov, P.; Barta, D. Model Investigation of the Performance of SI ICE Fueled by Gasoline, Methane, Hydrogen and SOFC Anode Off-Gas. In Proceedings of the 15th Electrical Engineering Faculty Conference, BulEF 2023, Varna, Bulgaria, 16–19 September 2023. [Google Scholar] [CrossRef]

- Grzybek, G.; Wasiłek, O.; Rudzińska, M.; Stelmachowski, P.; Legutko, P.; Greluk, M.; Kotarba, A. Developing alumina-based cobalt catalyst for efficient hydrogen production via the ethanol steam reforming process. Catal. Today 2024, 439, 114808. [Google Scholar] [CrossRef]

- Haoran, C.; Xia, Y.; Wei, W.; Yongzhi, Z.; Bo, Z.; Leiqi, Z. Safety and efficiency problems of hydrogen production from alkaline water electrolyzers driven by renewable energy sources. Int. J. Hydrogen Energy 2023, 54, 700–712. [Google Scholar] [CrossRef]

- Hassan, Q.; Algburi, S.; Sameen, A.Z.; Salman, H.M.; Jaszczur, M. Green hydrogen: A pathway to a sustainable energy future. Int. J. Hydrogen Energy 2024, 50, 310–333. [Google Scholar] [CrossRef]

- Iqbal, S.; Aftab, K.; Jannat, F.; Baig, M.A.; Kalsoom, U. A bibliographic analysis of optimization of hydrogen production via electrochemical method using machine learning. Fuel 2024, 372, 132126. [Google Scholar] [CrossRef]

- Jałowiec, T.; Grala, D.; Maśloch, P.; Wojtaszek, H.; Maśloch, G.; Wójcik-Czerniawska, A. Analysis of the Implementation of Functional Hydrogen Assumptions in Poland and Germany. Energies 2022, 15, 8383. [Google Scholar] [CrossRef]

- Ji, M.; Wang, J. Review and comparison of various hydrogen production methods based on costs and life cycle impact assessment indicators. Int. J. Hydrogen Energy 2021, 46, 38612–38635. [Google Scholar] [CrossRef]

- Makhsoos, A.; Kandidayeni, M.; Pollet, B.G.; Boulon, L. A perspective on increasing the efficiency of proton exchange membrane water electrolyzers—A review. Int. J. Hydrogen Energy 2023, 48, 15341–15370. [Google Scholar] [CrossRef]

- León, M.; Silva, J.; Ortíz-Soto, R.; Carrasco, S. A Techno-Economic Study for Off-Grid Green Hydrogen Production Plants: The Case of Chile. Energies 2023, 16, 5327. [Google Scholar] [CrossRef]

- Lin, Y.; Yang, H.; Ma, L.; Li, Z.; Ni, W. Low-Carbon Development for the Iron and Steel Industry in China and the World: Status Quo, Future Vision, and Key Actions. Sustainability 2021, 13, 12548. [Google Scholar] [CrossRef]

- Nouni, M.R.; Manna, J. Green Hydrogen: An Introduction. In Challenges and Opportunities in Green Hydrogen Production; Springer Nature: Singapore, 2024; pp. 9–38. [Google Scholar]

- Perna, A.; Jannelli, E.; Di Micco, S.; Romano, F.; Minutillo, M. Designing, sizing and economic feasibility of a green hydrogen supply chain for maritime transportation. Energy Convers. Manag. 2023, 278, 116702. [Google Scholar] [CrossRef]

- Rasul, G.; Hazrat, M.A.; Sattar, M.A.; Jahirul, M.I.; Shearer, M.J. The future of hydrogen: Challenges on production, storage and applications. Energy Convers. Manag. 2022, 272, 116326. [Google Scholar] [CrossRef]

- Ruan, X.; Meng, D.; Huang, C.; Xu, M.; Jiao, D.; Cheng, H.; Yu, J. Artificial photosynthetic system with spatial dual reduction site enabling enhanced solar hydrogen production. Adv. Mater. 2024, 36, 2309199. [Google Scholar] [CrossRef]

- Šalipur, H.; Manojlović, D.; Milošević, K.; Fronczak, M.; Silva, A.G.; Lončarević, D.; Dostanić, J. Unraveling the solar and visible light-induced deactivation mechanism of Pt-decorated carbon/TiO2 nanocomposite in photocatalytic hydrogen production. J. Environ. Chem. Eng. 2024, 12, 112862. [Google Scholar] [CrossRef]

