Abstract

This review emphasizes the recent ongoing shift in the wood coating industry towards bio-based resources and circular economy principles, promoting eco-friendly alternatives. In addressing wood’s vulnerabilities, this study investigates the use of natural compounds and biopolymers to enhance wood coatings. These materials contribute to protective matrices that safeguard wood surfaces against diverse challenges. Essential oils, vegetable oils, and bio-based polymers are explored for their potential in crafting eco-friendly and durable coating matrices. Furthermore, this review covers efforts to counter weathering and biological decay through the application of various natural compounds and extracts. It evaluates the effectiveness of different bio-based alternatives to traditional chemical preservatives and highlights promising candidates. This review also delves into the incorporation of sustainable pigments and dyes into wood coatings to enhance both protective and aesthetic qualities. Innovative pigments are able to provide visually appealing solutions in line with sustainability principles. As the wood coating industry embraces bio-based resources and the circular economy, researchers are actively developing protective solutions that encompass the coating matrix, preservatives, bio-based fillers, and natural-pigment dyes. This review showcases the continuous efforts of academia and industry to enhance wood coatings’ effectiveness, durability, and sustainability, while maintaining their aesthetic appeal.

1. Introduction

Wood, a resource that has historically been extensively harnessed by humans [1], owes its popularity to its unique physical and chemical attributes [2]. These characteristics encompass a remarkable strength-to-weight ratio [3] and ease of processing [4]. Moreover, wood’s contemporary significance lies in its natural abundance, material simplicity, and distinctive aesthetic qualities [5]. However, the inherent lignocellulose composition of wood renders it susceptible to challenges such as flammability [6], moisture-induced deterioration [7], and solar radiation-induced damage [8]. These processes impact wood’s inherent durability, dimensional stability, and surface integrity, leading to notable structural and colour changes, along with a gradual reduction in resistance to biological agents and mechanical properties.

To address these concerns, organic coatings are commonly employed on wooden components, bolstering their resilience by providing defence against solar radiation [9], humidity fluctuations [10], chemical assaults [11], mechanical stresses [12], and the proliferation of harmful organisms, like fungi [13,14], while preserving wood’s aesthetic appearance.

The widespread application of wood in outdoor settings has motivated both academia and industry to explore innovative techniques for enhancing wood coatings [15]. One such approach involves enhancing the UV absorption capabilities of wood coatings by incorporating various nanoparticles, such as TiO2 [16], ZnO [17], SiO2 [18], and CeO2 [19]. Similarly, nanostructures with enhanced hardness, stiffness, and thermal stability, like nanosilica [20], nanoalumina [21], nanoclay [22], and nanocellulose [23], have been utilized to augment the mechanical properties and water resistance of wood coatings [24]. Additionally, the antibacterial and fungicidal properties of wood coatings have been fortified by the integration of nanomaterials, like copper nanopowders [25], nanotitanium [26], and silver [27].

Nonetheless, the emerging trend of using coloured paint to impart specific aesthetic effects to wooden products, employing novel pigments [28] and distinct gloss values [29], is gaining traction in the wood protective coatings sector [30]. The stability of these pigments in wood paints has recently garnered significant attention [31]. It is crucial to ensure that the incorporation of innovative pigments delivers unique aesthetic effects without compromising the protective barrier properties of the organic coating. The combination of wood paints with different types of pigments may lead to significant challenges, such as reduced protective efficacy due to matrix discontinuities or concerns regarding the pigments’ limited durability [32].

At present, the wood coating industry is embracing two pivotal areas: bio-based resources and the circular economy. As the industry increasingly seeks ecologically friendly and multifunctional alternatives to conventional synthetic fillers [33], which often overlook environmental sustainability during production [34], scientific exploration is focusing on the integration of natural additives in coatings [35]. In this vein, researchers have recently examined the impact of incorporating various substances into wood coatings, including linseed oil [36], cellulose fibres [37], pigments derived from wood waste [38], microbial dyeing [39], and pigments extracted from fungi [40] and microalgae [41,42].

Hence, this review reveals the latest methods employed to develop protective solutions for wooden elements considering the four aspects shown in Figure 1, namely the coating matrix, the materials for preservatives and impregnating agents, the bio-based fillers, and the natural-pigment dyes. These studies are rooted in the utilization of eco-friendly, low-impact bio-based materials. This review underscores the significant endeavours and keen enthusiasm of both the industrial and academic domains in this regard.

Figure 1.

Graphical illustration of the bio-based materials employed in wood protective systems.

2. Bio-Based Coating’s Matrix

The matrix is the main constituent of a coating, with a fundamental function in the final protection provided by the coating layer. The research for the design of environmentally friendly and eco-sustainable coatings starts, therefore, from the identification of natural compounds to be employed as matrix constituents. Essential oils occupy a large fraction of the research in this field. Essential oils can be directly used for wood impregnation, or they can either be supplemented with particles or employed as starting material for the synthesis of organic coatings. Alternatively, the matrix of wood coatings might be synthetized starting from bio-based polymers, of which chitosan, cellulose, and lignin are the most famous.

A comparative study to evaluate the mechanical performance and the physico-chemical properties of bio-based and fossil-based acrylate monomers and oligomers [43] showed that the coatings based on biological monomers or oligomers exhibited a lower hardness and higher resistance to abrasion and scratching. Therefore, the study published by Samyn et al. highlights the potential of replacing fossil-based components with bio-based ones for the design of wood coatings to first achieve more effective protection, in parallel with increased sustainability and a reduced impact on the environment.

2.1. Vegetable Oils and Their Derivatives

Vegetable oils represent a “green” and eco-friendly solution to be used as wood coatings and preservatives. In fact, many essential oils, and some of their derivatives, have been known since ancient times for their antimicrobial or antifungal effects [44]. Another advantage of vegetable oils is the fact that they induce a smooth feel and provide the coated surface with a small coefficient of friction [45]. Natural oils can be directly applied to the wood surface, but they may also serve as the starting point for the synthesis of the bio-based coating matrix.

Oils can be classified as drying and non-drying. The former become harder when exposed to the atmospheric environment. On the other hand, non-drying oils remain in the liquid state and are, in general, not useful for the production of coatings. Indeed, coatings should be able to provide protection to the wood substrate, remaining adhered and intact, even when the wood object is moved, touched, or simply exposed to aggressive environmental conditions. The hardening process occurs because drying oils possess functional groups that are able to react and be oxidized by atmospheric oxygen [46]. Linseed oil and tung oil represent the most known and explored drying oils in the field of coatings. Linseed oil, alternatively referred to as flaxseed oil or flax oil when used for consumption, is a clear to slightly yellow oil derived from the matured, dried seeds of the flax plant (scientifically known as Linum usitatissimum). The oil can be acquired through a process involving pressing and, occasionally, solvent extraction. Similarly, tung oil, also known as China wood oil, is a drying oil derived from pressing the seed found within the nut of the tung tree, scientifically known as Vernicia fordii. When exposed to air, tung oil undergoes a process of polymerization, causing it to harden. This results in a transparent finish with a rich, almost glossy appearance, akin to a wet surface. It is primarily employed for the purpose of enhancing and safeguarding wood. Both tung and linseed oils provide hydrophobicity to the wood’s surface, but some differences in their performances have been reported [47]. On one hand, tung oil provides a hydrophobic effect that can be appreciated soon after its application; on the other hand, linseed oil requires a longer time to complete film formation. Nevertheless, after that time, a higher contact angle is measured for linseed oil than that for tung oil [47]. In addition to the hydrophobic properties, another important requirement for a wood coating is the ability to curb the colonization of wood-decay fungi. Both tung oil and linseed oil have been found to be protective against brown-rot and white-rot fungi, with better protective performance associated with tung oil [48]. He et al. reported that the treatment of wood with tung oil could improve the dimensional stability of the material and, most importantly, reduce moisture absorption [49]. The SEM micrographs in Figure 2 show how the pits visible in the untreated wood (left) were occluded after the application of tung oil (right), thus preventing the absorption of moisture.

