Abstract

The accidental spillage of flammable liquids on in-service ships and offshore installations may lead to pool fires, which are likely to spread over a particularly large area in large compartments under ship motion, resulting in extensive damage. However, the effect of the spreading extent of liquid fuel due to inclined ship motion on pool fire consequences has not been considered in the existing literature. Thus, in this study, fuel discharge experiments were conducted to investigate the spreading behaviour under different substrate inclination angles and discharge rates. The experimental results were analysed to derive closed-form expressions to predict the spreading extent of liquid fuel in large compartments. Additionally, the effects of surface inclination on fire consequences were investigated using the Fire Dynamics Simulator in terms of the heat release rate. The findings can provide guidance for effective fire safety design and establishing a realistic fire modelling methodology for ships and offshore installations.

1. Introduction

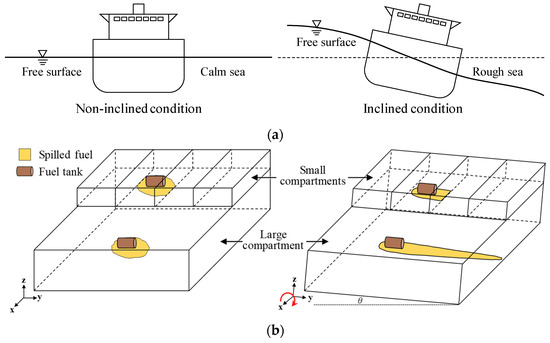

Despite advancements in technology, pool fire accidents still occur and cause substantial personnel harm and asset damage [1]. Operational ships and offshore installations are particularly prone to fuel spillage owing to several factors, such as equipment ageing and human error. As ships and offshore installations have numerous ignition sources, including hot surfaces and electric devices, there is the potential for pool fires to occur. Spillages that occur on ships and offshore installations under motion may form larger pools than in onshore events. As the heat release rate (HRR) of pool fires depends on the fire surface area, the fire consequences are expected to increase with the spreading extent of the spilled pool. Moreover, structural members that are not subjected to thermal loads under uninclined conditions may be affected under inclined conditions owing to the increased pool dimensions. In large compartments, which can be found in roll-on/roll-off (ro-ro) ships and aircraft carriers, fuel spillage accidents are more likely to result in increased pool spreading, as shown in Figure 1. Small compartments limit the spreading extent of spilled fuel, and for extreme cases, it can be assumed that the pool covers the whole compartment. However, this assumption would be inaccurate for large compartments, as the pool is unlikely to cover the whole compartment.

Figure 1.

Flammable liquid spread in ship compartments: (a) inclination due to ship motion; (b) pool spread in compartments without and with inclination.

The current Safety of Life at Sea (SOLAS) rules concerning the fire safety of ro-ro spaces address a wide range of functional requirements on subjects such as fire protection systems, ignition sources, and ventilation. However, the effects of deck inclination on pool fires and the related safety measures are not addressed [2]. As the basic design of firefighting systems in large compartments is based on the existing SOLAS rules for ro-ro ships, current measures may not be applicable to pool fires under inclined conditions. Therefore, the effects of substrate inclination on fire consequences need to be understood to enable correct assumptions for the fire design of ships and offshore installations.

Methods for determining fire loads on ships and offshore structures have been actively investigated [3,4,5,6,7], along with the responses of structures exposed to fire loads [8,9,10] and efficient fire suppression system design principles [11]. Additionally, although large spaces have been studied [12,13,14], previous studies did not consider pool spread characteristics under ship motion. As the fuel spread behaviour may be strongly affected by ship motion, and pool fire characteristics depend considerably on the pool shape and size [15,16,17], the fire consequences under ship motion cannot be accurately determined using the existing methods.

In contrast, the characteristics of onshore spillages have been extensively investigated. The spilled pool area on substrates without inclination can be predicted using the kinematic viscosity and fuel spill rate [18,19]. Simmons et al. [20] investigated fuel spillages on inclined pavements. However, these authors did not establish formulae for predicting the spill shape and focused only on instantaneous spillages. Ingason and Li [21] experimentally investigated spillages inside tunnels and found that the pool breadth was dependent only on the spill rate, and the inclination angle of the substrate could be assumed to have no effect. Their findings were subsequently verified [22]. However, the suggested formulae are not applicable to large compartments, as the studies focused on spaces with limited road width. Abbasi et al. [23] investigated the spilled pool area and velocity characteristics of flammable fuel spilled on inclined porous substrates. Additionally, the spread and evaporation behaviour of liquefied natural gas (LNG) have been explored [24,25]. Raja et al. [26] comprehensively reviewed relevant methods for predicting fuel spillage behaviour. Moreover, the pool fire characteristics on inclined surfaces have been experimentally investigated [27,28]. Table 1 summarises the above studies relevant to the present study on spillage characteristics. The studies mentioned above have limited applicability to in-service ships and offshore installations, as they did not consider the spreading behaviour of spilled fuel on inclined, impermeable substrates.

Table 1.

Summary of studies on spill characteristics.

Consequently, this study sought to experimentally characterise fuel spillages on ships or offshore installations in motion, which has not been considered in prior work, and a novel method for fire consequence analysis considering ship motion was proposed. Fuel spread extent was experimentally examined for 21 scenarios corresponding to different inclination angles and discharge rates. Empirical formulae for spill shape estimation were formulated based on the results. Furthermore, the effect of substrate inclination on pool fire consequences was numerically investigated using the large-eddy simulation code Fire Dynamics Simulator (FDS).

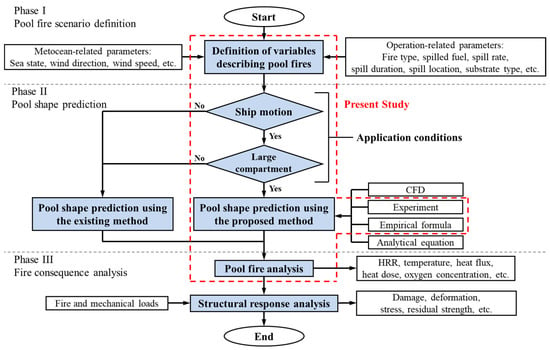

2. Research Procedure for Fire Consequence Analysis Considering the Spreading Extent of Spilled Flammable Liquid in Inclined Conditions

The procedure for analysing the effects of spilled liquid fuel on structures in large compartments under motion is illustrated in Figure 2. This procedure can be divided into four phases. In Phase I, the pool fire scenario is defined by determining the condition under which the spillage occurs. In Phase II, the pool shape, which represents the outline of the spilled flammable liquid spreading extent, is predicted based on the conditions defined in the previous phase. For scenarios where the ship or offshore installation is subjected to motion and the spillage occurs in a large compartment that extends to a substantial length of a ship or offshore installation (e.g., ro-ro space, hanger deck, etc.), the proposed method which considers substrate inclination is used. Otherwise, existing methods which do not consider the inclination of large compartments can be used. In Phase III, fire consequence analysis is conducted through pool fire analyses and structural response analyses.

Figure 2.

Research procedure for fire consequence analysis considering the spreading extent of spilled flammable liquid in inclined conditions.