- Singla, M.K.; Gupta, J.; Beryozkina, S.; Safaraliev, M.; Singh, M. The colorful economics of hydrogen: Assessing the costs and viability of different hydrogen production methods—A review. Int. J. Hydrogen Energy 2024, 61, 664–677. [Google Scholar] [CrossRef]

- Sun, Z.; Chen, X.; Kuo, P.-C.; Ding, L.; Aziz, M. Co-feeding biomass and municipal solid waste for enhanced hydrogen and synthetic natural gas yields employing chemical looping process. Chem. Eng. J. 2024, 493, 152487. [Google Scholar] [CrossRef]

- Wu, Q.; Huang, F.; Zhao, M.; Xu, J.; Zhou, J.; Wang, Y. Ultra-small yellow defective TiO2 nanoparticles for co-catalyst free photocatalytic hydrogen production. Nano Energy 2016, 24, 63–71. [Google Scholar] [CrossRef]

- Kandpal, V.; Jaswal, A.; Santibanez Gonzalez, E.D.; Agarwal, N. Sustainable Energy Transition, Circular Economy, and ESG Practices. In Sustainable Energy Transition: Circular Economy and Sustainable Financing for Environmental, Social and Governance (ESG) Practices; Springer Nature: Cham, Switzerland, 2024; pp. 1–51. [Google Scholar]

- Griffiths, S.; Sovacool, B.K.; Kim, J.; Bazilian, M.; Uratani, J.M. Industrial decarbonization via hydrogen: A critical and systematic review of developments, socio-technical systems and policy options. Energy Res. Soc. Sci. 2021, 80, 102208. [Google Scholar] [CrossRef]

- Marouani, I.; Guesmi, T.; Alshammari, B.M.; Alqunun, K.; Alzamil, A.; Alturki, M.; Hadj Abdallah, H. Integration of Renewable-Energy-Based Green Hydrogen into the Energy Future. Processes 2023, 11, 2685. [Google Scholar] [CrossRef]

- Gale, F.; Goodwin, D.; Lovell, H.; Murphy-Gregory, H.; Beasy, K.; Schoen, M. Renewable hydrogen standards, certifications, and labels: A state-of-the-art review from a sustainability systems governance perspective. Int. J. Hydrogen Energy 2024, 59, 654–667. [Google Scholar] [CrossRef]

- Genovese, M.; Cigolotti, V.; Jannelli, E.; Fragiacomo, P. Current standards and configurations for the permitting and operation of hydrogen refueling stations. Int. J. Hydrogen Energy 2023, 48, 19357–19371. [Google Scholar] [CrossRef]

- Mendrela, P.; Stanek, W.; Simla, T. Sustainability assessment of hydrogen production based on nuclear energy. Int. J. Hydrogen Energy 2024, 49, 729–744. [Google Scholar] [CrossRef]

- Muñoz Díaz, M.T.; Chávez Oróstica, H.; Guajardo, J. Economic Analysis: Green Hydrogen Production Systems. Processes 2023, 11, 1390. [Google Scholar] [CrossRef]

- Ma, N.; Zhao, W.; Wang, W.; Li, X.; Zhou, H. Large scale of green hydrogen storage: Opportunities and challenges. Int. J. Hydrogen Energy 2023, 50, 379–396. [Google Scholar] [CrossRef]

- Kulik, A.C.; Tonolo, É.A.; Scortegagna, A.K.; da Silva, J.E.; Urbanetz Junior, J. Analysis of Scenarios for the Insertion of Electric Vehicles in Conjunction with a Solar Carport in the City of Curitiba, Paraná—Brazil. Energies 2021, 14, 5027. [Google Scholar] [CrossRef]

- Ghotge, R.; Nijssen, K.P.; Annema, J.A.; Lukszo, Z. Use before You Choose: What Do EV Drivers Think about V2G after Experiencing It? Energies 2022, 15, 4907. [Google Scholar] [CrossRef]

- Vandewetering, N.; Hayibo, K.S.; Pearce, J.M. Open-Source Photovoltaic—Electrical Vehicle Carport Designs. Technologies 2022, 10, 114. [Google Scholar] [CrossRef]

- Ranganathan, E.; Natarajan, R. Spotted Hyena Optimization Method for Harvesting Maximum PV Power under Uniform and Partial-Shade Conditions. Energies 2022, 15, 2850. [Google Scholar] [CrossRef]

- Sokolovskij, E.; Małek, A.; Caban, J.; Dudziak, A.; Matijošius, J.; Marciniak, A. Selection of a Photovoltaic Carport Power for an Electric Vehicle. Energies 2023, 16, 3126. [Google Scholar] [CrossRef]