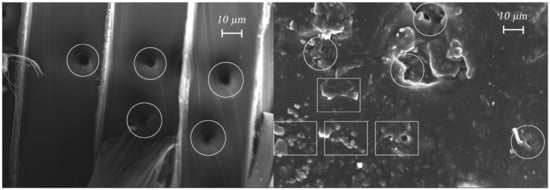

Figure 2.

SEM micrographs of untreated wood (left) and of the wood after treatment with tung oil (right) [49]. From Industrial Crops and Products, 140, Z. He, J. Qian, L. Qu, N. Yan, S. Yi, Effects of Tung oil treatment on wood hygroscopicity, dimensional stability and thermostability, 111647, Copyright (2019), with permission from Elsevier.

In addition to the protective effect provided by the oil, additives and/or pigments can be added to increase the performance of the coating. The presence of pigments and additives will certainly have an influence on the degree of wear and decay upon weathering [36]. For example, the addition of 5% hemp-derived biocarbon (BC) to tung oil resulted in increased hydrophobicity of the coated surface. Although the degree of hydrophobicity did not directly correlate with the amount of introduced BC, a higher BC content was associated with improved protection against the weathering effects [50]. Pigments extracted from wood-decay fungi solubilized in raw linseed oil could extend the service life of the coating [40], while the addition of nanofibrillated cellulose (NFC) has been reported to improve the wear resistance of linseed oil-based coatings [51]. A more comprehensive discussion of the effects of the use of pigments and additives on the coating resistance and performance is provided in Section 4 and Section 5. The synergistic effect of tung oil with natural beeswax has also been investigated. As the coating properties of a surface also depend on the surface exterior, micronized sodium chloride (NaCl) particles were added to impart a surface texture after the dip-coating of wood samples [52]. A superhydrophobic coating was obtained, and the presence of tung oil within the coating mixture was found to enhance the temperature stability compared with the one related to the coatings containing wax only.

In addition to directly treating the wood surfaces with oil as it is, another solution is to use oils of natural origin as a starting base for the synthesis of resins and coatings. For example, a bio-based epoxide amine nanocoating was synthesized starting from tung oil. The novel resin coating was found to enhance the density of the wood material, decrease water absorption, and improve the mechanical properties of the wood’s surface [53]. Acrylated vegetable oils have been used for the production of wood coatings, either in combination with propoxylated glycerol triacrylate [54] or together with a photoinitiator for the induction of the curing process [55]. A few years ago, Wang et al. exploited castor oil as a starting material to synthesize a multifunctional castor oil-based bio-mercaptan, with the addition of an organic phosphorus flame-retardant [56,57]. This wood coating promoted the degradation of films at lower temperatures, but, at the same time, it could reduce the maximum degradation rate and could delay the process of decomposition as well. In a different study, a transparent castor oil-based coating was successfully produced by combining siloxane oligomer and castor oil through epoxidation [58]. The coating object of the study contained grafted polydimethylsiloxane molecules that were associated with the provided roughness and surface morphology, and responsible for a reduced friction coefficient with oily contaminants. In a different study, epoxidized soybean oil was mixed with castor oil maleic anhydride adduct (COMA), which is “green” and environmentally sustainable because it is obtained from renewable materials, and methyl nadic anhydride (MNA), with the aim of generating a wood coating with a high content of renewable materials [15]. Castor oil is much exploited in the context of bio-based coatings, since it offers varying applications and the possibility to be modified to improve its properties, both in terms of protection and in terms of durability. For example, Patil and Jagtap started from a castor oil-based fatty amide to synthesize a hyperbranched alkyd resin, which was then used as a starting material for the generation of polyurethanes. These bio-based generated coatings displayed better performance and properties than the reference linear alkyd polyurethanes [59]. One of the possible solutions to improve the performance of coatings is the addition of additives or nanoparticles, which are able to provide improved properties. Based on this, SiO2 nanoparticles were added to a coating based on castor oil thiolated oligomers to improve its hydrophobicity, and the control of the wetting behaviour was achieved by varying the loading of SiO2 nanoparticles. When SiO2 nanoparticles were added at a concentration of 40 wt.%, the highest water contact angle was reported. In addition to hydrophobicity, the coating also showed self-cleaning properties, adding an additional benefit other than the protection for the wood substrate [60].

Another natural oil with a putative potential for wood protection is extracted from the seeds of the soybean. Among the many studies available in the literature, Li et al. reported that soybean oil could improve the functional performance of a waterborne polyurethane acrylate resin. After modification with acrylic acid, the researchers introduced the modified epoxy soybean oil into the resin, and this resulted in a fast-curing resin that provided good mechanical and thermal properties to the wood substrate [61]. Furthermore, the plasticizer effect of epoxidized soybean oil might be exploited to counter the issues related to the high brittleness and low toughness of furfuryl alcohol treatment. The work published by Liu et al. proved that epoxidized soybean oil improved the toughness and the mechanical properties of the wood substrate, with increased values of tensile stress and impact bending strength compared with the values reported for the simple furfurylated wood [62]. Epoxidized soybean oil has also been found to synergistically enhance the activity of succinic anhydride to protect wood samples against the photooxidation damage induced by ultraviolet (UV) radiation [63]. In another study, by mixing epoxidized soybean oil with epoxidized grapeseed and corn oils, diglycidyl ether of bisphenol A (DGEBA), and maleopimaric acid (MPA), a wood coating was obtained, which was able to reduce the passage of water and fungi into the sample and thus to provide anti-fungi resistance [13]. Ultimately, the addition of a modified betulin sample, an organic compound isolated from the bark of birch trees, could improve the coating properties of acrylated epoxidized soybean oil owing to the formation of a cross-linked rigid structure between the two components [64].

Huang et al. used acrylated epoxidized soybean oil together with the flame retardant FRC-6 and itaconic anhydride to prepare waterborne coatings with good hardness, adhesion, and solvent resistance [65]. Additionally, good flammability properties were provided by the presence of the flame retardant. Nonetheless, the coating performance of the acrylated epoxidized soybean oil was shown to be exceeded by an acrylate obtained from cardanol-modified fatty acid from camelina oil. Compared with the former, the latter displayed higher tensile strength and hardness, resistance to solvents, and higher thermal decomposition temperature [66]. Epoxidized camelina oil (ECO) and acrylated epoxidized camelina oil (AECO) were proven to be effective wood coatings with better mechanical properties and thermal behaviour compared with soybean oil polymers. Both typologies of camelin oil-based coatings had high pencil hardness values and good adhesion to the substrate. Nevertheless, ECO displayed reduced mechanical strength and gloss values compared with AECO [67].

Despite being less exploited compared with other most famous essential oils, peanut oil also represents a source of bio-precursors for the design of wood coatings. In the study published by Raychura and co-workers, N,N-bis(2-hydroxyethyl) fatty amide was produced from peanut oil and used as precursors for the synthesis of polyurethane [68]. The obtained wood coating displayed excellent behaviour, both in terms of mechanical and thermal properties, but also antimicrobial and chemical resistance, representing a valid alternative in substitution of petroleum-based coatings.

In addition to the most explored vegetable oils, for which many studies can be traced in the literature, other less-known oils of natural origin have been investigated for their potential to provide a barrier effect to wood. The Mahua tree is a medium/large-sized tree, which mostly grows in India. The oil extracted from this plant was identified as a possible precursor for the synthesis of polyurethane. Mahua oil was indeed used as raw material for the synthesis of polyetherimide polyol, and the consequently obtained polyurethane displayed high resistance to water, solvents and chemicals, and good mechanical, thermal, and antimicrobial properties [69]. Once again, the oil extracted from the seeds of Jatropha curcas, a plant typical of tropical regions, was combined with vegetable resins, and the performance of the obtained coating was assessed based on the physical properties of Ayous wood. Despite the reference varnish being more protective against fungi, the newly produced bio-based coating had a higher protection against termite attack [70], suggesting the possible wood-protection potential of extracts from these plants.