The pool fire analyses are conducted based on the defined scenario and predicted pool shape determined in the previous phases. Consequences such as temperature and heat flux are obtained which define the loading conditions of the structural response analysis. Based on such conditions, structural responses such as stress and deformation can be attained. This procedure is expected to yield more accurate results than previously reported procedures. The current study focuses on developing empirical formulae for predicting the pool shape of spilled fuel on inclined substrates. Each phase of the procedure is detailed below.

2.1. Pool Fire Scenario Definition

The conditions under which fuel spillages occur are determined by defining metocean- and operation-related parameters. Metocean-related parameters include sea state, wind direction, and wind speed. Sea state affects the motion of ships and offshore installations and is a major consideration in the design phase. The wind condition significantly influences fire behaviour and thus needs to be defined. The metocean-related parameters can be determined utilising available data for the route through which or the site in which the target structure is operational. Alternatively, they can be measured at the location of interest.

Operation-related parameters include the fire type, spilled fuel type, spill rate, spillage duration, spillage location, and substrate type. Various fire types which occur on ships and offshore installations, such as pool fires and jet fires, pose different kinds of hazards, and thus clarifying the fire type to be analysed is essential. Spilled fuel, spill rate, spillage duration, and substrate type can be determined by considering the design purpose and apparatus of the target structure. Spillage location should be considered in structural response analyses under thermal loads, as the magnitude of the thermal load acting on the structure may differ substantially by location.

The motion of ships and offshore installations induces substrate angles that vary over time. However, in this study, the inclination angle of the substrate was assumed to be constant to consider the most critical spillage scenario and analyse the spillage in a conservative manner. This assumption enabled the consideration of the maximum spreading extent of spilled fuel, as variation in the substrate angle may prevent the fuel from spreading as widely as it would under a constant substrate inclination angle. Furthermore, as this study aimed to characterise fuel spillage on inclined, impermeable substrates, only pool fires and spillages occurring in a sufficiently large compartment that does not physically confine the spilled fuel were considered. Moreover, the wind conditions were assumed to be calm.

2.2. Pool Shape Prediction

In this phase, the pool shape is predicted considering the conditions defined in the previous phase. Spillages that occur on a structure under motion inside a large compartment have a high probability of causing a large-scale pool fire. Thus, the spreading extent should be determined using the proposed method. In these cases, the pool shape can be determined by means of four methods: computational fluid dynamics (CFD) simulations, experiments, empirical formula-based calculations, and analytical equation-based calculations. CFD software capable of providing detailed spread properties of the pool has the advantage of yielding fairly accurate results for numerous scenarios. However, this approach requires considerable computing resources and knowledge. Appropriately set-up experiments yield realistic data but may be limited by resources and time. Empirical formula-based estimations are time-saving and reasonably accurate.

This approach is suitable for diverse scenarios, and formulae developed using a large amount of data for various conditions are generally more accurate. Analytical equations, on the other hand, describe the spillage and spread phenomenon analytically based on the principles of physics. Existing methods may be suitable for predicting the pool shapes of spillage scenarios which do not satisfy the two application conditions. The pool dimensions are evaluated using models that assume that the substrates are not inclined or that the pool spreads over the entire compartment.

The defined pool fire scenario satisfies both application conditions. In the present study, the spill shape was predicted using experiments and empirical formulae. Flammable liquid was discharged on an impermeable surface, and the spill shape was experimentally characterised under different substrate inclination angles and fuel discharge rates. Empirical formulae were developed using the experimental results.

2.3. Pool Shape Prediction

To analyse the effects of pool fire on the structure of interest, parameters such as the HRR, heat flux, and temperature are required. These parameters can be obtained analytically by solving existing governing equations, CFD simulation, or experimental studies. These approaches have their strengths and weaknesses, as described above.

Given this study’s focus on a specific scenario, existing analytical methods are likely to yield inaccurate results. Additionally, given the numerous fire scenarios that should be considered, the experimental approach is not ideal owing to resource and time limitations. Therefore, the approach utilising CFD simulations was selected. The large-eddy simulation code Fire Dynamics Simulator (FDS) was used for the pool fire simulations. The parameters describing pool fires and the predicted pool shape were modelled.

2.4. Structural Response Analysis

The purpose of structural response analyses is to investigate the action effects of structures under fire loads, including changes in material characteristics, physical deformation, etc. By analysing the response to fire accidents, the effects on humans and the environment can be investigated in terms of amount of damage up to limit state and safety criteria of structures. Therefore, fire consequences, such as temperature and heat flux which are derived through fire analyses, are utilised to quantitatively assess the magnitude of the structural response under fire loads and establish design guidelines of fire-resistance of structures.

3. Prediction of the Pool Shape

3.1. Fuel Discharge Experiment Considering Inclination Effects

In our experiment, JP-5, a type of fuel used in the jet engines of aircraft on naval ships and as ship fuel, was discharged onto a nonporous surface at various substrate inclination angles and fuel discharge rates.

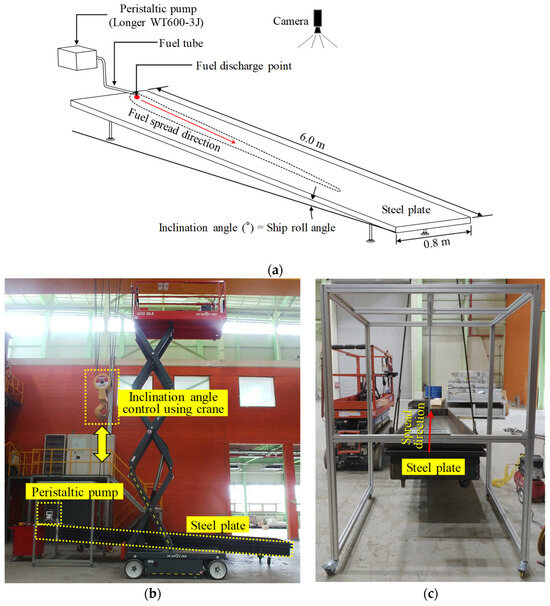

3.1.1. Experimental Setup

Figure 3 illustrates the experimental setup. The experiment was conducted indoors where the discharged fuel was not affected by wind conditions. A mild steel (SS400) plate with a length and breadth of 6.0 m and 0.8 m, respectively, was selected as the substrate. One end of the plate was attached to a 30-ton overhead crane, so that the inclination angle of the plate could be adjusted through the control of the crane height. A digital inclinometer was used to measure the inclination angle. The angle of the steel plate needed to be set carefully in both the length and breadth directions to keep the pool inside the boundaries of the plate. Because the substrate inclination angle was assumed to remain constant, the inclination angle of the plate was fixed in each experimental scenario. JP-5 was discharged using a peristaltic pump (WT600-3J), which controlled the discharge rate.

Figure 3.

Fuel discharge experiment setup: (a) schematic layout, (b) test layout, (c) steel plate (ship’s deck).

The material properties of JP-5 are summarised in Table 2 [20,29,30]. The contact angle represents the angle between the substrate and liquid surface of JP-5. The heat of combustion is the heat released when a unit quantity is oxidised completely, and the mass burning rate represents the mass loss rate caused by fuel combustion. kβ is an empirical constant. As the fuel spill rate considerably affects the spreading behaviour, several discharge rates were examined, and every experimental scenario was conducted twice to account for reproducibility of the experiment.