- Tashie-Lewis, B.C.; Nnabuife, S.G. Hydrogen Production, Distribution, Storage and Power Conversion in a Hydrogen Economy—A Technology Review. Chem. Eng. J. Adv. 2021, 8, 100172. [Google Scholar] [CrossRef]

- Reddy, V.J.; Hariram, N.P.; Maity, R.; Ghazali, M.F.; Kumarasamy, S. Sustainable E-Fuels: Green Hydrogen, Methanol and Ammonia for Carbon-Neutral Transportation. World Electr. Veh. J. 2023, 14, 349. [Google Scholar] [CrossRef]

- Sarker, A.K.; Azad, A.K.; Rasul, M.G.; Doppalapudi, A.T. Prospect of Green Hydrogen Generation from Hybrid Renewable Energy Sources: A Review. Energies 2023, 16, 1556. [Google Scholar] [CrossRef]

- Centi, G.; Perathoner, S. Rethinking chemical production with “green” hydrogen. Pure Appl. Chem. 2024, 96, 471–477. [Google Scholar] [CrossRef]

- Keelin, T.W.; Chrisman, L.; Savage, S.L. The metalog distributions and extremely accurate sums of lognormals in closed form. In Proceedings of the 2019 Winter Simulation Conference (WSC), National Harbor, MD, USA, 8–12 December 2019; pp. 3074–3085. [Google Scholar] [CrossRef]

- Keelin, T.W. The Metalog Distributions. Decis. Anal. 2016, 13, 243–277. [Google Scholar] [CrossRef]

- Available online: https://blogs.sas.com/content/iml/2023/02/22/metalog-distribution.html (accessed on 11 August 2024).

- Available online: https://download.bayesfusion.com/files.html?category=Academia (accessed on 11 August 2024).

- Patiño, J.J.; Velásquez, C.; Ramirez, E.; Betancur, R.; Montoya, J.F.; Chica, E.; Romero-Gómez, P.; Kannan, A.M.; Ramírez, D.; Eusse, P.; et al. Renewable Energy Sources for Green Hydrogen Generation in Colombia and Applicable Case of Studies. Energies 2023, 16, 7809. [Google Scholar] [CrossRef]

- Hassan, Q.; Abdulrahman, I.S.; Salman, H.M.; Olapade, O.T.; Jaszczur, M. Techno-Economic Assessment of Green Hydrogen Production by an Off-Grid Photovoltaic Energy System. Energies 2023, 16, 744. [Google Scholar] [CrossRef]

- Małek, A.; Karowiec, R.; Jóżwik, K. A review of technologies in the area of production, storage and use of hydrogen in the automotive industry. Arch. Automot. Eng.—Arch. Motoryz. 2023, 102, 41–67. [Google Scholar] [CrossRef]

- Cosgun, A.E.; Demir, H. Investigating the Effect of Albedo in Simulation-Based Floating Photovoltaic System: 1 MW Bifacial Floating Photovoltaic System Design. Energies 2024, 17, 959. [Google Scholar] [CrossRef]

- Shah, H.H.; Bareschino, P.; Mancusi, E.; Pepe, F. Environmental Life Cycle Analysis and Energy Payback Period Evaluation of Solar PV Systems: The Case of Pakistan. Energies 2023, 16, 6400. [Google Scholar] [CrossRef]

- Idzikowski, A.; Cierlicki, T.; Al-Zubiedy, A.; Zawada, M. Management the Operation Process of Photovoltaic Modules in Terms of Quality and Performance Evaluation—A Case Study. Energies 2022, 15, 1652. [Google Scholar] [CrossRef]

- Qureshi, M.A.; Torelli, F.; Musumeci, S.; Reatti, A.; Mazza, A.; Chicco, G. A Novel Adaptive Control Approach for Maximum Power-Point Tracking in Photovoltaic Systems. Energies 2023, 16, 2782. [Google Scholar] [CrossRef]

- Livera, A.; Tziolis, G.; Franquelo, J.G.; Bernal, R.G.; Georghiou, G.E. Cloud-Based Platform for Photovoltaic Assets Diagnosis and Maintenance. Energies 2022, 15, 7760. [Google Scholar] [CrossRef]

- Dall’Armi, C.; Pivetta, D.; Taccani, R. Hybrid PEM Fuel Cell Power Plants Fuelled by Hydrogen for Improving Sustainability in Shipping: State of the Art and Review on Active Projects. Energies 2023, 16, 2022. [Google Scholar] [CrossRef]