A different way to exploit vegetable oils as wood coatings was proposed by Sanson et al. In their work, the authors obtained the water-soluble fraction from fast-pyrolysis bio-oil, which showed encouraging results in protecting wood against physical wear and against the biological action of wood-decay fungi, such as Trametes versicolor and Gloeophyllum trabeum [71]. The addition of nanostructures of bentonite to the generated coating further improved the water-repellent effect and the antifungal activity of the isolated water-soluble fractions.

2.2. Natural Biopolymers for Wood Protection

Natural biopolymers, including the most famous chitosan and cellulose, are promising solutions to be used for wood protection. The drying behaviour of three natural biopolymers was investigated in the context of the preservation of archaeological wooden objects, namely chitosan, alginate, and cellulose [72]. The study concluded that chitosan and alginate improved the thermal stability of wood and could thus be considered as potential wood consolidants. However, cellulose nanocrystals did not display good performance in terms of wood protection, being, therefore, less promising in this field of application [72].

Chitosan is a natural biopolymer that can be isolated from the outer shells of shrimps and crustaceans. The potential of chitosan for the development of bio-based wood coatings has been widely explored. Woźniak et al. used chitosan to limit the leaching of caffeine out from the wood substrate. Indeed, despite having anti-fungal activity, caffeine is extremely prone to leaching in the presence of water, considerably limiting its exploitability, especially considering that outdoor wood objects are frequently exposed to conditions of potentially high humidity. While the wood treated just with caffeine had reduced anti-fungal activity and a mass loss of about 21%, the chitosan–caffeine preparation extended the resistance of wood owing to the limited caffeine leaching provided by the chitosan [73]. A modified chitosan was ionically cross-linked with nitrilotris(methylenephosphonic acid) (NTMP), and the obtained complexed formulation reduced the flammability of wood specimens, decreasing both the total heat release rate and the peak heat release rate [74].

One of the main damaging factors for coated wood surfaces is exposure to UV radiation. Janesch and colleagues attempted to deal with this issue by creating layer-by-layer coatings with chitosan and CeO2 nanoparticles as UV-protective molecules [19]. Owing to the addition of the CeO2 nanoparticles, the colour variation induced by exposure to UV rays was considerably reduced, especially the yellowing of the wood surface, which is a characteristic outcome when the wood substrate is exposed to solar radiation.

Cellulose nanofibril (CNF) is one of the most abundant and common biopolymer nanofibrils, and it possesses good qualities for it to be employed as a bio-carrier for coating formulation. Yuan et al. combined CNF with graphitic carbon nitride nanosheets (gCNNS) as a UV absorber to shield the wood material from UV radiation [75]. After 15 days of accelerated weathering, the gCNNS/CNF coating significantly improved the colour stability of the wood substrate, suggesting the excellent performance of this complex formulation as a barrier to UV radiation.

As one of the most common biopolymers, several studies have explored the characteristics of lignin for the development of wood coatings. For example, lignin-based polyurethane coatings have been produced, with a high content of lignin. When compared with the uncrosslinked lignin precursor, the new polyurethane coating had higher thermal stability and hydrophobicity, suggesting that this may represent a new direction to generate novel bio-based coatings [76]. Bergamasco et al. produced a bio-based polyurethane starting from lignin and isocyanate, testing the effectiveness of using different proportions between the two components [77]. From one side, the lignin-based coating resulted in a hydrophobic surface, but from the other side, superficial cracks were formed when the coating was formulated with a high lignin concentration. This represents an issue for its applicability to wooden surfaces, as cracks increase the permeability of the coating, and water uptake is known to have a negative impact on wood decay. Therefore, some expedients must be adopted to counter this problem. For example, additives might be introduced with low surface tension to reduce the rate of crack formation. These results show that, although some substances of natural origin have excellent protective qualities, further studies and improvements may be required in the view of industrial application to enhance their final performance.

The concept of flame retardancy is extremely vital, as a coating for wood should first reduce the risk of flammability in case of fire. Therefore, bio-based compounds have also been investigated for their anti-flammable performances. Some bio-based natural substrates are already known to display fire-retardant characteristics. A study conducted on several natural substrates, including starch, chitosan, rice bran, and fish gelatine, reported fish gelatine as a promising fire-proofing agent [78]. A waterborne flame-retardant itaconate-based unsaturated polyester was synthetized with the flame retardants FRC-6, N-(hydroxymethyl) acrylamide (NMA), and γ-methacryloxypropyltrimethoxysilane (MPS) [79]. The coating provided the wood with flame protection owing to the formation of a stable char layer, acting as a barrier. With the aim of generating a bio-based coating able to offer protection against flame propagation, Zhong et al. produced an epoxy flame retardant, PPDEG-EP [80]. After mixing with the curing agent diaminodiphenylmethane (DDM), the eugenol-derived coating proved to be effective in providing wood with anti-flammability properties. In a different study, researchers investigated the fire protection offered by an epoxy coating from the natural substance luteolin [81], which was mixed with a furan-derived hardener. Compared with the reference control, the new wood coating resulted in a decrease in the peak heat release rate of 55.8%, a reduced total heat release of 12.4%, and a decreased smoke production of 11.5%. Interestingly, the produced new coating was safe and nontoxic to human fibroblast cells, providing additional value for its use for wood protection. Another study proved eugenol to be a potential natural source for wood coatings synthesis [82], supporting future industrial investments and efforts for studies on this natural compound. Indeed, Faye and colleagues generated an epoxy monomer from eugenol, to obtain a final wood coating with high char yields and thermomechanical properties.

Tannins are plant-derived polyphenols, largely exploited as natural polymers with active protective properties. The potential of tannins as wood protective agents has been explored, in conjunction with the biopolymer lignin [83]. De Hoyos-Martínez et al. generated polyphenolic resins based on these two natural compounds and compared their protective properties for wood substrates with respect to the best commercially available fireproofing coatings. The novel resins based on tannins and lignin displayed reduced heat release during combustion and delayed propagation of flames, showing the potential of compounds of natural origin for the design of wood coatings with anti-flammable performance.

Good flame-retardant performance has also been associated with the natural compound benzoxazine (BZ) [84]. BZ can be mixed with polyurethane to create an interpenetrating network system, with excellent hydrophobicity values and improved resistance both to acids and to basic substances, compared with the reference polyurethane. Most importantly, the investigated network could provide the wood-coated sample with fire protection.

A promising biopolymer for the production of “green” wood coatings is poly(lactic acid) (PLA), produced from the bacterial fermentation of sugar beet or cornstarch. A polyester methacrylate resin, obtained from PLA and ε-caprolactone (CL), was mixed with cellulose nanocrystals (CNCs), and the coating was applied to pine wood [85]. This formulation reduced the rate of water absorption by 65%, and the presence of CNCs was found to further positively contribute to the slow water absorption.

Vanillin is a phenolic aldehyde, which is mainly extracted from vanilla bean. Its potential for wood protection has been investigated through the synthesis of a vanillin-based polyurethane [86]. The results showed that, when divanillin was incorporated with a proportion of 30% into a polyurethane dispersion, the coating displayed the highest measured hardness. Moreover, the innovative bio-based coating conferred the wood samples high resistance towards acid substances, but also towards alkali substances. Additionally, a vanillin-derived epoxy was cross-linked with polysiloxane to obtain a wood coating with high thermal stability. When applied to bamboo wood, the new coating formulation was shown to improve the flammability resistance of the substrate [87].

In a separate study, polyurethane coatings were synthetized, starting from oleic and dimer fatty acids, which were investigated as renewable sources to obtain environmentally sustainable wood coatings [88]. According to the illustrated results, the bio-based polymer afforded good coating properties to wood, with high mechanical properties and resistance to natural weathering, validating the potential for the protection of wood surfaces. As a natural compound, citric acid has also been exploited for the synthesis of a coating matrix for the treatment of wood surfaces. Maity et al. started from citric acid to generate a hyperbranched polyester–urethane–acrylate [89], which exhibited improved thermal properties compared with a commercially available urethane acrylate. Nevertheless, the chemical resistance of the new coatings was found to be lower if compared with that of a standard used as a reference, suggesting that further studies are needed to optimize the properties of citric acid-based wood coatings.