Table 2.

Material properties of JP-5.

The pump was calibrated prior to the experiment to discharge the fuel at the intended rates. The outlet of the pipe connected to the pump was positioned near one of the shorter edges of the plate. This configuration allowed the discharged fuel to flow parallel to the longer edge of the inclined substrate. The discharge duration was 30 s, and after each experiment the steel plate was cleaned using oil-absorbent wool and compressed air. To ensure that no fuel remained on the plate, a 10 min break was observed between experiments. The spill shape was recorded using a camera positioned atop the steel plate.

Table 3 summarises the experimental conditions. Temperature and humidity measurements are tabulated for each scenario. Twenty-one scenarios with different inclination angles (1–10°) and discharge rates (200–400 mL/min) were examined. The inclination angles were determined to emulate certain sea state conditions under which the target structure is subjected. Table 4 [31] provides roll angles for conventional surface ships with varying beams under different sea state conditions. In this study, the sea states up to sea state four were considered. The examined fuel discharge rates of 200–400 mL/min were determined based on the breadth of the steel plate, as for larger discharge rates, the pool tended to reach the long edges of the plate.

Table 3.

Summary of the experimental conditions.

Table 4.

Roll motion for conventional surface ships.

3.1.2. Experimental Results

To correctly assess the fire-affected area in large compartments under motion, defining the spreading extent of the spilled fuel is vital. The spreading extent can be quantitatively represented in terms of the distance, direction, and area of the spilled pool. The pool length and breadth determine the direction and distance in which the spilled pool spreads. The pool length was defined as the spreading distance of the pool along the inclination direction of the substrate, while the breadth is defined as the maximum distance perpendicular to the pool length. The area represents the surface area of the spilled pool, which affects the HRR of pool fires. The pool shape definitions above have been widely adopted in the literature [21,22].

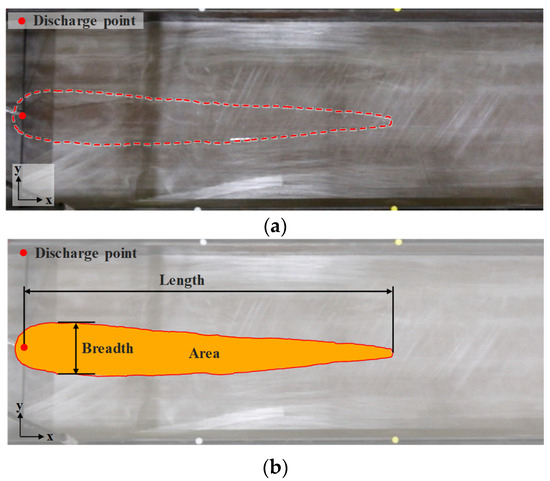

Figure 4a shows the pool shape with an inclination angle of 3° and discharge rate of 300 mL/min. The discharged fuel flowed from the left to the right of the figure due to the inclination of the steel plate. The pool dimensions are not easily discernible in the original form and thus were processed as shown in Figure 4b.

Figure 4.

Experimental result: (a) recorded pool shape, (b) processed pool shape.

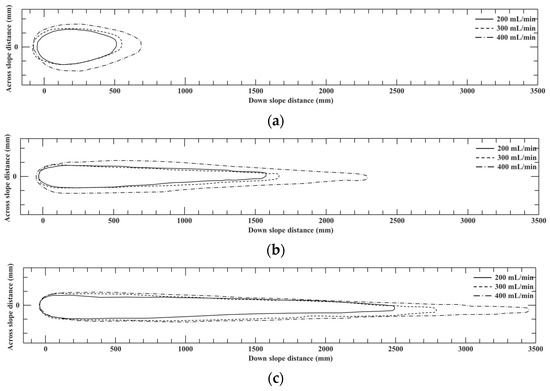

Figure 5 shows the outlines of the experimentally measured pools 30 s after the start of fuel discharge for each experiment. The pool spread from left to right, with the fuel discharge point as the origin. Figure 5a displays the outline of the spilled pool on a 1°-inclined substrate. Higher discharge rates resulted in a larger pool length, breadth, and area. The maximum pool length and breadth were 691.7 mm and 351.4 mm, respectively. Figure 5b shows the pool shapes on the 5°-inclined substrate. For each discharge rate, the pool lengths were longer and the breadths shorter than those of the 1° inclination case (see Figure 5a). Figure 5c shows the pool outlines for the 10°-inclined substrate. Similarly, higher discharge rates resulted in larger pools in terms of length, breadth, and area. Furthermore, longer pool lengths and shorter breadths were measured compared with the cases with lower inclination angles.

Figure 5.

Pool shapes of spilled fuel after 30 s with the inclination angles of (a) 1°, (b) 5°, and (c) 10°.

The parameters defining the spill shape were tracked with respect to dimensionless time, calculated as the ratio of the time at which the parameters were measured tm (i.e., the duration from the start of the discharge to the moment at which the parameter was measured) to the total discharge duration td, which was 30 s for all experiments. To obtain the pool shape variation trend over time, the parameters were measured at nine time points with equal intervals.

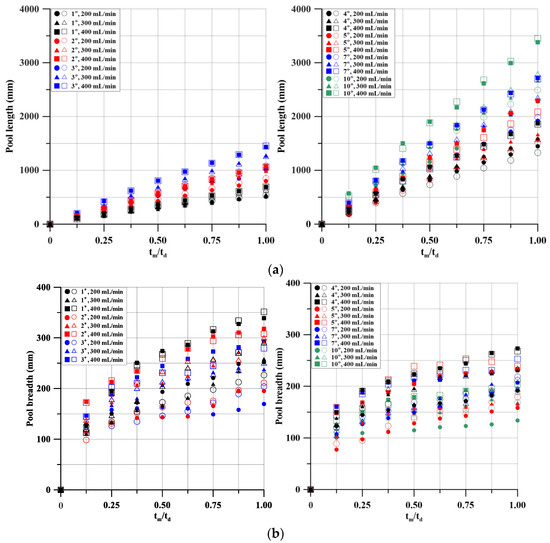

Figure 6a displays the pool length with respect to dimensionless time. In the left part of the figure, experimental measurements of the pool length for lower substrate inclination angles are shown, whereas the measurements for higher inclination angles is shown on the right side. The length was proportional to both the discharge rate and inclination angle, with the inclination angle exerting a stronger influence. Furthermore, the measured pool lengths increased almost linearly with respect to time for every experimental case. Figure 6b shows the breadth of the spilled pool as a function of dimensionless time. The breadth was proportional to the discharge rate while inversely proportional to the inclination angle.

Moreover, the breadth increases rapidly at the start of the experiments, with the rate of change decreasing over time. A clear relationship between the inclination angle, discharge rate, and the measured pool breadth, as seen in Figure 6a, was not found. Figure 6c presents the experimentally measured spilled pool area as a function of dimensionless time. The area increased almost linearly with time for each scenario. Moreover, the area was proportional to the inclination angle and discharge rate, with the discharge rate having a stronger effect.

Figure 6.

Experimentally measured pool dimensions: (a) length, (b) breadth, (c) area.