- Folgado, F.J.; Orellana, D.; González, I.; Calderón, A.J. Processes Supervision System for Green Hydrogen Production: Experimental Characterization and Data Acquisition of PEM Electrolyzer. Eng. Proc. 2022, 19, 36. [Google Scholar] [CrossRef]

- Cao, X.; Wang, J.; Zhao, P.; Xia, H.; Li, Y.; Sun, L.; He, W. Hydrogen Production System Using Alkaline Water Electrolysis Adapting to Fast Fluctuating Photovoltaic Power. Energies 2023, 16, 3308. [Google Scholar] [CrossRef]

- Faqeeh, A.H.; Symes, M.D. A standard electrolyzer test cell design for evaluating catalysts and cell components for anion exchange membrane water electrolysis. Electrochim. Acta 2023, 444, 142030. [Google Scholar] [CrossRef]

- Ghazian, N.; Lortie, C.J. A Review of the Roots of Ecological Engineering and its Principles. J. Ecol. Eng. 2024, 25, 345–357. [Google Scholar] [CrossRef]

- Available online: https://handbook.enapter.com/electrolyser/el41/ (accessed on 13 August 2024).

- Yang, R.; Mohamed, A.; Kim, K. Optimal design and flow-field pattern selection of proton exchange membrane electrolyzers using artificial intelligence. Energy 2023, 264, 126135. [Google Scholar] [CrossRef]

- Vidales, A.G.; Millan, N.C.; Bock, C. Modeling of anion exchange membrane water electrolyzers: The influence of operating parameters. Chem. Eng. Res. Des. 2023, 194, 636–648. [Google Scholar] [CrossRef]

- Xu, Y.; Cai, S.; Chi, B.; Tu, Z. Technological limitations and recent developments in a solid oxide electrolyzer cell: A review. Int. J. Hydrogen Energy 2023, 50, 548–591. [Google Scholar] [CrossRef]

- Martinez Lopez, V.A.; Ziar, H.; Haverkort, J.W.; Zeman, M.; Isabella, O. Dynamic operation of water electrolyzers: A review for applications in photovoltaic systems integration. Renew. Sustain. Energy Rev. 2023, 182, 113407. [Google Scholar] [CrossRef]

- Available online: https://www.enapter.com/faqs/ (accessed on 13 June 2024).

- Illa Font, C.H.; Siqueira, H.V.; Machado Neto, J.E.; Santos, J.L.F.d.; Stevan, S.L., Jr.; Converti, A.; Corrêa, F.C. Second Life of Lithium-Ion Batteries of Electric Vehicles: A Short Review and Perspectives. Energies 2023, 16, 953. [Google Scholar] [CrossRef]

- Nováková, K.; Pražanová, A.; Stroe, D.-I.; Knap, V. Second-Life of Lithium-Ion Batteries from Electric Vehicles: Concept, Aging, Testing, and Applications. Energies 2023, 16, 2345. [Google Scholar] [CrossRef]

- Li, N.; Lukszo, Z.; Schmitz, J. An approach for sizing a PV–battery–electrolyzer–fuel cell energy system: A case study at a field lab. Renew. Sustain. Energy Rev. 2023, 181, 113308. [Google Scholar] [CrossRef]

- Sarker, M.T.; Haram, M.H.S.M.; Shern, S.J.; Ramasamy, G.; Al Farid, F. Second-Life Electric Vehicle Batteries for Home Photovoltaic Systems: Transforming Energy Storage and Sustainability. Energies 2024, 17, 2345. [Google Scholar] [CrossRef]

- Vinci, G.; Arangia, V.C.; Ruggieri, R.; Savastano, M.; Ruggeri, M. Reuse of Lithium Iron Phosphate (LiFePO4) Batteries from a Life Cycle Assessment Perspective: The Second-Life Case Study. Energies 2024, 17, 2544. [Google Scholar] [CrossRef]

- Guenther, L.H.; Klein, V.; Loef, G.; Pohl, A.; Okube, H.; Winterbur, R.; Röwer, G.; Wegener, B.; Goertz, R.; Bracke, S. Second Life for Lithium-Ion Traction Batteries. Sustainability 2024, 16, 7288. [Google Scholar] [CrossRef]

- Apachitei, G.; Heymer, R.; Lain, M.; Dogaru, D.; Hidalgo, M.; Marco, J.; Copley, M. Scale-Up of Lithium Iron Phosphate Cathodes with High Active Materials Contents for Lithium Ion Cells. Batteries 2023, 9, 518. [Google Scholar] [CrossRef]