A different and Innovative approach involves the exploitation of a biofinish coating based on living cells. Poohphajai et al. investigated the potential of the living fungus Aureobasidium pullulans to protect Scots pine wood during natural weathering [90]. The innovative wood coating was able to improve the colour stability and aesthetic properties of the wood surface, suggesting a new route of research for the identification of wood protective solutions.

It has been shown that the research toward new bio-based components for the matrix of wood coatings is a current and hot field of study, which is attracting the interest of both industries and academic scientists.

Table 1 presents a condensed overview of the key findings provided by bio-derived matrices used in wood coatings.

Table 1.

Summary of the main insights regarding the use of bio-based matrices in the formulation of wood coatings.

3. Bio-Based Preservatives and Impregnators

One of the most immediate barriers to counter the weathering and/or biological-induced decay of wood is the application of preservatives or impregnators on wood samples. The manifested trend toward environmental sustainability and eco-friendly solutions calls for the need to shift from the classical chemical wood preservatives, which can be harmful to the environment, toward bio-based products. A comparative study was conducted to investigate the impacts and effectiveness of bio-based and commercially available chemicals for wood preservation [91]. According to the documented results, Colatan GT10, a Quebracho tannin mix, was identified as the most promising bio-based wood preservative, with lower toxicity compared with copper-based chemicals, which are frequently commercially sold. Although it is generally assumed that bio-based chemicals have lower ecotoxicity, this is not always true. As pointed out in the same study, in some circumstances, bio-products may be even more toxic than the commercially available ones, highlighting the importance of conducting extensive ecotoxicity studies before the employment of a product and carefully investigating the environmental effects possibly associated with it [91].

Several natural wood preservatives are extracts derived from plants and from vegetables. They include plant essential oils as well as plant extracts, containing several and varying active molecules. For example, stilbenes have been investigated as possible impregnators for Scots pine sapwood (Pinus sylvestris L.). The impregnation of wood with crude heartwood extract containing the stilbenes pinosylvin (PS) and pinosylvin monomethyl ether (PSM) was able to reduce fungal growth and, consequently, the decay of the material [92]. The main issue related to stilbenes is that they are prone to fungi-induced degradation, especially by Rhodonia placenta. Positive outcomes were obtained from pyrolysis distillates from the bark of spruce, which could inhibit fungal growth over 40% at a concentration of 0.1% [93]. Yildiz et al. investigated the performance of lichen and leaves of mistletoe for wood preservation [94]. Even if the results of the fungal decay test were not satisfactory, according to the standard reference, some promising outcomes were highlighted, prompting efforts toward this trend of research flow.

Tannins, of which many plants are a great source, are among the most explored and investigated natural extracts with potential as antifungal agents. Low concentrations of tannins extracted from cones of spruce and pine and from spruce barks could inhibit the growth of brown-rot fungi. However, they could not block the growth of white-rot and soft-rot fungi [95]. Therefore, although tannins might constitute promising agents for wood preservation, further deeper investigation is required. In a later study [96], tannins were reported as natural wood preservatives, where they could improve resistance toward the white-rot fungus Pycnoporus sanguineus at a comparable level to that of the chromate copper borate preservative. The potential inhibitory characteristics of valonia, chestnut, tara, and sulphited oak tannins were also tested. Similarly, these tannins displayed anti-fungal performance against brow-rot fungi, but not against white-rot fungi [97]. Among the tested tannin molecules, valonia and chestnut tannins resulted in the lowest mass loss after fungi-induced degradation. Despite the encouraging findings for tannin molecules, one of the main limitations for their exploitation is their elevated water solubility, which makes them easily leach out. Therefore, expedients are to be taken into consideration to foresee the future use of tannins as wood preservatives. Tannin copolymer formulations, prepared with hexamine, formaldehyde, furfural, glyoxal, furfuryl alcohol, and maleic anhydride, revealed improved leaching and fire resistance, as well as increased hardness [98]. However, the properties of these new formulations were negatively affected by artificial weathering. Overall, these studies reveal the great potential of tannins as wood preservatives but, at the same time, they highlight the requirement for further research and investigations. Monoterpenes are extracted from several plants and plant oils. A systematic study identified the monoterpene carvacrol as a possible agent with anti-fungal activity. In fact, this compound was found to be toxic to the wood white-rot fungi Trametes hirsuta, Schizphylhls commune, and P. sanguineus, with low values of IC50 [99]. Extracts of propolis were also investigated for anti-fungal characteristics [100]. When used as a wood impregnant, the extracts derived from propolis could limit the fungal decay induced by the brown-rot fungus Coniophora puteana. Additionally, phenolic compounds were identified within the propolis extract, which were able to provide antimicrobial activity. Shiny et al. reported that a coconut shell pyrolytic oil distillate (CSPOD) was effective in protecting wood from both brown-rot and white-rot fungi. This anti-fungal activity was mainly attributed to the presence of phenolic compounds in the distillate [101].

Caffeine is an alkaloid that can be easily extracted from plants. This widespread natural compound has been found to improve the resistance of spruce wood against termites and brown-rot fungi. The main drawback is that caffeine is prone to leaching out from wood in the presence of water, making it not perfectly suitable for the treatment of outdoor wood [102].

Since ancient times, essential oils have been widely applied for different purposes. Considering their long history of use, also in the traditions of ancient local civilizations, they represent a valid and promising alternative as wood preservatives. In fact, many essential oils are reported to have anti-fungal properties. For example, essential oils extracted from Lippia origanoides displayed elevated anti-fungal properties, and the effect was attributed to the presence of thymol [103]. Overall, several plant essential oils have been proven to exhibit anti-fungal properties, such as Origanum vulgare, Cymbopogon citratus, Thymus vulgaris, Pelargonium graveolens, Cinnamomum zeylanicum, and Eugenia caryophyllata, and they and/or their main constituents can be employed to impregnate wood surfaces in order to ensure their preservation [104]. Eventually, Bardage et al. conducted a comprehensive study to investigate the effect of several natural products on the inhibition of fungi growth on southern yellow pine. The best inhibitory effect was reported for salicylic acid, tea tree oil, and cinnamon bark oil, with highly encouraging outcomes after a test in the mould chamber [105].

Finally, one of the most environmentally sustainable lines of research involves the recovery of active substances from waste products. This offers the dual advantages of having a recyclable raw material, instead of searching for new sources, and reusing a waste product, thus reducing the issues related to waste disposal. Coffee silverskin is the perfect example of an extremely diffused industrial waste derived from the process of coffee roasting. Its potential for wood preservation was first explored by Barbero-Lopez et al. However, the results were not encouraging, as the authors showed that coffee silverskin was not as effective as commercial wood preservatives, despite being able to inhibit fungal growth at a level of 60–70% [106]. Nevertheless, it is highly likely that, in the future, research will be aimed at more deeply investigating industrial waste products as possible sources of active agents for their ultimate application as wood preservatives.

Table 2 provides a concise summary of the significant discoveries attributed to bio-based preservatives and impregnators within wood coatings.

Table 2.

Summary of the main insights regarding the use of bio-based preservatives and impregnators in the formulation of wood coatings.

4. Bio-Based Fillers

The renewed attraction towards wood as a building material is driven by growing concerns about sustainability and evolving aesthetic preferences. Nevertheless, due to its organic nature, wood is vulnerable to changes in humidity and exposure to UV radiation. These factors instigate the creation of unstable molecules and lead to the breakdown of its lignin and cellulose constituents [9]. When used outdoors, wooden structures can experience issues like expansion, susceptibility to mould and fungi, changes in colour, yellowing, and a decline in both gloss and structural integrity [107,108]. As a result, the industrial field is progressively focusing on utilizing novel bio-derived additives in wood coatings. These fillers have the potential to enhance the component’s ability to withstand weathering, serve as strengthening agents, or afford properties, such as antibacterial, antifungal, or flame retardant capabilities, as summarized in Figure 3.

Figure 3.

Illustration of the functionality of bio-based fillers in wood protective systems.

4.1. Weathering Resistance Bio-Based Fillers

Certainly, ensuring the ability to withstand weathering is a crucial factor for a wood coating, given that wood is especially vulnerable to the effects of outdoor elements. Bearing this in mind, different varieties of bio-derived additives have recently exhibited impressive performance in enhancing the coating’s longevity. As a result, they contribute to prolonging the lifespan of outdoor wood components.