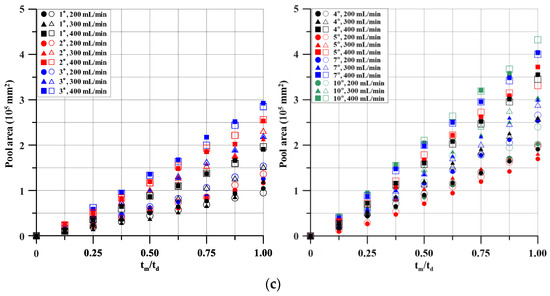

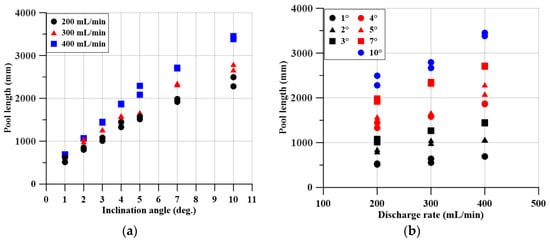

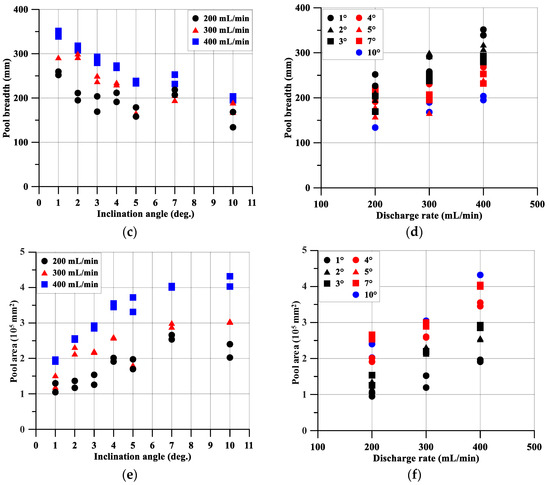

Figure 7 illustrates the effects of the inclination angle and discharge rate on the pool shape using the experimental measurements at . Figure 7a,b show the influence of the substrate inclination angle and discharge rate on the pool length, respectively. Near-linear relationships between the pool length and both the inclination angle and discharge rate was found. Furthermore, as already seen in Figure 6, the pool length was more affected by the inclination angle. Similarly, the pool breadth is plotted in Figure 7c,d. The breadth decreases with larger inclination angle and increases for higher discharge rates, except for the inclination angle of 7°. It is thought that the condition of the surface affected the measurements. Furthermore, the experimental results were inconsistent with the findings of Ingason and Li [21], in that in this study, the pool breadth was dependent on the discharge rate and the inclination angle. This inconsistency is due to the fundamental difference in the experimental setups. Ingason and Li [21] investigated the spilled pool shape in narrow tunnels, where the spilled fuel was spilled until it reached drainage gutters at the roadside. In contrast, the present study considered large compartments which do not physically confine the spilled pool, and the pool breadth was measured as it spread. The difference in the pool breadth definition caused disagreement between the results. Figure 7e,f show the relationship between the pool area, inclination angle, and discharge rate. The pool area increased in a predictable manner until the 4°-inclined cases, with the cases under larger inclination angles displaying a lower increment in area. Furthermore, higher discharge rates resulted in larger pool areas, and with a few exceptions higher inclination angles resulted in larger areas, regardless of the discharge rate.

Figure 7.

Experimentally measured pool dimensions (): (a) length with respect to inclination angle; (b) length with respect to discharge rate; (c) breadth with respect to inclination angle; (d) breadth with respect to discharge rate; (e) area with respect to inclination angle; (f) area with respect to discharge rate.

The experimental measurements of each case are summarised in Table 5, with only one of the repetitions displayed. The length, breadth, and area of the spilled pool are tabulated for the dimensionless times of 0.50 and 1.00. As emphasised above, higher discharge rates resulted in a larger pool length, breadth, and area. Moreover, the pool length and area were larger at greater inclination angles.

Table 5.

Experimentally measured pool dimensions.

The spreading behaviour of JP-5 was experimentally characterised through fuel discharge experiments on an inclined steel plate. The experimental parameters were determined considering the limitations of the testing laboratory capacity. The breadth of the steel plate limited the range of the fuel discharge rate that could be examined. However, even within this limited test condition, the pool length, breadth, and area exhibited clear trends under different discharge conditions. In future work, experiments must be conducted using additional substrate inclinations and fuel discharge rates to improve the applicability of the proposed formulae. Furthermore, the effects of the material properties of various flammable liquids, such as the liquid viscosity, density, and surface tension, as well as the friction of the metal plate, under various substrate conditions must be explored.

The pool length, breadth, and area can be predicted through the substitution of the inclination angle, spill rate, and duration of spillage accidents into the empirical formulae, rendering them valuable and reliable inputs for fire simulation. Therefore, the experimental results are expected to be useful in the early fire safety design stages.

3.2. Empirical Formulae Predicting the Spreading Extent of Spilled Pools on Inclined Surfaces

Empirical formulae for predicting the pool shape that forms upon the spillage of JP-5 on an inclined steel plate were developed based on the experimental results. The pool shape was predicted under different inclination angles, spill rates, and spillage duration. To derive the formulae for predicting these variables, the effect of each variable on the pool shape was evaluated. The correlation between the pool length, substrate inclination, and discharge rate is shown in Figure 7. This relationship was used to formulate the effects of the substrate inclination and discharge rate on the pool length for each time interval, which can be found in Figure 6. Three coefficients, , , and , were derived using the experimental results. and represent the coefficients of the inclination angle and spill rate terms, respectively. represents the effect of time without the influence of the inclination angle and spill rate. These coefficients were fitted with respect to the spillage duration.

The length (m), breadth (m), and area (m2) of the spilled pool can be empirically predicted using the inclination angle (°), spill rate (mL/min), and spillage duration (s):

where

where

where .

The HRR of a pool fire can be predicted using an equation which correlates the HRR with the pool dimensions, thermochemical constants, and empirical constants of liquid fuels [30]. The formula for pool area prediction is substituted into this equation to estimate the HRR on inclined surfaces with improved accuracy. The following equation is the proposed equation for HRR prediction for inclined conditions:

where , , , , , and represent the HRR, heat of combustion, mass burning rate per unit area, the product of the extinction absorption coefficient and the beam-length corrector , equivalent pool diameter, and surface area of the pool fire, respectively.

The range of the substrate inclination angle and discharge rate at which the formulae can be reliably used is limited by the experimental scenarios, as the formulae above were developed based on the experimental results.