- Vasconcelos, D.d.S.; Tenório, J.A.S.; Botelho Junior, A.B.; Espinosa, D.C.R. Circular Recycling Strategies for LFP Batteries: A Review Focusing on Hydrometallurgy Sustainable Processing. Metals 2023, 13, 543. [Google Scholar] [CrossRef]

- Neunzling, J.; Winter, H.; Henriques, D.; Fleckenstein, M.; Markus, T. Online State-of-Health Estimation for NMC Lithium-Ion Batteries Using an Observer Structure. Batteries 2023, 9, 494. [Google Scholar] [CrossRef]

- Accardo, A.; Dotelli, G.; Musa, M.L.; Spessa, E. Life Cycle Assessment of an NMC Battery for Application to Electric Light-Duty Commercial Vehicles and Comparison with a Sodium-Nickel-Chloride Battery. Appl. Sci. 2021, 11, 1160. [Google Scholar] [CrossRef]

- Yang, J.; Beatty, M.; Strickland, D.; Abedi-Varnosfaderani, M.; Warren, J. Second-Life Battery Capacity Estimation and Method Comparison. Energies 2023, 16, 3244. [Google Scholar] [CrossRef]

- Available online: https://monitoringpublic.solaredge.com/solaredge-web/p/site/public?name=Robert%20D.&locale=pl_PL#/dashboard (accessed on 23 August 2024).

- Available online: https://monitoringpublic.solaredge.com/solaredge-web/p/site/public?name=GioDomOvestSudEst&locale=pl_PL#/dashboard (accessed on 23 August 2024).

- Nestler, S.; Keelin, T. Introducing the Metalog Distributions. Significance 2022, 19, 31–33. [Google Scholar] [CrossRef]

- Małek, A.; Taccani, R.; Kasperek, D.; Hunicz, J. Optimization of Energy Management in a City Bus Powered by the Hydrogen Fuel Cells. Commun.—Sci. Lett. Univ. Zilina 2021, 23, E56–E67. [Google Scholar] [CrossRef]

| Energy Production [kWh] | |

|---|---|

| Count | 12 |

| Minimum | 57.044 |

| Maximum | 945.084 |

| Mean | 529.221 |

| StdDev | 350.765 |

| Probability | Energy Production [kWh] |

|---|---|

| 0.05 | 57.04399871826 |

| 0.25 | 212.4069976807 |

| 0.5 | 634.7689819336 |

| 0.75 | 871.0469970703 |

| 0.95 | 945.083984375 |

| Energy Production [kWh] | Probability ≤ | Probability > |

|---|---|---|

| 200 | 0.25 | 0.75 |

| 400 | 0.4167 | 0.5833 |

| 600 | 0.5 | 0.5 |

| 800 | 0.6667 | 0.3333 |

| Energy Production [kWh] | |

|---|---|

| Count | 12 |

| Minimum | 251.033 |

| Maximum | 1132.73 |

| Mean | 711.584 |

| StdDev | 324.064 |

| Probability | Energy Production [kWh] |

|---|---|

| 0.05 | 251.0330047607 |

| 0.25 | 485.2600097656 |

| 0.5 | 780.6019897461 |

| 0.75 | 1028.311035156 |

| 0.95 | 1132.729003906 |

| Energy Production [kWh] | Probability ≤ | Probability > |

|---|---|---|

| 400 | 0.25 | 0.75 |

| 600 | 0.4167 | 0.5833 |

| 800 | 0.5833 | 0.4167 |

| 1000 | 0.75 | 0.25 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Małek, A.; Dudziak, A.; Caban, J.; Matijošius, J. Probabilistic Analysis of Low-Emission Hydrogen Production from a Photovoltaic Carport. Appl. Sci. 2024, 14, 9531. https://doi.org/10.3390/app14209531

Małek A, Dudziak A, Caban J, Matijošius J. Probabilistic Analysis of Low-Emission Hydrogen Production from a Photovoltaic Carport. Applied Sciences. 2024; 14(20):9531. https://doi.org/10.3390/app14209531

Chicago/Turabian StyleMałek, Arkadiusz, Agnieszka Dudziak, Jacek Caban, and Jonas Matijošius. 2024. "Probabilistic Analysis of Low-Emission Hydrogen Production from a Photovoltaic Carport" Applied Sciences 14, no. 20: 9531. https://doi.org/10.3390/app14209531

APA StyleMałek, A., Dudziak, A., Caban, J., & Matijošius, J. (2024). Probabilistic Analysis of Low-Emission Hydrogen Production from a Photovoltaic Carport. Applied Sciences, 14(20), 9531. https://doi.org/10.3390/app14209531