For instance, hemp-based biocarbon (BC) particles have been incorporated into tung oil to function as UV absorbers [50]. The introduction of these particles led to an enhancement in the water-repellent characteristics of the coating and resulted in improved colour preservation throughout the on-site weathering examination. Likewise, Nowrouzi et al. [109] utilized olive leaf extract as a supplement in polyacrylate coatings along with TiO2 or ZnO nanoparticles and a UV-absorber of the 2-(2-hydroxyphenel)-benzotriazole (BTZ) type. This combination was investigated for its ability to withstand natural or accelerated weathering. The study emphasized a decrease in the occurrence of wood discolouration due to the inclusion of olive leaf extract, which enhanced resistance against UV radiation. Adopting a distinct strategy, Cheumani Yona et al. [110] developed a wood coating through the curing of levulinic acid (LLA),Ich served aI an innovative bio-derived solvent for the mild solvolysis liquefaction of wood. The resulting cured coatings exhibited robust pull-off adhesion to the beech wood surface, demonstrated water resistance, and displayed minimal colour change upon exposure to UV light.

Lignin itself stands as another interesting functional asset. Indeed, Zikeli et al. [111] extracted lignin from wood waste, utilizing a non-solvent technique to produce lignin nanoparticles (LNPs). Consequently, wooden specimens that were dip-coated with these LNPs exhibited encouraging surface alterations reminiscent of a cohesive film composed of merged LNPs. These treated samples demonstrated notably superior performance in simulated weathering trials compared with untreated control samples. Much like lignin, tannins, which are also derived from wood, offer an opportunity to enhance the protective qualities of coatings. In alignment with this objective, Tomak et al. [112] endeavoured to enhance the weathering durability of Scots pine wood by applying water-based wood coatings infused with valex, mimosa, and pine tannins. The investigation demonstrated that, among the tannin varieties, valex and pine tannins stood out as the most effective agents in transparent coatings, offering substantial resistance against surface deterioration. In a similar vein, condensed tannins derived from tree bark have been evaluated as effective additives to impart a protective function to acrylic-based coating resins [113]. Beyond their potent antioxidant capabilities, the UV-absorbing properties of both original and chemically altered tannins have been observed to be influenced by factors such as pH and the extent of esterification or etherification. Native and modified tannins containing maleate or methylcarboxylate groups, while maintaining robust antioxidant activity, exhibited notably enhanced coating durability and performance when compared with the utilization of synthetic photostabilizers. Furthermore, condensed tannins subjected to esterification with a high degree of substitution also outperformed synthetic additives, underscoring the intrinsic UV-absorbing potential of these materials in enhancing the effectiveness of acrylic and styrene–acrylic coating systems.

Lastly, carnauba wax has been combined harmoniously with zinc oxide nanoparticles within multi-layer coatings to thwart the deterioration and extend the lifespan of timber [114]. The resultant coating exhibited a distinct blend of superhydrophobicity, exceptional moisture buffering capacity, and partial UV shielding. This achievement was realized through an eco-friendly coating procedure, contributing to the preservation of wood’s innate look and enhancing indoor air quality and comfort.

Consequently, modern advancements in research have opened doors to the utilization of bio-based fillers and additives, offering the potential to enhance the longevity of wood coatings while prioritizing ecological concerns and the reduction and reutilization of waste materials. Whether serving as UV-absorbers, antioxidants, or hydrophobic agents, bio-based fillers appear poised to surpass conventional synthetic additives, showcasing a heightened emphasis on both environmental sustainability and economic viability.

4.2. Reinforcing Bio-Based Fillers

Similar to the necessity for weather endurance, wood coatings must also exhibit favourable mechanical attributes, encompassing traits such as hardness and resistance to abrasion. Once again, an array of bio-derived additives can be harnessed to enhance the capabilities of protective layers, infusing multifaceted functionality into the polymer matrix of the coating.

For instance, a recent study aimed to unveil the combined effects of two natural additives on the longevity and protective attributes of a bio-based wood coating [41]. This research highlighted the intriguing synergy between spirulina and wax, which afforded vivid colouring and specific aesthetic qualities to the paint. Additionally, they enhanced the surface’s water-repellent characteristics and increased the abrasion resistance of the composite layer.

Likewise, consistent with strategies aimed at reinforcing the coating’s ability to withstand environmental influences, the primary focus lies on utilizing lignocellulose material to elevate the mechanical attributes of the coating. For example, Henn et al. presented new strategies for lignin applications in durable particulate coatings [115]. They outlined the benefits of these strategies in comparison with both conventional synthetic and bio-based coatings presently in use. In particular, bio-based surface coatings with multiple protective features have been formulated by utilizing water-dispersible colloidal lignin particles (CLPs) alongside an epoxy compound known as glycerol diglycidyl ether (GDE). By employing GDE/CLP ratios of 0.65 and 0.52 g/g, the resulting cured films of CLP-GDE exhibited remarkable resistance against abrasion and elevated temperatures. The unique spherical morphology and chemical composition of CLPs enabled them to serve as both a hardening agent and a particulate element within the coating. This multifunctional role negated the necessity for an underlying binding polymer matrix. Likewise, a recent investigation showcased the enhanced application of lignin and proposed innovative avenues for crafting versatile waterborne wood coatings [116]. The organosolv lignin derived from biorefineries underwent a transformation into colloidal lignin micro-nanospheres (LMNS), reinforcing and fortifying the polymer matrix of the coating. This intervention led to a notable 55% surge in tensile strength and a 40% increase in elongation. Furthermore, the waterborne coating displayed substantial enhancements in wear resistance, adhesion, and various other attributes upon application to wood surfaces.

Nevertheless, cellulose currently stands as the material with the most significant capacity for enhancing the protective qualities of wood coatings. Indeed, both the industrial sector and academia are profoundly focused on exploring the protective attributes offered by cellulose derivatives. On a broader scale, an investigation aimed at unveiling the impact of a substantial concentration of cellulose fibres on the durability and protective characteristics of a bio-based wood coating [37]. The study focused on the advantages and disadvantages associated with the extensive incorporation of cellulose fibres as fillers in wood paint. It cautioned against an overabundance of these fibres, indicating the necessity for a defined threshold to prevent significant alterations in the coating’s composition and subsequent weakening of its protective attributes. However, the optimal capabilities of cellulose can be harnessed most effectively on a nanoscale level. A recent research investigation showcased that the integration of nanocellulose derived from blueberry pruning residues, along with titanium dioxide and silica dioxide nanoparticles, into waterborne varnishes yielded advancements in the mechanical strength and durability of wooden surfaces [16]. Notably, enhancements were observed in adhesion and resistance to abrasion, all while maintaining stability in other aspects, such as optical clarity, colour, and coating gloss. These findings hold encouraging prospects for diverse applications within the realm of circular economy-driven product development, spanning furniture, flooring, and wood panelling. In a comparable manner, Veigel et al. [51] presented an eco-friendly method to enhance the effectiveness of linseed oil coatings through the incorporation of nanofibrillated cellulose (NFC). During abrasion testing, all linseed oil coatings modified with NFC demonstrated superior performance compared with the original oil coating. Notably, NFC that was solely suspended in propylene carbonate, devoid of chemical alteration, exhibited the most potent enhancement in wear resistance for the coating. This improvement was largely attributed to the loose network structure of this specific NFC variant, which effectively obstructed the oil’s infiltration into the wood surface. Consequently, a protective composite layer of NFC and oil was formed on the wood surface, contributing to enhanced protection. In conclusion, cellulose nanocrystals (CNC) have exhibited remarkable protective capabilities, as evidenced by numerous recent studies in the literature. For instance, a commercially available acrylic varnish underwent modification through the incorporation of cellulose nanocrystals and lignin extracted from beech wood [117]. The addition of CNC proved to be advantageous, particularly in improving the water absorption properties of the modified coating. Likewise, Tamantini et al. [118] assessed the efficacy of incorporating CNC into a commercially available waterborne acrylic coating. The inclusion of these nanoparticles resulted in a noticeable enhancement in scratch resistance while not causing any notable alteration to the coating’s visual appearance. Ultimately, advanced high-performance wood coating systems with elevated solid content, capable of UV curing, were formulated through the incorporation of CNC [119]. The outcomes revealed that the presence of CNC led to enhancements in both barrier and optical characteristics within the nanocomposite coatings. The glass transition temperature (Tg) of the polymer matrix displayed minimal alteration upon the addition of CNC. The effectiveness of the CNC dispersion within the polymer matrix was influenced by the CNC concentration. Despite notable agglomeration at higher CNC levels (3%), this clustering did not exert any adverse effects on the coating’s performance.