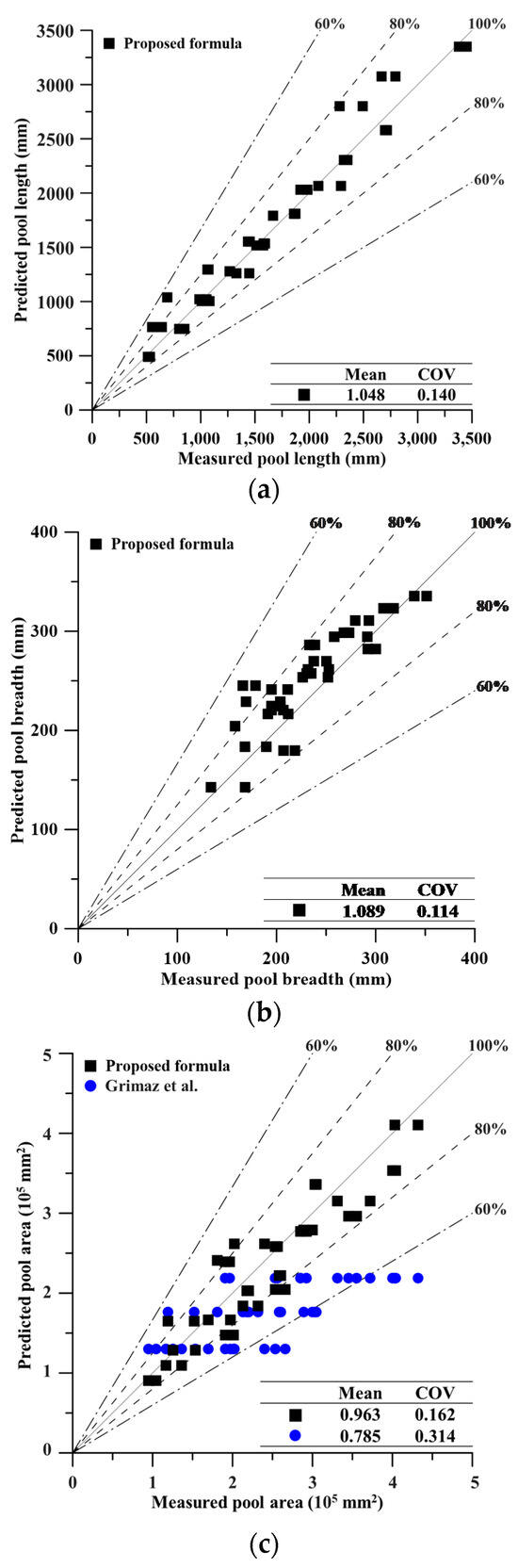

The pool lengths obtained using the proposed empirical formula were compared with the experimentally measured data in Figure 8a. The predicted and measured values at the final state () are shown. As no study listed in Table 1 predicted the pool length and breadth as defined in this study, no inter-study comparisons are provided. The pool length predicted using the proposed formula agreed well with the experimental values, and the maximum error was within 10% when excluding predictions with low area values. The mean and coefficient of variance (COV) were 1.048 and 0.140, respectively. This result was expected, as the proposed formulae were developed using the experimental results.

Figure 8b compares the predicted and experimentally measured pool breadths. The predicted values were obtained using the proposed formula. The accuracy of the proposed formula in predicting the breadth was relatively low compared with the results shown in Figure 8a, attributable to the nonlinearity of the pool breadth with time displayed in Figure 6b.

Figure 8c compares the experimentally measured pool area with those predicted by the proposed formula and a previously reported model [18]. The corresponding mean and COV indicate that the values predicted by the proposed formula agreed well with the measured data, regardless of the pool area magnitude. However, the predictions of the model proposed by Grimaz et al. [18] yielded relatively large errors. This was expected because the model was designed for spillages on substrates without inclination, which is evident, as the predicted values for different substrate inclinations were identical. Nevertheless, the predictions revealed a certain trend.

The assumption regarding the motion of ships and offshore installations influenced the applicability of the proposed formulae. Decks of actual ships or offshore installations are characterised by six-DOF motion (roll, pitch, and yaw for rotational axes and surge, sway, and heave for translational axes). However, the motion of decks was represented by a constant substrate angle. Although the pool shape of actual spillages may differ from the shape predicted by the proposed formulae, the assumption of a constant substrate angle yielded more conservative scenarios. Therefore, the proposed method is expected to be useful in the early design stages of relevant ships.

Figure 8.

Comparison of the experimental data and pool dimensions predicted by empirical formulae: (a) length, (b) breadth, (c) area, Grimaz et al. [18].

4. Fire Consequences of Pool Fires on Inclined Substrates

Differences in fire consequences of the pool fires on substrates with and without inclination were investigated in terms of HRR, heat flux, and temperature. Representative pool fires of the two substrate conditions were simulated using the large-eddy simulation code FDS [32]. The computational model was validated by comparing the model predictions with experimental measurements.

4.1. Computational Model Validation

The HRR of the pool fire and mesh resolution of the control volume, among other parameters, need to be defined adequately to ensure a certain degree of accuracy of the model. The HRR for the computational model can be calculated using the proposed formula for HRR prediction on inclined surfaces (Equation (4)). The material properties of JP-5 shown in Table 2 were used for the calculation.

The mesh resolution of the computational model was determined using the plume resolution index , where denotes the characteristic fire diameter and represents the nominal mesh size. The characteristic fire diameter is defined in Equation (5). The recommended plume resolution for liquid pool fires ranges from 4 to 16 [33].

where , , , , and represent the HRR, air density, air specific heat, ambient temperature, and gravitational acceleration, respectively. The severity and duration of the fire were controlled using the RAMP function.

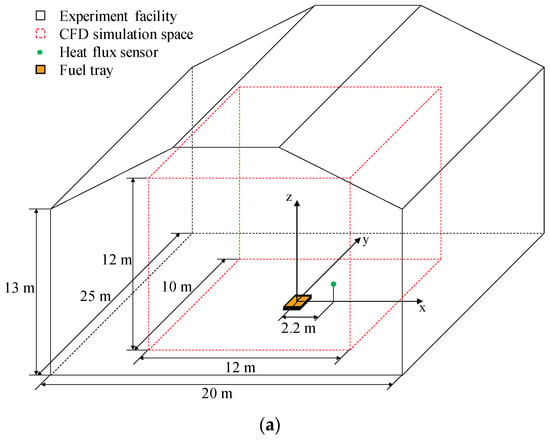

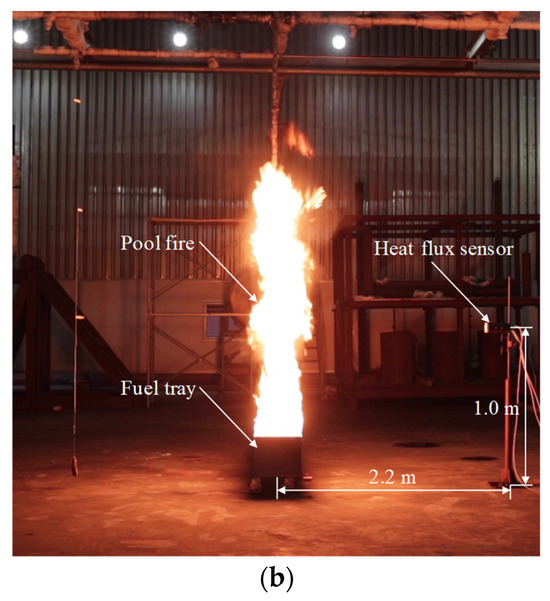

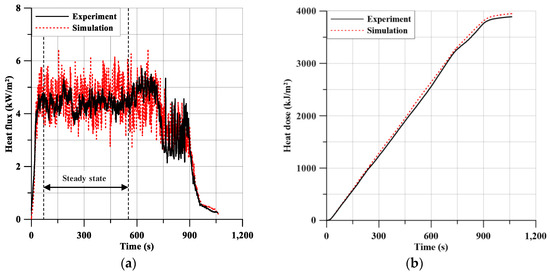

To confirm the validity of the computational model, heat flux and heat dose predictions based on this model were compared with experimental measurements. An indoor pool fire experiment was conducted in a 12 m × 10 m × 12 m room, where JP-5 was ignited in a square tray, with the surface area of 0.5 m2, located in the centre of the room. The heat flux was measured using heat flux transducers (Medtherm 64 series), which were positioned 2.2 m, 3.2 m, 4.2 m, and 5.2 m away from the centre of the pool in the x-direction. Figure 9 illustrates the setup of the pool fire experiment. The control volume of the computational model is indicated with a red dashed line.