Ultimately, recent studies have demonstrated the potential for enhancing the durability of wood coatings, encompassing aspects such as hardness, resistance to abrasion, and barrier properties through the incorporation of bio-based fillers. These substances not only tend to be more cost-effective than conventional synthetic and industrial additives, but also offer enhanced eco-friendliness. Furthermore, they introduce new dimensions of multi-functionality to wood coatings.

4.3. Bio-Based Additives for Antimicrobial Wood Systems

Over time, wood preservatives have seen a steady enhancement in their effectiveness, safety during usage, and eco-friendliness. This progress has been driven by the gradual replacement of certain chemical elements, prompted by concerns about their efficiency and impact on the environment. While numerous wood preservatives effectively hinder fungal decay, their adverse environmental effects have led to restrictions on their usage in numerous countries.

Hence, there is a notable ongoing pursuit for novel, ecologically friendly, and environmentally conscious antimicrobial supplements. In particular, researchers are exploring inventive bio-based fillers to enhance wood coatings, equipping them with the ability to combat fungi. This is vital because fungi pose a significant risk to the durability of wooden materials.

Considering this, a recent investigation conducted an assessment of the impact of certain chosen organic substances and modified versions thereof (including tea tree oil, propyl gallate, hydrogenated gum oil, salicylic acid, cinnamon bark oil, butylene oxide, and furfural) on the suppression of blue stain and mould fungi [105]. The study’s findings indicated that salicylic acid, tea tree oil, and cinnamon bark oil exhibited the lowest level of mould proliferation following a four-week exposure within a mould chamber experiment. However, the literature is full of recent studies on the fungicidal effect of natural extracts. For instance, a raw extract obtained from crude heartwood, which contains the compounds pinosylvin (PS) and pinosylvin monomethyl ether (PSM), was employed as an antifungal treatment for Scots pine sapwood [92]. The study demonstrated that saturating the wood with a substantial amount of these stilbene compounds (at a rate of 60 milligrams per gram of dry wood) effectively inhibited fungal growth and notably decelerated the wood degradation process, particularly when dealing with the G. trabeum fungus. Furthermore, coffee extracts have exhibited effective antifungal properties as well. For instance, Barbero-Lopez et al. [120] highlighted the promise of cinnamates derived from used coffee as agents against microorganisms. When used at concentrations of 1% and higher, spent coffee substantially inhibited the growth of various fungi under examination, indicating its potential utility as an environmentally friendly ingredient in the composition of wood preservatives. Likewise, a recent examination explored the potential application of coffee silverskin, a byproduct generated during coffee roasting, as a raw material for antifungal components in wood preservatives [106]. In this subsequent scenario, the attempt to repurpose silverskin from industrial leftovers did not prove effective as a wood preservative. Nevertheless, it continued to hold promise as a prospective reservoir of antifungal compounds for the development of wood preservative formulations. However, various extracts exhibiting favourable antifungal characteristics are readily available in the natural world. For instance, Wozniak et al. [100] conducted an investigation into the effectiveness of propolis extract in safeguarding Scots pine wood against the brown-rot fungus C. puteana. The findings indicated that, when wood was treated with propolis extract at concentrations exceeding 12%, the advancement of fungal decay was restricted. Furthermore, the propolis extract employed for wood treatment was abundant in phenolic compounds, notably chrysin, pinocembrin, and galangin, all of which possess antimicrobial properties. These findings suggest that the propolis extract derived from Poland holds potential as a promising natural wood preservative, ensuring safety for both humans and the environment. Lastly, Zhang et al. [99] conducted an experiment involving 41 individual monoterpenes to assess their toxicity against wood white-rot fungi, namely T. hirsuta, S. commune, and P. sanguineus. The outcomes of the antifungal evaluations revealed that b-citronellol, geraniol, carvacrol, thymol, eugenol, and citral exhibited noteworthy antifungal properties against all three fungi under examination. These findings underscore the potential of carvacrol for future development as a natural fungicidal agent, suggesting the need for further investigation into its potential for wood preservation treatments.

Natural oils represent another category with efficient fungicidal performance, specifically analysed in recent years. For example, Moutaouafiq et al. [121] examined the antifungal effects of essential oil from Pelargonium graveolens and its constituent fractions on four wood-decaying fungi (C. puteana, Coriolus versicolor, Poria placenta, and G. trabeum). Their aim was to showcase the value of Moroccan aromatic and medicinal plants. The study revealed impressive outcomes, implying the potential utilization of this substance for safeguarding wood against fungal deterioration. Likewise, a recent study concentrated on creating an environmentally conscious wood preservative solution using distillate derived from the pyrolysis of coconut shells (CSPOD) [101]. The notable presence of phenolic compounds within the oil distillate conferred considerable resistance to decay in the treated wood, effectively combatting both white-rot and brown-rot fungi. Consequently, the potential exists for CSPOD to be refined into a formulation for wood preservation. Another study revealed the efficient antifungal activity of an essential oil extracted from the Brazilian savannah species Lippia origanoides Kunth against G. trabeum and T. versicolor [103], while Xie et al. [104] analysed the positive antifungal activity of six plant essential oils (Origanum vulgare, Cymbopogon citratus, Thymus vulgaris, Pelargonium graveolens, Cinnamomum zeylanicum, and Eugenia caryophyllata) against the wood-rot fungi. Similarly, Humar et al. [48] assessed the effectiveness of Norway spruce and beech wood treated with linseed and tung oil in resisting wood-decay fungi. Finally, Mustata et al. [15] examined the response of fungi to a sustainable thermoset composed of epoxidized soybean oil (ESO), castor oil maleic anhydride adduct (COMA), and methyl nadic anhydride (MNA), demonstrating effective fungal resistance offered by the environmentally friendly coating.

In addition to being a positive reinforcing filler, cellulose has been shown to act as a bio-based fungicidal additive. Jusic et al. [117] enhanced a standard commercial acrylic varnish by incorporating CNC and lignin sourced from beech wood. However, the resulting protection against bacterial deterioration was found to be inadequate. On the other hand, in another work, CNC led to an enhancement in fungal resistance [118]. This improvement was evident through decreased mass loss and changes observed in FTIR spectroscopy, attributed to the formation of crosslinks. These crosslinks also contributed to a reduction in water absorption. Likewise, lignin can be utilized in fungicidal applications, as emphasized in the research conducted by Andeme Ela et al. [122]. They investigated the effectiveness of lignin nanocapsules containing the fungicide propiconazole as an environmentally friendly wood preservative. The innovative preservation approach displayed improved capacity to resist fungal activity when compared with the individual components.

Additional extracts from wood, such as tannins, can exhibit remarkable antimicrobial capabilities. Anttila et al. [95] directed their attention towards utilizing condensed tannins sourced from conifer trees as eco-friendly alternatives to synthetic wood preservatives. They extracted eight distinct tannin fractions from spruce cones, spruce barks, and pine cones. The research findings highlighted that, even at minimal concentrations, these tannins effectively restrained the growth of brown-rot fungi. On the other hand, Tomak et al. [97] infused Scots pine wood specimens with varying concentrations of valonia, chestnut, tare, and sulphited oak tannins at levels of 3%, 5%, 10%, and 15%. These treated samples were subsequently exposed to attacks by the brown-rot fungi C. puteana and Postia placenta, as well as the white-rot fungi T. versicolor and Pleurotus ostreatus. The aim was to identify the most suitable tannin type and optimal concentration required to ensure effective resistance against decay. Tannins demonstrated their efficacy in suppressing brown-rot fungal assaults when no leaching was performed prior to the decay assessment. In a similar vein, Da Silvera et al. [96] conducted a comparison between the preservative impact of tannic extract and a conventional preservative blend containing CCB (chromated copper borate) against the biodeterioration of Acacia mearnsii wood. The tannin concentrations exhibited comparable outcomes to those achieved with the CCB mixture across all assessments. Notably, the tannins bolstered the material’s resistance to biological degradation, leading to its classification as highly resistant to fungal activity. Taken together, the outcomes indicate the potential of tannins to serve as a viable natural preservative solution.