Figure 9.

Pool fire experiment setup: (a) schematic layout, (b) actual layout.

Figure 10a shows the experimentally measured heat flux (located closest to the fire in Figure 9) and heat flux predicted by the fire simulation. The fire duration of the experiment was 1062 s, whereas it was 1064 s in the simulation. The overall trend of the experimental measurement was accurately simulated, with an error of 15.8% between the two measurements in the steady state (70–550 s). In Figure 10b, the heat dose, which is defined as the time integral of the heat flux, as shown in Equation (6), is shown. The heat dose at the end of the fire duration was 3890.7 kJ/m2 for the experiment and 3953.4 kJ/m2 for the simulation, which corresponds to an error of 1.5%. The comparison shows that the computational model can reasonably accurately simulate JP-5 pool fires.

where , , , and represent the heat dose, heat flux, thermal conductivity, and temperature, respectively.

Figure 10.

Comparison of the experimental data and simulation results: (a) heat flux, (b) heat dose.

4.2. Pool Fire Simulation Considering Substrate Inclination

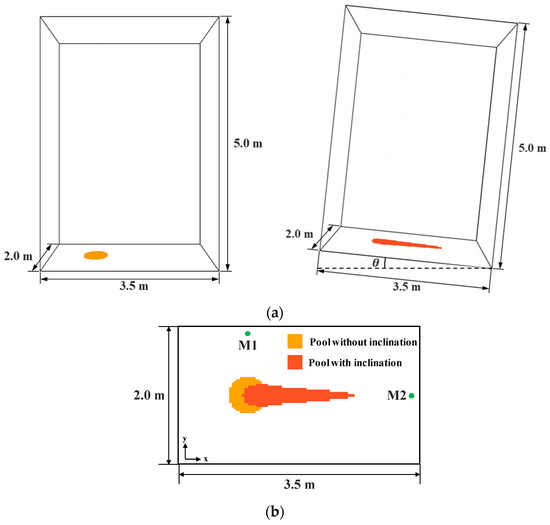

The pool shapes for the fire scenarios without and with inclination are tabulated in Table 6. The formula proposed by Grimaz et al. [18] was used to predict the pool radius of spilled fuel for the case without inclination, while the formulae proposed in this study were used for the inclined case. The conditions of the experimental case 3-3 in Table 3 (i.e., inclination angle and spill rate of 3° and 400 mL/min, respectively) were used for calculating the pool dimensions of the two scenarios. It was assumed that JP-5 was spilled on a steel surface and flowed in the positive x-direction with a uniform thickness across the surface area. As large compartments are known to have drain holes along the edges, the pool thickness was assumed to be uniform. Furthermore, the spillage was assumed to occur in a large compartment without any wind interference.

Table 6.

Predicted pool dimensions for pool fires without and with inclination.

Once the pool surface areas were estimated, the HRR and duration of the pool fires could be calculated. The HRR was calculated using Equation (4), as explained above. The material properties in Table 2 were substituted into the equation. The estimated HRR and fire duration values for the scenarios without and with inclination are presented in Table 7. The HRR estimated using the proposed empirical formula was 36.0% higher than the estimation obtained using the formula proposed by Grimaz et al. [18]. The increase in HRR for pool fires on an inclined substrate was due to the larger pool area, which also resulted in a shorter fire duration, as the same amount of fuel was spilled for all of the scenarios.

Table 7.

Comparison of the estimated HRR and fire duration.

The mesh resolution for the computational model was determined using Equation (5). According to Rengel et al. [34], the recommended mesh sizes for the fire scenarios without and with substrate inclination are 0.036–0.143 m and 0.041–0.165 m, respectively. In this study, a mesh size of 0.03 m was used for both scenarios, which corresponds to the plume resolution indices of 19.1 and 22.0 for the scenarios without and with substrate inclination, respectively. The number of meshes was approximately 1,300,000.

Figure 11 shows the model used in the pool fire analyses. The dimensions of the computational domain were determined such that the fire was not affected by the exterior boundaries, which were set to behave as passive openings to the outside. Moreover, no objects other than the floor were modelled. These settings ensured that only the effects of substrate inclination were observed. Figure 11b shows the pool and locations of the measuring devices. Because all objects inside the computational domain were forced to conform with the mesh in a rectilinear manner, the pool was modelled as shown in the figure.

Figure 11.

Numerical model for pool fire analysis: (a) computational domain, (b) pool and locations of measuring devices.

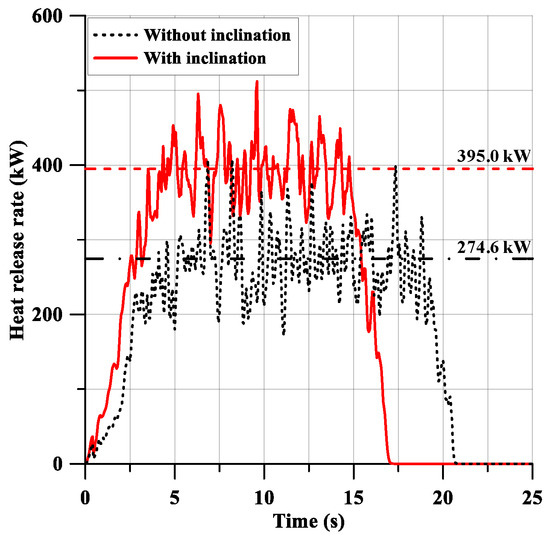

The fire analysis results are presented in Figure 12, Figure 13 and Figure 14. The HRR of each pool fire with respect to time is shown in Figure 12. While the HRR for the pool fire with inclination was approximately 36% higher than that of the fire without inclination, it decreased more rapidly. The estimated HRR for each pool fire, shown in Table 7, is also marked in the figure. Excluding the stages where the HRR rises or falls, the HRR estimation was reasonably well reproduced by the simulations.

Figure 12.

Heat release rates for the pool fires without and with inclination.