Similarly, other wood extracts have demonstrated interesting biocidal behaviour. For instance, Barbero-Lopez et al. [93] investigated and analysed pyrolysis distillates derived from the barks of spruce and birch trees, as well as hemp. They examined various fractions obtained from these distillates to evaluate their potential as antifungal agents for deterring wood decay. The notable capacity of the pyrolysis distillates to effectively inhibit decay, even at concentrations of 1% and below, highlighted their potential for serving as a resource for developing sustainable formulations of wood preservatives. In contrast, Vek et al. [123] conducted an evaluation indicating that extractives from knotwood in Scots pine effectively hindered the proliferation of wood-decay fungi. On the other hand, heartwood extracts from black locust demonstrated considerably higher effectiveness as scavengers of free radicals compared with extracts from Scots pine. These extracts were deposited within the cavities and on the cell walls of impregnated sapwood. The treatment of sapwood blocks with extracts from both Scots pine and black locust led to a reduction in the fungal decay of the wood. Lastly, the ability of extracts obtained from wound-related beech wood (Fagus sylvatica L.) to act as fungicides against specific brown (G. trabeum) and white (T. versicolor)-rot fungi was evaluated [124]. The analysis of the fungicidal attributes of extracts from wound-related wood revealed that the pronounced inhibitory impact on wood-decaying fungi could be attributed to both methanolic extracts of wound-related wood and the healthy sapwood.

Apart from displaying notable resilience against fungal attacks, contemporary wood coatings are frequently expected to possess the capability to hinder the proliferation of bacteria and viruses. Certainly, with the global outbreak of the novel coronavirus pneumonia in 2020, there was a substantial rise in the demand for antibacterial products. As a result, recent endeavours have been focused on developing environmentally friendly antibacterial fillers and additives to address this requirement. For example, citric acid stands out for its cost-effectiveness and its natural origin, alongside its antimicrobial properties. Dixit et al. [125] developed an oligomer derived from citric acid, which was subsequently blended with epoxy acrylate and tri(propylene glycol) diacrylate (TPGDA) to create a UV-curable coating. The investigation demonstrated that the area where the growth of Staphylococcus aureus was inhibited expanded as the proportion of UV-curable unsaturated oligomer in the coating formulation increased. Nonetheless, Feng et al. [126] devised a method involving an ecologically conscious Ag+ in situ reduction process to produce a soy protein isolate nano-silver hydrosol. This involved combining soy protein with polyacrylic resin through ultrasonication, resulting in a polyacrylate–nano silver antibacterial coating for wood. The resultant composite film demonstrated effective antibacterial attributes against both Gram-negative Escherichia coli and Gram-positive S. aureus bacteria. Consequently, this study introduces a novel approach for crafting waterborne polyacrylate coatings boasting remarkable antibacterial characteristics.

Hence, it is evident that incorporating antimicrobial substances into wood has become a subject of significant importance within both the scientific and industrial realms. These requirements align seamlessly with the contemporary emphasis on a circular economy, promoting the creation of environmentally friendly resources that leave a minimal ecological footprint. Across the globe, researchers are progressively exploring feasible substitutes for conventional synthetic additives, striving for performance that matches or even surpasses existing standards. In essence, recent research has convincingly showcased the feasibility of implementing environmentally conscious yet highly functional systems to safeguard wooden materials.

4.4. Green Flame Retardant and Intumescent Systems

Since the 1970s, flame retardants have been utilized in a wide array of consumer and industrial goods with the aim of diminishing a material’s susceptibility to ignition or serving as a barrier (absorbing heat) to combustion. Notably, substantial emphasis has been placed on synthetic fire retardants throughout this time period. A considerable portion of commercially accessible flame retardants comprises organic compounds derived from oil sources (such as organo-halogenated, organo-phosphorous, and organo-nitrogen compounds). However, owing to their reliance on petroleum, these compounds face concurrent challenges, including depleting petroleum resources, geopolitical complexities, and contributions to global warming. Furthermore, certain compounds, particularly those with halogen components, have come under scrutiny owing to potential links to specific health and environmental issues. Thus, during recent times, there has been a notable surge in the scholarly literature focusing on the creation of flame retardants derived from sustainable sources [127,128]. The prohibition of certain halogenated substances and the pursuit of substitute options have played a pivotal role in motivating the exploration and formulation of these novel bio-based additives.

Given this perspective, recent developments have highlighted the effectiveness of vanillin as a promising bio-based option. For instance, Li et al. [86] successfully synthesized an innovative epoxy reactive flame retardant with phosphate content. This was achieved through a single-step reaction involving vanillin and benzene phosphorous oxydichloride (BPOD). Comprehensive analyses demonstrated marked enhancements in both the thermal stability and flame retardancy of the environmentally friendly coatings. As a result, this study introduced a sustainable and eco-friendly approach to crafting flame-retardant wood coatings, showcasing substantial potential for applications in the realm of wood-related endeavours. Similarly, Huang et al. [129] synthesized a polybasic carboxylic acid (HCPVC) by combining vanillin and hexachlorocyclotriphosphazene. This compound was utilized as a curing agent in a wood epoxy coating. Consequently, the resultant coating displayed an elevated char yield alongside notable flame retardant properties. Additionally, the study unveiled that the formation of a compact and swelling char layer effectively curtailed further combustion and pyrolysis within the condensed phase. Furthermore, the outcomes of thermogravimetric analysis coupled with infrared spectrometry (TGA-FTIR) confirmed that the environmentally friendly coating released more inert gases during the heating process, while concurrently impeding extensive decomposition within the gaseous phase.

In a recent development, Trovagunta et al. [130] conducted an assessment of the viability of suberin, a bio-polyester found in cork, for the creation of bio-based flame-retardant substances. Meanwhile, Li et al. [131] accomplished the synthesis of a bio-based co-curing agent that imparted flame-retardant capabilities to both epoxy and wood. This innovation was aimed at constructing functional thermosetting coatings with enhanced flame resistance.

Continuing the exploration of environmentally friendly additives, Song et al. [132] successfully produced a bio-derived flame-retardant curing agent for ammonium hydrogen phytate (AHP). This was achieved through the precise control of the molar ratio between phytic acid and urea in the reaction process. When compared with a control sample of wood coating prepared with a commercial curing agent containing ammonium chloride, the resulting wood coating (referred to as MP) not only showcased significantly enhanced thermal stability and flame retardancy, but also demonstrated comparable characteristics in terms of Tg, hardness, adhesion, and water resistance. Notably, the preparation process for MP was straightforward, amenable to scaling up, and employed an environmentally friendly water-based solvent. This study presents a sustainable and ecologically mindful approach to developing high-performance, flame-retardant wood coatings, showing substantial promise within the wood and furniture industries.

Employing an alternative approach, Qian et al. [133] successfully developed an eco-friendly and highly effective flame-retardant coating utilizing tea saponin (TS) derived from natural sources. Through their findings, the researchers demonstrated that, when integrated with other elements within flame-retardant coatings, TS exerts a direct and noteworthy influence on the microstructure of the char layer, as well as flame retardancy and pyrolysis performance. These effects contribute to TS serving a dual role: functioning as a gas-phase flame-retardant mechanism by acting as a blowing agent, and simultaneously acting as a carbon agent within the condensed-phase flame-retardant mechanism. The significant synergistic effects of natural-based TS, as revealed in this study, establish a solid theoretical foundation for the development of emerging environmentally friendly, bio-based flame-retardant materials. Moreover, this research uncovers a novel avenue for harnessing the potential of TS, thus exploring a fresh pathway for its utilization.