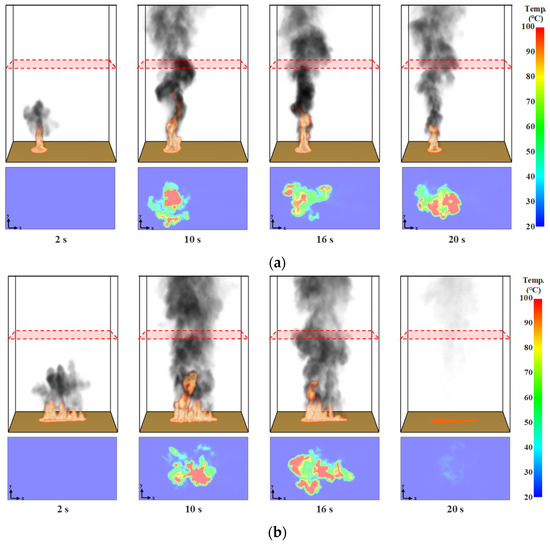

Figure 13 shows the growth and decay of the simulated pool fires with the temperature fields at a height of 3 m. At the early stage (i.e., within 4 s of the start of the fire), the pool fires on both the substrates without and with inclination were still developing. They were fully developed 10 s after the start of the fire. The fire on an inclined surface was in the decaying stage after 16 s, whereas the case without inclination was still fully developed. At all stages, the plume of the fire with inclination was longer in the length direction.

Figure 13.

Stages of the pool fire with temperature fields (z = 3 m): (a) without inclination, (b) with inclination.

Additionally, given that the gas temperature above the fire is dependent on the plume shape, it is plausible that the thermal load acting on structures above the fire is different for the two cases, which was assessed through the temperature fields in the figure. In the early stage of the fire, no significant rise in the temperature was observed. However, before the fire on the inclined substrate started to decay at 16 s, a wider temperature field was produced compared with the scenario without inclination. At the fully developed fire stage (10 s,) the areas with temperatures above 50 °C and 100 °C were 0.774 m2 and 0.280 m2, respectively, for the case without inclination, whereas they increased to 0.886 m2 and 0.328 m2, respectively, for the fire with inclination. This difference in temperature field is expected to considerably affect the loading conditions of structures above the fire.

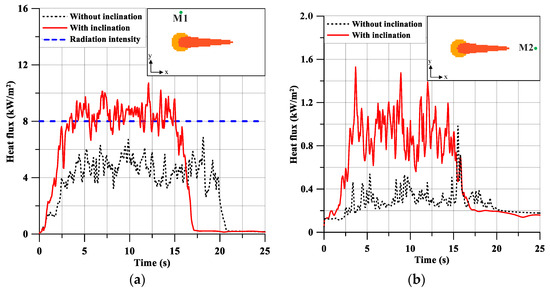

Figure 14 compares the heat flux measurements at points M1 and M2. A similar trend observed for the HRR was noted. The scenario with substrate inclination exhibited higher heat flux levels and a shorter duration for both measuring points. The two scenarios differed slightly in the M1-measured heat flux and more significantly in the M2-measured heat flux (Figure 14a,b), because of the difference in fire scale and pool shape. To quantitatively evaluate the effect of the measured heat flux, the level of concern (LOC), a criterion used in measuring thermal radiation, is illustrated in Figure 14a [35]. The radiation intensity of 8 kW/m2, which causes severe pain when being applied for 7 s on bare skin, was used for the evaluation. The thermal loads for the pool fire considering substrate inclination were above this value, whereas those for the fire without inclination were not.

Figure 14.

Heat flux measurements: (a) M1, (b) M2.

5. Concluding Remarks

Pool fires on ships and offshore installations pose a serious threat because of the spreading behaviour of the spilled flammable liquid under motion. Spillages in large compartments are more likely to induce large-scale pool fires owing to the larger spilling extent.

This study experimentally investigated the spreading behaviour of spilled fuel on inclined surfaces due to ship motion. JP-5 was discharged onto a steel plate under different inclination angles and spill rates, and the spilled pool shape was measured. Empirical formulae for predicting the length, breadth, and area of the spilled pool were developed based on the experimental results. To validate the proposed formulae, the experimental conditions were substituted into the formulae, and the predictions were compared with the measured data. Furthermore, a modified formula predicting the HRR of pool fires in inclined conditions was proposed. Finally, the effects of substrate inclination on the fire consequences were investigated by conducting fire analyses. The main findings are as follows:

- The experiment revealed that the length and area of the spilled pool were proportional to the inclination angle and spill rate, whereas the pool breadth was proportional to the spill rate and inversely proportional to the inclination angle.

- The empirical formulae for the pool dimensions agreed well with the experimental data and exhibited higher accuracy compared with an existing model, as confirmed by the corresponding mean and COV. Thus, the proposed formulae are more applicable to fuel spillages on inclined surfaces compared with the existing models.

- The fire analyses of pool fires on surfaces without and with inclination revealed that the substrate inclination significantly influenced fire consequences. In particular, compared with the scenario without substrate inclination, the fire on an inclined substrate exhibited 36% higher HRR and thermal loads acted further from the spillage location.

In future studies, the structural response to pool fires on inclined surfaces will be analysed using the empirical formulae. Furthermore, the effects of the material properties of fuel, such as fuel viscosity, density, and surface tension, on the spill shape will be examined for different fuel types and substrate conditions. Additionally, further experiments for additional substrate inclinations and fuel discharge rates will improve the applicability of the proposed formulae.

Author Contributions

D.B.: Conceptualisation, methodology, software, writing—original draft; H.L.: Methodology, writing; S.L.: data curation; J.K.S.: Conceptualisation, writing—review and editing, supervision. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Defense Rapid Acquisition Technology Research Institute (DRATRI) of Korea project code 912849501.

Data Availability Statement

The data presented in this study are available in the article.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Wikman, J.; Evegren, F.; Rahm, M.; Leroux, J.; Breuillard, A.; Kjellberg, M.; Gustin, L.; Efraimsson, F. Study Investigating Cost Effective Measures for Reducing the Risk from Fires on Ro-Ro Passenger Ships (FIRESAFE); Technical Report, Project EMSA/OP/01/2016; European Maritime Safety Agency: Lisbon, Portugal, 2017.

- International Maritime Organization (IMO). Chapter II-2. In SOLAS, Consolidated Edition; Consolidated Edition; IMO: London, UK, 2020. [Google Scholar]

- Seo, J.K.; Lee, S.E.; Park, J.S. A method for determining fire accidental loads and its application to thermal response analysis for optimal design of offshore thin-walled structures. Fire Saf. J. 2017, 92, 107–121. [Google Scholar] [CrossRef]

- Paik, J.K.; Czujko, J.; Kim, J.H.; Park, S.I.; Islam, S.; Lee, D.H. A New Procedure for the Nonlinear Structural Response Analysis of Offshore Installations in Fires. In Proceedings of the SNAME Maritime Convention, Bellevue, WA, USA, 8 November 2013. [Google Scholar] [CrossRef]

- Wang, J.; Jiao, Y.; Shi, L.; Xie, Q.; Li, G.; Liu, J.; Chen, W.; Zhang, S. An experimental and non-dimensional study on the vertical temperature distribution of a sealed ship engine room fire. Ocean. Eng. 2018, 165, 22–33. [Google Scholar] [CrossRef]

- Leblanc, D. Fire Environments Typical of Navy Ships; Worcester Polytechnic Institute Worcester: Worcester, MA, USA, 1998; pp. 4–5. [Google Scholar]

- Paik, J.K.; Czujko, J.; Kim, B.J.; Seo, J.K.; Ryu, H.S.; Ha, Y.C.; Janiszewski, P.; Musial, B. Quantitative assessment of hydrocarbon explosion and fire risks in offshore installations. Mar. Struct. 2011, 24, 73–96. [Google Scholar] [CrossRef]