In the context of intumescent coatings, Aqlibous et al. [134] developed wood coatings containing varying proportions of industrial fillers, namely titanium dioxide (TiO2) and aluminium trihydroxide (Al(OH)3), in conjunction with bio-fillers like eggshell and rice husk ash. The inclusion of these bio-based fillers within water-based intumescent formulations led to a significant enhancement in the fire resistance of wooden substrates. For instance, at an incident heat flux of 30 kW/m2, the effective heat of combustion witnessed a reduction of over 40%. Similarly, the average peak to heat release rate decreased from 193.2 to 150.3 kW/m2 for the wood sample protected by the formulation containing both industrial and bio-fillers. Additionally, the application of these investigated coatings yielded a notable decrease in the back surface temperature of the wooden specimens. Likewise, in a recent investigation, montmorillonite (MMT) was harnessed as an inorganic synergistic agent to formulate a water-based intumescent flame retardant (IFR) decorative coating designed for plywood [135]. The findings highlight that the IFR coating, which was modified with 7 wt.% MMT, showcased the most robust fire resistance among the samples subjected to testing, exhibiting a fire duration surpassing 20 min. This enhanced fire performance was evident in a substantial reduction of the specific extinction area by 44.12 m2 kg−1 as compared with the coating lacking MMT, as determined via cone calorimeter analysis.

Ultimately, bio-derived flame retardants emerge as environmentally friendly, cost-effective, and readily accessible substances. Incorporating these bio-based flame retardants into polymeric materials contributes to reducing their flammability characteristics, thereby enhancing the safeguarding of wood substrates. Furthermore, they function as a heat barricade, constraining the spread of fuel or flames, thus providing protection to the composite surface against heat and air exposure. Even in this specific capacity, recent studies have underscored the remarkable efficacy of bio-based additives, which present applications with considerable assurances, to the extent that they could replace outdated systems that are less attuned to environmental preservation.

Table 3 provides a brief encapsulation of the noteworthy findings linked to bio-based fillers and additives in wood coatings.

Table 3.

Summary of the main insights regarding the use of bio-based fillers and additives in the formulation of wood coatings.

5. Bio-Based Pigments and Dyes

Presently, a prevailing trend within the protective wood coatings market involves the utilization of tinted paints [30] to impart specific visual enhancements to wooden items [28]. This trend encompasses the integration of innovative pigments [28] and aims to achieve specific gloss levels [29]. Recent scholarly endeavours have been directed toward investigating the longevity of these pigments when employed in wood coatings [31,136]. It is imperative to bear in mind that these new-age pigments should contribute distinct visual effects while maintaining the protective attributes of the organic coating. The synergy between hardwood finishes and various types of colourants can potentially introduce notable challenges, as it may compromise the preservative efficiency of organic films by creating voids in the polymer structure or displaying insufficient inherent pigment durability [32,137]. In today’s context, the field of wood finishing is progressively shifting its focus towards two pivotal realms: sustainable raw materials and the eco-friendly economy. Escalating emphasis is being placed on ecologically conscious and adaptable alternatives to traditional chemical additives [33,138], which are often produced without adequate consideration of environmental sustainability [34]. Academic exploration is presently centred on the application of untreated additives within coatings [35,139]. Aligned with this aim, recent research has investigated the outcomes of introducing different components into wood coatings, encompassing both natural and microbial pigments.

5.1. Natural Pigments

Contemporary society is realizing that industrial waste frequently holds untapped potential that can be valued and utilized for other purposes. This principle applies to various industries, including wood coatings, where there is a growing inclination to seek novel pigments and additives. These components not only impart distinct colours to coatings, but also align with environmental considerations and the principles of a circular economy.

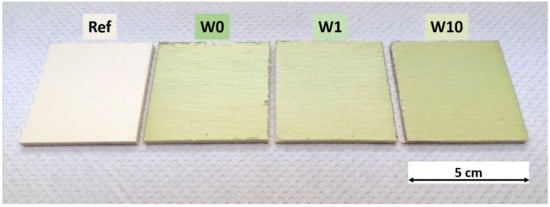

Considering this perspective, a recent investigation explored the pros and cons of utilizing pigment from spirulina as a natural colourant for wood treatment solutions [42]. Spirulina (Spirulina platensis) is a type of cyanobacteria acknowledged as one of the most prominent microalgal reservoirs for the industrial synthesis of phycobiliproteins [140,141], encompassing light-harvesting protein pigments. The study highlighted the impressive colour effects achieved with the introduction of a spirulina-based additive. Nevertheless, the natural pigment showed notable issues related to its susceptibility to UV-B rays, which could lead to the degradation, as well as the potential fading, of the phycocyanin part present in spirulina. As a result, research underscores the significance of adopting suitable precautions to protect bio-based pigment from external elements, like temperature, sunlight, and liquids. Therefore, from this standpoint, a subsequent study aimed to uncover the combined effects of two natural additives on the endurance and protective characteristics of a bio-based wood paint [41]. While spirulina is utilized as an organic pigment, carnauba wax serves as a versatile filler. The analyses demonstrated the impressive colouring capability of spirulina, imparting a distinct green hue to the paint and enhancing its reflective properties. Conversely, the wax influenced the surface texture of the sample, heightening its roughness and diminishing the coating’s glossiness, as highlighted in Figure 4, which reveals the appearance of the different samples. Consequently, these two bio-based additives substantially transformed the coating’s visual attributes, modifying both its colour and reflective traits. Furthermore, the inclusion of wax in this scenario led to an improvement in the water resistance of the coatings, implying enhanced barrier properties of the layer. Additionally, it introduced a reinforcing effect within the coating, potentially reducing the risk of mechanical wear due to abrasion. Ultimately, spirulina and wax emerged as two intriguing natural additives for wood coatings, whose combined action can offer diverse aesthetic enhancements and boost the durability of wood finishes.

Figure 4.

Appearance of the coatings containing spirulina-based pigment and carnauba wax filler [41]. Modified from Progress in Organic Coatings, 182, M. Calovi, S. Rossi, Synergistic contribution of bio-based additives in wood paint: The combined effect of pigment deriving from spirulina and multifunctional filler based on carnauba wax, 107713, Copyright (2023), with permission from Elsevier.

However, a recent investigation has also assessed the coloration impact of an eco-friendly black pigment sourced from discarded wood materials and incorporated into a bio-based wood paint [38]. The pigment was created by utilizing wood waste originating from industries such as paper, lumber, furniture, and flooring. To produce the pigment, the wood underwent a heat treatment within oxygen-free chambers. This controlled environment prevented the wood from combusting and releasing CO2 into the atmosphere. Consequently, the wood underwent a process of carbonization, effectively capturing the carbon that would typically be emitted during wood combustion. This unique characteristic led to the pigment being categorized as carbon-negative. The thermal energy and biogas generated during the manufacturing process were harnessed to power certain sections of the facility and produce the exclusive pigment itself. Additionally, the pigment was made available in the form of a water-based dispersion, entirely composed of bio-based components. In conclusion, this study showcases the potential of utilizing a bio-renewable waterborne solution derived from wood waste and initially intended for the denim industry as a functional pigment within eco-friendly wood paint. This pigment has the ability to alter the coating’s visual characteristics while maintaining its protective capabilities. This research highlights how naturally sourced products and pigments, including those originating from industrial by-products and previously employed in different sectors, like textiles, can be successfully repurposed for practical use in wood coatings.

Likewise, organosolv lignin derived from biorefinery operations was repurposed into colloidal lignin micro-nanospheres (LMNS) and employed as a versatile natural filler for waterborne wood coatings [116]. The creation of LMNS involved a straightforward self-assembly technique, resulting in micro-nanospheres with an average size of around 260 nm. Beyond enhancing the coating’s mechanical attributes and long-lasting qualities, the inclusion of LMNS also amplified the wood’s colour and texture. This underscores the substantial aesthetic value brought forth by this bio-based substance.