- Ryu, M.G.; He, K.; Lee, D.H.; Park, S.I.; Thomas, G.; Paik, J.K. Finite element modeling for the progressive collapse analysis of steel stiffened-plate structures in fires. Thin-Walled Struct. 2021, 159, 107262. [Google Scholar] [CrossRef]

- Woo, D.; Seo, J.K. Numerical validation of the two-way fluid-structure interaction method for non-linear structural analysis under fire conditions. J. Mar. Sci. Eng. 2021, 9, 400. [Google Scholar] [CrossRef]

- Kim, S.J.; Lee, J.; Kim, S.H.; Seo, J.K.; Kim, B.J.; Ha, Y.C.; Paik, J.K.; Lee, K.S.; Park, B.; Ki, M.S.; et al. Nonlinear structural response in jet fire in association with the interaction between fire loads and time-variant geometry and material properties. Ocean. Eng. 2017, 144, 118–134. [Google Scholar] [CrossRef][Green Version]

- Lee, D.H.; Paik, J.K.; Seo, J.K. Efficient water deluge nozzles arrangement on offshore installations for the suppression of pool fires. Ocean. Eng. 2018, 167, 293–309. [Google Scholar] [CrossRef]

- Ha, G.; Shin, W.G.; Lee, J. Numerical analysis to determine fire suppression time for multiple water mist nozzles in a large fire test compartment. Nucl. Eng. Technol. 2021, 53, 1157–1166. [Google Scholar] [CrossRef]

- Lei, J.; Deng, W.; Liu, Z.; Mao, S.; Saito, K.; Tao, Y.; Wu, H.; Xie, C. Experimental study on burning rates of large-scale hydrocarbon pool fires under controlled wind conditions. Fire Saf. J. 2022, 127, 103517. [Google Scholar] [CrossRef]

- Chu, T.; Jiang, L.; Usmani, A. Introducing an active opening strategy to mitigate large open-plan compartment fire development. Fire Saf. J. 2023, 141, 103981. [Google Scholar] [CrossRef]

- Chen, Y.; Fang, J.; Zhang, X.; Miao, Y.; Lin, Y.; Tu, R.; Hu, L. Pool fire dynamics: Principles, models and recent advances. Prog. Energy Combust. Sci. 2023, 95, 101070. [Google Scholar] [CrossRef]

- Ditch, B.D.; de Ris, J.L.; Blanchat, T.K.; Chaos, M.; Bill, R.G.; Dorofeev, S.B. Pool fires—An empirical correlation. Combust. Flame 2013, 160, 2964–2974. [Google Scholar] [CrossRef]

- Sung, K.; Chen, J.; Bundy, M.; Fernandez, M.; Hamins, A. The Thermal Character of a 1 m Methanol Pool Fire; US Department of Commerce, National Institute of Standards and Technology (NIST): Gaithersburg, MD, USA, 2020. [CrossRef]

- Grimaz, S.; Allen, S.; Stewart, J.; Docetti, G. Predictive evaluation of surface spreading extent for the case of accidental spillage of oil on the ground. AIDIC Chem. Eng. Trans. 2007, 11, 389–394. [Google Scholar]

- Huppert, H.E. Gravity currents: A personal perspective. J. Fluid Mech. 2006, 554, 299–322. [Google Scholar] [CrossRef]

- Simmons, C.S.; Keller, J.M.; Hylden, J.L. Spills on Flat Inclined Pavements; PNNL Report No. PNNL-14577; Pacific Northwest National Lab. (PNNL): Richland, WA, USA, 2004. [CrossRef]

- Ingason, H.; Li, Y.L. Spilled liquid fires in tunnels. Fire Saf. J. 2017, 91, 399–406. [Google Scholar] [CrossRef]

- Klein, R.; Maevski, I.; Ko, J.; Li, Y. Fuel pool development in tunnel and drainage as a means to mitigate tunnel fire size. Fire Saf. J. 2018, 97, 87–95. [Google Scholar] [CrossRef]

- Abbasi, T.; Kumar, V.; Tauseef, S.M.; Abbasi, S.A. Spread rate of flammable liquids over flat and inclined porous surfaces. J. Chem. Health Saf. 2018, 25, 19–27. [Google Scholar] [CrossRef]

- Briscoe, F.; Shaw, P. Spread and evaporation of liquid. Prog. Energy Combust. Sci. 1980, 6, 127–140. [Google Scholar] [CrossRef]

- Kim, M.B.; Do, K.H.; Han, Y.S.; Choi, B.I. First-order perturbation solutions of liquid pool spreading with vaporization. Int. J. Hydrogen Energy 2011, 36, 3268–3271. [Google Scholar] [CrossRef]

- Raja, S.; Abbasi, T.; Tauseef, S.M.; Abbasi, S.A. Equilibrium models for predicting areas covered by accidentally spilled liquid fuels and an assessment of their efficacy. Process Saf. Environ. Prot. 2019, 130, 153–162. [Google Scholar] [CrossRef]

- Li, Y.; Huang, H.; Zhang, L.; Su, B.; Zhao, J.; Liu, Q. An experimental investigation into the effect of substrate slope on the continuously released liquid fuel spill fires. J. Loss Prev. Process Ind. 2017, 45, 203–209. [Google Scholar] [CrossRef]

- Zhao, J.; Zhu, H.; Zhang, J.; Hong, H.; Yang, R. Experimental study on the spread and burning behaviors of continuously discharge spill fires under different slopes. J. Hazard. Mater. 2020, 392, 122352. [Google Scholar] [CrossRef] [PubMed]

- NOAA Office of Response and Restoration. “Jet Fuels, [JP-5]”. Cameo Chemicals, 1999. Available online: https://cameochemicals.noaa.gov/chemical/11699 (accessed on 4 January 2024).

- Babrauskas, V. Heat Release Rates. In SFPE Handbook of Fire Protection Engineering, 5th ed.; National Fire Protection Association: Quincy, MA, USA, 2016; pp. 799–980. [Google Scholar]

- MIL-STD-1399-301; Interface Standard for Shipboard Systems. Department of the Navy Naval Sea Systems Command: Washington, DC, USA, 1986.

- McGrattan, K.; Hostikka, S.; Floyd, J.; McDermott, R.; Vanella, M. Fire Dynamics Simulator User’s Guide; National Institute of Standards and Technology (NIST): Gaithersburg, MD, USA, 2022.

- McGrattan, K.; Hostikka, S.; Floyd, J.; McDermott, R.; Vanella, M. Fire Dynamics Simulator Technical Reference Guide; National Institute of Standards and Technology (NIST): Gaithersburg, MD, USA, 2022.

- Rengel, B.; Mata, C.; Pastor, E.; Casal, J.; Planas, E. A priori validation of CFD modelling of hydrocarbon pool fires. J. Loss Prev. Process Ind. 2018, 56, 18–31. [Google Scholar] [CrossRef]

- Federal Emergency Management Agency. Available online: https://response.restoration.noaa.gov/oil-and-chemical-spills/chemical-spills/resources/thermal-radiation-levels-concern.html (accessed on 4 January 2024).

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).